Liebherr HS8100HD User Manual

Hydraulic

Diaphragm Wall Grab

Mechanical

Diaphragm Wall Grab

Stop End Pipes

Hydraulic Tube Extracting

Equipment

Interlocking Tremie Pipes

Hydraulic

Diaphragm Wall Grab

Technical Data

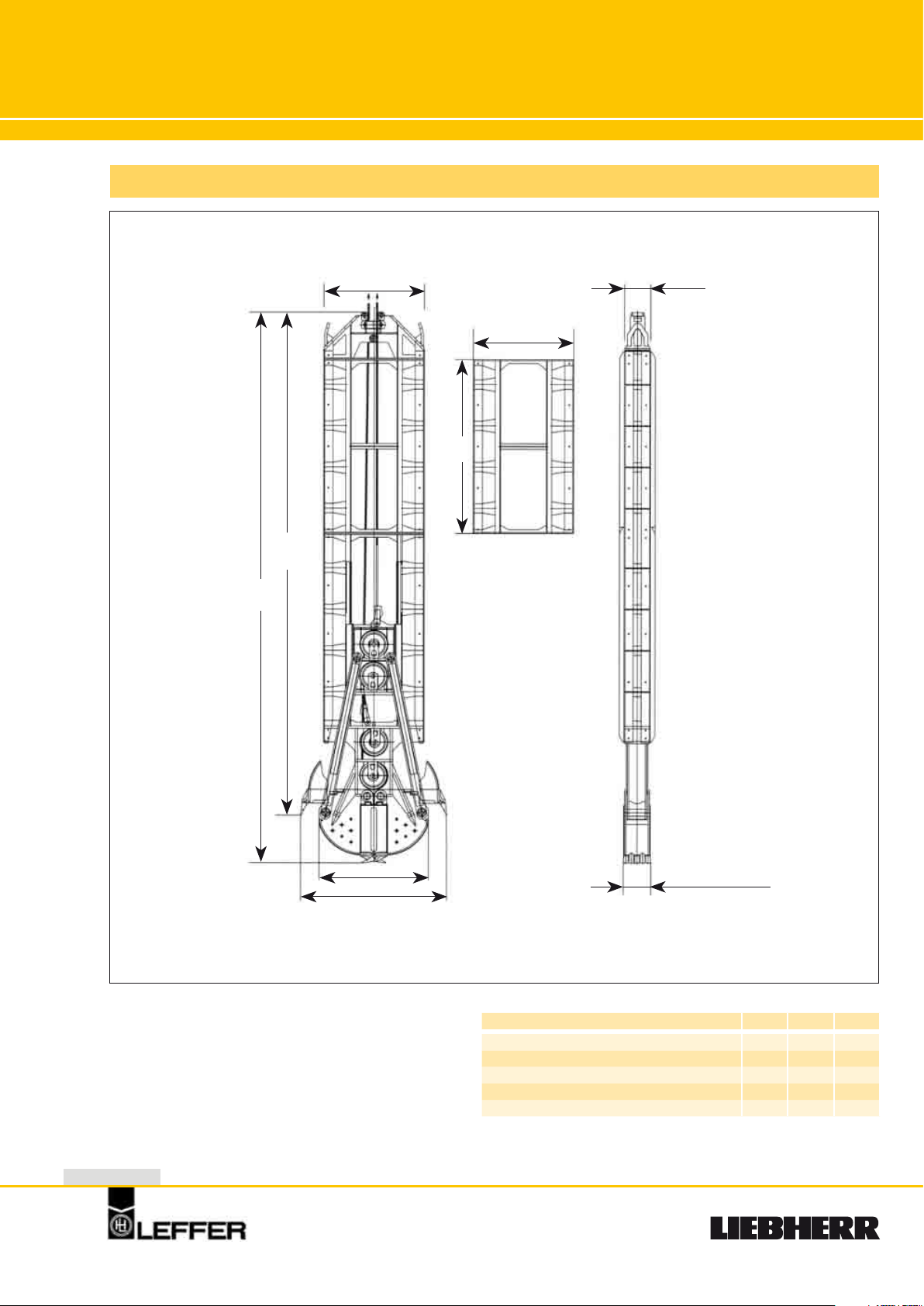

Hydraulic tilting of the grab

X, Y and rotation ± 100°

The hydraulic tilting with inclination measuring and monitoring of the operator's

cabin guarantees a verticality of the diaphragm wall of 1:800. To certify the verticality of the trench the measured data can

be stored and printed out. (Patents in

many countries).

