Page 1

Technical data

Hydraulic crawler crane

HS 8300 HD

Page 2

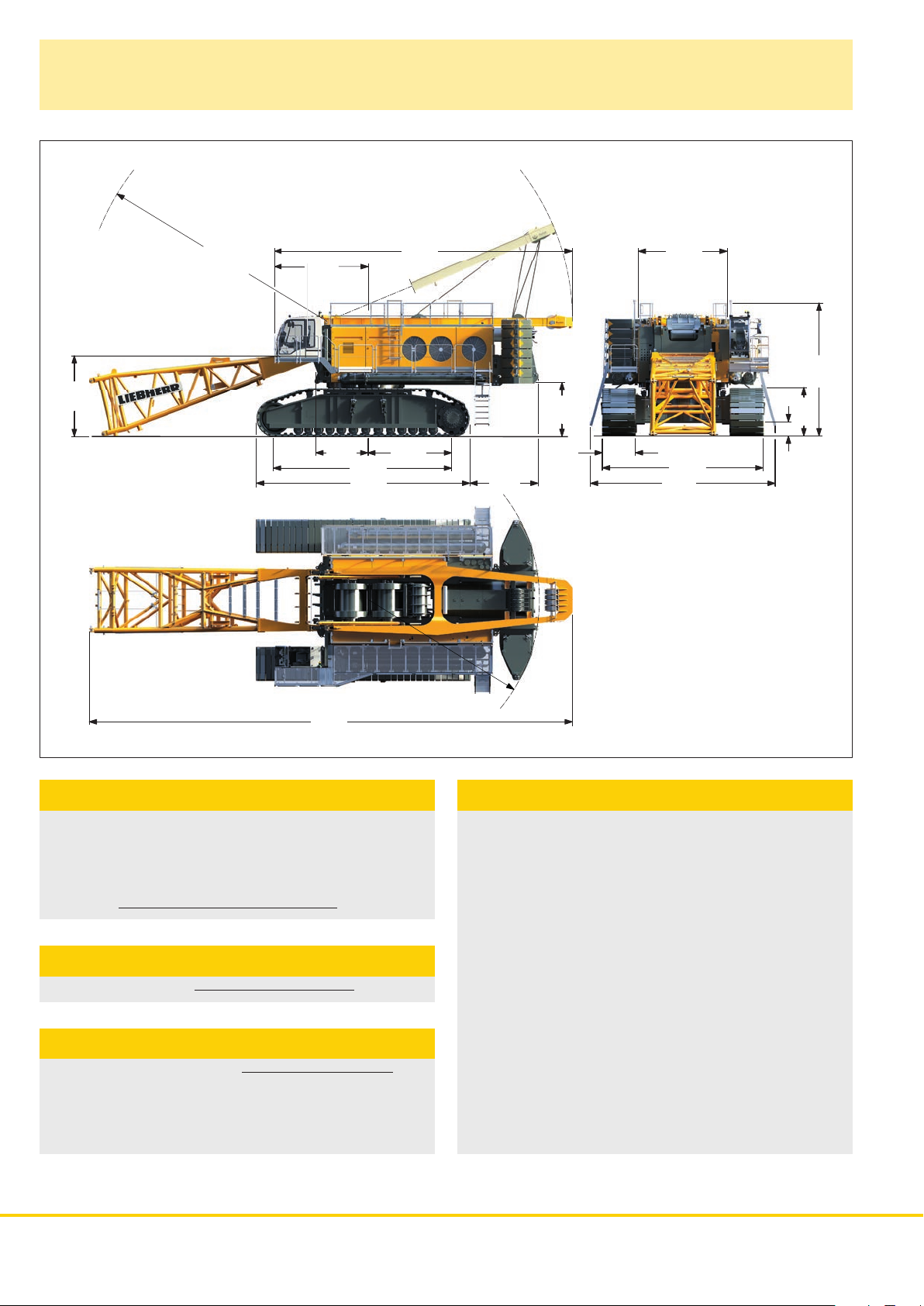

Dimensions

Basic machine with undercarriage

3620

R 10950

3655

2200

7915

9545

13300

3855

3030

R 7835

2390

1200

3980

7150

8250

5950

2180

640

21650

Operating weight

The operating weight includes the basic machine with HD undercarriage, 2 main winches 500 kN including wire ropes (250 m) and

20 m main boom, consisting of A–frame, boom foot (10 m) and boom

head (10 m), 78.7 t basic counterweight, 1200 mm track pads and

50 t hook block.

Total weight approx. 352 t

Ground pressure

Ground bearing pressure 1.85 kg /c m

Equipment

Main boom (No. 2724 .32) max. length 68 m

Modular designed equipment for operation as crane, with dragline or

clamshell.

For dragline operation, a rotating fairlead is fi tted into the boom foot.

This minimizes the rope angle to drum, which results in lower rope

wear.

Remarks

1. The lifting capacities stated are valid for lifting operation only

(corresponding with crane classifi cation according to F.E.M.

1.001, crane group A1).

2. Crane standing on fi rm, horizontal ground.

3. The weight of the lifting device (hoisting ropes, hook block,

shackle etc.) must be deducted from the gross lifting capacity

to obtain a net lifting value.

