Page 1

The Chamberlain Group, Inc.

Elmhurst, Illinois 60126-1196

BG770 & BG790

INDUSTRIAL-DUTY BARRIER GATE OPERATOR

OWNER'S MANUAL

845 Larch Avenue

www.liftmaster.com

MODELS BG770 AND BG790 ARE FOR VEHICULAR PASSAGE GATES ONLY

AND ARE NOT INTENDED FOR PEDESTRIAN PASSAGE GATE USE

Page 2

TABLE OF CONTENTS

WARNING

CAUTION

WARNING

SPECIFICATIONS

Operator Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Operator Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

OPERATOR WARNINGS

Safety Installation Information . . . . . . . . . . . . . . . . . . . . . . . . . . .4

PREPARATION

Carton Inventory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Site Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Operation Preparation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

INSTALLATION

Pad Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Arm Fabrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Calculate Arm Length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Wiring Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Wiring Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Arm Attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-9

Arm and Turnbuckle Shaft Adjustments . . . . . . . . . . . . . . . . . . .10

Limit Switch Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

OPTIONAL ACCESSORIES

Vehicle Detectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Radio Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Card Readers, Keypads or Other. . . . . . . . . . . . . . . . . . . . . . . . . 12

Mounting Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

OPERATING INSTRUCTIONS

Electrical Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Manual Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

TROUBLESHOOTING

Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Primary Voltage Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Low Voltage Circuit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

General Reference Information . . . . . . . . . . . . . . . . . . . . . . . . . .15

IMPORTANT NOTES

• BEFORE attempting to install, operate or maintain the operator,

you MUST read and fully understand this manual and follow

ALL safety instructions.

• These instructions are intended to highlight certain safety

related issues. These instructions are not intended to be

comprehensive. Because each application is unique, it is the

responsibility of the purchaser, designer, installer and end user

to ensure that the total gate system is safe for its intended use

Mechanical

Electrical

When you see these Safety Symbols and Signal Words on the

following pages, they will alert you to the possibility of SERIOUS

INJURY or DEATH if you do not comply with the warnings that

accompany them. The hazard may come from something

mechanical or from electric shock. Read the warnings carefully.

When you see this Signal Word on the following pages, it will

alert you to the possibility of damage to your gate and/or the gate

operator if you do not comply with the cautionary statements that

accompany it. Read them carefully.

REPAIR PARTS

Illustrated Parts - Model BG770 . . . . . . . . . . . . . . . . . . . . . . . . .16

Repair Parts - Model BG770 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Illustrated Parts - Model BG790 . . . . . . . . . . . . . . . . . . . . . . . . .18

Repair Parts - Model BG790 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

MAINTENANCE

Limited Bearing Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Grease Turnbuckle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

WIRING DIAGRAMS

Single Phase Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Three Phase Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Control Connection Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . .23

WARRANTY POLICY AND SERVICE

. . . . . . . . . . . . . . . . 24

2

Page 3

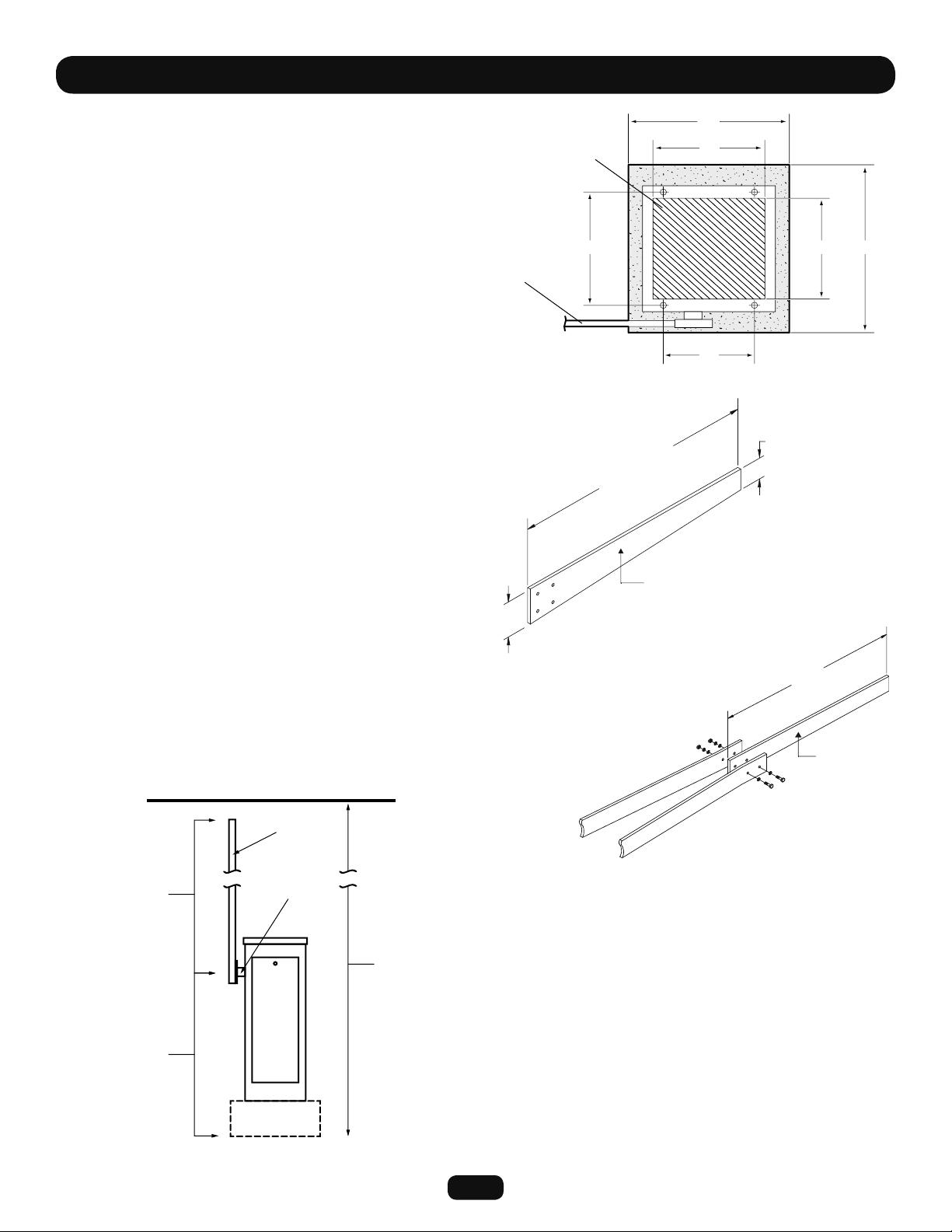

SPECIFICATIONS

MOTOR

Squirrel cage induction type (3 phase) or capacitor start

induction type (1 phase), continuous duty, 1725 RPM.

Horsepower is designated by second suffix of operator part

number.

-50; 1/2 Horsepower

POWER

Line voltage is designated by third suffix of gate part number.

For amp draw, see motor nameplate.

-11; 115Vac, 1 Phase, 60Hz

-21; 230Vac, 1 Phase, 60Hz

-81; 208Vac, 1 Phase, 60Hz

-83; 208Vac, 3 Phase, 60Hz

-23; 230Vac, 3 Phase. 60Hz

-43; 460Vac, 3 Phase, 60Hz

-53; 575Vac, 3 Phase, 60Hz

OPERATION

Prewired terminal strip accepts field connection of any access

control device with normally open (N.O.) output contact (most

access control equipment) and when required, a separate

OPEN/CLOSE pushbutton (provided).

Plug-in connectors are included for addition of a loop detector

to open and/or a loop detector to hold open (not provided).

Activation of access device open button, or loop detector to

open will raise gate. Gate will lower automatically unless hold

open loop detector is activated or unless CLOSE button wiring

has been made, in which case gate will remain open until

CLOSE button is pushed.

An optional timer will extend the time that the gate remains

open. AUTO/MANUAL switch holds arm in vertical position.

ENCLOSURE

Weatherproof, heavy gauge, pregalvanized steel, powdercoat

finish, top and side access covers with key lock.

ELECTRICAL

OVERLOAD PROTECTION

Automatic reset (3 phase operators) or manual reset (1 phase

operators) thermal overload.

ELECTRICAL BOX

NEMA 1 general purpose painted steel enclosure, contains all

motor control equipment. Enclosure removable from operator.

CONTROL CIRCUIT

Class II, 24Vac

LIMIT SWITCHES

Adjustable, driven limit switches, operate in class II circuit. Not

affected by removal of motor.

POWER ON/OFF SWITCH

Enclosed toggle switch, HP rated.

MECHANICAL

SPEED REDUCTION

Wormgear-in-oil-bath, 60:1

ARM TYPE

MODEL BG770: One piece type to 15'

MODEL BG790: Counterweighted wishbone type to 24'

ARM SPEED

MODEL BG770: Opens in 4 seconds

MODEL BG790: Opens in 11 seconds

LUBRICATION

Permanently lubricated bearings in motor. Low temperature

gear oil normally never needs replacement. Gear oil is

Mobil SHC 630 or equivalent.

