Page 1

8205 CABLE CROSS OVER

ASSEMBLY INSTRUCTIONS

1Part # 6790401 Revision: 7/13/98

Page 2

IMPORTANT NOTES

Please note:

* Thank you for purchasing the LIFE FITNESS 8205 CABLE CROSS OVER. Please read these instructions thoroughly and

keep them for future reference. This product must be assembled on a flat, level surface to assure its proper function.

* We recommend cleaning your product (pads and frame) on a regular basis, using warm soapy water. Touch-up paint can be

purchased from your LIFE FITNESS customer service representative at (800) 328-9714.

There is a risk assumed by individuals who use this type of equipment. To minimize risk, please follow these rules:

1. Inspect equipment daily. Tighten all loose connections and replace worn parts immediately. Failure to do so may

result in serious injury.

2. Do not allow minors or children to play on or around this equipment.

3. Exercise with care to avoid injury.

4. If unsure of proper use of equipment, call your local LIFE FITNESS STRENGTH distributor or call the LIFE FITNESS

STRENGTH customer service department at (800) 328-9714.

5. Consult your physician before beginning any exercise program.

Tools Required for Assembly

* Rubber mallet or hammer

* 3/4” wrench

* 9/16” wrench

* Ratchet with 3/4” and 9/16” sockets

* 5/16” Allen wrench,

* Adjustable wrench

* Tape measure

2

Page 3

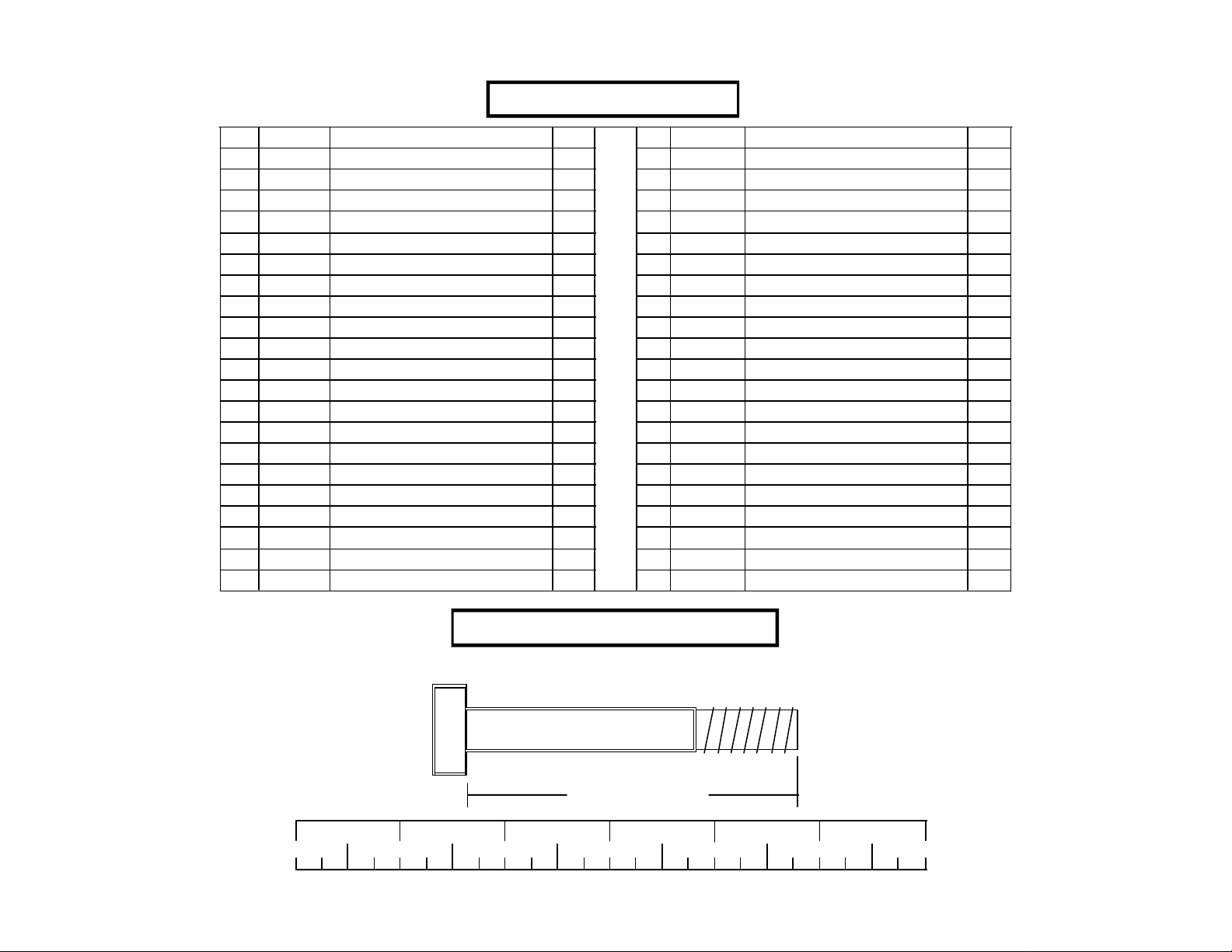

KEY

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

PART #

6788503

6744102

6789002

