Liftmaster Bigbtykt User Manual

Battery Box

Control Box

WARNINGWARNING

This kit is compatible with most 12Vdc LiftMaster® Gate Access

Systems. The combination of this kit and a sealed lead-acid (SLA)

battery (not provided) enables the operator to function for short

durations in temperatures as low as -20 °C. An additional benefit of

the kit is extended battery backup time for solar powered

applications.

See chart for battery manufacturers.

BATTERIES

Manufacturer Part Number Specifications

Jolt XSA12800B 12V, 80AH

Werker WKA12-80C/FR 12V, 80AH

Universal UB12750 12V, 75AH

PowerSonic PS-12750 12V, 75AH

Genesis NP75-12 12V, 77.5AH

SOURCES

www.batterygiant.com

www.apexbattery.com

www.batteriesplus.com

BEFORE STARTING

• A UL Recognized BCI Group 24, 12V 75 or 80 AH sealed lead-acid

(SLA) batter y MUST be purchased.

• Make sure the battery is fully charged BEFORE installing.

• The battery cable has ring terminals that are to be attached to the

battery terminals. Select a battery that uses ring terminals,

otherwise purchase terminals that match the battery.

MODEL BIGBTYKT

To reduce the risk of FIRE or INJURY to persons:

• Use ONLY LiftMaster part BIGBTYKT.

• DO NOT dispose of the batteries in fire. The cells may explode.

Check with local codes for possible disposal instructions.

• DO NOT open or mutilate the batteries. Released electrolyte is

corrosive and may cause damage to the eyes or skin. It may be

toxic if swallowed.

• Exercise care in handling batteries in order not to short the

battery with conducting materials such as rings, bracelets, and

keys.

• Charge ONLY the batteries identified for use with this product

in accordance with the instructions and limitations specified in

this manual.

• Observe proper polarity orientation between the batteries and

charging circuit.

INSTALLATION

The battery box MUST be located close to the gate operator’s

control box in an area that is not prone to flooding, hit by gate or

knocked over.

1. Place the battery box in the selected site near the control box.

2. Remove the battery box cover. Set the sealed lead-acid battery

(not provided) inside the batter y box with the terminals on top.

3. Connect the battery cable to the battery. Attach the ring terminal on

the red wire to the positive (+) terminal of the battery. Attach the

ring terminal on the black wire to the negative (-) terminal of the

battery.