4. Additional equipment on boom (e.g. boom walkways, auxiliary

jib) must be deducted to get the net lifting capacity.

2

5. For max. wind speed please refer to lift chart in operator‘s cab

or manual.

6. Working radii are measured from centre of swing and under

load.

7. The lifting capacities are valid for 360 degrees of swing.

8. Calculation of stability under load is based on ISO 4305

Table 1 + 2, tipping angle 4°.

9. The structures are calculated according to F.E.M. 1.001 - 1998

(EN 13001-2 / 2004).

2 HS 8300 HD

Page 3

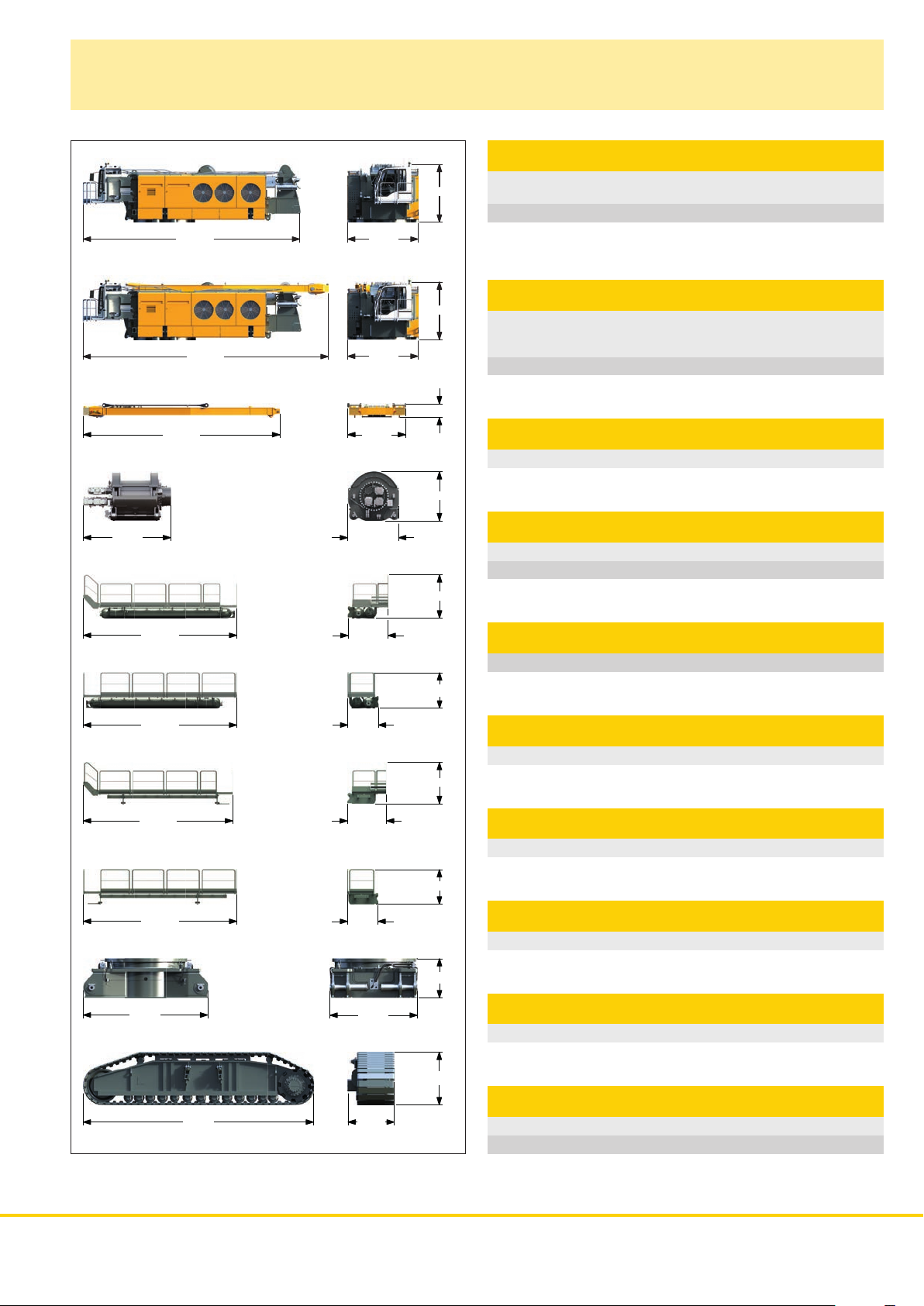

Transport dimensions and weights

Basic machine with HD undercarriage

Basic machine

without HD undercarriage, boom, boom backstops, A-frame, main

winches (2x 500 kN), walkways and counterweight.

Weight 68950 kg

12250

3260

3980

2830

7765

7665

11080

13840

3270

1630

2040

1540

3980

3260

690

1580

2195

1785

Basic machine

with A-frame, boom backstops, main winches (2x 500 kN) without

wire ropes (250 m), without walkways, HD undercarriage, boom and

counterweight.