6744803

6789102

6789403

6789703

6788203

6788103

6459401

6785602

3202402

3116101

3116201

6793201

6284501

6714601

6790101

6020601

6480301

6214401

DESCRIPTION

TOWER

NOVATRAK SWIVEL

CENTER PULLEY BRACKET

TOWER BRACE

SWIVEL HOLDER

LOWER PULLEY HOUSING

SWIVEL UPRIGHT

UPPER PULLEY HOUSING

CHIN-UP SUPPORT

81” GUIDE ROD

SHROUD

1/2 X 3/4” BTN HD CAP SCREW

4-1/2” PULLEY

3-1/2” PULLEY

STRAP

WEIGHT STACK SHAFT

HEAD PLATE

CABLE

1/2” FLANGE BEARING

3/8” FLANGE SPACER

WEIGHT STACK PIN

PARTS LIST

QTY

2

2

2

2

2

2

2

2

1

4

2

2

14

2

2

2

2

2

4

20

2

KEY

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

PART #

3108002

6382301

3103801

6412001

3102501

3102502

3102802

3102801

3102804

3202401

3102901

3102933

3102922

3202101

3102918

3202103

3102944

6703801

6189501

6214501

3103302

DESCRIPTION

WEIGHT STACK CUSHION

PLATE BUSHING (10 CT.)

5/16” SNAP HOOK

3/8” SPRING PIN ASSEMBLY

3/8" FLAT WASHER

1/2" FLAT WASHER

3/8” LOCK NUT

1/2" LOCK NUT

1/2" LOW HT LOCK NUT

3/8 X 1” BTN HD CAP SCREW

3/8 X 1-1/4" BOLT

3/8 X 2" BOLT

3/8 X 2-3/4” BOLT

1/2 X 1-1/4" BOLT

1/2 X 3-1/4” BOLT

1/2 X 4” BOLT

1/2 X 5” BOLT

WEIGHT STACK LABEL (LBS.)

WEIGHT STACK LABEL (1-25)

WEIGHT PLATE

13/16” SHAFT COLLAR

QTY

4

8

2

2

2

12

16

18

6

8

2

6

10

8

6

10

2

2

2

40

4

BOLT LENGTH RULER:

0

1/2 1/2 1/2 1/2 1/2 1/2

1 2 3 4 5 6

Bolt Length Ruler

NOTE: Bolt length is measured from the underside of the head of the bolt.

