Page 1

Liebherr hydraulic

crawler cranes

Page 2

Defining

new standards

Flexibility, rentability and excellent performance are the

distinguishing features of the hydraulic crawler cranes (HS

series). On the international building machinery market

Liebherr-Werk Nenzing GmbH, Austria, is the leading producer of modern hydraulic crawler cranes, lift cranes and

carrier machines for special deep foundation applications.

2

Page 3

3

2

1

4

5

Performance through

leading technology

The hydraulic crawler cranes achieve excellent performance due to leading technology developed in-

1

performance winches with integrated brakes, the electronic

control as well as the machine and process data recording

system defi ne new standards.

house. State-of-the-art Liebherr diesel engines, high

2

Flexibility in all respects

With their modular concept Liebherr hydraulic crawler cranes fulfi l all requirements,

especially in the fi elds of special and deep

foundation, extraction, material handling

as well as demolition and recycling.

3

Economy in all respects

Effi cient transport, easy assembly and

high productivity combined with low operational costs are convincing features

of Liebherr hydraulic crawler cranes.

First-class comfort for

higher productivity

Even the standard equipment includes numerous innovative tech-

4

eration. The ergonomic cabin design provides the

operator with an unobstructed view of the entire

working area.

5

Liebherr guarantees continuous availability of its hydraulic crawler cranes throughout the world.

nical features ensuring ease of op-

Effective service

Thanks to low maintenance requirements, the possibility of remote diagnosis, quick assistance on site

and an effi cient spare parts supply,

3

Page 4

1

Performance through

leading technology

High fl exibility and excellent performance determine the application possibilities of Liebherr hydraulic crawler cranes.

Whether used with dragline bucket, slurry wall grab or casing oscillator – the large dimensioned Liebherr diesel engines always guarantee maximum performance. Equipment such as vibrators or casing oscillators can be operated

without additional power pack. Moreover, the powerful and maintenance-free free-fall winches are designed to fulfi l

1

highest demands and afford effi cient and safe operation.

4

Page 5

Unique selling points:

• State-of-the-art electronic control system

• Powerful Liebherr diesel engines

• Large dimensioned and maintenance-free free-fall winches

• Strong crawler and swing drive components

• Extremely robust steel structure

5

Page 6

Control system

The core of the Liebherr hydraulic crawler cranes is the Litronic control

system. Developed and manufactured by Liebherr, this comprehensive

system encompasses all control and monitoring functions and is designed for extreme environmental conditions in tough assignments.

All information, warnings and failure indications required for the current machine operation are clearly displayed on the monitor in the

operator‘s cab and stored. Documentation of operating data enables

optimum diagnosis as well as early detection and prevention of more

serious defects.

An electro-hydraulic proportional control allows several movements to

be performed simultaneously. This ensures that all categories of loads

can be positioned with utmost precision.

Automated control systems, e.g. for dynamic soil compaction or an

“Interlock” control system for dragline application are available as an

option.