Weight 99900 kg

A-frame

Weight 740 0 k g

Main winches 2x

Weight winch I without wire ropes 12000 kg

Weight winch II without wire ropes 12000 kg

Walkway with Pactronic

Weight 6550 kg

Walkway with Pactronic

Weight 6450 kg

®

(left) option

®

(right) option

7765

7765

5080

9545

2040

1540

3560

1940

2195

Standard walkway (left)

Weight 670 kg

1785

Standard walkway (right)

Weight 630 kg

1610

Centre section of undercarriage

Weight 36250 kg

2180

Crawlers 2x

Weight of crawler left 48300 kg

Weight of crawler right 48300 kg

HS 8300 HD 3

Page 4

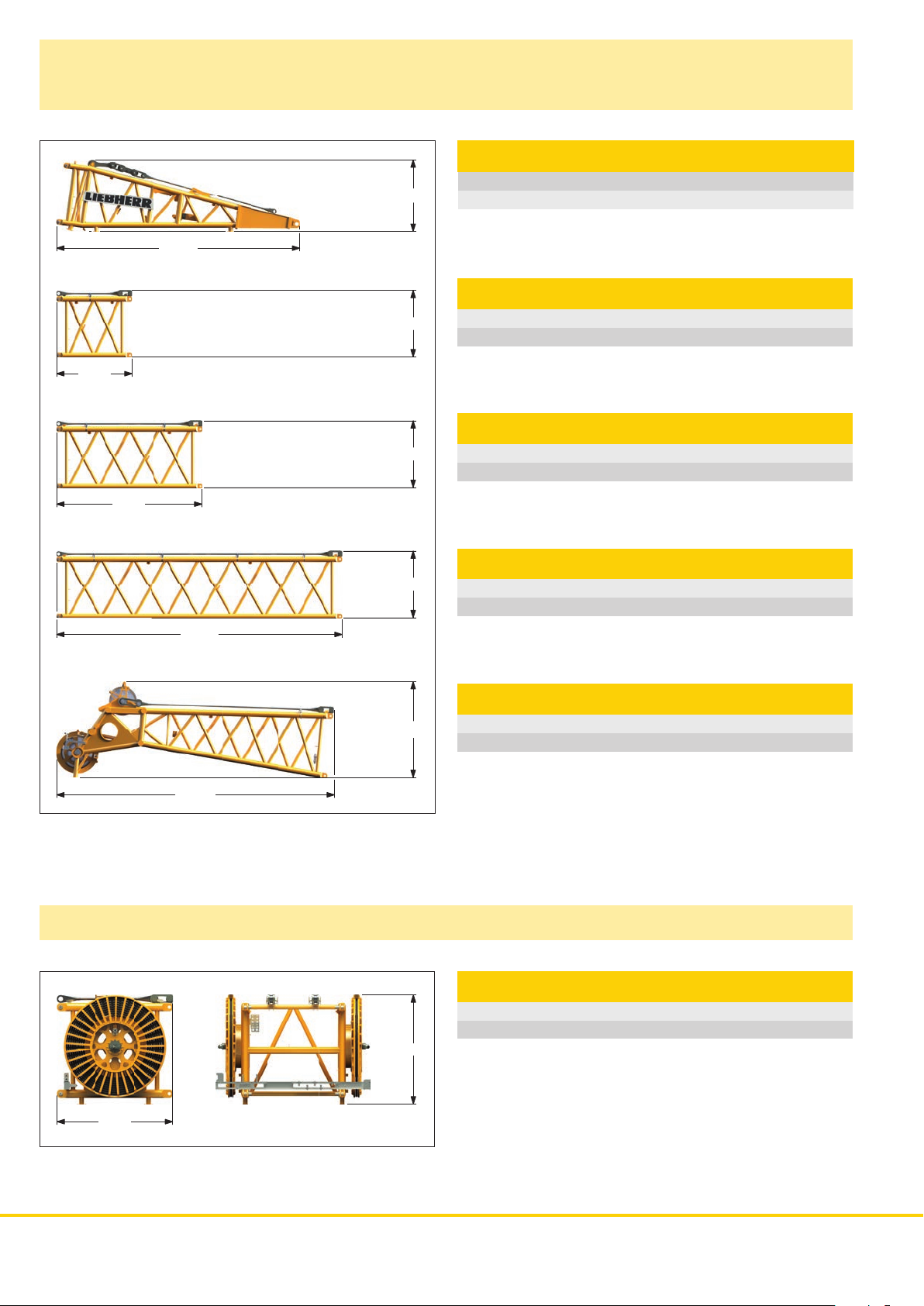

Transport dimensions and weights

Main boom (No. 2724.32)

Boom foot (No. 2724.32)

3000

10330

2860

3240

2860

6240

Width 3090 mm

Weight* 1030 0 kg

Boom section (No. 2724.32) 3 m

Width 2940 mm

Weight* 2500 kg

Boom section (No. 2724.32) 6 m

Width 2940 mm

Weight* 3600 kg

12240

10940

Boom section with hydraulics

2860

4015

3140

Boom section (No. 2724.32) 12 m

Width 2940 mm

Weight* 6300 kg

Boom head

Width 2940 mm

Weight* 1010 0 kg

*) Including pendant ropes, without auxiliary equipment

**) Steel sheaves

**

(No. 2724.32)

