Page 1

Technical data

Hydraulic crawler crane

Complies with ANSI B 30.5

HS 895 HD

Page 2

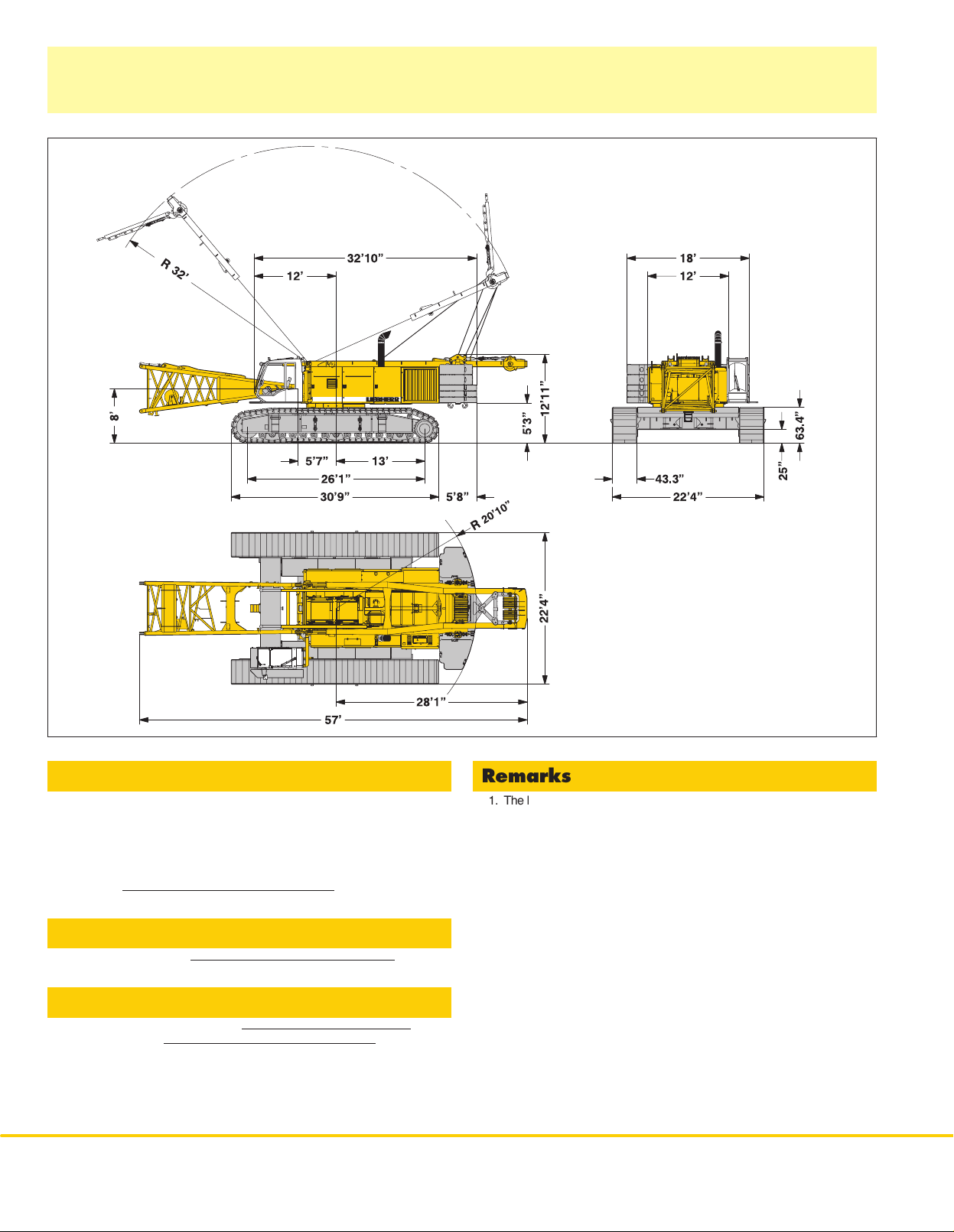

Dimensions

Basic machine with undercarriage

Operating weight

The

operating weight includes the basic machine with HD undercarriage,

2

main winches 66,200 lbs including wire ropes (492

consisting

(20 ft), 121,500 lbs basic counterweight, 43.3 inch flat track shoes and

110,200

T

otal weight

o

f A

–frame

lbs hook block.

, boom foot (23 ft), boom head (23 ft), boom section

ft) and 66 ft b

approx. 373,000 lbs

Ground pressure

Ground bearin

g p

ressur

e 13,8 P

Equipment

Main boom

Fixe

Modular designed equipment for operation as crane, with dragline or

clamshell.

For dragline operation, a rotating fairlead is fitted into the boom foot. This

minimizes

2

(No. 2

d jib

(No. 0806.xx)

the rope a

HS 895 HD

220.xx)

max. l

ngl

e t

o d

engt

rum

h

, w

hic

h r

esult

276 f

3

6 f

t – 105 f

s i

n l

owe

r rope w

ear.

oom,

Remarks

1. The liftin

2. Crane

3. The

4. Additional

SI

t

t

5. For

6. Working

7. Th

8. Calculation

9. Th

10. ANS

ponds wit

s

w

eigh

must

b

e d

value.

b

e d

educte

max. wind s

e l

iftin

and IS

O 4305 T

e s

tructure

(E

N 1

3001–2

I B 3

g c

apacitie

h c

tandin

t o

educte

e

d t

r

adi

g c

apacitie

o

0.5

ran

f the l

quipmen

i are m

f s

s are c

/ 2

s s

tate

e c

lassificatio

g o

n f

irm

, h

iftin

g d

evic

d from the g

t o

pee

tabilit

abl

004).

n boom (

d p

leas

easure

s are v

y u

nde

e 1 + 2

alculate

o get the net l

d are v

n a

orizonta

e (

ros

iftin

g c

e r

efe

d from c

ali

d for 360 d

r load i

, t

ippin

d a

ccordin

ali

d for l

ccordin

l g

round.

hoistin

s l

iftin

e.g

. boom w

apacity.

r t

o lift c

entr

s b

g a

ngl

ase

iftin

g t

o F

g r

opes

g c

apacit

har

e o

egree

d o

e 4

g t

o F

g o

.E.M

alkways

t i

n o

f s

win

s o

n DIN 1

º.

.E.M

peratio

. 1

.001

, hook b

y t

o o

perator’

g and u

f s

wing.

501

. 1

.00

n only (

, c

ran

lock

, s

hackl

btai

n a net l

, a

uxiliar

s cab o

nde

r l

9 / part 2 / c

1 – 1998

corre

s

e g

rou

p A

e e

iftin

g

y jib) must

r m

anual.

oad.

har

tc.)

t 1

1)

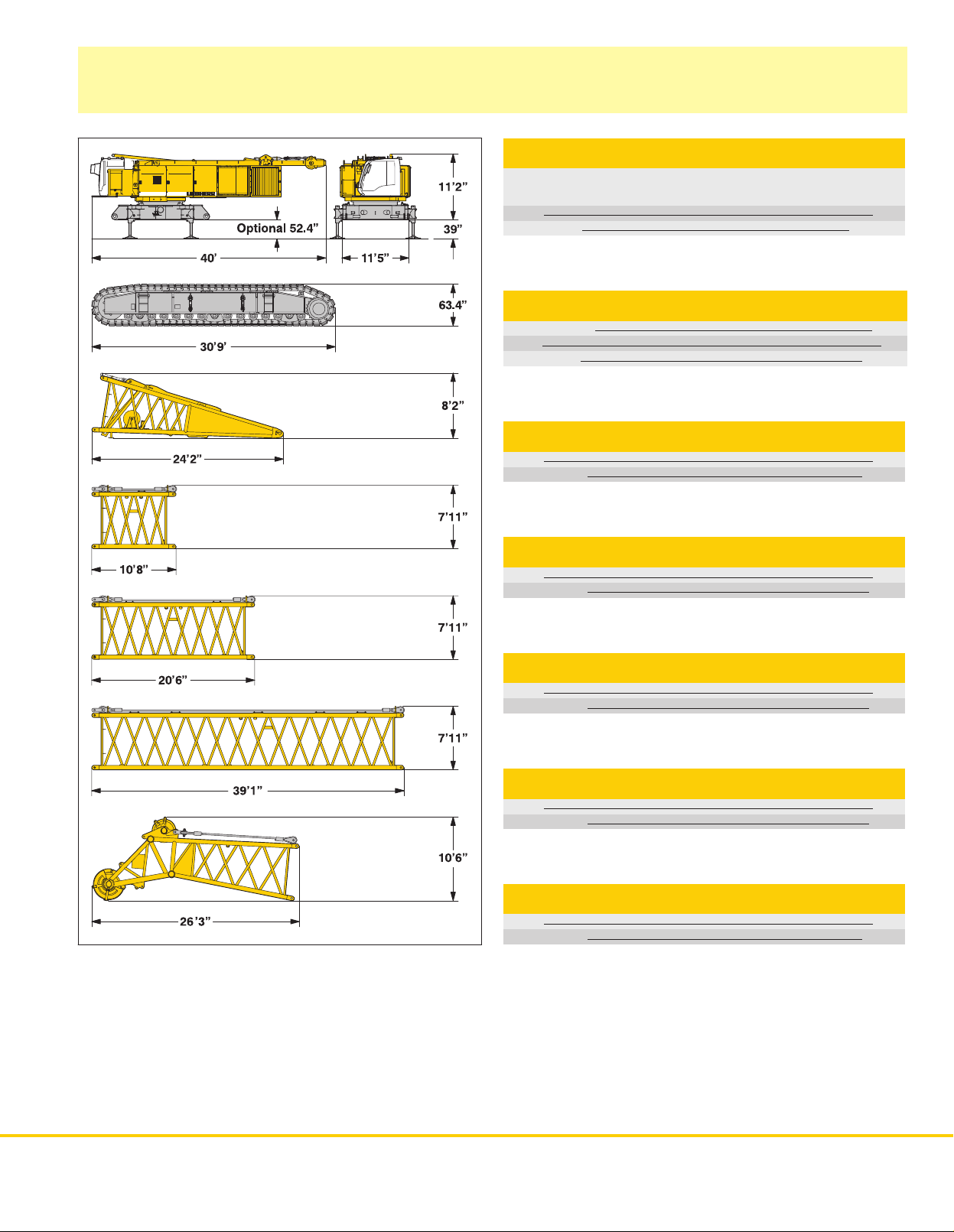

Page 3

T ransport dimensions and weights

Basic machine and boom (No.

