Page 1

Technical data

Hydraulic crawler crane

Complies with ANSI B 30.5

HS 885 HD

Page 2

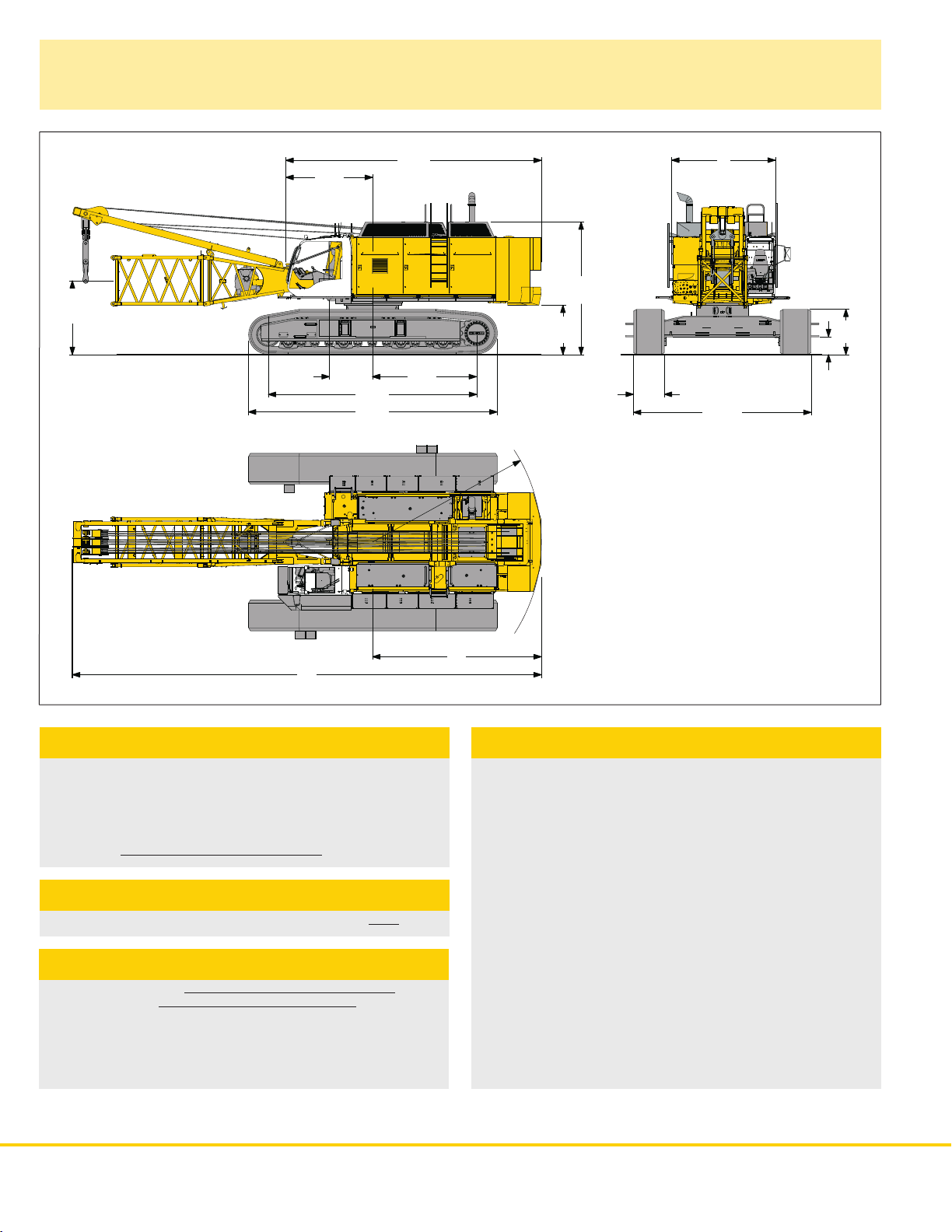

Dimensions

4´7´´

11´1´´

26´5´´

22´2´´

14´1´´

5´2´´

7´9´´

27´2´´

9´3´´

R 18´2´´

50´

17´

39.4´´

18´10´´

21.6´´

56´´

11´

Basic machine with undercarriage

Operating weight

The operating weight includes the basic machine with HD undercarriage,

2 main winches 66,200 lbs with speed change gear and 36 f t boom,

consisting of A–frame, boom foot (13 ft), boom head section (21 ft),

boom head (2 ft) and 53,200 lbs basic counterweight, 33,900 lbs add.

counter weight and 15,400 lbs carbody counterweight.

Total weight approx. 296,700 lbs

Ground pressure

Ground bearing pressure over side, on compact ground 24 psi

Equipment

Main boom max. length 184 f t

Fixed jib (N o. 080 6.xx) 36 ft – 105 f t

Universal boom head with interchangeable rope pulleys.

