Liftmaster MGJ User Manual

OWNER'S MANUAL

LISTED DOOR OPERATOR

41B6

MODEL

MGJ (S-Series)

INDUSTRIAL DUTY DOOR OPERATOR

FOR USE WITH SS90 FIRE DOOR CONTROLLER

2 YEAR WARRANTY

Serial #

(located on electrical box cover)

Installation Date

Wiring Type

NOT FOR RESIDENTIAL USE

Before attempting to install, operate or maintain the operator, you must read and fully understand this

manual and follow all safety instructions.

These instructions are intended to highlight certain safety related issues. These instructions are

not intended to be comprehensive. Because each application is unique, it is the responsibility of

the purchaser, designer, installer and end user to ensure that the total door system is safe for its

intended use.

TABLE OF CONTENTS

OPERATOR SPECIFICATIONS

Hardware Packing List . . . . . . . . . . . . . . . . . . . . .2

Operator Specifications . . . . . . . . . . . . . . . . . . . .3

Operator Dimensions . . . . . . . . . . . . . . . . . . . . . .3

Safety Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Site Preparation . . . . . . . . . . . . . . . . . . . . . . . . . .4

Handing Preparation . . . . . . . . . . . . . . . . . . . . . . .4

Operator Mounting

Entrapment Protection . . . . . . . . . . . . . . . . . . . . .7

Limit Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . .7

Maintenance Schedule . . . . . . . . . . . . . . . . . . . . .8

. . . . . . . . . . . . . . . . . . . . . . . . . .5 & 6

Control Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Single Phase Wiring Diagram . . . . . . . . . . . . . . . .10

Three Phase Wiring Diagram . . . . . . . . . . . . . . . .11

Replacement Parts Electrical Box . . . . . . . . . . . . .12

Electrical Box Diagram . . . . . . . . . . . . . . . . . . . . .13

Replacement Parts Frame . . . . . . . . . . . . . . . . . .14

Frame Diagram . . . . . . . . . . . . . . . . . . . . . . . . . .15

Control Connections . . . . . . . . . . . . . . . . . . . . . . .16

9

HARDWARE PACKING LIST

Before beginning your installation check that all components were supplied and received undamaged. Refer to list below

for Factor y Supplied par ts.

HARDWARE KIT MGJ SSSI (K77-18599)

PAR T #

01-18600

02-103-R

10-10463

19-41119MB

77-13709

OWNERS MANUAL, MGJ SSSI

REWORK, PBS, RED PAINT

KEY HOLE BRACKET

CHAIN #41X119 W/ MASTER

LABEL KIT MED DUTY

DESCRIPTION

2

QTY.

1

1

1

1

1

SPECIFICATIONS

MOTOR

TYPE: .................................Intermittent Duty

HORSEPOWER:.................1/2Hp 1 or 3 Phase

SPEED:...............................1050 RPM

VOLTAGE: ..........................115, 60HZ, 1Ph

230V, 60Hz, 3Ph

CURRENT: See motor nameplate

MECHANICAL

DRIVE REDUCTION:.... . . . . . . . . . . 40:1 Reduction

(Heavy duty wormgear-in-oil-bath speed reducer)

OUTPUT SPROCKET:..........Size #41

DOOR SPEED:. . . . . . . . . 1Ph, 23RPM

3Ph, 39RPM

BEARINGS: Heavy duty wormgear-in-oil-bath

speed reducer.

ELECTRICAL

TRANSFORMER:.............24VAC

CONTROL STATION: ......NEMA 1 three button station.

WIRING TYPE:.................B2-C2 (Factory Shipped)

LIMIT ADJUST: ................Linear driven, fully adjustable

screw type cams. Adjustable to 24 feet.

OPEN/CLOSE/STOP

SAFETY

DISCONNECT :.......................Floor level disconnect for

emergency manual door operation.

REVERSING EDGE:...............(Optional) Electric

A REVERSING EDGE IS STRONGLY RECOMMENDED

ALL

FOR

REQUIRED

IS OUT OF SIGHT OF DOOR OR ANY OTHER CONTROL (AUTOMATIC OR MANUAL) IS USED.

COMMERCIAL OPERATOR INSTALLA TIONS.

