Page 1

Casing Rotator

Casing Oscillators

Casings up to 3000

Special Hammer Grab

Chisels

Interlocking Tremie Pipes

Page 2

Hydraulic

A

B

H2 H1

S

D

L

A

C 2400-3400

Hub

F

L M

Y

K

Z

C

E

H2 H1

A

B

A

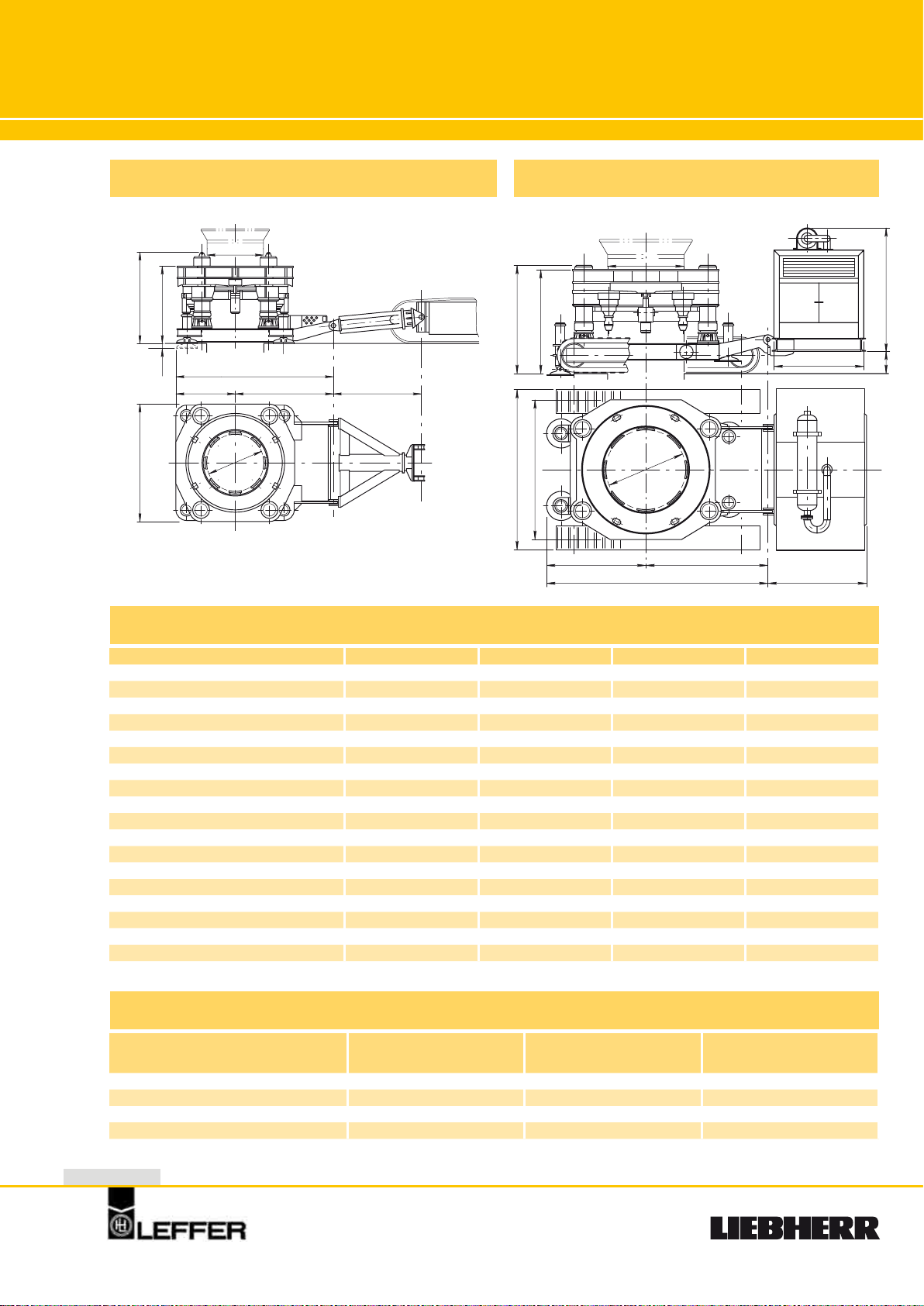

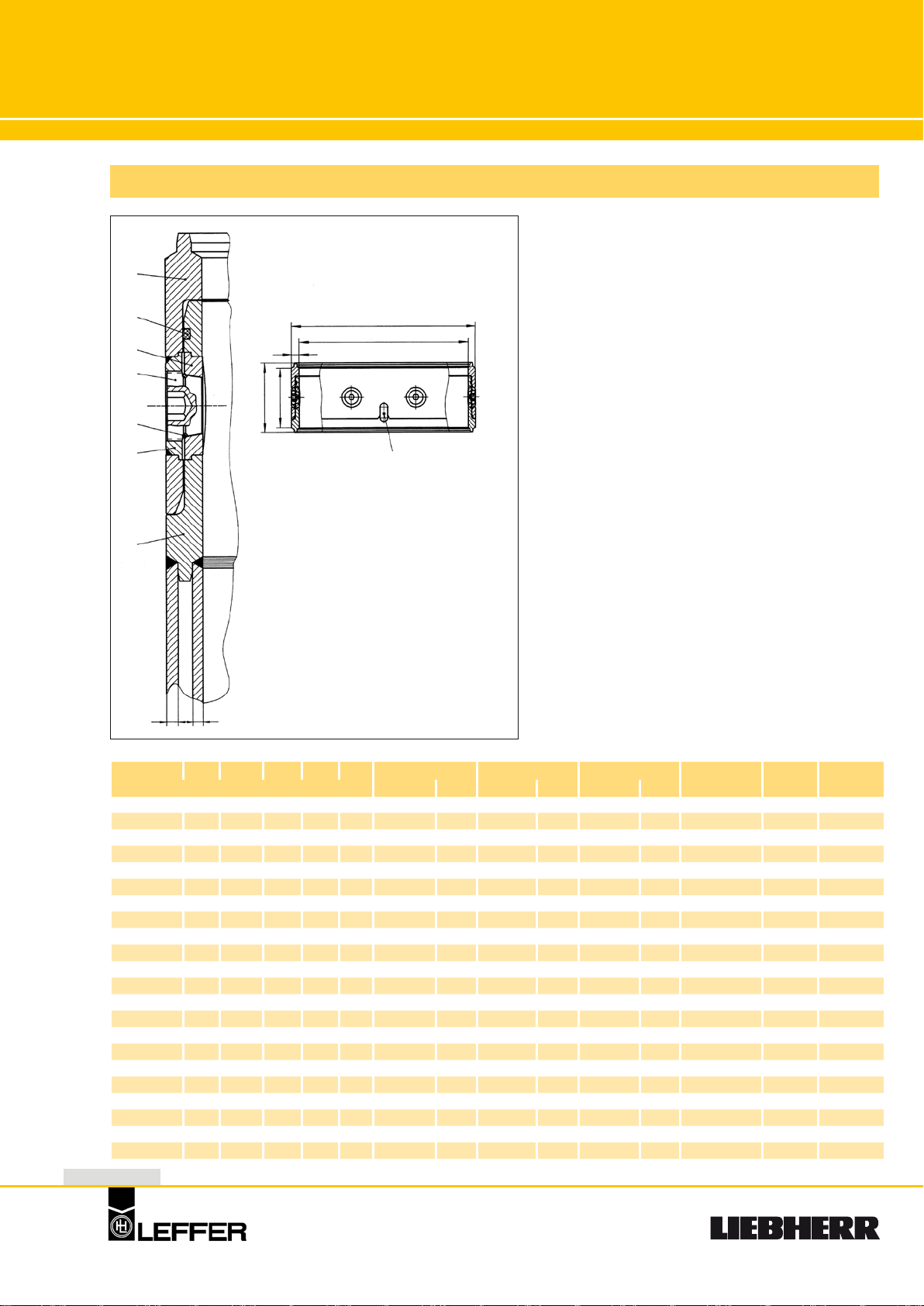

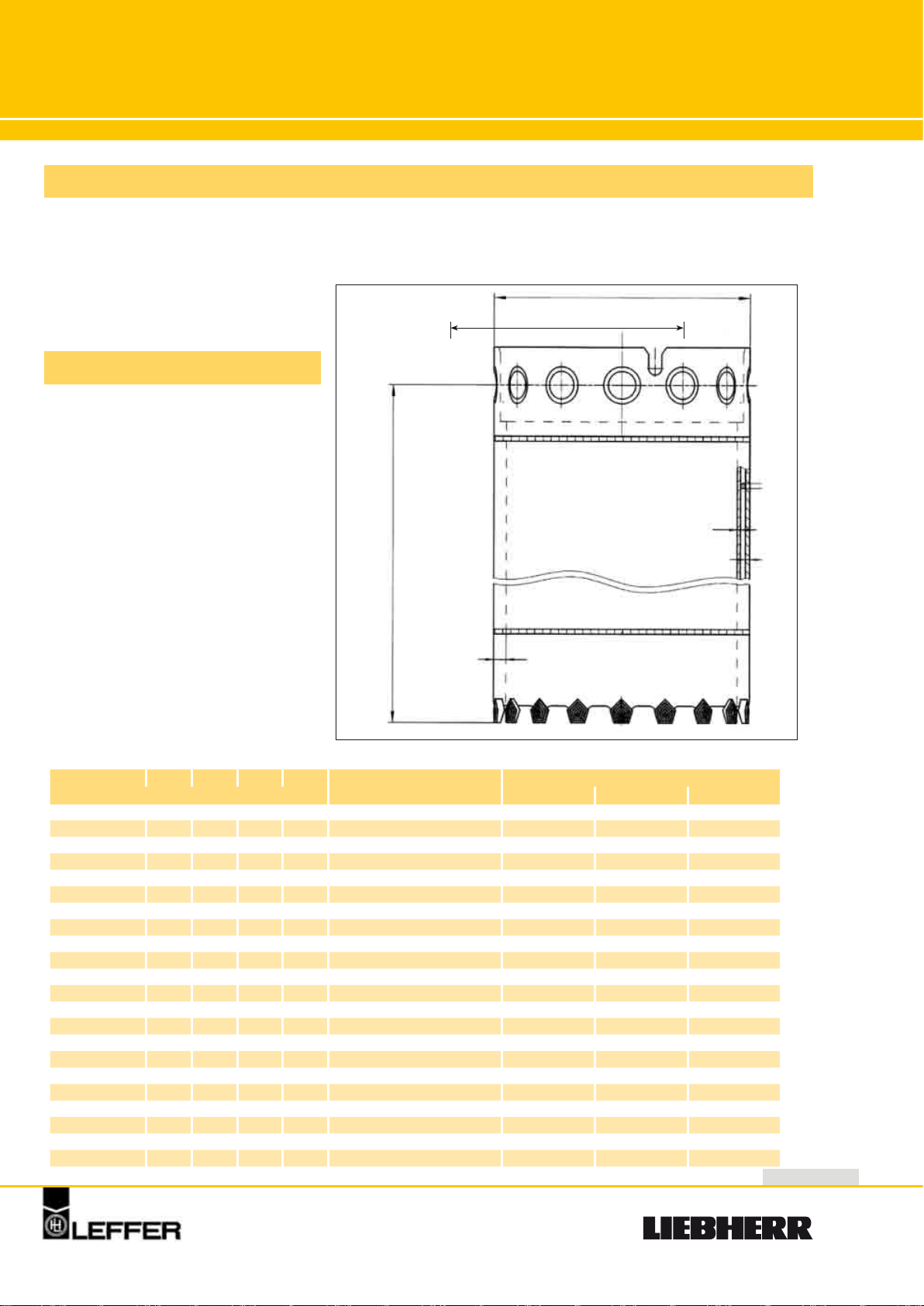

Casing Rotator

RDM/RDM-M

Hydraulic Casing Rotator Type RDM

Technical Data Type RDM und Type RDM-M

Type RDM-M

RDM 1500 RDM 2000 RDM 2500 RDM 3000

A

Max./min. casing dia mm 1500-800 2000-1200 2500-1500 3000-2000

L x B

Length x width

C

D

Min. spacing mm 1550 2530 3000 3200

E

Width mm 4000 4000 5300 5730

F

Min. spacing mm 2200 2600 3000 3200

H1/H2

RDM-M

Technical Data Hydraulik Power Pack

Power kW 273 338 485

Pump rating l / min 2 x 280 – 1 x 200 3 x 300 – 1 x 200 2 x 600 – 1 x 300

Dimensions (XYZ) mm 4000 x 1900 x 2200 4000 x 2200 x 3000 5500 x 2400 x 3000

