Liftmaster R900 User Manual

copyright © 2008 chamberlain professional products - www.Liftmaster.com

TABLE OF CONTENTS

2

2

3

3

4-6

7

8

9

10

11

12

13

14

15

16

17

18

19

19

20

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35-36

37

38

39

40-41

41

42

43

Role of Specifiers and Designers

Role of Dealers, Installers and Trained Gate System Technicians

Role of End Users / Home Owners

Swing Gate Systems

Warnings and Precautions

Safely Operating Gate

Configuration and Specifications

Concrete Pad and Gate Attachment

Standard Installation

Compact Installation

Gate Arm Installation

Gate Movement Direction

Adjustment of Output Shaft

Earth Ground Rod

DC Power Supply Connection

“Optional” Solar Panel

Surge Suppressor Terminal Input Connections

Adjusting Gate Traveling Distance

Timer Adjustment

Reversing Sensor

Warning Placard Placement

Emergency Release

Safety Device Wiring

“Optional” Input Board

Maglock Wiring Connection

Optional 12 VDC Photo Beam Wiring

3-Push Button Wiring Connection

3-Push Button Wiring Master / Second

Single Operator Loop Size and Placement

Master / Second Loop Size and Placement

Loop Installation and Number of Wire Turns

Wiring Loop Detector to Operator

Master and Second Operators with Timer

Master and Second Operators without Timer

Control Board Functions

Control Board LED Descriptions

Troubleshooting

How to Reset Breaker Switch / How to Check Fuses

Gate will not close! / Gate will not open!

If you hear a “BEEP” sound (Audio Alarm)

Robo Swing Parts Illustrations, Robo Swing Parts List

Maintenance

Elite Robo Swing Accessories

Owners Checklist of Installation

1

ROLE OF SPECIFIERS AND DESIGNERS

Specifiers and designers should design an automatic vehicular gate system to:

• Utilize an operator suited for gate system type, size, frequency of use, location and

user population.

• Separate pedestrian access from vehicle access.

• Reduce or eliminate pinch points.

• Reduce risk of entrapment injuries by minimizing all gaps in the gate and

enclosing the area of the travel of the gate.

• Secure controls from unauthorized use.

• Locate all controls out of reach from the gate.

• Allow the user full view of the gate when operating.

• Consider special populations, such as children or the elderly.

• Be consistent with DASMA’s Automatic Gate Opener System Safety Guide.

ROLE OF DEALERS, INSTALLERS AND

TRAINED GATE SYSTEM TECHNICIANS

Installers, during the course of the installation proceedings for each job, should:

• Confirm that the gate operator being installed is appropriate for the application.

• Confirm that the gate is designed and built according to current published industry

standards.

• Confirm that all appropriate features and accessory devices are being

incorporated, including both primary and secondary entrapment protection

devices.

• Make sure that the gate works freely before installing the operator.

• Repair or service worn or damaged gate hardware before installing the operator.

• Install the gate operator according to the manufacturer’s installation instructions.

• Adjust the operator clutch or load-sensing device to the minimum force setting

that allows reliable gate operation.

• Install operator inside fence line (DO NOT install operator on public side of fence

line).

• Install a proper electrical ground to a gate operator.

• Install keypad controls where users cannot touch, or reach through gate while

operating controls.

• Install controls where user has full view of gate operation.

• Test all features for proper functions before placing the automatic vehicular gate

into service.

• Demonstrate the basic functions and safety features of the gate system to

owners/end users/general contractors, including how to turn off power and how to

operate the manual disconnect feature.

• Leave safety instructions, product literature, installation manual and maintenance

manual with end user.

• Explain to the owners the importance of a service contract that includes a routine

re-testing of the entire system including the entrapment protection devices, and

explain the need for the owners to insure that this testing is performed routinely.

• Offer the owner/end user a maintenance contract, or contact them regularly to

offer maintenance.

2

ROLE OF END USERS/HOME OWNER

End users should be made aware that they must:

• Contact a trained gate systems technician to maintain and repair the gate system

(End users should never attempt to repair the gate)

• Retain and utilize the installation and maintenance manual and safety instructions.

• Routinely check of all gate operator functions and gate movement.

• Discontinue use if safety systems operate improperly, the gate is damaged, or the

gate is difficult to move.

• Never overtighten the operator clutch of load sensing device to compensate for a

damaged or stiff operating gate.

• Keep all obstructions clear of the vicinity of the path of the gate system.

• Actively discourage pedestrian use of the vehicular gate operating system.

• Prevent anyone from playing near any part of the gate system.

• Never allow anyone to climb under, over or through a gate or the adjacent fence

area.

• Never allow children to operate gate

• Keep portable controls out of reach of children.

• Never allow anyone to install an operating control within reach of the gate.

• Always be certain that the gate area is clear of pedestrians before operating the

gate.

SWING GATE SYSTEMS

• Entrapment Zone Hazard - Body parts may become entrapped between a gate and a sta-

tionary object when the gate begins to move, which can result in serious injury or death.

Pedestrians must stay clear of the gate path, and any area where gate motion is close to

stationary objects.