MOUNTING

Pad mount

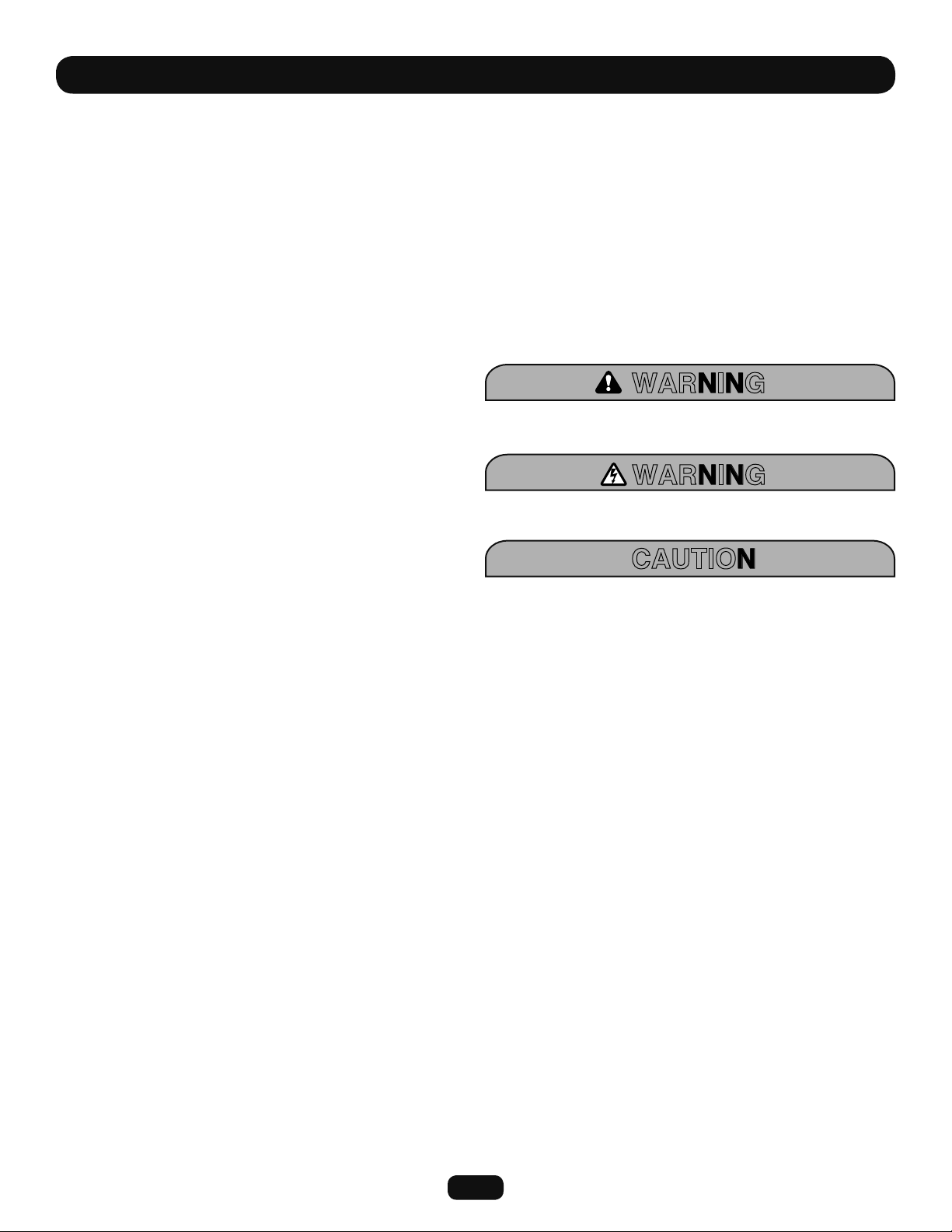

Model BG770 Model BG790

Typical

Installation

17"

35"

17"

44"

3

Counterweighted

Wishbone Arm

DIMENSIONSDIMENSIONS

Typical

Installation

17"

17"

Up to 24'Up to 15'

35"

22"

44"

Page 4

OPERATOR WARNINGS

SAFETY INSTALLATION INFORMATION

1. Vehicular gate systems provide convenience and security. Gate systems are comprised of many component parts. The gate

operator is only one component. Each gate system is specifically designed for an individual application.

2. Gate operating system designers, installers and users must take into account the possible hazards associated with each individual

application. Improperly designed, installed or maintained systems can create risks for the user as well as the bystander. Gate

systems design and installation must reduce public exposure to potential hazards.

3. A gate operator can create high levels of force in its function as a component part of a gate system. Therefore, safety features

must be incorporated into every design. Specific safety features include:

• Gate Edges • Guards for Exposed Rollers • Photoelectric Sensors

• Screen Mesh • Vertical Posts • Instructional and Precautionary Signage

4. Install the gate operator only when:

a. The operator is appropriate for the construction and the usage class of the gate.

b. All openings of a horizontal slide gate are guarded or screened from the bottom of the gate to a minimum of 4' (1.2 m) above

the ground to prevent a 2 1/4" (6 cm) diameter sphere from passing through the openings anywhere in the gate, and in that

portion of the adjacent fence that the gate covers in the open position.

c. All exposed pinch points are eliminated or guarded, and guarding is supplied for exposed rollers.

5. The operator is intended for installation only on gates used for vehicles. Pedestrians must be supplied with a separate access

opening. The pedestrian access opening shall be designed to promote pedestrian usage. Locate the gate such that persons will not

come in contact with the vehicular gate during the entire path of travel of the vehicular gate.

6. The gate must be installed in a location so that enough clearance is supplied between the gate and adjacent structures when

opening and closing to reduce the risk of entrapment. Swinging gates shall not open into public access areas.

7. The gate must be properly installed and work freely in both directions prior to the installation of the gate operator.

8. Controls intended for user activation must be located at least six feet (6') away from any moving part of the gate and where the

user is prevented from reaching over, under, around or through the gate to operate the controls. Outdoor or easily accessible

controls shall have a security feature to prevent unauthorized use.

9. The Stop and/or Reset (if provided separately) must be located in the line-of-sight of the gate. Activation of the reset control shall

not cause the operator to start.

10. A minimum of two (2) WARNING SIGNS shall be installed, one on each side of the gate where easily visible.

11. For a gate operator utilizing a non-contact sensor:

a. Reference owner’s manual regarding placement of non-contact sensor for each type of application.

b. Care shall be exercised to reduce the risk of nuisance tripping, such as when a vehicle trips the sensor while the gate is

still moving.

c. One or more non-contact sensors shall be located where the risk of entrapment or obstruction exists, such as the perimeter

reachable by a moving gate or barrier.

12. For a gate operator utilizing a contact sensor such as an edge sensor:

a. One or more contact sensors shall be located where the risk of entrapment or obstruction exists, such as at the leading edge,

trailing edge and post mounted both inside and outside of a vehicular horizontal slide gate.

b. One or more contact sensors shall be located at the bottom edge of a vehicular vertical lift gate.

c. A hard wired contact sensor shall be located and its wiring arranged so the communication between the sensor and the gate

operator is not subject to mechanical damage.

d. A wireless contact sensor such as the one that transmits radio frequency (RF) signals to the gate operator for entrapment

protection functions shall be located where the transmission of the signals are not obstructed or impeded by building

structures, natural landscaping or similar obstruction. A wireless contact sensor shall function under the intended end-use

conditions.

e. One or more contact sensors shall be located on the inside and outside leading edge of a swing gate. Additionally, if the bottom

edge of a swing gate is greater than 6" (152 mm) above the ground at any point in its arc of travel, one or more contact sensors

shall be located on the bottom edge.

f. One or more contact sensors shall be located at the bottom edge of a vertical barrier (arm).

4

Page 5

PREPARATIONS

WARNING

CARTON INVENTORY

1. Unpack the carton, checking for possible damage during

shipping. The arm (when provided) is packed separately.

Damage claims MUST be filed with the freight carrier.

2. Check that the nameplate data (inside service cover) accurately

matches the operator that was ordered.

3. Verify that the following parts are included with the standard

unit.

MODEL BG770 PACKING LIST MODEL BG790 PACKING LIST

PART NUMBER DESCRIPTION QTY

02-102 Open/Close Push Button 1

07-8007 Gate Arm Hub 1

10-8007M Gate Bracket 1

80-G0187 Key, 1/2 x 1/2 x 1-3/8 1

82-NH38-06 Cone Point Set Screw, 3/8-16 x 3/8 2

82-HN50-25 Hex Bolt, 1/2-13 x 2-1/4 4

82-RH-50 Hex Nut, 1/2-13 4

85-LS-50 Split Lock Washer, 1/2 4

01-G0674 Owner’s Manual 1

SITE PREPARATION

1. Be sure that selected gate location has required clearance for

arm movement (and counterweights on model BG790). Refer to

the dimensional drawings on page 3.

2. Run electrical power to the site according to local electrical

codes (Figure 1). See chart on page 7 for correct wire size and

length of run. If the wire gauge is too high (wire too small) or

the run is too long, the gate may not run properly or may not

run at all. Damage to components may result.

IMPORTANT NOTE: Be sure that the available power is the proper

voltage, phase, frequency, and amperage to supply the gate.

Refer to gate nameplate located inside the service cover.

3. Select locations for control equipment and run any control

wiring that may be needed (such as loop wires, card readers,

ticket spitters, pushbuttons, etc.).

To reduce the risk of SEVERE INJURY or DEATH, disconnect

power BEFORE performing ANY adjustments.

