Page 1

1

CDO Protector System

®

OWNER’S MANUAL

Models: CPS-N4, CPSII-N4 and CPS-LN4

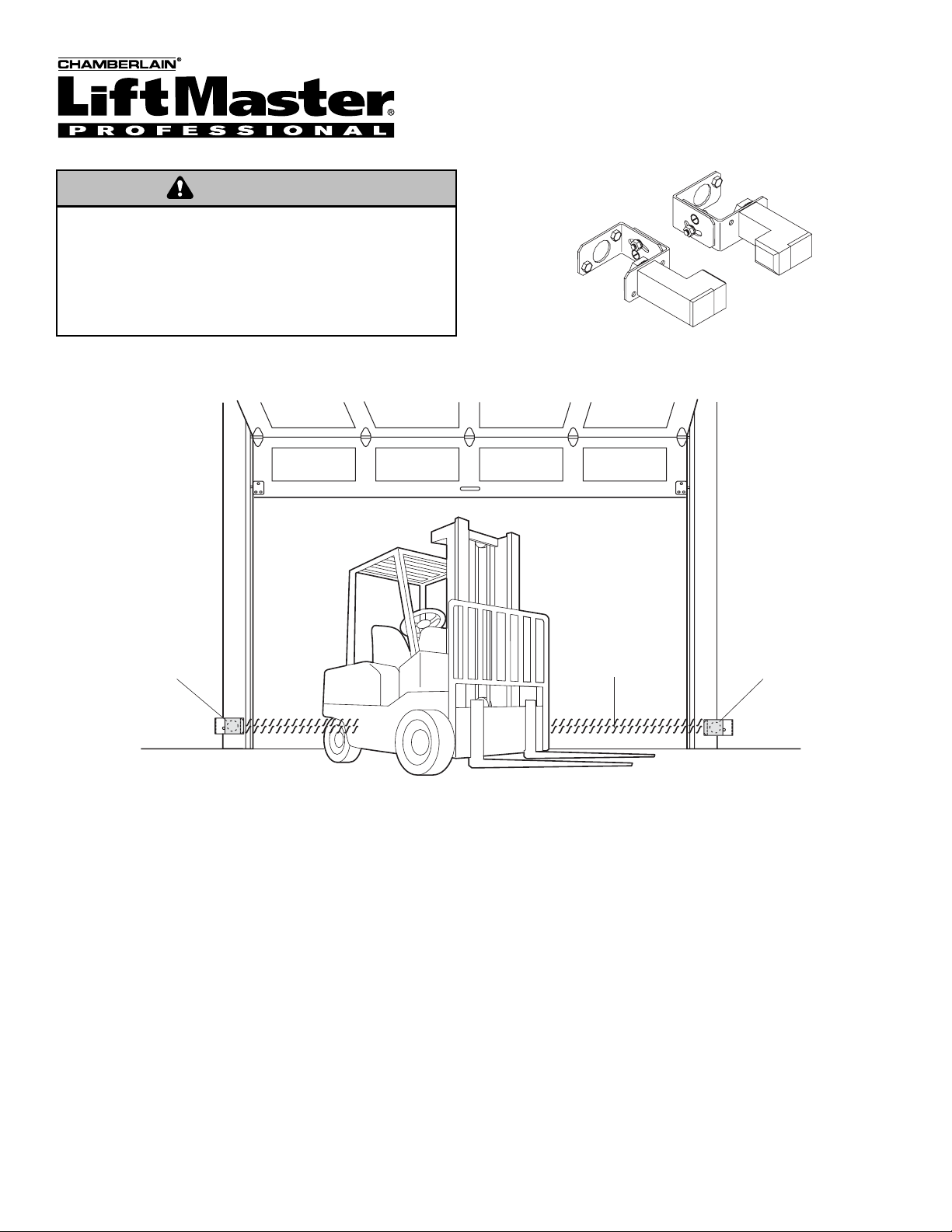

Install the Commercial Protector

System

®

IMPORTANT INFORMATION ABOUT THE SAFETY

REVERSING SENSOR

Be sure power to the opener is disconnected.