Boom section with hydraulics 3 m

Width 4300 mm

Weight 7700 kg

3240

4 HS 8300 HD

Page 5

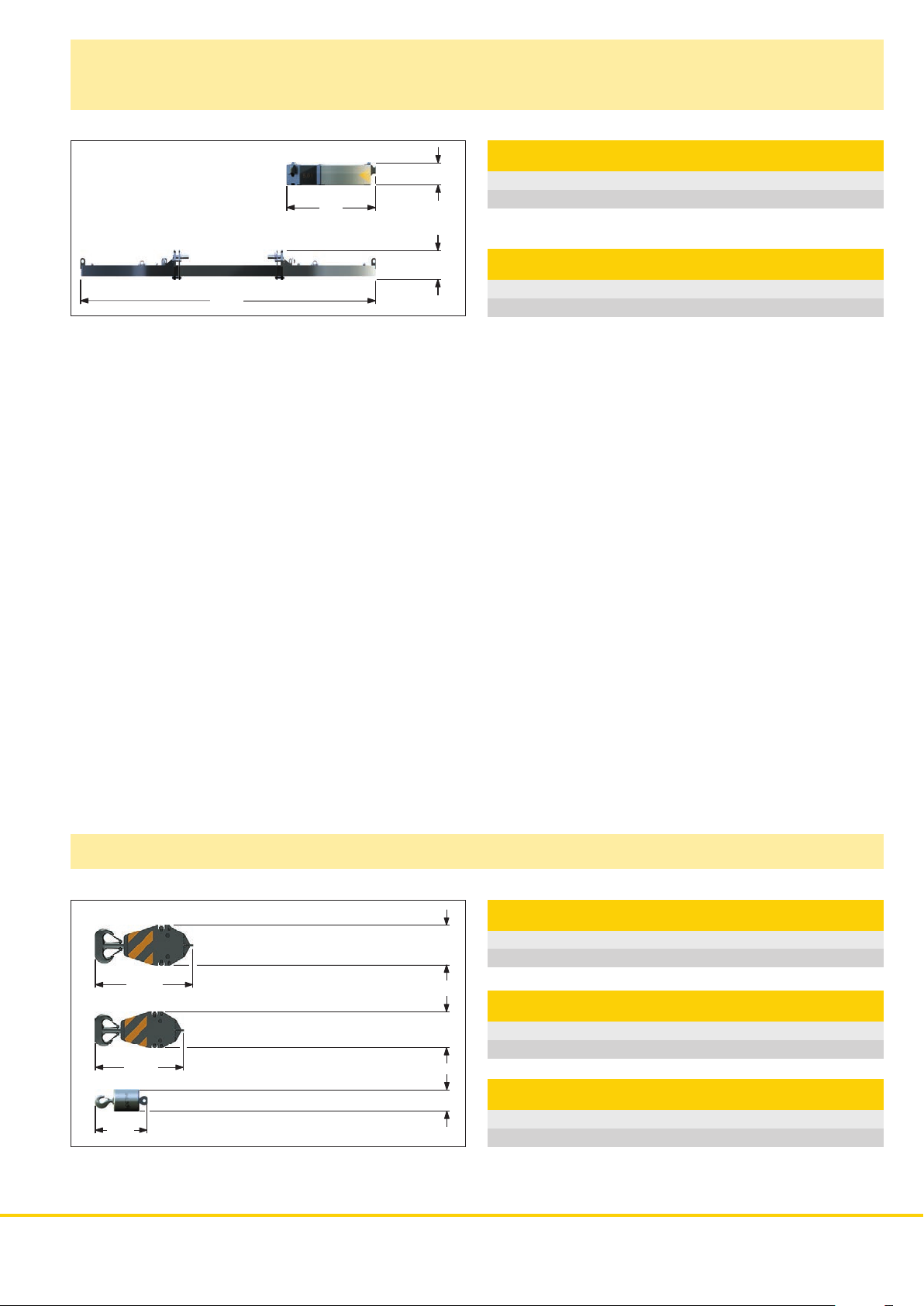

Transport dimensions and weights

Counterweight

Counterweight 12 x

475

960

Width 850 mm

Weight 5000 kg

3500

475

Counterweight 1 x

Width 10 50 mm

Weight 1870 0 kg

Hooks

3050

2760

1450

1300

1300

600

300 t hook block - 4 sheaves

Width 840 mm

Weight 4000 kg

150 t hook block - 1 sheave

Width 630 mm

Weight 3000 kg

50 t single hook

Width 600 mm

Weight 160 0 kg

HS 8300 HD 5

Page 6

Hydraulic crawler crane HS 8300 HD Hybrid

Powerful, energy-effi cient hybrid drive

The new HS 8300 HD is fi tted with the Pactronic® system developed

by Liebherr. This innovative hybrid drive based on hydraulics of fers

both economic and ecological advantages. Storing and subsequent

regenerating of surplus power allows to increase turnover and to

signifi cantly lower fuel consumption. The proven technology of the

hydraulic accumulator ensures low maintenance requirements and

maximum reliability. The decreased energy consumption considerably

lowers emissions and thus improves environmental compatibility.

Pactronic® - Lowering mode

• A secondary energy source is added to the drive system.

• The accumulator is charged by regenerating the reverse power while

lowering the load.

• The additional surplus power of the primar y energy source is used

for charging.

Winch diagram without Pactronic

1100

1000

900

800

700

600

500

400

300

200

100

0

0 20 40 60 80 100 120

Hoisting speed [m/min]

®

Pactronic® - Hoisting mode

• Stored energy is transferred to the system when the crane requires

peak power for hoisting.