6

Page 7

7

Page 8

Drives

8

Page 9

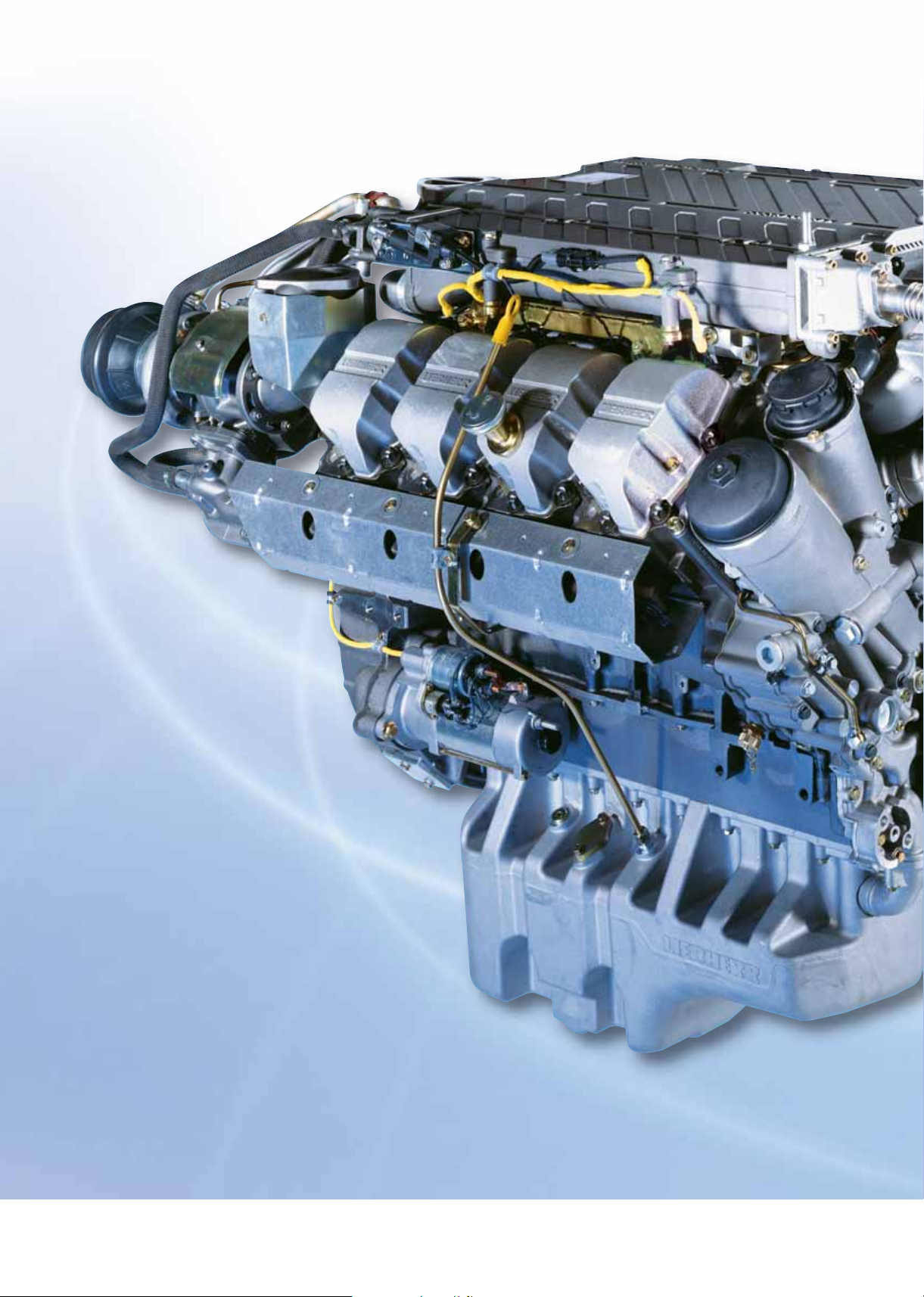

Liebherr hydraulic crawler cranes are equipped

with powerful Liebherr diesel engines. Specially designed for dynamic applications in heavy-duty construction tasks, they are extremely reliable, durable

and easy to service. The electronic control monitors

and checks all machine data. Since engine electronics and crane control are optimally matched,

the diesel engine can be directly inter-linked with

the regulation of the hydraulic system, thus affording even more ease of operation. Possible failures

are detected and localized immediately by the diagnostics system. All movements can be carried out

simultaneously. Depending on the machine class,

diesel engines ranging from 180 kW to 670 kW

power are available.

9

Page 10

Winches

The maintenance-free Liebherr free-fall winches are installed as complete

units. The new concept with integrated drive and multi-disc brakes allows

increased drum width with the same outside dimensions, thereby increasing

rope capacity on the fi rst layer. This produces a longer rope life and reduced

operational costs. The integrated free-fall brakes prove their worth espe-

cially in diffi cult free-fall operations with heavy loads. The main winches are

driven via an axial piston displacement pump and a variable fl ow oil motor

in closed circuit. This design allows precise work cycles for all winch

movements. The supplied energy is ideally used in acceleration and

braking of the winches and regained when operating in the power

lowering mode.

Through automatic speed adjustment according to line pull

the high pressure controlled, variable fl ow hydraulic motors

allow full utilization of engine power even when working

with intermediate load.

10

Page 11

For example, an “Interlock” control system for dragline operations allows

power lowering of the grab line when raising the dragline bucket with the

hoist rope which signifi cantly reduces fuel consumption. The tagline winch

is used as a constant tension or free-fall winch and enables effi cient work

with grab or demolition ball.

11

Page 12

Steel construction

The hydraulic crawler cranes’ uppercarriage with its robust and torsion-resistant box design is mounted on a large undercarriage featuring wide track

and long crawlers. This results in good ground pressure characteristics and

stability.