When properly connected and aligned, the sensor will detect an

obstacle in the path of its electronic beam. The sending eye

(emitter with an amber indicator light) transmits an invisible light

beam to the receiving eye (receiver with a green indicator light).

If an obstruction breaks the light beam while the door is closing,

the door will stop and reverse to full open position.

The units must be installed inside the garage so that the

sending (emitting)and receiving eyes face each other across

the door, no more than 6" (15 cm) above the floor. Either can

be installed on the left or right of the door as long as the sun

never shines directly into the receiving eye lens.

The brackets must be securely fastened to a solid surface such

as the wall framing. If installing in masonry construction, add a

piece of wood at each location to avoid drilling extra holes in

masonry if repositioning is necessary.

The invisible light beam path must be unobstructed. No part of

the garage door (or door tracks, springs, hinges, rollers or other

hardware) may interrupt the beam while the door is closing. If it

does, use a piece of wood to build out each sensor mounting

location to the minimum depth required for light beam

clearance.

Facing the door from inside the garage

This device is for use ONLY with LiftMaster Commercial Door

Operators. Use on other than recommended equipment voids

warranty, and may cause PROPERTY DAMAGE or SERIOUS

PERSONAL INJURY. Read and follow all instructions.

Have door in full open or closed position and disconnect power to

the garage door opener BEFORE installing the CDO Commercial

Protector System

®

.

WARNING

WARNING

Installation procedures are the

same for all door types.