• Pinch Points Hazard - The opening mechanism may have arms that can overlap with a

scissoring effect, which can result in serious injury. Pedestrians must stay clear of the

opening mechanism at all times, particularly when gate is opening.

3

WARNINGS AND PRECAUTIONS

IMPORTANT!

Instructions regarding

Robo Swing Installation.

A) Install the gate operator only when all exposed pinch points are eliminated

or guarded.

B) The operator is intended for installation only on gates used for vehicles.

Pedestrians must be supplied with a separate access opening.

C) The gate must be installed in a location so that enough clearance is

supplied between the gate and adjacent structures when opening and

closing to reduce the risk of entrapment. Swinging gates shall not open

into public access areas.

D) The gate must be properly installed and work freely in both directions

prior to the installation of the gate operator.

E) Controls must be far enough from the gate so that the user is

prevented from coming in contact with the gate while operating the

controls.

4

WARNINGS AND PRECAUTIONS

F) For a gate operator utilizing a non-contact sensor such as a photo beam:

1) See instructions on the placement of non-contact sensor for

each type of application.

2) Care shall be exercised to reduce the risk of nuisance tripping,

such as when a vehicle trips the sensor while the gate is still

moving.

3) One or more non-contact sensors shall be located where the

risk of entrapment or obstruction exists, such as the perimeter

reachable by a moving gate or barrier.

G) For a gate operator utilizing a contact sensor such as an edge sensor:

1) A hardwired contact sensor shall be located and its wiring arranged

so that the communication between the sensor and the gate operator

is not subjected to mechanical damage.

2) A wireless contact sensor such as the one that transmits radio

frequency (RF) signals to the gate operator for entrapment

protection functions shall be located where the transmission of

the signals are not obstructed or impeded by building structures,

natural landscaping or similar obstruction. A wireless contact sensor

shall function under the intended end-use conditions.

3) One or more contact sensors shall be located on the inside and

outside leading edge of a swing gate. Additionally, if the bottom edge

of a swing gate is greater than 6 inches (152 mm) above the ground at

any point in its arc of travel, one or more contact sensors shall be

located on the bottom edge.

5

WARNINGS AND PRECAUTIONS

IMPORTANT SAFETY INSTRUCTIONS!

WARNING - To reduce the risk of Injury or Death:

1. READ AND FOLLOW ALL INSTRUCTIONS.

2. Never let children operate or play with gate controls. Keep the

remote control away from children.

3. Always keep people and objects away from the gate.

NO ONE SHOULD CROSS THE PATH OF THE MOVING GATE!

4. Test the gate operator monthly. The gate MUST reverse on

contact with a rigid object or stop when an object activates

the non-contact sensors. After adjusting the force or the limit of

travel, retest the gate operator, Failure to adjust and retest the gate

operator properly can increase the risk of injury or death.

4. Use the emergency release only when the gate is not moving. Make

sure the power for the gate operator is off.

5. KEEP GATES PROPERLY MAINTAINED. Read the manual. Have a

qualified service person make repairs to the gate or gate hardware.

6. The entrance is for vehicles only. Pedestrians must use separate

entrance.

