Page 1

1

CENTER MOUNT MODIFICATION

For Use With GH Operator

659001

PART # DESCRIPTION QTY

Instructions 1

10-10882 Chain Guard 1

11-5220 20' Cold Rolled Steel. 1" Round Bar 1

12-11438 Bearing 2

Nylon Shaft Collar 1" (Rework) 1

15-48B14LXX Sprocket #48B14 1" Bore 1

19-40013 Roller Chain #40, 13 Pitches 1

19-40ML Masterlink #40 1

75-10733 Chain Wheel 1

Eye Bolt 5/16-18 X 3-1/4" 2

Cable Clamp 2

80-206-10 Spacer 1-1/32 X 1-1/2 X 1/64 5

80-206-11 Spacer 1-1/16 X 1-1/2 X 1/16 5

86-RP08-108 Long Roll Pin 1/4 X 1-1/2" 1

86-RP10-208 Long Roll Pin 5/16 X 2-1/2" 2

86-RP10-100 Long Roll Pin 5/16 X 1" 2

Cable 1/16" 1

Sash chain-12' 1

APPLICATION

This modification is available for model GH operators. For use on

sectional doors only.

FUNCTIONS

This allows emergency hoist access to either side of the door.

Must be factory supplied with operator.

PREPARATION

We have set up the handing of the chain hoist based on your

order. If you find due to the job conditions that the chain hoist

needs to be on the opposite side of the operator, it can be moved.

If this is the situation, do this modification before mounting the

operator. Refer to the operator owner’s manual.

PACKING LIST

NOTE: Chain hoist shown on right, drive shown on left.

