Liebherr HS8070HD User Manual

Technical data

Hydraulic crawler crane

HS 8070 HD

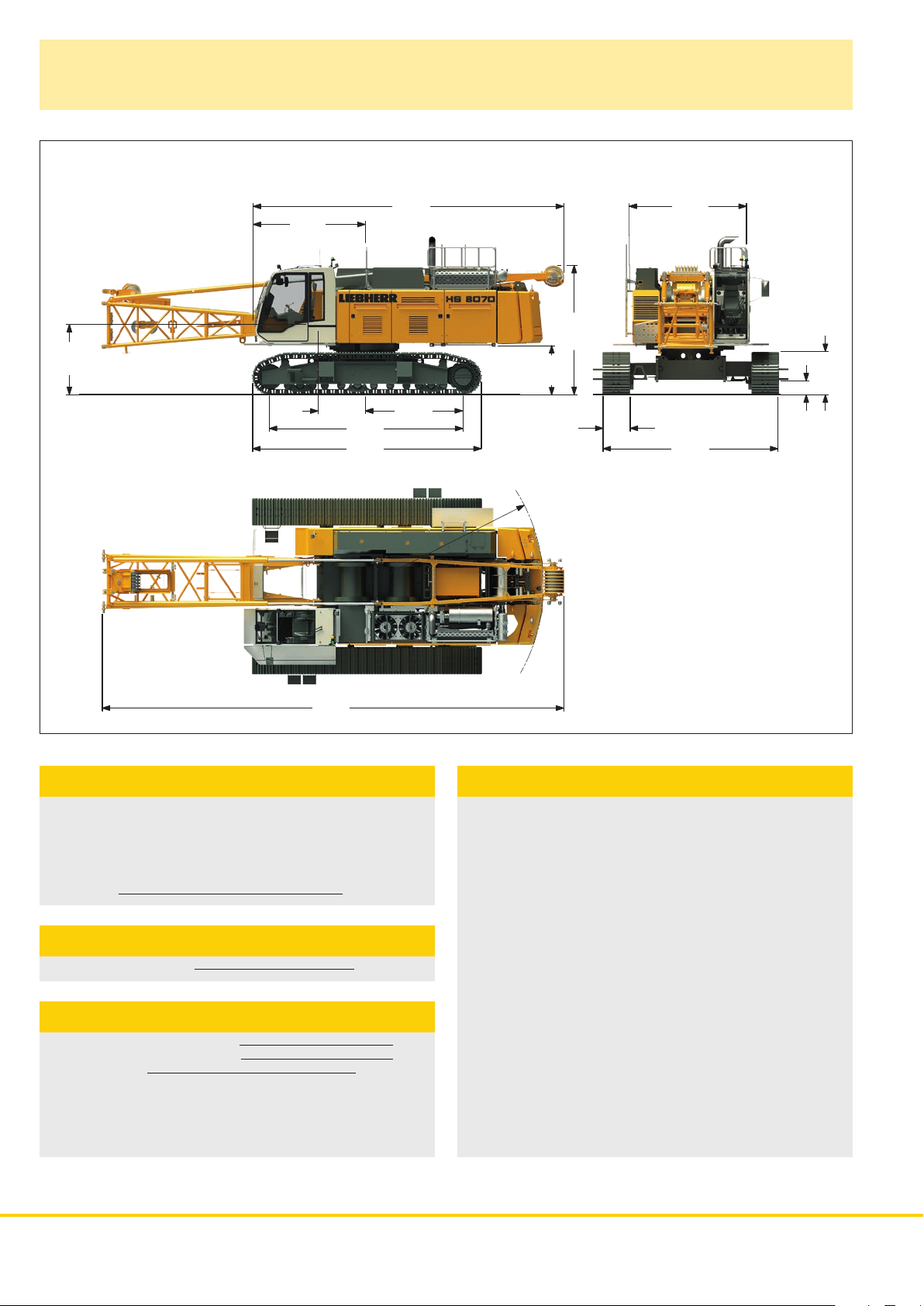

Dimensions

Basic machine with undercarriage

1800

2870

1200

5000

5920

8000

2500

R 4580

1330

3350

700

3000

1100

330

4500

11860

Operating weight

The operating weight includes the basic machine with HD undercarriage, 2 main winches 200 kN including wire ropes (90 m) und

11 m main boom, consisting of A–frame, pulley block, boom

foot (5.5 m) and boom head (5.5 m), 20 t basic counterweight,

700 mm 3-web grousers and 60 t hook block.

