Page 1

AUTO RECONNECT TROLLEY

KIT (ARK)

Models MT and T

(1/3 & 1/2HP only)

PACKING LIST

1. Disconnect trolley straight arm from door curved arm.

2. Locate masterlinks at either end of trolley slider and disconnect

drive chain.

3. Remove front idler assembly at the head of the track. Remove

trolley slider.

PART # DESCRIPTION QTY

10-10203 Curved Arm 1

10-10204 Door Bracket 1

10-10205 Track Header Bracket 1

10-10371 Straight Arm 1

Trolley / Slide Caution Label 2

Door Opening Warning Sign 1

K75-10259 Track Spacer 2

K75-10387 Trolley Slider (Carriage) 1

K75-10388 Front Idler (Chain Tensioner) Assembly 1

K75-10406 Drive Link Assembly 1

Hardware Bag With (2) Two

#48 Master Links 1

Hex Head Bolt 3/8-16 X 3/4" 12

Hex Head Bolt 3/8-16 X 1-1/4" 3

Carriage Bolt 5/16-18 X 2" 2

Lock Nut, Serrated Flange 5/16-18 2

Lock Nut, Serrated Flange 3/8-16 14

Lock Nut, Nylon 3/8-16 1

1

Instructions to install Auto Reconnect Trolley Kit (ARK). Spring

loaded trolley features nylon inserts for quiet operation. Autoreconnect feature eliminates the need to manually re-attach the

door arm to the trolley after emergency disconnect.

BEFORE INSTALLATION

• Refer to disassembly instructions below for all existing

installations.

• Refer to owner's manual provided with operator for all

mounting and wiring instructions.

• Refer to backside for pre-assembly instructions of auto

reconnect trolley kit.

• Disconnect power to operator.

EXISTING INSTALLATIONS

If this kit is being installed on a existing trolley operator, you will

be required to disassemble track and operator assembly to allow

removal of the front idler and the trolley slider.

Ensure you have adequate support of the operator as you

disassemble. It may be necessary to completely detach operator

from the overhead supports and reassemble trolley reconnect kit

at floor level.

To prevent possible SERIOUS INJURY or DEATH, disconnect

electric power to operator BEFORE installing.

ALL installations and electrical connections MUST be made by

a qualified individual.