7. SAVE THESE INSTRUCTIONS.

6

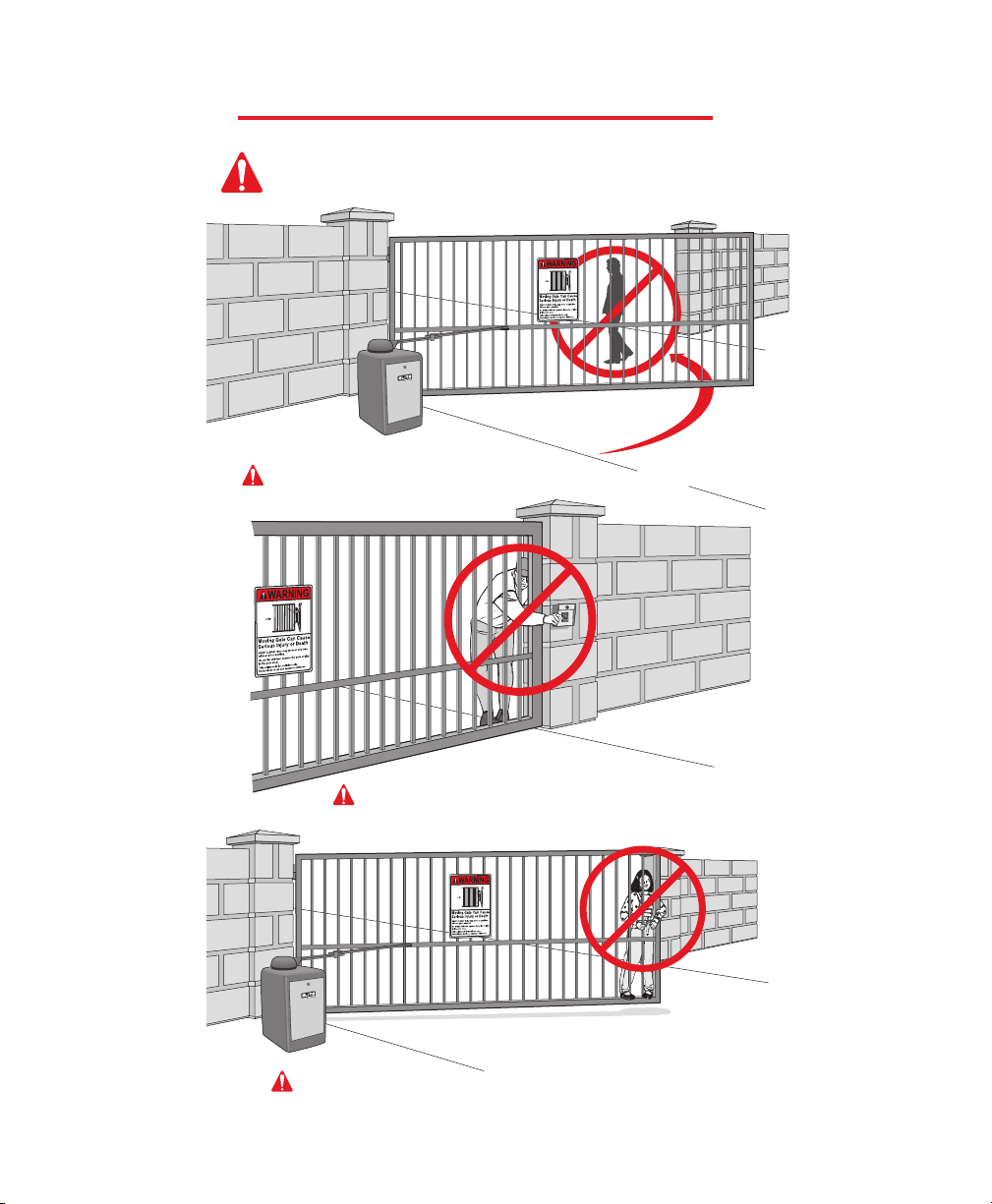

SAFELY OPERATING GATE

The Robo Swing is for Single Home Applications

DO NOT Use for Apartment or Condominium Applications.

Property owners must never let pedestrians cross the path of a moving gate!

Property owners must never mount any gate

operating device accessible through the gate!

Property owners must never let anyone hang or ride on the gate!