• The total hoisting power is the sum of the conventional hydrostatic

power and the secondary energy from the accumulator.

Key advantages of Pactronic

• 725 kW diesel engine combined with Pactronic® allows to achieve

a system power comparable to a conventional drive system with

1,250 kW

• Effective hoisting power of 800 kW

• Reduced fuel consumption resulting in less C0

• Lower noise emission

• Increased hoisting power

• Increased lowering power

• Higher turnover with identical prime mover

®

emission

2

2-winch operation

1-winch operation

Winch diagram with Pactronic

1100

1000

900

800

700

600

500

400

Line pull [kN] Line pull [kN]

300

200

100

0

0 20 40 60 80 100 120

Hoisting speed [m/min]

Machine class 300 t

Engine power Tier 4i

according to

EPA /CARB 725 kW

System power with

Pactronic

Winches

Boom - crane

Boom - clamshell

®

®

1250 kW

500 kN

68 m

68 m

6 HS 8300 HD

Page 7

Technical description

Engine

Power rating according to ISO 9249, 725 kW (972 hp) at 1700 rpm

Engine type

Fuel tank

The diesel engine runs with optimum fuel efficiency.

Power rating according to ISO 9249, 725 kW (972 hp) at 1700 rpm

Modell

Fuel tank

Engine complies with NRMM exhaust certification EPA / CARB Tier 4i.

Liebherr D 9512 A7

1170 l capacity with continuous level

indicator and reserve warning

Liebherr D 9512 A7 SCR

1170 l capacity with continuous level

indicator and reserve warning

Hydraulic system

The main pumps are operated by a distributor gearbox. Axial piston

displacement pumps work in closed and open circuits supplying

oil only when needed (flow control on demand). To minimize peak

pressure an automatically working pressure cut-off is integrated.

This spares pumps and saves energy. The hydraulic oil is cleaned

through electronically controlled pressure and return filters. Possible

contamination is signaled in the cabin.

Ready made hydraulic retrofit kits are available to customize

requirements e.g. powering casing oscillators, VM–vibrators, hydraulic

grabs, fixed leaders etc.

Working pressure

Oil tank capacity

max. 400 bar

2800 l

Main winches

Winch options:

Line pull (nom. load)

Rope diameter

Drum diameter

Rope speed

Rope capacity 1st layer

The winches are outstanding in their compact design and easy

assembly. Clutch and braking functions on the free-fall system are

provided by a compact designed, low wear and maintenance-free

multi– disc brake.

The drag and hoist winches use pressure controlled, variable flow

hydraulic motors. This system features sensors that automatically

adjust oil flow to provide max. winch speed depending on load.

500 kN

46 mm

1100 mm

0-125 m /min

69 .1 m

Crawlers

The track width of the undercarriage is changed hydraulically.

Propulsion through axial piston motor, hydraulically released spring

loaded multi–disc brake, maintenance-free crawler tracks, hydraulic

chain tensioning device.

Track pads

Drive speed

1200 mm

0 – 1.4 km/h

Boom winch

Line pull max. 150 kN

Rope diameter

Boom up

24 mm

130 sec. from 15° to 84°

Swing

Consists of rollerbearing with external teeth for lower tooth flank

pressure, fixed axial piston hydraulic motor, spring loaded and

hydraulically released multi–disc holding brake, planetary gearbox and

pinion.

Swing speed from 0 –3.6 rpm continuously variable, selector for 3

speed ranges to increase swing precision.

Standard:

4 swing drives

Control

The core of the Liebherr hydraulic crawler cranes is the Litronic control

system.

Developed and manufactured by Liebherr, this comprehensive system

encompasses all control and monitoring functions and is designed

to withstand extreme temperature changes and the rough heavy

duty tasks common in the construction industry. Complete machine

operating data, warnings and failure indications are clearly displayed in

the required language on the high resolution monitor in the operator’s

cab.

Documentation of operating data (PDE) enables optimum diagnosis as

well as early detection and prevention of more serious defects.

An electro-hydraulic proportional control allows several movements to

be performed simultaneously. This ensures that all categories of loads

can be positioned with utmost precision.

Options:

• PDE:Processdatarecording

• GSM/GPRStelematicsmodule

• Specialdemolitioncontrolsystem

Noise emission

Noise emissions correspond with 2000/14/EC directive on noise

emission by equipment used outdoors.

HS 8300 HD 7

Page 8

Equipment (78.7 t counterweight)

Orange-peel grab

Orange-peel grab

Winch options 2 x 500 kN

Line speed 1st layer 0-125 m/min

8 HS 8300 HD

Page 9

Load chart for duty cycle operation (main boom No. 2724.32)

78.7 t counterweight

Capac ities in metric tonnes for boom lengths (20 m - 68 m) Counterweight 78.7 t

Boom length (m)

Radius 20 23 26 29 32 35 38 41 44 47 50 53 56 59 62 65 68 Radius

(m) t t t t t t t t t t t t t t t t t (m)