2

220.xx)

Basic machine

with A–frame, 2x 66,20

crawlers,

Width

Weight

boom f

in lbs

oot

0 l

bs winches including wire ropes (492 ft), without

, b

asi

c and c

Crawler 2x

Flat

track shoes

Width

Weight

in lbs

arbody counterweight.

1

1’6”

121,250

43.3”

47”

55,120

Boom foot (No.

Width

Weight

in lbs*

2

220.xx)

Boom section (No.

Width

Weight

in lbs*

Boom section (No.

Width

Weight

in lbs*

Boom section (No.

Width

Weight

in lbs*

12,400

2

220.xx) 10 ft

2,500

2

220.xx) 20 ft

4,150

2

220.xx) 38 ft

6,400

7’1

7’1

7’1

7’1

1”

1”

1”

1”

)

*

Including pendan

t r

opes

Boom head (No.

Width

Weight

in lbs*

2

220.xx)

H

S 895 H

7’1

1”

10,350

D3

Page 4

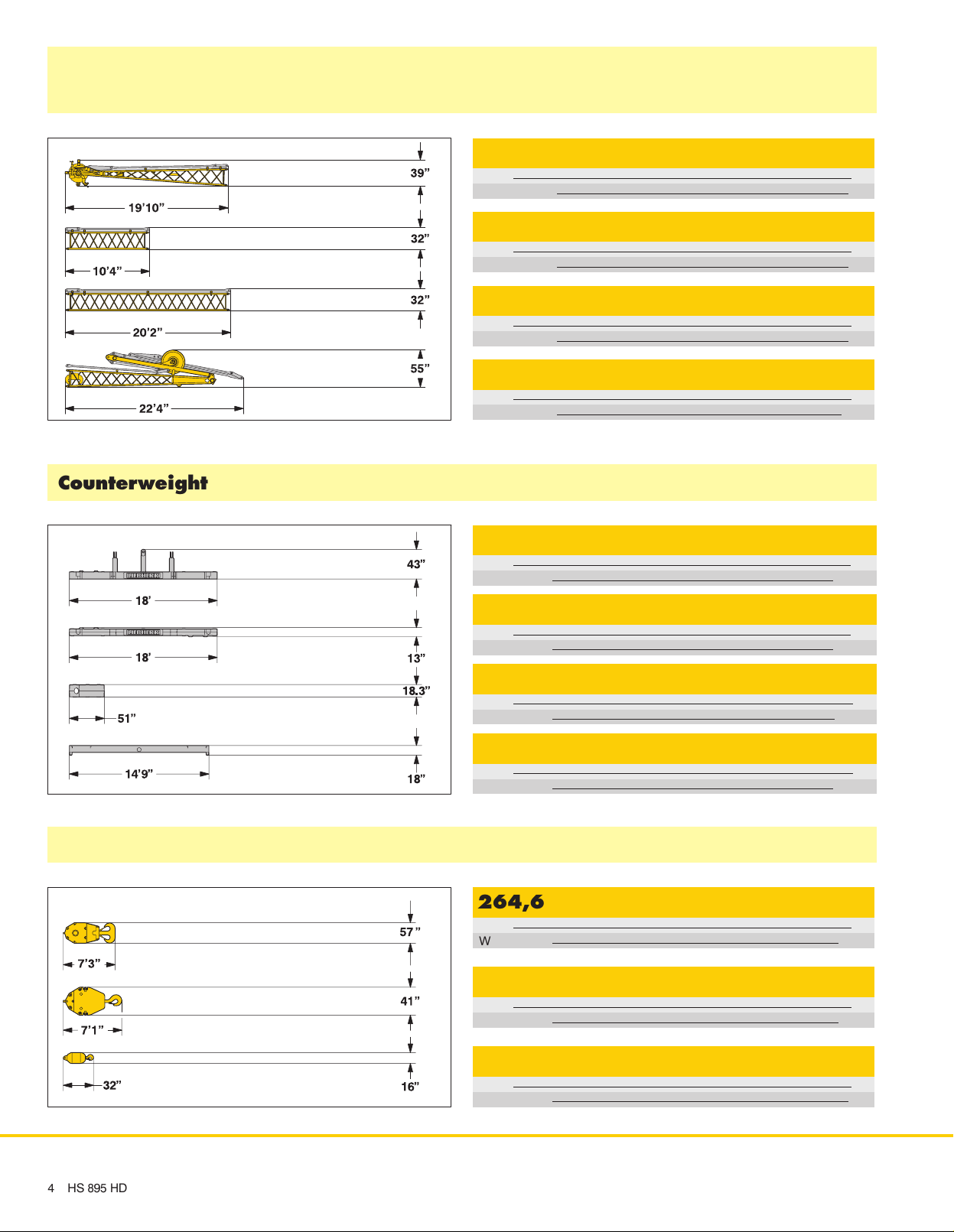

Transport dimensions

Fixed jib (No.

0

806.xx)

)

*

Including pendan

t s

traps

Counterweight

Fixed jib head (No.

Width

Weight

in lbs*

Fixed jib section (No.

Width

Weight

in lbs*

Fixed jib section (No.

Width

Weight

in lbs*

Fixed jib foot with A-frame (No.

Width

Weight

in lbs*

0

806.xx)

0

806.xx

0

806.xx

45”

980

)

)

0

806.xx)

10 ft

37”

245

20 ft

37”

430

59”

2050

Counterweight 1x

Width

W

eight in lbs

5’5”

29,300

Hooks

Counterweight 2x

Width

W

eight in lbs

5’5”

23,400

Counterweight 4x optional 8x

Width

Weight

in lbs

1

55”

1,250

Carbody counterweight optional 2x

Width

Weight

in lbs

35”

29,800

264,600 lbs hook block-2sheaves

Width

Weight

in lbs

13”

3,100

132,300 lbs hook block-1sheave

Width

Weight

in lbs

12”

2,150

4HS 89

5 H

66,150 lbs single hook

Width

Weight

in lbs

D

16”

880

Page 5

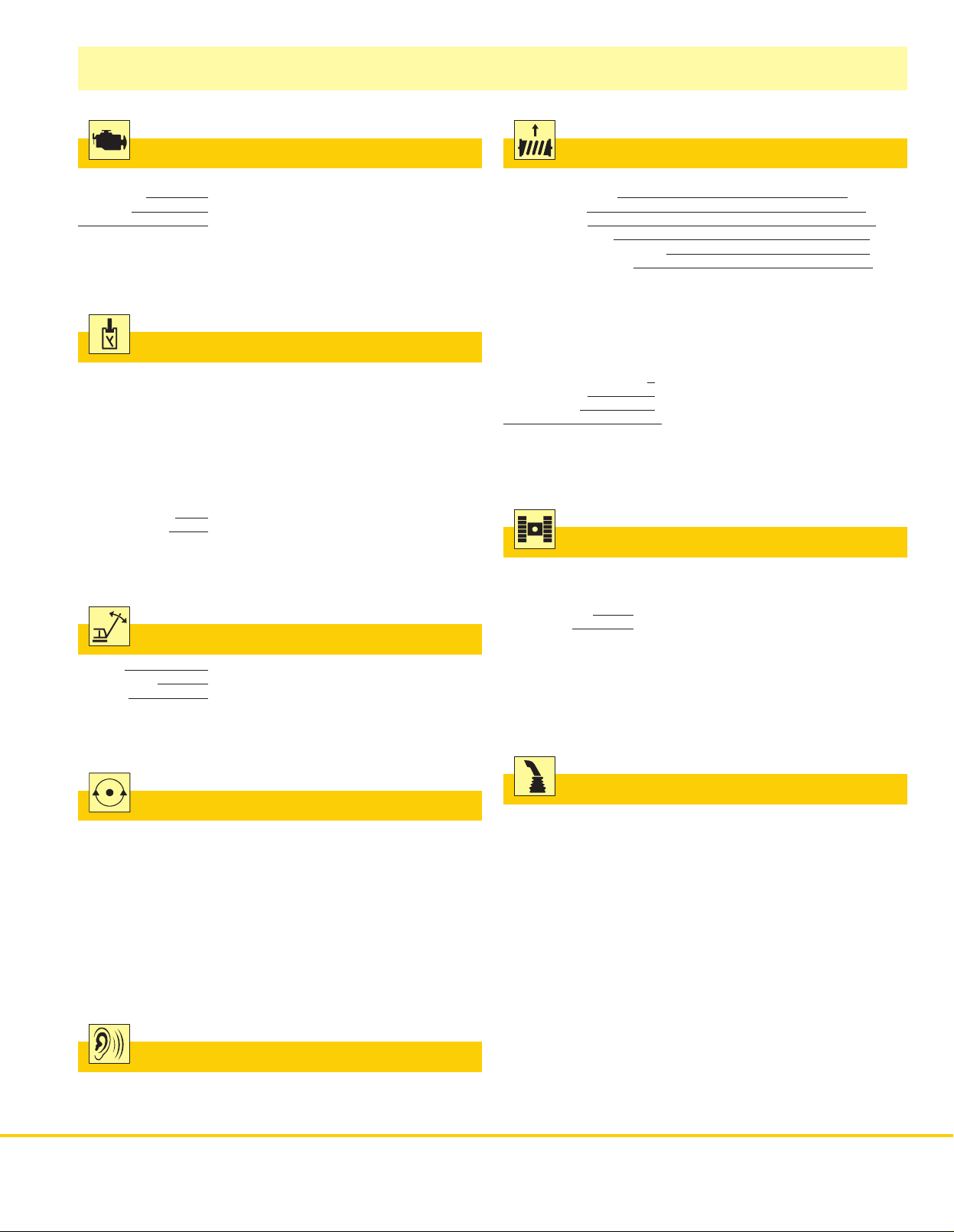

Technical description

Engine

Power rating according to ISO 3046 IFN, 670 kW (898 hp) at 1900 rpm

Engine type

Fuel tank

Engine complies with NRMM exhaust certification EP

MAN D 2842 LE

264 gal capacity with continuous level indicator

and reserve warning

A / CARB T

ier 2.