7

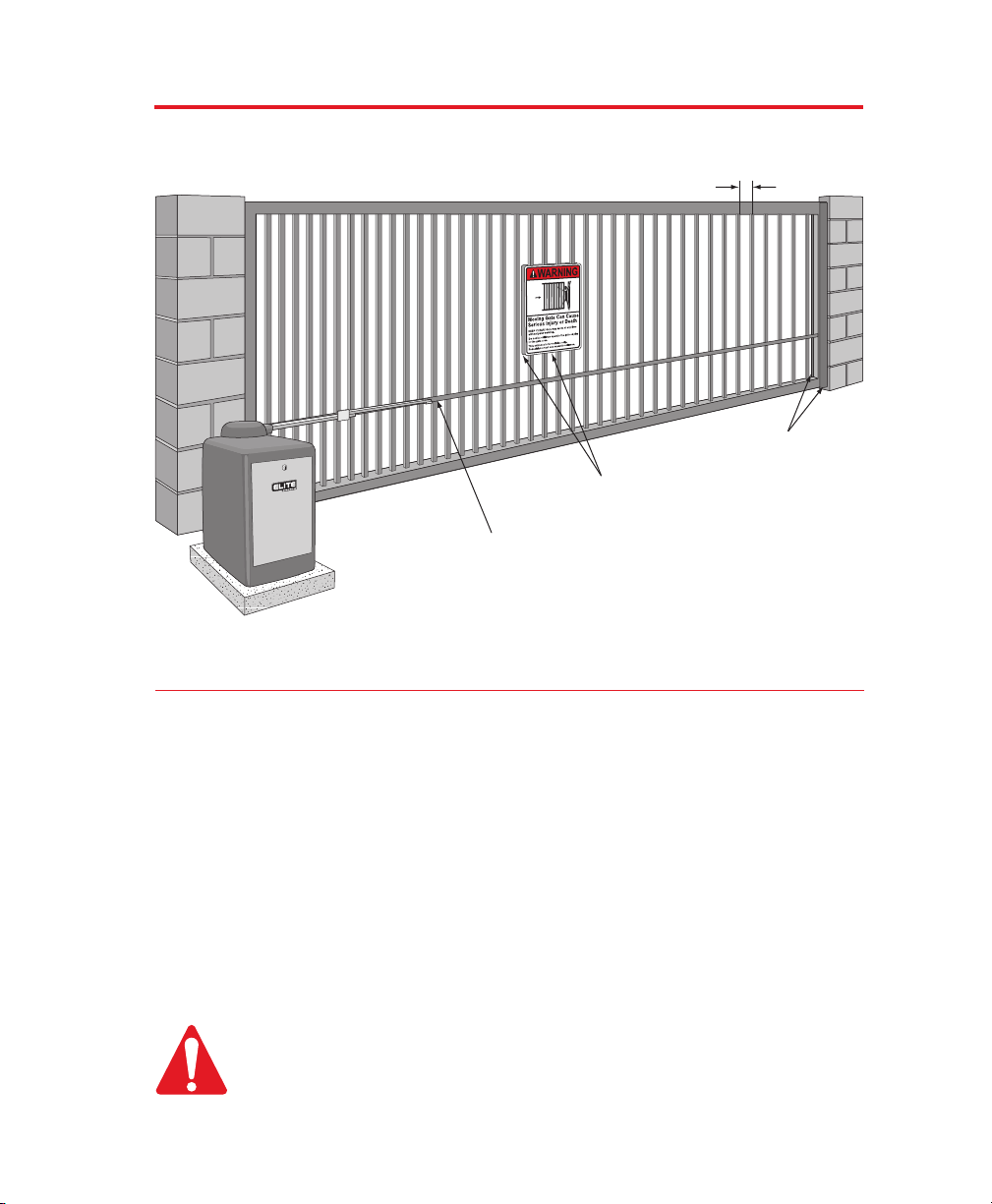

CONFIGURATION AND SPECIFICATIONS

Recommended Gate Setup Configuration

Gate Attachment Bar Must Go Completely

Across the Gate for Full Strength

Warning Placards Permanently

mounted on Both Sides of Gate

4" Max. Width

CAUTION

Robo Swing Specifications:

Gate Speed – 15 - 17 seconds per 90 cycle

Maximum Gate Length – 16 feet

Maximum Gate Weight – 400 pounds

Maximum Cycles – 250 cycles per day with Elite's Plug-In Transformer. (Gate size 16 ft x 6 ft)

– Solar power cycles per day varies, Contact Chamberlain Elite for more

Information

– Battery back-up cycles (50 cycles total)

AC Power Supply – 25 Vdc 1.6 Amp Plug-In Transformer (Part # A POW-1)

AC Power Supply Wire – 14 gauge or greater landscape lighting cable rated for direct burial and

300 watts at maximum length of 1000 ft

DC Power Supply – Built-in, back-up for AC or Solar power failure only

Solar Power – Optional (Part # SOLAR 3)

Be sure to read and follow all Chamberlain Elite's instructions before installing and

operating any Chamberlain Elite product. Always disconnect the gate operator's

power source before repairs are attempted. Chamberlain Elite Access Systems, Inc. is

not responsible for improper installation or failure to comply with local building

codes.

All “Pinch Points” MUST have protective safety devices.