—Left Side of Garage—

Safety Reversing

Sensor

— Right Side of Garage —

Invisible Light Beam

Protection Area

Safety Reversing

Sensor

Page 2

2

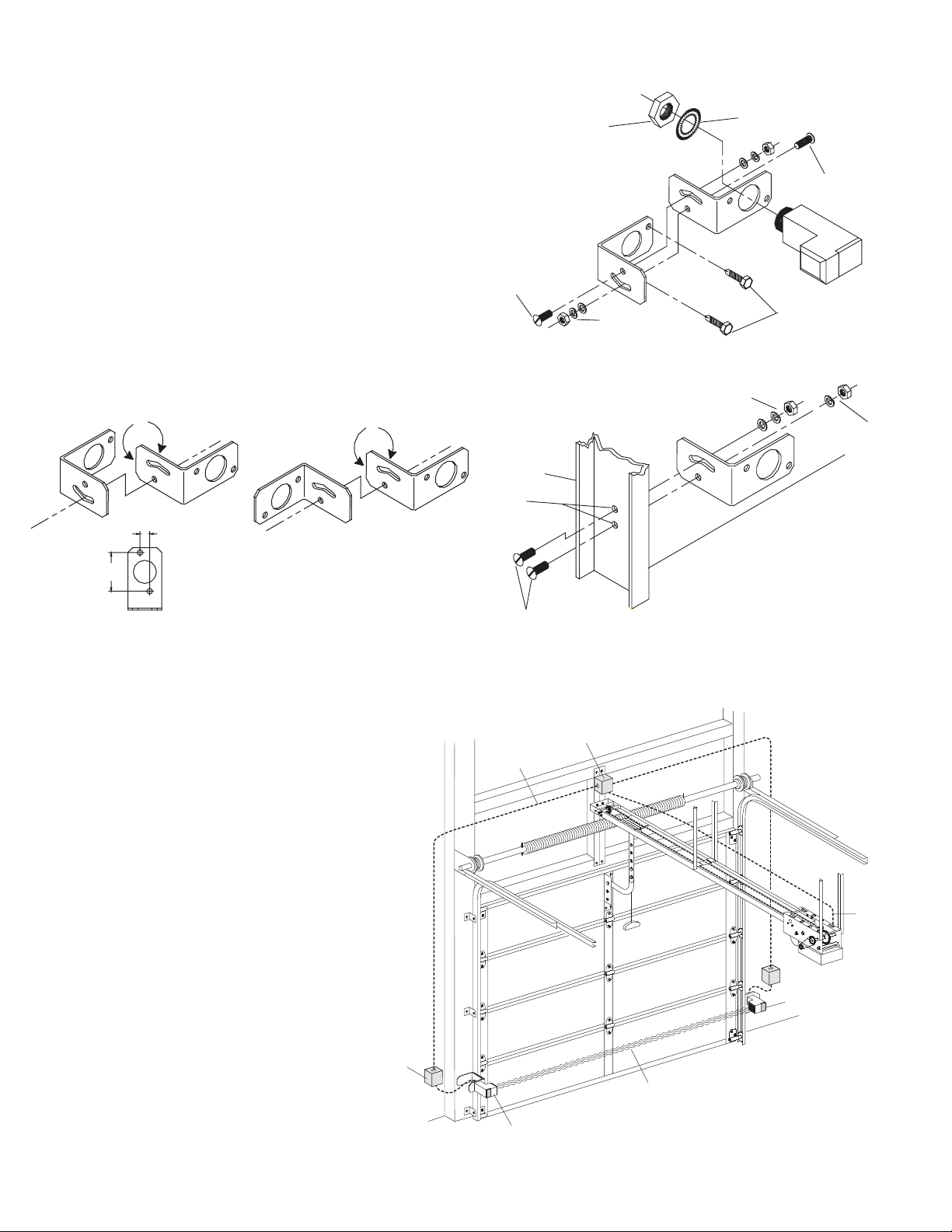

INSTALLING THE BRACKETS

IMPORTANT: Mount sensors 4"-6" (10-15 cm) above the floor.

Do not exceed 6" (15 cm). For sensing above 6" (15 cm), a

second set of eyes would be required.

Floor or Wall Mount

For typical floor or wall mounting applications see Figure 1. If

necessary, see Figure 2 for various assembly options to fit your

application. Always use flat washer next to slot with radius

(Figure 1). Insert track bolts through holes as shown. NOTE:

Putting track bolts in slots will prevent brackets from pivoting.

Attach assembly to wall with lag screws provided. To attach to

concrete use concrete anchors (not provided).

Track Mount

To mount to door track use only one bracket per side

(Figure 3).

To attach vertically to 2" x 4" wall stud and prevent wood from

splitting, bracket may also be rotated with leg on top. Shown

with leg on bottom.

CONDUIT CONNECTIONS

Use a liquid tight fitting (1/2" trade size) with sealing

washer to connect to sensors. The sensors are provided

with 36" long leads. We recommend the use of a liquid

tight junction box near each sensor to make the connection

to the sensor leads. (Figure 4). Use rigid or flexible liquid

tight conduit (depending on local codes) from junction

boxes to operator.

IMPORTANT: Use a minimum size 20 ga. copper wire for

connection between the sensors and the operator.