Hydraulic system

The main pumps are operated by a distributor gearbox. Axial piston

displacement

needed (flow control on demand). To minimize peak pressure an

automatically

saves

pressure and return filters. Possible contamination is signaled in the cabin.

The

use of synthetic environmentally friendly oils is possible.

Ready made hydraulic retrofit kits are available to customize requirements

e.g. powering casing oscillators, VM–vibrators, hydraulic grabs, hanging

leads

W

orking pressure

Oil tank capacity

pumps work in closed and open circuits supplying oil only when

working pressure cut of

energy

. The hydraulic oil is cleaned through

etc.

max. 5076 PSI

290 gal

f is integrated. This spares pumps

electronically controlled

and

Boom winch

Line pul

l

Rop

e d

iamete

Boo

m u

r

p 137 sec. from 15º t

max. 3

2

4 m

m

3,10

0 l

bs

o 8

6º

Main winches

Winch

options:

Line pull (nom. load)

Rope diameter

Drum diameter

Rope speed (ft/min)

With change gear box (ft/min)

Rope capacity 1st layer

The winches are outstanding in their compact design and easy assembly

Clutch and braking functions on the free fall system are provided by a

compact

designed, low wear and maintenance free multi–disc brake.

The

drag and hoist winches use pressure controlled, variable flow hydraulic

motors. This system features sensors that automatically adjust oil flow to

provide

max. winch speed depending on load.

Option:

Crane winch (main winch)

Auxiliary winch

T

agline winch

33,100

15,500

15,500

6,600

lbs with multi–disc holding brake

lbs in boom foot

lbs with free fall

lbs with free fall

66,200 lbs

36 mm

32.7”

0–252

0–515

180 ft

.

Crawlers

Propulsion through axial piston motor, hydraulically released spring loaded

multi–disc

device.

Flat track shoes

Drive speed

Option:

F

F

brake, maintenance free crawler tracks,

43.3 inch

0 – 0.8 mph

2 speed hydraulic motor for higher travel speed

Self assembly system, jack up system

hydraulic chain tensioning

Swing

Consists of rollerbearing wit

fixed axial piston hydraulic motor, spring loaded and hydraulically released

multi–disc

Swing speed from 0 – 3.6 rpm continuously variable, selector for 3 speed

ranges

Standard:

Second swing drive

Optional:

Third swing drive

holding brake, planetary gearbox and pinion.

to increase swing precision.

h e

xternal teeth for lower tooth flank pressure,

Noise emission

Noise emissions correspon

equipmen

t used o

utdoors.

d with 2

000/14/E

C d

irectiv

e on n

ois

e e

missio

n b

y

Control

The

control system – developed and manufactured by Liebherr – is designed

to

withstand

common

shown on a high resolution display

control

Dragline

It is designed for power lifting of the dragline bucket without using the drag

winch

An additional option is the ”Redundant Control System”, whic

restricted

base

On

request, Liebherr also of

free

Operation:

for

winch I and II. Crawler control is actuated with the two

Additionally,

Options:

F

F

F

F

extreme temperature changes and the rough heavy duty tasks

in the construction industry

for all movements, which can be carried out simultaneously

operation: A special

brake.

operation of the machine in the event of a failure on the electronic

control or its sensors.

fers special custom designed control systems

fall winches.

Left joy stick for boom

hand levers can be attached to the pedals.

Special demolition control system

MDE: Machine data recording

PDE: Process data recording

GSM modem

. Complete machine operating data are

. The crane is equipped with proportional

”Interlock” control system is an option available.

winch and swing, right two directional levers

central foot pedals.

HS

.

h a

895 HD

llows

for

5

Page 6

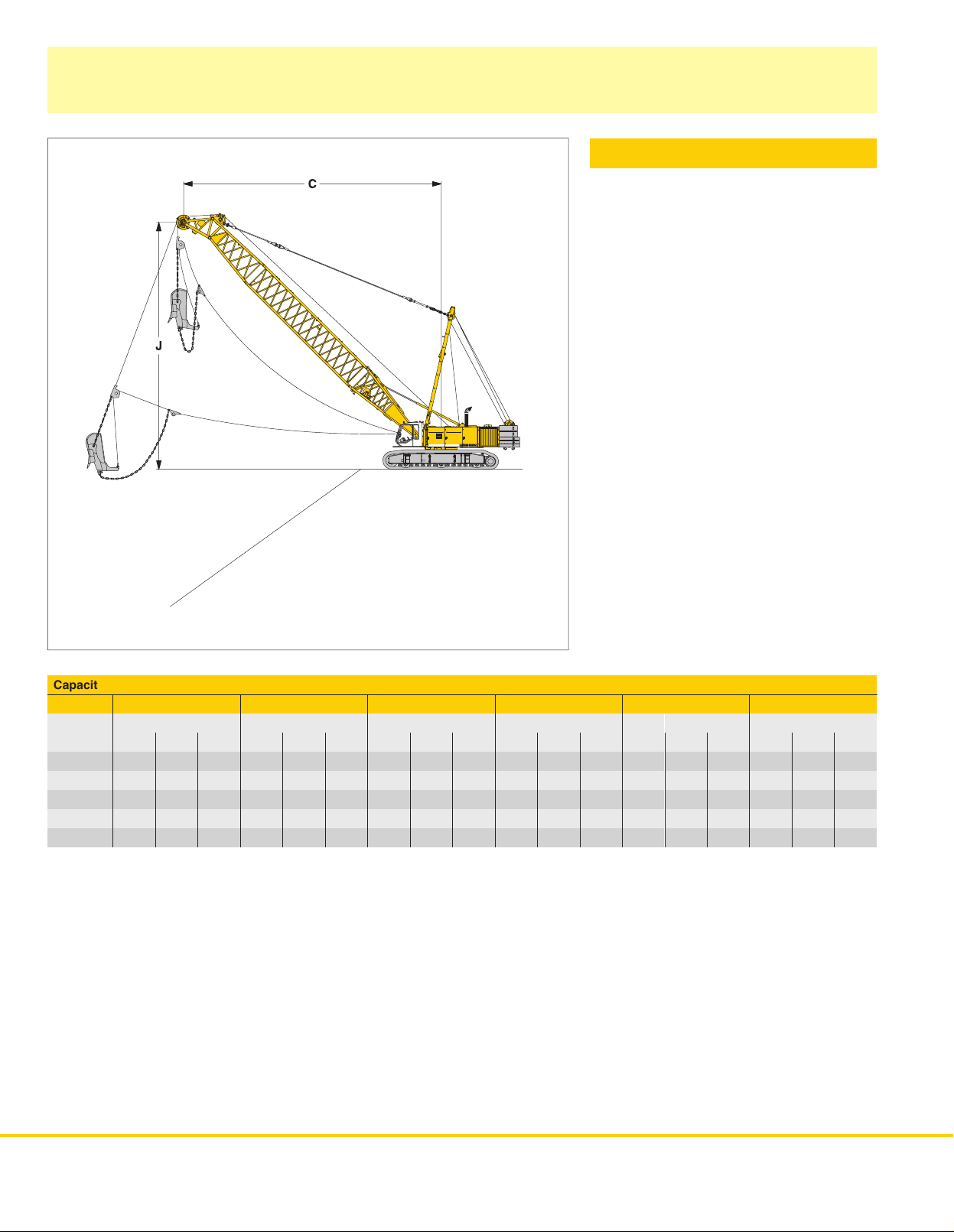

Dragline equipment

121,500 lbs counterweight

Working diagram

C =Radius / dumping radius

J =

Height of boom head sheave centre above

ground level

Capacities

Max. capacities in 1000 lbs do not exceed 75% of tipping load.

in 1000 lbs for boom lengths (84 ft – 181 ft)

84 ft

C J C J C J C J C J C J

α

45 69.2 64.6 64,4 83.0 78.7 49,4 96.1 91.9 39,9 110.2 106.0 31,5 123.4 119.1 25,6 137.1 132.9 20,3

40 73.8 59.7 58,6 88.9 72.2 44,7 103.3 84.3 35,9 118.4 96.8 28,2 132.5 108.9 22,5 147.6 121.7 17,2

35 78.1 54.1 54,2 94.2 65.3 41,2 109.6 76.1 32,6 125.7 87.3 25,6 141.1 98.1 20,3 157.2 109.3 15,0

30 81.7 48.2 50,7 98.7 57.1 38,4 114.8 67.3 30,2 131.9 77.1 23,4 149.9 86.6 18,3 165.4 96.5 13,2

25 84.9 42.0 46,9 102.6 50.2 35,7 119.7 58.1 27,6 137.5 66.3 21,2 154.5 74.1 16,1 172.2 82.7 11,5