Edge Sensors

8

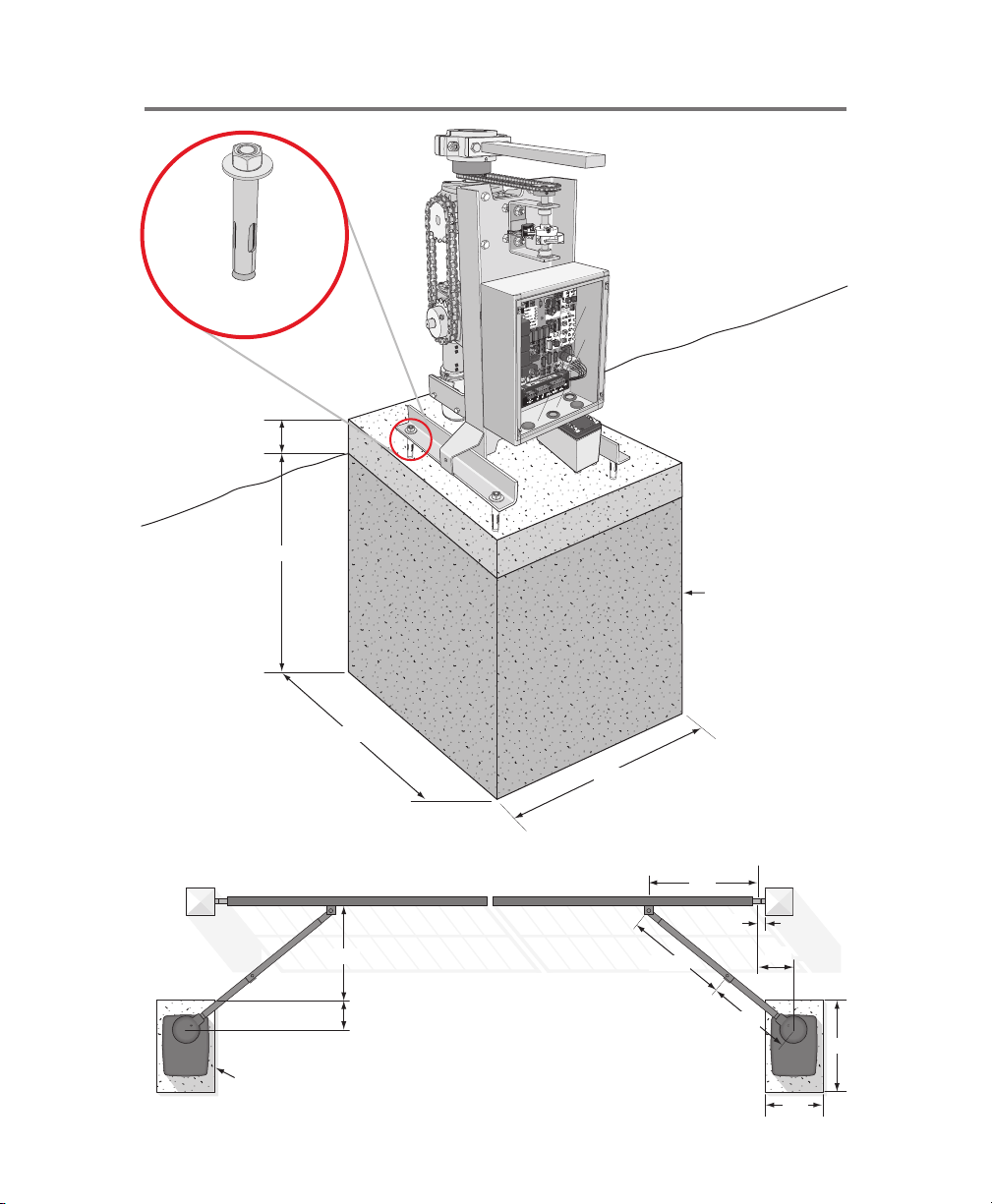

CONCRETE PAD AND GATE ATTACHMENT

6"

Out

In

Post

Concrete Pad

Concrete Pad

Above

Ground

Below

Ground

Short Arm

Long Arm

Hinge

Center

14"

2"

24"

35.5"

46"

28"

25"

10"

29.5"

30"

28"

24"

Concrete Fastener

1/2" x 3 1/2"

Sample Standard Installation

J2

1.5A - 250V

1.5A - 250V

9

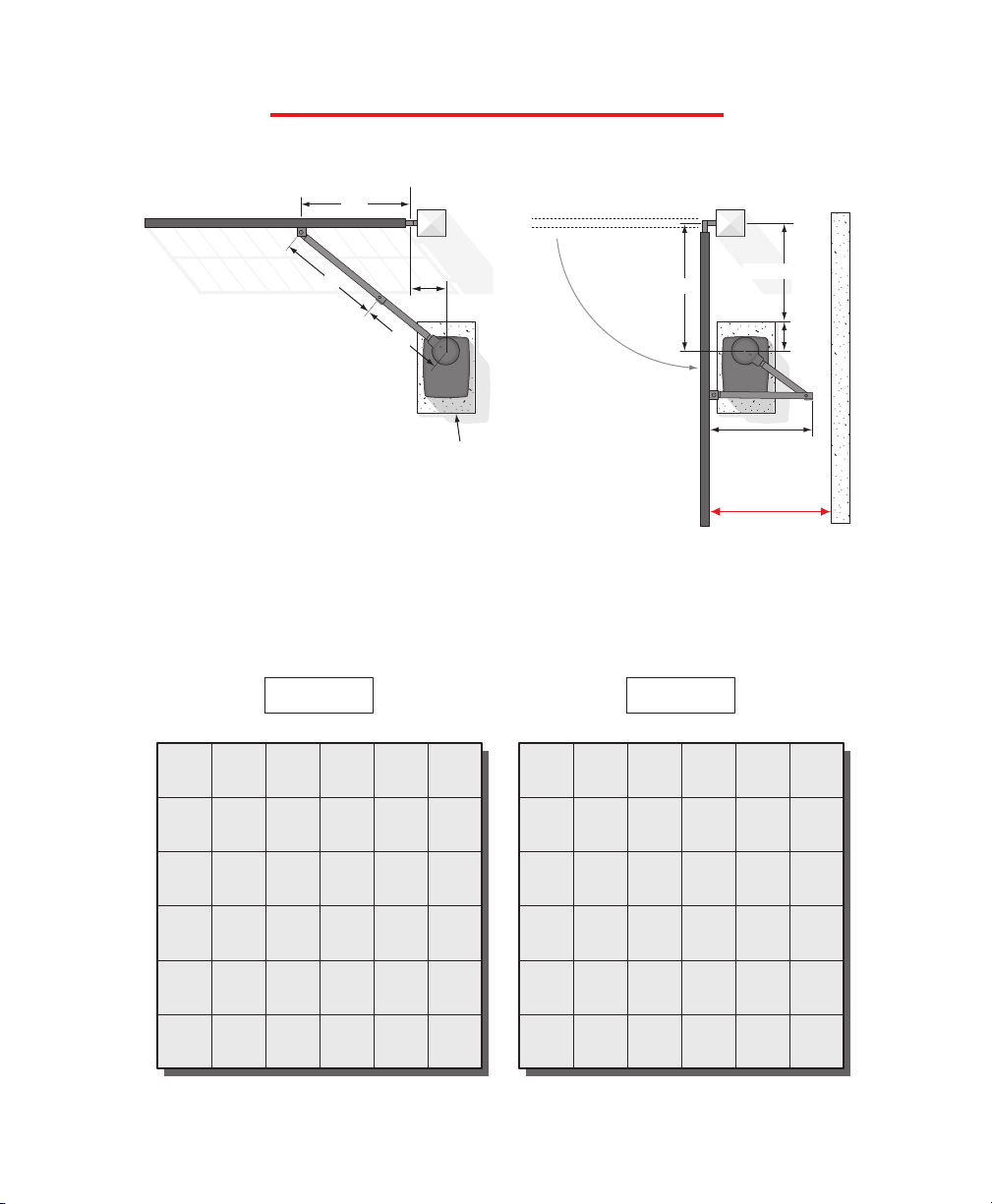

STANDARD INSTALLATION

D

10"

Out

Long Arm

In

Out

In

*Refer to Note

Concrete Pad

Hinge Center

E

B

A

C

Sample Standard Installation is Shown on Previous Page.