PART NUMBER DESCRIPTION QTY

02-102 Open/Close Push Button 1

07-8007 Arm Hub 2

10-8055 Counter Weight Clamp 2

80-G0135 Threaded Rod, 3/8-16 x 18 2

80-G0187 Key, 1/2 x 1/2 x 1-3/8 2

82-HN50-25 Hex Head Bolt, 1/2-13 x 2-1/4 12

82-HN50-28 Hex Head Bolt, 1/2-13 x 3 2

82-NH38-06 Cone Point Set Screw, 3/8-16 x 3/8 4

84-RH-50 Hex Nut, 1/2-13 14

84-WH-38 Serrated Flange Nut, 3/8-16 8

85-FW-38 Flat Washer, 3/8 8

85-FW-50 Flat Washer, 1/2 8

85-LS-50 Split Lock Washer, 1/2 16

01-G0674 Owner’s Manual 1

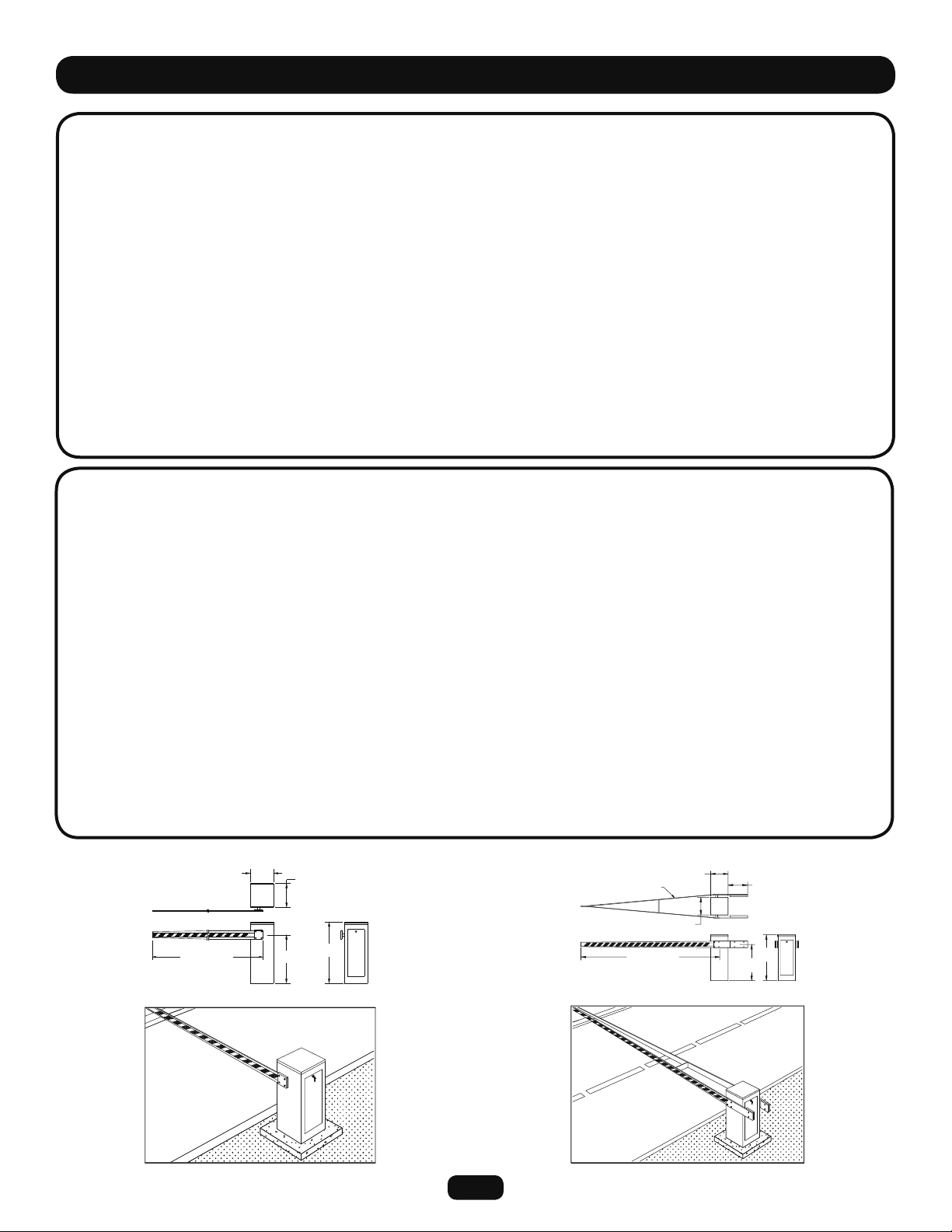

Figure 1

NOTE: Install line power here. Do not

install line power in panel shown below.

Power switch should be in the OFF position.

OPERATOR PREPARATION

1. Remove the wood base from the unit and discard.

2. Locate the keys for the access panel (taped to the arm

mounting flange) and remove.

3. Open the side access panel and check the position of the power

ON/OFF switch.

4. Open the cover of the electrical cabinet and be sure that the

AUTO/MANUAL switch is in the “AUTO” position.

5. OPTIONAL CONTROL EQUIPMENT: If loop detectors, radio

controls, or other control equipment will be added at the site,

do so now. Refer to the instructions in this manual for

installation of factory-provided optional open and/or hold open

loop detectors and for connection of factory-provided optional

radio controls (see Optional Accessories on page 12).

AUTO/MANUAL switch should

be in the “AUTO” position.

5

Page 6

INSTALLATION

PAD MOUNTING

1. Layout the concrete pad (Figure 2). Be sure to locate electrical

conduit inside the hatched 14" x 13" area.

2. Excavate required area for pad and conduit. Pad depth should

be below the frost line or as required by local codes.

3. Pour concrete pad. Concrete pad should be level and above the

ground line.

4. Allow the concrete to set at least two days before installing

operator.

5. Secure operator with four concrete anchors (not provided).

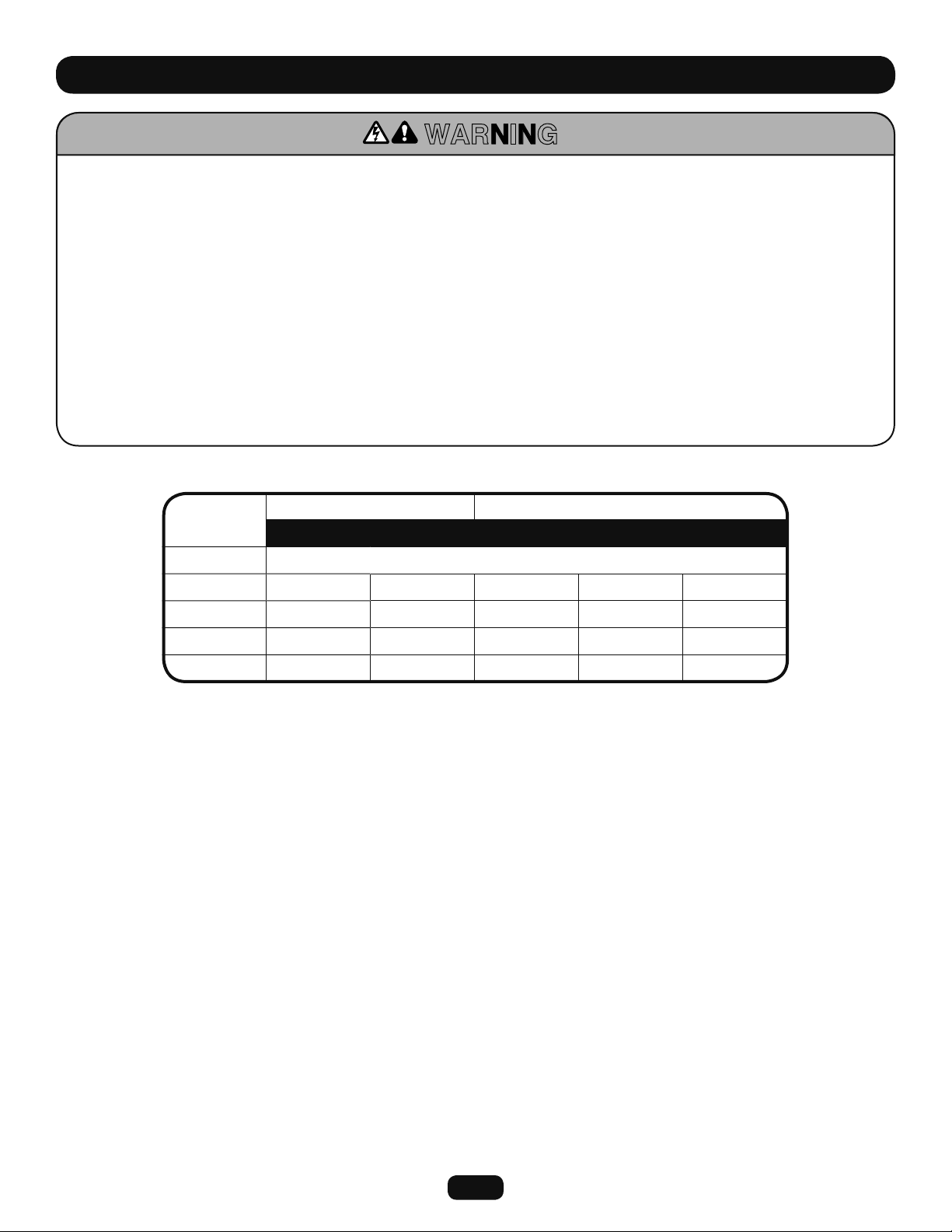

ARM FABRICATION

MODEL BG770 (SINGLE ARM)

If you are making the arm yourself, refer to Figure 3 and its

suggestions for the single arm design.

1. Drill four 1/2" diameter holes using the arm clamp as a

template. Tapering the wood as shown helps reduce the

weight and allows you to reduce any warping common

with long lengths of lumber.

2. Cut to desired length. Refer to Calculate Arm Length below.

3. Finish arm with exterior grade paint and stripe with paint or

adhesive backed tape as required.

Figure 2

Conduit Entry Area

Arm

Figure 3

14-1/2"

Length as needed

up to 12'

20"

14"

13" 22"

12"

3"

Material:

6: x 1" Pine or Redwood

MODEL BG790 (WISHBONE ARM)

A 24' wishbone arm is provided as standard with every BG790

gate. If a shorter arm is desired, the extension may be shortened

(Figure 4). The maximum arm extension is 8' for a total arm

length of 24'.

1. Cut to desired length. Refer to Calculate Arm Length below.

2. Finish with an exterior grade paint and stripe with paint or

adhesive backed tape as required.

Figure 5

Arm length

Height of the

output shaft and

concrete pad (40")

Arm

Output Shaft

Height to

ceiling

5-12"

Length up to 8'

Figure 4

Material:

4: x 1" Pine or Redwood

Arm Extension

CALCULATE ARM LENGTH

To calculate the arm length:

Subtract the height of the output shaft and concrete pad (40")

from the height to ceiling (see Figure 5).

EXAMPLE:

If height to ceiling is 8'3" (99"), calculation is as follows:

99" (height to ceiling) - 40" (height of the output shaft and

concrete pad) = 59"

Lower arm should be 59".

6

Page 7

INSTALLATION

WARNING

To reduce the risk of SEVERE INJURY or DEATH:

• ANY maintenance to the operator or in the area near the

operator MUST not be performed until disconnecting the

electrical power and locking-out the power via the operator

power switch. Upon completion of maintenance the area

MUST be cleared and secured, at that time the unit may be

returned to service.

• Disconnecting power at the fuse box BEFORE proceeding.

Operator MUST be properly grounded and connected in

accordance with local electrical codes. NOTE: The operator

should be on a separate fused line of adequate capacity.

• DO NOT install ANY wiring or attempt to run the operator

without consulting the wiring diagram. We recommend that

you install an optional reversing edge BEFORE proceeding

with the control station installation.

WIRING SPECIFICATIONS

SINGLE PHASE THREE PHASE

115 Vac 230 Vac 230 Vac 460 Vac 575 Vac

AWG Maximum Length of Wire Run in Feet

6 700 3,100 4,750 14,225 35,550

8 450 1,925 3,000 8,975 22,425

• ALL electrical connections MUST be made by a qualified

individual.

• ALL power wiring should be on a dedicated circuit and well

protected. The location of the power disconnect should be

visible and clearly labeled.

• ALL power and control wiring MUST be run in separate

conduit.

• BEFORE installing power wiring or control stations be sure to

follow ALL specifications and warnings described below.

Failure to do so may result in SEVERE INJURY to persons

and/or damage to operator.

• A ground screw is provided in the switch box for connection

of the power supply ground wire. Failure to properly ground

this unit could result in electrical shock and SERIOUS

INJURY.

10 275 1,225 1,900 5,650 14,075

12 175 775 1,175 3,525 8,825

WIRING CONNECTIONS

Locate the electrical enclosure inside the cabinet. The enclosure

(shipped loose) may be removed from the cabinet to help in the

connections described below. When all connections are complete,

hang the enclosure as described in step 7.

1. Open the cover of the electrical enclosure. Refer to the wiring

diagram supplied inside for all electrical connections.

2. Be sure that power supply is of the correct voltage, phase,

frequency, and amperage to supply operator. Refer to the

operator nameplate on electrical cabinet cover.