ft ft lbs ft ft lbs ft ft lbs ft ft lbs ft ft lbs ft ft lbs

104 ft 123 ft 142 ft 161 ft 181 ft

counterweight 121,500 lbs

6

HS 895 HD

Page 7

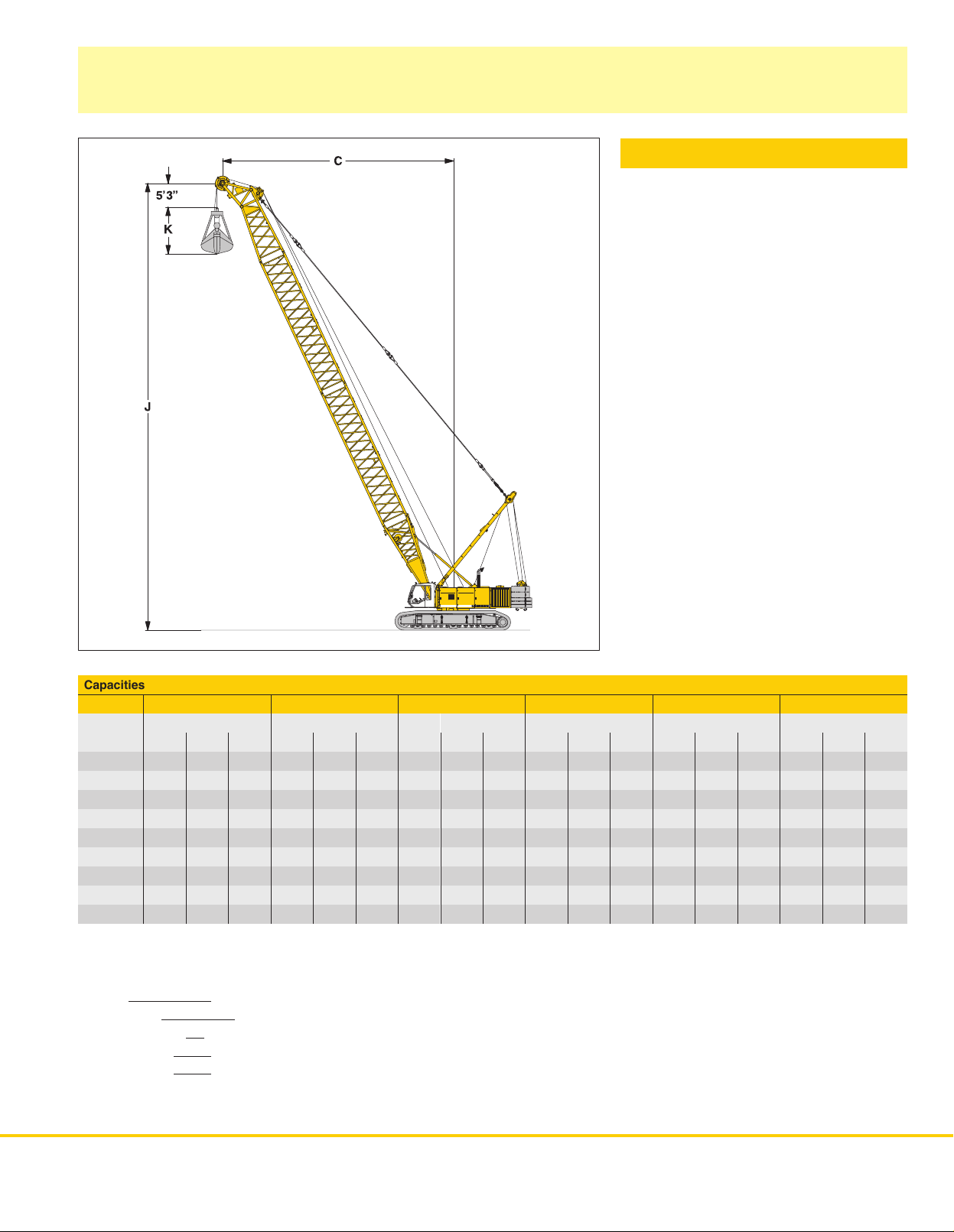

Clamshell equipment

121,500 lbs counterweight

Working diagram

C =Radius / dumping radius

J =

Height of boom head sheave centre above

ground level

K =

Length of clamshell (depending on type and

capacity of bucket)

Capacities in 1000 lbs for boom lengths (84 ft – 181 ft)

84 ft

C J C J C J C J C J C J

α

65 45.9 81.0 71,7 54.1 98.8 71,7 62.0 115.8 65,0 70.2 133.5 54,0 78.1 150.6 46,1 86.6 168.3 38,8

60 52.2 77.7 71,7 62.0 94.8 65,5 71.5 110.9 53,6 81.3 127.9 44,1 90.6 144.0 37,3 100.4 161.1 30,9

55 58.1 73.8 71,4 69.6 89.9 56,0 80.4 105.3 44,8 91.5 121.4 37,0 102.4 136.8 30,6 113.5 152.9 25,1

50 64.0 69.6 63,1 76.4 84.6 48,9 88.6 99.1 39,5 101.0 114.2 31,7 113.2 128.3 26,0 126.0 143.3 20,8

45 69.2 64.6 56,7 83.0 78.7 43,7 96.1 91.9 35,1 110.2 106.0 27,8 123.4 119.1 22,7 137.1 132.9 18,1

40 73.8 59.7 51,6 88.9 72.2 39,5 103.3 84.3 31,5 118.4 96.8 24,7 132.5 108.9 19,8 147.6 121.7 15,6

35 78.1 54.1 47,8 94.2 65.3 36,4 109.6 77.7 28,7 125.7 87.3 22,5 141.1 98.1 17,8 157.2 109.3 13,7

30 81.7 48.2 44,5 98.8 58.1 33,7 114.8 67.3 26,5 131.9 77.1 20,5 148.3 86.6 16,3 165.4 96.5 12,1

25 85.0 42.0 41,4 102.7 50.2 31,1 119.8 58.1 24,0 137.5 66.3 18,5 154.5 74.1 14,8 172.2 82.7 10,6

Max. capacities in 1000 lbs do not exceed 66.7 % of tipping load.

Load diagram restricted by safety factors of standard ropes:

Winches

Rope diameter

Calc. breaking load

1–rope clamshell

2–rope clamshell

ft ft lbs ft ft lbs ft ft lbs ft ft lbs ft ft lbs ft ft lbs

66,200

lbs

36

mm

260,550

51,800

69,000

lbf

lbs

lbs

104 ft 123 ft 142 ft 161 ft 181 ft

counterweight 121,500 lbs

HS

895 HD

7

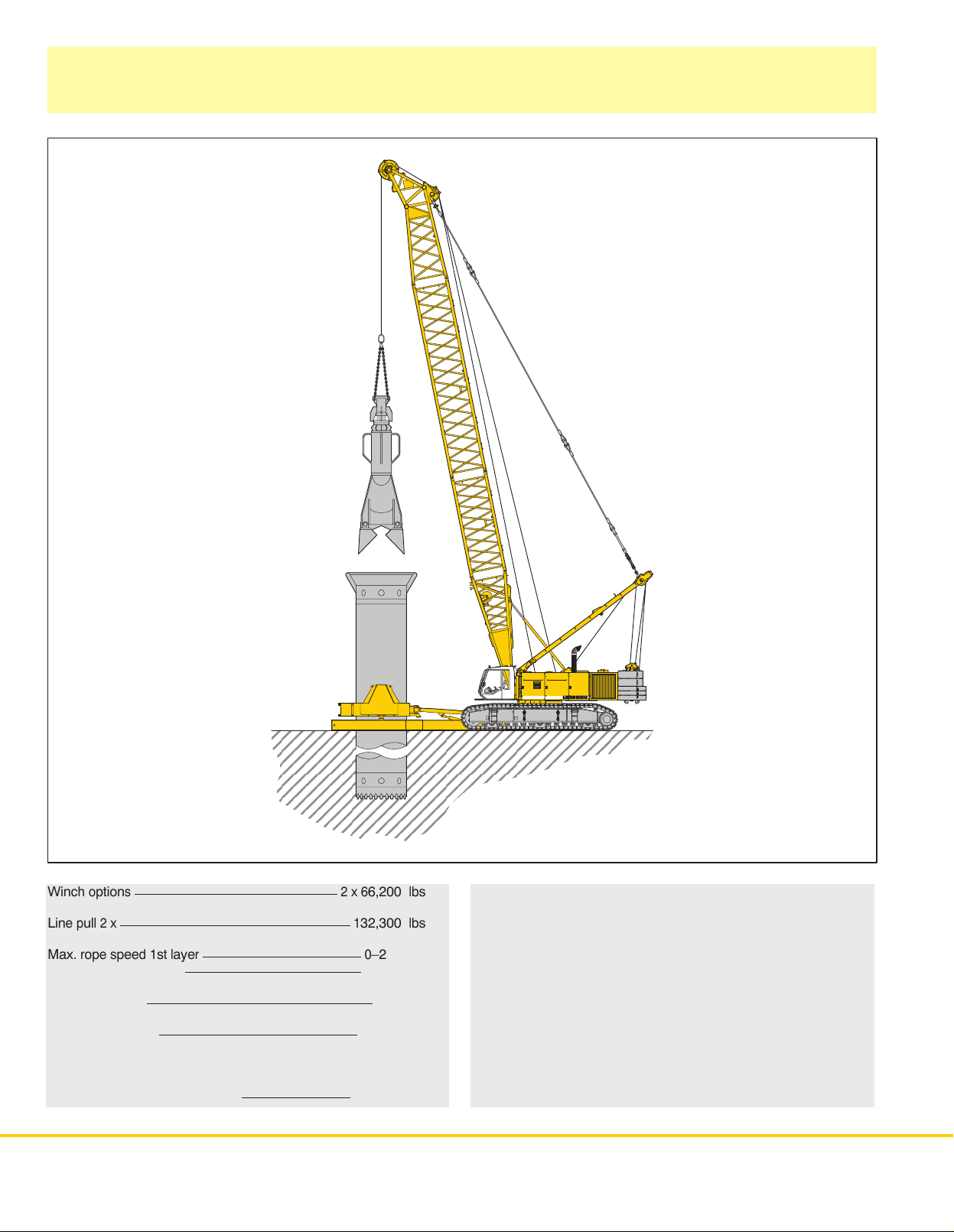

Page 8

Equipment

Casing oscillator

Winc

h o

Lin

e pull 2 x

Max

. rope s

h c

hang

(wit

Drillin

g d

Max

. c

hise

Max

. c

apacit

directio

a

t 33 f

t r

8HS

895 HD

ption

s

pee

e gear box)

iamete

l w

eigh

y with boom p

n o

f u

ndercarriag

adiu

s (75% t

d 1st l

r

t

aye

r

e with 104 f

ippin

g l

ositio

oad

n in l

ongitudina

t main boom

)

l

2 x 6

1

32,300 lbs

0

0

3

1

68,900 lbs

6,200 lbs

–253 ft/min

–515 ft/min

1

0.8 ft

9,700 lbs

Free fal

brake working in an oil bath. Simultaneous working of both

winches

Hydrauli

q = 2 x 106 g

P = 4350 PSI m

Mechanica

Automatic

the drilling process the engine power can be freely divided

between

l w

i

c s

inche

s a

o

c

asin

ssure

uppl

y for c

al/min.

ax.

l c

onnectio

peratio

g o

s with m

aintenanc

d t

hroug

h our h

asin

g o

n c

asin

n for one and two rope g

scillato

r and h

ydrauli

scillato

g o

scillato

oistin

e f

r

ree

g w

, s

prin

c s

ystem

r o

n u

ndercarriage.

rab

inche

g l

oade

.

s (

optional)

s a

s r

d m

ult

. D

equired.

i d

isc

uring

Page 9

Equipment

Dynamic soil compaction

Capacities in 1000 lbs for boom lengths (84 ft – 142 ft)

Radius 84 ft

(ft) lbs lbs lbs lbs

29.5 88,2 88,2 88,2 83,8

32.8 88,2 83,8 79,4 75,0

36.1 77,2 77,2 70,6 68,4

39.4 70,6 70,6 66,2 61,7

Max.

capacities in 1000 lbs do not exceed 75% of tipping load.