Modular designed equipment for operation as crane, with dragline or

clamshell. For dragline operation, a rotating fairlead is fitted into the

boom foot. This minimizes the rope angle to drum, which results in

lower rope wear.

Remarks

The lifting capacities stated are valid for lifting operation only

1.

(corresponds with crane classification according to F.E.M. 1.001,

crane group A1)

Crane standing on firm, horizontal ground.

2.

The weight of the lifting device (hoisting ropes, hook block, shackle

3.

etc.)must be deducted from the gross lifting capacity to obtain

a net lifting value.

Additional equipment on boom (e.g. boom walkways, auxiliary jib)

4.

must be deducted to get the net lifting capacity.

For max. wind speed please refer to lift chart in operator’s cab or

5.

manual.

Working radii are measured from centre of swing and under load.

6.

The lifting capacities are valid for 360 degrees of swing.

7.

The structures are calculated according to F.E.M. 1.001 – 1998

8.

(EN 13001–2/ 2004).

ANSI B 30.5

9.

2 HS 885 HD

Page 3

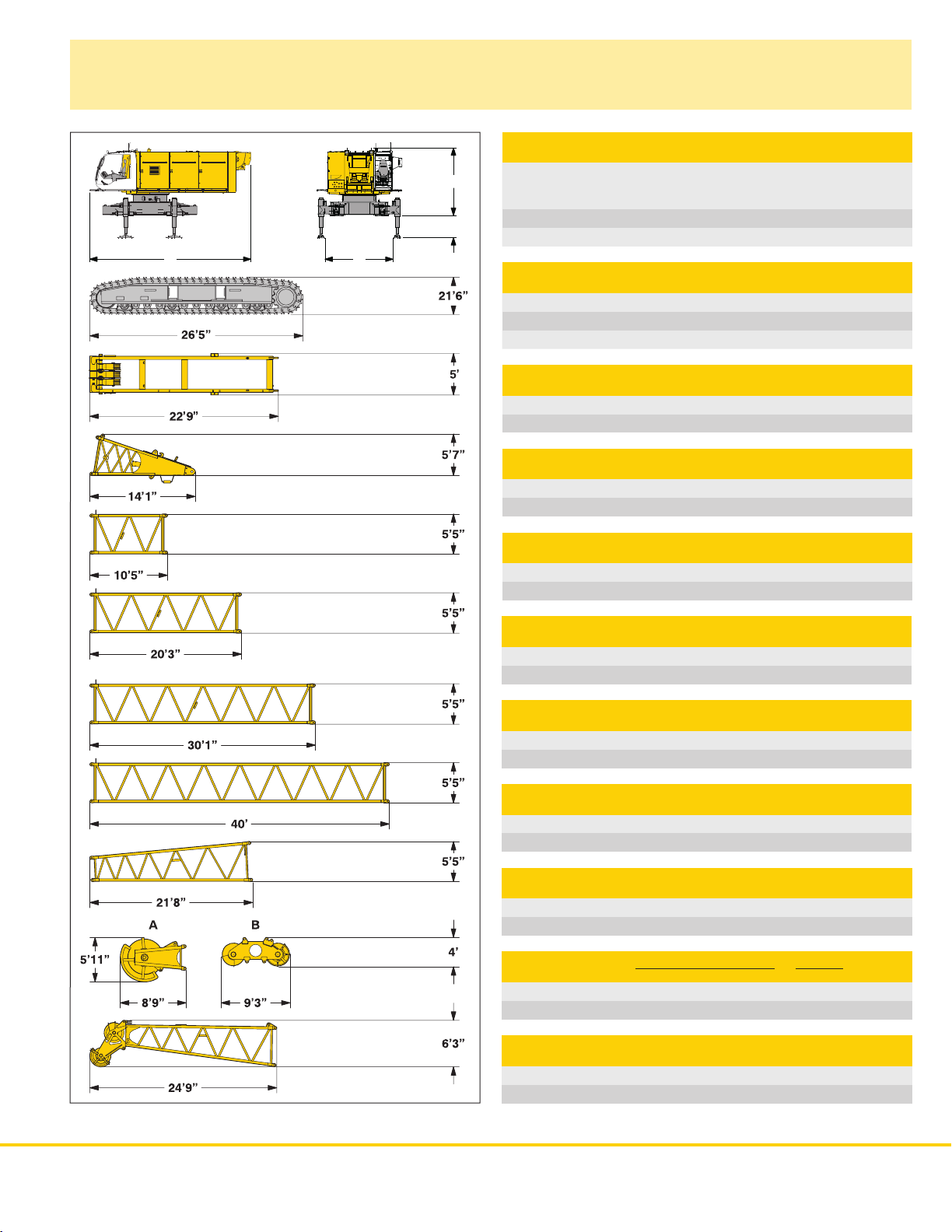

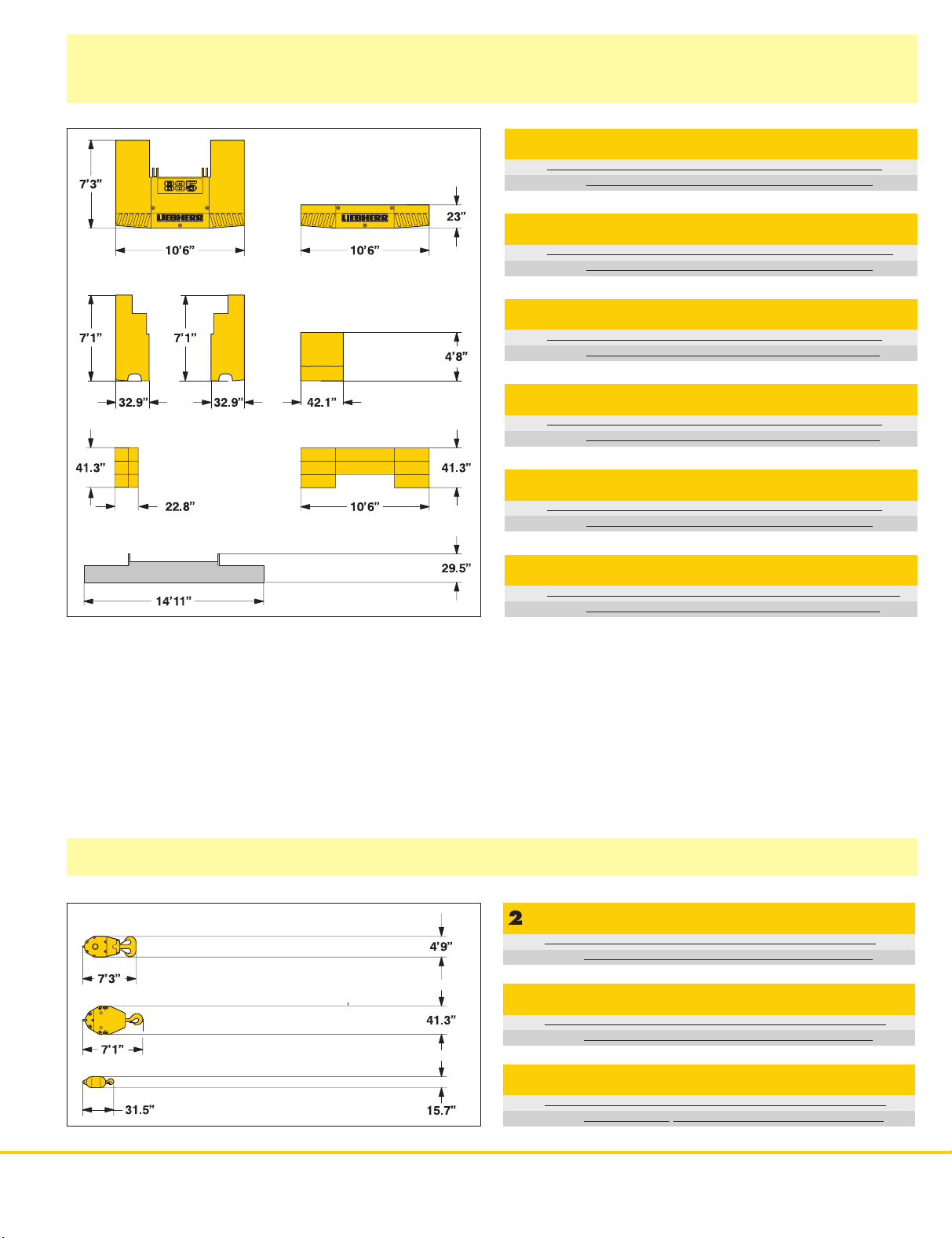

Transport dimensions and weights

27´

45.3´´

11´1´´

12´

Basic machine and boom

Basic machine

with HD undercarriage, V12- Mercedes Benz diesel engine, 2x66,200 lbs

winches with change gear box, without counterweight, coom foot and

A–frame

Width 16´2´´

Weight 96,700 lbs

Crawler

Double grouser track shoes 39.4´´

Width 41.7´´

Weight 41,300 lbs

A–frame

Width 24´´

Weight 4,850 lbs

Boom foot

Width 5´5´´