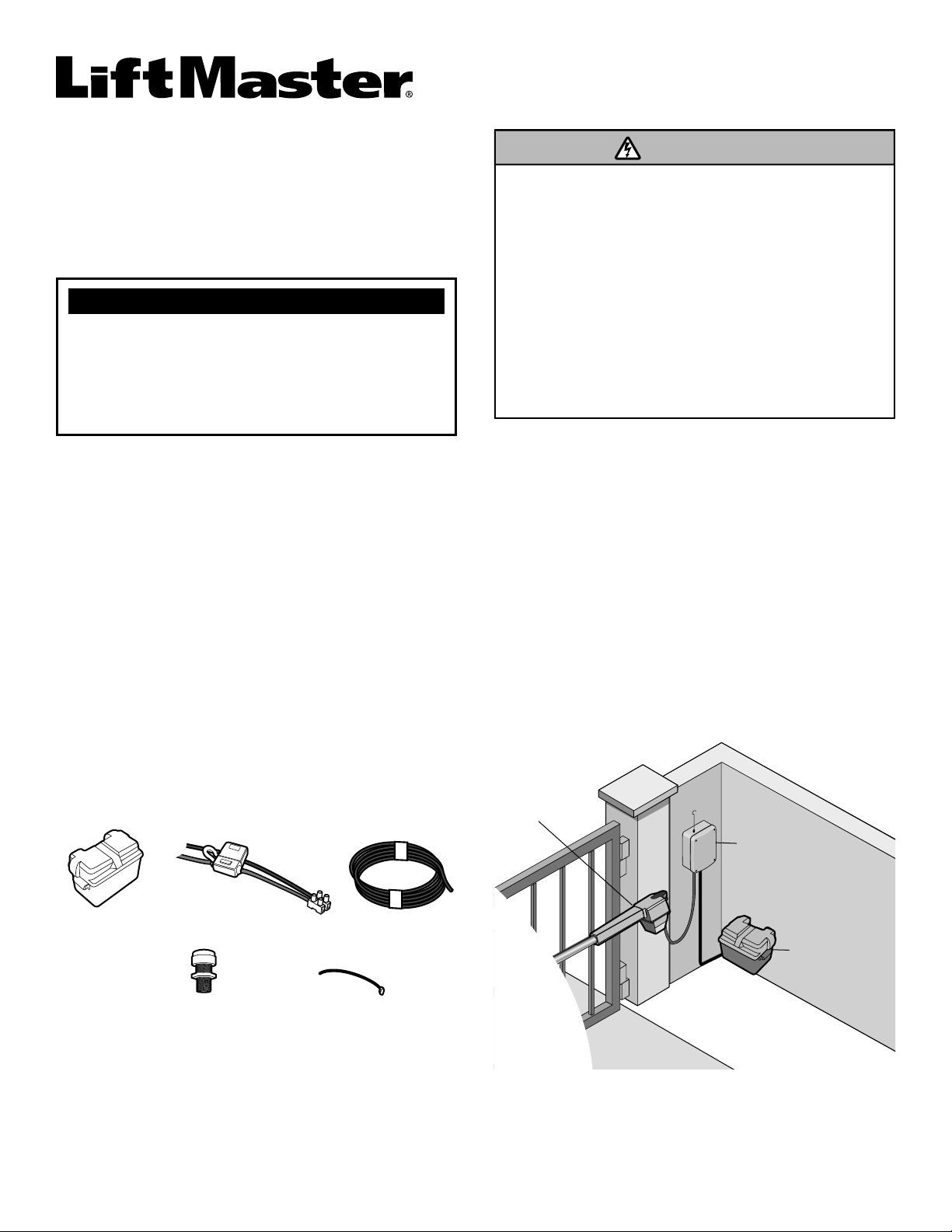

CARTON INVENTORY

Battery Box (1)

Watertight Connector (1)

Battery Cable w/ 20A fuse (1)

Your gate operator

may look different

Extension Cable (1)

Wire Tie (4)