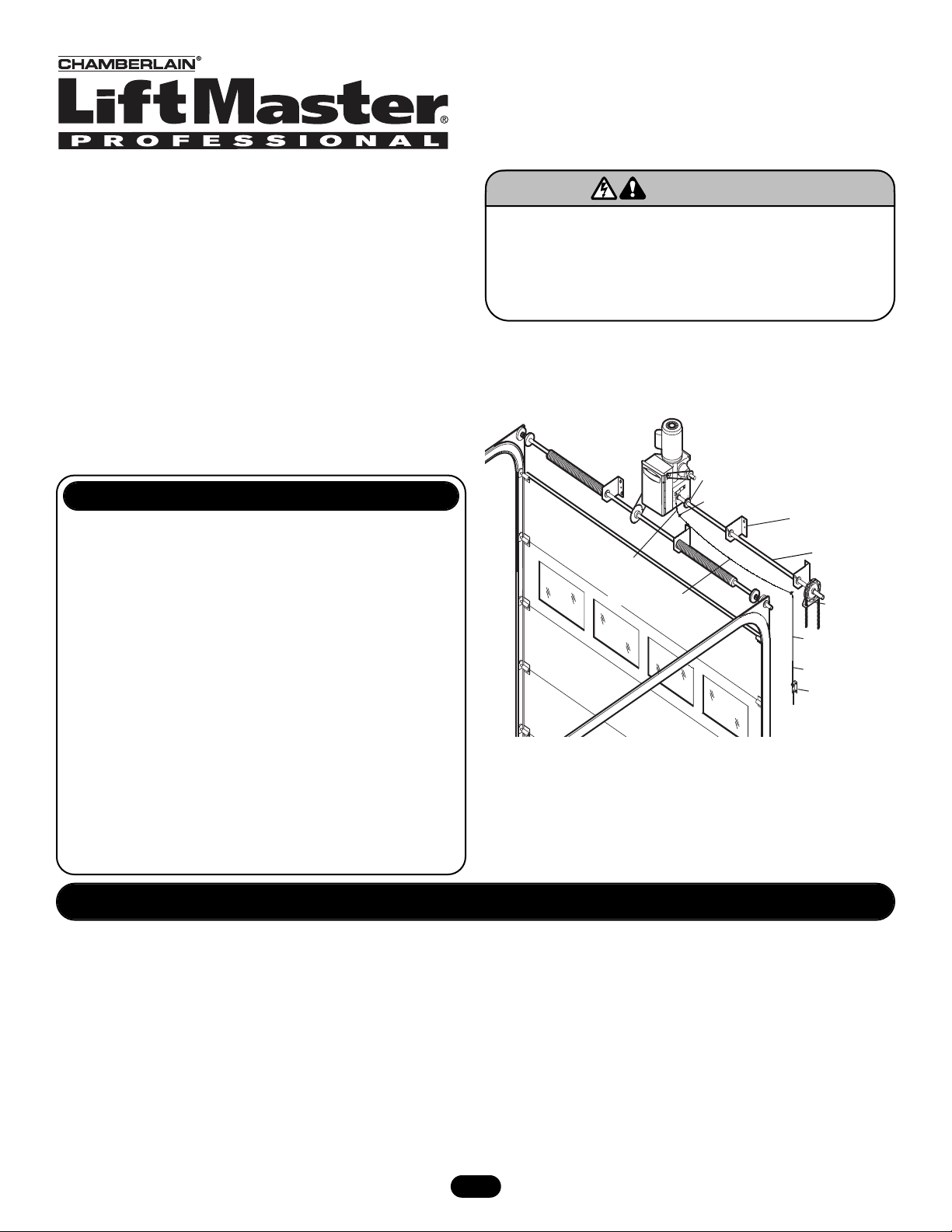

FIGURE 1

INSTALLATION

1. Install the driven sprocket on the door shaft and mount the

operator based on the location of this sprocket. If necessary

cut the unused side of the hand chain shaft off so that the drive

chain does not interfere with the operator mechanism.

2. This kit includes a length of cold rolled 1" shaft that is half the

door width plus 2' based on a center mounted door operator.

Be sure that this is long enough for your application. If not,

secure a longer shaft before continuing. Install the 48B14

sprocket provided on the end of the shaft by drilling a 1/4" hole

through the sprocket and shaft and secure with the 1/4" by

1-1/2" long roll pin provided. Be sure that the shaft does not

extend past the end of the sprocket and that the teeth of the

sprocket are at the end of the shaft (Figure 2).

To prevent possible SERIOUS INJURY or DEATH, disconnect

electric power to operator BEFORE installing.

ALL installations and electrical connections MUST be made by

a qualified individual.

WARNING

WARNING

3. Raise the shaft and sprocket assembly into position so that this

sprocket is butted against the sprocket on the operator hand

chain shaft and support the shaft temporarily. Use the piece of

#40 chain provided to connect the two sprockets together.

4. Slide bearing onto the shaft and securely mount it so that the

shaft turns freely without binding.

5. Use the instructions below to complete the assembly of the

chain hoist.

CENTER MOUNT GH MODIFICATION

Sprocket and Chain Two Identical

#48 Sprockets Butted Together and

Wrapped With #40 Chain (Figure 2).