3. Connect power supply wires to the ON/OFF power switch as

shown on the operator wiring diagram. DO NOT connect power

at control panel (L1, L2, L3). Route wires away from belt and

limit switches.

4. A 2-button control station (OPEN/CLOSE) is provided as

standard equipment with every BG770 and BG790 barrier gate.

If you are not using automatic controls to control the gate, the

2-button control station may be connected as shown on the

wiring diagram supplied with the gate to control the gate

manually. However, the AUTO/MANUAL switch should be kept

in the “AUTO” position.

IMPORTANT NOTE: Use 16 gauge wire or larger for all control

wiring connections. If the control wire is too small, damage to

the operator components may result.

5. The control station must be mounted in a location adjacent to

and within clear sight of the gate. If you will mount the control

station outdoors, replace the standard station supplied with the

operator with a weatherproof station.

6. The BG770 and BG790 barrier gates will interface with almost

all types of commonly used control stations, radio controls, and

access control equipment. Refer to the wiring diagram for

connection of these devices.

If you are using a loop detector to open and/or hold open and

close, mounting space and plug-in harnesses are provided in

the electrical cabinet for installation of optional factory supplied

detectors. You may also use other detectors. Refer to the

Optional Accessories section on page 12.

7. When all wiring connections are complete, mount the electrical

enclosure to the shelf housing shelf. MODEL BG770: Hang

electrical enclosure on the two screws provided on the front of

the shelf in the housing. MODEL BG790: Hang electrical

enclosure on the two screws provided on the cross angle under

shelf in the housing.

7

Page 8

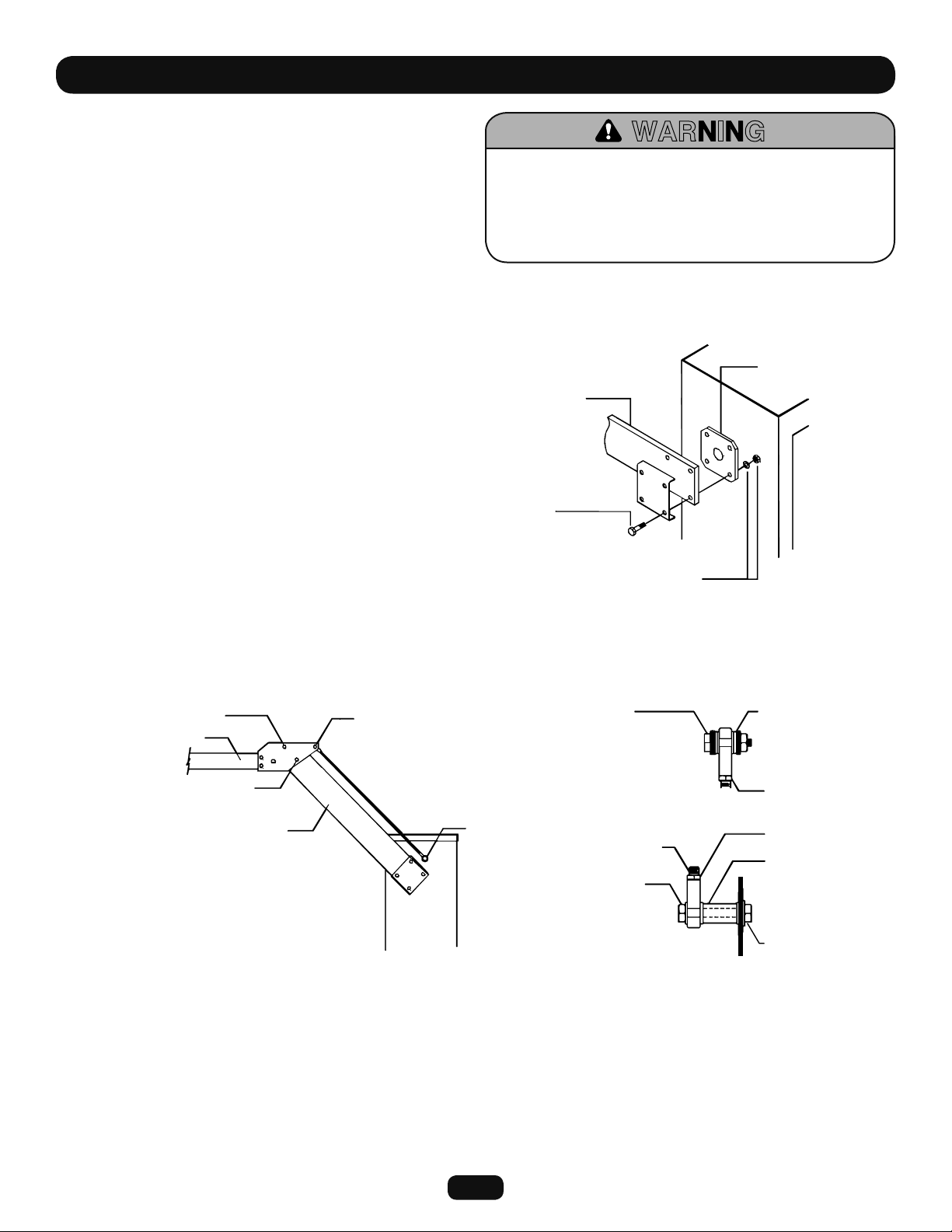

INSTALLATION

WARNING

ARM ATTACHMENT

For easier access during installation, the top cover of the unit may

be opened by removing the two wing nuts from underneath,

inside the cabinet.

MODEL BG770: STANDARD ARM

Attach arm to the arm hub flange (Figure 5).

MODEL BG770: OPTIONAL ARM

Attach arm to the arm hub flange (Figure 6).

When following the procedure below, the motor belt will turn

and the drive shaft will move during some of the steps. Keep

hands and tools out of the gate cabinet and away from the

belt and drive shaft or SERIOUS INJURY may result. Be sure

to DISCONNECT power while installing the arm attachment.

Figure 5

Hub Flange

Gate Arm

Hex Bolt

1/2"-13 x 2-1/4"

Figure 6

(4) Hex Bolts

Extension Arm

S Screw

Lift Arm

See Detail A

See Detail B

Lock Washer and

1/2"-13 Hex Nut

Hex Bolt

(2) Flat Washers

DETAIL A

Threaded Rod

Hex Bolt

Flat Washer

DETAIL B

(2) Flat Washers

Hex Nut

Hex Nut

Hex Nut

Flat Washer

Threaded Spacer

Flat Washer

Flat Washer

Hex Bolt

8

Page 9

INSTALLATION

WARNING

MODEL BG790: WISHBONE COUNTERWEIGHTED ARM

1. Bolt counterweights to ends of arms clamps (Figure 7). Use

caution lifting 57 lb. weights.

2. Bend and fasten the two arms together (Figure 8). If an

extension arm is required, sandwich the extension arm

between the two halves of the wishbone arm before bolting

together. Refer to Arm Fabrication on page 6 for extension

arm preparation.

3. Assemble the two 3/8" threaded rods to the arms for center

support.

4. Be prepared for gate to start when you turn the power on. Turn

on power and test the gate.

When following the procedure below, the motor belt will turn

and the drive shaft will move during some of the steps. Keep

hands and tools out of the gate cabinet and away from the

belt and drive shaft or SERIOUS INJURY may result. Be sure

to DISCONNECT power while installing the arm attachment.

Figure 7

18-5/8"

30" Radius

Wishbone Arm Arc of Travel

Ensure adequate clearance for travel of arm.

Figure 8

3/8"-16 Nut

3/8" Flat Washer

(2) 1/2"-13 x 3" Bolts

(2) 1/2" Flat Washers

(2) 3/8"-16 x 18"

Threaded Rods

Extension Arm

Wishbone Arm

(8) 3/8"-16 Nuts

(4) 3/8" Lock Washers

(8) 3/8" Flat Washers

(2) 1/2"-13 Hex Nuts

(2) 1/2" Lock Washers

(2) 1/2" Flat Washers

(8) 1/2"-13 x 2-1/4"

Hex Bolts

Arm Clamp

See Detail A

(8) 1/2"-13 Hex Nuts

(8) 1/2" Lock Washers

(4) 1/2"-13 x 2-1/4"

Bolts

Counterweight

(4) 1/2" Flat Washers

(4) 1/2" Lock Washers

(2) 1/2"-13 Hex Nuts

9

Page 10

ARM AND TURNBUCKLE SHAFT ADJUSTMENTS

CAUTION

INSTALLATION

MODEL BG770 ADJUSTMENTS

1. If necessary, rotate the pulley on the motor by hand until the

crank arm on the gear reducer is perfectly aligned with the

turnbuckle shaft (Figure 9). This is the lowest point of the arm

travel and should be preset in this position at the factory.

2. If the arm is not level, loosen the jam nuts at both ends of the

turnbuckle shaft Insert a screwdriver or other similar tool into

the hole in the shaft. Rotate the shaft either clockwise or

counterclockwise as necessary until the gate arm is in the

desired horizontal position. Retighten jam nuts.

MODEL BG770 TURNBUCKLE SHAFT ALIGNMENT

If necessary, align turnbuckle shaft with center of crank arm for

lowest point of travel of pivot arm (Figure 10).

MODEL BG790 ADJUSTMENTS

1. If necessary, rotate the pulley on the motor by hand until the

upper and lower cranks are in a vertical position (Figure 11).

This is the lowest point of travel and should be preset in this

position at the factory.

2. If the arm is not level, loosen the jam nuts on both the top and

bottom end of the turnbuckle shaft.

3. Rotate the shaft either clockwise or counterclockwise as

necessary until the gate arm is in the desired horizontal

position.

NOTE: While the arm is raising, the upper and lower cranks

should travel toward the side access cover.

Turn off power BEFORE making ANY adjustments.

Figure 9

Crank Arm

Pivot Arm

Pulley

Figure 10

Jam Nut

Turnbuckle Shaft

Figure 11

10

Jam Nut

Lower Crank Arm

in Closed Position

See Note

Pulley

Turnbuckle Shaft

Upper Crank Arm

in Closed Position

Page 11

LIMIT SWITCH ADJUSTMENTS

INSTALLATION

CLOSE LIMIT SWITCH

The CLOSE limit switch is preset at the factory. If you rotated the

pulley in section Arm and Turnbuckle Shaft Adjustments, you will

need to reset the cam on the CLOSE limit switch.

1. Loosen the set screw on the cam. Then rotate the cam in the

close direction so that the switch is activated when the gate

arm is in its lowest position (Figure 12).

2. When the cam is in the desired position, retighten the set

screw. This adjustment may have to be fine tuned after turning

on power and running the unit for the first time.