5.4 260.0 5.4

6 260.0 242.9 222.2 6

7 252.4 242.9 222.2 203.6 187.6 172.8 7

8 200.1 200.3 200.5 197.4 187.6 172.8 159.6 147.4 136.8 8

9 165.2 165.4 165.5 165.4 165.3 162.1 157.4 147.4 136.8 126.6 117.5 108.9 9

10 140.3 140.4 140.4 140.3 140.3 140.1 139.9 136.1 132.5 126.6 117.5 108.9 101.4 94.0 87.3 10

12 107.7 107.8 107.8 107.6 107.5 107.3 107.1 106.9 106.6 106.3 103.7 101.1 97.6 94.0 87.3 81.4 77.0 12

14 86.4 86.4 86.4 86.2 86.1 85.9 85.6 85.3 85.0 84.8 84.4 84.1 82.9 80.9 78.8 76.9 74.0 14

16 71.6 71.6 71.6 71.3 71.3 71.0 70.7 70.4 70.1 69.8 69.5 69.1 68.7 68.4 67.4 65.6 64.0 16

18 60.6 60.6 60.6 60.4 60.4 60.1 59.8 59.4 59.2 58.8 58.4 58.1 57.7 57.3 57.0 56.6 55.2 18

20 52.2 52.2 52.3 52.0 52.0 51.7 51.4 51.0 50.8 50.4 50.0 49.6 49.3 48.9 48.5 48.1 47.7 20

22 45.5 45.6 45.4 45.4 45.1 44.8 44.4 44.1 43.7 43.4 43.0 42.6 42.2 41.8 41.4 41.0 22

24 39.5 40.2 40.0 40.0 39.7 39.4 39.0 38.8 38.4 38.0 37.6 37.2 36.8 36.4 35.9 35.5 24

26 35.7 35.5 35.5 35.2 35.0 34.6 34.3 33.9 33.5 33.1 32.7 32.3 31.9 31.4 31.0 26

28 31.7 31.8 31.5 31.2 30.8 30.6 30.1 29.8 29.3 29.0 28.5 28.1 27.7 27.3 28

30 28.5 28.2 28.0 27.6 27.4 26.9 26.6 26.1 25.8 25.3 24.9 24.4 24.1 30

32 25.5 25.4 25.2 24.8 24.6 24.2 23.8 23.3 23.0 22.6 22.1 21.7 21.3 32

34 23.0 22.8 22.4 22.2 21.8 21.4 20.9 20.6 20.1 19.7 19.2 18.9 34

36 20.6 20.2 20.1 19.6 19.3 18.8 18.5 18.0 17.6 17.1 16.7 36

38 18.3 18.2 17.7 17.4 16.9 16.6 16.1 15.7 15.2 14.8 38

40 15.6 16.4 16.0 15.7 15.2 14.9 14.4 14.0 13.5 13.2 40

42 14.6 14.5 14.2 13.7 13.4 12.9 12.5 12.0 11.6 42

44 13.0 12.8 12.3 12.0 11.5 11.1 10.6 10.3 44

46 9.8 11.4 11.0 10.8 10.3 9.9 9.4 9.0 46

48 9.4 9.7 9.6 9.1 8.7 8.2 7.8 48

50 7.9 8.5 8.1 7.7 7.0 6.6 50

55 4.4 4.6 4.3 3.8 55

Above load chart is for reference only. For actual lift duty please refer to load char t in operator’s cab or manual.

TLT 11238471 M00000 Vorab1

HS 8300 HD 9

Page 10

Equipment (78.7 t counterweight)

Dragline bucket

Dragline bucket

Winch options 2 x 500 kN

Line speed 1st layer 0-125 m/min

10 HS 83 00 HD

Page 11

Dragline equipment

78.7 t counterweight

(Main boom No. 2724.32)

C

J

E

Capac ities in metric tonnes for boom lengths (20 m - 5 0 m) Counterweight 78.7 t

alpha C J C J C J C J C J C J C J t

(m) (m) (t) (m) (m) (t) (m) (m) (t) (m) (m) (t) (m) (m) (t) (m) (m) (t) (m) (m) (t)

60 13.8 20.3 50.0 16.8 25.5 50.0 19.8 30.7 50.0 22.8 35.8 48.4 25.8 41.0 37.8 27.3 43.6 33.5 28.8 46.2 29.6

55 15.2 19.2 50.0 18.6 24.2 50.0 22.1 29.1 50.0 25.5 34.0 39.5 28.9 38.9 30.5 30.7 41.4 26.7 32.4 43.8 23.4

50 16.5 18.1 50.0 20.4 22.7 50.0 24.2 27.3 44.8 28.1 31.9 32.3 31.9 36.5 24.7 33.9 38.8 21.4 35.8 41.1 18.5

45 17.7 16.8 50.0 22.0 21.1 50.0 26.2 25.3 35.6 30.4 29.6 26.7 34.7 33.8 20.1 36.8 35.9 17.2 38.9 38.0 14.4

40 18.8 15.5 50.0 23.4 19.3 40.5 28.0 23.2 29.8 32.6 27.0 22.2 37.2 30.9 16.4 39.5 32.8 13.8 41.8 34.8 10.5

35 19.8 14.0 50.0 24.7 17.5 33.9 29.6 20.9 25.2 34.5 24.4 18.4 39.5 27.8 13.3 41.9 29.5 10.9 44.4 31.2 7.4

30 20.6 12.5 39.6 25.8 15.5 28.8 31.0 18.5 21.2 36.2 21.5 15.2 41.4 24.5 10.6 44.0 26.0 8.3 46.6 27.5 4.9

25 21.4 10.9 33.5 26.8 13.4 24.4 32.2 16.0 17.8 37.7 18.5 12.4 43.1 21.0 8.2 45.8 22.3 6.2 48.5 23.6 3.1

D

20 26 32 38 44 47 50

Digging diagram

C = Radius / dumping radius

D = Max. digging radius = approx.