CONNECT TO GATE OPERATOR CONTROL BOX

+

–

18

R93

L1

D42

K2

D1

Ø

Z22

P1

F2

MOV1

D1

Q12

U4

OFF

MAX

OPEN

SINGLE BUTTON

RESET

STOP

CHGR

OVLD

COM

COM

D129

Z4

U

3

D2

D44

C11

C13

C12

D16

F9

R1Ø1

ØØ

K1

Q22

F3

K3

K4

R196

F1

Z12

GATE 2

GATE 1

MAGR

SOL

GR

WH

YL

BL

RD

BR

GR

WH

YL

BL

RD

BR

F7

24V

CTRL

OVLD

TIMER

RUNNING

GATE 2

SET

OPEN

LIMIT

SET

CLOSE

LIMIT

LEARN

LIMITS

GATE 1

LEARN

XMITTER

LOCK /

OFF

C69

OFF

MAX

J2

Ø

PWR

AC PWR

/SOLAR

D8

D4

R9

R329

R27

MOV2

R4

C2

BIPART DELAY

LOCK

GND

Z1

R1

R2

K5

F12

Q9

R9

Ø

F8

Q6

Q1

J19

R182

Ø1

C75

C73

C72

C71

C7

Ø

C66

C65

C68

C33

F11

R186

R42

Ø

R423

J24 J23 3

Ø

A 32V

3

Ø

A 32V

J21

30

30

C64

R22

U2

J18

K6

JU1

JU1

JU2

DB1

D36

R184

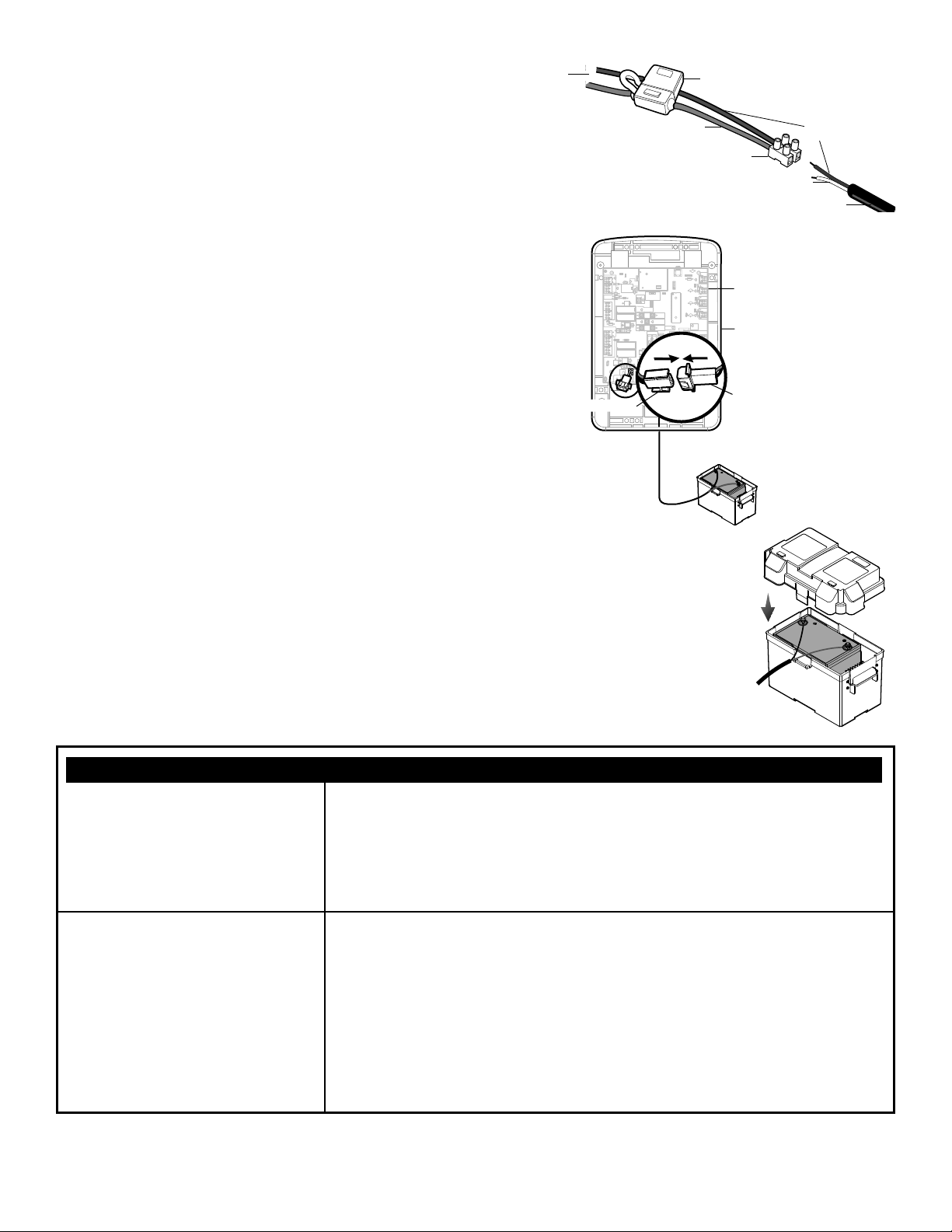

1. Disconnect all power to the gate operator before proceeding.

2. Use a screwdriver to punch out the plastic knockout at the

bottom of the control box. Install the water tight connector.

3. Feed the non-connector end of the extension cable through the

watertight connector from the inside of the control box. Tighten

the watertight connector until the cable is secure.