All

loads given are max. values and must not be exceeded. They are

with

max. inclination of 1 %. Lifting heigths must not exceed 98.4 ft.

Boom length

104 ft 123 ft 142 ft

only permitted in two rope automatic operation and are valid for work on a surface

HS

895 HD

9

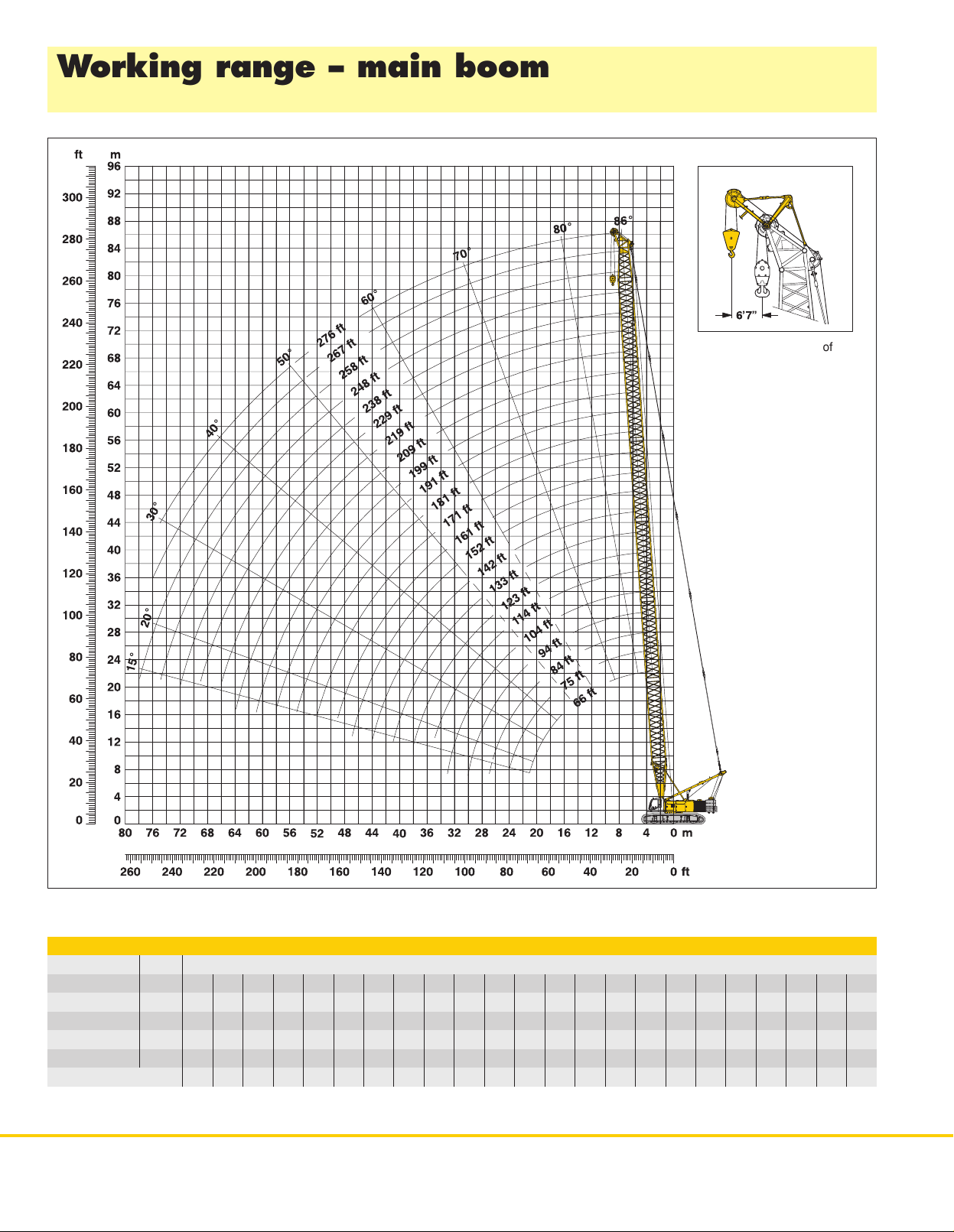

Page 10

Working range - main boom (No. 2220.xx) 86° -15°

166,000 lbs counterweight and 59,500 lbs carbody counterweight

Auxiliary jib 66,200 lbs

The

maximum capacity of the

auxiliary

jib is 66,200 lbs.

The correspondin

is programmed in the LMI

system.

g load c

hart

Main boom configuration

Configuration fo

Boom foot 2

Boo

m e

xtension 1

Boo

m e

xtension 2

Boo

m e

xtension 3

Boo

m h

ead 2

Boo

m l

engt

*Actual

lengths of boom sections are metric (e.g. 3 m, 6 m, 1

10 HS

895 HD

r boom l

ength

s (66 f

t – 276 f

t)

Length Amoun

3 f

t 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

0 f

t* 1 1 1 1 1 1 1 1 1 1 1

0 f

t* 1 1 1 1 1 1 1 1 1 1 1 1

8 f

t* 1 1 1 1 2 2 2 2 3 3 3 3 4 4 4 4 5 5 5 5 6

3 f

t 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

h i

n (

ft) 66 75 84 94 104 11 4 123 133 142 152 161 171 181 191 199 209 219 229 238 248 258 267 276

(table

1 – No. 2

220.xx)

t of boom e

1.7 m). The figures shown above are approximate conversions to feet.

xtensions

Page 11

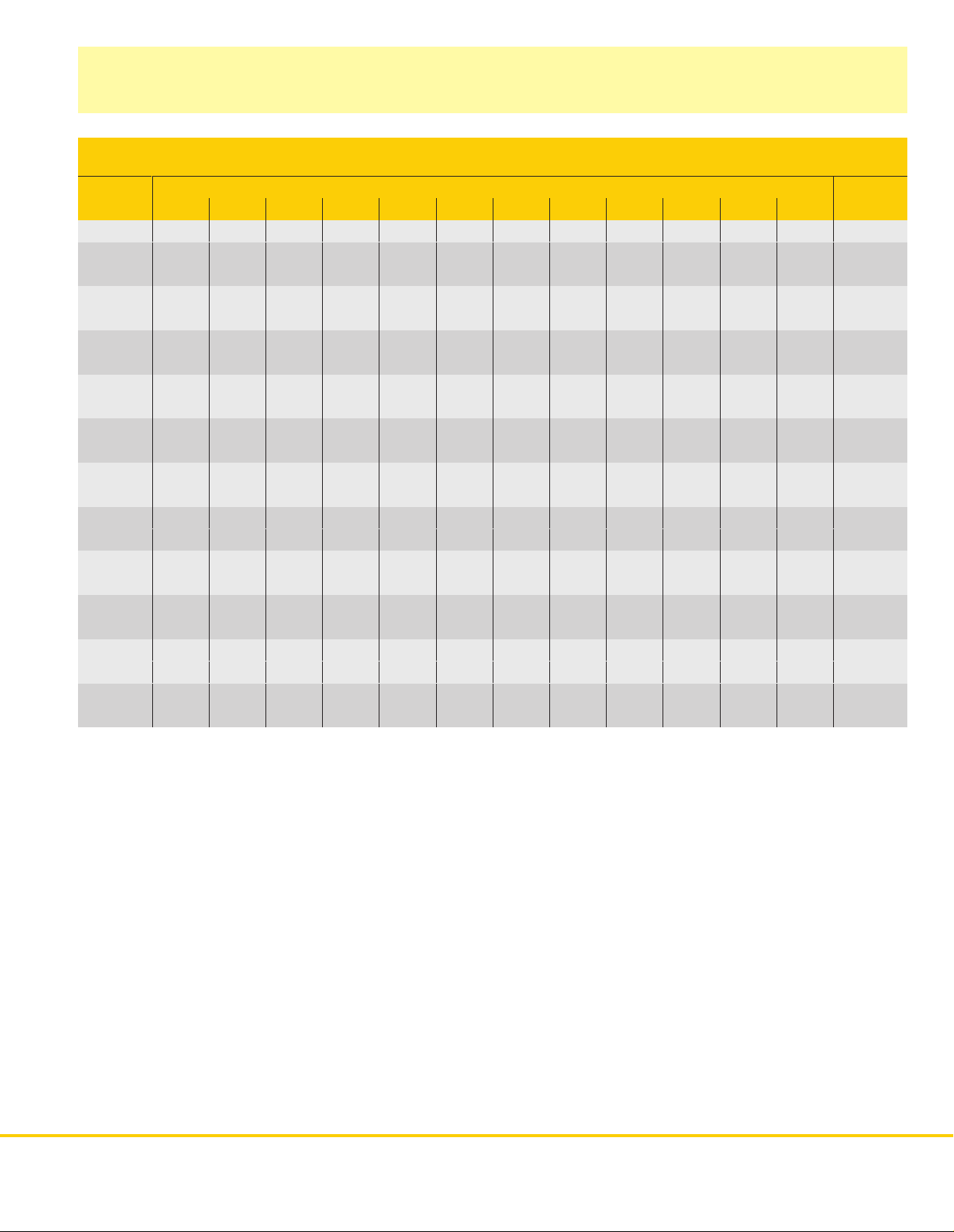

Lift chart for main boom (No. 2220.xx)

143,500 lbs counterweight and 59,500 lbs carbody counterweight

Capacities

Counterweight 143,500 lbs and 59,500 lbs carbody counterweight

Radius 66 84 104 123 142 161 181 199 219 238 258 267 Radius

in 1000 lbs for boom lengths (66 ft – 267 ft) – with 66,200 lbs winches

Boom length in (ft)

(ft) lbs lbs lbs lbs lbs lbs lbs lbs lbs lbs lbs lbs (ft)

16 *440,9 16

20 *440,9 *424,6 *432,2 20

25 *338,3 *339,2 *339,5 *313,3 *321,2 25

30 252.6 253.2 253.3 253.3 252.3 244.5 220.4 181.3 30

35 200.7 201.2 201.0 200.9 200.5 200.2 197.3 168.4 144.9 120.0 35

40 165.8 166.3 166.0 165.8 165.3 164.9 164.3 155.1 133.7 114.0 111.0 100.8 40

45 140.8 141.2 140.9 140.6 140.0 139.5 138.9 138.3 124.0 105.9 106.1 94.6 45

50 121.9 122.4 121.9 121.6 121.0 120.4 119.7 119.1 116.7 95.7 101.9 90.7 50

55 107.1 107.6 107.2 106.8 106.1 105.6 104.8 104.1 103.3 91.6 96.8 87.5 55

60 95.2 95.8 95.3 95.0 94.2 93.6 92.8 92.1 91.3 87.6 89.7 85.0 60

65 85.3 86.0 85.6 85.3 84.5 83.9 83.0 82.3 81.4 80.7 79.8 79.3 65

85 59.6 59.5 59.2 58.4 57.7 56.8 56.0 55.0 54.2 53.2 52.7 85

105 44.2 44.1 43.3 42.7 41.7 41.0 40.0 39.1 38.1 37.6 105

120 36.0 35.4 34.8 33.8 33.1 32.0 31.2 30.1 29.6 120

140 27.5 27.0 26.1 25.3 24.3 23.4 22.4 21.8 140

160 21.1 20.3 19.6 18.6 17.7 16.6 16.1 160

180 15.7 15.1 14.1 13.3 12.2 11.6 180

200 11.4 10.6 9.8 8.7 8.1 200

215 8.3 7.5 6.5 5.9 215

235 4.9 4.0 3.4 235

245 2.8 2.3 245

250 2.3 250

Above lift chart is for reference only

*) Only with special boom head

. For actual lift duty please refer to lift chart in operator’s cab or manual.

