Page 1

Liebherr BOS

Offshore Cranes

Page 2

BOS 14000-500 D Litronic

2

Page 3

Table of Contents

Product Range 4

Applications

Crane Layout -

Structure Overview 7

Slewing Platform and A-Frame 8

6

Boom 10

Driver Comfort

Optional Equipment 12

Environmental Record

Production and Transportation 14

11

12

Liebherr Service Worldwide 16

The Liebherr Group –

Your Partner for the Future 18

3

Page 4

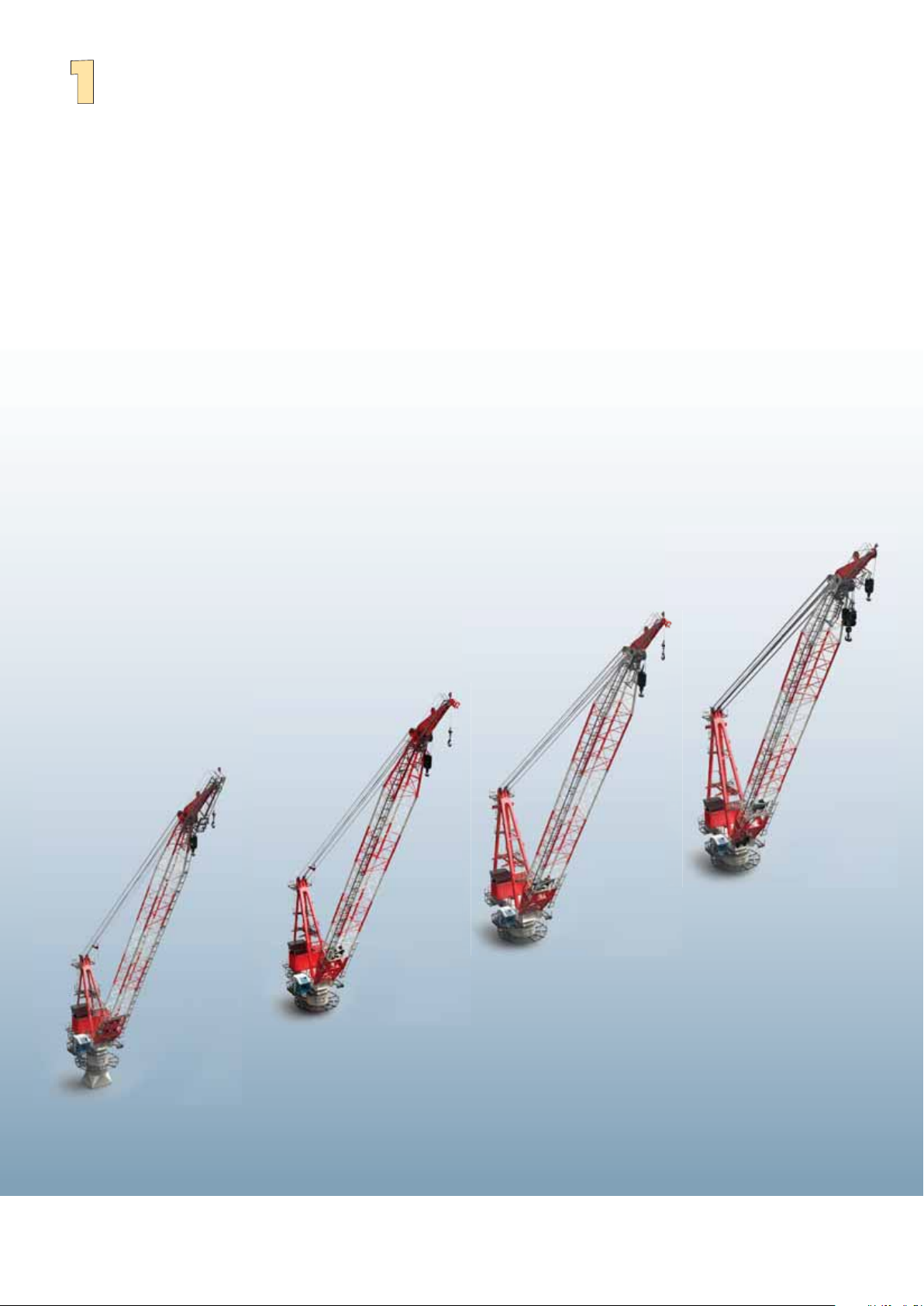

Product Range

Through many years of experience and technology strictly orientated towards customer requirements, a range of products has

been created which sets new standards in innovation, quality and reliability.