Weight* 4,600 lbs

Boom section 10 ft

Width 5´5´´

Weight* 1,700 lbs

Boom section 20 ft

Width 5´5´´

Weight* 2,750 lbs

Boom section 30 ft

Width 5´5´´

Weight* 3,700 lbs

Boom section 40 ft

Width 5´5´´

Weight* 4,700 lbs

Boom head section 21 ft

Width 9´9´´

Weight* 11,900 lbs

Boom head B A

Width 30.7´´ 42.1´´

Weight* 3,300 4,000 lbs

*) Including pendant ropes

L–boom head

Width 5´5´´

Weight* 2,600 lbs

HS 885 HD 3

Page 4

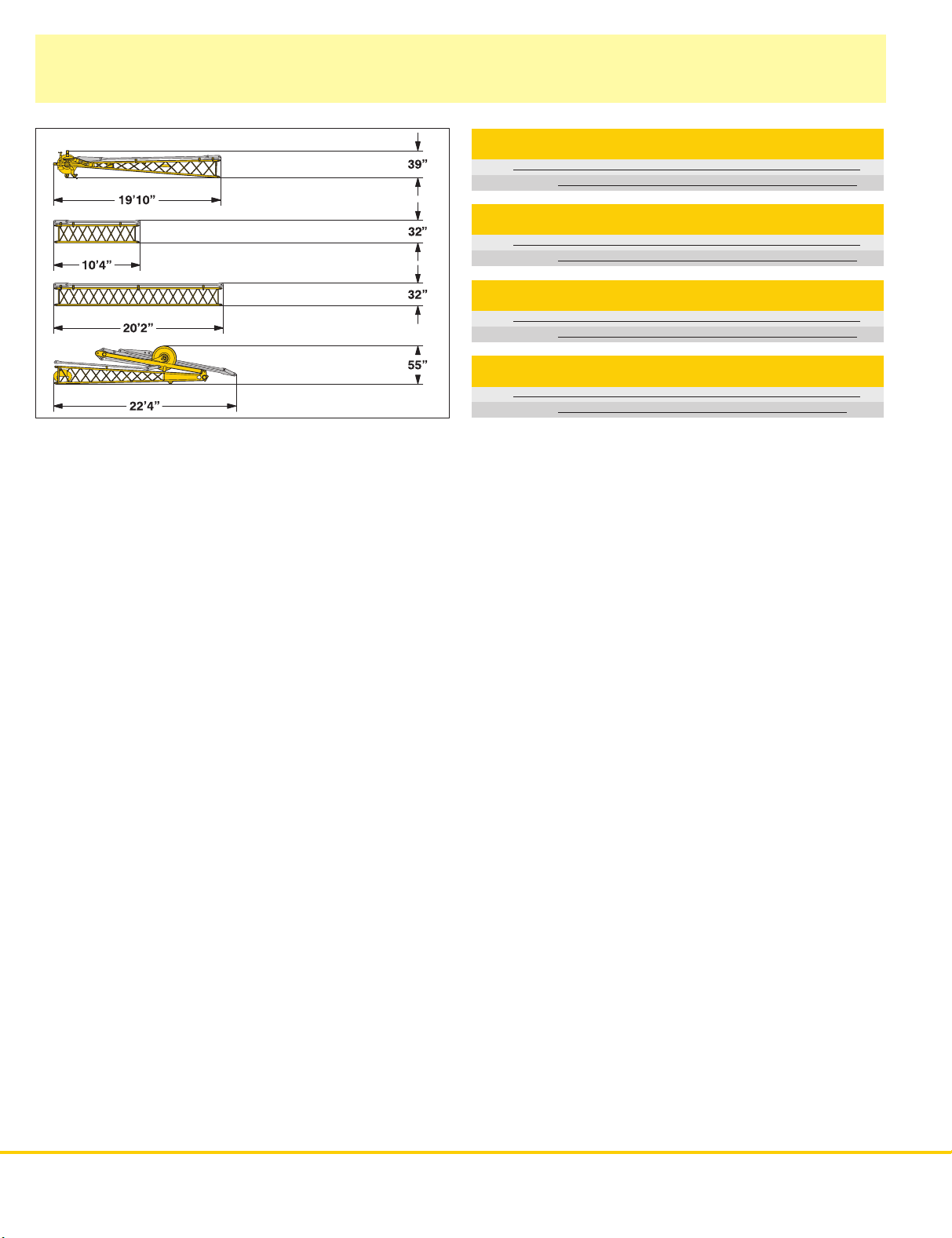

Transport dimensions and weights

Fixed jib (No.

0806.xx)

)

*

Including pendan

t s

traps

Fixed jib head (No.

Width

Weight

in lbs*

Fixed jib section (No.

Width

Weight

in lbs*

Fixed jib section (No.

Width

Weight

in lbs*

0

806.xx)

0

806.xx

0

806.xx

)

)

Fixed jib foot with A-frame (No.