C + 1/3 to 1/2 J

E = Digging depth = approx.

40 - 50% of C

J = Height to centre rope pulley

boom head

Max. capacities in metric tonnes do not exceed 75% of tipping load.

Capacities in duty cycle operation are for reference only and are not programmed in the LMI system.

The size of the bucket has to be determined according to local conditions.

Boom length (m)

TLT 11238543 M00000 Vorab1

Maximum capacity in duty cycle operation with standard ropes

Line pull (1st layer) 500 kN

Rope diameter 46 mm

Minimum breaking load 176 0 kN

Line pull - 1-rope duty cycle operation 50 t

Line pull - 2-rope duty cycle operation

Capacities in duty cycle operation are for reference only and are not programmed in the LMI system.

All loads and counterweight confi gurations are max. values and must not be exceeded.

Weight of additional equipment on boom (e.g. walkways, hose drums etc.) must be deducted to get the net capacity.

1)

75.8 t

1) Lifting a load exceeding the line pull of one winch is only allowed

if it can be ensured that each individual winch is not overloaded.

When working with a mechanical 2-rope grab the total load

to be lifted is limited by the line pull of one winch.

Rigging and ropes are part of the load.

2) Max. capacities in metric tonnes do not exceed 75% of

tipping load. Crane standing on fi rm, horizontal ground.

HS 8300 HD 11

Page 12

Equipment (78.7 t counterweight)

Clamshell

Clamshell

Winch options 2 x 500 kN

Line speed 1st layer 0-125 m/min

12 HS 83 00 HD

Page 13

Clamshell equipment (main boom

78.7 t counterweight

No. 2724.32)

C

Working diagram

C = Radius / dumping radius

J = Height of boom head sheave

centre above ground level

2000

K = Length of clamshell

(according to manufacturer‘s

specifi cation)

J

K

Max. capacities in metric tonnes do not exceed 66.7% of tipping load.

Capacities in duty cycle operation are for reference only and are not programmed in the LMI system.

Capac ities in metric tonnes for boom lengths (20 m - 5 0 m) Counterweight 78.7 t

Boom length (m)

20 26 32 38 44 47 50

alpha C J C J C J C J C J C J C J

(m) (m) (t) (m) (m) (t) (m) (m) (t) (m) (m) (t) (m) (m) (t) (m) (m) (t) (m) (m) (t)

65 12.3 21.2 75.8 14.8 26.6 75.8 17.3 32.0 63.6 19.9 37.5 51.9 22.4 42.9 43.0 23.7 45.6 39.2 24.9 48.3 35.8

60 13.8 20.3 75.8 16.8 25.5 67.0 19.8 30.7 52.9 22.8 35.8 42.6 25.8 41.0 34.8 27.3 43.6 31.5 28.8 46.2 28.5

55 15.2 19.2 75.8 18.6 24.2 57.8 22.1 29.1 45.2 25.5 34.0 36.0 28.9 38.9 29.0 30.7 41.4 26.0 32.4 43.8 23.3

50 16.5 18.1 68.5 20.4 22.7 51.0 24.2 27.3 39.5 28.1 31.9 31.1 31.9 36.5 24.7 33.9 38.8 21.4 35.8 41.1 18.5

45 17.7 16.8 62.0 22.0 21.1 45.8 26.2 25.3 35.1 30.4 29.6 26.7 34.7 33.8 20.1 36.8 35.9 17.2 38.9 38.0 14.4

40 18.8 15.5 56.9 23.4 19.3 40.5 28.0 23.2 29.8 32.6 27.0 22.2 37.2 30.9 16.4 39.5 32.8 13.8 41.8 34.8 10.5

35 19.8 14.0 51.2 24.7 17.5 33.9 29.6 20.9 25.2 34.5 24.4 18.4 39.5 27.8 13.3 41.9 29.5 10.9 44.4 31.2 7.4

30 20.6 12.5 39.6 25.8 15.5 28.8 31.0 18.5 21.2 36.2 21.5 15.2 41.4 24.5 10.6 44.0 26.0 8.3 46.6 27.5 4.9

25 21.4 10.9 33.5 26.8 13.4 24.4 32.2 16.0 17.8 37.7 18.5 12.4 43.1 21.0 8.2 45.8 22.3 6.2 48.5 23.6 3.1

TLT 11238473 M00000 Vorab1

HS 8300 HD 13

Page 14

Working range - main boom (No. 2724.32) 84° – 15°

84°

78.7 t counterweight

ft

m

72

80°

84°

220

200

180

160

140

120

100

80

60

68

64

60

56

52

48

44

40

36

32

28

24

20

16

30°

40°

70°

60°

50°

68 m

65 m

62 m

59 m

56 m

53 m

50 m

47 m

44 m

41 m

38 m

35 m

32 m

29 m

26 m

23 m

20 m

15°

40

12

8

20

4

0

200 180 160 140 120 100 80 60 40 20 ft0

48525660 40 2444 36 2032 1628 12 048 m

Main boom confi guration (Table 1 - No. 2724.32)