The BOS crane is a rope luffing type offshore crane with open

A-frame design. The crane is available in various sizes and

different lifting capacities ranging from 25 t up to 1200 t. The

boom length is adjustable and can be extended up to 102 m for

some models.

The BOS cranes are suitable for any kind of offshore installation,

either floating or bottom supported, as they provide all

appropriate safety and safeguarding systems and features.

The crane provides its own onboard power pack (either

electric-hydraulic or diesel-hydraulic, each with closed

hydraulic loops) which is located in an enclosed and weatherproof compartment underneath the A-frame. As an option the

BOS crane can be upgraded and certified for man riding and for

personnel rescue operations.

BOS 2600

Boom length from 30 m to 60 m

Max. capacity 100 t

4

BOS 7500

Boom length from 36 m to 84 m

Max. capacity 300 t

BOS 6000

Boom length from 36 m to 72 m

Max. capacity 150 t

BOS 4200

Boom length from 33 m to 72 m

Max. capacity 150 t

Page 5

BOS 14000

Boom length from 39 m to 102 m

Max. capacity 600 t

BOS 45000

Boom length from 51 m to 102 m

Max. capacity 1200 t

BOS 35000

Boom length from 51 m to 102 m

Max. capacity 1000 t

5

Page 6

Applications

Offshore Cranes

In general, offshore cranes are slewing cranes with safe working

loads up to 150 metric tonnes, mounted on a bottom-supported

or floating offshore installation. Typical duties include load and

cargo handling to and from supply vessels, barges or semisubmersibles as well as the support of oil drilling and production

activities.

Heavy Lift Offshore Cranes

Heavy lift offshore cranes are lifting appliances mounted on

barges, semi-submersibles or other vessels. They are typic

used in construction, deconstruction and salvage operations in

a marine environment with safe working loads higher than 150

metric tonnes.

ally

Cranes for Subsea Operation

Cranes for subsea operation are used to handle loads in water, as

well as lower and lift loads to or from the seabed.

© DSME

6

Page 7

Crane Layout - Structure Overview

Liebherr offshore cranes use the most advanced design, engineering and production technology and consist of the following main

constructional groups:

Design Philosophy / Structural Design

The use of modern 3D design tools and finite element analysis

allow detailed structural studies, including fatigue analysis and

weight optimisation.

Our offshore cranes are designed and manufactured in strict

accordance with the applicable design rules and regulations and

the appropriate norms and standards.

Structural Materials

All materials for the primary steel structure of the crane and the

crane pedestal meet or even exceed the requirements of the

certifying authorities.

As a standard, materials are certified according to the relevant

EN standards, certification level 3.1. Other certification levels are

optional and can be quoted upon request (e.g. for low temperature

applications, class notation etc.).

Auxiliary hoist

Main hoist

Walkway

A-frame

Cooler

Machinery house

Luffing winch

Base column

Boom

Auxiliary hoist winch

Main hoist winch

Operator‘s cabin

Slewing platform

7

Page 8

Slewing Platform and A-Frame

The slewing platform is designed to house the machinery compartment, the luffing winch, the counterweight (if installed),

the slewing gears and the operator‘s cabin.

Machinery House / Machinery

The machinery house and the machinery located inside are

protected against weather. Cooling is achieved via hydraulically

driven fans.

Also situated in the machinery house are the electrical switch

compartments, containing the in-house designed Liebherr

Litronic® crane control system (VME-CAN-Bus 2-line).

Features of Liebherr Litronic

®

control system

s¬ Availability of spare parts: 25 years

s¬ All upgrades are downward compatible

s¬ Ease of maintenance – no additional software specialist

required

s¬ Designed and tested for maritime environment

s¬ Spacious arrangement for optimal service accessibility

The crane drive consists of a splitter gearbox feeding variable

displacement axial piston pumps for the hoisting, slewing and

the luffing gear. The splitter gearbox can either be driven by an

electric motor or alternatively by a diesel motor.

Closed hydraulic circuits technology is used for maximum

performance and high efficiency. This technology guarantees

a highly responsive, smooth and sensitive operation with a

minimum of components, maximising the operating safety even in

continuous operation or low/high ambient temperatures (-25°C to

+45°C). As an option an arctic temperature package is available,

which allows to operate the crane within an ambient temperature

range of -40 °C to +45 °C.

s¬ Immediate and short system reaction times for rapid and safe

operation

s¬ All crane motions are carried out continuously, precisely and

simultaneously with adjustable speed and load

s¬ High performance density requiring a minimum of power

s¬ Faster acceleration and deceleration due to low masses of

inertia

s¬ Easy fault-finding and diagnosis due to spare circuits for each

crane function

s¬ Reduced service and maintenance costs compared to open

loop systems of equivalent capacity

s¬ Up to zero reverse power

Luffing winch and machinery house Machinery house - diesel engine & splitter gearbox

8

Page 9

Machinery house - electric motor & splitter gearbox

9

Page 10

5

The boom is a lattice framework construction with the boom tip being a shell structure which accommodates the luffing and main

hoist sheaves. The hoist winches (main and auxiliary winches) are located in the pivot section of the boom. A boom extension and

auxiliary hoist are available as an optional extra.

