Liebherr HRB1110 Installation Guide

Installation

Instructions

Refrigerators and freezers, fully

integrated

Instructions

de montage

Réfrigérateurs et congélateurs,

entièrement intégrables

Instrucciones

de montaje

Frigoríficos y congeladores,

integrables en mueble alto

HRB 1110/ HF 851

111012 7084158 - 03

General safety information

Contents

1 General safety information........................... 2

2 Setting up the appliance............................... 2

3 Kitchen cabinet setup................................... 3

3.1 Air circulation in the kitchen cabinet................. 3

3.2 Kitchen cabinet setup....................................... 5

3.3 Kitchen cabinet setup for the water filter........... 5

3.4 Cabinet door setup........................................... 6

4 Reversing the door........................................ 7

4.1 Detaching the soft stop mechanism................. 8

4.2 To remove the door.......................................... 8

4.3 Swapping bearing parts................................... 8

4.4 Installing the door again................................... 8

4.5 Re-attaching the soft stop mechanism............. 8

5 Water connection........................................... 9

6 Installation...................................................... 10

6.1 Assembling the appliance................................ 10

6.2 Installing the unit door...................................... 12

7 Installing the water filter............................... 14

8 Connecting the appliance............................. 15

The manufacturer is constantly working to improve all

models. Therefore please understand that we reserve the

right to make design, equipment and technical modifications.

To get to know all the benefits of your new appliance,

please read the information contained in these instructions carefully.

The instructions apply to several models, so there may be

differences. Sections which only apply to certain appliances are indicated with an asterisk (*).

Instructions for action are marked with a

results of action are marked with a .

, the

1 General safety information

Note indicates useful advice and tips.

It is important that the guidelines and instructions

in this manual are followed so that the appliance

is correctly installed and operates properly.

Read and understand all information in this

manual before the appliance is installed.

2 Setting up the appliance

WARNING

Risk of fire due to moisture!

If live parts or the power cord get wet, this can cause a

short circuit.

u

The appliance is designed for use in enclosed spaces.

Do not operate the appliance in open space or in damp

areas or where there is spray.

u

Only operate the appliance after it has been installed.

WARNING

Risk of fire due to short circuit.

If the power cable or plug of the appliance or another

appliance and the back of the appliance touch each other

the power cable or plug will be damaged by the vibrations

of the appliance which could lead to a short circuit.

u

Install the appliance so that it does not touch any plugs

or power cables.

u

Do not connect the appliance or other appliances to the

sockets on the back of the appliance.

WARNING

Danger of fire and damage!

u

Do not place devices that give off heat, e.g. microwaves, toasters, etc. on the appliance.

Read and follow these instructions. They contain

safety advice which is important for safe and

problem-free installation and operation. Always

read and follow the safety advice.

DANGER indicates a hazardous situation,

which if not avoided, will result in

death or serious injury.

WARNING indicates a hazardous situation,

which if not avoided, could result in

death or serious injury.

CAUTION indicates a hazardous situation,

which if not avoided, will result in

minor or moderate injury.

NOTICE indicates a hazardous situation,

which if not avoided, could result in

damage to property.

2

CAUTION

Risk of personal injury!

u

Have two people move this appliance into place.

NOTICE

Risk of damage caused by condensation

Installing the appliance next to any other refrigerator or

freezer can cause condensation or damage to the Liebherr appliance.

u

Do not install this appliance next to any other refrigerator or freezer except another Liebherr model. Liebherr

models are designed to allow side-by-side installation.

They are equipped with a heating system to eliminate

condensation when refrigerators or freezers are

installed side-by-side.

Kitchen cabinet setup

NOTICE

Risk of damage for the finished floor surface!

u

Protect the finished floor surface before you uncrate the

unit.

Verify that:

q

The floor under the appliance is flat and level.

q

The floor can support the appliance's weight plus

approximately 1200 pounds (544 kg) of food weight.

q

The appliance is not placed in direct sunlight or near

the stove, range top, radiators and similar heat

sources.

q

The kitchen cabinet that the appliance is installed in is

shimmed to the floor level if the floor heights are not

equal.

q

Cutout dimensions are accurate.

q

Electrical outlet is in correct location.

q

The air flow is not restricted. Air flow must be provided

for the appliance to operate properly. The factory air

vents provide 31 square inches (200 cm2) of air flow

per appliance. If you are replacing the air vents with an

overlay, the air flow must be the same or greater than

the factory air vents.

u

Examine the unit and packaging for shipping damage.

Contact the carrier immediately if you suspect there is

any damage.

u

Note the type (model, number), index, appliance/serial

number, date of purchase and where purchased .

u

Remove anything attached to the rear or side walls of

appliance that would prevent proper installation or

impede proper ventilation.

u

Unscrew the red transport

lock. Close the vacated

retaining hole using the

stopper (70).

With side-by-side configurations,

provide a separate kitchen

cabinet for each appliance.

If possible, have a professional install the appliance in

your kitchen cabinet unit.

The wall of the adjacent cabinet must be at least 5/8 ''

(16 mm) thick.

3.1 Air circulation in the kitchen cabinet

Note

u

Clean the appliance .

If the appliance is set up in humid areas, condensation

may build on the outside of the appliance.

u

Always ensure proper ventilation.

u

Assemble appliances according to separate installation

instructions.

3 Kitchen cabinet setup

This is a built-in appliance and is therefore completely

enclosed by a kitchen cabinet. The kitchen cabinet

surrounding the appliance must be set up exactly in

accordance with the specified fitting dimensions and must

allow sufficient air circulation to ensure correct operation

of the appliance.