Total weight approx. 68 t

Ground pressure

Ground bearing pressure 0.91 kg /cm

2

Equipment

Main boom (No. 1311.18 ) max. length 56 m

Main boom (No. 1311.22 ) max. length 50 m

Fixed jib (No. 080 6.) 11 m - 32 m

Modular designed equipment for operation as crane, with dragline or

clamshell.

For dragline operation, a rotating fairlead is fitted into the boom foot.

This minimizes the rope angle to drum, which results in lower rope

wear.

Remarks

1. The lifting capacities stated are valid for lifting operation only

(corresponding with crane classification according to F.E.M.

1.001, crane group A1).

2. Crane standing on firm, horizontal ground.

3. The weight of the lifting device (hoisting ropes, hook block,

shackle etc.) must be deducted from the gross lifting capacity

to obtain a net lifting value.

4. Additional equipment on boom (e.g. boom walkways, auxiliary

jib) must be deducted to get the net lifting capacity.

5. For max. wind speed please refer to lift chart in operator‘s cab

or manual.

6. Working radii are measured from centre of swing and under

load.

7. The lifting capacities are valid for 360 degrees of swing.

8. Calculation of stability under load is based on ISO 4305

Table 1 + 2, tipping angle 4°.

9. The structures are calculated according to F.E.M. 1.001 - 1998

(EN 13001-2 / 2004).