Screw Eye

Bearing Assembly

Sash Chain

Cable Extension

Extension Shaft

Cable Extension

Sash Chain

Chain Retaining

Bracket

Chain Hoist

Page 2

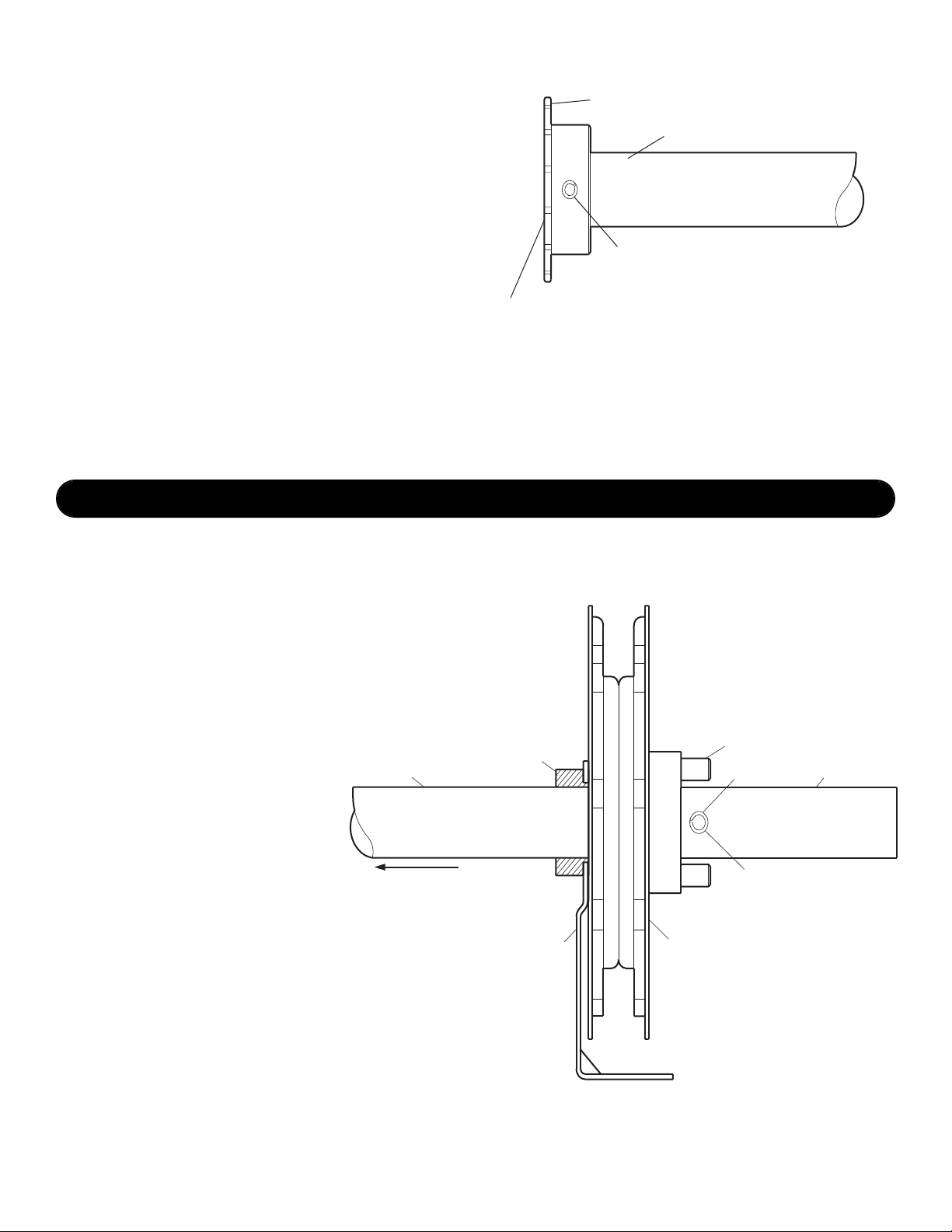

FIGURE 26. Cut off the excess shaft if necessary but allow for another

bearing on the outside of the chain hoist to support the load

when the hoist is used.

7. Install the second bearing.

8. Cut the disconnect sash chain close to the operator and splice

in the cable provided with a cable clamp (provided). Run the

cable through screw eyes and down the wall under the chain

hoist. Use the other cable clamp to reattach the sash chain to

this cable. It is necessary to have chain at the floor end of the

cable so that the hand chain engagement mechanism can be

locked down with the chain retaining bracket.

CHAIN HOIST INSTALLATION

1. Determine location for the hand chain assembly. Slide the 1"

shaft collar on the shaft, reworked side toward the end of the

shaft, and tighten down.

2. Starting against shaft collar, slide the chain guide on the end of

the shaft collar that has been reworked. Slide the chain wheel

assembly on next.

3. Install (2) 5/16" x 1" long roll pins in the holes in the chain

wheel hub.

4. Drill a 5/16" hole next to the hub on the chain wheel assembly

and install a 5/16" x 2-1/2" roll pin. Do not make

the assembly too tight. Thick and thin

washers are provided to take out extra

slack or to allow more movement.

FIGURE 3

© 2005, The Chamberlain Group, Inc.

01-12500B All Rights Reserved Printed in Mexico

48B14 Sprocket 1" Bore

Extension Shaft 1" Diameter Cold Rolled Steel

Drill 1/4" Hole -Through Pin With 1/4"x1-1/2" Roll Pin

Sprocket Teeth at End

of Shaft. Do Not Let Shaft

Protrude Beyond End

of Sprocket.

Extension Shaft

Towards Operator

1" Shaft Collar

(Reworked)

Chain Guard

Roll Pin 5/16"x1" Long

Drill 5/16" Hole

Roll Pin

5/16"x2-1/2" Long

Chain Wheel Assembly

Free End of Shaft

Loading...

Loading...