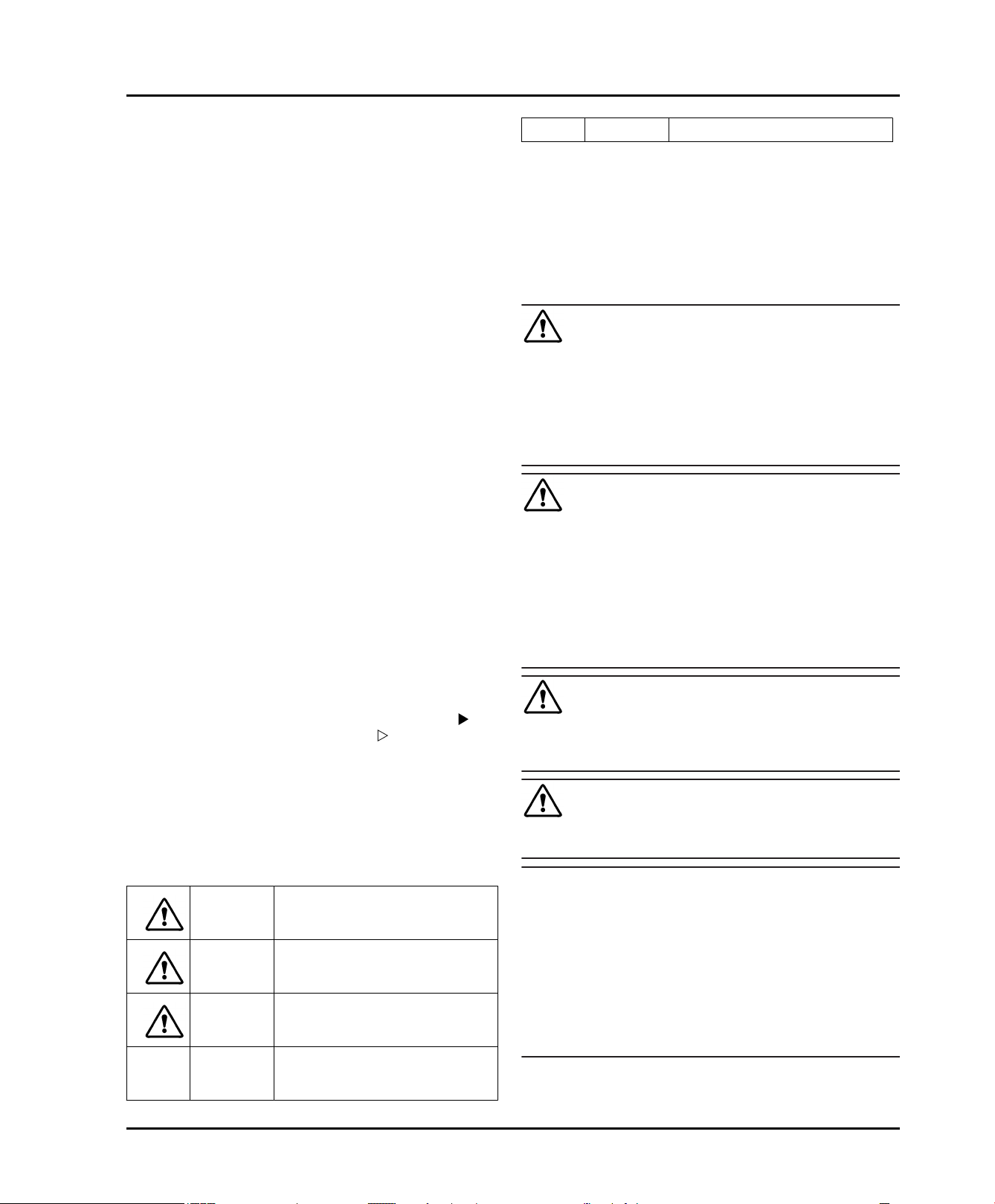

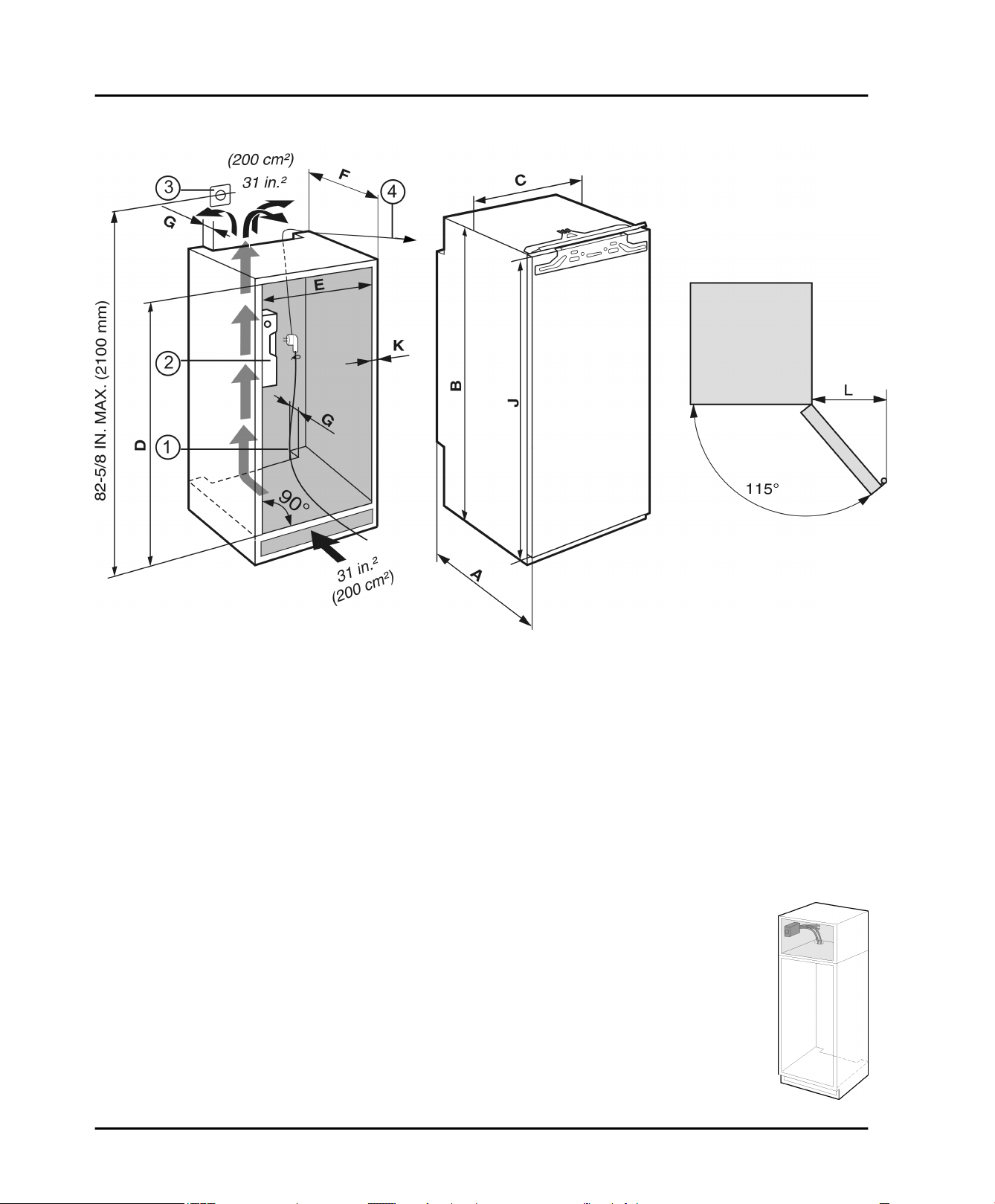

Fig. 1

- An effective ventilation cross-section of at least 31 in

(200 cm2) must be present at the air intake

air outlet

- The upper ventilation cross-section can be set up

directly above the appliance

above a cabinet

mediate ceiling

Fig. 1 (2)

Fig. 1 (4)

.

Fig. 1 (3)

.

Fig. 1 (2)

, or as an air vent in an inter-

Fig. 1 (1)

, near the ceiling

and

2

3

Kitchen cabinet setup

- An unobstructed air way with a depth of at least

1 1/2 in. (38 mm) must be ensured at the back of the

kitchen cabinet.

u

The air-circulation clearances indicated above must be

maintained.

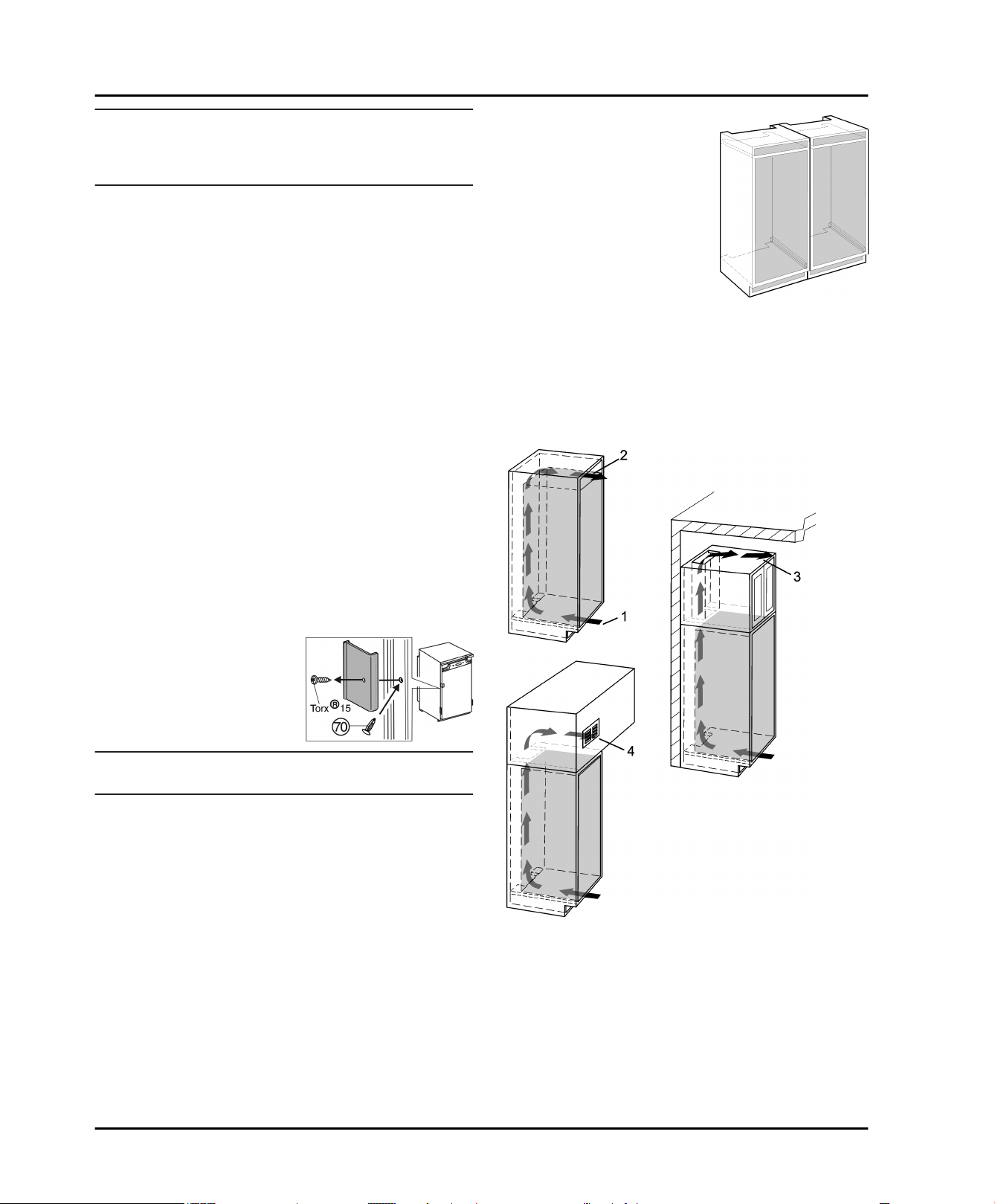

The ventilation from below through the cabinet floor can

be provided with the supplied ventilation grille

a ventilation opening of with a cross-sectional area of at

least 31 in2 (200 cm2). If you are using the supplied ventilation grille

u

In the cabinet floor, cut a ventilation opening

17 23/32 in. (450 mm) wide and 2 7/32 in. (56 mm)

high.

u

Insert the ventilation grille

cabinet floor

u

Slide the snap connectors

behind until the hooks touch the cabinet floor.

u

Fit the cabinet floor (with the ventilation grille snapped

into place) into the cabinet.

Fig. 3 (1)

Fig. 3 (2)

, proceed as follows:

Fig. 3 (1)

.

Fig. 3 (3)

into the cutout in the

into the grille from

Fig. 3 (3)