WHEN THE 3 BUTTON CONTROL STATION

MGJ WEIGHTS AND DIMENSIONS

HANGING WEIGHT: .........80-110 LBS.

7.50”

11.05”

7.00”

9.25”

10.50”

11.00”

3

3.00”

MOUNTING DIMENSIONS

5.50”

4.75”

WARNING

CAUTION

WARNING

WARNING

WARNING

IMPORTANT SAFETY NOTES

CAUTION

TO AVOID DAMAGE TO DOOR AND OPERATOR,

MAKE ALL DOOR LOCKS INOPERATIVE. SECURE

LOCK(S) IN "OPEN" POSITION.

IF THE DOOR LOCK NEEDS TO REMAIN FUNCTIONAL, INSTALL AN INTERLOCK SWITCH.

DO NOT CONNECT ELECTRIC POWER UNTIL

INSTRUCTED TO DO SO.

SITE PREPARATIONS

It is imperative that the wall or mounting surface provide

adequate support for the operator.

This surface must:

a) Be rigid to prevent play between operator and

door shaft.

b) Provide a level base.

c) Permit the operator to be fastened securely and

with the drive shaft parallel to the door shaft.

The safety and wear of the operator will be adversely

affected if any of the above requirements are not met.

For metal buildings, fasten 2” x 2” x 3/16” (or larger) angle

iron frames to the building purlins. For proper spacing,

retain .2.75” between. See Figure 1.

WARNING

KEEP DOOR BALANCED. STICKING OR BINDING

DOORS MUST BE REPAIRED. DOORS, DOOR

SPRINGS, CABLES, PULLEYS, BRACKETS AND

THEIR HARDWARE MAY BE UNDER EXTREME TENSION AND CAN CAUSE SERIOUS PERSONAL

INJURY. CALL A PROFESSIONAL DOOR SERVICEMAN TO MOVE OR ADJUST DOOR SPRINGS OR

HARDWARE.

Shaft Support Bracket

with Bearing (Not Supplied)

Door Sprocket

2-1/4"

2.75

FIGURE 1

OPPOSITE HANDING PREPARATIONS

Shipped from the factory for either left hand or right hand mounting.Refer to next to last digit in the model number for handing of your unit. If necessar y, model MGJ may also be field modified to accommodate opposite handing. Refer to the conversion instructions below and on page 5.

1. Remove Disconnect Assembly Components

Remove the master link from the limit chain, remove the

chain and set it aside.

KEYS

SPRING

DISCONNECT

HUB

SPROCKET

E RING

SHAFT

BRACKET

YOKE

Remove the two E Rings securing the sprocket on the

gear reducer shaft. Remove the screws securing the yoke

to the disconnect shaft, set the yoke aside.

DISCONNECT

LEVER

4

Remove the three cotter pins from the disconnect shaft.

Do not discard the pins. Slide the disconnect shaft out of

the support bracket. The release lever will now be free

inside the motor frame. Remove the release lever and

sash chain from the motor frame. Slide the disconnect

hub, compression spring, and flatwasher from the end of

the gear reducer shaft. Remove the disconnect support

bracket by first removing the the two gear reducer housing screws. Replace the screws in the gear reducer and

firmly tighten.

2. Re-assemble Disconnect Assembly

Remove the two screws on the opposite side of the gear

reducer and mount the disconnect support bracket with

the notched side facing the motor. For the remainder of

the installation, follow the steps outlined above in reverse

order, referring to the illustration as necessary.