4. Run the extension cable to the battery box and connect the

black wire of the extension cable to the black wire of the

terminal block on the battery cable. Connect the white wire to

the red wire.

5. Connect the batter y connectors on the control board to the

connector on the extension cable in the control box.

NOTE: Disconnect one of the internal 7 AH batteries and use the

connector to connect the external battery. The unused 7 AH battery

can be removed from the system.

6. Verify that the gate operator operates correctly.

IMPORTANT NOTE: If the gate operator does not operate correctly, the

wiring may be incorrect. Also, if the battery has been discharged,

disconnect it and charge separately. Refer to troubleshooting for

more tips.

7. Use the wire ties to secure the cables.

8. Reconnect power to the operator.

9. Close the cover on the control box.

10. Place the cover on the top of the batter y box. Be sure all drain

holes and air vents are properly opened.

Batter y Cable

Control Board Connector

Fuse Holder

Red

Black

Ter m i nal B l ock

White

Extension Cable

R182

C1C1Ø1

D36

SOL

GND

MAGR

D42

LOCK

Z1

R1

GATE 1

BR

GR

WH

YL

BL

RD

F8

Z12

24V

R1R1ØØ

R1

BR

GR

WH

YL

BL

RD

GATE 2

D16

F9

F1

J21

30

3

A 32V

P1

J19

K5

F12

LEARN

R2

XMITTER

D1

K2

SET

K1

OPEN

LIMIT

Q9

R9

K4

K3

Q22

R196

J24 J23 3

F3

30

A 32V

C66

C65

J18

C68

L1

ONONOFF

LOCK /

BIPART DELAY

OFF

D44

D8

D4

R9

D1

R329

R27

C64

R22

U2

Z22

C33

CTRL

PWR

OVLD

OPEN

RESET

STOP

COM

COM

C2

MOV2

R4

Control Board

Control Box

R184

Q6

U4

C75

C7

C71

Q12

C72

C73

F11

18

R93

GATE 1

Q1

SET

LEARN

CLOSE

LIMITS

LIMIT

TIMER

GATE 2

RUNNING

J2

SINGLE BUTTON

R186

MAX

OFF

MAX

C12

F7

Z4

U

C13

D2

3

D129

F2

CHGR

C69

MOV1

OVLD

R42

R423

JU1

C11

AC PWR

/SOLAR

K6

JU2

DB1

JU1

External Battery Connector

–

+

TROUBLESHOOTING

PROBLEM SOLUTION

System does not power up when

external battery is connected.

System powers up but does not

run correctly.

FOR TECHNICAL SUPPORT CALL OUR TOLL FREE NUMBER: 1-800-528-2806

© 2011, The Chamberlain Group, Inc.

01-34506C All Rights Reserved

1. Wires may be swapped. Verify that all wires are properly connected.

2. Battery is not charged. It is possible that the 12V battery (not provided) was not fully charged

when installed. Use a voltmeter to make sure this battery is good and has at least 12V across

the open circuit terminals.

3. Blown fuse. It is possible that a fuse, either in the battery cable harness or on the operator

control board, may have been blown during the installation. If a blown fuse is found, first check

all wiring to make sure it is correct, and then replace the fuse with the same size and type.

1. Wires may not be properly connected. Verify all connections for the installation. Batteries are

required for the operator to run.

2. Blown fuse. It is possible that a fuse, either in the battery cable harness or on the operator

control board, may have been blown during the installation. If a blown fuse is found, first check

all wiring to make sure it is correct, and then replace the fuse with the same size and type.

3. Battery is not charged. It is possible that the 12V battery (not provided) was not fully charged

when installed. Use a voltmeter to make sure this battery is good and has at least 12V across

the open circuit terminals.

4. Debris or other obstructions are affecting gate travel. Make sure that the battery box and

connecting wires are clear of the gate. Clear the gate of all obstructions and verify all safety

devices are operating properly.

Loading...

Loading...