Short Arm

DistanceDistance

Caution: If the gate is longer than 18 feet, follow Chart A : A-2.

Suggestion: The dimension between the gate and the concrete pad is always 10 inches less than the dimension D.

Example: D = 42", if the dimension between the gate and the concrete pad is 32".

1

2

3

4

5

6

34.5"

44"

44"

45"

44.75"

41"

34.75"

36.5"

37"

37"

35.75"

39"

29.5"

32.5"

30.5"

30.5"

29.5"

27.5"

35"

42"

40"

37"

32"

28.5"

14"

14"

14"

14"

14"

14"

43"

32"

40"

43"

44"

41"

ABC

Chart B

DE

DistanceDistance

1

2

3

4

5

6

46"

46.75"

46.75"

47.25"

47"

42.5"

35.5"

35.5"

37"

37.25"

35"

33"

29.5"

33.5"

31.5"

30"

29.5"

26.5"

35"

42"

40"

37"

32"

28.5"

11"

11"

11"

11"

11"

11"

45"

37"

41"

45"

45"

41"

ABC

Chart A

DE

DistanceDistance

D minus 10"

*Note - If this dimension is between 20 and 32 inches, compact installation is necessary. (Refer to Page 11)

Dimension (A) thru (E) are from the center of one pivot point

to the center of another pivot point.

Wall

10

20"

Minimum

Width

COMPACT INSTALLATION

4"22"

4" 20"

24"

36"

10"

Long Arm

Cut Cut

Short Arm

Cut

Follow the exact measurements, then cut the standard arm to meet the shorter measurements.

Compact Installation Only!

DO NOT Use These Measurements for a Standard Installation.

Gate ClosedGate Open

Hinge Center

9"

2"

33"

25.5"

23"

20"

to

32"

26.5"

It is necessary to protect against the

entrapment that could occur with this

type of installation.

(See page 22, Photo Beam Entrapment Protection)