WARNING

WARNING

Page 2

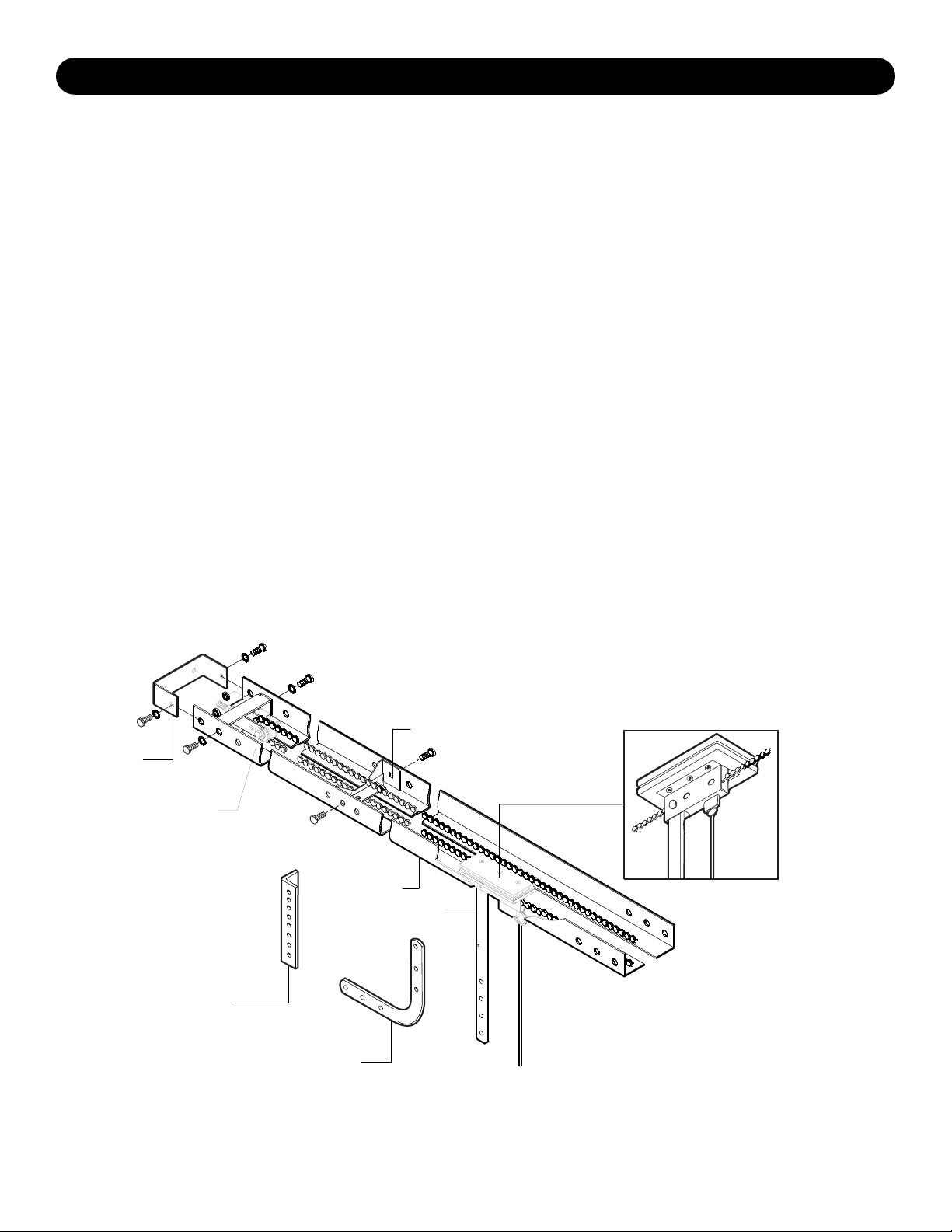

TROLLEY CARRIAGE / CHAIN ATTACHMENT

1. Uncoil the chain and run it up through the front idler of the

chain tensioner assembly. Pull it towards the operator running

it over the nylon spacer brackets and over the top of the trolley

carriage. Pull the chain around the final drive sprocket on the

operator and back toward the trolley carriage. Pull the release

clip on the carriage and push one end of the chain through the

chain slot (see illustration). Using one of the masterlinks

connect the drive link to one end of the chain. Pull the drive link

toward the free end of the chain and determine where to cut

chain for proper adjustment. Be sure the chain tensioning bolt

is loose before removing links. Using the other masterlink

fasten the adjusted chain to the free end of the drive link.

2. Slide the trolley carriage back and forth past the drive link to

assure that there will be no binding. Turn the chain tensioner

adjustment bolt to take out most of the chain lack.

• With trolley positioned at either end of the track, a properly

adjusted chain will sag about 3" at the midpoint. If necessary,

remove links from the chain to achieve proper adjustment.

3. Tie the release cord to the trolley carriage as shown.

4. Reconnect power to operator.

TRACK ASSEMBLY

1. Using the 3/8"-16 x 3/4 " bolts and flange hex nuts provided,

assemble the operator track by installing and tightening the

track spacer brackets. Position the spacers evenly over the

length of the track.

NOTE: The nylon pad on the spacer bracket should face up.

2. Using (2) 3/8"-16 x 3/4" bolts and flange hex nuts, install the

front idler assembly to the second set of holes of one end of

the track. Be sure the take-up bolt faces the front(toward door).

Refer to the illustration below.

3. Slide the trolley carriage onto the track so that the hole of the

door arm faces the front (towards door).

OPERATOR ATTACHMENT

1. Position the track assembly on the frame of the operator so

that the motor side of operator is in back (away from door ).

2. Align both the first and third holes from the end of the track

with holes located in the operator.

3. Connect the track to the operator by fastening four

3/8"-16 x 3/4" bolts and nuts through the frame and the end

holes in track. Tighten all four bolts to secure the track to

the operator.

© 2005, The Chamberlain Group, Inc.

01-12151C All Rights Reserved Printed in Mexico

INSTALLATION

Header

Bracket

Chain Tensioner

(Front Idler)

Door Bracket

Curved Arm

Track

Straight Arm

Refer To Instruction Manual

Provided With Operator For

Complete Mounting Instructions.

Spacer Bracket

Trolley Carriage

Loading...

Loading...