BOLT LENGTH

3

Page 4

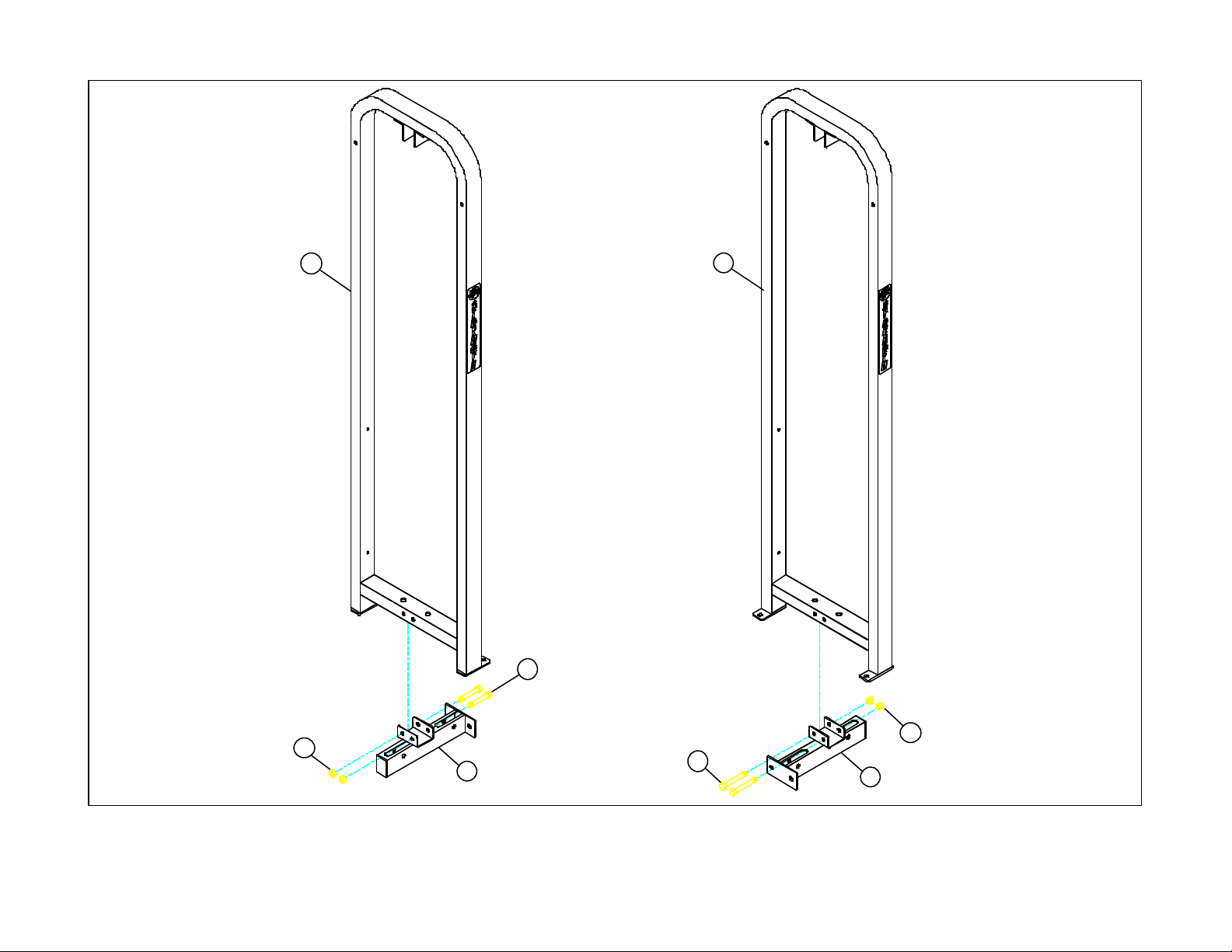

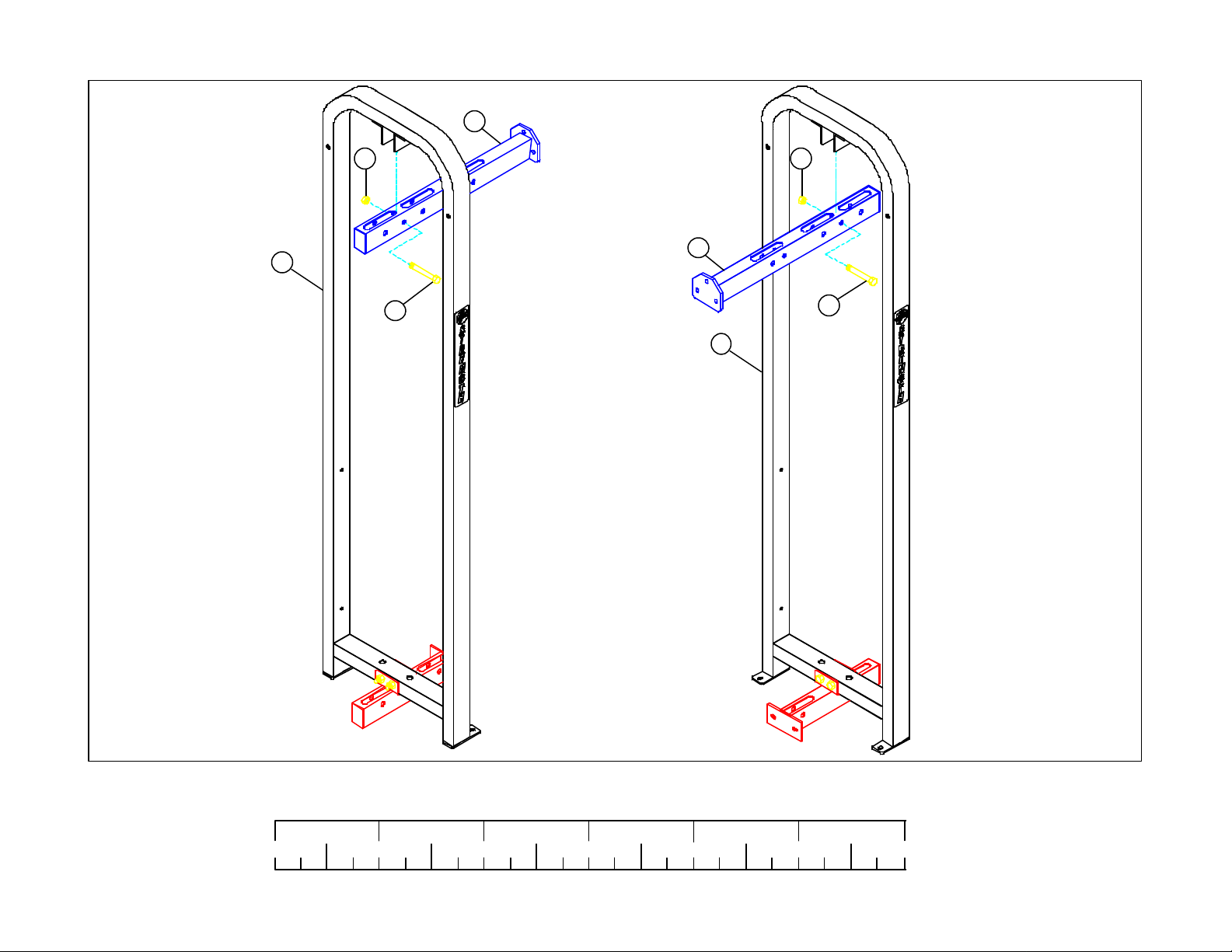

1

1

37 1/2 X 4”

29

6

1/2 X 4” 37

29

6

FIGURE 1

STEP 1

• LOOSELY assemble the two LOWER PULLEY HOUSINGS (6) to the two TOWERS (1) using four 1/2 X 4” BOLTS (37) and four 1/2” LOCK NUTS (29) as shown in

FIGURE 1.

4

Page 5

8

1

29

36

1/2 X 3-1/4”

29

8

36

1/2 X 3-1/4”

1

FIGURE 2

STEP 2

• LOOSELY assemble the two UPPER PULLEY HOUSINGS (8) to the two TOWERS (1) using two 1/2 X 3-1/4” BOLTS (36) and two 1/2” LOCK NUTS (29) as shown in

FIGURE 2.