HS 895 HD

11

Page 12

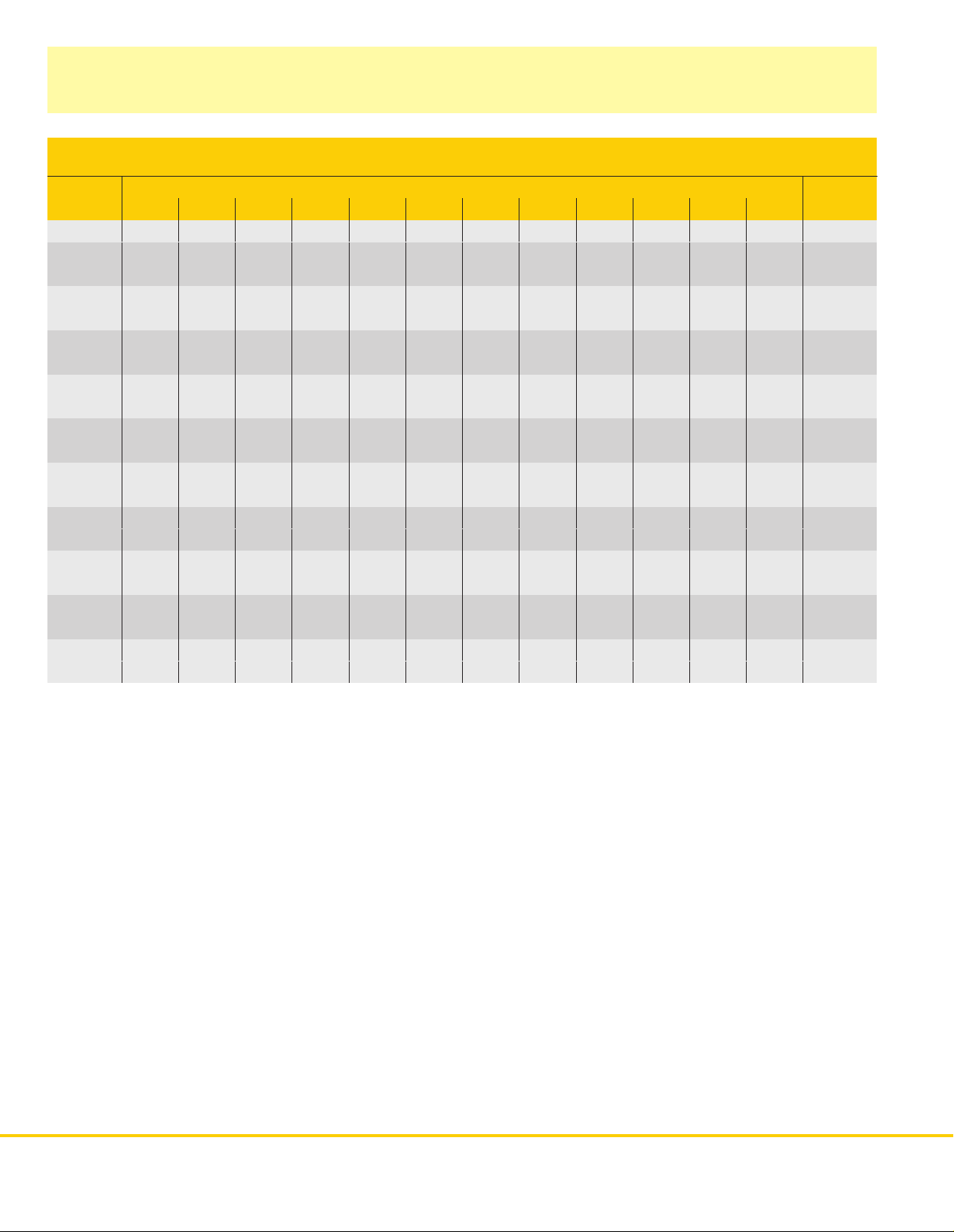

Lift chart for main boom (No. 2220.xx)

166,000 lbs counterweight and 59,500 lbs carbody counterweight

Capacities in 1000 lbs for boom lengths (66 ft – 276 ft) – with 66,200 lbs winches

Counterweight 166,000 lbs and 59,500 lbs carbody counterweight

Boom length in (ft)

Radius 66 84 104 123 142 161 181 199 219 238 258 276 Radius

(ft) lbs lbs lbs lbs lbs lbs lbs lbs lbs lbs lbs lbs (ft)

25 *369,3 *360,2 *349,2 *322,9 25

30 275.3 275.9 275.7 275.9 *275,2 244.5 220.4 181.3 30

35 218.9 219.4 219.2 219.1 218.7 218.4 201.2 168.4 144.9 120.0 35

40 181.0 181.5 181.2 181.0 180.5 180.0 179.5 155.1 133.7 114.0 111.0 89.3 40

45 153.8 154.3 153.9 153.6 153.0 152.5 151.9 142.9 124.0 105.9 106.1 85.6 45

50 133.3 133.8 133.4 133.0 132.4 131.9 131.1 130.5 116.7 95.7 101.9 82.5 50

55 117.3 117.8 117.4 117.0 116.3 115.7 115.0 114.3 109.9 91.6 96.8 79.9 55

60 104.3 104.9 104.5 104.1 103.4 102.8 102.0 101.3 100.5 87.6 93.1 77.7 60

65 93.6 94.4 94.0 93.6 92.8 92.2 91.3 90.6 89.8 84.1 87.8 74.6 65

85 65.7 65.6 65.3 64.5 63.8 62.9 62.1 61.2 60.3 59.4 58.5 85

105 49.0 48.9 48.1 47.5 46.6 45.8 44.8 44.0 42.9 42.1 105

120 40.2 39.6 39.0 38.0 37.2 36.2 35.4 34.3 33.4 120

140 31.0 30.5 29.6 28.8 27.8 27.0 25.9 25.0 140

160 24.2 23.4 22.6 21.6 20.8 19.7 18.8 160

180 18.4 17.8 16.8 16.0 14.9 14.0 180

200 13.9 13.0 12.2 11.1 10.2 200

215 10.5 9.8 8.7 7.8 215

235 7.0 6.0 5.1 235

255 3.6 2.8 255

260 2.3 260

Above lift chart is for reference only

*) Only with special boom head

. For actual lift duty please refer to lift chart in operator’s cab or manual.

12 HS

895 HD

Page 13

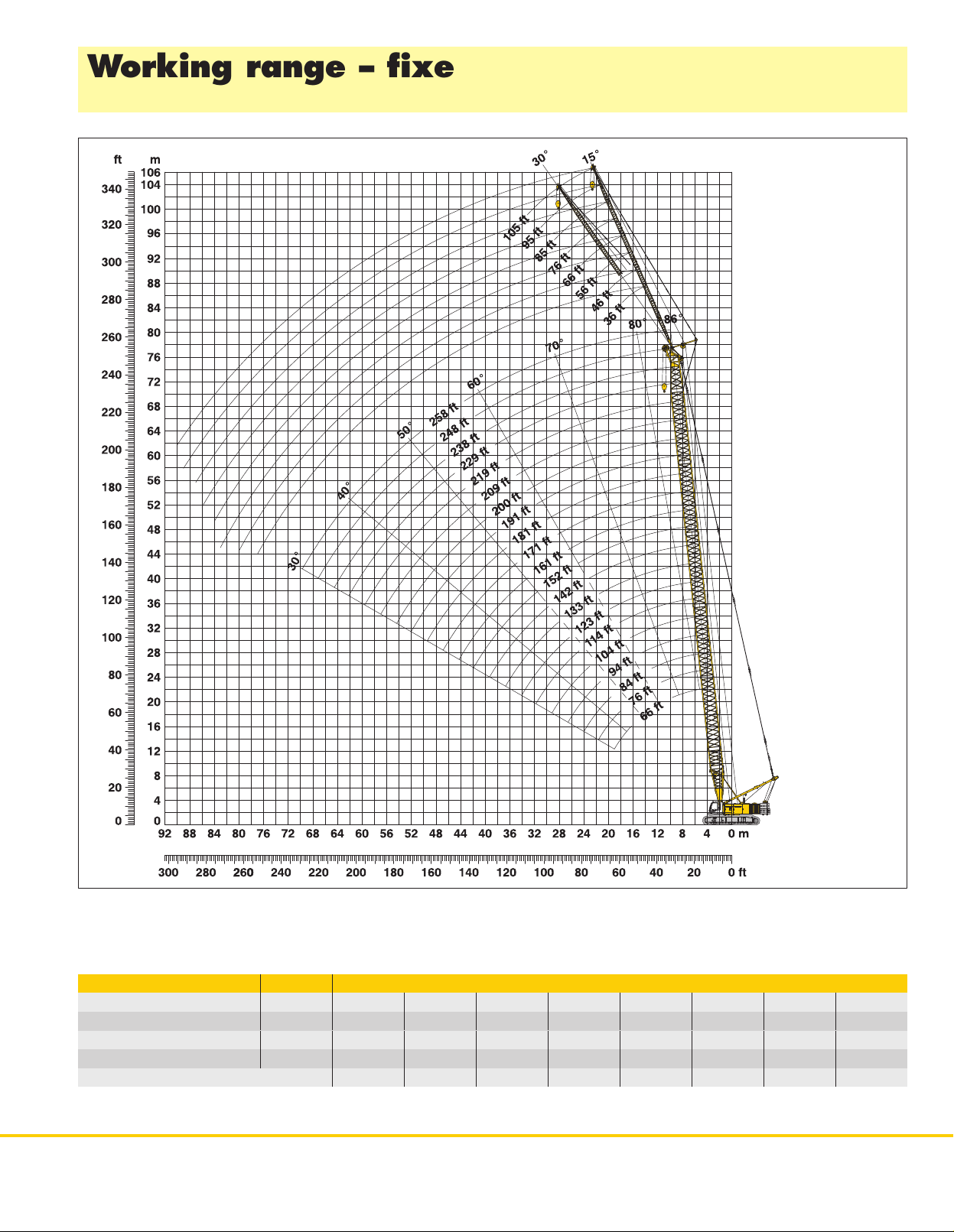

Working range - fixed jib (No. 0806.xx) 15° and 30°

Main boom 86° -30°

Boom configuration for boom lengths (66 ft - 258 ft) – se

e t

abl

e 1 o

n page 1

Fixed jib configuration for fixed jib lengths (36 ft - 105 ft)