To achieve the required working outreach, the standard boom pivot sections and standard boom heads can be combined with variable

intermediate sections. For the connections between the various boom sections bolted flanges are provided.

Luffing and hoisting sheaves on the boom head are lubricated from a centralised greasing point located next to the boom head which is

accessible from the boom walkway. A hook garage is available for the main and auxiliary hoist.

Boom Pivot Bearing

Maintenance-free, capsuled spherical bearings ensure optimal transmission of force and maximal lifetime expectation.

Boom

Boom with optional auxiliary hoistBoom with optional auxiliary hoist

10

Page 11

Driver Comfort

The operator‘s control desk is fully equipped with all controls and indicators as required for safe and reliable crane operation. The

design and layout of the cabin is based on the need for visibility, comfort and operability.

It provides a comfortable, low noise environment, essential for ensuring uninterrupted concentration for the driver when operating the

crane. Vibrations are reduced through swing equalisers.

The window sections are of tinted anti-glare toughened safety glass mounted in an innovative glass frame providing a clear view of the

operational area and the handled loads.

Control Meets Comfort

s¬ Optimal position near boom (standard)

s¬ 70% glass proportion (safety glass)

s¬ Unrestricted and reliable view for the operator

s¬ Integrated Litronic

s¬ Closed-circuit video system on the jib head with coloured monitor in the cabin (available as an

s¬ Air conditioning (standard)

s¬ Noise- and vibration insulated cabin

®

touch-screen (one monitor for displaying all relevant information to the operator )

optional item)

Operator‘s cabin

11

Page 12

Optional Equipment

s¬ RotaBolt® for slewing bearing bolts

s¬ RotaBolt® Vision for boom section bolts

s¬ Access to operator‘s cabin platform via stairway

s¬ Enlarged operator‘s cabin (10 m

s¬ Crane EX-rated

s¬ Arctic temperature package down to -40°C ambient temperature

s¬ Stainless steel package

s¬ Emergency power pack system

s¬ CCTV camera system (safe/EX-rated) for main and auxiliary hoist

s¬ Slewing bearing inspection device

s¬ Factory Acceptance Test (FAT)

s¬ LiDAT

s¬ Hook garage for main and auxiliary hoist

s¬ Sector limit (sector operation)

s¬ Anti-Collision System

®

remote troubleshooting and analysis/diagnosis tool

3

)

12

Page 13

Environmental Record

With its headquarters located in an environmentally protected area, ecological issues have always been high on the agenda for

Liebherr. The implementation of economy software, biodegradable oils and special noise insulation throughout its offshore crane

range are just a few examples of Liebherr’s ecological awareness.

Operating Liquids

Upon request, all Liebherr offshore cranes can be run on bio-diesel to comply with local regulations and the transition to alternative

fuels in customer equipment fleets.

Liebherr offers biodegradable oil especially developed for the Liebherr product line. In combination with spectrographic oil analysis

techniques, oil lifetime is extended

Eco-control

On request, Liebherr offers a special power management feature for diesel engine driven cranes. This "Eco-control" renders savings

in fuel consumption of up to 25% depending on the crane application and therefore results in reduction of noise exposure and

environmental contaminants.

thus providing components such as pumps and motors with even longer lifetimes.

Oil rig "Seafox" in the North Sea with Liebherr offshore cranes

13

Page 14

Production and Transportation

A clearly defined company strategy guarantees that only top quality products are developed and built in the most modern

production facilities.

Liebherr-MCCtec Rostock

In order to further expand its position in the international

maritime market, Liebherr established an additional production

site for offshore cranes in Rostock’s harbour district on the

German Baltic Coast in 2006.

The production facility in Rostock plays an important role in

the further growth and development of the international market

position of our maritime product divisions.

Overall, the Liebherr Group has three state-of-the-art production

sites for offshore cranes (Nenzing/Austria, Rostock/Germany

and Sunderland/UK).

Factory Testing

Upon request, each offshore crane can be put through an intense

factory testing programme (FAT). This means that every single

crane is fully assembled and load tested before delivery which

results in an extraordinarily quick commissioning schedule.