2 HS 8070 HD

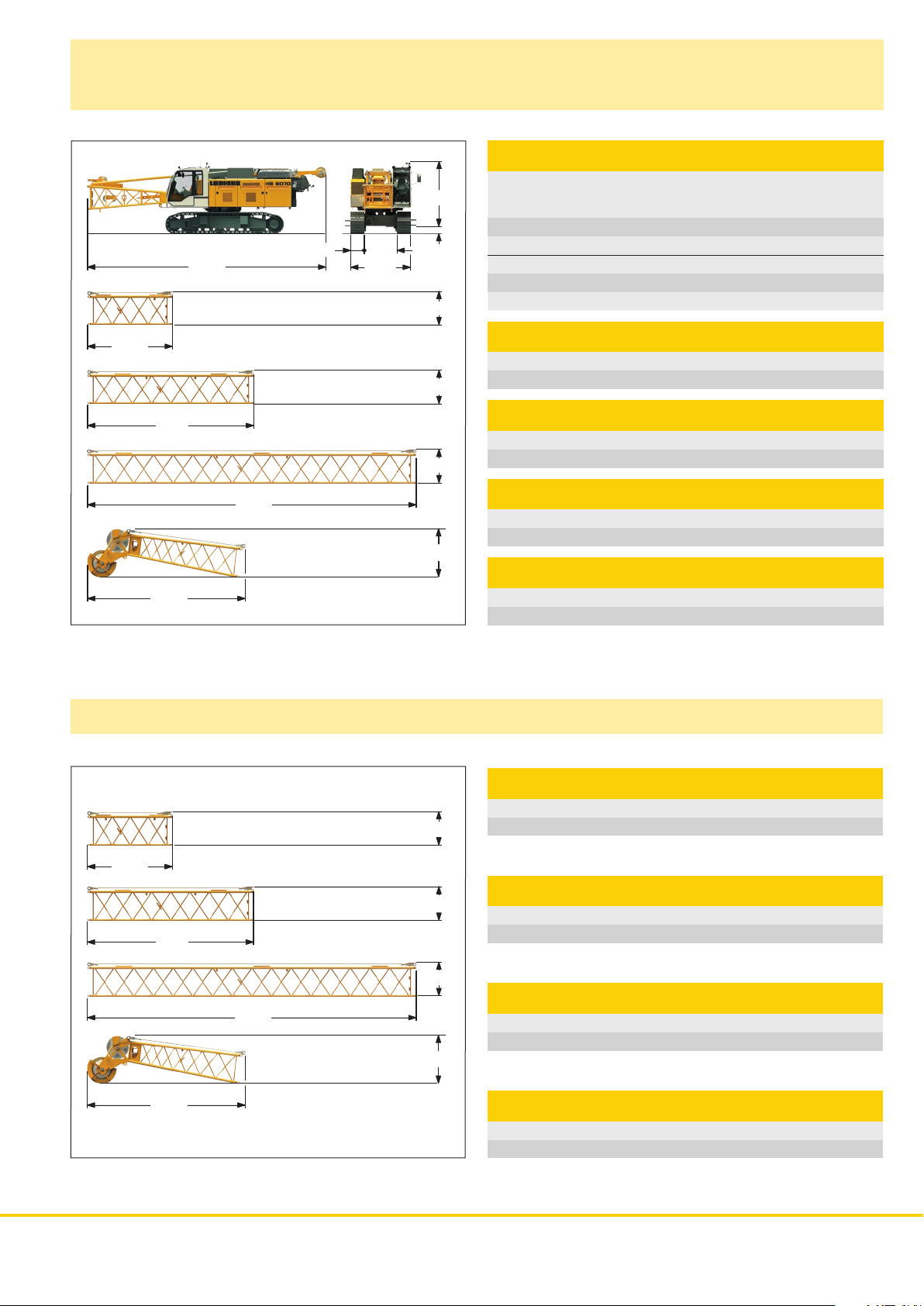

Transport dimensions and weights

Basic machine and boom (No. 1311.18)

Basic machine

with HD undercarriage, boom foot, pulley block, A-frame,

2x 200 kN winches including wire ropes (90 m), without basic

counterweight

Width with 700 mm 3-web grousers

Weight 47000 kg

Option:

Width with 800 mm 3-web grousers

Weight 47540 kg

11860

700 1600

3000

2990

330

1350

3000 mm

3390 mm

3140

1350

6140

1350

12140

1900

Boom section (No. 1311.18) 3 m

Width 1430 mm

Weight* 390 kg

Boom section (No. 1311.18) 6 m

Width 1430 mm

Weight* 620 kg

Boom section (No. 1311.18) 12 m

Width 1430 mm

Weight* 1085 kg

Boom head

6250

*) Including pendant ropes, without auxiliary equipment 1) Polyamide sheaves

Width 1400 mm

Weight* 1420 kg

Main boom (No. 1311.22)

Boom section (No. 1311.22) 3 m

Width 1430 mm

1350

Weight* 470 kg

1)

(No. 1311.18)

3140

6140

12140

6250

*) Including pendant ropes, without auxiliary equipment

1350

1350

1900

Boom section (No. 1311.22) 6 m

Width 1430 mm

Weight* 730 kg

Boom section (No. 1311.21) 12 m

Width 1430 mm

Weight* 1260 kg

Boom head

Width 1400 mm

Weight* 1610 kg

1) Polyamide sheaves

1)

(No. 1311.22)