Weight t 7 12 20

2

Height min. / max. mm 2050 / 2320 2600 / 2695 2600 / 2695 2600 / 2695

K

M

S

Lifting stroke mm 600 600 600 600

Lifting force KN 1890 2400 3750 4560

Rotation speed rpm 0 - 1,1 0 - 1,0 0 - 1,1 0 - 0,9

Torque KNm 2300 2900 4700 7400

Casing retaining force KN 800 800 1200 1500

Working pressure bar 250 (max. 300) 250 (max. 300) 250 (max. 300) 250 (max. 300)

RDM

Weight t 32 42 68 80

Weight t 44 65 97 115

mm 4150 x 3100 6100 x3500 6200 x4300 6500 x4600

mm 2600 3550 3000 3200

mm 800 900 900 900

mm 2000 2100 2600 2600

mm 150 350 450 450

760 / 370

RDM 1500 / RDM 2000

1100 / 460

RDM 2500

1500 / 660

RDM 3000

Page 3

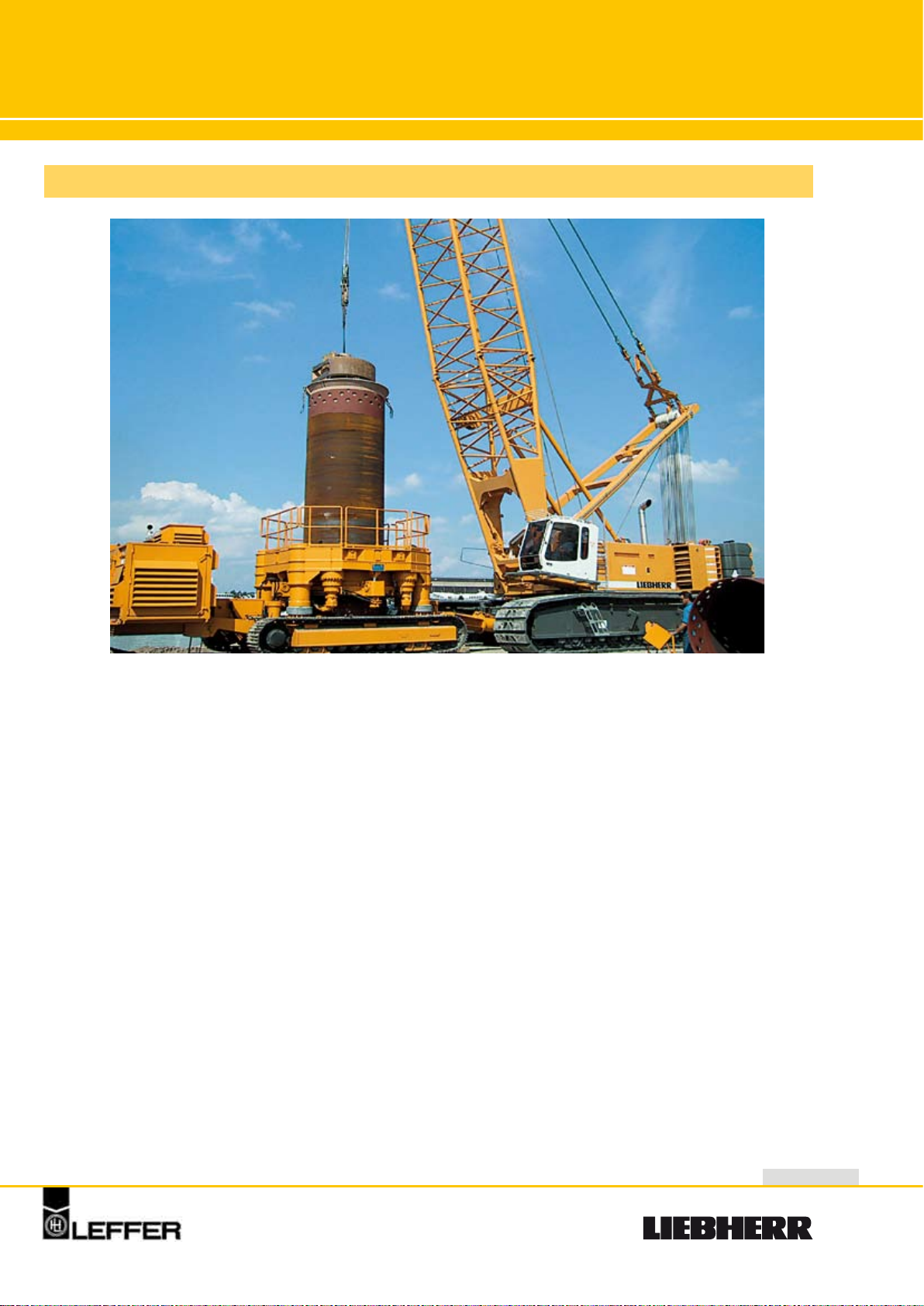

Hydraulic

Casing Rotator

General Remarks

RDM/RDM-M

RDM-M 2000 in operation

The hydraulic full 360 degree turning casing rotators

are economically used to construct bored piles with

the full casing method under hard soil conditions.