Width

Weight

in lbs*

0

806.xx)

45”

980

10 ft

37”

245

20 ft

37”

430

59”

2,050

4HS

885 HD

Page 5

Transport dimensions and weights

Counterweight

Add.

counterweight II

Carbody counterweight

Basic counterweight

Add.

counterweight

Add.

counterweight

Add.

counterweight IV

III

Basic counterweight 1x

Width

Weight

in lbs

28.3”

43,200

Add. counterweight 1x

Width

Weight

in lbs

26”

10,000

Add. counterweight II 2x

Width

Weight

in lbs

13.4”

5,725

Add. counterweight III 1x

Width

Weight

in lbs

14.8”

7,050

Add. counterweight IV 1x

Width

Weight

in lbs

22.8”

15,400

Carbody counterweight 2x

Width

Weight

in lbs

7,700

8”

Hooks

264,600 lbs hook block-2sheaves

Width

Weight

in lbs

12.6”

3,100

132,300 lbs hook block-1sheave

Width

Weight

in lbs

12”

2,150

66,150 lbs single hook

Width

Weight

in lbs

HS 885 HD

16”

880

5

Page 6

Dragline equipment

71,700 lbs counterweight

Working diagram

C =Radius / dumping radius

J =

Height of boom head sheave centre

above ground level

Capacities

Max. capacities in metric tons do not exceed 75% of tipping load.

in 1000 lbs for boom lengths (59 ft – 108 ft)

59 ft 69 ft 79 ft 89 ft 98 ft

C J C J C J C J C J C J

α

45 48.2 48.9 46,3 55.4 55.8 36,8 62.3 62.6 29,5 69.2 69.9 24,7 76.4 76.8 20,7 83.0 84.0 18,7

40 51.8 44.9 40,1 59.4 51.5 30,8 66.9 57.7 25,1 74.5 64.0 21,2 82.0 70.2 17,9 89.6 76.8 16,8

35 55.1 41.0 33,5 63.0 49.9 26,5 71.2 52.1 22,6 79.1 57.7 19,0 87.3 63.6 15,9 95.5 69.6 15,0

30 57.7 36.7 29,3 66.3 41.7 24,0 74.8 46.6 19,8 83.3 51.5 16,5 91.9 56.4 13,9 100.4 61.4 13,7

25 60.0 32.2 26,2 68.9 36.0 21,4 78.0 40.4 18,1 86.9 44.6 15,0 95.8 48.6 12,6 104.7 53.1 12,3

ft lbs lbs ft ft lbs ft ft lbs ft ft lbs ft ft lbs ft ft t

counterweight 71,700 lbs

108 ft

6

HS 885 HD

Page 7

Clamshell equipment

71,700 lbs counterweight

Working diagram

C =Radius / dumping radius

J =

Height of boom head sheave centre

above ground level

K =

Length of clamshell (depending on type

and capacity of bucket)

Capacities in 1000 lbs for boom lengths (59 ft – 108 ft)

59 ft 69 ft 79 ft 89 ft 98 ft

C J C J C J C J C J C J

α

65 31.5 60.7 66,1 35.8 69.6 62,2 40.0 78.4 52,9 43.9 87.2 45,8 48.2 96.1 39,9 52.4 105.3 35,1

60 36.0 58.0 61,3 41.0 66.6 51,1 45.9 75.1 43,7 50.8 83.7 37,5 55.8 92.2 32,4 60.7 101.0 28,2

55 40.7 55.4 52,5 46.3 63.6 43,6 51.8 71.5 37,0 57.4 79.7 31,5 63.0 87.6 27,3 68.9 96.1 23,6

50 44.6 52.1 46,1 50.8 59.7 38,1 57.0 67.3 32,2 63.6 74.8 27,3 69.9 82.3 23,4 76.1 90.2 20,0

45 48.2 48.9 41,2 55.4 55.8 34,2 62.3 62.7 28,7 69.2 69.9 24,0 76.1 76.8 20,5 83.0 82.7 17,4

40 51.8 44.9 37,5 59.4 51.5 30,2 66.9 57.7 25,1 74.4 64.0 21,2 82.0 70.2 17,6 89.6 76.8 17,8

35 55.1 41.0 33,1 63.0 46.6 26,7 71.2 52.1 22,3 79.1 58.7 18,7 87.2 63.6 15,6 95.5 69.6 13,2

30 57.7 36.7 29,3 66.3 41.7 24,0 74.8 46.6 19,8 83.3 51.5 16,7 91.8 56.4 13,9 100.4 61.3 11,5

25 60.0 32.1 26,2 68.9 36.0 21,4 78.0 40.4 17,6 86.9 44.6 14,8 95.8 48.6 12,1 104.7 53.1 9,9

Max. capacities in metric tons do not exceed 66.7 % of tipping load.