HS 8070 HD 3

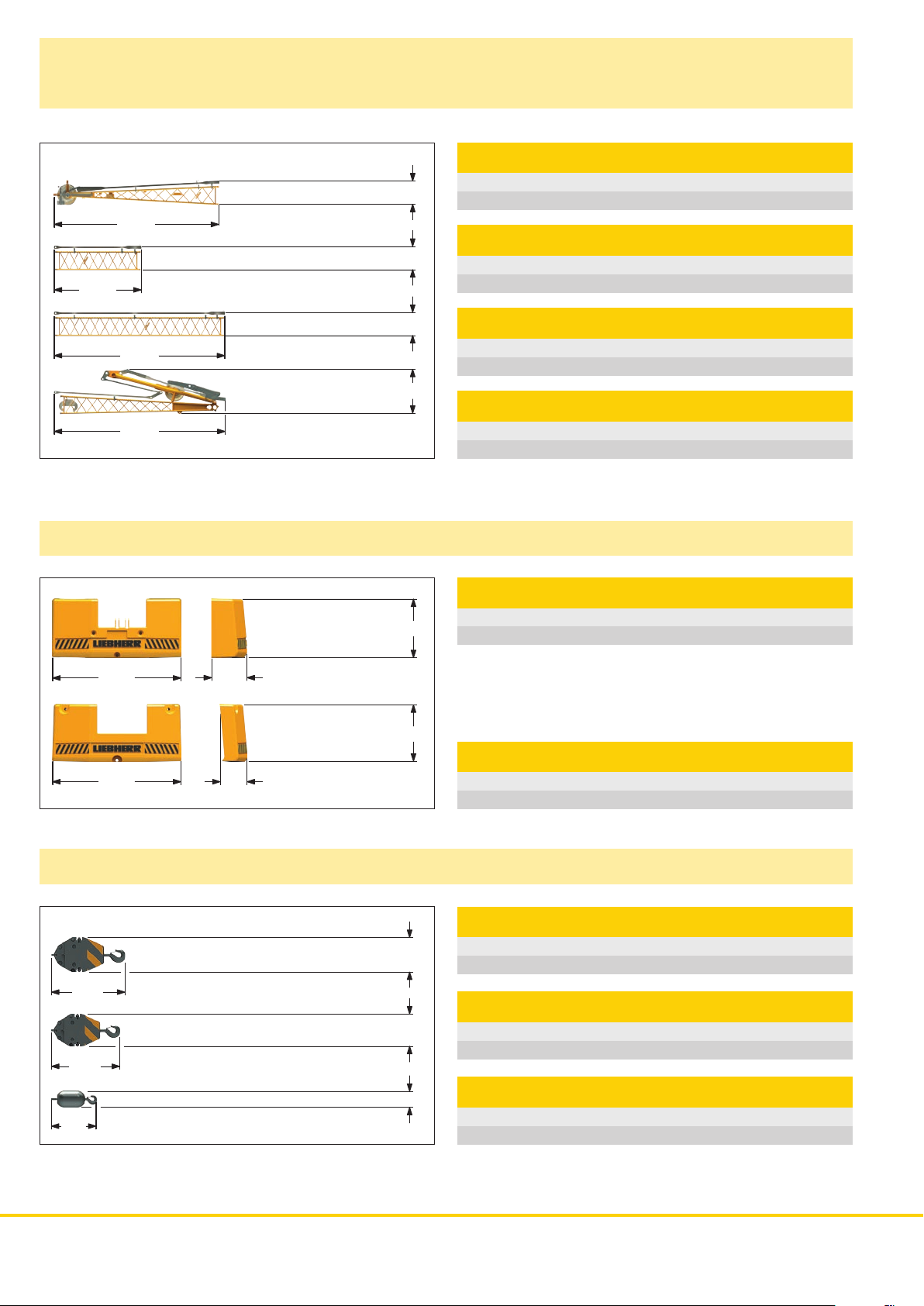

Transport dimensions and weights

Fixed jib (No. 0806.xx)

Fixed jib head (No. 0806.16)

900

6050

880

3140

Width 1140 mm

Weight* 475 kg

Fixed jib section (No. 0806.15) 3 m

Width 950 mm

Weight* 150 kg

6140

6800

*) Including pendant ropes

Counterweight

3000

3000

830

625

880

1400

1365

1330

Fixed jib section (No. 0806.15) 6 m

Width 950 mm

Weight* 252 kg

Fixed jib foot with A-frame (No. 0806.16)