The continuous cutting of the hard ground guarantees a boring speed satisfying today's requirements, even for compressive resistance of up to

2500 kg/cm2.

The full 360 degree continuous turning of the casing

minimizes the friction compared to the oscillating

method allowing the casing to drill down to 100 m

depth with the casing rotator machines.

The first casing is fitted with carbide bits which can

be adapted to the requirements of the soil conditions offering major advantages when coring

through hard rock layers or when constructing

secant walls.

The full 360 degree continuous turning of the casing

by powerfull hydraulic motors eliminates the possibility of pile misalignment.

Beyond that, the casing rotators are especially suitable for the construction of full casing displacement

piles because of the ability to apply very high

torque, push down and lifting forces on the casing

which is not possible with the known drilling rigs.

3

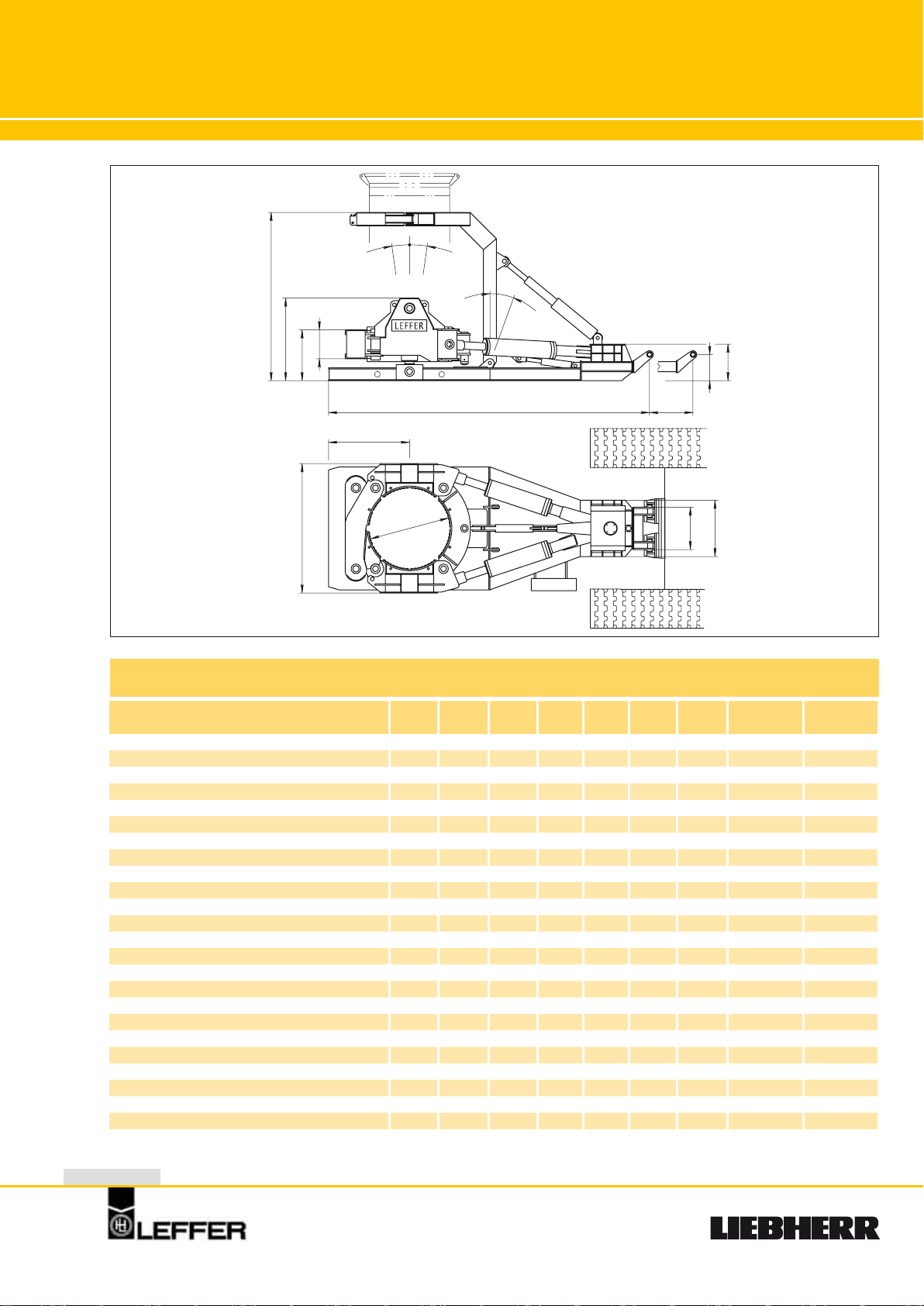

Page 4

Hydraulic

P

C G

B

A

D

L

M

F

E

J

K

I

H

N

O

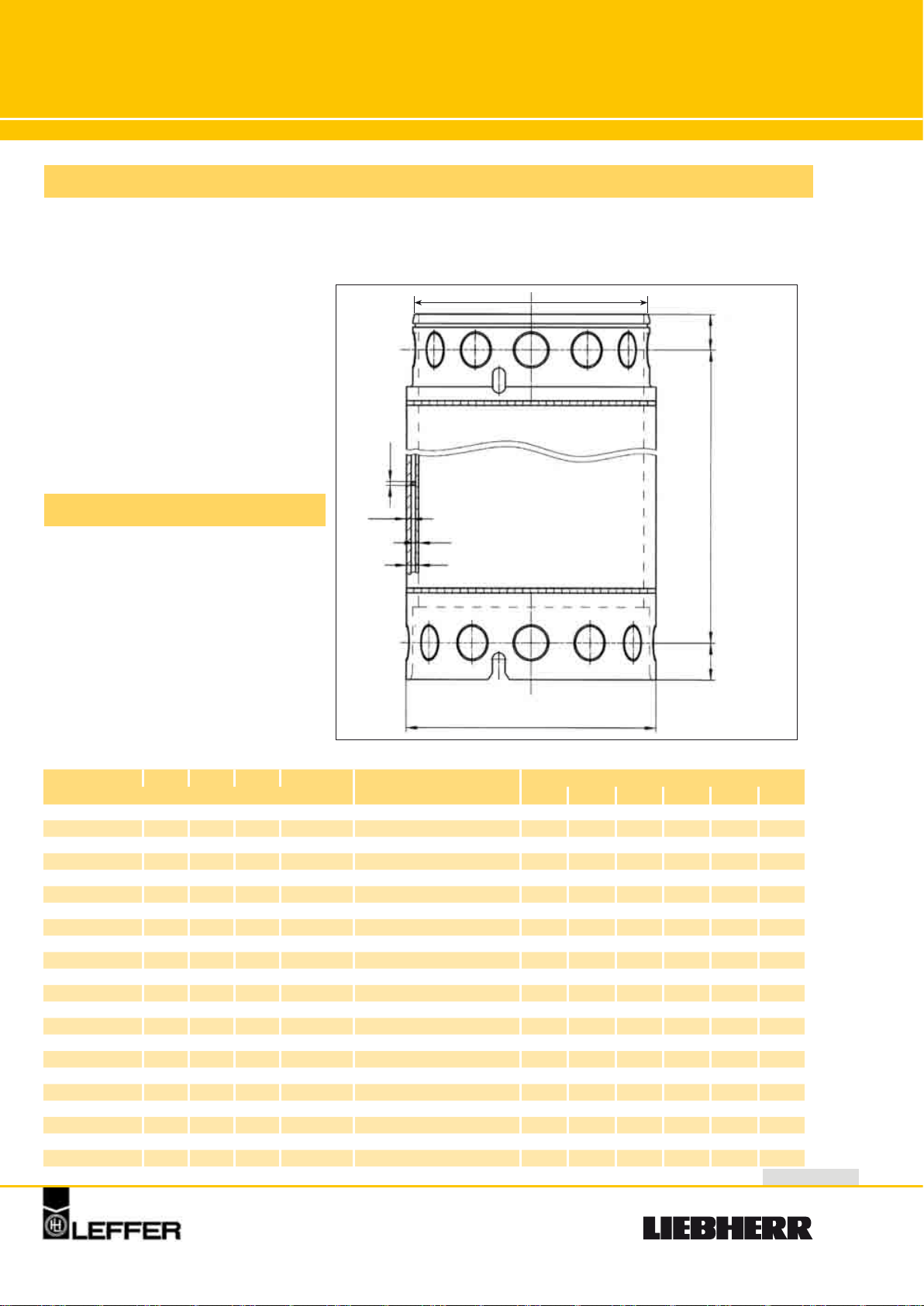

Casing Oscillators

VRM

Technical Data

VRM VRM VRM VRM VRM VRM VRM VRM VRM

1300 1500 2000 2200 2500 2800 3000 3000T1100 3300T1260

Stroke

Lifting force

Clamping force

Rotation angle

Torque

Operating pressure

Travel of casing

Weight

A

Max. casing diameter mm 1300 1500 2000 2200 2500 2800 3000 3000 3300

B

Width of machine mm 2350 2850 3200 3400 4000 4300 4500 4500 4880

C

Length of machine mm 6500 6500 7500 7500 8800 9100 9140 9900 10470

D

Min. spacing mm 1200 1300 1600 1730 2230 2400 2600 2670 2950

E

Width of cradle mm 1015 1015 1015 1015 1015 1015 1015 1015 1015

F

Width of machine excavator side mm 1200 1400 1400 1400 1500 1500 1500 1600 1600

G

Cradle path mm 1300 1600 1300 1300 - - - - -

H

Axis excavator side mm 700 700 700 700 700 700 700 700 700

I

Height of machine excavator side mm 870 870 900 940 1130 1130 1165 1225 1265

J

K

L

M

N

O

P

Height of cradle guide mm 600 650 650 650 700 700 800 800 800

Height from ground to top of cradle guide mm 1100 1200 1300 1300 1400 1400 1500 1500 1620

Height of machine mm 1800 1850 1950 2050 2580 2580 2610 2610 2730

Height of casing guide mm 2820 3220 3220 3220 - - - - Angle of inclination, in front ° 6 6 6 6 - - - - Angle of inclination, in rear ° 8 8 8 8 - - - - Angle of inclination, casing guide ° 20 20 20 20 - - - - -

The casing oscillators can be kept in continuous operation with the specified torque and forces.

mm 600 600 600 600 650 650 650 650 650

kN 1530 2050 2650 2650 5150 7250 7250 7250 9000

kN 1320 1660 2170 2170 3780 4780 4780 4780 5100

° 25 25 25 25 25 22 21 21 24

kNm

1660 2900 4110 4520 7070 8000 8350 11000 12620

bar 270 270 270 270 300 300 300 300 300

mm 284 327 436 480 546 538 550 550 690

t 12 17 25 27 40 48 52 54 63

4

Page 5

Hydraulic

Casing Oscillators

General Remarks

The hydraulic casing oscillators

have been designed in accordance with the latest technical

know-how. Extremely sturdy construction guarantees cost-effective use on site. By means of exact statical calculations in conjunction with higher quality material, an optimum conformity of

loads, weight and material

strength is achieved. The internal

wielding stresses – difficult to determine for static calculations,

which would affect the construction considerably – are eliminated

by means of stress relieving prior

to machining. A prominent feature

of the equipment is the clamping collar consisting