Length Amount

Fixed jib foot

Fixed jib insert

Fixed jib insert

Fixed jib head

Fixed jib length in (ft)

*Actual lengths of boom sections are metric (e.g. 3 m, 6 m,). The figures shown above are approximate conversions to feet.

18 ft

10 ft*

20 ft*

18 ft

1 1 1 1 1 1 1 1

1 1 1 1

1 1 2 2 3 3

1 1 1 1 1 1 1 1

36 46 56 66 76 85 95 105

of fixed jib extensions

0

HS

895 HD

13

Page 14

Lift chart - fixed jib (No. 0806.xx)

Offset 15°

Main boom 66 ft

Fixed

jib length in (ft)

36 66 85 105

Radius (ft)

30 54.3

45 42.3 23.4

50 40.7 22.3 15.6

60 38.4 20.9 12.8 10.0

70 36.6 19.9 11.8 8.6

80 35.3 18.9 11.1 8.2

90 34.4 18.2 10.3 7.9

95 34.0 17.8 10.0 7.8

110 16.8 9.2 7.3

120 16.0 8.7 7.1

140 8.1 6.7

160 6.7

lbs lbs lbs lbs

Main boom 152 ft

Fixed

jib length in (ft)

36 66 85 105

Radius (ft)

38 50.8

55 42.0 22.6

65 40.7 21.9 13.3

75 39.8 21.1 12.8 8.8

80 39.1 20.7 12.5 8.7

100 37.1 19.6 11.4 8.2

120 35.5 18.5 10.5 7.7

140 31.3 17.7 9.7 7.3

170 22.4 16.7 8.8 6.9

200 15.3 8.2 6.6

215 8.0 6.5

235 6.5

lbs lbs lbs lbs

Main boom 94 ft

Fixed

jib length in (ft)

36 66 85 105

Radius (ft)

29.9 55.5

45 44.1 26.2

55 41.1 22.3 13.6

65 39.3 21.1 12.8 9.0

70 38.5 20.6 12.4 8.8

80 37.2 19.8 11.6 8.4

90 35.9 19.0 11.0 8.1

100 35.0 18.5 10.4 7.8

120 33.8 17.3 9.4 7.3

150 15.4 8.4 6.8

170 7.9 6.6

190 6.6

lbs lbs lbs lbs

Main boom 181 ft

Fixed

jib length in (ft)

36 66 85 105

Radius (ft)

41.9 48.6

60 41.3 22.0

70 40.1 21.4 13.2

80 39.3 20.8 12.8 8.8

100 37.5 19.7 11.8 8.3

120 36.1 18.7 11.0 7.9

140 29.9 18.0 10.1 7.5

160 23.7 17.3 9.5 7.2

195 15.9 16.2 8.6 6.8

225 12.8 8.1 6.5

245 7.9 6.5

260 6.5

lbs lbs lbs lbs

Main boom 123 ft

Fixed

jib length in (ft)

36 66 85 105

Radius (ft)

33.9 53.1

50 43.2 23.2

60 41.3 22.1 13.4

70 39.8 21.2 12.8 8.9

80 38.4 20.4 12.1 8.6

90 37.5 19.7 11.5 8.3

100 36.4 19.0 11.0 8.0

120 34.8 18.0 10.0 7.5

140 32.8 17.2 9.2 7.2

170 15.6 8.4 6.8

190 8.0 6.6

210 6.6

lbs lbs lbs lbs

Main boom 209 ft

Fixed

jib length in (ft)

36 66 85 105

Radius (ft)

45.9 45.7

65 39.9 21.4

70 39.4 21.1 15.1

80 38.5 20.8 12.8 9.7

100 37.1 19.7 12.0 8.4

120 35.6 18.9 11.2 8.0

140 28.4 18.1 10.5 7.6

180 17.4 16.9 9.3 7.0

215 11.1 13.0 8.6 6.7

245 8.9 8.1 6.5

265 7.6 6.4

285 6.4

lbs lbs lbs lbs

Main boom 229 ft

Fixed

jib length in (ft)

36 66 85 105

Radius (ft)

48.6 43.6

65 39.0 21.1

75 38.1 20.7 13.1

85 37.3 20.4 12.6 8.8

100 36.4 19.6 12.1 8.4

120 35.1 18.9 11.3 8.0

160 21.1 17.5 10.0 7.4

200 12.4 14.3 9.1 6.9

235 7.2 9.1 8.4 6.6

265 5.6 6.6 6.4

285 4.6 5.5

305 3.8

Capacities in 1000 lbs with fixed jib (No. 0806.xx) 166,000 lbs counterweight + 59,500 lbs carbody counterweight. Above lift chart is for reference only

For actual lift duty please refer to lift chart in operator’s cab or manual.

14 HS

895 HD

lbs lbs lbs lbs

Main boom 248 ft

Fixed

jib length in (ft)

36 66 85 105

Radius (ft)

51.3 41.3

70 37.3 20.4

80 36.5 20.1 12.8

85 36.1 19.9 12.6 9.6

120 33.3 18.7 11.4 8.1

160 20.1 17.4 10.2 7.4

200 11.5 13.4 9.2 6.9

240 5.7 7.5 8.4 6.6

250 4.6 6.3 7.4 6.5

280 3.2 4.2 5.2

300 2.5 3.4

310 2.5

lbs lbs lbs lbs

Main boom 258 ft

Fixed

jib length in (ft)

36 46 56

Radius (ft)

52.6 40.4

60 37.3 30.7

65 36.9 30.4 24.7

80 36.0 29.7 24.1

100 34.7 28.6 23.3

120 32.5 27.8 22.6

160 19.6 20.4 21.1

200 10.9 11.6 12.3

240 5.2 5.8 6.4

260 2.9 3.5 4.2

270 2.5 3.1

275 2.7

lbs lbs lbs

.

Page 15

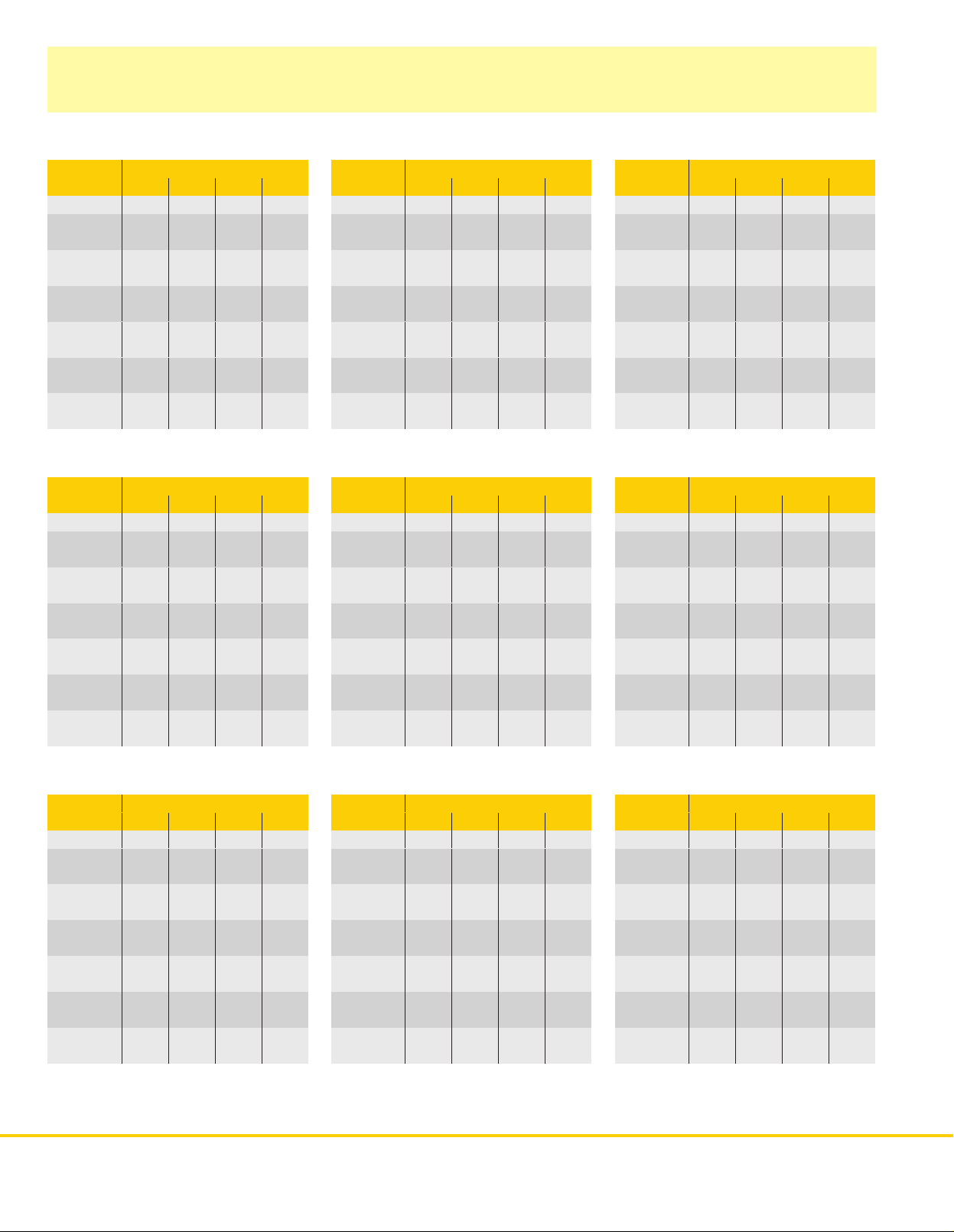

Lift chart - fixed jib (No. 0806.xx)