Fig. 3

or

Fig. 2

4

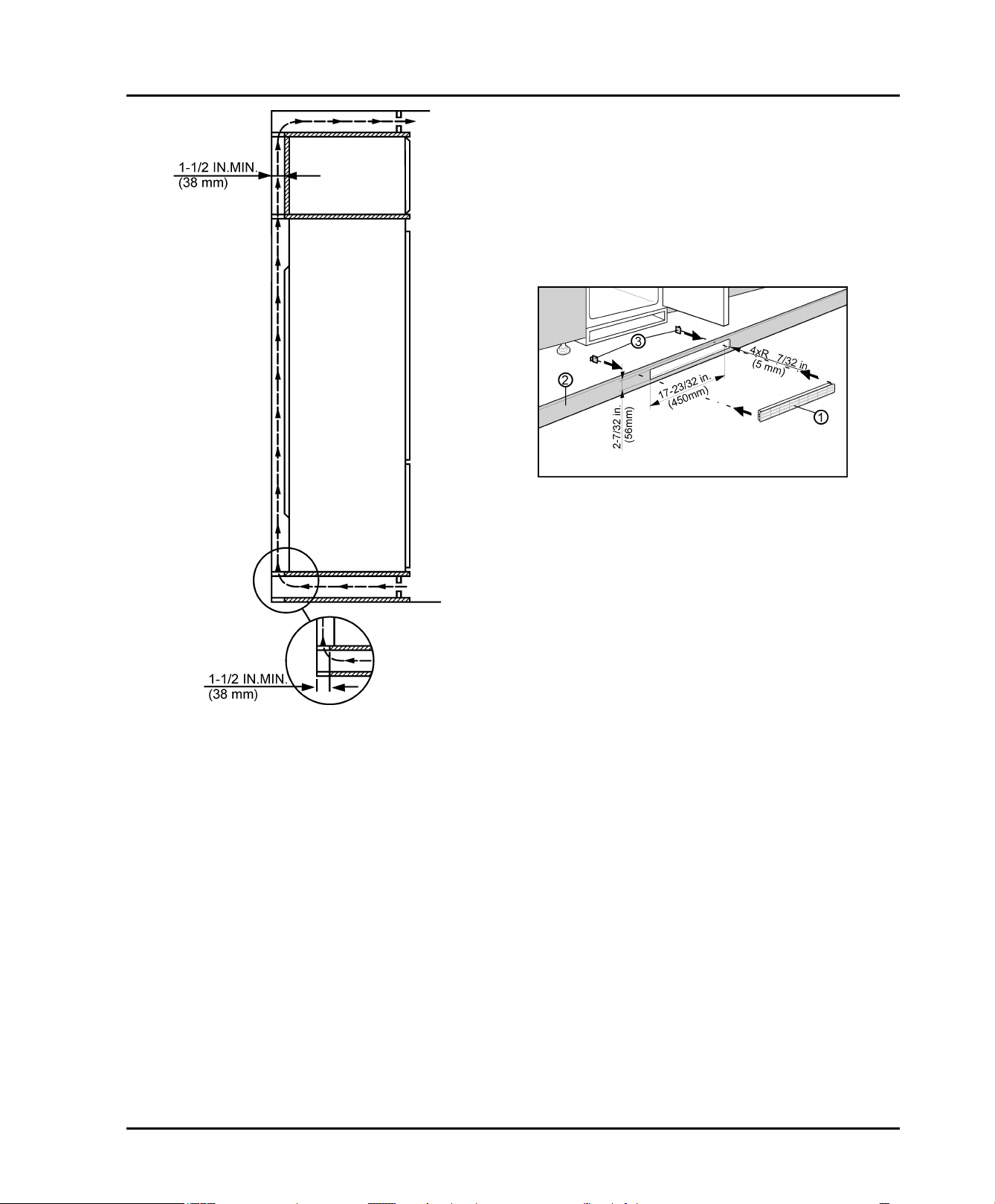

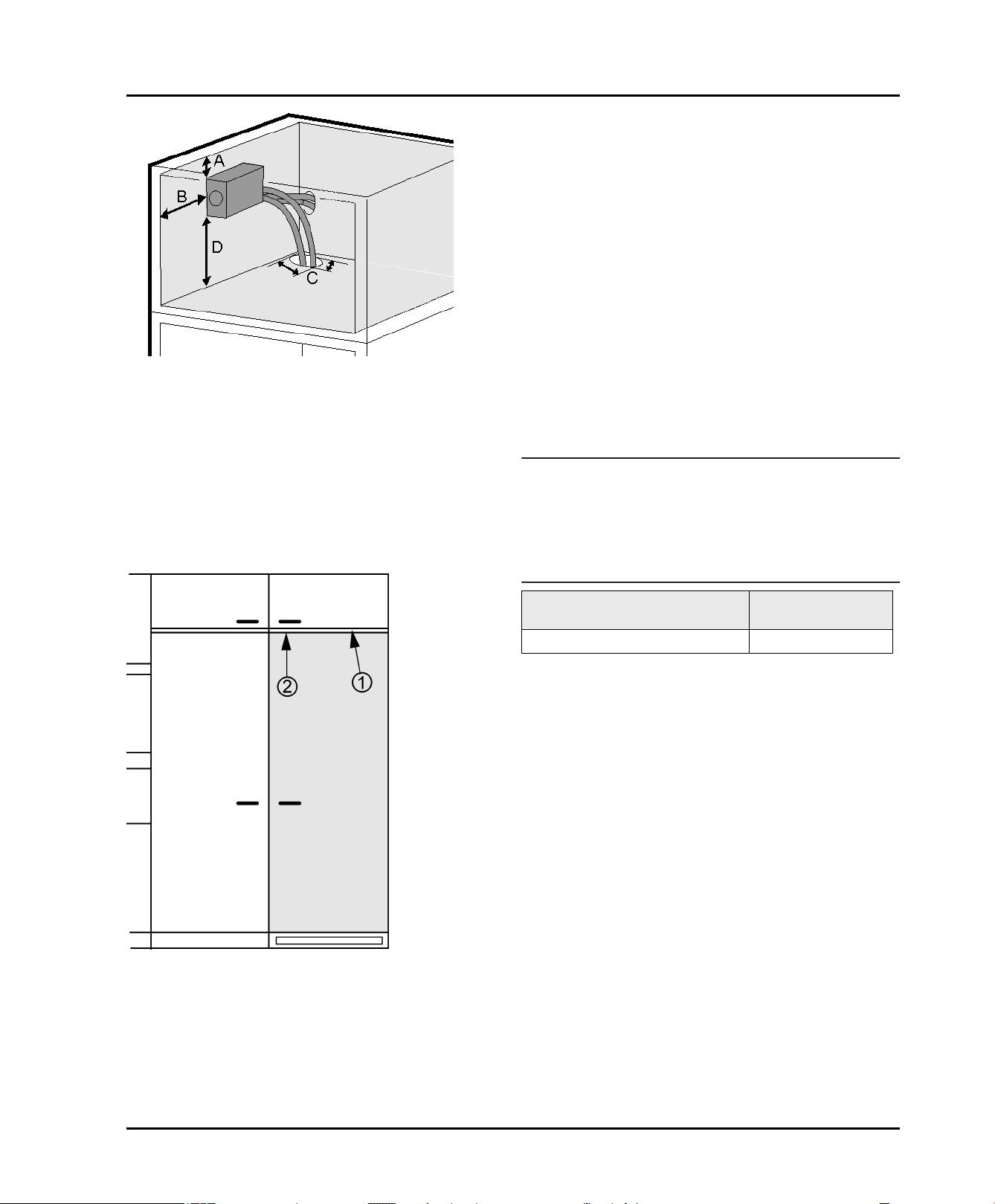

3.2 Kitchen cabinet setup

Kitchen cabinet setup

Fig. 4

1 Power cord 3 Electrical socket

2 Spirit level 4 Pull-in cable for power cord

A 21-7/32 in. (539 mm) B 69-21/32 in. (1769.5 mm)

C 21-15/16 in. (557 mm) D 69-3/4 in. - 70-3/8 in. (1772 mm) - (1788 mm)

E min. 22 in. (560 mm) F 21-21/32 in. (550 mm)

max. 22-3/4 in. (578 mm) G 1-1/2 in. (38 mm)

J 66-1/2 in. (1689.9 mm) K max. 3/4 in. (19 mm)

L 9-21/32 in. (245 mm)

u

Install the appliance in fixed cabinets only.

u

Build the cabinet with the dimensions shown in

u

Align the cabinet with a spirit level

square. If necessary, level the cabinet up by placing

something underneath.

w

The floor and side walls must be at right angles.

Maintain clearance L to the wall to ensure that the

drawers can be pulled out without obstruction.

u

Maintain the fitting dimensions shown in

Fig. 4 (2)

Fig. 4

Fig. 4

and a try

.

3.3 Kitchen cabinet setup for the

.

water filter*

The water filter module is supplied with the

appliance. It should be installed near the

appliance in the cabinet, for example, in

the adapter cabinet above the appliance.

To connect the filter to the appliance, it

may be necessary to make an opening (C)

in the floor of the adapter cabinet through

which the hoses will be routed. The

maximum length of the water hose is

98-7/16 '' (2.5 m).

The filter cover must be installed during

assembly to leave sufficient space around

the filter module.

5

Kitchen cabinet setup

Fig. 5

(A) 13/16in (20mm) (C) 1-3/16in. x 3/8in.

( 30mm x 10mm )

(B) 3-15/16in (100mm) (D) min. 4in (100mm)

u

Maintain the dimensions shown in

can be replaced and the cover can be removed. The

two hoses of the water filter can run alternatively

through the back of the cabinet or through the base

depending on the specific installation situation.

u

The tape on the water filter is not needed and can be

cut off.