11

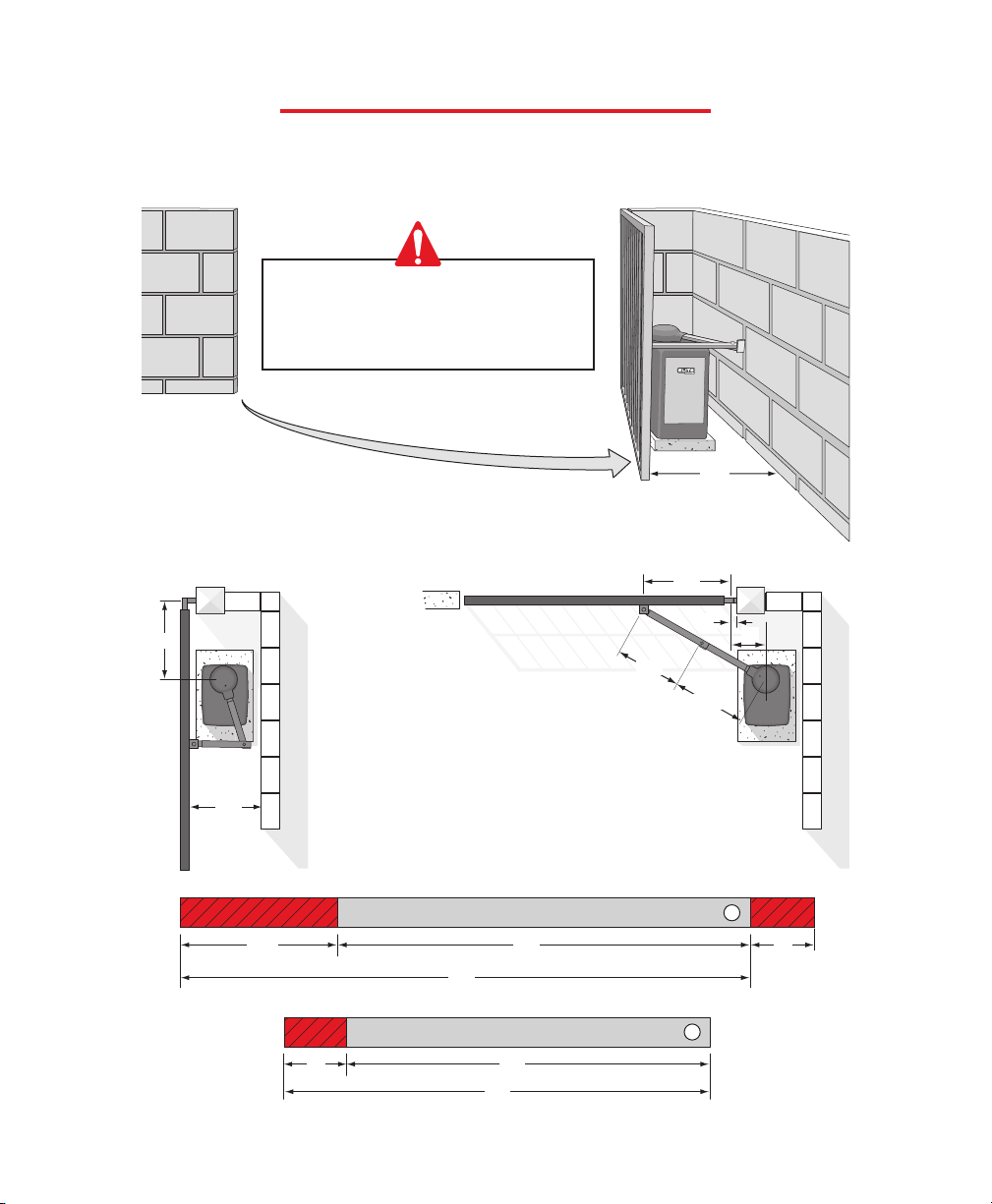

GATE ARM INSTALLATION

Incorrect

Installation

Correct

Installation

Weld Completely Around the Rectangular Tubes

........then weld the shorter arm.

Weld the longer arm..........

Once the gate arm measurements are calculated:

weld the bracket on the gate.