0

1/2 1/2 1/2 1/2 1/2 1/2

1 2 3 4 5 6

5

Page 6

1/2 X 4” 37

1/2 X 4” 37

25

19

25

5

2

28

29

3/8 X 2” 33

14

2

28

14

FIGURE 3

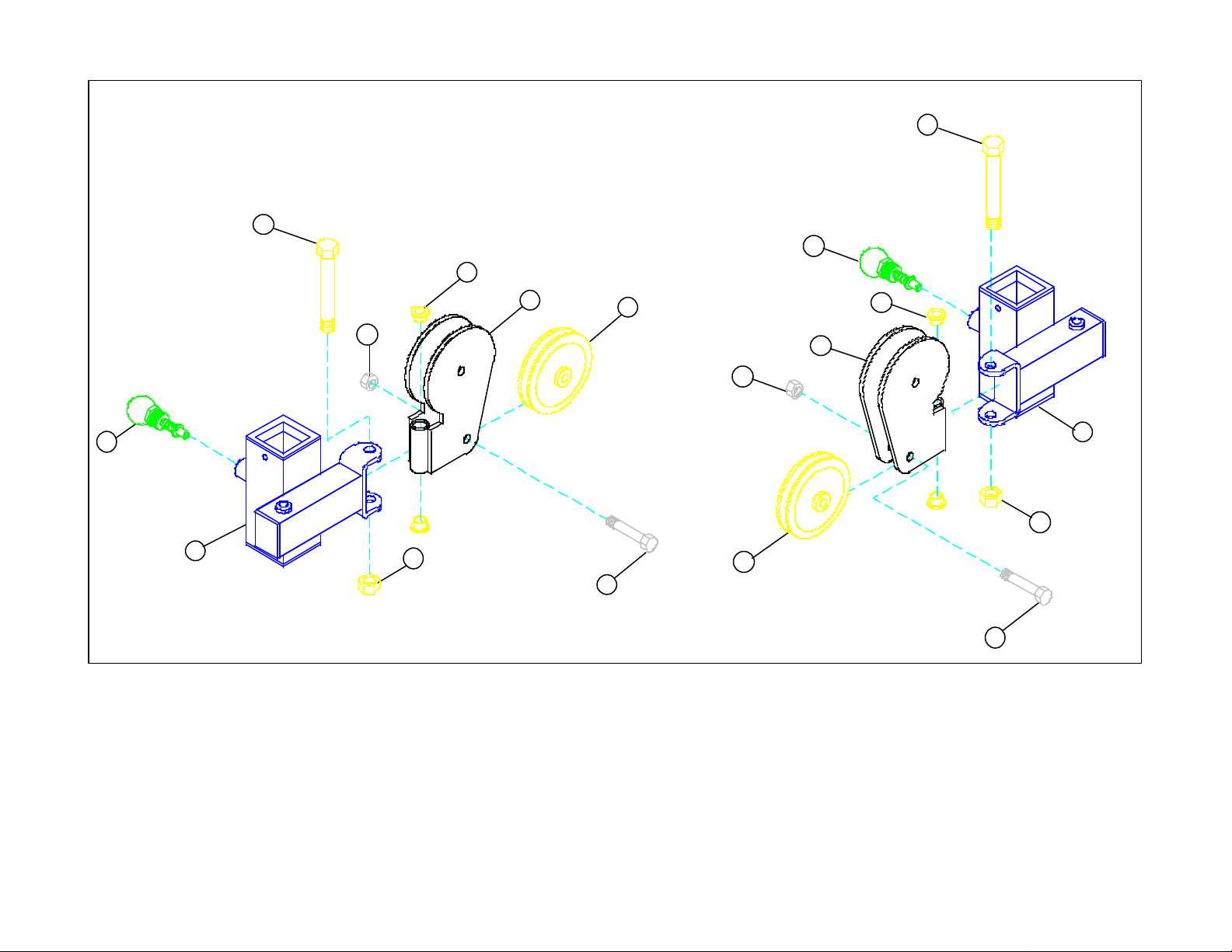

STEP 3

• SECURELY assemble two 3-1/2” PULLEYS (14) to the two NOVATRAK SWIVELS (2) using two 3/8 X 2” BOLTS (33) and two 3/8” LOCK NUTS (28). See FIGURE 3.

• Insert two 1/2” FLANGE BEARINGS (19) into each end of the NOVATRAK SWIVELS (2) and assemble them to the SWIVEL HOLDERS (5) using two 1/2 X 4” BOLTS

(37), and two 1/2” LOCK NUTS (29). (NOTE: Tighten connection enough to remove play, yet allowing the SWIVEL HOLDER (2) to rotate freely.) See FIGURE 3.

19

5

29

3/8 X 2” 33

• SECURELY assemble two 3/8” SPRING PIN ASSEMBLIES (25) to the SWIVEL HOLDERS (5). See FIGURE 3.

6

Page 7

STEP 4

• Pull back the SPRING PINS on the SWIVEL HOLDERS

(5) and slide assemblies over the SWIVEL UPRIGHTS

(7) as shown in FIGURE 4.

• LOOSELY assemble the two SWIVEL UPRIGHTS (7)

to the LOWER PULLEY HOUSING (6) using four 1/2

X 3-1/4” BOLTS (36), four 1/2” WASHERS (27), and

four 1/2” LOCK NUTS (29) as shown in FIGURE 4.

FIGURE 4

29

5

29

5

8

27

38

1/2 X 5”

• LOOSELY assemble the SWIVEL UPRIGHTS (7) to

the UPPER PULLEY HOUSING (8) using two 1/2 X

5” BOLTS (38), four 1/2” WASHERS (27), and two 1/

2” LOCK NUTS (29) as shown in FIGURE 4.

• SECURELY assemble all loose connections made to

this point.