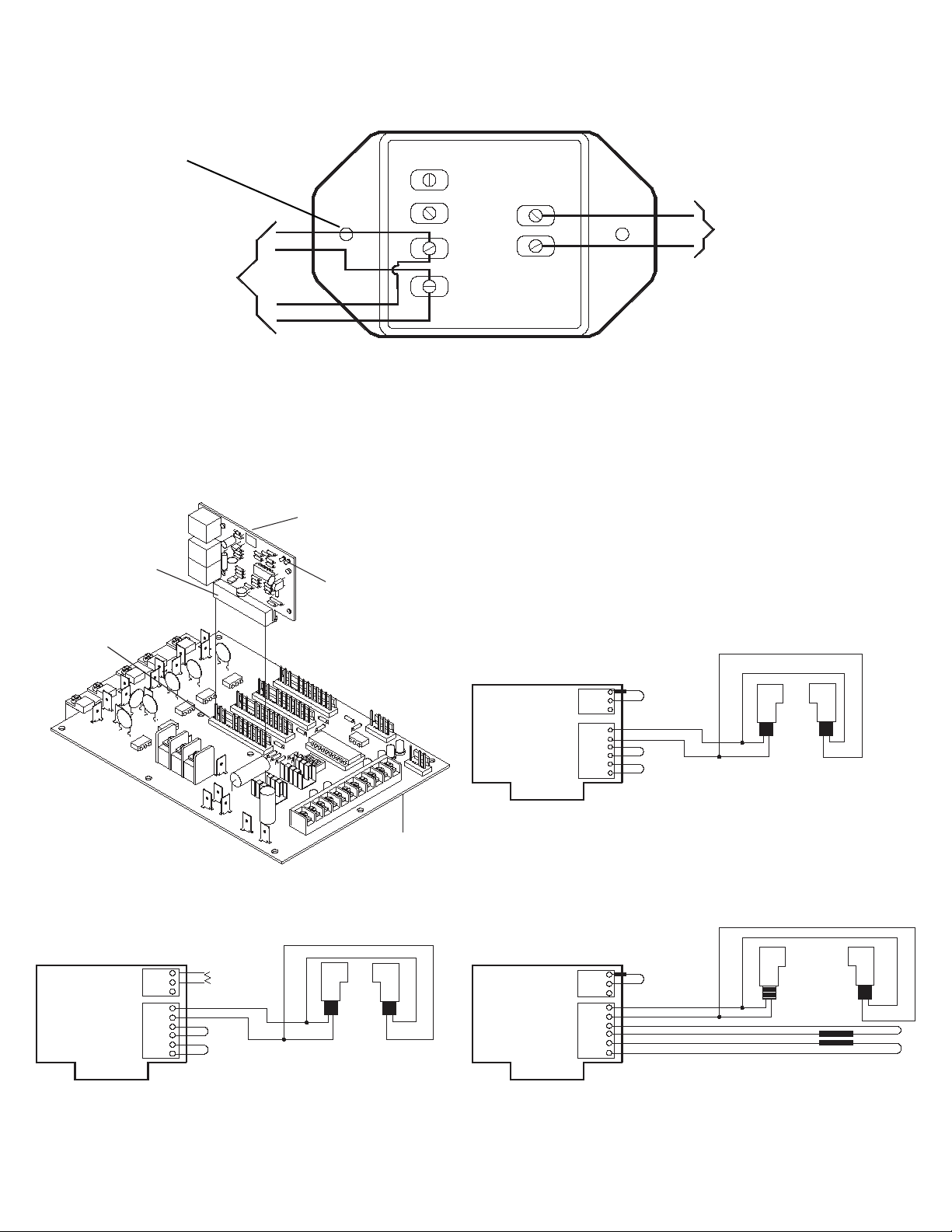

WIRING CONNECTIONS

CPS-N4: See top of page 3

CPSII-N4: See middle of page 3

CPS-LN4: See page 4 and 5

See Wiring

Connections

Sensor Beam

6" (15 cm) max. above floor

Sensor Beam

6" (15 cm) max. above floor

Invisible Light Beam

Protection Area

Liquid Tight

Conduit

Liquid Tight

Junction Box

Liquid Tight

Junction Box

Figure 4

Hex Mounting Nut

for Sensor

1/4"-20 x 5/8"

Track Bolts

Figure 1 Wall or Floor Mounting

Lock Washer for Sensor

1/4" Flat Washer

1/4" Lock Washer

1/4"-20 Hex Nut

1/4" x 1-1/2"

Lag Screws

1/4"-20 x 5/8"

Track Bolts

Figure 2 Assembly Variations

Assemble to either side

1/2" Hole Spacing

2" Hole Spacing

Flip one bracket and

assemble to either side

Figure 3 Door Track Mounting

1/4" Flat Washer

1/4" Lock Washer

1/4"-20 Hex Nut

1/4" Lock Washer

1/4"-20 Hex Nut

Door

1/4" Drill

Holes

1/4"-20 x 5/8" Track Bolts

Page 3

3

CPS-N4 Wiring Connections

CPSII-N4 Wiring Connections for use with Solid State Logic Control Board

CDO Sensing

Edge Input

To Sending Eye

(Emitter) and

Receiving Eye

(Receiver)

Commercial Protector

Interface

24V

Common

Sensor

Brown

Sensor

Blue

NOTE: Logic 2 Board will have the same connection.

CPSII Option PCB

Terminals

Green Lights

Insert PCB into

any or four slots

IR Protector Only

CDO Motherboard

A

B

C

D

E

F

G

H

I

J

A

B

C

D

E

F

G

H

I

J

IR Protector and 4-Wire Fail Safe Door EdgeIR Protector and 2-Wire Fail Safe Door Edge

A

B

C

D

E

F

G

H

I

J

Page 4

4

CPS-LN4 Wiring Connections for use with Solid State II (Logic Control Board Ver 2)

TO ACTIVATE SAFETY SENSOR EYES

1.