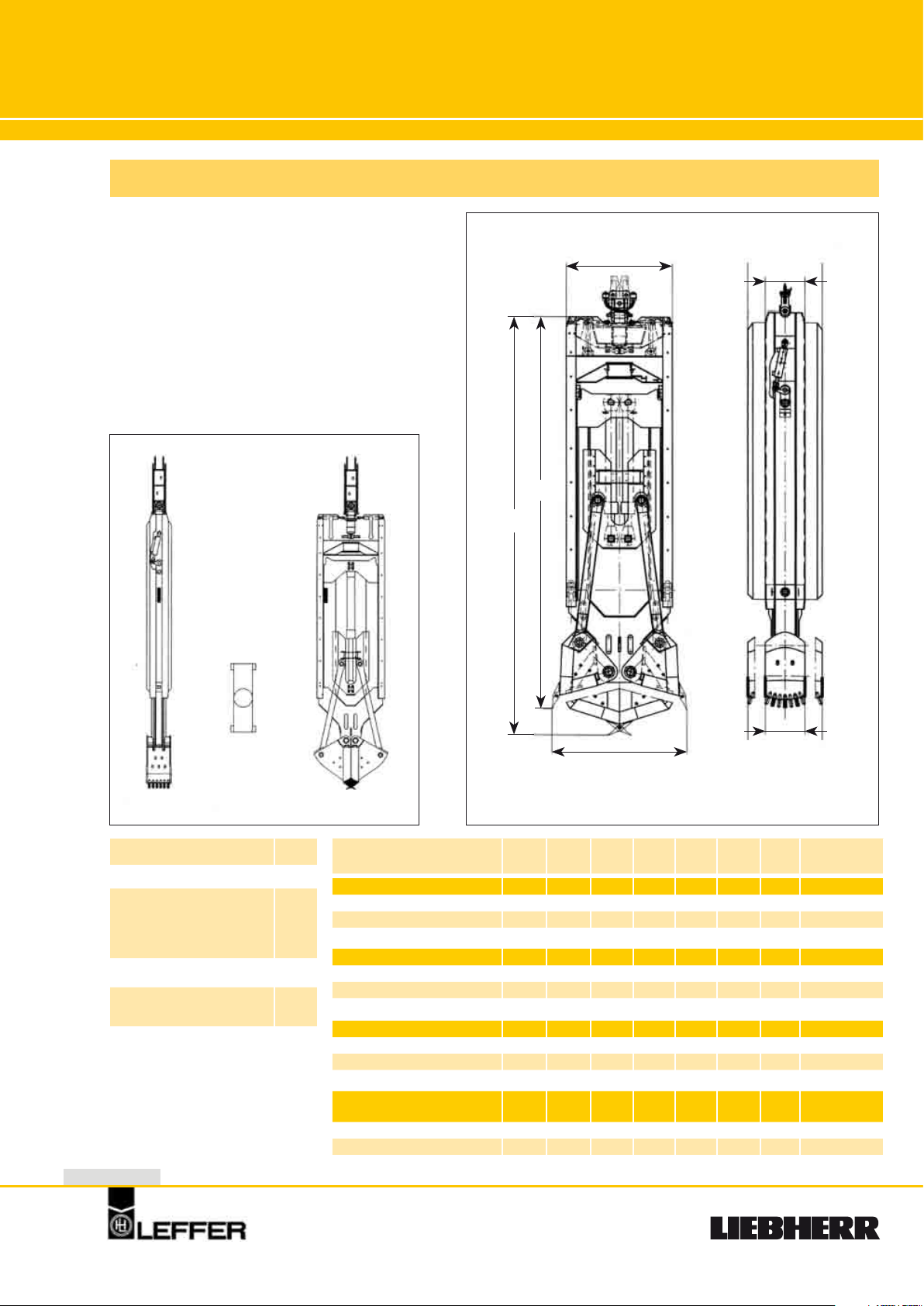

HSWG

2200

800

~8200

Inclination detection x,y

Inclination adjusting ±2°

Lifting and lowering

speed (max.)