The external, large dimension teeth of the Liebherr swing drive guarantee optimum absorption of the high torque combined with minimum wear. Roller bearings in the swing drive ensure a superior,

low-fi t connection between upper and undercarriage. For

special applications, e.g. rotary drilling or dragline application, an additional increase in torque is achieved through

the installation of a second and/or third swing drive.

12

Page 13

13

Page 14

2

Flexibility

in all respects

A wide range of possible applications is the secret of the

Liebherr hydraulic crawler cranes’ fl exibility and lays the

foundation for optimum utilization.

2

leading to a virtually unlimited variety of applications. The hydraulic crawler

cranes are suitable for material handling with grab or dragline bucket,

demolition jobs, dynamic soil compaction, applications with slurry wall

grab or casing oscillator.

Thanks to the modular design, which is typical for Liebherr,

every crawler crane can be confi gured for its special job,

14

Page 15

151617

Page 16

Page 17

Dragline operation

The electro-hydraulic continuous proportional control of Liebherr hydraulic crawler cranes enables precise and simultaneous crane movements, which are indispensable for dragline applications. In addition, a second or third swing drive – if

required – increases swing torque resulting in short swing cycles and fast loading

cycles. The “Interlock” control system, which has been specially developed for

dragline applications, allows power lowering of the grab line when raising the

dragline bucket with the hoist rope, which saves energy and prolongs service life

of the hoist rope. The hydrostatic winch drive adapts the rope speed to the soil

conditions and always provides optimum fi lling of the dragline bucket.

Machines offering production levels of 80 - 400 m³ per hour and digging

depths of 6 - 24 m are available.

Page 18

Grab operation

The robust design of Liebherr hydraulic crawler cranes combined with the high line pull of the main

winches is ideal for working with heavy grabs. Hydrostatically driven hoist winches with variable fl ow

hydraulic motors for optimum fi lling, precise lowering and emptying of the grab, automatically distribute

the load on both winches and convert the installed engine power into maximum hoisting speed even

when working with intermediate load.

When working with material handling grabs, the constant tension winch with free-fall prevents swinging

of the grab and ensures exact positioning of the material. In combination with the powerful swing drive

this results in quick work cycles and excellent turnover in material handling.

18

Page 19

When working with a slurry wall grab, the hydraulic free-fall winches enable

precise grab handling e.g. during emptying directly onto a truck. Furthermore,

precise grab control is supported by electronic multi-functional joysticks. These

joysticks incorporate all operating elements required during operation as well

as engine speed control. Thus, the operator is able to fully concentrate on his

operating area.

19

Page 20

Soil compaction

and demolition

For dynamic soil compaction Liebherr offers an automated free-fall control system creating rope tension just before the drop weight hits the ground which reduces rope wear to a

minimum. Furthermore, this control system avoids any slacking of the rope on the winches

which is typical during free-fall applications.

Although demolition jobs present an extreme situation for operator and machine, the

design of the Liebherr hydraulic crawler cranes guarantees optimum stability even when

working with long booms. The large dimensions of the tubular booms enable lateral striking

with the demolition ball even at great heights.

20

Page 21

Special equipment for demolition

and soil compaction:

• Massive protection and armoured glass for the operator’s cab

• Hoist rope guides on the boom

• Winch for use of a personnel basket

• Cab tilting device for a better upward view

• Additional hydraulics for operation of concrete cutters

• Tagline winch for the demolition grab

• Control system for soil compaction

• High-pressure windscreen wiper system

21

Page 22

Lifting application

Only the extremely fl exible, extendable and highly effi cient boom system

of Liebherr hydraulic crawler cranes is capable of fulfi lling the widest

variety of jobsite requirements. Due to the integration of the load moment limitation in the control system some additional components, which

otherwise would have been necessary, are no longer required. The boom

confi guration can be pre-selected quickly and easily on the monitor in the

operator’s cab. The powerful system allows every possible equipment

confi guration to be operated without changing the software.

22

Page 23

Liebherr hydraulic crawler cranes

offer the following boom configurations:

• Main boom

• Auxiliary jib

• Fixed jib

Thereby, the fi xed jib sections and heads can be used for all

hydraulic crawler crane types.

23

Page 24

Special equipment

All product-related innovations have been developed in close co-operation

with customers and operators. This guarantees optimum rentability and

user-friendliness. The close contact between customers and manufacturer

is of benefi t to all Liebherr partners, whenever the customers’ own ideas

and solutions are put into practice.