Start with door in the “CLOSED” position.

2. Connect the CPS-LN4 eyes as shown in figure to the left.

Confirm that the LEDs on both eyes are lit.

3. Set DIP switches to desired operating mode. (Refer to

owner’s manual for switch settings.)

4. Run the door through one full close-open-close cycle to

“Learn” the sensor eyes.

NOTE: Test the Safety Sensor Eyes operation by interrupting

the eyes while closing the door.

5. Once the sensor eyes are “Learned” and it becomes

necessary to remove the sensors, the sensors will

need to be “unlearned” by setting DIP switch to “Timer

to Close” mode and pressing the Close Button.

Brown

Blue

CPS-LN4 Wiring Connections for use with LGO Operator

IR PROTECTOR ONLY IR PROTECTOR AND SAFETY EDGE

Important Note: When sensors (IRs) are used, wiring mode

B2 must be reprogrammed. Sensors must be connected and

sending a pulse prior to programming. See LGO owner’s

manual for further information.

ON

ON

SET

TIMER

TO CLOSE

1 2 3 4

OFF

Page 5

5

CPS-N4 Wiring Connections for use with LiftMaster Operators Featuring Estate Series X3 or B3 Control Board

CPS-N4 Wiring Connections for use with LiftMaster Operators Featuring GL Control Board

Page 6

6

Testing the Protector System

®

TEST THE CDO COMMERCIAL PROTECTOR

SYSTEM

®

• Press the OPEN button to fully open the door.

• Press the CLOSE button to close the door.

• Obstruct the light beam while the door is closing. The door

should stop and reverse.

The door opener will not close if the indicator light in

either sensor is not glowing steadily, alerting you to the

fact that the sensor is misaligned or obstructed.

Troubleshooting

1. If the sending eye and receiving eye indicator lights do not

glow steadily after installation, check for:

• Electric power to the opener.

• A short in the Blue or Brown wires.

• Incorrect wiring between sensors and interface.

• An open wire (wire break).

2. If receiving eye indicator light is off (and the invisible light

beam path is not obstructed), check for an open wire to the

receiving eye.

Without a properly working CDO Commercial Protector System®,

persons (particularly children) could be SERIOUSLY INJURED or

KILLED by a closing garage door. Repeat this test once a month.

Professional service is required if the openercloses the door when

the CDO Protector System

®

is obstructed.

WARNING

NOTE: For non-solid state operators, if the door is stopped in a

mid position, activation of the sensors will cause the door to

open. This is similar to activating a sensor edge.

3. If the sending eye and receiving eye indicator lights are both

lit but interrupting the photo eyes does not cause the door to

reverse when closing, refer to “To Activate Safety Sensor

Eyes” on page 4.

WARNING

Page 7

7

Replacement Parts

CPS-N4 Commercial Protector Interface . . . .41K4629

CPSII-N4 CPSII PC Board . . . . . . . . . . . . . . . .41K4654

CPS-N4 / CPSII-N4 / CPS-LN4

Sensor Hardware Kit . . . . . . . . . . .K77-16011

Emitter . . . . . . . . . . . . . . . . . . . . . . .50-15514

Receiver . . . . . . . . . . . . . . . . . . . . .50-15515

How to Order Repair Parts

Our large service organization spans America. Installation and

service information are available six days a week. Call our toll free

number: 1-800-528-2806

HOURS: (Mountain Std. Time)

7:00 A.M. to 3:30 P.M. Monday through Saturday

When ordering repair parts, please supply the following

information:

PART NUMBER DESCRIPTION MODEL NUMBER

Address orders to:

THE CHAMBERLAIN GROUP, INC.

Technical Support Group

6020 S. Country Club Road

Tucson, Arizona 85706

Page 8

© 2005, The Chamberlain Group, Inc.

01-16013K All Rights Reserved Printed in Mexico

Loading...

Loading...