Confi guration for boom lengths (20 m - 68 m)

Length Amount of boom extensions

Boom foot 10.0 m 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

Boom section 3.0 m 1 1 1 1 1 1 1 1

Boom section 6.0 m 1 1 1 1 1 1 1 1

Boom section 12.0 m 1 1 1 1 2 2 2 2 3 3 3 3 4

Boom head 10.0 m 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

Boom length (m) 20 23 26 29 32 35 38 41 44 47 50 53 56 59 62 65 68

14 HS 8 300 HD

Page 15

Load chart for lift crane operation

(

main boom No. 2724.32)

78.7 t counterweight

Capacities in metric tonnes for boom lengths (20 m - 68 m) - with 500 kN winches and 78.7 t counterwe ight

Boom length (m)

Radius 20 23 26 29 32 35 38 41 44 47 50 53 56 59 62 65 68 Radius

(m) t t t t t t t t t t t t t t t t t (m)

5.4 300.0 5.4

6 299.8 299.6 286.5 6

7 258.9 249.0 239.8 230.9 222.7 216.5 7

8 218.4 211.0 204.1 197.4 191.1 185.0 179.2 173.7 168.3 8

9 188.4 182.6 177.2 171.9 167.0 162.1 157.4 152.8 148.5 144.3 140.2 136.3 9

10 165.3 160.7 156.3 151.9 147.9 143.8 139.9 136.1 132.4 128.9 125.4 122.0 118.7 115.6 112.1 10

12 129.0 128.8 125.8 122.6 119.7 116.7 113.8 110.9 108.2 105.5 102.8 100.2 97.6 95.1 92.7 90.3 87.9 12

14 103.2 103.2 103.1 102.0 99.9 97.5 95.2 92.9 90.7 88.5 86.3 84.2 82.1 80.0 78.0 76.0 74.0 14

16 85.3 85.3 85.2 84.9 84.8 83.2 81.3 79.3 77.5 75.6 73.8 71.9 70.2 68.4 66.6 64.9 63.2 16

18 72.1 72.1 72.1 71.7 71.6 71.2 70.4 68.7 67.2 65.5 63.9 62.2 60.7 59.1 57.6 56.0 54.5 18

20 61.8 61.9 62.0 61.6 61.5 61.1 60.7 60.1 58.9 57.4 55.9 54.4 53.1 51.6 50.2 48.8 47.4 20

22 38.8 53.8 53.9 53.6 53.5 53.1 52.7 52.1 51.8 50.6 49.3 47.9 46.7 45.4 44.1 42.7 41.5 22

24 46.0 47.4 47.1 47.1 46.6 46.2 45.6 45.3 44.7 43.8 42.5 41.4 40.1 38.9 38.2 37.0 24

26 41.9 41.6 41.7 41.2 40.8 40.3 39.9 39.3 38.8 38.3 37.3 36.1 35.0 33.8 32.7 26

28 32.7 37.0 37.5 37.1 36.7 36.1 35.8 35.3 34.7 34.1 33.3 32.2 31.1 30.0 29.0 28

30 32.9 33.6 33.1 32.8 32.3 31.9 31.4 30.9 30.3 29.8 28.8 27.7 26.6 25.7 30

32 30.1 29.7 29.4 28.9 28.6 28.0 27.5 26.9 26.4 25.8 24.8 23.7 22.8 32

34 26.7 26.5 25.9 25.6 25.1 24.6 24.0 23.5 22.9 22.1 21.1 20.2 34

36 23.7 23.8 23.3 23.1 22.5 22.0 21.4 20.9 20.3 19.7 18.7 17.9 36

38 21.4 21.0 20.7 20.2 19.7 19.1 18.6 18.0 17.4 16.6 15.8 38

40 18.9 18.7 18.1 17.6 17.0 16.6 16.0 15.4 14.7 13.9 40

42 16.8 16.8 16.2 15.8 15.2 14.7 14.1 13.6 12.9 12.2 42

44 15.0 14.5 14.1 13.5 13.1 12.4 11.9 11.2 10.6 44

46 13.0 12.5 11.9 11.5 10.9 10.4 9.7 9.2 46

48 11.2 11.1 10.5 10.2 9.5 9.0 8.3 7.8 48

50 9.8 9.2 8.9 8.2 7.7 7.0 6.6

55 6.0 5.4 4.9 4.3 3.8 55

60 2.

Above load chart is for reference only. For actual lift duty please refer to load char t in operator’s cab or manual.

9 2.6 60

TLT 10593659 M00000 Vorab3

50

HS 8300 HD 15

Page 16

Liebherr-Werk Nenzing GmbH

Dr. Hans Liebherr Str. 1, 6710 Nenzing/Austria

Tel.: +43 50809 41–473, Fax: +43 50809 41–499

crawler.crane@liebherr.com, www.liebherr.com

facebook.com/LiebherrConstruction

HS 8300 HD – 11244650 – 03/2013 Subject to cha nge wit hout not ice.

Loading...

Loading...