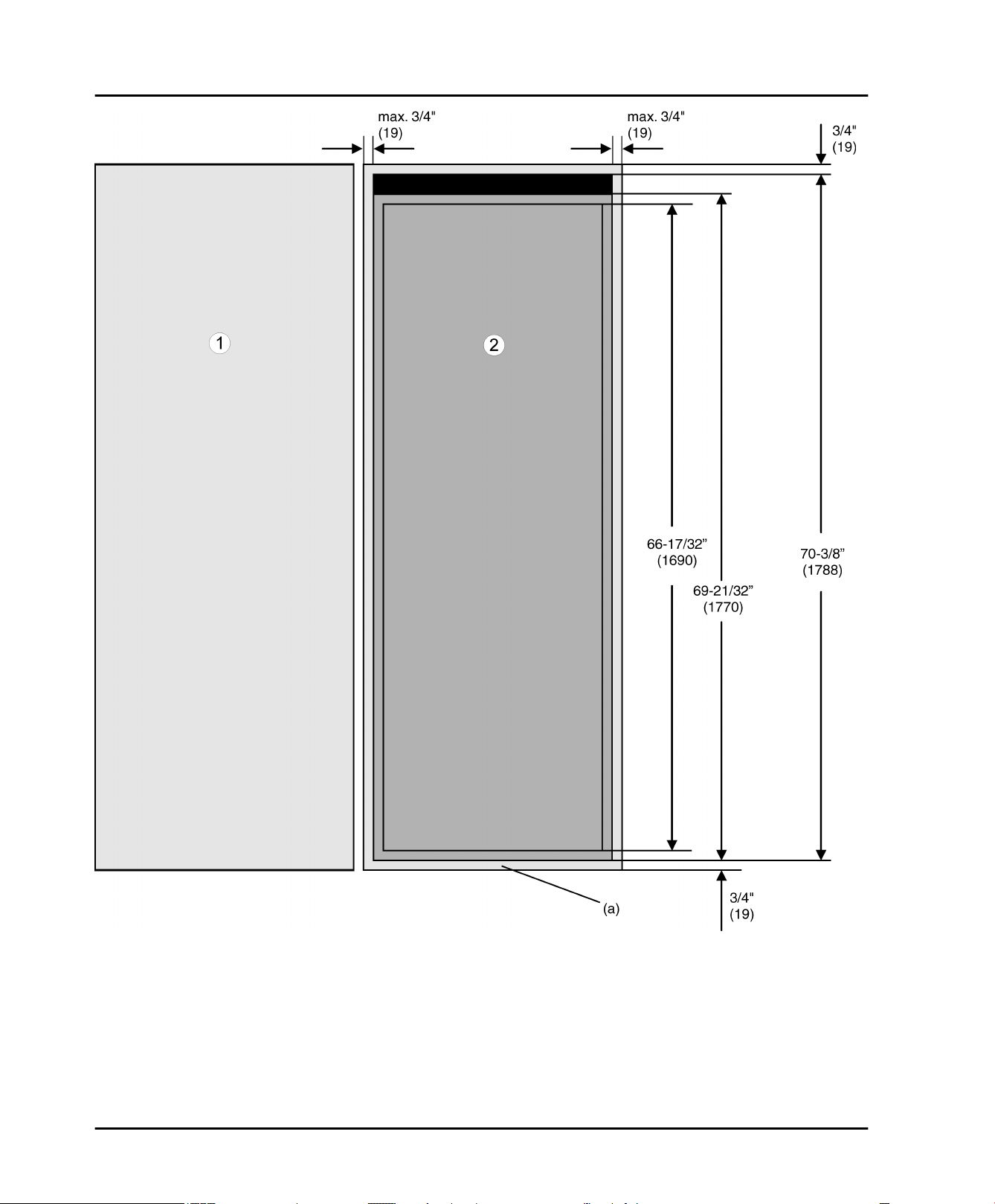

3.4 Cabinet door setup

Fig. 5

so that the filter

The cabinet must have a door.

This door is generally constructed as follows:

The door must be at least 5/8 in. (16 mm) and at most

3/4 in. (19 mm) thick so that the connecting rails can be

fixed on it.

There must be a gap

wide between the door and the cabinet door above it (if

present).

The width of the cabinet doors depends on the kitchen

style and size of the gaps between the door panels of

the cabinetry. Generally, a 1/8 in. (3 mm) vertical gap

between the cabinet doors is recommended.

The upper edge of the door

with the door of the adjacent cabinet (or cabinets), if

other cabinets are present.

The unit doors must be assembled flat and free from

tension.

Align the door before installing the appliance. Once you

have installed the appliance, you can no longer correct

the door position.

NOTICE

An excessively heavy unit door can cause potential

damage!

If the unit door is too heavy, we cannot rule out damage to

the hinges, which may compromise the use of the unit.

u

Before installing the unit door, ensure the door does not

exceed the permissible weight.

Fig. 6 (1)

Fig. 6 (2)

at least 1/8 in. (3 mm)

should be level

Fig. 6

Model Maximum weight of

unit door

HRB 1110, HF 851 50.71 lbs (23 kg)

u

Check the fitting dimensions according to the specifications in

Fig. 4

.

6

Reversing the door

Fig. 7

1 Cabinet door 2 Appliance door

The height of the cabinet door is calculated as follows:

u

Total cabinet height (i. e., 69-21/32 in. (1769.5 mm))

plus the thickness of the cover plate and floor plate

Fig. 7 (a)

+ 3/4 in. = 71-5/32 in. ( 1769.5 mm + 19 mm + 19 mm =

1807.5 mm )

(usually 3/4 in. (19 mm))/ 69-21/32 in. + 3/4 in.

4 Reversing the door

Make sure you have the following tools on hand:

q

Phillips screwdriver

q

Slot screwdriver

q

Torx® 15 cordless screwdriver

•

Torx® 20 cordless screwdriver

•

Torx® 25 cordless screwdriver

•

7

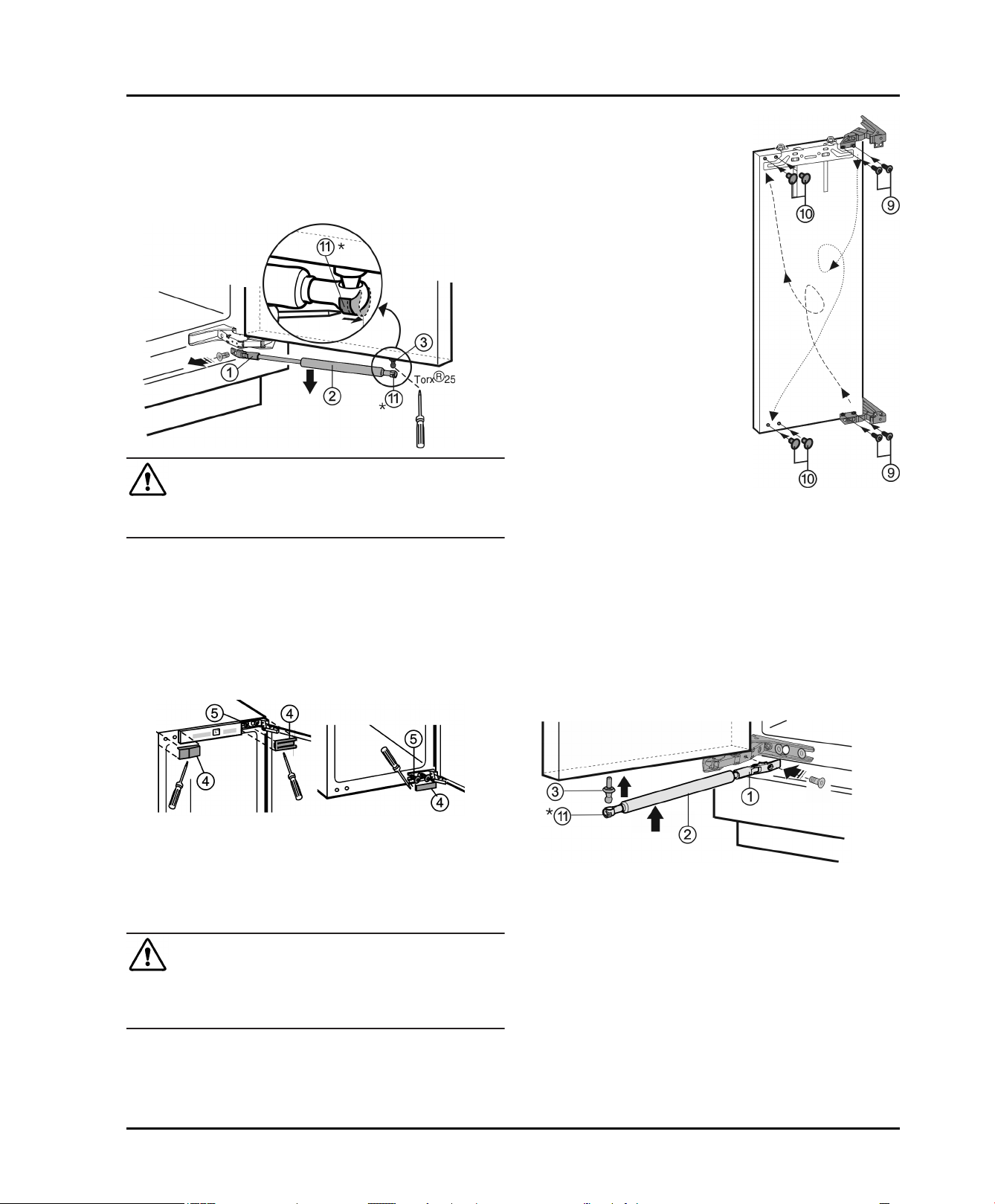

Reversing the door

Disconnect the power plug.

Open the door.

4.1 Detaching the soft stop mechanism

Fig. 8

CAUTION

Risk of injury if soft stop contracts!

u

Carefully remove soft stop damper.

u

Use a screwdriver to slide the tension spring

outwards.*

u

Remove the soft stop mechanism

downwards.

u

Unscrew the retainer

u

Unscrew the ball stud

Fig. 8 (1)

Fig. 8 (3)

Fig. 8 (2)

.

(Torx® 25).

Fig. 8 (11)

by pulling it

u

Swap the fixing screws

Fig. 9 (5)

bottom to the opposite

side.

The screws are selftapping. Use a cordless

screwdriver:

u

Unscrew

hinges from the door,

move to the other side

and secure tightly by

applying a screw

torque of 3 lb-ft (4 Nm).

u

Close off the now unused

holes with plugs

Fig. 10 (10)

on the top and

Fig. 10 (9)

.

the

4.4 Installing the door again

u

Hang the appliance door on the pre-fitted fixing screws

Fig. 9 (5)

u

Tighten the fixing screws

applying a screw torque of 3 lb-ft (4 Nm).

u

Re-attach the covers

.

Fig. 9 (4)

Fig. 9 (5)

.

securely by

Fig. 10

4.2 To remove the door

Fig. 9

u

Remove the covers

u

Just loosen the fixing screws

u

Remove door: Push outwards, unhook and put to one

side.

Fig. 9 (4)

.

Fig. 9 (5)

.

4.3 Swapping bearing parts

CAUTION

Hinges are spring-loaded and can cause pinching injuries!

u

Leave hinges open.

4.5 Re-attaching the soft stop mechanism

Fig. 11

u

Screw the

fastening hole by applying a torque of 3 lb/ft (4 Nm)

(Torx® 25).

u

Slide the tension spring

u

Tightly screw on theretainer

torque of at least 2.5 lb-ft (3 Nm).

u

Attach the soft stop mechanism

stud.

Fig. 11 (3)

ball stud securely into the new

Fig. 8 (11)

inwards again.*

Fig. 11 (1)

Fig. 11 (2)

by applying a

onto the ball

8

WARNING

Risk of bodily injury due to the door falling off.

If the fasteners are not installed with the proper torque,

the door may fall off. In addition, the door may not close,

thus impairing the cooling performance of the appliance.

u

Tightly secure the hinges along ball stud of the soft

stop mechanism by applying a torque of 3 lb-ft (4 Nm).

u

Tighten the soft stop mechanism retainer firmly with

2.5 lb-ft (3 Nm).

u

Check all screws and retighten if necessary.