29

8

6

27

38

1/2 X 5”

7

7

6

29

27

36 1/2 X 3-1/4”

36 1/2 X 3-1/4”

27

0

1/2 1/2 1/2 1/2 1/2 1/2

1 2 3 4 5 6

7

Page 8

STEP 5

• SECURELY assemble the CHIN-UP SUPPORT (9) to

the two UPPER PULLEY HOUSINGS (8) using six

1/2 X 1-1/4” BOLTS (35) and six 1/2” LOW

HEIGHT LOCK NUTS (30) as shown in FIGURE 5.

FIGURE 5

9

1/2 X 1-1/4” 35

30 LOW HT.

8

8

7

Page 9

• Loop the ball end of the CABLE (18) around one 4-1/

2” PULLEY (13) and SECURELY assemble the 4-1/

2” PULLEY (13) to the NOVATRAK SWIVEL (2)

using one 3/8 X 2” BOLT (33) and one 3/8” LOCK

NUT (28) as shown in FIGURE 6.

FIGURE 6

28

13

• Route the threaded end of the CABLE (18) through

the opening in the UPPER PULLEY HOUSING (8)

and around two 4-1/2” PULLEYS (13) as shown in

FIGURE 6.

• SECURELY assemble the two 4-1/2” PULLEYS

(13) to the UPPER PULLEY HOUSING (8) using

two 3/8 X 2-3/4” BOLTS (34), four 3/8” FLANGE

SPACERS (20), and four 3/8” LOCK NUTS (28).

See FIGURE 6.

20

8

3/8 X 2-3/4” 34

18

2

28

13

3/8 X 2” 33

0

1/2 1/2 1/2 1/2 1/2 1/2

1 2 3 4 5 6

9

Page 10

FIGURE 7 FIGURE 8

35 1/2 X 1-1/4”

3

3

FIGURE 9

32 3/8 X 1-1/4”

26

17 31

16

STEP 7:

• SECURELY assembly the CENTER PULLEY

BRACKETS (3) to the WEIGHT STACK SHAFTS

(16) using one 1/2 X 1-1/4 BOLT (35) as shown in

FIGURE 7.

16

STEP 8:

• Slide HEAD PLATES (17) up the WEIGHT STACK

SHAFTS (16) and SECURELY assemble the CEN-

TER PULLEY BRACKETS (3) to the HEAD

PLATES (17) using two 3/8 X 1-1/4” BOLTS (32) and

two 3/8” WASHERS (26) as shown in FIGURE 8.

49

STEP 9:

• Snap two WEIGHT PLATE BUSHINGS (23) each,

into the top side of the forty WEIGHT PLATES (41)

as shown in FIGURE 9.

10

Page 11

STEP 10:

• Insert the two GUIDE RODS (10) into the base of the

TOWER (1) as shown in FIGURE 10. Lubricate the

GUIDE RODS with a slicon or teflon spray that is

available at most hardware stores.

• Slide two WEIGHT STACK CUSHIONS (22) down

over the GUIDE RODS (10). See FIGURE 10.

• Using EXTREME CARE slide twenty WEIGHT

PLATES (41) down over the GUIDE RODS (10) with

the key-hole facing as shown in FIGURE 10.

10

41

1

22

FIGURE 10

1/2 1/2 1/2 1/2 1/2 1/2

0 1 2 3 4 5 6

11

Page 12

STEP 11:

• Run CABLE (18) under and around the 4-1/2” PULLEY

(13) and SECURELY assemble the 4-1/2” PULLEY (13)

to the CENTER PULLEY BRACKET (3) using one 3/8 X

2” BOLT (33) and one 3/8” LOCK NUT (28). See

FIGURE 11.

• Carefully slide the HEAD PLATE ASSEMBLY (17) down

over the GUIDE RODS (10) onto the weight stack as

shown in FIGURE 11.

18

13

FIGURE 11

12

28

10

3

33 3/8 X 2”

17

Page 13

42

27

4

29

1

10

1/2 X 4” 37

FIGURE 12

STEP 12

• Slide two 13/16” SHAFT COLLARS (42) down over the GUIDE RODS (10) as shown in FIGURE 12.

• Slide the TOWER BRACE (4) over the GUIDE RODS (10) as shown in FIGURE 12.

• SECURELY assemble the TOWER BRACE (4) to the TOWER (1) using two 1/2 X 4” BOLTS (37), two 1/2” WASHERS (27), and two 1/2” LOCK NUTS (29) as shown in

FIGURE 12.