of five links operating on the boring implement. The

individual links surround the casing like a chain so

that a consistent surface pressure is exerted on the

casing circumference. In addition, the large height

of the collar (600 to 800 mm) prevents any damage

to the casings. By means of easily exchangeable

reducer pieces the oscillator can be converted,

within a few minutes, to a smaller casing diameter.

The collar opens uniformly and enables unproblematic insertion of the casing with the cutting shoe.

Another advantage of the machine is the low height

on the excavator side. The excavator can be swiveled by 360° in coupled condition.

VRM 3000 in operation

VRM

Attachment at the excavator itself is torque rigid

and guarantees the transmission of the full rotating

movement of 25° to the casing if the excavator is

firmly situated.

The design and construction of the casing oscillator

is based on the experience of many years of co-operation with companies specializing in pile foundations. In view of the high costs which would result

from a breakdown of the equipment on-site, great

emphasis has been put on exeptionally sturdy construction.

Accessories

• Upper tube guide

• Inserts

Special types

Short series for the use with rotary boring equipment or light duty types please refer to the special brochure!

• Lower locking device

• Suspension

• Power pack

• Hose unit

5

Page 6

Casing Joint

Technical Data

1

7

4

6

8

5

2

s1 s2

H h

∅ D1

s

∅ D2

3

1. Female Part

2. Male Part

3. Locating Key

4. Conical Ring

5. Threaded Ring

6. Bolt

7. Sealing

8. O-Ring

D1/D2 H1 H2 S1 S2 B Conical ring Threaded ring Conical bolt Locating key Sealing Weight

mm Quantity Type Quantity Type Quantity Type Quantity mm kg

540/478

620/558

600/520

620/540

640/560

660/580

700/620

710/630

720/640

750/670

800/720

880/800

900/820

1000/920

1080/1000

1180/1100

1200/1120

1250/1170

1300/1220

1500/1420

1800/1720

2000/1910

6

340 380 10 8 31 6 K 61 6 G 61 6 29 S 3 - 130

340 380 10 8 31 8 K 61 8 G 61 8 29 S 4 - 150

340 380 15 10 40 8 K 64 8 G 64 8 38 S 4 10 x 510 197

340 380 15 10 40 8 K 64 8 G 64 8 38 S 4 10 x530 199

340 380 15 10 40 8 K 64 8 G 64 8 38 S 4 10 x 550 205

340 380 15 10 40 8 K 64 8 G 64 8 38 S 4 10 x550 212

340 380 15 10 40 8 K 64 8 G 64 8 38 S 4 10 x 610 226

340 380 15 10 40 8 K 64 8 G 64 8 38 S 4 10 x630 230

340 380 15 10 40 8 K 64 8 G 64 8 38 S 4 10 x 630 232

340 380 15 10 40 10 K 88 10 G 88 10 38 S 4 10 x655 266

340 380 15 10 40 10 K 88 10 G 88 10 38 S 4 10 x 700 286

340 380 15 10 40 10 K 88 10 G 88 10 38 S 4 10 x785 315

340 380 15 10 40 10 K 88 10 G 88 10 38 S 4 10 x 785 318

340 380 15 10 40 10 K 88 10 G 88 10 38 S 4 10 x900 327

340 380 18 10 40 12 K 118 12 G 118 12 38 S 4 12 x 975 336

340 380 18 10 40 12 K 118 12 G 118 12 38 S 4 12 x1075 414

340 380 18 10 40 12 K 118 12 G 118 12 38 S 4 12 x 1075 418

340 380 18 10 40 12 K 118 12 G 118 12 38 S 4 12 x1145 421

340 380 18 10 40 12 K 118 12 G 118 12 38 S 4 12 x 1200 425

340 380 18 10 40 18 K 150 18 G 150 18 38 S 6 12 x1370 535

430 470 18 10 40 20 K 150 20 G 150 20 38 S 5 12 x 1680 724

385 425 18 12 45 20 K 200 20 G 200 20 43 S 5 12 x1880 874

Page 7

Casings

and Accessories

General Remarks

The casings are designed to create cased holes down to a depth

of 35 m. Especially for the construction of bored piles by rotary

drilling rigs precisely fitting casing

joints guarantee a fast placement

and bolting of the casings as well

as ideal power transmission.