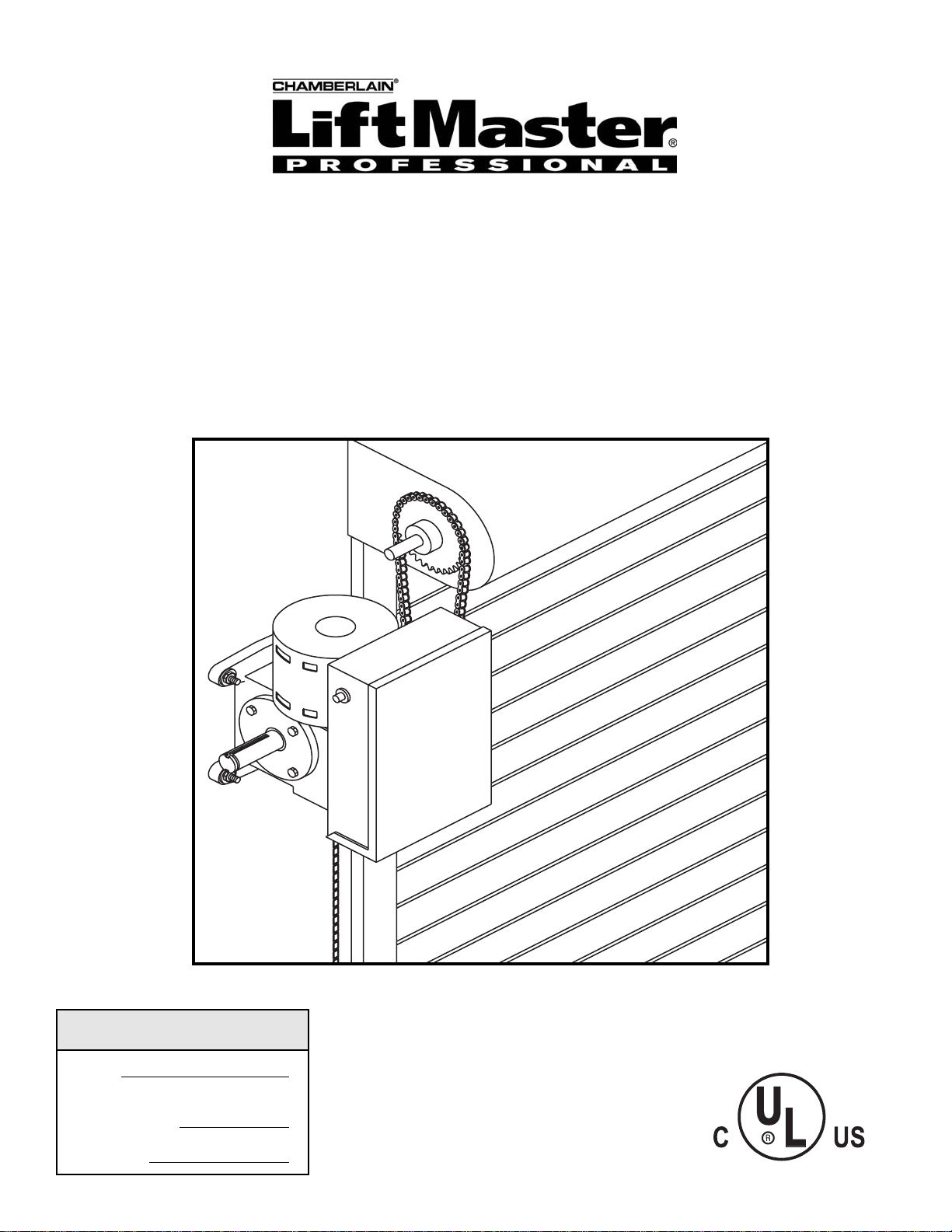

OPERATOR MOUNTING

Before your operator is installed, be sure the door has been properly aligned and is working smoothly. The operator may

be wall mounted or mounted on a bracket or shelf. If necessary, refer to the operator preparations on page 3. Refer to the

illustration and instructions below that suits your application.

1a.Wall Mounting

The operator should generally be installed below the door

shaft, and as close to the door as possible. The optimum

distance between the door shaft and operator drive shaft is

between 12” - 15”.Refer to Figure 3.