1/2 1/2 1/2 1/2 1/2 1/2

0 1 2 3 4 5 6

13

Page 14

STEP 13:

• Loop the threaded end of the CABLE (18) around a 4-1/

2” PULLEY (13) and SECURELY assemble the 4-1/2”

PULLEY (13) to the UPPER PULLEY HOUSING (8)

using one 3/8 X 2-3/4” BOLT (34), two 3/8” FLANGE

SPACERS (20), and two 3/8” LOCK NUTS (28). See

FIGURE 13.

• Slide the 13/16” SHAFT COLLARS (42) to the top of

the GUIDE RODS (10) and SECURELY tighten the set

screws of the SHAFT COLLARS (42). See FIGURE 13.

FIGURE 13

13

28

18

20

8

34 3/8 X 2-3/4”

42

14

Page 15

STEP 14:

• Route the threaded end of the CABLE (18) through the

LOWER PULLEY HOUSING (6) as shown in FIGURE 14.

• Slip one 4-1/2” PULLEY (13) over the CABLE (18) and

SECURELY assemble the 4-1/2” PULLEY (13) to the

LOWER PULLEY HOUSING (6) using one 3/8 X 2-3/4”

BOLT (34), two 3/8” FLANGE SPACER (20) and one 3/8”

LOCK NUT (28) as shown in FIGURE 14. (Make sure the

CABLE is in the groove of the PULLEY.)

18

28

STEP 15:

• Slip one 4-1/2” PULLEY (13) over the CABLE (18) and

SECURELY assemble the 4-1/2” PULLEY (13) to the

LOWER PULLEY HOUSING (6) using one 3/8 X 2-3/4”

BOLT (34), two 3/8” FLANGE BEARINGS (20) and one

3/8” LOCK NUT (28) as shown in FIGURE 15. (Make

sure the CABLE is in the groove of the PULLEY.)

FIGURE 14

FIGURE 15

28

13

18

20

20

34 3/8 X 2-3/4”

13

6

6

34 3/8 X 2-3/4”

1/2 1/2 1/2 1/2 1/2 1/2

0 1 2 3 4 5 6

15

Page 16

STEP 16

• Screw the threaded end of CABLE (18) approximately 3/4” into the

SWIVEL HOLDER (5) and tighten jam nut SECURELY as shown

in FIGURE 16.

FIGURE 16

12

5

• SECURELY assemble one 1/2 X 3/4” BUTTON HEAD CAP

SCREW (12) to the SWIVEL HOLDER (5). See FIGURE 16.

• Attach one 5/16” SNAP HOOK (24) and one STRAP (15) to the ball

end of the CABLE (18). See FIGURE 16.

• Apply one set of WEIGHT STACK LABELS - LBS. OR 1-25 (39)

(40) to each WEIGHT PLATE (41) as shown in FIGURE 16.

• Insert the WEIGHT STACK PIN (21) into the first WEIGHT PLATE

(41) of the WEIGHT STACK as shown in FIGURE 16.

• If the HEAD PLATE (17) does not sit on top of the first WEIGHT

PLATE (41), push the head plate down, insert the SELECTOR PIN

(21) and perform several repetitions on the machine. This will relax

the cable system and prevent the HEAD PLATE (17) from lifting up.

• If after completing the previous step the HEAD PLATE (17) still

does not sit on top of the first WEIGHT PLATE (41) or if there is

excess slack in the cable system, adjust the threaded end of the

CABLE (18) accordingly and RETIGHTEN the jam nut.

15

24

21

39

18

17

40

41

• Repeat STEPS 6-16 to assemble cable on other

side of the CABLE CROSS OVER.

16

Page 17

3/8 X 1” 31

BUTTON

HEAD

11

MAKE SURE

CABLE IS

ROUTED

BEHIND

SHROUD!

1

FIGURE 17

STEP 17:

• SECURELY assemble the SHROUD (11) to the TOWER (1) using four 3/8 X 1” BUTTON HEAD CAP SCREWS (31) as shown in FIGURE 17.

• Repeat STEP 17 to assemble SHROUD on other side of the CABLE CROSS OVER.

1/2 1/2 1/2 1/2 1/2 1/2

0 1 2 3 4 5 6

17

Page 18

STEP 18:

• Make sure all connections are tight and secure.

Thank you for purchasing the LifeFitness 8205

CABLE CROSS OVER. If unsure of proper use

of equipment, call your local LifeFitness distributor or call the LifeFitness customer service

department at (800) 328-9714.

FIGURE 18

18

Loading...

Loading...