AUXILIARY CLOSE LIMIT SWITCH

The AUXILIARY CLOSE limit switch is preset at the factory. If you

made an adjustment to the CLOSE cam, you will need to adjust

the cam on the AUXILIARY CLOSE limit switch also.

1. Position the AUXILIARY CLOSE cam slightly ahead of the

CLOSE cam. When the gate arm is on its down travel, the

AUXILIARY CLOSE switch will activate just before the CLOSE

switch.

2. When the cam is in the desired position, retighten the set

screw.

Figure 12

Close Limit Switch

Auxiliary Close

Limit Switch

Open Limit Switch

CLOSE

Direction

OPEN

Direction

OPEN LIMIT SWITCH

The OPEN limit switch is preset at the factory. This setting may

have to be fine tuned after running the unit for the first time.

1. Loosen the OPEN cam and rotate in the open direction until the

switch is activated (Figure 12).

2. Retighten the cam.

11

Page 12

OPTIONAL ACCESSORIES

CAUTION

VEHICLE DETECTORS

Almost all types of vehicle detectors may be used in conjunction

with both model BG770 and BG790. More than one detector may

be connected to the gate, and may be mounted inside of the

cabinet. Connect the detector(s) according to the instructions on

the wiring diagrams supplied with the gate and with the detector

itself.

FACTORY SUPPLIED PLUG-IN DETECTORS

LiftMaster P/N 71-416-7NH = 24V

PLEASE NOTE: Previous models used 115V detectors

(P/N 71-416-3NH).

OPEN LOOP DETECTOR

1. Snap the detector onto one set of the four board mount

standoffs located on the inside of the electrical cabinet. Plug the

harness into the connector marked “OPEN.”

2. Connect the two loop wires to terminals P1 and P2 as shown

on the wiring diagram.

HOLD OPEN LOOP DETECTOR

1. Snap the detector onto one set of the four board mount

standoffs located on the inside of the electrical cabinet. Plug the

harness into the connector marked “HOLD OPEN.”

2. Connect the loop wires to terminals P3 and P4 as shown on the

wiring diagram.

RADIO CONTROLS

All types of standard radio controls may be used in conjunction

with model BG770 and BG790. If the receiver is mounted inside of

the gate enclosure, a commercial coaxial antenna should be used

and extended through the side of the cabinet.

Turn off power BEFORE working inside gate enclosure.

CARD READERS, KEYPADS OR OTHER

Almost all types of access control devices may be connected to

models BG770 and BG790. More than one device may be

connected in parallel. All devices connected according to the

instructions below will open the gate and reverse the gate if it

is closing.

MOUNTING LOCATION

Mount or install the access control device within sight of the gate

and according to the instructions supplied with the device. Some

devices require their own power supply. Do not use the 24 volt

power in the gate to supply other devices. Use either direct line

voltage (115V or 230V) or other external power source as

required by the particular device.

NOTE: Most access control devices have an isolated, normally

open output contact to connect to the gate. If yours does not, or if

you are unsure of or unfamiliar with these terms, consult the

supplier of the device or a qualified gate installer.

CONTROL CONNECTION

TURN OFF POWER and connect the two output terminals (or

wires) of the access control device to the terminals #1 and #3 on

the control wiring terminal strip. Use a wiring method that will

provide a permanent, durable and weatherproof connection

between the gate and the access device.

POWER CONNECTION

All radio receivers require a power supply. If the receiver requires

24Vac, you may power the unit from the gate control circuit. To

do this, connect the radio receiver power wires to Terminals #3

and #6 on the control terminal strip. If the receiver requires

115Vac or other power, you will need a separate power source.

A standard residential door radio receiver has a three wire

connection marked 1, 2, 3. If you have this type, you may connect

to operator terminals R3, R1, and R6. The transmitter button will

open the gate if it is fully closed.

CONTROL

If you have a standard residential 3 wire receiver and made the

power connection described above, you are finished with the radio

connections. If you want to use a radio control (such as a single

button), you must order an optional kit (P/N 90-PGR).

12

Page 13

OPERATING INSTRUCTIONS

CAUTION

ELECTRICAL OPERATION

The BG770 and BG790 barrier gate operators are designed to

provide years of trouble-free operation. The gate may be operated

by means of the two button control station, or by other means if

provided.

ON/OFF POWER SWITCH

The gate is provided with an ON/OFF power switch. To shut power

off, remove the access cover and move the toggle switch on the

right side of the main electrical cabinet to the “OFF” position.

OVERLOAD PROTECTION

The motor is protected by either a manual reset (Single Phase

unit) or automatic reset (3 phase unit) thermal overload protector.

The overload protector will trip when the motor temperature is too

hot.

DO NOT ATTEMPT TO BYPASS THIS UNIT

If the overload trips, the gate could start by itself when the

overload is reset (either manual or automatic). Exercise caution

when resetting the overload. On one phase units, the reset

button is located on the cover of the electrical cabinet.

If after resetting, the overload continues to trip, consult a qualified

service company.

Keep hands clear of moving parts. The motor will start when

AUTO/MANUAL switch is flipped to the “MANUAL” position.

MANUAL OPERATION

ACCESS CONTROL “EMERGENCY” BYPASS

To open the gate in an emergency, remove the keyed access cover

and open the electrical cabinet. Flip the AUTO/MANUAL switch to

the “MANUAL” position.

The gate arm will remain in the up position, and no other control

device will have any effect until the switch is set back to the

“AUTO” position.

13

Page 14

TROUBLESHOOTING

When troubleshooting, one of the first things to do is try to isolate

the problem area. The four (4) main areas to check out are:

• Power

• Accessories

• Operator’s Primary Voltage

• Operator’s Low Voltage

POWER

Always use extreme caution! Some possible symptoms of power

problems include:

• The obvious one is - the operator will not run.

• The operator runs slow.

• Circuit breakers or fuses keep tripping.

• Motor overload keeps tripping.

• Operator starts but then stops.

Using a volt-ohmmeter, take a voltage reading at the control

transformer’s primary terminals. You should get a reading as

follows:

Nominal Voltage Minimum Maximum

120V 108 132

230V 207 253

460V 414 506

ACCESSORIES

Add-on accessories can create many of the problems that are

credited to the operator. Many applications have more than one

accessory item attached to the operator and some of these items

even draw their power from the operator.

Some of the symptoms that can show up because of accessories:

• The operator will not close.

• The operator will not open. The operator will not run.

• The operator begins to run, then stops or reverses.

Whenever the problem is thought to be an accessory and there

are more than one connected to the operator, always disconnect

one accessory at a time and then test the system. This will

hopefully isolate which item is causing the problem.

If an accessory item is being used as an access control device

(used to open or close), falls in the closed position or sends out a

continuous signal. The operator will hold the gate in one position

until the signal from the accessory is removed.

In some applications, the gate may begin to move then either stop

or stop and reverse within a couple of seconds. This can be

caused by an external obstruction device that has failed.

If there are many accessories attached to and powered by the

operator, there may be too much current draw for the operator’s

control transformer. This operator can only supply approximately

2 amps @ 24Vac. Double check all accessories for their current

requirements.

If you get a reading that does not fall into the minimum/maximum

area, then check out your main power supply. Also, make sure

that the operator was ordered with the proper voltage and phase.

Another item to check is the wire run from the power supply to

the operator. Double check the gauge of the wire versus the

distance.

If the voltage reading is okay from 1A, then take the same voltage

reading with the operator running. If voltage drops below the

minimum with this reading, then there could be an excessive

current draw somewhere, or a wire AWG is too small.

In some cases, power drops can occur at only specific times

during the day or night. This can be caused by increased power

demands in a general area at a specific time-particularly areas

undergoing rapid growth.

14

Page 15

TROUBLESHOOTING

PRIMARY VOLTAGE CIRCUIT

Use extreme caution when troubleshooting the primary voltage

circuit! There are five (4) items in this circuit that could be

causing trouble, and they are:

• Motor

• Transformer

• Contactor (Figure 13)

• Power Disconnect Switch

The first thing to check is the incoming power. Is it there at the

incoming side of the power disconnect switch?

If there is power, then check for it at the transformer primary

terminals. If there is voltage at the switch and none at the

transformer, then you probably have a bad power disconnect and

it should be replaced. Check secondary output of transformer for

24Vac output.

If the first two check out okay, then manually disconnect the

operator from the gate. Very carefully, using a screwdriver with

an insulated handle, press down on the open side of the

contactor. Then do the same to the close side of the contactor.

Did the operator run in both directions? If it did, the problem may

be in the low voltage control circuit. It if did not, then the problem

is either in the contactor or the motor.

If the contactor is suspected to be causing the problem, first

carefully check all wiring connections at the contacts (Figure 13).

Disconnect Power! Using a volt-ohmmeter, take continuity

readings across the contacts of the contactor. Remove wires from

one side of the contactor. Place one probe on 1 and the other

on 2. You should get NO continuity; now press down on the

contactor; you should get a continuity reading. Repeat this on all

of the contactor’s contact points.

If the problem is thought to be the motor, it is recommended that

it be replaced. It is possible that the thermal overload inside the

motor has overheated. Wait approximately 15 minutes, then try

running unit.

NOTE: Some motors have the overload built into the motor itself,

while other units have a separate overload in the controller

(Model BG770 uses a manual reset overload).

Figure 13

Contactor

LOW VOLTAGE CIRCUIT

The first thing to check is the circuit breaker.

The secondary voltage must be between 22 and 30Vac. This

voltage can be checked at the circuit board at terminals 3 and 6.

The contactor coils receive 24Vac. To activate the motor in either

the open or close direction. There are two contactor coils (one for

open and one for close).

The limit switches are S.P.D.T. (single pole, double throw). These

limit switches tell the operator to shut off at either the full open or

full close position.

GENERAL REFERENCE INFORMATION

THE GATE

Double check the gate and its related hardware. Does the

gate move freely? Are there unprotected pinch points? If yes,

then correct.

WIRING DIAGRAM

Always reference the wiring diagram that was supplied with the

operator. Note that some of the accessory items may have their

own wiring diagram.

If you cannot correct the problem or if you feel you will require

technical assistance, contact your local distributor or dealer. If you

do not have a distributor or dealer, then contact us for technical

assistance. Please when calling for assistance, make sure you

have the gate operator model number, voltage, phase, horsepower

and a list of all accessories that are attached to the operator.