Width 1500 mm

Weight* 1210 kg

Counterweight I 1x

Width 830 mm

Weight 12600 kg

Counterweight II 1x

Width 625 mm

Weight 7400 kg

Hooks

2100

1950

800

4 HS 8070 HD

1100

940

350

60 t hook block – 1 sheave

Width 350 mm

Weight 1100 kg

40 t hook block - 1 sheave

Width 350 mm

Weight 515 kg

20 t single hook

Width 350 mm

Weight 350 kg

Technical description

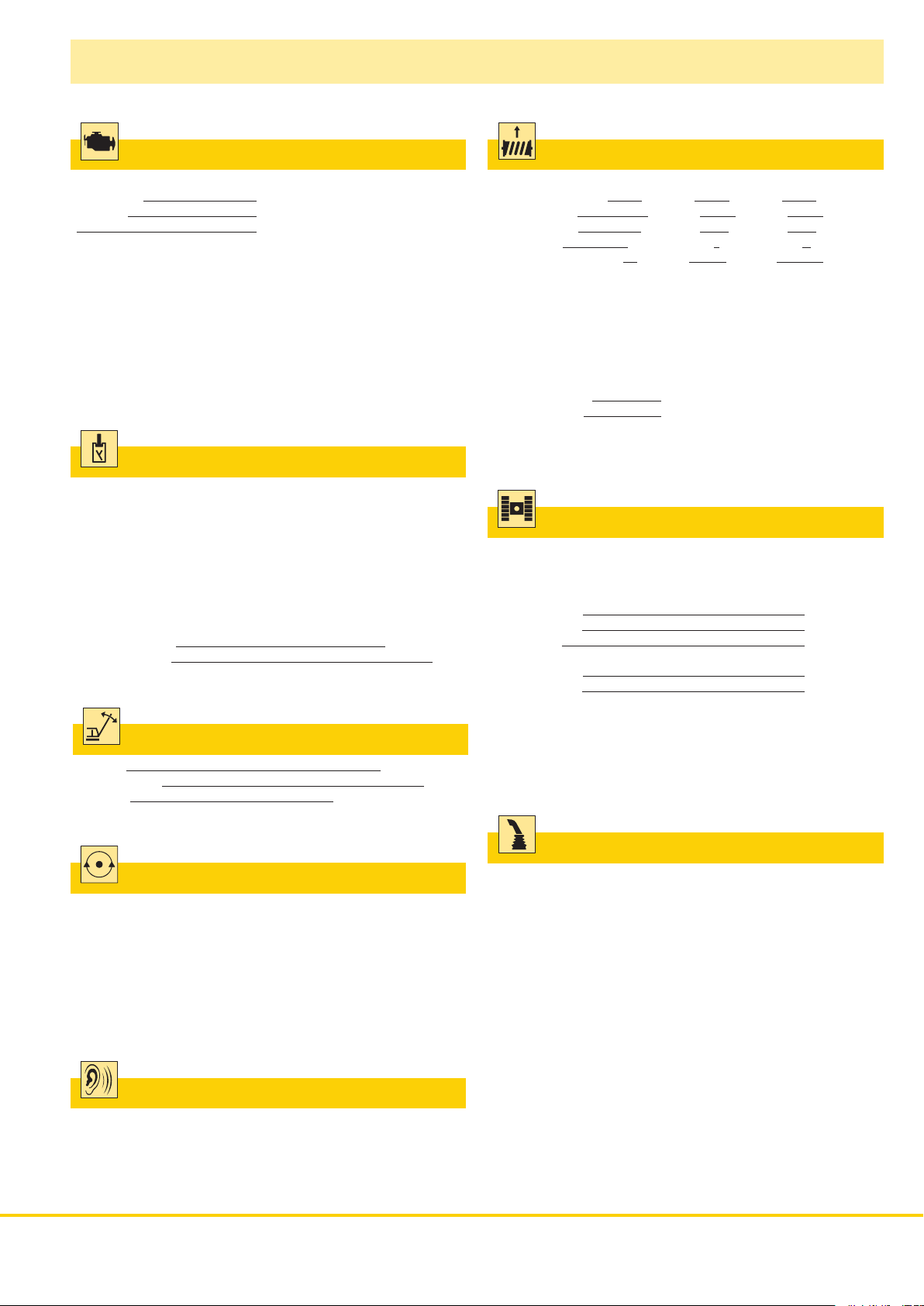

Engine

Power rating according to ISO 9249, 390 kW (523 hp) at 1900 rpm

Engine type

Fuel tank

indicator and reserve warning

Engine complies with NRMM exhaust certification EPA / CARB Tier 4i

or 97/68 EC Stage III B.