5 Water connection*

WARNING

Electrical Shock Hazard!

u

Do not make the water connection while the appliance

is connected to an electrical outlet.

u

Disconnect the water supply before connecting the

water lines for the IceMaker.

u

The connection to the water supply may only be made

by a trained and licensed plumber.

WARNING

Poisoning Hazard!

u

The water quality must comply with the drinking water

regulations for the geographical area where the appliance is located.

u

The IceMaker is designed exclusively to make ice

cubes in quantities needed by a household and must

only be operated with water appropriate for this

purpose.

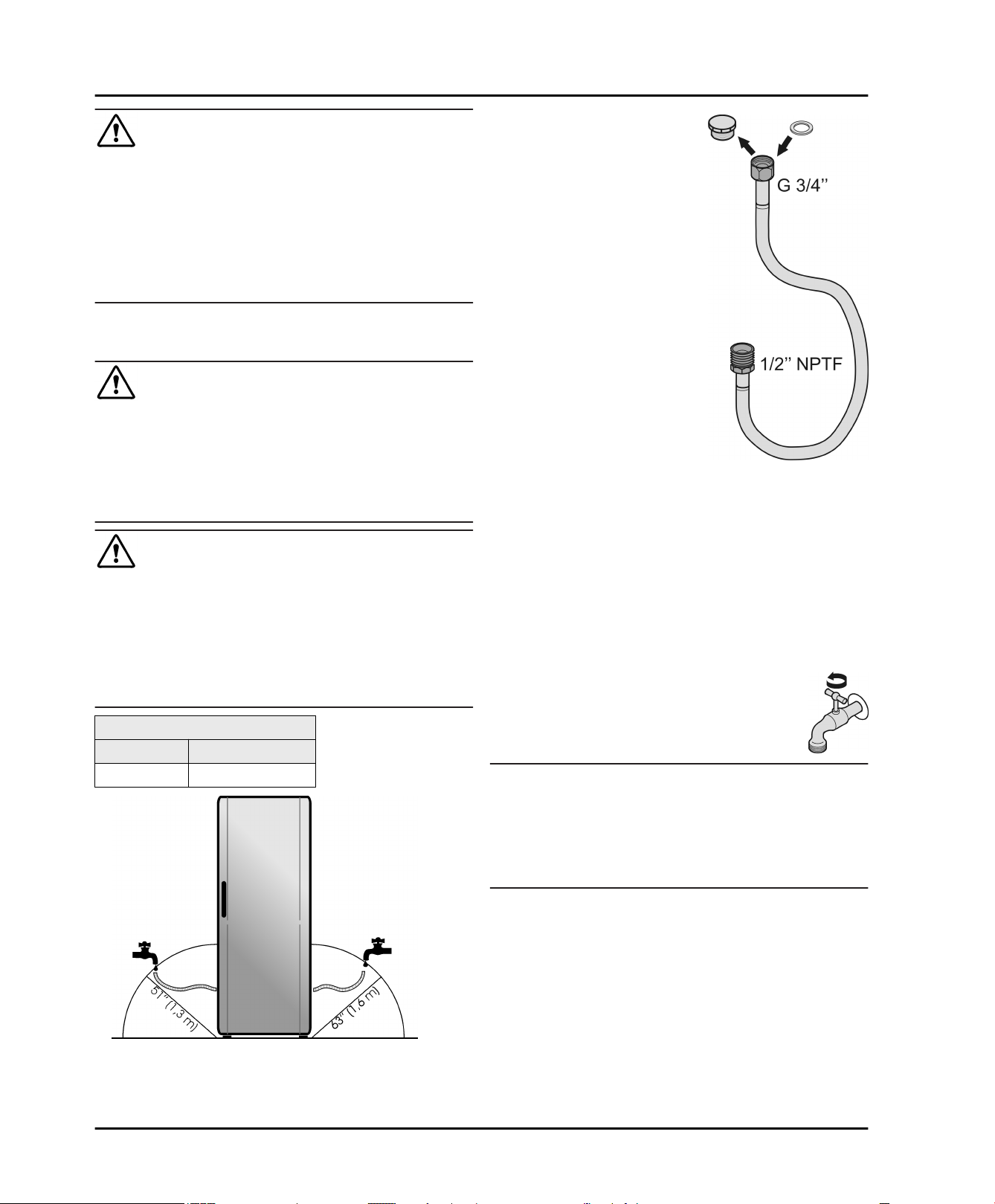

Water pressure:

psi MPa (bar)

21.76 to 87.02 0,15 to 0,6 (1.5 to 6)

Water connection

- Water must be supplied to

the appliance through a cold

water pipe that complies with

hygiene standards and can

withstand the operating pressure.

- Use the supplied stainlesssteel hose (78-3/4 '' (2 m)).

Do not reuse old hoses.

- A stopcock must be placed

between the hose line and

the domestic water connection to cut off the water

supply, if necessary. The

stopcock should be located

away from the back of the

appliance and within easy

reach.

- All devices and equipment

used to supply water must

comply with the regulations in

force in the respective

country.

- Do not damage or kink the

water supply line during

installation.

- The solenoid valve is located

at the bottom of the back of

the appliance. It has a metric

R3/4 connecting thread.

u

Unscrew the cap from the hose and insert the seal.

u

To install the stainless-steel hose: connect the G 3/4”

coupling to the solenoid valve and the 1/2” NPTF

coupling to the stopcock.

u

Open the stopcock for the water supply and

check the entire water system for leaks.

Before using for the first time:

u

Have the water line bled by a competent

professional.

NOTICE

Malfunction of the water intake!

If the water intake is shut off during operation but the

IceMaker remains in operation, the water intake pipe may

ice up.

u

Switch off the IceMaker if the water supply is interrupted (e.g. holiday).