D2

114

∅ d

Technical Data

s1

s2

B

Double-walled

∅ D1

D1/D2 S1 S2 d B Z L - Working length (kg)

mm Quantity of longitudinal bars 1 m 2 m 3 m 4 m 5 m 6 m

540/478

620/558

600/520

620/540

640/560

660/580

700/620

710/630

720/640

750/670

800/720

880/800

900/820

1000/920

1080/1000

1180/1100

1200/1120

1250/1170

1300/1220

1500/1420

1800/1720

2000/1910

10 8 10 31 16 295 535 770 1015 1255 1495

10 8 10 31 18 335 610 895 1185 1440 1720

15 10 13 40 18 440 805 1170 1540 1905 2270

15 10 13 40 18 450 830 1205 1590 1970 2345

15 10 13 40 18 465 855 1245 1640 2030 2420

15 10 13 40 18 480 880 1285 1690 2095 2495

15 10 13 40 20 510 940 1370 1805 2230 2660

15 10 13 40 21 520 950 1385 1820 2255 2690

15 10 13 40 21 530 960 1410 1860 2305 2755

15 10 13 40 22 575 1035 1495 1965 2425 2890

15 10 13 40 24 615 1110 1600 2105 2600 3095

15 10 13 40 26 670 1215 1760 2315 2860 3405

15 10 13 40 26 685 1245 1805 2370 2930 3485

18 10 10 40 30 780 1465 2145 2840 3525 4210

18 10 10 40 32 830 1570 2310 3060 3800 4540

18 10 10 40 36 925 1740 2550 3370 4185 4995

18 10 10 40 36 965 1790 2615 3440 4280 5396

18 10 10 40 38 995 1855 2715 3585 4450 5410

18 10 10 40 40 1025 1920 2810 3725 4620 5520

18 10 10 40 45 1225 2265 3300 4350 5390 6430

18 10 10 40 55 1460 2750 4040 5320 6610 7900

18 12 13 45 62 1590 3080 4570 6060 7550 9050

L

115

7

Page 8

Adapter

Technical Data

L

(upon

request)

290

∅ D

D Nominal diameter Quantity of locking bolts

546 540/478 2

626 620/558 2

606 600/520 2

626 620/540 2

646 640/560 2

666 660/580 2

706 700/620 2

716 710/630 2

726 720/640 2

756 750/670 4

806 800/720 4

886 880/800 4

906 900/820 4

1006 1000/920 4

1086 1080/1000 4

1186 1180/1100 4

1206 1200/1120 4

1256 1250/1170 4

1306 1300/1220 4

1506 1500/1420 6

1806 1800/1720 5

2006 2000/1910 5

Reinforced

female part

with quick

locking bolts

8

Page 9

Bottom Casing

General Remarks

Cutting shoes can be supplied with

half-casing connection or as weld-on

type.

Technical Data

∅ D1

D2

L

∅ d

S1

S2

B

D1/D2 S1 S2 d B Z L - Working length (kg)

mm Quantity of longitudinal bars 4 m 5 m 6 m

540/478

620/558

600/520

620/540

640/560

660/580

700/620

710/630

720/640

750/670

800/720

880/800

900/820

1000/920

1080/1000

1180/1100

1200/1120

1250/1170

1300/1220

1500/1420

1800/1720

2000/1910

10 8 10 31 16 1030 1270 1510

10 8 10 31 18 1200 1460 1740

15 10 13 40 18 1560 1920 2290

15 10 13 40 18 1610 1990 2370

15 10 13 40 18 1660 2050 2440

15 10 13 40 18 1710 2120 2520

15 10 13 40 20 1830 2250 2680

15 10 13 40 21 1840 2280 2710

15 10 13 40 21 1880 2330 2780

15 10 13 40 22 1980 2440 2900

15 10 13 40 24 2120 2610 3110

15 10 13 40 26 2330 2870 3420

15 10 13 40 26 2390 2950 3500

18 10 10 40 30 2870 3560 4240

18 10 10 40 32 3090 3830 4570

18 10 10 40 36 3400 4210 5020

18 10 10 40 36 3470 4310 5330

18 10 10 40 38 3630 4490 5450

18 10 10 40 40 3770 4660 5560

18 10 10 40 45 4380 5420 6460

18 10 10 40 55 5310 6600 7900

18 12 13 45 62 6070 7560 9060

s1

s2

9

Page 10

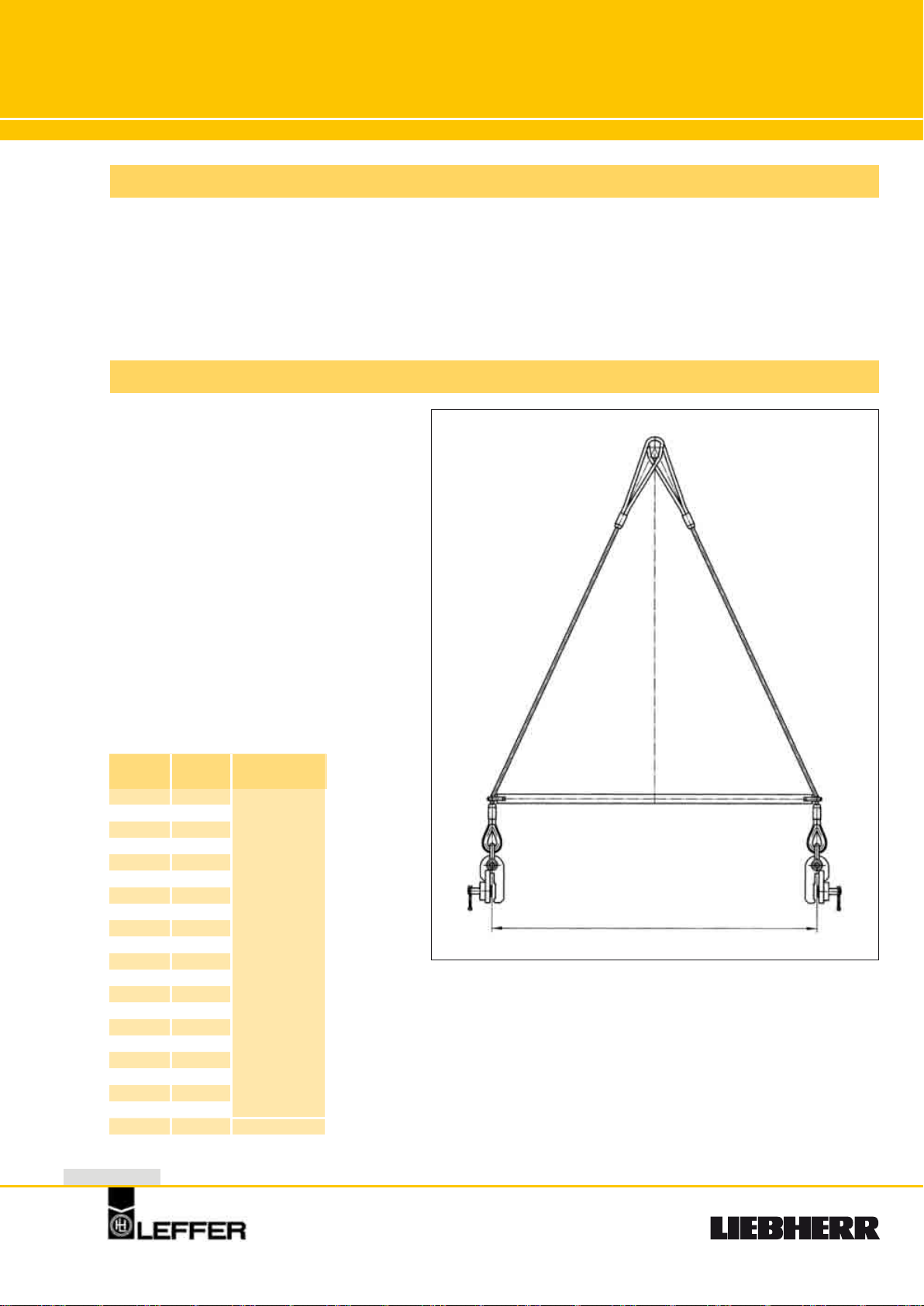

Lifting

Device

General Remarks

The lifting device enables a quick

assembly and dismantling of the

casings without damaging the

conical rings.

Technical Data

D Weight Capacity

mm kg KN

540 90

600 100

620 100

640 100

660 100

700 100

710 100

720 100

750 100

800 102

880 102

900 102

1000 142

1080 142

1180 145

1200 145

1250 145

1300 145

1500 147

1800 150

2000 172

10

100

Quick release

200

Page 11

Casing Funnel

General Remarks

The casing funnel serves as protection for the casing joint and facilitates

the insertion of the drilling tools.