15

Page 16

ILLUSTRATED PARTS - MODEL BG770

8

5

34

19

11

6

18

20

37

10

30

43

44

14

38

15

3

17

41

31

2

42

36

35

45

4

40

16

39

46

7

22

29

9

27

28

24

13

48

12

33

25

26

47

32

21

1

9

23

Operator Assembly

16

Page 17

REPAIR PARTS - MODEL BG770

INDIVIDUAL PARTS

ITEM PART # DESCRIPTION QTY

1 03-8024-K 3 Pole Contactor 1

2 07-8003 Lower Crank 1

3 07-8004 Upper Crank 1

4 07-8005 Crank Link 1

5 07-8007 Gate Arm Hub 1

6 10-3522 Reducer Shim 2

7 10-8001-T Tan Barrier Gate Enclosure 1

8 10-8007-M Gate Bracket 1

9 10-8014 Switch Bracket 1

10 10-8016-T Tan Top Cover 1

11 10-8017-T Tan Access Cover 1

12 10-8021 Electrical Panel 1

13 10-8022 Elec. Panel Mounting Bracket 1

14 11-8031 Shaft 1

15 12-8032 4 Bolt Flange 2

16 12-8033 Female Rod End 1

17 12-8034 Female Rod End 1

18 16-8001 V-Belt 1

19 17-2001 8" Pulley 1

20 17-2002 2" Pulley 1

21 21-3260-1 Transformer 1

22 23-2017 SPDT Limit Switch 3

23 23-2761 Rocker Switch 1

24 23-8001 Toggle Outlet 1

25 24-24-1 24Vac DPDT Relay 1

27 28-3000 Switch Box 1

28 28-8003 Duplex Outlet Cover 1

29 31-10-17 1-32 x 1/8 Spacer 2

30 31-2712 Nylon Sensor Spacer 6

31 32-8002 Barrier Gate Gear Reducer 1

32 42-110 8 Position Terminal Block 1

33 42-110-2 10 Position Terminal Block 1

34 65-1209 Single Arm (Optional) 1

35 80-1003 6-32 Tinnerman Nut 1

36 80-575 3/4 Flat Washer 6

37 80-8001 Access Panel Lock 1

38 82-HN52-18 1/2-20 x 1-1/4 Hex Head Bolt 8

39 82-HN75-28 3/4-10 x 3 Hex Head Bolt 1

40 84-JH-76 3/4-16 Jam Nut 1

41 84-JH-76L 3/4-16 Left Hand Jam Nut 1

42 84-RH-75 3/4-10 Hex Nut 1

43 85-FW-50 1/2 Flat Washer 6

44 85-LS-50 1/2 Split Flat Washer 12

45 91-G0122 Limit Collar 4

NOT SHOWN

02-102 Key Switch 1

03-ABDIN-4 DIN Rail 1

13-8000 Metal Gasket 14

13-8001 Rubber Grommet 1

42-3608 8 Position Terminal Block 1

74-G0120 115V Control Box 1

80-1904N Failsafe Board Stand Off 8

80-207-36 1/4 x 1/4 x 1-1/4 Key 1

80-5001 3/16 x 3/16 x 3/4 Key 2

80-G0186 1/2 x 1/2 x 1-3/4 Key 1

INDIVIDUAL PARTS

ITEM PART # DESCRIPTION QTY

NOT SHOWN

80-G0187 1/2 x 1/2 x 1-3/8 Key 1

81-8000 Shock Mount 8

81-PX06-06T 6-32 x 3/8 Self Tapping Screw 6

82-CB31-26 5/16-18 x 2-1/2 Carriage Bolt 4

82-HN25-08 1/4-20 x 1/2 Hex Head Bolt 2

82-HN25-18 1/4-20 x 1-1/4 Hex Head Bolt 4

82-HN31-16 5/16-18 x 1 Hex Head Bolt 4

82-HN38-24 3/8-16 x 2 Hex Head Bolt 4

82-HN50-25 1/2-13 x 2-1/4 Hex Head Bolt 4

82-NH31-06 5/16-18 x 3/8 Set Screw 1

82-NH38-06 3/8-16 x 3/8 Cone Point Set Screw 4

82-PX06-28 6-32 x 3 Pan Head Slotted Screw 2

82-PX08-04T 8-32 x 1/4 Self Tapping Screw 6

82-PX08-10T 8-32 x 5/8 Self Tapping Screw 4

82-QN31-12 5/16-18 x 3/4 Square Head Bolt 2

82-QN75-26 5/16-18 x 3/4 Square Head Bolt 1

82-RS10-20 10-32 x 1-1/2 Slotted Screw 2

84-JH-75 3/4-10 Jam Nut 1

84-RH-50 1/2-13 Hex Nut 4

84-WH-10 10-32 Serrated Washer Head Nut 2

84-WH-25 1/4-20 Serrated Flange Nut 12

84-WH-31 5/16-18 Serrated Flange Lock Nut 8

84-WH-38 3/8-16 Serrated Flange Lock Nut 4

84-WN-25 1/4-20 Wing Nut 2

85-FW-31 5/16 Flat Washer 4

85-FW-38 3/8 Flat Washer 4

85-LS-75 3/4 Split Lock Washer 2

91-G0128 Electrical Enclosure 1

VARIABLE PARTS

ITEM PART # DESCRIPTION QTY

46 20-XXXXX-X Motor 1

20-1050B-2P 1/2HP - 115/208/230Vac - 10-60Hz

Used on: BG770-50-11,

BG770-50-21, BG770-50-81

20-3050B-4E 1/2HP - 208/230/460Vac - 30-60Hz

Used on: BG770-50-23,

BG770-50-43, BG770-50-83

20-3050M-5 1/2HP - 575Vac - 30-60Hz

Used on: BG770-50-53

47 24-XXX-X Relay 1

24-115-1 115Vac Relay

Used on: All 115Vac, 10 Models

24-230-5 208/230Vac Relay

Used on: All 208/230Vac,

10 Models

48 25-XXXX Fuse 1

25-2006 6A Fuse

Used on: BG770-50-21

25-2010 10A Fuse

Used on: BG770-50-11

17

Page 18

12

34

2

33

7

14

2 33

34

44

39

45

23

46

35

14

47

11

49

20

36

30

8

37

14

44

43

5

16

40

40

41

4

14

13

42

3

15

18

1

22

9

32

31

32

26

48

27

6

24

10

17

21

19

38

45

44

12

25

29

28

ILLUSTRATED PARTS - MODEL BG790

Operator Assembly

(Wishbone Arm not shown)