Fig. 12

9

Installation

6 Installation

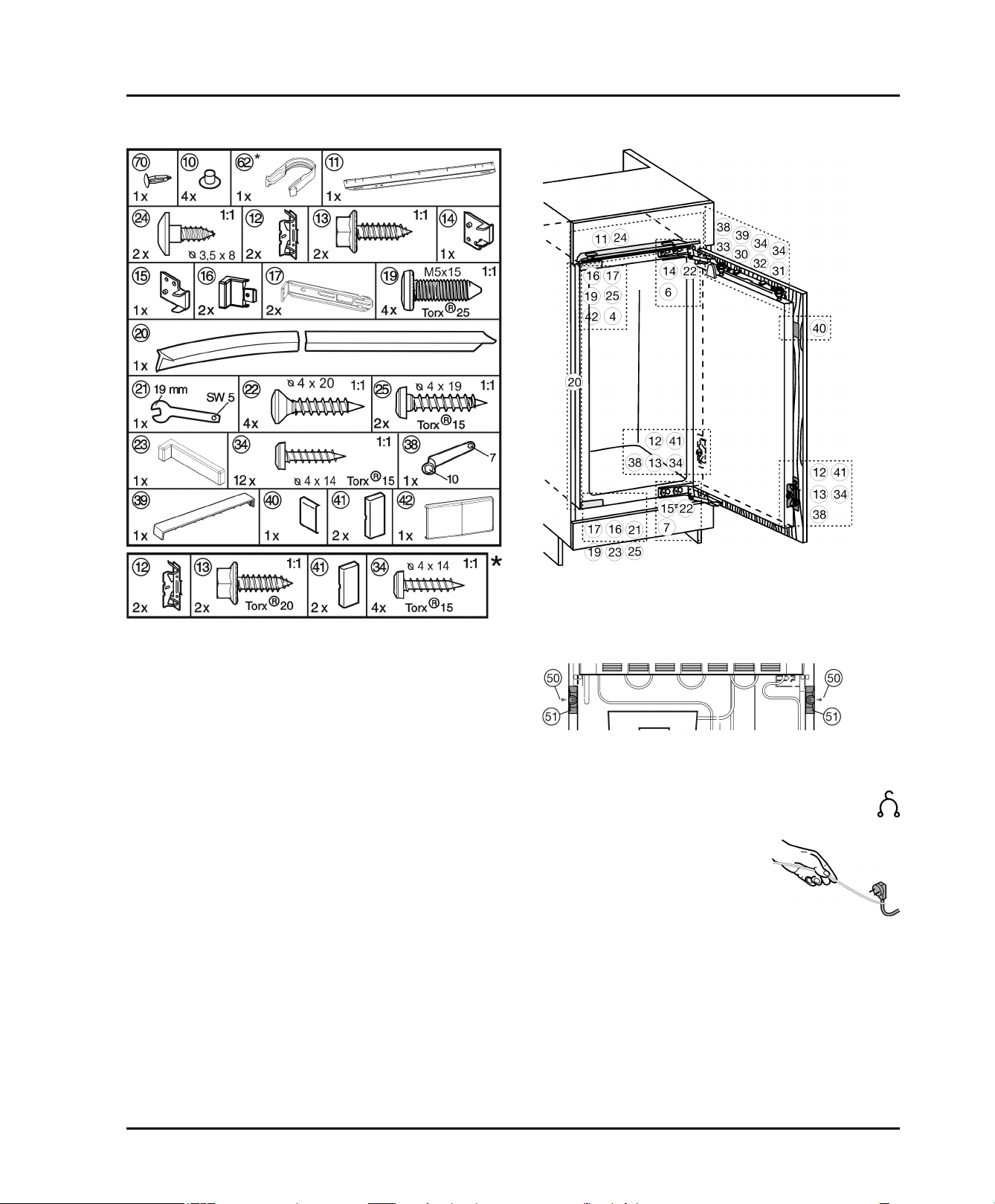

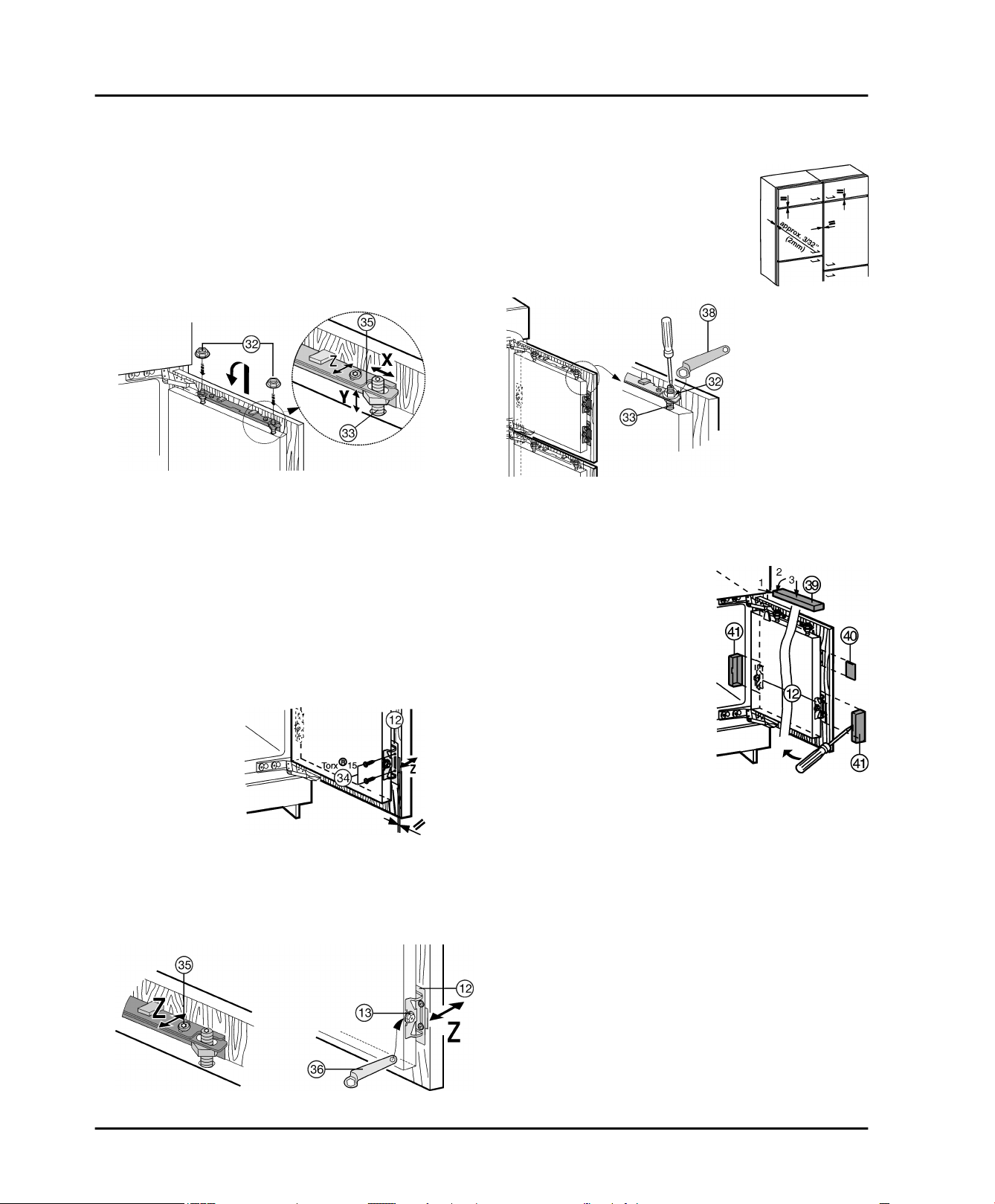

6.1 Assembling the appliance

Fig. 13

All fasteners are supplied with the appliance.

Make sure you have the following tools on hand:

q

Cordless screwdriver Torx® 15, 20, 25

q

Hex wrench 13

q

Screwdriver

Fig. 14

Unit depth less than 21 3/4 in. (553 mm) Detach the

spacers from the rear of the appliance so that you can

slide the appliance completely into the recess. Removing

the spacers may cause the appliance to use more energy,

as this reduces the ventilation cross-section.

Fig. 15

u

Undo the screw

Fig. 15 (51)

All appliances:

u

Remove the power cord from the back of the appliance. Also remove the cable holder, otherwise

there will be vibration noise!

u

Position the power cord using

a piece of string so that the

appliance can easily be

connected to the electricity

supply after it has been builtin.

For appliances with a water filter:*

.

Fig. 15 (50)

and detach the spacer

Fig. 16

10

For large or divided unit doors:

u

Fit a 2nd pair of mounting brackets

Fig. 33 (12)

u

Use the holes pre-drilled in handle area

.

of the appliance door for this purpose.

Installation

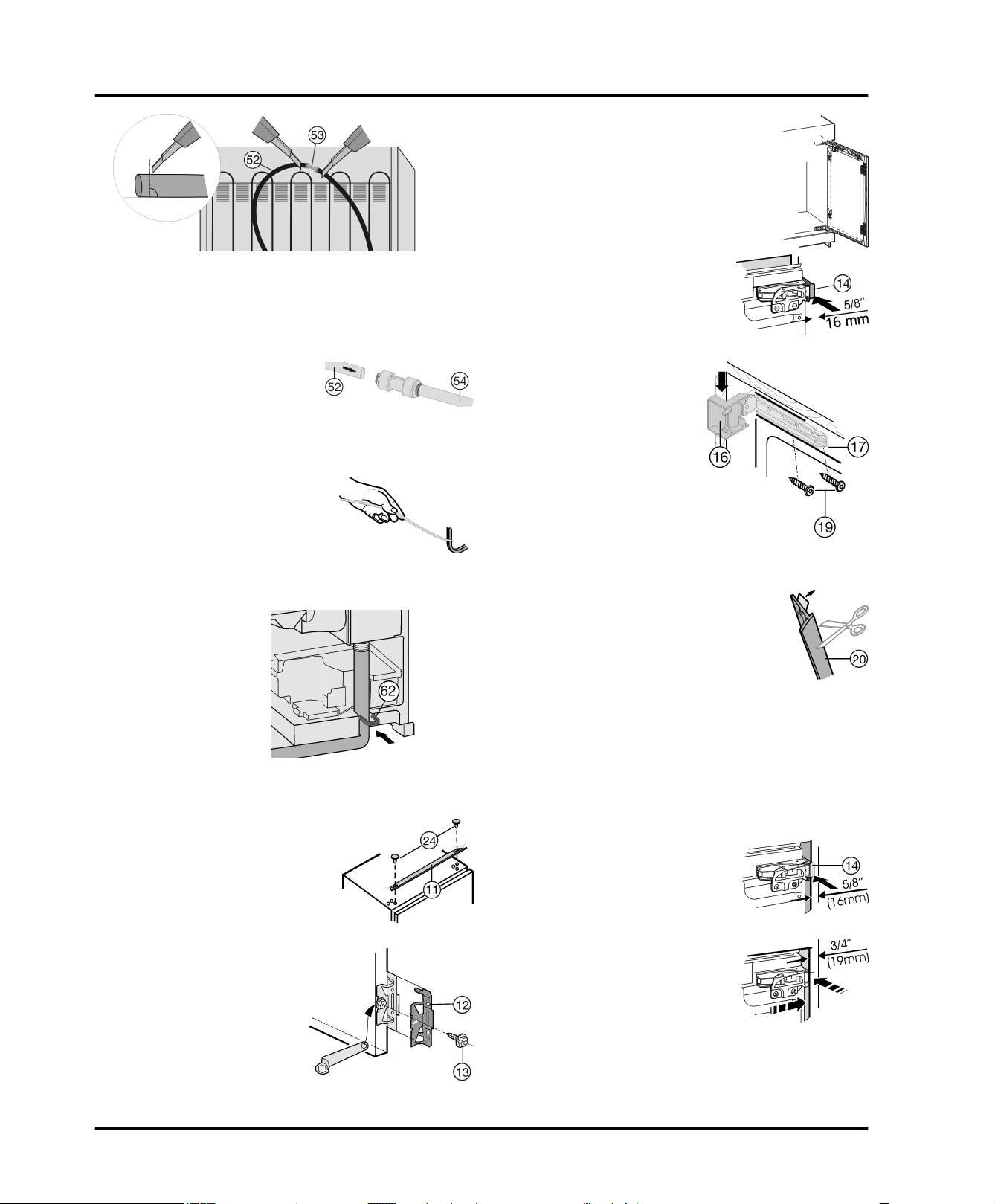

Fig. 17

*

u

Slice open the water hose

Fig. 17 (52)

located behind

the appliance both in front of and behind the connector

Fig. 17 (53)

(90° to direction of hose).*

When doing so, make sure the hose does not become

kinked and the cross-section of the hose remains round.*

u

Connect the supplied extension hoses

appliance hoses

Slide the appliance hoses

Fig. 18 (54)

Fig. 18 (52)

to the

:

Fig. 18

into the connectors as far as

they will go (approx. 21/32 ''

(17 mm)).*

u

Position the hoses using a piece

of string so that they can be

connected to the water filter later

(see 3.3) .*

Appliances with a plumbed-in connection for the

IceMaker:

u

Connect the IceMaker .*

u

Install the detent clip

Fig. 19 (62)

.*

Fig. 19

All appliances:

u

Push the appliance 3/4 of the way into the recess.

u

Remove covers

u

Screw

Fig. 20 (11)

equalizer trim

Fig. 14 (4,6,7)

the

Fig. 20 (24)

.

onto the top of the appliance through the oblong

holes.

Fig. 20

u

Fasten a pair of

mounting brackets

Fig. 21 (12)

into the prebored holes in the

appliance door with a

hex head screw

Fig. 21 (13)

.

Fig. 21

With 5/8 '' (16 mm) thick

unit walls:

u

Clip spacer

spacer

Fig. 22 (14)

Fig. 14 (15)

and

onto the

hinge.

u

Place the covers

Fig. 23 (16)

top and

bottom onto the

mounting brackets

Fig. 23 (17)

u

Fasten the mounting

brackets

.