24

Page 25

25

Page 26

26

Page 27

3

Economy

in all respects

Economy and good customer service commence with the machine’s transportation. Low weight and the possibility to load the single components in

a space-saving manner enable smooth transportation of Liebherr hydraulic

crawler cranes on all roads. This provides maximum savings in time and costs

3

The self-assembly and self-loading system signifi cantly reduces expenditure of time and

money. Even auxiliary cranes, which are usually required, become redundant.

For the operation of Liebherr hydraulic crawler cranes the main focus is put on economy, reliability and cost-effectiveness. These features are provided by robust and durable components,

low fuel consumption and low maintenance requirements. This is true for the powerful Liebherr

diesel engine as well as for the crane winches, the undercarriage and all other components.

even before the machine starts work on the jobsite.

27

Page 28

Efficient transport

Solid but light construction and compact design distinguish the components of Liebherr

hydraulic crawler cranes. Both of these basic features – low transport weight and low dimensions – enable Liebherr to guarantee unhindered transport on all roads on the way to the site.

All equipment can be transported on standard trucks and many crane parts are designed to

fi t into standard containers.

28

Page 29

Furthermore, the transport volume is reduced by placing the luffi ng jib sections into the main

boom sections and thanks to their low dimensions, counterweight pieces can be placed below the boom sections for transportation. Specially designed brackets allow storage of the

pendants and pins on the boom sections.

29

Page 30

Quick and easy

assembly

A special feature from Liebherr is the time and cost saving self-assembly

and self-loading system. The auxiliary crane usually needed and its related

costs are eliminated thanks to this standardized system.

For transportation of the heavy hydraulic crawler cranes the crawlers have

to be removed from the basic machine. Self-assembly starts with the

unloading of the basic machine. The hydraulic crawler crane raises itself

using hydraulic jacks (Jack-Up System) allowing the low loader to simply drive away. Subsequently the uppercarriage unloads the crawlers,

counterweight and boom sections using either its A-frame or boom foot.

Hydraulically activated pins, quick connections and an auxiliary winch for

rope reeving facilitate and accelerate the assembly process. All boom confi gurations can be erected by the crawler cranes themselves.

30

Page 31

31

Page 32

Cost-effective operation

For the contractor the costs per achieved production unit are of vital importance.

This is why Liebherr offers a highly effi cient machine with low operational costs.

All applied components are designed for reliability and longevity in order to reduce

downtime and minimize repair costs.

Apart from their excellent performance, Liebherr diesel engines are outstanding in

their economical consumption. Moreover, the maintenance-free free-fall winches

as well as the lifetime lubricated undercarriage components are equally customerfriendly and signifi cantly reduce maintenance requirements.

32

Page 33

33

Page 34

4

First-class comfort for

higher productivity

In the spacious cabin featuring a seat with multiple adjustments as well

as air conditioning, all operating elements are clearly and ergonomically arranged. All machine movements are controlled proportionally

and precisely by one joystick, one double T-lever and foot pedals. As

4

view of the entire working area.

Everything has been done to facilitate the handling of the hydraulic crawler crane for the

operator. Stepless cabin tilting up to 20 degrees for a better upward view is available

as an option. For special applications Liebherr also offers hydraulic cabin elevation. All

service points are easy to access which considerably facilitates maintenance work.

an option two joysticks for crane operation and special applications

can be delivered. Generous all-round glazing ensures an unobstructed

34

Page 35

35

Page 36

5

Effective service

Liebherr guarantees its customers optimum worldwide service and availability of spare parts at any

operating point. Moreover, failures can be detected

and sometimes directly repaired via GSM service

5

this modem. Downtime is reduced, the machine is available for a

longer period of time and consequently time and costs are saved.

modem and remote diagnosis. Software updates as

well as maintenance work can be carried out with

36

Page 37

37

Page 38

Rapid service

on site

Permanent readiness for operation is a major prerequisite for a smooth

and effi cient application on the jobsite. Downtime is enormously expensive and has to be reduced to a minimum. A tight network of

service stations with qualifi ed contacts and well-trained personnel

guarantees quick assistance at any place and any time. The required

spare parts are also available at short notice.

38

Page 39

39

Page 40

Liebherr-Werk

Nenzing GmbH

Printed in Germany by Höhn BK-RP LWN-10350607-2.5-04.07

Liebherr-Werk Nenzing GmbH

Postfach 10, A-6710 Nenzing

콯 +43 (0) 50809 41-473, Fax +43 (0) 50809 41-499

www.liebherr.com, E-Mail: crawler.crane@liebherr.com

Illustrations and data may differ from standard equipment. Subject to change without notice.

Loading...

Loading...