FIGURE 3

Typical Left Hand

Wall Mounted Operator

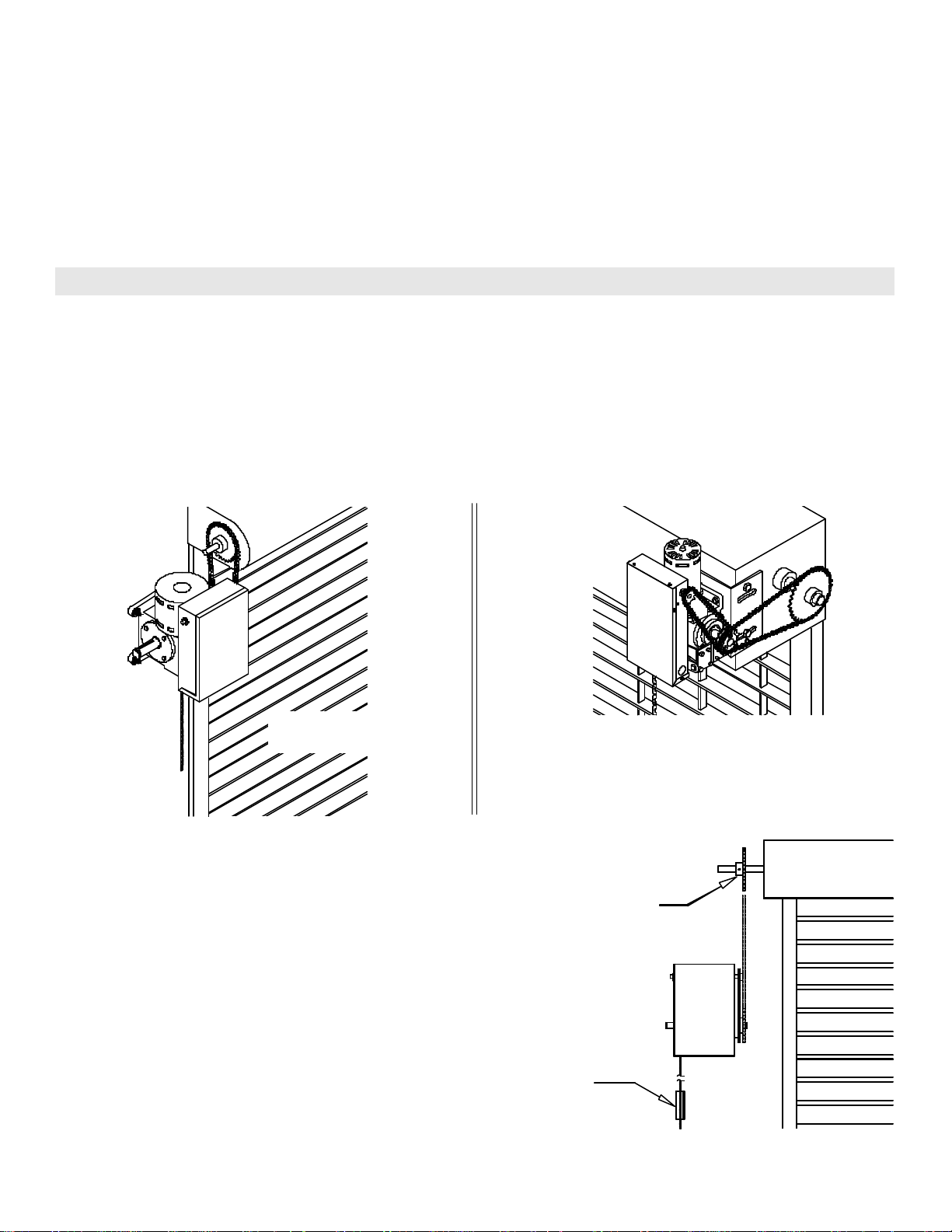

1b.Bracket or Shelf Mounting

The operator may be mounted either above or below the

door shaft. The optimum distance between the door shaft

and operator drive shaft is between 12” - 15”. Refer to

Figure 4.

FIGURE 4

IMPORTANT:The shelf or bracket must provide adequate

support, prevent play between operator and door shaft,

and permit operator to be fastened securely and with the

drive shaft parallel to the door shaft.

FIGURE 5

1c.Place door sprocket on the door shaft. Do not insert the

key at this time.

2. Wrap drive chain around door sprocket and join roller

chain ends together with master link.

3. Raise operator to approximate mounting position and

position chain over operator sprocket.

4. Raise or lower operator until the chain is slightly taut

(not tight). Make sure the operator output shaft is parallel to door shaft and sprockets are aligned. When in

position, secure the operator to wall or mounting bracket.

5. Align sprockets and secure, (see Figure 5).

Be sure door

sprocket is properly

aligned with drive

before securing to

the shaft.

Chain Keeper

5

Loading...

Loading...