18

Page 19

REPAIR PARTS - MODEL BG790

INDIVIDUAL PARTS INDIVIDUAL PARTS

ITEM PART # DESCRIPTION QTY

1 03-8024-K 3 Pole Contactor 1

2 07-8007 Arm Hub 2

3 07-8058 Crank Link 1

4 07-8063 Upper Crank 1

5 07-8064 Lower Crank 1

6 10-8014 Switch Bracket 1

7 10-8016-T Tan Top Cover 1

8 10-8017-T Tan Access Cover 1

9 10-8021 Electrical Panel 1

10 10-8026 Bearing Plate 1

11 10-8051-T Tan Housing 1

12 10-8055 Counterweight Clamp 2

13 11-8061 Main Shaft 1

14 12-8032 4 Bolt Flanged Bearing 5

15 12-8033 Female Rod End 1

16 12-8034 Female Rod End 1

17 15-5032 50B32 Sprocket 1

18 15-9020 50B12 Sprocket 1

19 16-8002 Cogged Belt 1

20 17-2001 8" Pulley 1

21 17-2002 2" Pulley 1

22 21-3260-1 Transformer 1

23 23-2017 SPDT Limit Switch 3

24 23-2761 Rocker Switch 1

25 23-8001 Toggle/Outlet Combination 1

26 24-24-1 24Vac DPDT Relay 1

27 24-24-6 3 PDT 24V Relay 1

28 28-3000 Switch Box 1

29 28-8003 Duplex Outlet Cover 1

30 32-8002 Gear Reducer 1

31 42-110-2 10 Position Terminal Block 1

32 42-3608 8 Position Terminal Block 1

33 65-1208 Wishbone Arm 1

34 65-8056 Counterweight Kit 1

35 80-1003 6-32 Tinnerman Nut 1

36 80-207-36 1/4 x 1/4 x 1-1/4 Disconnect Key 1

37 80-8001 Access Panel Lock 1

38 82-HN52-18 1/2-20 x 1-1/4 Hex Head Bolt 18

39 82-HN52-20 1/2-20 x 1-1/2 Hex Head Bolt 6

40 82-HN75-26 3/4-10 x 2-1/2 Hex Head Bolt 2

41 82-NH38-06CP 3/8-16 x 3/8 Cone Point Set Screw 8

42 84-JH-76 3/4-16 Jam Nut 1

43 84-RH-75 3/4-10 Hex Nut 2

44 85-FW-50 1/2 Flat Washer 24

45 85-LS-50 1/2 Split Lock Washer 38

46 91-G0122 Limit Collar 4

NOT SHOWN

02-102 Open/Close Key Switch 1

03-ABDIN-4 DIN Rail 1

10-8027 Electrical Panel Hanger Kit 1

11-8062 Intermediate Shaft 1

13-8000 Metal Gasket 14

13-8001 Rubber Grommet 2

19-5051 #50 Chain 1

19-9024 #50 Chain Master Link 1

19-9025 #50 Chain Half Link 1

31-10-17 1-32 x 1-1/8 Spacer 2

31-2712 Nylon Sensor Spacer 6

74-G0133 Control Box 1

80-1904N Failsafe Board Stand Off 8

80-5001 3/16 x 3/16 x 1-3/4 Key 1

80-575 3/4 Flat Washer 4

ITEM PART # DESCRIPTION QTY

NOT SHOWN

80-G0135 3/8-16 x 18 Threaded Rod 2

80-G0185 1/2 x 1/2 x 2-1/2 Key 1

80-G0187 1/2 x 1/2 x 1-3/8 Key 3

80-G0188 1/2 x 1/2 x 2 Key 1

80-G0211 5/16 x 1-1/4 Stud 4

81-8000 Shock Mount 8

82-CB31-26 5/16-18 x 2-1/2 Carriage Bolt 4

82-HN25-08 1/4-20 x 1/2 Screw 2

82-HN25-18 1/4-20 x 1-1/4 Screw 4

82-HN31-16 5/16-18 x 1 Hex Head Bolt 4

82-HN50-20 1/2-13 x 1-1/2 Hex Head Bolt 4

82-HN50-25 1/2-13 x 2-1/4 Hex Head Bolt 12

82-HN50-28 1/2-13 x 3 Hex Head Bolt 2

82-NH31-06CP 5/16-18 x 3/8 Set Screw 1

82-PX06-06T 6-32 x 3/8 Self Tapping Screw 6

82-PX06-28 6-32 x 3 Screw 2

82-PX08-04T 8-32 x 1/4 Self Tapping Screw 6

82-PX08-10T 8-32 x 5/8 Self Tapping Screw 4

82-RS10-20 10-32 x 1-1/2 Screw 2

82-SH10-18 10-32 x 1-1/4 Screw 2

84-JH-76L 3/4-16 Left Hand Jam Nut 1

84-RH-50 1/2-13 Hex Nut 18

84-WH-10 10-32 Serrated Washer Nut 10

84-WH-25 1/4-20 Serrated Flange Nut 14

84-WH-31 5/16-18 Serrated Flange Lock Nut 12

84-WH-38 3/8-16 Serrated Flange Nut 8

84-WN-25 1/4-20 Wing Nut 2

85-FW-31 5/16 Flat Washer 8

85-FW-38 3/8 Flat Washer 12

85-LS-31 5/16 Split Lock Washer 4

85-LS-75 3/4 Split Lock Washer 2

91-G0128 Electrical Enclosure 1

94-G0233 Power Cable 1

94-G0234 Motor Cable 1

VARIABLE PARTS

ITEM PART # DESCRIPTION QTY

47 20-XXXXX-X Motor 1

20-1050B-2P 1/2HP - 115/208/230Vac - 10-60Hz

Used on: BG790-50-11,

BG790-50-21, BG790-50-81

20-3050B-4E 1/2HP - 208/230/460Vac - 30-60Hz

Used on: BG790-50-23,

BG790-50-43, BG790-50-83

20-3050M-5 1/2HP - 575Vac - 30-60Hz

Used on: BG790-50-53

48 24-XXX-X Relay 1

24-115-1 115Vac Relay

Used on: All 115Vac, 10 Models

24-230-5 208/230Vac Relay

Used on: All 208/230Vac,

10 Models

49 25-XXXX Fuse 1

25-2006 6A Fuse

Used on: BG790-50-21

25-2010 10A Fuse

Used on: BG790-50-11

19

Page 20

MAINTENANCE

WARNING

IMPORTANT SAFETY INSTRUCTIONS

To reduce the risk of SEVERE INJURY or DEATH:

1. READ AND FOLLOW ALL INSTRUCTIONS.

2. NEVER let children operate or play with gate controls.

Keep the remote control away from children.

3. ALWAYS keep people and objects away from the gate.

NO ONE SHOULD CROSS THE PATH OF THE MOVING

GATE.

4. Test the gate operator monthly. The gate MUST reverse

on contact with a rigid object or stop when an object

activates the non-contact sensors. After adjusting the

force or the limit of travel, retest the gate operator.

Failure to adjust and retest the gate operator properly

can increase the risk of INJURY or DEATH.

5. Use the emergency release ONLY when the gate is not

moving.

6. KEEP GATES PROPERLY MAINTAINED. Read the

owner’s manual. Have a qualified service person make

repairs to gate hardware.

7. The entrance is for vehicles ONLY. Pedestrians MUST

use separate entrance.

8. Disconnect ALL power BEFORE performing ANY

maintenance.

9. ALL maintenance MUST be performed by a LiftMaster

professional.

10.

SAVE THESE INSTRUCTIONS.

CHECK AT LEAST ONCE EVERY

DESCRIPTION TASK 1 MONTH 6 MONTHS 12 MONTHS

External Safety Systems Check for proper operation

Gate Caution Systems Make sure they are present

Drive Chain (see notes) Check for excessive slack and lubricate

Sprockets and Pulleys Check for set screw tightness

Gate Inspect for wear or damage

Accessories Check all for proper operation

Electrical Inspect all wire connections

Frame Bolts Check for tightness

Total Unit Inspect for wear or damage

NOTES:

• Inspection and service should always be performed anytime a

malfunction is observed or suspected.

• Limit switches may have to be reset after any major drive chain

adjustments.

• BG790: If lubricating chain, use only a proper chain lube spray

or a lightweight motor oil. Never use grease or silicone spray.

• When servicing, please do some “house cleaning” of the

operator and the area around the operator. Pick up any debris

in the area. Clean the operator if needed.

• Severe or high cycle usage will require more frequent

maintenance checks.

• It is suggested that while you are at the site, take some voltage

readings of the operator. Using a VOM, double check the

incoming voltage to the operator to make sure it is within ten

percent of the operator’s rating.

• While you are at the site, now would be a good time to let the

owner or manager know about any new items available or any

safety items that could and should be added to the site.

LIMITED BEARING LUBRICATION

The barrier gates require very little in the way of maintenance.

Motor and shaft bearing normally should not require lubrication.

The gear oil in the gear reducer is sealed in. Unless a severe

problem causes a seal to break, it should never need replacement.

If gear oil is required, use Mobilube C SAE140 or equivalent.

GREASE TURNBUCKLE

Periodically grease the ball ends of the turnbuckle, depending on

the gate’s frequency of use.

XX

XX

XX

XX

XX

XX

XX

XX

X

20

Page 21

To protect against fire and electrocution:

• DISCONNECT power BEFORE installing

or servicing operator.

• Replace ONLY with fuse of same type

of rating. Fuse 3.2A, 3AG, 250V, SLO-BLO

115V

ACCESSORIES

EDGE

(OR)

(OR)

R1

AUTO/MANUAL

OPEN

OPEN LOOP–PRESENCE

J3–4

(OPTIONAL)

7

R1

OP

14

13

(Y)

(YEL)

(GN)

SENSING

3

(OR)

(GN)

(GN)

(W)

1 PHASE

INCOMING LINE

(SEE NOTE 3)

(BK)

(YEL)

J3–6

AUX.

CLOSE L/S

(W)

R2

IR

(OR)

CLOSE

WIRING DIAGRAM

(W)

(GY)

(W)

115V ONLY

0/L

(BK)

(BK)

SEE NO TE 2

(BK)

(BK)

(W)

1

5

(BK)

IR

115V ONLY

SEE NO TE 1

1) REMOVE JUMPER WHEN TIMER TO

CLOSE IS USED.

2) REMOVE JUMPER TO CAUSE GATE

ARM TO CLOSE IMMEDIATELY UNLESS

HOLD OPEN LOOP IS ACTIVATED.

L2

L1

(W)

H1

H2

(GN)

24V SEC.

(OR)

(OR)

CL

4

OP

4

OP

2

CL

6

230V ONLY

(PUR)

3

3

1

5

(W)

OP

5

CL

12

R1

24V COIL

OP

24V COIL

(1 of 2)

MOTOR CONNECTION SAME

AS INCOMING POWER.

FOR BG770, INTERCHANGE

GREEN AND RED WIRES

115V MOTOR

BR

(BK)

(W)

BR

BR

BR

(GN)

(R)

(GN)

(BK)

(W)

(R)

FUSE 3.2A

(BR)

C

CONNECTION

YW

4

8

BK

5

OR

1

W

4

R

8

Y BL

BK

5

OR

1

230V MOTOR

CONNECTION

(BL)

2

O/L SEE

NOTE 4

BL

3

O/L SEE

NOTE 4

2

3

6

6

(BL)

(OR)

OPEN L/S

NO

HOLD OPEN

(GN)

(OR)

TIMER

(OPTIONAL)

TERMINAL BLOCK

WIRE CONNECTION FOR STANDARD CONTROL DEVICES

WIRE CONNECTION FOR OPTIONAL DEVICES

WIRE CONNECTION FOR 230V UNITS ONLY

J3

IS CONNECTOR FOR 24V OPEN LOOP DETECTOR

J4

IS CONNECTOR FOR 24V HOLD OPEN LOOP DETECTOR

NOTES:

1) TRANSFORMER PRIMARY VOLTAGE SAME AS OPERATOR LINE VOLTAGE

CL

14 13

(BR)

2

REMOVE JUMPER WHEN

TIME R IS ADDED

J4–4

(R)

(R)

IR

LOOP–PRESENCE

(OPTIONAL)

8

J4–6

R2

)

(R

J3–9

J3–10

J4–9

J4–10

24V SECONDARY.

2) RELAY COIL VOLTAGE SAME AS OPERATOR LINE VOLTAGE.

3) WE RECOMMEND USING A DEDICATED CIRCUIT BREAKER FOR EACH OPERATOR.

4)

BROWN WIRES INSIDE MOTOR NOT USED, SHOULD BE WIRE NUTTED.

10

(W)

ADD JUMPER WHEN USING CLOSE BUTTON

DO NOT USE WITH HOLD OPEN LOOP

(BRN)

(GY)

(BRN)

(GY)

(BK)

9

P1

P2

P3

P4

(GY) (BL)

R1

OPEN LOOP

LOOP WIRES

(OPTIONAL)

HOLD OPEN LOOP

LOOP WIRES

(OPTIONAL)

APPLICATIONS:

CONTROL WIRING TYPE L2

MODEL TYPES:

HORSEPOWER:

VOLTAGE/PHASE:

DRAWING NUMBER:

DATE:

08/28/00

R2

24V COIL

24V OPEN

LOOP

CLOSE L/S

NO

(R)

(BK)

(PUR)

CL

24V COIL

FIELD WIRING

BG770, BG790

1/2

115/230V, 60Hz, 1 PHASE ONLY

01-G1014

REVISION:

F-3/20/08

(BL)

C

J3–7

(R)

24V HOLD

OPEN LOOP

(BK)

J3–8

(OPTIONAL EQUIPMENT)

ECN:

J4–7

J4–8

08-7165

1

21

Page 22

WIRING DIAGRAM

(1 of 2)

To protect against fire and electrocution:

• DISCONNECT power BEFORE installing

or servicing operator.

• Replace ONLY with fuse of same type

of rating. Fuse 3.2A, 3AG, 250V, SLO-BLO

4

(GN)

3

(OR)

(OR)

(OPTI ONAL)

TERMINAL BLOCK

WIRE CONNECTION FOR STANDARD CONTROL DEVICES

WIRE CONNECTION FOR STANDARD CONTROL DEVICES

J3

IS CONNECTOR FOR 24V OPEN LOOP DETECTOR

IS CONNECTOR FOR 24V HOLD OPEN LOOP DETECTOR

J4

(YEL)

SENSING

EDGE

(OR)

(GN)

TIMER

AUTO/MANUAL

OPEN LOOP–PRESENCE

J3–4

(OR)

14

R1

14

(OPTIONAL)

R1

OP

13

(Y)

CL

13

2

REMOVE JUMPER WHEN

TIMER IS A DDED

(GN)

3–PHASE

INCOMING LINE

(SEE NOT E 2)

115V

GEARBOX

HEAT ER

(OPTIONAL EQUIPMENT)

(YEL)

OPEN

J3–6

CLOSE L /S

(W)

7

R2

(GN)

(OR)

CLOSE

HOLD OPEN

LOOP–PRESENCE

J4–4

(OPTI ONAL)

(R)

(BR)

AUX.