Technical Data

∅ A

H

D1 H A Weight

mm kg

540

620 830 190

600 810 185

620 830 190

640 850 200

660 870 210

700 910 230

710 920 240

720 930 250

750 960 260

800 1010 270

880 1090 280

900 1110 290

1000 1210 310

1080 1290 330

1180 1390 350

1200 1410 365

1250 1460 390

1300 1510 410

1500 1710 450

1800 2010 540

2000 2210 600

500

750 170

∅ D1

11

Page 12

Casings

General Remarks

HD

For a diameter of up to 1500 mm we recommend double-walled casings. For

weight reasons single walled casings

can be used for larger diameters. The

bottom casings would always be double-walled.

Technical Data

D1

B

S

L

D2

D1/D2 S B L - Working length (kg)

mm 1 m 2 m 3 m 4 m 5 m 6 m 8 m

600/520

640/560

700/620

750/670

800/720

880/800

900/820

1000/920

1080/1000

1180/1100

1200/1120

1300/1220

1500/1400

1800/1700

2000/1880

2200/2080

2500/2380

2500/2380

2800/2680

2800/2680

2800/2640

2800/2640

2980/2840

2980/2840

3000/2840

3000/2840

3200/3040

12

20 40 380 672 993 1255 1546 1838 2421

20 40 409 720 1032 1345 1657 1969 2593

20 40 447 789 1131 1473 1815 2157 2841

20 40 481 848 1215 1582 1949 2316 3050

20 40 514 906 1298 1690 2082 2474 3258

20 40 566 998 1430 1862 2294 2726 3590

20 40 580 1022 1464 1906 2348 2790 3674

20 40 640 1133 1626 2119 2612 3105 4091

20 40 690 1190 1720 2260 2820 3350 4420

20 40 760 1350 1925 2510 3100 3680 4840

25 40 860 1600 2340 3080 3820 4560 6030

25 40 945 1745 2545 3375 4150 4950 6550

25 50 1440 2370 3300 4230 5160 6090 7950

25 50 1720 2830 3950 5070 6190 7310 9550

25 60 2190 3430 4670 5910 7150 8390 10870

25 60 2410 3780 5140 6510 7880 9250 11990

25 60 2680 4230 5790 7350 8910 10470 13590

30 60 2810 4670 6530 8400 10270 12140 15880

30 60 3150 5240 7330 9420 11510 13600 17780

32 60 3210 5440 7660 9890 12120 14350 18810

32 80 3890 6120 8340 10570 12800 15030 19490

34 80 3950 6310 8670 11040 13410 15780 20520

32 80 4230 6600 8970 11340 13710 16080 20820

34 80 4290 6810 9330 11850 14370 16890 21930

32 80 4260 6640 9030 11420 13810 16200 20980

34 80 4320 6850 9390 11930 14470 17010 22090

34 80 4610 7315 10020 12725 15430 18140 23550

Page 13

Casings

and Accessories

General Remarks

Heavy Duty Design (Patents in

many countries)

Because of the further development of hydraulic casing oscillators (type VRM) and the new development of hydraulic full 360

degree turning casing rotators

(type RDM) we are now in a position to sink bored piles into

depths of 100 m. In order to meet

the greater demands facing casing columns operating at such

depths, »heavy duty type« casings have been developed.

HD

D1

B

L

s2

s1

∅ d

Technical Data

D2

D1/D2 S1 S2 d B Z L - Working length (kg)

600/520

640/560

700/620

750/670

800/720

880/800

900/820

1000/920

1080/1000

1180/1100

1200/1120

1300/1220

1500/1400

1800/1700

2000/1880

2200/2080

2500/2380

2800/2680

2800/2640

2980/2840

3000/2840

3200/3040

mm

15 10 13 40 18 433 805 1177 1549 1921 2293 3037

15 10 13 40 18 465 862 1259 1656 2053 2450 3244

15 10 13 40 20 509 945 1381 1817 2253 2689 3561

15 10 13 40 22 549 1019 1489 1959 2429 2899 3839

15 10 13 40 24 587 1090 1593 2096 2599 3102 4108

15 10 13 40 26 637 1179 1720 2260 2801 3342 4424

15 10 13 40 26 653 1206 1759 2312 2865 3418 4524

15 10 13 40 30 724 1343 1962 2581 3200 3819 5057

15 10 13 40 32 790 1440 2155 2845 3530 4210 5570

15 10 13 40 36 860 1590 2340 3070 3810 4540 6020

15 10 13 40 36 870 1620 2365 3120 3870 4610 6110

15 10 13 40 40 950 1770 2480 3400 4210 5020 6650

15 10 22 50 45 1485 2520 3555 4590 5625 6660 8735

20 15 13 50 55 1910 3505 5085 6675 8270 9865 13055

20 20 18 60 60 2530 4600 6670 8730 10800 12870 17010

20 20 18 60 66 2785 5065 7350 9635 11920 14205 18775

20 20 18 60 76 3105 5710 8315 10920 13525 16130 21340

25 25 8 60 86 3730 7210 10685 14165 17645 21125 28085

25 25 27 80 86 4530 8335 12135 15945 19755 23565 31185

25 25 27 80 90 4910 8960 13010 17060 21110 25160 33260

25 25 27 80 90 4940 9015 13090 17170 21250 25330 33490

25 25 27 80 98 5280 9640 14000 18440 22800 27160 35960

Quantity of longitudinal bars

1 m 2 m 3 m 4 m 5 m 6 m 8 m

115

13

Page 14

Bottom Casing

General Remarks

Cutting shoes

can be supplied with half-casing

connection or as a weld-on shoe.

Technical Data

HD

114

L

∅ d

s1

s2

S2

S1

200

B

D1/D2 S1 S2 d B Z L - Working length (kg)

600/520

640/560

700/620

750/670

800/720

880/800

900/820

1000/920

1080/1000

1180/1100

1200/1120

1300/1220

1500/1400

1800/1700

2000/1880

2200/2080

2500/2380

2800/2680

2800/2640

2980/2840

3000/2840

3200/3040

mm

15 12 10 40 18 1660 2060 2450 3230

15 12 10 40 18 1780 2200 2620 3450

15 12 10 40 20 1960 2420 2880 3800

15 12 10 40 22 2110 2600 3100 4090

15 15 8 40 24 2430 3010 3600 4760

15 15 8 40 26 2680 3330 3970 5260

15 15 8 40 26 2750 3410 4070 5380

15 15 8 40 30 3060 3800 4540 6010

15 15 8 40 32 3320 4110 4910 6510

15 15 8 40 36 3640 4510 5390 7130

15 15 8 40 36 3700 4590 5480 7260

15 15 8 40 40 4020 4990 5960 7890

15 15 18 50 45 5140 6325 7510 9880

20 20 8 50 55 7380 9156 10950 14520

20 20 18 60 60 8820 10900 12990 17110

20 20 18 60 66 9730 12010 14300 18860

20 20 18 60 76 11070 13670 16280 21490

20 25 8 60 86 14260 17740 21220 28170

20 25 27 80 86 16170 19970 23770 31380

20 25 27 80 90 17260 21310 25350 33450

20 25 27 80 90 17370 21440 25510 33660

20 25 27 80 98 21290 25650 30010 38810

Quantity of longitudinal bars

4 m 5 m 6 m 8 m

D2

∅ D1

14

Page 15

Casing Joint

Technical Data

∅ D1

B

s1 s2

2

3

∅ D2

Fitting for double walled casings

HD

H1

5

7

Z

3

H2

1. Female Part

2. Male Part

6

4

8

3. Locating Key

4. Conical Ring

5. Threaded Ring

6. Schraube Bolt

7. Sealing

1

S

B

Fitting for single walled casings

D1/D2 H1 H2 S S1 S2 B Conical ring Threaded ring Conical bolt Locating key Sealing Weight