Load diagram restricted by safety factors of standard ropes:

Winches

Rope diameter

Calc. breaking load

1–rope clamshell

2–rope clamshell

ft ft lbs ft ft lbs ft ft lbs ft ft lbs ft ft lbs ft ft lbs

44,100 lbs 55,200 lbs

30 mm 34 mm 36 mm

181,000 lbf 232,000 lbf

36,400 lbs 46,300 lbs

48,500 lbs 61,700 lbs

66,200 lbs

261,000 lbf

51,800 lbs

69,000 lbs

counterweight 71,700 lbs

108 ft

HS

885 HD

7

Page 8

Equipment

Casing oscillator and slurry wall grab

Casing oscillator

Winch options

Lin

e s

Lin

e s

Drillin

g d

Maximu

tw

o rope o

8

HS 885 HD

pee

d 1st gear (

pee

d 2nd gear (

iamete

m a

llowabl

peratio

ft/min

ft/min

r

e w

eigh

n 5

Slurry wall grab

2 x 5

5,20

0 lbs

2 x 6

6,20

0 l

bs

)

)

t i

n

0

0

6,20

–22

–40

8’3”

0 lbs

6

3

7

1,70

0

0

–180

–390

9

’10”

0 l

bs

Winch options

Lin

e s

pee

d 1st gear (

Lin

e s

pee

d 2nd gear (

Max

. c

hise

l w

Maximu

m a

llowabl

tw

o rope o

peratio

ft/min

)

ft/min

)

eigh

t

e w

eigh

t i

n

n 5

2 x 5

5,20

6,20

0

0

0 lbs

–22

–40

2

0 t

0 lbs

2 x 6

6,20

0 l

bs

6

3

7

1,70

0

0

–180

–390

2

5 t

0 l

bs

Page 9

Equipment

Dynamic soil compaction

Capacities in metric tons for boom lengths (69 ft – 108 ft)

Boom length

Radius

(ft) lbs lbs lbs lbs lbs

26.2 66,200 66,200 55,200 55,200 55,200

29.5 44,100 44,100 44,100 44,100 44,100

Max.

capacities in metric tons do not exceed 75% of tipping load.

All loads given are max. values and must not be exceeded. They are only permitted in two rope automatic operation and are valid for work on a surface with

max. inclination of 1 %. Lifting heigths shall not exceed 82 ft.

69 ft 79 ft 89 ft 98 ft

HS

108 ft

885 HD

9

Page 10

Working range - main boom 86° -15°

87,100 lbs counterweight and 15,400 carbody counterweight

Auxiliary

The

auxiliary jib is 66,200 lbs.

The

is programmed in the LMI

system.

jib 66,200 lbs

maximum capacity of the

corresponding load chart

Main boom configuration (table

Configuration for boom lengths (36 ft – 184 ft)

Length

Boom foot

Boom extension

Boom extension

Boom extension

Boom extension

Boom head section

Boom head

Boom length in (ft)

*

Actual lengths of boom sections are metric (e.g. 4 m ,3 m, 6 m, 9 m, 12 m, 0.6 m). The figures shown above are approximate conversions to feet.

10

HS 885 HD

13 ft*

10 ft*

20 ft*

30 ft*

40 ft*

21 ft

2 ft*

1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

1 1 1 1 1 1 1 1

1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

36 46 56 66 75 85 95 105 115 125 135 144 154 164 174 184

1

)

Amount of boom extensions

1 1 1 1 1 1 1

1 1 1 1 2

2 2 2 2 3 3 3 3

Page 11

Lift chart for main boom

87,100 lbs counterweight and 15,400 lbs carbody counterweight

Capacities

87.100 lbs counterweight and 15.400 carbody counterweight

Radius 36 46 56 66 75 85 95 105 115 135 154 164 184 194 203 223 243 Radius

(ft) lbs lbs lbs lbs lbs lbs lbs lbs lbs lbs lbs lbs lbs lbs lbs lbs lbs (ft)