Offset 30°

Main boom 66 ft

Fixed

jib length in (ft)

36 66 85 105

Radius (ft)

40 38.6

60 33.3 18.7

70 31.4 17.4 11.8

85 28.0 15.7 9.4 7.5

90 27.3 15.3 9.2 7.4

95 26.6 14.9 9.0 7.3

120 13.4 8.1 6.9

125 13.3 8.0 6.8

140 7.8 6.6

145 7.8 6.6

160 6.5

165 6.5

lbs lbs lbs lbs

Main boom 152 ft

Fixed

jib length in (ft)

36 66 85 105

Radius (ft)

46.9 40.0

70 34.7 18.6

85 33.6 17.9 10.1

100 31.8 16.7 9.6 7.4

110 31.0 16.2 9.3 7.3

120 29.7 15.5 9.0 7.2

140 27.6 14.6 8.5 7.0

160 25.3 13.9 8.2 6.8

170 22.6 13.6 8.0 6.7

200 13.2 7.8 6.5

220 7.8 6.4

240 6.4

lbs lbs lbs lbs

Main boom 94 ft

Fixed

jib length in (ft)

36 66 85 105

Radius (ft)

38.8 41.8

60 34.8 21.3

75 32.4 17.6 10.2

90 29.9 16.2 9.5 7.5

95 29.0 15.8 9.3 7.4

100 28.3 15.4 9.1 7.3

105 27.6 15.0 9.0 7.2

110 27.1 14.8 8.8 7.1

120 26.2 14.2 8.4 7.0

150 13.2 7.9 6.7

170 7.8 6.5

190 6.4

lbs lbs lbs lbs

Main boom 181 ft

Fixed

jib length in (ft)

36 66 85 105

Radius (ft)

50.8 38.8

75 34.5 18.5

90 33.6 17.9 10.1

100 32.7 17.2 9.8 8.3

120 31.1 16.1 9.2 7.3

140 29.1 15.1 8.8 7.0

160 24.2 14.4 8.4 6.9

180 19.2 13.8 8.1 6.7

195 16.1 13.5 7.9 6.6

225 13.1 7.8 6.4

245 7.8 6.4

265 6.4

lbs lbs lbs lbs

Main boom 123 ft

Fixed

jib length in (ft)

36 66 85 105

Radius (ft)

42.7 41.0

65 34.8 18.8

80 33.1 17.8 10.2

100 30.6 16.2 9.4 7.4

110 29.0 15.5 9.1 7.3

120 27.8 14.9 8.8 7.1

130 26.9 14.5 8.5 7.0

140 26.2 14.0 8.3 6.9

145 25.8 13.8 8.2 6.8

175 13.2 7.8 6.6

195 7.8 6.4

215 6.4

lbs lbs lbs lbs

Main boom 209 ft

Fixed

jib length in (ft)

36 66 85 105

Radius (ft)

56.2 37.5

80 33.8 18.3

95 32.9 17.8 10.1

105 32.5 17.3 9.8 8.2

120 31.6 16.6 9.4 7.3

140 28.8 15.7 9.0 7.1

160 22.4 14.9 8.6 6.9

200 13.4 13.8 8.1 6.7

225 9.4 11.5 7.8 6.5

255 7.5 7.7 6.4

275 6.4 6.3

295 5.4

lbs lbs lbs lbs

Main boom 229 ft

Fixed

jib length in (ft)

36 66 85 105

Radius (ft)

57.5 37.0

80 33.4 18.1

95 32.6 17.7 10.1

110 32.0 17.1 9.7 7.4

120 31.5 16.6 9.5 7.3

140 28.3 15.9 9.0 7.1

160 21.8 15.0 8.7 6.9

200 12.9 13.9 8.1 6.6

235 7.5 9.6 7.8 6.5

265 5.8 7.1 6.3

285 4.9 6.0

305 4.0

Capacities in 1000 lbs with fixed jib (No. 0806.xx) 166,000 lbs counterweight + 59,500 lbs carbody counterweight. Above lift chart is for reference only

For actual lift duty please refer to lift chart in operator’s cab or manual.

lbs lbs lbs lbs

Main boom 248 ft

Fixed

jib length in (ft)

36 66 85 105

Radius (ft)

60.1 36.0

85 32.5 17.8

95 32.0 17.6 11.5

110 31.3 17.1 9.7 7.4

120 30.8 16.7 9.5 7.3

140 27.5 16.0 9.1 7.1

180 16.0 14.6 8.4 6.8

220 8.7 11.0 8.0 6.5

255 4.2 6.2 7.5 6.4

285 2.9 4.2 5.3

305 2.2 3.4

315 2.5

lbs lbs lbs lbs

Main boom 258 ft

Fixed

jib length in (ft)

36 46 56

Radius (ft)

61.5 35.6

70 32.8 26.5

80 32.4 26.1 21.4

100 31.5 25.4 20.9

120 30.7 24.8 20.1

140 27.0 23.8 19.5

160 20.5 21.5 18.4

200 11.5 12.3 13.2

240 5.5 6.2 7.0

265 2.6 3.3 4.0

275 2.2 2.9

280 2.4

lbs lbs lbs

HS

895 HD

.

15

Page 16

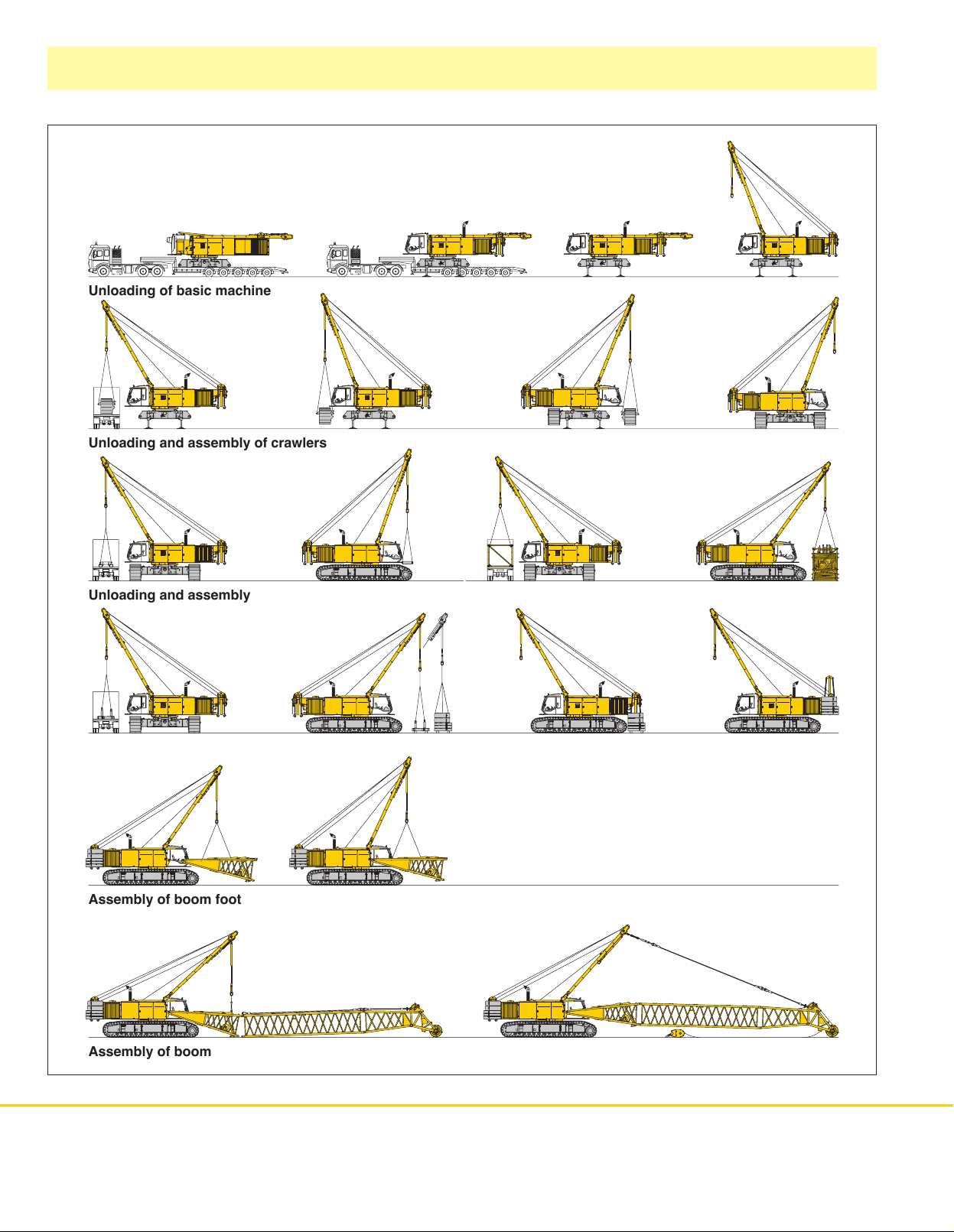

Self assembly system

Unloading

Unloading and assembly of crawlers

Unloading and assembly of carbody counterweight (option)

of basic machine

Unloading and assembly of boom

Unloading and assembly of counterweight

Assembly of boom foot

Assembly of boom

Liebherr-Werk Nenzing GmbH

P.O. Box 10, A-6710 Nenzing/Austria

Tel.: +43 50809 41 - 473

Fax: +43 50809 41 - 499

crawler.crane@liebherr.com

www.liebherr.com

Reeving of hoist ropes

895 HD – 10223036 – 02/2008 Subject to change without notice.

HS

Loading...

Loading...