mm Quantity Type Quantity Type Quantity Type Quantity Z (mm) kg kg

600/520

640/560

700/620

750/670

800/720

880/800

900/820

1000/920

1080/1000

1180/1100

1200/1120

1300/1220

1500/1400

1800/1700

2000/1880

2200/2080

2500/2380

2800/2680

2800/2640

2980/2820

3000/2840

3200/3040

340 380 22 17 12 40 8 K 75 8 G 75 8 B 32 8 40 10 x 510 188

340 380 22 17 12 40 8 K 75 8 G 75 8 B 32 8 40 10 x550 203

340 380 22 17 12 40 8 K 75 8 G 75 8 B 32 8 40 10 x 610 221

340 380 22 17 12 40 8 K 75 8 G 75 8 B 32 8 40 10 x655 239

340 380 22 17 12 40 8 K 75 8 G 75 8 B 32 8 40 10 x 700 255

340 380 22 17 12 40 8 K 75 8 G 75 8 B 32 8 40 10 x785 281

340 380 22 17 12 40 8 K 75 8 G 75 8 B 32 8 40 10 x 785 288

340 380 22 17 12 40 10 K 115 10 G 115 10 B 32 5 40 10 x900 315

340 380 22 17 12 40 12 K 115 12 G 115 12 B 32 4 40 12 x 975 333

340 380 27 17 12 40 12 K 115 12 G 115 12 B 32 4 40 10 x1075 374

340 380 27 17 12 40 12 K 115 12 G 115 12 B 32 4 40 10 x 1075 375

340 380 27 17 12 40 12 K 115 12 G 115 12 B 32 4 40 10 x1200 413

585 625 27 17 17 50 16 K 165 16 G 165 16 B 42 4 50 10 x 1370 1049

585 625 27 22 17 50 20 k 165 20 G 165 20 B 42 4 50 10 x1670 1241

585 625 27 22 22 60 20 K 220 20 G 220 20 B 48 4 50 12 x 1860 1659

585 625 27 22 22 60 20 K 220 20 G 220 20 B 48 4 50 12 x2050 1830

585 625 27 22 22 60 20 K 220 20 G 220 20 B 48 4 50 12 x 2300 2018

585 625 35 28 28 60 24 K 220 24 G 220 24 B 48 6 50 12 x2600 2268

585 625 35 28 28 80 24 K 300 24 G 300 24 B 65 6 50 12 x 2600 2950

585 625 35 28 28 80 24 K 300 24 G 300 24 B 65 6 50 12 x2800 3230

585 625 35 28 28 80 24 K 300 24 G 300 24 B 65 6 50 12 x 2800 3250

585 625 35 28 28 80 24 K 300 24 G 300 24 B 65 6 50 12 x3000 3470

8. O-Ring

15

Page 16

Lifting

Device

General Remarks

The lifting device enables a quick assembly and dismantling of the casings without damaging the threaded

rings.

Technical Data

HD

D Weight Capacity

mm kg t

600 75

640 75

700 76

750 80

800 85

880 90

900 95

1000 120

1080 120

1180 120

1200 121

1300 150

1500 167

1800 170

2000 171

2200 175

2500 180

2800 260

2980 260

3000 260

3200 260

16

10

Lifting point

20

30

40

Page 17

Casing Funnel

General Remarks

The casing funnel serves as protection for the casing joint and facilitates

the insertion of the drilling tools.

Technical Data

HD

∅ A

∅ D1

H

Nominal diameter D1 H A Weight

mm kg

600 550 460 775 150

640 590 460 815 160

700 650 460 875 175

750 700 460 925 185

800 750 460 975 200

880 830 460 1055 220

900 850 460 1075 225

1000 950 460 1175 250

1080 1030 460 1255 260

1180 1130 460 1355 285

1200 1150 460 1375 295

1300 1250 460 1475 315

1500 1440 530 1655 500

1800 1740 530 1955 600

2000 1930 545 2150 870

2200 2130 545 2350 950

2500 2430 545 2650 1090

2800 2730 545 2950 1230

2800 2710 565 2910 1640

2980 2890 565 3090 1680

3000 2910 565 3110 1700

3200 3110 565 3310 1800

17

Page 18

Single/Double

� 770 � 770

� 970

930

� 850

� 890

L

L

� 1050

� 1070

930

� 1290

1200

� 1360

1200

� 1170

� 1460

Rope Pulley Grab

L 770 - 1460 SK/SZ

Single Rope

Pulley Grab

Chandelier

Lower part

Grab

body

Lower

part

Double Rope

Pulley Grab

Body

Extension

Technical Data

Type Casing diameter Length Jaw capacity Weight

L770 SK

L770 SZ 3325 2410

L850 SK

L850 SZ 3355 2430

L890 SK

L890 SZ 3365 2480

L970 SK

L970 SZ 3535 3150

L1050 SK

L1050 SZ 3565 3180

L1070 SK

L1070 SZ 3585 3240

L1170 SK

L1170 SZ 3630 3335

L1290 SK

L1290 SZ 3805 4550

L1360 SK

L1360 SZ 3860 4445

L1460 SK

L1460 SZ 3895 4570

18

mm mm l kg

880/800 · 900/820

980/900

1000/920

1080/1000 · 1100/1020

1180/1100 · 1200/1120

1180/1100 · 1200/1120

1300/1220

1400/1320

1500/1420 · 1500/1400

1600/1520 · 1600/1500

3725

3755

3765

3935

3965

3985

4030

4205

4260

4295

140

180

210

260

340

440

520

710

830

1060

2740

2760

2810

3480

3510

3570

3665

4880

4775

4900

Page 19

Special Hammer

Grab for Bored Piles

General Remarks

Robust free-fall grab with high closing force especially suitable for boring in detritus soils and for water-logged pile foundations. The pulleys are

equipped with oil-filled maintenance-free life-time

bearings.

Technical Data

Casing Types

600-1000 L 490-890 S

900-1600 L 770-1460 S

1500-2500 L 1350-2250 S

2500-3000 L 2170-2570 S

600 - 3000 mm

Special Hammer Grab

19

Page 20

Single/Double

Rope Pulley Grab

L 1350 - 2100 RK/RZ

Single Rope

Pulley Grab

with teeth

Chandelier

L

1650

Grabbody

Double Rope

Pulley Grab

with teeth

L

1650

Jaw rods

1860 mm

Jaw rods

1700 mm

1800 2100

Technical Data

Type Casing diameter Length Jaw capacity Weight

L1350 RK

L1350 RZ 5080 7750

L1650 RK

L1650 RZ 5220 8000

L1800 RK

L1800 RZ 5240 8310

L2100 RK

L2100 RZ 5420 8840

20

mm mm l kg

1500/1420 · 1500/1400

1800/1720 · 1800/1700

200/1910 · 2000/1880

2500/2400 · 2500/2380

5620

5760

5780

5960

800

900

110

1300

8480

8730

9065

9595

Page 21

� 490

� 490

� 640

� 770

� 850

� 890

� 690

� 530

� 590

L

L

Single/Double

Rope Pulley Grab

L 490 - 890 SK/SZ

Single Rope

Pulley Grab

Chandelier

Lower part

Grab

body

Lower

part

Double Rope

Pulley Grab

Body

Extension

Technical Data

Type Casing diameter Length Jaw capacity Weight

mm mm l kg

L490 SK

L490 SZ 2800 1140

L530 SK

L530 SZ 2820 1145

L590 SK

L590 SZ 2855 1175

L640 SK

L640 SZ 2690 1280

L690 SK

L690 SZ 2710 1305

L770 SK

L770 SZ 2870 1945

L850 SK

L850 SZ 2900 1960

L890 SK

L890 SZ 2910 2010

600/520 · 620/540

620/558 · 640/560 ·

660/580

700/620 · 720/640

750/670

800/720

880/800 · 900/820

980/900

1000/920

3080

3100

3135

2970

2990

3150

3180

3190

45

58

70

70

90

140

180

210

1300

1305

1335

1440

1470

2105

2125

2175

21

Page 22

Single/Double

Rope Pulley Grab

L 2350 - 2750 RK/RZ

Single Rope

Pulley Grab

with teeth

Chandelier

Double Rope

Pulley Grab

with teeth

Grab

body

with

jaw rods

L

2350

L

2750 2350

Technical Data

Type Casing diameter Length Jaw capacity Weight

L2350 RK

L2350 RZ 6435 17375

L2750 RK

L2750 RZ 6605 18540

22

mm mm l kg

2500/2400 · 2500/2380

3000/2840

6970

7140

2500

4500

17700

18865

Page 23

Single/Double

Rope Pulley Grab

L 1350 - 2250 SK/SZ

Single Rope

Pulley Grab

Chandelier

Double Rope

Pulley Grab

Grabbody

LL

1350 1350 1800 2100

Jaw rods

1860 mm

Jaw rods

1700 mm

2250 1650 1650

Technical Data

Type Casing diameter Length Jaw capacity Weight

mm mm l kg

L1350 SK

L1350 SZ 4940 7350

L1650 SK

L1650 SZ 5090 8205

L1800 SK

L1800 SZ 5150 8830

L2100 SK

L2100 SZ 5270 9520

L2250 SK

L2250 SZ 5340 10085

1500/1420 · 1500/1400

1800/1720 · 1800/1700

2000/1910 · 2000/1880

2500/2400 · 2500/2380

2500/2400 · 2500/2380

5480

5630

5690

5810

5880

800

1100

1200

1500

1800

8425

8930

9555

10425

10425

23

Page 24

Hydraulic

Spherical Grab

HLKG/HLKG“CD”

General Remarks

The Hydraulic Spherical Grab type HLKG is used on

jobs, where drilling has to be carried out free of vibrations and/or where partially cased or uncased

drilled shafts are to be produced.