ECO-Silent-Mode:

For work not requiring high engine power, the diesel engine can be

operated in the ECO-Silent-Mode (e.g. for inserting reinforcement

cages, for dragline or lift crane operation).

Due to the ECO-Silent-Mode which can be preselected by the operator

the engine runs with optimum fuel efficiency. This lowers consumption

and reduces noise emission.

Liebherr D 856 A7 SCR

680 l capacity with continuous level

Hydraulic system

The main pumps are operated by a distributor gearbox. Axial piston

displacement pumps work in closed and open circuits supplying

oil only when needed (flow control on demand). To minimize peak

pressure an automatically working pressure cut-off is integrated.

This spares pumps and saves energy. The hydraulic oil is cleaned

through electronically controlled pressure and return filters. Possible

contamination is signaled in the cabin.

Ready made hydraulic retrofit kits are available to customize

requirements e.g. powering casing oscillators, VM–vibrators, hydraulic

grabs, fixed leaders etc.

Working pressure

Oil tank capacity

max. 400 bar

880 l

Boom winch

Main winches

Winch options:

Line pull (nom. load) 120 kN 160 kN 200 kN

Rope diameter 24 mm 26 mm 30 mm

Drum diameter 525 mm 580 mm 630 mm

Rope speed 0–133 m/min 0 -111 m/min 0-90 m/min

Rope capacity 1st layer

The winches are outstanding in their compact design and easy

assembly. Clutch and braking functions on the free-fall system are

provided by a compact designed, low wear and maintenance-free

multi–disc brake.

The drag and hoist winches use pressure controlled, variable flow

hydraulic motors. This system features sensors that automatically

adjust oil flow to provide max. winch speed depending on load.

Option:

• Auxiliar ywinch 70 kN in boom foot (13 11. 22)

• Taglinewinch 30 kN with free fall

43.5 m 51.9 m 40 m

Crawlers

The track width of the undercarriage is changed hydraulically.

Propulsion through axial piston motor, hydraulically released spring

loaded multi–disc brake, maintenance-free crawler tracks, hydraulic

chain tensioning device.

3-web grousers

Transport width

Drive speed

Option:

3-web grousers

Transport width

Option:

• 2-speedhydraulicmotorforhighertravelspeed

700 mm

3000 mm

0 – 1.5 km/h

800 mm

3390 mm

Line pull max. 2x 50 kN

Rope diameter

Boom up

18 mm

45 sec. from 15° to 82°

Swing

Consists of rollerbearing with external teeth for lower tooth flank

pressure, fixed axial piston hydraulic motor, spring loaded and

hydraulically released multi–disc holding brake, planetary gearbox and

pinion.

Swing speed from 0 –4.5 rpm continuously variable, selector for 3

speed ranges to increase swing precision.

Option:

Second swing drive

Noise emission

Noise emissions correspond with 2000/14/EC directive on noise

emission by equipment used outdoors.

Control

The core of the Liebherr hydraulic crawler cranes is the Litronic control

system.

Developed and manufactured by Liebherr, this comprehensive system

encompasses all control and monitoring functions and is designed

to withstand extreme temperature changes and the rough heavy

duty tasks common in the construction industry. Complete machine

operating data, warnings and failure indications are clearly displayed in

the required language on the high resolution monitor in the operator’s

cab.

Documentation of operating data (PDE) enables optimum diagnosis as

well as early detection and prevention of more serious defects.

An electro-hydraulic proportional control allows several movements to

be performed simultaneously. This ensures that all categories of loads

can be positioned with utmost precision.

Options:

• PDE:Processdatarecording

• GSM/GPRStelematicsmodule

• Specialdemolitioncontrolsystem

HS 8070 HD 5

Loading...

Loading...