(BK)

(W)

(GN)

(BL)

(R)

LOOP

NO

(BK)

(R)

(W)

(GN)

(R)

(W)

(GN)

(R)

(W)

CLOSE

NO

CLOSE

(BL)

(BL)

(BL)

(BL)

(BL)

(OR)

(BR)

(BL)

J3–7

J3–8

(BK)

L1

(BK)

L2

L3

H1

H2

(W)

GY

J4–6

(R)

(BK)

(W)

(BK)

1

5

TD–2

(W)

R2

(W)

ADD JUM PER WHEN USING C LOSE BUTTO N

DO NOT US E WITH HOLD OPE N LOOP

(BRN)

J3–9

J3–10

(BRN)

J4–9

J4–10 P4

(R)

(GN)

8

CL

(W)

4

(W)

(W)

10

(GY)

(GY)

3

OP

(W)

4

3

OP

(W)

12

CL

65

(W)

SEE NOT E 1

1) REM OVE JUMPER WH EN TIMER TO

CLOSE IS U SED.

2) REM OVE JUMPER TO C AUSE GATE

ARM TO CLO SE IMMEDIATELY UN LESS

HOLD OP EN LOOP IS ACTIVAT ED

(BK) (BL)

9

P1

P2

P3

24V SEC.

(OR)

(GY)

R1

FUSE 3.2A

(W)

(PUR)

TD1

(PUR)

HOLD OPEN LOOP

OPEN LOOP

LOOP WIR ES

(OPTI ONAL)

OP

(W)

5

6

CL

2

1

WIRE COL OR: 208V– (R),

230V–(OR), 480–(VT),

575V–(GY)

O/L IN

MOTOR

(BL)

J1 J2

R1

24V COIL

24V COIL

(OR)

24V COIL

(PUR)

LOOP WIR ES

(OPTI ONAL)

OP

TD1

24VAC

DPDT

R2

24V COIL

24V COIL

CL

TD2

24VAC

DPDT

(OR)

(PUR)

24V OPEN

7

4

1

8

5

2

9

6

3

MOTOR CONNECTION SAME

AS INCO MING POWER

4

1

7

58 2

396

1

2

3

(BL)

L/S

C

L/S

C

(BK)

J4–7

24V HOLD

OPEN LOOP

(R)

J4–8

(OPTIONAL EQUIPMENT)

J

J

J

J

J

J

(OR)

480V MOTOR

CONNECTION

208/230V

MOTOR

CONNECTION

575V MOTOR

CONNECTION

NOTES:

1) TRANSFORM ER PRIMARY VOLTAGE SAME AS OPERATOR LIN E VOLTAGE

24V SECO NDARY

2) WE RECOMMEND USING A DEDICATED CIRCUIT BRE AKER FOR E ACH OPERATOR.

APPLICATIONS:

CONTROL WIRING TYPE

FIELD WIRING & ADJUSTMENTS

MODEL TYPES: BG770 (PG) BG790 (HBG)

HORSEPOWER:

VOLTAGE/PHASE:

DRAWING NUMBER:

DATE : REVISION:

1/2

208/230/480/575V

01-G1015

E-3/20/0808/28/00 08-7165

22

1

ECN:

Page 23

CONTROL CONNECTION DIAGRAM

IT IS IMPORTANT TO READ ALL SAFETY RULES INCLUDED IN THE INSTALLATION MANUAL BEFORE

BEGINNING INSTALLATION. FAILURE TO COMPLY WITH THE SAFETY INSTRUCTIONS MAY RESULT

IN SERIOUS PERSONAL INJURY OR PROPERTY DAMAGE.

OPEN BUTTON

OR OTHER

OPEN CONTROL

CONTROL WIRING

SEE

NOTE #1

SENSING EDGE

CLOSE BUTTON

SEE NOTE #2

ELECTRICAL CABINET

MANUAL

OPEN

SEE NOTE #2

LINE VOLTAGE SUPPLY

ON

OFF

ON

OFF

SWITCH

115V

OUTLET

SEE

NOTE #3

1 PHASE

INCOMING LINE

SWITCH

(GN)

(BK)

(W)

(GN)

(SEE NOTE #5)

(W)

(BK)

(R)

WARNING

(SEE NOTE #5)

115V

ACCESSORIES

(0.2A MAX)

OPEN

LOOP

LOOP WIRE CONNECTIONS FOR

FACTORY SUPPLIED (PLUG-IN)

DETECTORS ONLY

LOOP DETECTORS BY OTHERS

CONNECTIONS FOR LOOP DETECTORS

NOT SUPPLIED BY THE FACTORY

PRESENCE CONTACT OF

LOOP TO OPEN

LOOP WIRES AND POWER FOR LOOP DETECTORS

SHOULD BE DIRECTLY WIRED TO DETECTOR ITSELF.

REFER TO INSTRUCTIONS ACCOMPANYING DETECTOR.

PRESENCE CONTACT OF

LOOP TO HOLD OPEN

HOLD OPEN

LOOP

3 PHASE

INCOMING LINE (SEE NOTE #5)

RADIO CONTROL

CONNECTIONS FOR STANDARD

3-WIRE 24 VAC RADIO CONTROL

RADIO CONTROL WILL OPEN GATE

AND REVERSE IF CLOSIN G. ITWILL

NOT STOP OR CLOSE THE GATE.

NOTES:

1) REMOVE THIS JUMPER TO CAUSE GATE ARM TO CLOSE IMMEDIATELY WHENEVER IT IS OPENED, UNLESS A VEHICLE IS ON THE

HOLD OPEN LOOP. IF THIS JUMPER IS NOT REMOVED, ARM WILL REMAIN OPEN UNTIL A VEHICLE ENTERS AND EXITS THE HOLD

OPEN LOOP.

2) ADD JUMPER FROM TERMINAL #8 TO #9 WHENEVER CLOSE BUTTON IS USED. DO NOT USE WITH HOLD OPEN LOOP.

3) 115V UTILITY OUTLET (4 AMP MAX.) PROVIDED ON 115V MODELS ONLY.

4) SEE REVERSE SIDE FOR INTERNAL OPERATOR WIRING.

5) DO NOT CONNECT INPUT POWER LINES TO L1 & L2 TERMINALS. POWER LINES MUST BE CONNECTED TO THE POWER SWITCH.

23

Page 24

WARRANTY POLICY AND SERVICE

LIFTMASTER® TWO YEAR LIMITED WARRANTY

The Chamberlain Group, Inc. warrants to the final purchaser of this product, for the structure in which this product is originally

installed, that it is free from defect in materials and/or workmanship for a period of two years from the date of purchase. The proper

operation of this product is dependent on your compliance with the instructions regarding installation, operation, maintenance and

testing. Failure to comply strictly with those instructions will void this limited warranty in its entirety.

If, during the limited warranty period, this product appears to contain a defect covered by this limited warranty, call 1-800-528-2806,

toll free, before dismantling this product. Then send this product, pre-paid and insured, to our service center for warranty repair. You

will be advised of shipping instructions when you call. Please include a brief description of the problem and a dated proof-of-purchase

receipt with any product returned for warranty repair. Products returned to Seller for warranty repair, which upon receipt by Seller are

confirmed to be defective and covered by this limited warranty, will be repaired or replaced (at Seller’s sole option) at no cost to you

and returned pre-paid. Defective parts will be repaired or replaced with new or factory-rebuilt parts at Seller’s sole option.

ALL IMPLIED WARRANTIES FOR THE PRODUCT, INCLUDING BUT NOT LIMITED TO ANY IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, ARE LIMITED IN DURATION TO THE TWO YEAR LIMITED

WARRANTY PERIOD SET FORTH ABOVE, AND NO IMPLIED WARRANTIES WILL EXIST OR APPLY AFTER SUCH PERIOD. Some

States do not allow limitations on how long an implied warranty lasts, so the above limitation may not apply to you. THIS LIMITED

WARRANTY DOES NOT COVER NON-DEFECT DAMAGE, DAMAGE CAUSED BY IMPROPER INSTALLATION, OPERATION OR CARE

(INCLUDING, BUT NOT LIMITED TO ABUSE, MISUSE, FAILURE TO PROVIDE REASONABLE AND NECESSARY MAINTENANCE,

UNAUTHORIZED REPAIRS OR ANY ALTERATIONS TO THIS PRODUCT), LABOR CHARGES FOR REINSTALLING A REPAIRED OR

REPLACED UNIT, OR REPLACEMENT OF BATTERIES.

THIS LIMITED WARRANTY DOES NOT COVER ANY PROBLEMS WITH, OR RELATING TO, THE GATE OR GATE HARDWARE,

INCLUDING BUT NOT LIMITED TO THE GATE ALIGNMENT OR HINGES. THIS LIMITED WARRANTY ALSO DOES NOT COVER ANY

PROBLEMS CAUSED BY INTERFERENCE. ANY SERVICE CALL THAT DETERMINES THE PROBLEM HAS BEEN CAUSED BY ANY OF

THESE ITEMS COULD RESULT IN A FEE TO YOU.

UNDER NO CIRCUMSTANCES SHALL SELLER BE LIABLE FOR CONSEQUENTIAL, INCIDENTAL OR SPECIAL DAMAGES ARISING IN

CONNECTION WITH USE, OR INABILITY TO USE, THIS PRODUCT. IN NO EVENT SHALL SELLER’S LIABILITY FOR BREACH OF

WARRANTY, BREACH OF CONTRACT, NEGLIGENCE OR STRICT LIABILITY EXCEED THE COST OF THE PRODUCT COVERED HEREBY.

NO PERSON IS AUTHORIZED TO ASSUME FOR US ANY OTHER LIABILITY IN CONNECTION WITH THE SALE OF THIS PRODUCT.

Some states do not allow the exclusion or limitation of consequential, incidental or special damages, so the above limitation or

exclusion may not apply to you. This limited warranty gives you specific legal rights, and you may also have other rights which vary

from state to state.

HOW TO ORDER REPAIR PARTS

OUR LARGE SERVICE ORGANIZATION

SPANS AMERICA

FOR INSTALLATION AND SERVICE INFORMATION,

CALL OUR TOLL FREE NUMBER

1-800-528-2806

www.liftmaster.com

WHEN ORDERING REPAIR PARTS,

ALWAYS GIVE THE FOLLOWING INFORMATION:

PART NUMBER DESCRIPTION MODEL NUMBER

ADDRESS ORDERS TO:

THE CHAMBERLAIN GROUP, INC.

Technical Support Group

6050 Country Club Road

Tucson, Arizona 85706

01-G0674M All Rights Reserved

© 2011, The Chamberlain Group, Inc.

Loading...

Loading...