Fig. 23 (17)

on

top with screws

Fig. 23 (19)

and on the

bottom with Screws

Fig. 14 (19)

bracket still has a slight

*

such that the

bit of play to the left and

right.

u

Remove the protective film from the

trim

Fig. 24 (20)

u

Place the trim

of the cover

.

Fig. 24 (20)

Fig. 23 (16)

on the flange

, on the handle

side and flush with the front, and adhesively affix it to the side wall of the

appliance.

u

If necessary, shorten the trim

Fig. 24 (20)

Fig. 24 (20)

*

above the upper edge of the bottom

mounting bracket

at the bottom: The trim

must end 1/8 '' (3 mm)

Fig. 14 (17)

.

Insert and align appliance:

u

Slide the appliance in until it contacts

covers

Fig. 23

on the side wall of the unit.

Fig. 23 (16)

With 5/8 '' (16 mm) thick

unit walls:

u

Slide the appliance into the

recess until it touches the

spacers on the side wall of

the unit.

With 3/4 '' (19 mm) thick

unit walls:

u

Align the front edges of the

hinges flush with the side

wall of the unit.

Units (5/8 '' (16 mm) and 3/4 '' (19 mm)) with door

stop components (knobs, sealing lips, etc.):

Fig. 22

Fig. 23

Fig. 24

the

Fig. 25

Fig. 26

11

Installation

u

Note the additional space needed (for depth of door

stop components): Allow the hinges and covers

Fig. 23 (16)

to protrude by the additional distance.

All appliances:

u

Adjust the adjustable feet with the supplied openended wrench

Fig. 14 (21)

to align the appliance verti-

cally.

w

The appliance is now positioned correctly depthwise.

The distance between the front edge of the unit side

wall and the appliance itself is 42 mm all around. (Note

the additional space needed for door stop components

such as knobs and sealing lips.)

Note

Malfunction due to incorrect assembly!

If the spacing is not observed, the appliance door may not

seal completely. This can cause icing up, the formation of

condensate, and malfunctions.

u

A continuous space of 1-21/32 '' (42 mm) must be

maintained. (Note the additional space needed for door

stop components such as knobs and sealing lips.)

To secure the appliance in the recess:

u

Screw long chipboard screws

Fig. 27 (22)

at the top and at the

bottom through the hinge plates.

Take care that screws will not

protrude from an exposed end

cabinet wall.

u

Loosen the screws

Fig. 29 (19)

u

Secure the bottom

slightly.

mounting bracket

Fig. 29 (17)

with a ø4x19

chipboard screw

Fig. 29 (25)

to the unit

wall.

u

Break off the protruding

end of the cover

Fig. 29 (16)

u

Tighten the screws

Fig. 29 (19)

u

Place the cover

Fig. 29 (23)

.

.

onto the

bottom mounting

bracket

u

Slide the equalizer trim

Fig. 29 (17)

.

Fig. 20 (11)

side as far as it will go.

u

Close the appliance door.

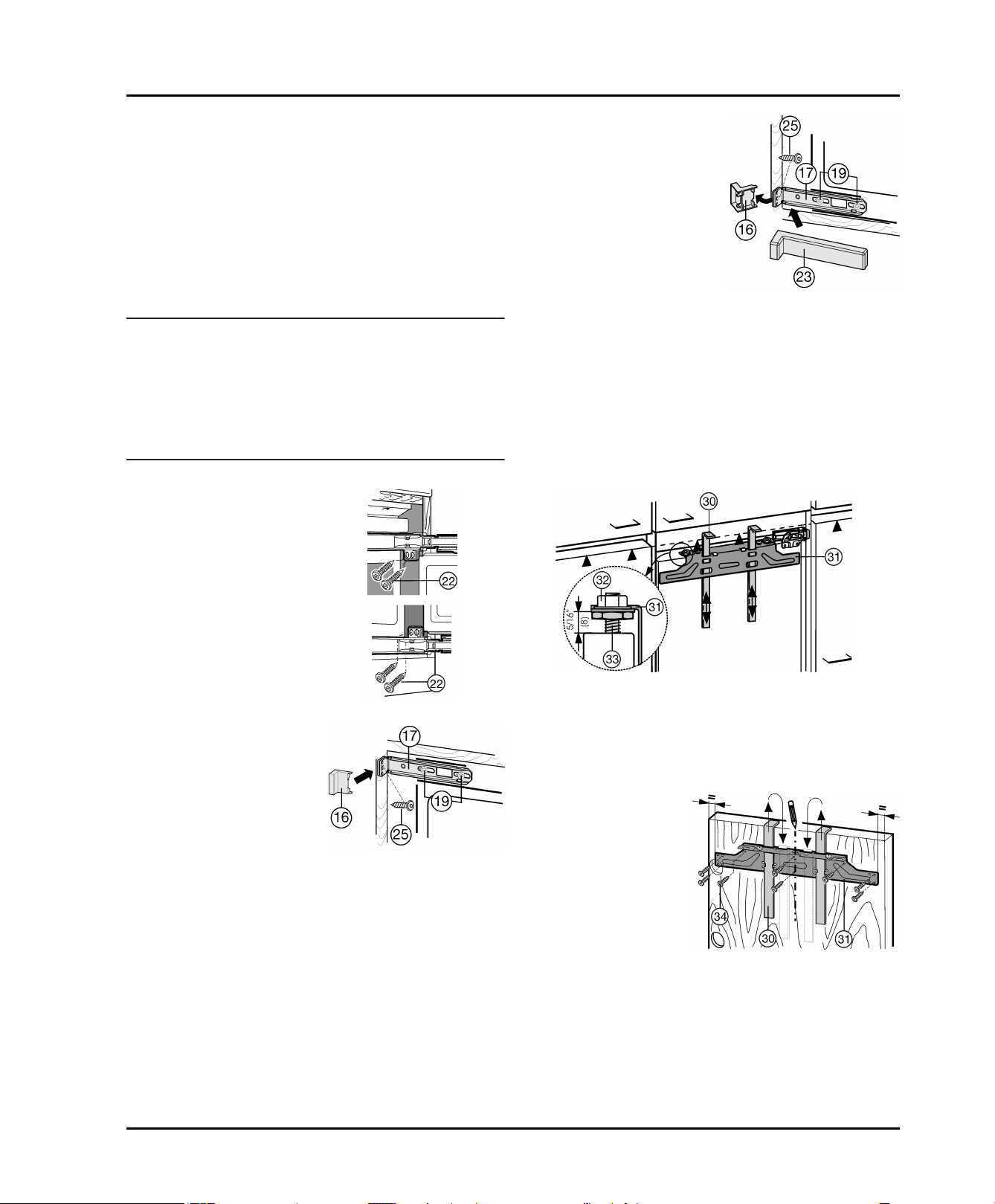

6.2 Installing the unit door

Fig. 29

toward the handle

On the top handle side:

u

Loosen the screws

Fig. 28 (19)

u

Secure the top

slightly.

mounting bracket

Fig. 28 (17)

with a ø4x19

chipboard screw

Fig. 28 (25)

to the unit

wall.

u

Break off the

protruding end of the

cover

Fig. 28 (16)

u

Tighten the screws

u

Place cover

.

Fig. 28 (19)

Fig. 28 (16)

in position.

On the bottom handle side:

Fig. 30

u

Fig. 27

Check 5/16 '' (8 mm) presetting (distance between

appliance door and lower edge of crosspiece).

u

Raise the fitting aids

Fig. 30 (30)

to the unit door height.

Bottom stop angle ▲of fitting aid = upper edge of the

unit door to be fitted.

u

Unscrew the crosspiece

locknuts

u

Hang the crosspiece

Fig. 30 (32)

Fig. 31 (31)

on

.

Fig. 31 (31)

by undoing the

the inside of the unit

Fig. 28

door using the fitting

aids

Fig. 31 (30)

.

With a 23-5/8 ''

(600 mm) wide

.

cabinet:

u

To center the crosspiece

Fig. 31 (31)

Mark a short center

:

Fig. 31

line on the unit door

and put the tip of

the arrow on the

crosspiece on it.

w

Distances to the outer edges are the same to the right

and to the left.

With a 24 '' (609.6 mm) wide cabinet:

12

Installation

u

To align the crosspiece

Fig. 31 (31)

: Mark a short center

line on the unit door and put the tip of the arrow on the

crosspiece on it. Then slide the crosspiece

Fig. 31 (31)

3/16 in. (5.5 mm) toward the hinge side.

For chipboard doors:

u

Secure the crosspiece

Fig. 31 (34)

.

Fig. 31 (31)

with at least 6 screws

For frame and panel doors:

u

Secure the crosspiece

Fig. 31 (34)

u

Lift up the fitting aids

at the edge.

Fig. 31 (31)

Fig. 31 (30)

with 4 screws

, turn around and insert

into the adjacent openings.

u

Attach the unit door on the adjusting bolts

and loosely screw the locknuts

Fig. 32 (32)

Fig. 32 (33)

onto the

adjusting bolts.

u

Close the door.

u

Check the gap between the door and the surrounding

unit doors.

u

To laterally align the unit door: Move the unit door in the

X direction.

u

To align the unit door in the Y direction (height) and in

lateral inclination: Adjust the adjusting bolts

Fig. 32 (33)

with a screwdriver.

w

The unit door is flush and in alignment with the

surrounding unit fronts.

u

Tighten the locknuts

Fig. 32 (32)

.

Ensure that both metal edges are flush, symbol //:

u

Drill pilot holes in the door of the unit taking care not to

go all the way through the panel (you could make a

preliminary hole with a bradawl).

u

Screw the appliance door to the unit door with screws

Fig. 33 (34)

through the mounting brackets

Fig. 33 (12)

Fig. 32

Fig. 33

.

u

To align the unit door in depth Z: Undo top screws

Fig. 34 (35)

, bottom hex head screws

Fig. 34 (13)

, then

move the door.

u

Do not allow the knobs and sealing

lips to contact the door - important for

functioning!

u

Set an air gap of 3/32 '' (2 mm)

between the door of the unit and the

body of the unit.