Hydraulic pressure

(max.)

Closing force kN 1000

Closing/opening

time

2

m/min 50

bar 320

sec 8/5

~8750

800

2.8 or 3.2

Wall width mm 600 700 800 900 1000 1200 1500

HSWG 3.2/600-1000

Grab weight kg 14000 14500 15000 15500 16000 - Open shell width (max.)

Capacity l 900 1100 1300 1500 1700 - -

HSWG 3.2/800-1200

Grab weight kg - - 15000 - 17000 19000 Open shell width (max.)

Capacity l - - 1500 - 1700 2200 -

HSWG 3.2/800-1500

Grab weight kg - - 23000 - 24500 25500 27000

Open shell width (max.)

Capacity l - - 1500 - 1700 2200 3000

HSWG 3.2/1000-1500

Grab weight kg - - - - 17000 19000 22000

Open shell width (max.)

Capacity l - - - - 1700 2200 3000

m 3,2 3,2 3,2 3,2 3,2 - -

m - - 3,2 - 3,2 3,2 -

m - - 3,2 - 3,2 3,2 3,2

m - - - - 3,2 3,2 3,2

Liebherr

Crawler crane

HS 845

HS 855

HS 855

HS 875 or

HS 885

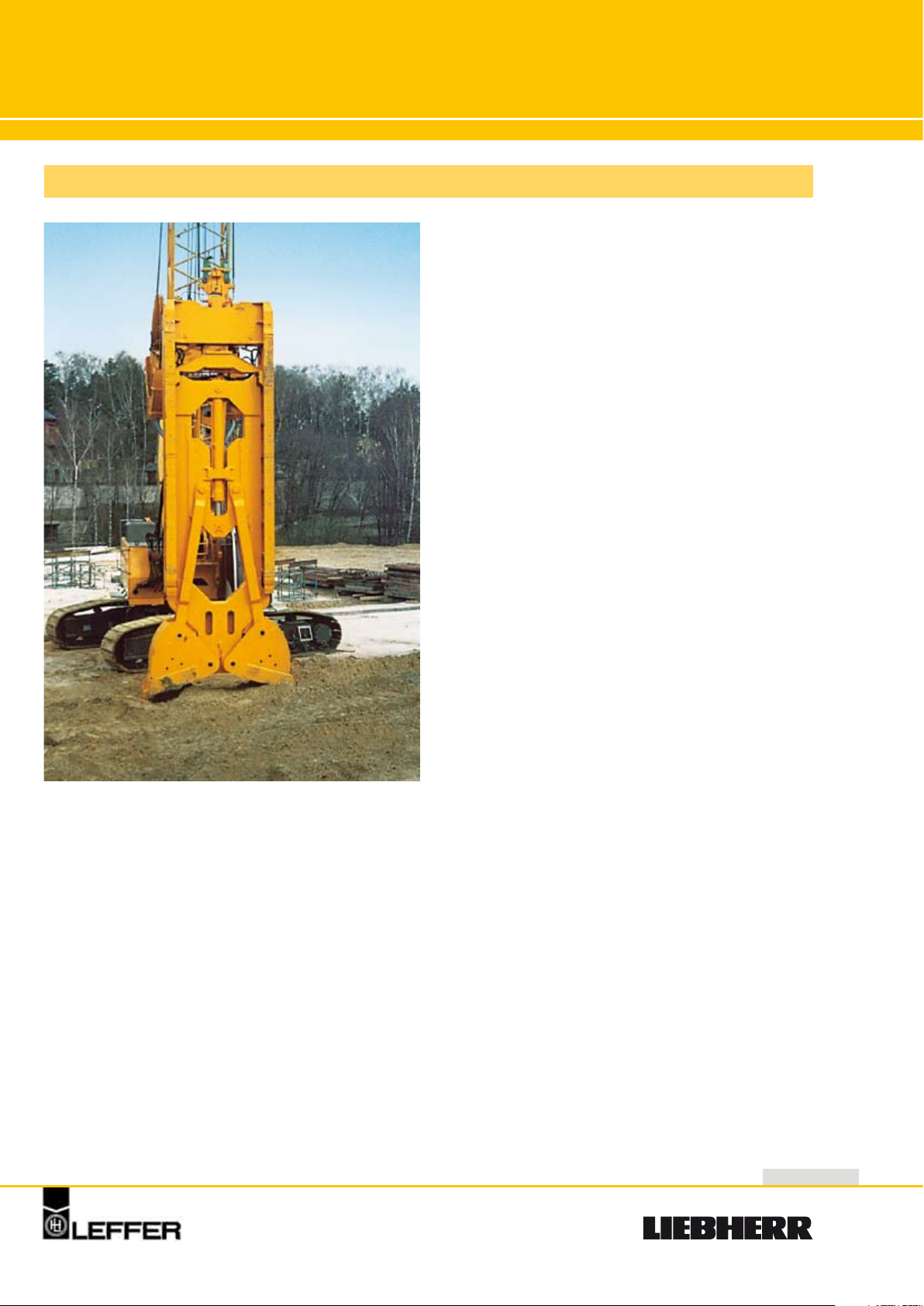

Hydraulic

Diaphragm Wall Grab

General Remarks

HSWG

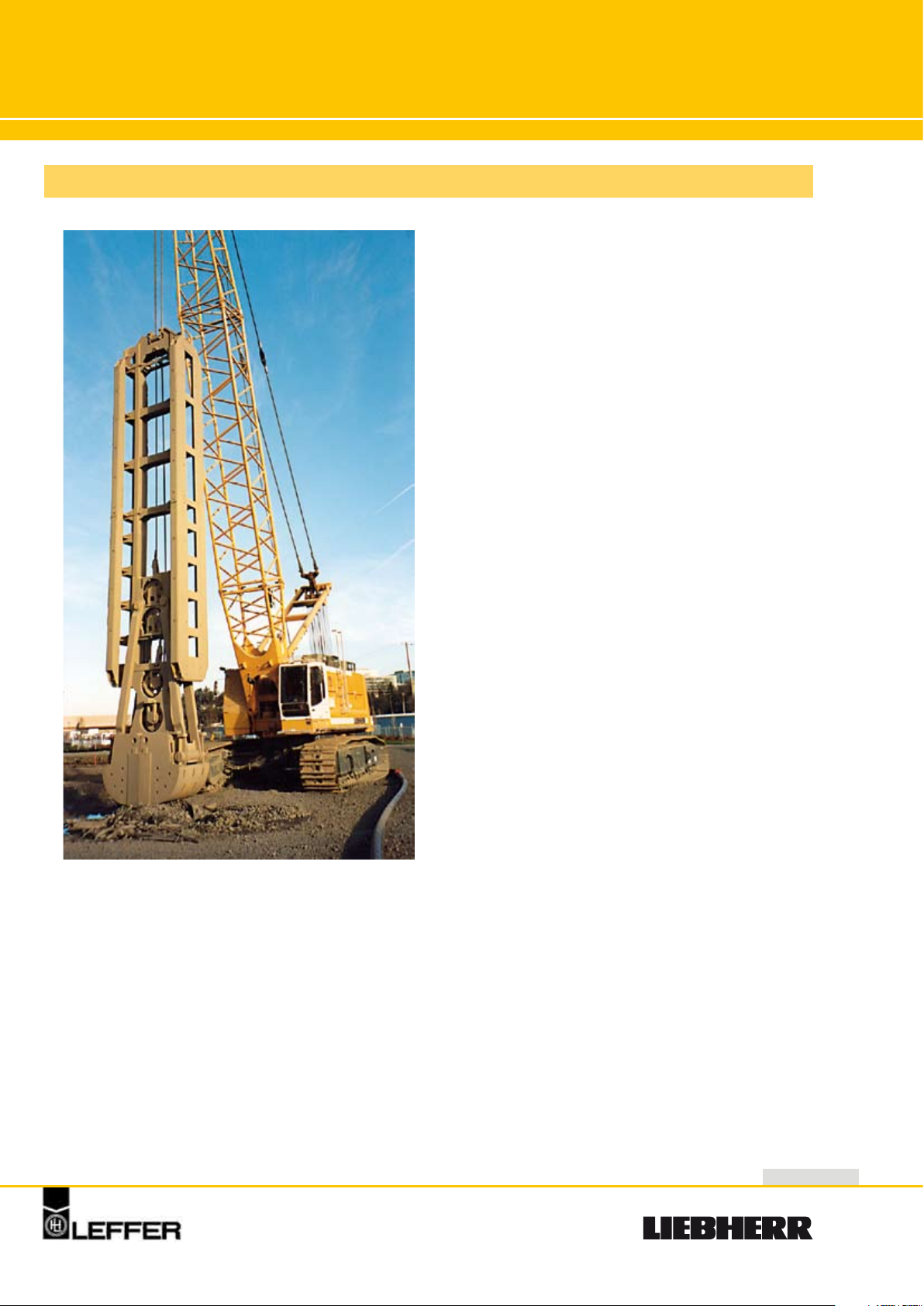

The hydraulic diaphragm wall grab HSWG is

equipped with a permanent measuring and control

system which makes it possible primarily to recognize any deviation of the vertical excavating direction immediately, and to indicate it to the control

panel of the operator and secondarily to correct any

deviation of the vertical position by means of a

modification of the direction of the grab. Thus, high

accuracy is obtained also at deeper depths (more

than 50 m) and the construction of diaphragm walls

by means of grab excavation is thus perfected. The

hydraulic diaphragm wall grab operates free of

noise and vibration.

Operation is easy compared to the mechanical diaphragm wall grab. By means of the special suspension via two ropes, each of which is deflected once,

the hydraulic diaphragm wall grab can be operated

by means of a smaller carrier unit whereby a more

economical application with improved mobility is

achieved.

The HSWG XY 200° is equipped with a deviation

control system for the x-axis and the y-axis, as well

as with a rotation control including data read-out

and monitoring system.