12

OVERLOAD

POWER

CHARGE OK

BATTERY LOW

OPEN RELAY

CLOSE RELAY

TIMER

UP

ON

W1

OFF

OPEN TO RIGHT

Socket 1

Socket 2

60

0

PW

CENTRAL CONTROL

SYSTEM ON

DC OPERATOR v 5M

MADE IN USA

ALARM

SENSOR

REVERSE

SENSOR

HEAVY

GATE

FIRE

DEPT

STRIKE

OPEN

SAFETY

LOOP

EXIT

LOOP

RADIO

REC

CHARGING

POWER

BOARD

POWER

CHECK

FUSE

J2

OPEN

CLOSE

STOP

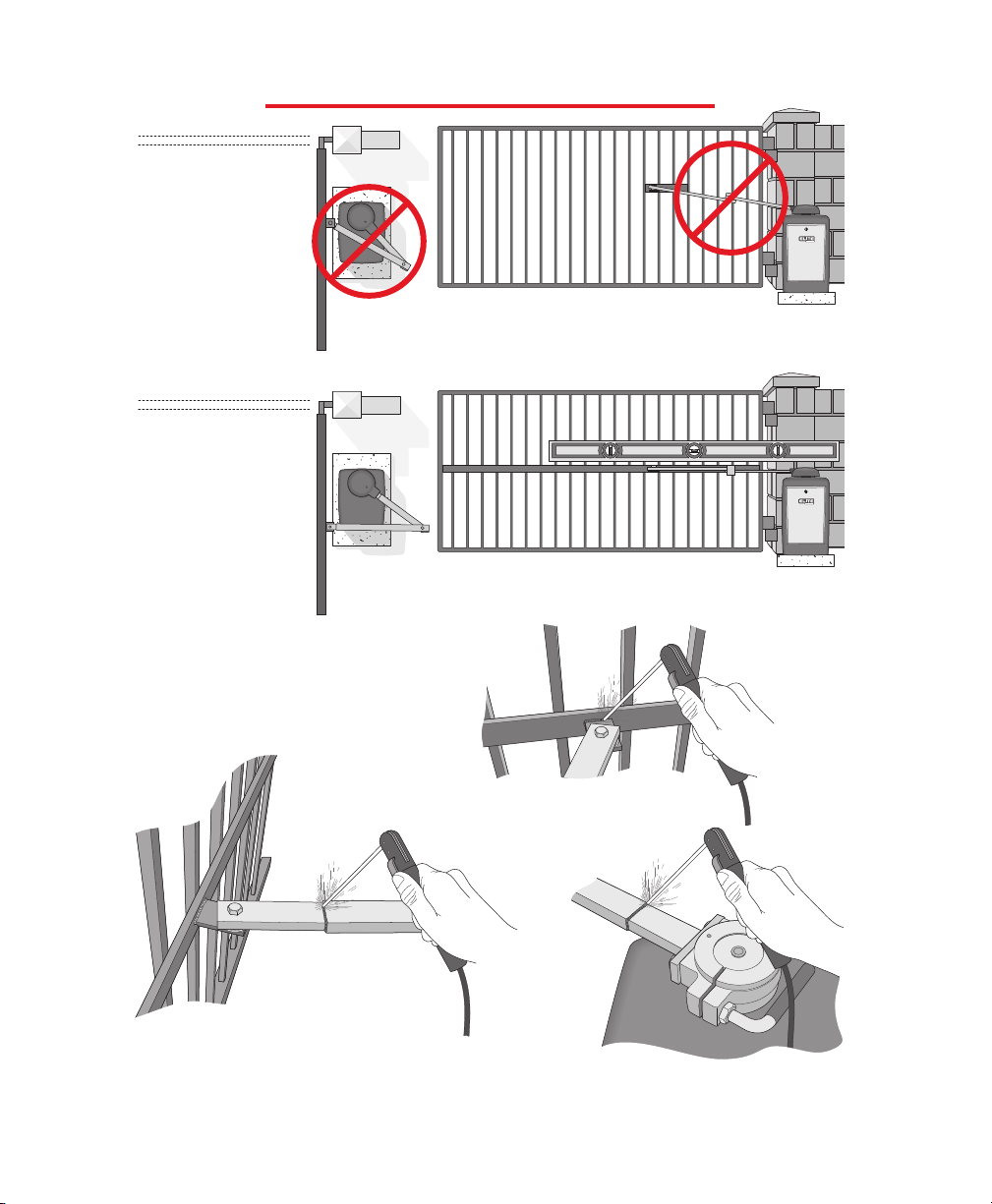

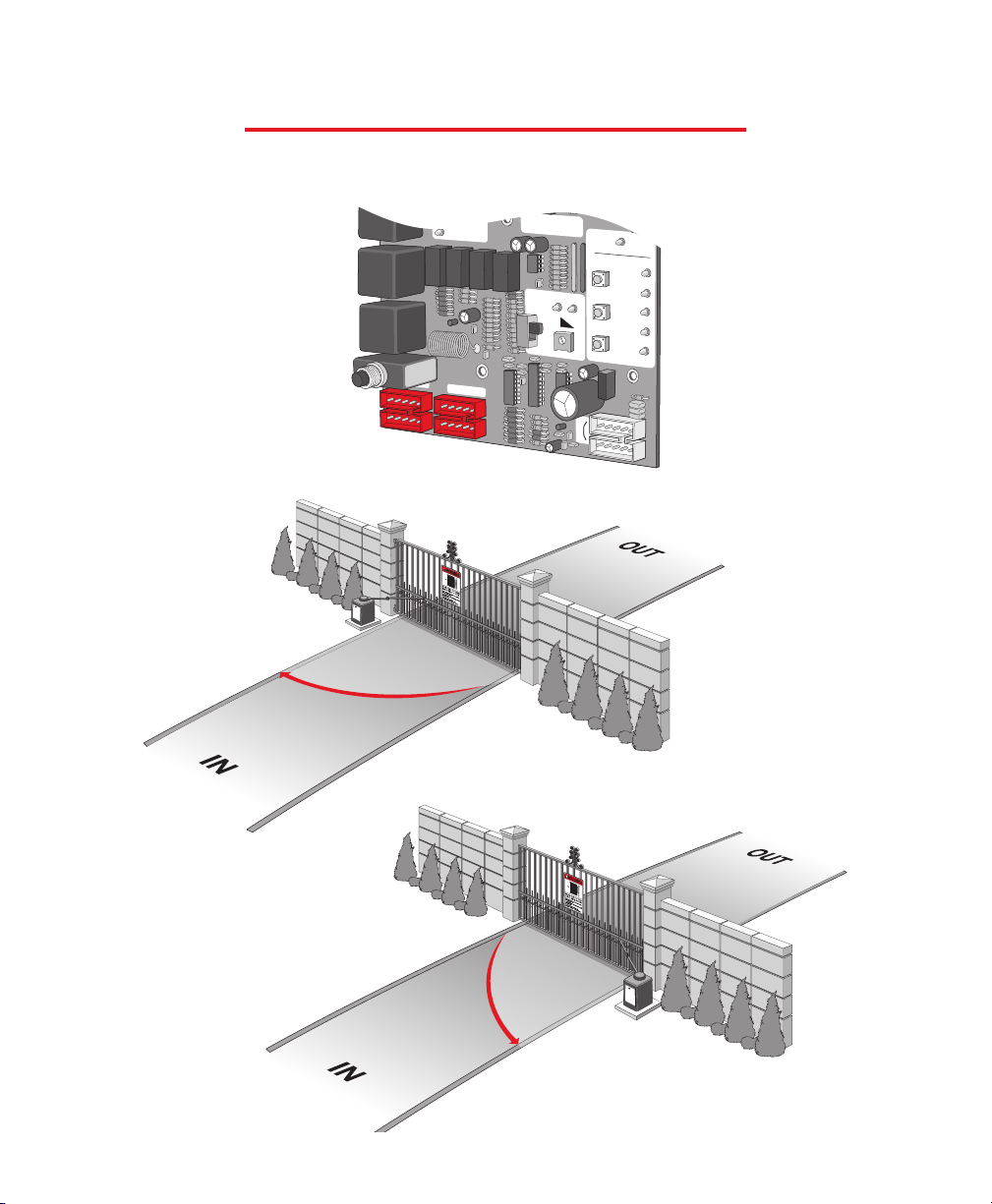

GATE MOVEMENT DIRECTION

Plug in the motor harness wires to the left (Socket 1) if your gate, from the inside of the

property, opens to the left. Plug into the right (Socket 2) if the gate opens to the right.

Socket 1

Open to Left

Open to Right

Socket 2

13

Loading...

Loading...