Fig. 35

u

Check the fit of the door and re-adjust, if necessary.

u

Tighten all screws.

u

Tighten the locknuts

Fig. 35 (38)

Fig. 35 (33)

u

Position the upper cover

Fig. 36 (39)

, while counter-holding the adjusting bolts

with a screwdriver.

and snap into

Fig. 35 (32)

with the ring wrench

place.

u

Place the lateral cover

Fig. 36 (40)

in position,

slide to the limit and then

press until it snaps audibly

into place.

u

Attach covers

Fig. 36 (41)

to the side and then draw

them forward with a

screwdriver, so that they

snap properly into place.

Fig. 36

With a 24 '' (609.6 mm) wide recess:

u

Position the covers

Fig. 14 (6,7,42)

and snap them into

place.

With a 23-5/8 '' (600 mm) wide recess:

u

Position the covers

Fig. 14 (4,6,7)

and snap them into

place.

Check the following points to make sure the appliance is

installed correctly. Otherwise, icing up, the formation of

condensate, and malfunctions can occur.

w

The door must close properly.

w

The unit door must not touch the body of the unit.

w

The seal on the upper corner on the handle side must

be fitted securely. To verify this, darken the room, place

a flashlight in top part of the appliance, and close the

door. If you see light shining out, check the assembly.

Fig. 34

13

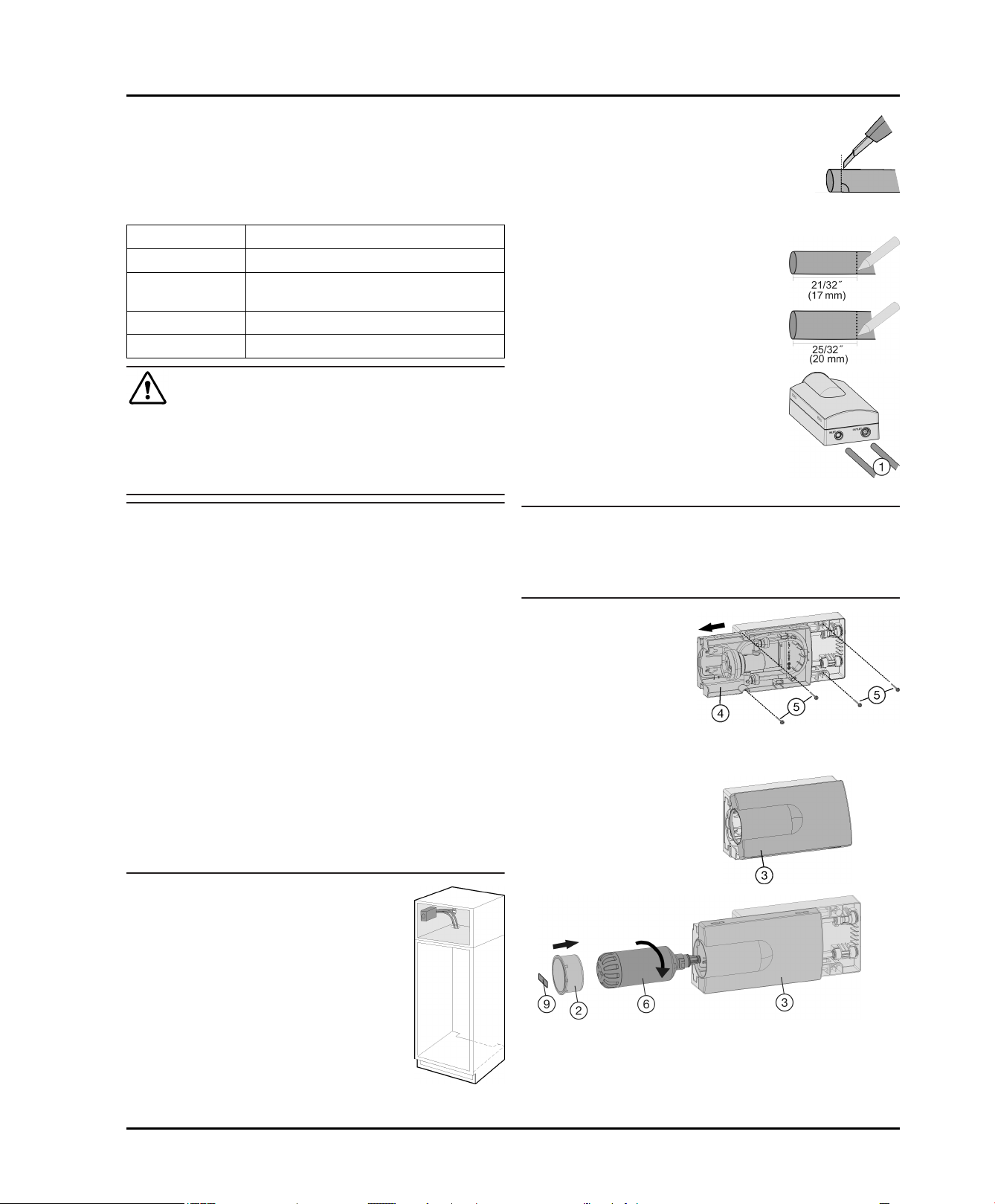

Installing the water filter

7 Installing the water filter*

The water filter guarantees optimal water quality and

should be installed the first time you use the appliance.

Alternatively, the appliance can also be operated without

the water filter.

Flow rate 0.5 gpm (1.89 lpm)

Water connection potable

Water pressure 40 psi - 90 psi ( 2.8 bar - 6.2 bar/ 0.28 MPa

- 0.62 MPa )

Water temperature 33 °F - 100 °F ( 0.6 °C - 37 °C )

Capacity 300 gal. (1135 l)

WARNING

Consuming contaminants can be harmful to your health!

u

If there is a chance the water may contain harmful

bacteria or if the water quality is unknown, do not use

this system without appropriate disinfection measures

upstream or downstream of the system.

u

Hoses have been shortened, if necessary (cut at 90° angle to the direction of

the hose).

When doing so, make sure the hoses do not become

kinked and the cross-section of the hose remains round.

u

On the thin hose, measure the insertion depth (E) of 21/32 '' (17 mm) and

mark it.

u

On the thick hose, measure the

insertion depth (E) of 25/32 ''

(20 mm) and mark it.

u

Insert the hoses

Fig. 37 (1)

all

the way into the water filter

module (i.e., up the the mark

you made), past the point of

resistance.

Fig. 37

NOTICE

Leakage water may damage the system!

u

Do not install this system on hot water lines. The

maximum operating temperature of the water in this

system is 100 °F (37.7 °C).

u

This system MUST be installed and used in compliance with federal and local installation regulations.

u

Do not install under water hammer conditions. A water

hammer arrestor must be used to prevent water

hammering. If you are unsure how to check these

conditions, consult a professional installer.

u

Do not install with a water pressure greater than 90 psi

(6.2 bar). If your water pressure exceeds 80 psi, install

a pressure limiting valve. If you are unsure how to

check the water pressure, consult a professional

installer.

u

Protect against frost; if temperatures below 33 °F

(0.6 °C) are expected, remove the filter.

u

When used as indicated, the disposable filter

cartridges must be replaced every 6 months or whenever you notice a considerable decrease in the flow

rate.

Make sure that the following conditions are

fulfilled:

q

The hoses have been positioned such

that they can now be connected to the

filter.

q

The installation position has been

selected according to the instructions

(see 3.3) .

q

The connectors have been removed

from the hose ends.

Note

u

If you need to disassemble the unit: Push back the dark

grey ring on the connector and hold it in this position.

While still holding the ring back, briefly push the hose

into the connector, then pull it out.

u

Pull the tray

Fig. 38 (4)

out until it

catches.

u

Secure the module

with 4 screws

Fig. 38 (5)

through

the recesses in the

front and directly

through the module

in the back.

u

Place the tray cover

Fig. 40 (3)

Fig. 40

u

Insert the water filter

in position.

Fig. 40 (6)

and turn it approximately

100° to the right until it locks into position.

u

Place the cover

u

Slide the tray in.

Fig. 40 (2)

on the filter.

Fig. 38

Fig. 39

14

u

Write the date of the next filter replacement on the

supplied adhesive label

module.

u

Make sure the filter is leak-tight and no water is coming

out.

Note

New water filters may contain particulate matter.

u

Do not consume or use ice cubes produced within 72

hours after replacing the filter.

w

The water filter is now ready for use.

Fig. 40 (9)

and affix it to the

8 Connecting the appliance

WARNING

Electrical shock hazard!

u

Start-up should only take place once the appliance has

been installed according to these instructions.

u

Electrically ground appliance.

u

Do not ground to a gas pipe.

u

Check with a qualified electrician if you are not sure the

appliance is properly grounded.

u

Do not have a fuse in the neutral or grounding circuit.

u

Do not use an extension cord, power bar or a multiple

socket adapter.

u

Do not use a power cord that is frayed or damaged.

Connecting the appliance

The socket must be easily accessible so that the appli-

ance can be disconnected from the mains quickly in an

emergency. It must not be behind the back of the appliance.

The top of the electric outlet must be located within

82-5/8 in. (2100 mm) from the top of the base in the

cabinet.

WARNING

Electrical shock hazard!

This appliance is equipped with a three-prong (grounding)

polarized plug for your protection against possible shock

hazards. Electrical Grounding Required.

u

Do not remove the round grounding prong from the

plug.

u

Do not use a two-prong grounding adapter.

Wait 1 hour after installation before you plug in the

appliance. This allows the refrigerant and system lubrication to reach equilibrium.

Make sure incoming voltage is the same as the appli-

ance rating. A 110-120 Volt, 60 Hz, 15 Amp electrical

supply (20 Amp for side-by-side installations) circuit

that is controlled by a circuit breaker or fuse is required.

We recommend using a dedicated circuit for this appli-

ance to prevent electrical overload.

Follow all Federal, State and local electrical, fire and

building codes and ordinances when installing the

receptacle and / or the appliance.

In some communities, a wall switch is required to turn

power to the appliance ON and OFF.

To reduce the risk of fire, electric shock, or personal

injury, installation work and electrical wiring must be

done by a qualified electrician in accordance with all

applicable codes and standards, including fire-rated

construction.

15

Loading...

Loading...