*14.4 300.0 *14.4

*15 286.4 276.7 251.5 *15

100 23.4 23.1 22.4 21.7 21.3 19.3 20.4 19.6 17.9 16.0 100

110 19.8 19.2 18.5 18.0 16.4 17.2 16.7 15.0 13.3 110

115 17.8 17.0 16.6 15.1 15.9 15.4 13.7 11.9 115

120 16.5 15.8 15.4 14.0 14.6 14.1 12.6 10.6 120

125 15.3 14.6 14.2 13.0 13.4 12.9 11.6 9.4 125

130 14.2 13.5 13.1 12.1 12.1 11.8 10.6 8.6 130

135 12.5 12.1 11.1 11.1 10.6 9.7 7.9 135

140 11.6 11.2 10.1 10.2 9.6 8.8 7.2 140

145 10.5 10.3 9.2 9.5 8.9 7.9 6.5 145

150 9.3 9.3 8.3 8.7 8.1 7.0 5.7 150

155 8.2 7.6 7.9 7.4 6.3 5.0 155

160 7.2 6.9 7.1 6.7 5.7 4.3 160

165 6.1 6.4 6.0 5.1 3.6 165

170 5.2 5.7 5.4 4.4 3.2 170

175 4.4 5.1 4.7 3.8 2.7 175

180 3.6 4.5 4.1 3.3 2.3 180

185 3.9 3.5 2.8 185

190 3.3 3.0 2.3 190

195 2.4 1.8 195

Above lif

* Capacities over 246,300 lbs require a special heavy duty boom head.

in 1000 lbs for boom lengths (36 ft – 243 ft) – with 66,200 lbs winches

Boom length in (ft)

Standard boom head

20 223.1 219.6 215.9 213.4 208.8 203.7 20

25 166.7 167.2 167.4 167.4 166.9 162.8 161.1 151.0 140.4 25

30 126.9 127.4 127.6 127.6 127.5 127.4 127.2 127.0 124.8 108.0 88.5 30

35 101.8 102.4 102.6 102.6 102.4 102.3 102.1 101.8 101.6 94.6 83.4 76.1 63.3 58.2 35

40 85.1 85.3 85.3 85.2 85.0 84.8 84.5 84.2 83.7 75.7 70.6 59.4 55.8 50.9 42.3 40

45 72.4 72.7 72.8 72.6 72.4 72.2 71.9 71.6 71.0 69.3 64.4 55.3 52.6 48.1 40.3 32.6 45

50 63.0 63.1 63.0 62.8 62.5 62.2 61.9 61.3 60.6 58.9 51.4 48.4 45.8 38.4 31.1 50

55 55.3 55.5 55.4 55.2 55.0 54.6 54.3 53.7 53.0 51.4 50.7 44.0 42.8 37.4 29.9 55

60 49.6 49.5 49.3 49.1 48.8 48.4 47.8 47.1 46.5 45.1 40.6 39.6 36.3 29.2 60

65 44.4 44.4 44.2 44.0 43.7 43.4 42.7 42.0 41.6 40.3 37.0 35.9 33.7 28.4 65

70 40.0 39.9 39.7 39.4 39.1 38.4 37.7 37.3 36.4 33.8 32.7 30.6 26.7 70

75 36.3 36.3 36.1 35.8 35.4 34.8 34.0 33.7 32.9 30.9 29.9 27.9 24.7 75

80 33.1 32.9 32.6 32.3 31.6 30.9 30.5 29.3 28.3 27.4 25.4 22.7 80

85 30.3 30.2 29.9 29.6 28.9 28.2 27.8 26.1 26.0 25.1 23.2 20.7 85

90 27.7 27.4 27.2 26.5 25.8 25.3 23.3 24.0 23.1 21.3 18.9 90

95 25.5 25.3 25.0 24.3 23.6 23.2 21.0 22.1 21.3 19.5 17.3 95

t c

har

t i

s for r

eferenc

e o

nly

. For a

ctua

l lift duty p

leas

e r

efe

r t

o lift c

har

t i

n o

perator’

s cab o

r m

anual.

L – boom head

L - boom configuration

Configuration

Boom foot

Boom extension

Boom extension

Boom extension

L – boom head

L – boom length in (ft)

*

Actual lengths of boom sections are metric (e.g. 4 m .3 m. 6 m. 12 m. 7 m). The figures shown above are approximate conversions to feet.

for boom lengths (194 ft – 243 ft)

Length

13 ft*

10 ft*

20 ft*

40 ft*

23 ft*

1 1 1 1 1 1

4 4 4 4 5 5

1 1 1 1 1 1

194 203 213 223 233 243

Amount of boom extensions

1 1 1

1 1

HS 885 HD

11

Page 12

Working range - fixed jib (No.

Main boom 80° -30°

0

806.xx

)

15° and 30°

Boom configuration for boom lengths (36 ft - 164 ft) – se

e t

abl

e 1 o

n page 1

Fixed jib configuration for fixed jib lengths (36 ft - 105 ft)

Length Amount

Fixed jib foot

Fixed jib insert

Fixed jib insert

Fixed jib head

Fixed jib length (ft)

*Actual lengths of boom sections are metric (e.g. 3 m, 6 m). The figures shown above are approximate conversions to feet.