3

Diaphragm Wall Grab

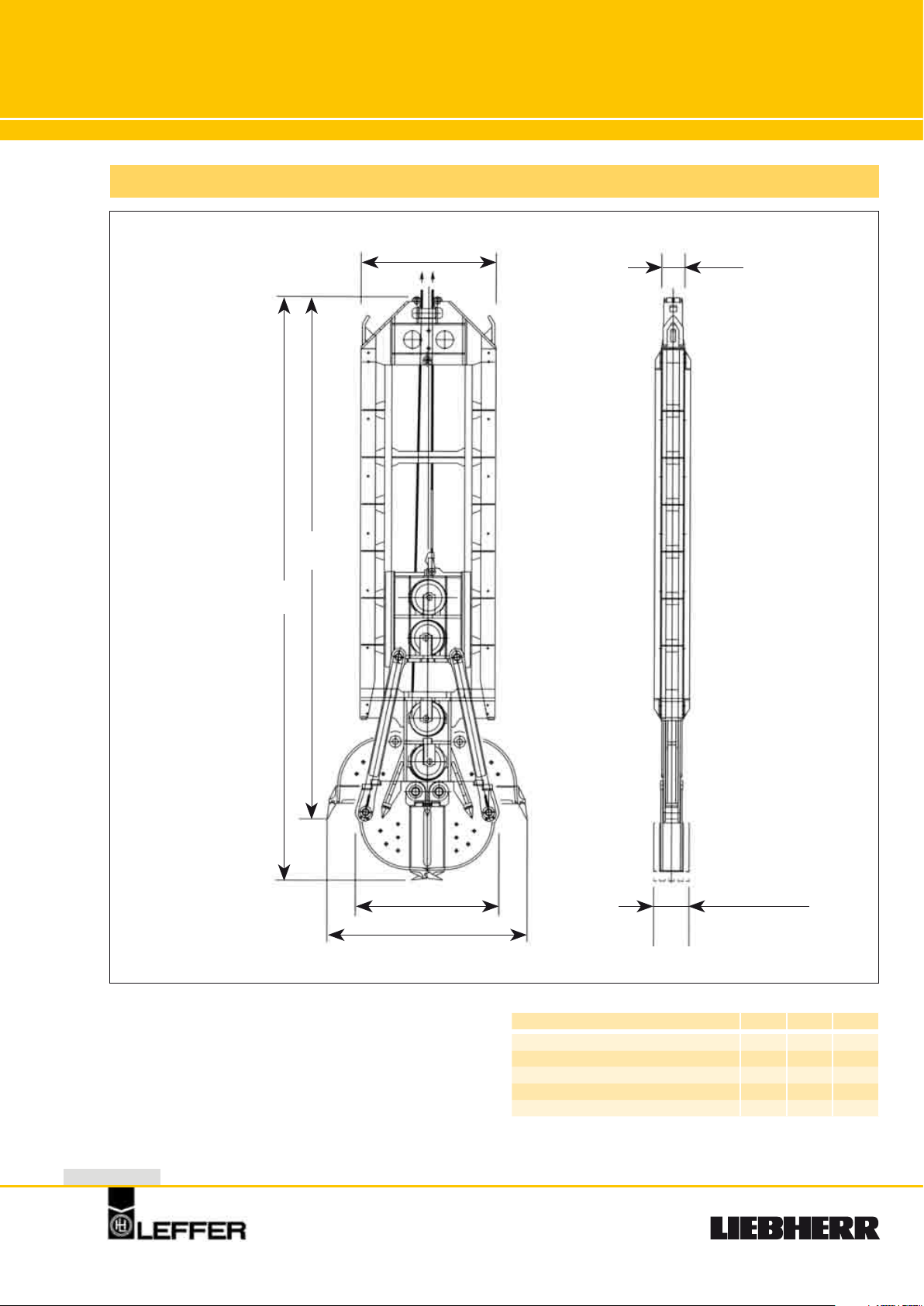

SWG 2.8 (3.4)-5/400-600

SWG

10000

8900

2300

395

2450

2800 (max. 3400)

Width of diaphragm wall mm 400 500 600

Width of basic body mm 395 395 395

Jaw capacity (2800 mm) (approx.) l 570 710 890

Jaw capacity (3400 mm) (approx.) l 690 860 1080

Quantity of pulleys 5 5 5

Weight (approx.) kg 9800 11000 11600

4

400/500/600

Diaphragm Wall Grab

General Remarks

SWG

Jaws of angular or round shape are available. The

jaws, ropes and rope pulleys can quickly be replaced on site without any problem. The teeth are

replaceable. Light chiseling work is possible. All

rope and guide pulleys have adequatley dimensioned, maintenance-free bearings filled with oil.

5

Diaphragm Wall Grab

SWG 2.8 (3.3)-6/600-1000

SWG

12000

10975

2200

575

2000

3800

Removable

extension piece

2390

2800 (max. 3300)

Width of diaphragm wall mm 600 800 1000

Width of basic body mm 580 580 580

Jaw capacity (approx.) l 890 1250 1600

Quantity of pulleys 6 6 6

Weight with extension piece (approx.) kg 12000 13700 15000

Weight without extension piece (approx.) kg 9800 11000 11600

6

600/800/1000

Loading...

Loading...