The high deadweight in conjunction with the high

closing force ensures a high efficiency. The hydraulic turning device enables the grab to be turned

100° to ensure a calibration of the borehole.

To recognize and correct any deviation of the vertical excavation direction, all hydraulic spherical

grabs are equipped with a two-axis inclination sensor. The inclination sensor values are monitored inside the operator’s cabin. For uncased drilled shafts

the grab type HLKG “CD” is used. The jaw dimensions are adapted to the respective shaft diameter.

Technical Data

L1L2L

B1 S

Pile diameter Type L L1 L2 B B1 B2 S Weight Capacity

mm kg l

1200

cased

1200

uncased

1300

cased

1300

uncased

1500

cased

1500

uncased

1800

cased

1800

uncased

2000

cased

2000

uncased

HLKG1-118

HLKG1-1200

“CD”

HLKG1-130

HLKG1-1300

“CD”

HLKG1-150

HLKG1-1500

“CD”

HLKG1-180

HLKG1-1800

“CD”

HLKG1-200

HLKG1-2000

“CD”

5760

5760

5760

5760

5760

6640 6715

6690 6800 1160 1170 1200 10550 230

6690 6800

6740 6900 1260 1270 1300 10850 400

6800

6850 7135 1460 1470 1500 12115 680

6975 6975

7030 7345 1720 1750 1800 13850 1030

7030 7470

7115 7625 1900 1950 2000 14290 1500

7045

870

990

990

990

990

1020 960 1080 8650 165

1010 1060 1180 8850 23

1350 1260 1380 9420 420

1650 1560 1670 11050 810

1800 1700 1800 11290 1030

24

Page 25

Single/Double

Rope Pulley Grab

L 2170 - 2570 SK/SZ

Single Rope

Pulley Grab

2350

Double Rope

Pulley Grab

Chandelier

Grab body with

jaw rods

LL

2750 2170 2370 2570

Technical Data

Type Casing diameter Length Jaw capacity Weight

mm mm l kg

L2170 SK

L2170 SZ 6040 17055

L2370 SK

L2370 SZ 6125 17755

L2570 SK

L2570 SZ 6210 18505

2500/2400 · 2500/2380

2800/2680

2800/2680 · 3000/2840

6575

6655

6745

2500

3500

4500

17380

18080

18830

25

Page 26

Mechanical

Spherical Grab

Technical Data

B B2

LKG 0

Guide

Body

L

Lower part

Set of jaws

B1

S

L1

L2

Casing Type L L1 L2 B B1 B2 S Weight Capacity

mm kg l

880/800

900/820

1000/920 LKG 0-100 3700 4380 4700 600 900 870 890 6000 200

1180/1100/

1200/1120

26

LKG 0-88 3700 4295 4545 600 670 740 785 5800 175

LKG 0-118 3700 4460 4815 600 1000 1040 1065 6750 230

Page 27

Mechanical

Spherical Grab

General Remarks

for bored piles 880 – 3200 mm diameter

Double rope grab with high closing force especially

suitable for vibration-free boring in semi-hard and

hard soil conditions.

880-3200 mm

27

Page 28

Mechanical

Spherical Grab

Technical Data

LKG 3

B2

B

Guide

Body

L

L1

L2

Lower part

Set of jaws

B1

Casing Type L L1 L2 B B1 B2 S Weight Capacity

mm kg l

2000/1880 LKG 3-200 4600 5700 6100 1500 1770 1650 1810 15050 970

2200/2080 LKG 3-220 4600 5800 6280 1500 1980 1900 2010 18200 1450

2500/2380 LKG 3-250 4600 6000 6615 1500 2290 2200 2310 19750 2250

2800/2640

2800/2680

2980/2820

3000/2840

3200/3040 LKG 3-320 4600 6325 7230 1500 2980 2900 2980 22100 4650

LKG 3-280 4600 6125 6850 1500 2560 2460 2580 20800 3050

LKG 3-300 4600 6215 7000 1500 2760 2660 2710 21500 3900

S

28

Page 29

Mechanical

Spherical Grab

Technical Data

LKG 1

B

L

B2

Guide

Body

L1

L2

Lower part

Set of jaws

B1

Casing Type L L1 L2 B B1 B2 S Weight Capacity

mm kg l

1180/1100/

1200/1120

1300/1220 LKG 1-130 4700 5630 5745 870 1130 1060 1180 9700 230

1500/1400/

1500/1420

1800/1700

1800/1720

2000/1880

2000/1910

LKG 1-118 4700 5580 5655 870 1020 960 1080 8300 165

LKG 1-150 4700 5745 5955 870 1350 1260 1380 11250 420

LKG 1-180 4700 5915 6285 870 1650 1560 1670 12000 810

LKG 1-200 4700 5980 6460 870 1800 1700 1800 12900 1030

S

29

Page 30

Interlocking

A

D

B

J

K

H

D

d

D

E

Rope

Joint-O

Joint-O

Tremie Pipes

General Remarks

Water-tight interlocking tremie

pipes

The tremie pipes can be supplied in all

diameters and all lengths, also with charging

funnel.

Technical Data

Charging

funnel

NW 150 - NW 250

Tremie pipes 250 mm , 2.5 m long, prior to shipment

Tremie pipe

Collar

Lifting cap

Tube connection

Nominal diameter NW 150 NW 200 NW 250

Tubes for concrete work

D/d mm 194/159 241/203 300/267

Length 1 m kg 26 35 45

Length 2 m kg 42 55 70

Length 3 m kg 57 74 96

Length 4 m

Length 5 m kg 87 113 147

Length 6 m kg 102 132 173

Charging funnel

B mm 400 750 1000

Height A mm 1000 1100 1300

Weight kg 45 85 160

Lifting cap

Height E mm 125 125 125

Weight kg 9 11 12

Tremie pipe

K mm 164 208 272

Width H mm 400 400 450

Length J mm 1200 1200 1500

Weight kg 65 65 75

kg

72 93 121

30

Page 31

30°

500

50

150 150

Chisel

General Remarks

To drive casings through rock

For the different rock conditions we offer two types

of chisel:

Type A - Type B

Type A: Cross chisel with additional tangential cut

ting edges for rock with a compression

strength of less than 1500 kg/cm2.

Type B: Round chisel with a cross inside for rock

with a compression strength of more than

1500 kg/cm2. The teeth are made of high

manganeze steel.

Technical Data

-

Chisel Type B for hard rock

Diameter of casings Width of chisel Length of chisel Weight

mm mm mm kg

640 530 3500 1930

700 590 3500 2200

Cross chisel type A

Round chisel type B

750 640 3500 2400

800 690 3150 2550

880 770 3150

900 770 3150 2700

1000 890 3000 3300

1080 970 3000 3600

1100 970 3000 3700

1180 1070 3500 5000

1200 1070 3500 5000

1300 1190 3500 5200

1500 1370 3500 7000

1800 1640 3500 8000

2000 1840 3850 10000

2200 2040 4000 12000

2500 2220 4000 14000

2800 2520 4000 16000

3000 2700 4000 18000

2700

31

Page 32

Due to improvement and engineering progress we reserve the right to change specifications without notice.

Copyright © · #71006 · 1st Ed · 04/07 · kom DESIGN·1 GmbH München

Stahl- und Apparatebau Hans Leffer GmbH & Co. KG

P.O. Box

20 03 60, D-66044 Saarbrücken/Germany

Tel.: +49 (0) 68 97-7 93-0

Fax: +49 (0) 68 97-7 93-330

info@leffer.de

www.leffer.de

Liebherr-Werk Nenzing GmbH

P.O. Box 10, A-6710 Nenzing/Austria

Tel.: +43 50809 41-0

Fax: +43 50809 41-499

crawler.crane@liebherr.com

www.liebherr.com

Loading...

Loading...