12 HS

885 HD

18 ft

10 ft*

20 ft*

18 ft

1 1 1 1 1 1 1 1

1 1 1 1

0 0 1 1 2 2 3 3

1 1 1 1 1 1 1 1

36 46 56 66 76 85 95 105

of fixed jib extensions

0

Page 13

Technical description

Engine

Power rating according to ISO 9249, 450 kW (603 hp) at 1900 rpm

Engine type Liebherr D 9508 A7

Fuel tank 920 l capacity with continuous level

indicator and reserve warning

Engine complies with NRMM exhaust certification EPA / CARB Tier

3 and 97/68 EC Stage III

Option:

Power rating according to ISO 3046, 670 kW (898 hp) at 1900 rpm

Engine type MAN D 2842 LE

Fuel tank 920 l capacity with continuous level

indicator and reserve warning

Engine complies with NRMM exhaust certification EPA / CARB Tier 2.

Hydraulic system

The main pumps are operated by a distributor gearbox. Axial piston

displacement pumps work in closed and open circuits supplying oil only

when needed (flow control on demand). To minimize peak pressure an

automatically working pressure cut off is integrated. This spares pumps

and saves energy. The hydraulic oil is cleaned through electronically

controlled pressure and return filters. Possible contamination is signaled

in the cabin. The use of synthetic environmentally friendly oils is possible.

Ready made hydraulic retrofit kits are available to customize requirements

e.g. powering casing oscillators, VM–vibrators, hydraulic grabs, hanging

leads etc.

Working pressure max. 5076 psi

Oil tank capacity 238 gal

Main winches

Winch options:

Line pull (nom. load)

Rope diameter

Drum diameter

Rope speed (ft/min)

With change gear bos (ft/min)

Rope capacity 1st layer

The winches are outstanding in their compact design and easy assembly.

Propulsion is via a planetar y gearbox in an oil bath. Load suppor t by the

hydraulic system; additional safety factor provided by a spring loaded,

multi–disc holding brake. The main winches use pressure controlled,

variable flow hydraulic motors.This system features sensors that

automatically adjust oil flow to provide max. winch speed depending on

load.

Option:

Crane winch (main winch)

Auxiliary winch

Tagline winch

15,500 lbs with free fall

47,400 lbs 55,200 lbs 66,200 lbs

30 m 34 m 36 m

24.8´´ 29.5´´ 32.3´´

0–279 0–226 0–180

0– 403 0–390

153 ft 151 ft 151 ft

35,300 lbs with multi–disc holding brake

15,500 lbs in boom foot

15,500 lbs with free fall

Crawlers

The track width of the undercarriage is changed hydraulically.

Propulsion through axial piston motor, hydraulically released spring

loaded multi–disc brake, maintenance free crawler tracks, hydraulic

chain tensioning device.

Flat or double grouser track shoes

Drive speed 0 – 0.8 mph

Option:

• 2 speed hydraulic motor for higher travel speed

Boom winch

Line pull max. 2 x 15,500 lbs

Rope diameter 20 mm

Boom up 84 sec. from 15° to 82°

Swing

Consists of rollerbearing with external teeth for lower tooth flank pressure,

fixed axial piston hydraulic motor, spring loaded and hydraulically

released multi– disc holding brake, planetar y gearbox and pinion. Swing

speed from 0 – 3.6 rpm continuously variable, selector for 3 speed ranges

to increase swing precision.

Standard:

Second swing drive

Noise emission

Noise emissions correspond with 2000/14/EC directive on noise emission

by equipment used outdoors.

Control

The control system – developed and manufactured by Liebherr – is

designed to withstand extreme temperature changes and the rough

heavy duty tasks common in the construction industry. Complete

machine operating data are shown on a high resolution display. The

crane is equipped with proportional control for all movements, which can

be carried out simultaneously. Dragline operation: A special ”Interlock”

control system is an option available. It is designed for power lifting of the

dragline bucket without using the drag winch brake.

An additional option is the ”Redundant Control System”, which allows

restricted operation of the machine in the event of a failure on the

electronic base control or its sensors.

On request, Liebherr also offers special custom designed control

systems for free fall winches.

Operation: Left joy stick for boom winch and swing, right two directional

levers for winch I and II. Crawler control is actuated with the two central

foot pedals. Additionally, hand levers can be attached to the pedals.

Options:

• Special demolition control system

• MDE: Machine data recording

• PDE: Process data recording

• GSM modem.

HS 885 HD 13

Page 14

Notice

14

HS 885 HD

Page 15

Notice

HS 885 HD

15

Page 16

Liebherr-Werk Nenzing GmbH

P.O. Box 10, A-6710 Nenzing/Austria

Tel.: +43 50809 41-473

Fax: +43 50809 41-499

crawler.crane@liebherr.com

www.liebherr.com

885 HD – 102 23 035 – 12/2007 Subject to change without notice.

HS

Loading...

Loading...