Fully Assembled Transportation

Thanks to its direct access to the sea, Rostock is very well

situated in terms of worldwide sales logistics, especially when

shipping large equipment. Crane in parts, semi-erected or even

fully assembled, are possible means of transportation from the

Rostock location.

Liebherr-Werk Nenzing GmbH

Liebherr-MCCtec Rostock GmbH

Liebherr Sunderland Works Ltd.

14

Page 15

Test facility Liebherr-MCCtec Rostock GmbH

Boom section

15

Page 16

Liebherr Service Worldwide

Over 800 offshore cranes are serviced by our service department. Our worldwide network of customer service centres guarantees

the supply of spare parts and service throughout the entire lifetime of all machines.

Competence on Site

Speed and reliability have always been part of our service. Liebherr fully appreciates the value of a quick response for reduced

downtime and immediate restoration of the crane productivity. Qualified specialists are in charge to deal with any issue without

delay – if necessary, around the clock.

Logistic Service – High Speed Organisation 24/7

For an offshore crane, every operational hour is vital. Liebherr original spare parts and service staff are there for our clients around

the clock, even on weekends and public holidays. The standardised Liebherr overnight logistic service guarantees fast and safe

delivery of the original parts to their destination.

Reliable Partnership

Extensive know-how ensures first class and effective performance of all service and maintenance work, contributing to our offshore

cranes' av

services.

s¬ 0REVENTIVE¬MAINTENANCE¬AND¬SAFETY¬CHECKS

s¬ 4AILORMADE¬SERVICE¬CONTRACTS¬FROM¬INSPECTION¬AGREEMENTS¬TO¬FULL¬SERVICE¬CONTRACTS

s¬ #OMPREHENSIVE¬TRAINING¬FOR¬OPERATORS¬SERVICE¬AND¬MAINTENANCE¬PERSONNEL

s¬ 7ORLDWIDE¬CUSTOMER¬HOTLINE¬AROUND¬THE¬CLOCK

s¬ )MPLEMENTATION¬OF¬TECHNICAL¬MODIlCATIONS¬AND¬UPGRADES¬

s¬ 2EMOTE¬DIAGNOSES¬FOR¬FAULT¬ANALYSIS¬AND¬REPAIR¬WITH¬,I$!4

ailability and reliability. Liebherr combines expertise with clients' experience to continuously optimise products and

®

package)

Organization with high-speed guarantee

16

Page 17

Spare parts depots worldwide in all our service stations

17

Page 18

The Liebherr Group –

Partner for the Future

Today, Liebherr is among the leading manufacturers in the fields of hoisting technology and materials handling equipment. The name

Liebherr stands for products and services. It has become a synonym for ideas and innovations.

Liebherr – A Family Enterprise

In family-operated companies, ownership merges with active

entrepreneurship. This results in characteristic principles.

Liebherr is both a family business and a corporation. This does

not have to be a contradiction, as the continuous success and

steady growth prove.

To create top products, the development capacities and production facilities must measure up to the highest standards. This

requires substantial investments. From stable locations, Liebherr

is following a solidly financed expansion course. The profits

made are almost entirely retained within the Group. This provides

ample scope for extensive investments. The economic power of

the Liebherr Group is best shown by its unusually high equity

ratio of more than 50%. This sound economic basis makes

Liebherr highly independent in its strategic decisions, and it

provides an important basis for future investment and innovation

strategies. Offering high-quality products and services which are

aimed towards customers’ needs remains the benchmark.

18

Page 19

Mastering Key Technologies

In view of the high quality that Liebherr demands of its products, mastering key technologies internally and keeping core

competencies in-house has always been of great importance

to the company. Therefore, Liebherr develops and produces

crucial components, such as the entire propulsion and control

technology, themselves. Further examples are hydraulic

components, slip ring elements, and diesel engines. Here, Group

suppliers are measured against the best and most efficient

external provider.

Decentralized and International,

Based on Tradition

Operating efficiently in manageable, self-dependent units and

aiming strategically at emerging markets have always formed

part of the basic business principles. Thus, Liebherr regularly

invests substantially in further marketing and service companies

as well as in new production sites. Entering and expanding

into new markets means being locally available to assure the

customer receives full and lasting manufacturer support.

While maintaining the proven decentralized organizational form,

a divisional company structure, whose international expansion is

being carried forward, was implemented globally.

19

Page 20

Offshore Equipment Worldwide

Sunderland

s¬Manufacturing Sites

s¬Service Stations

s¬3ALES¬3TATIONS

Rostock

Nenzing

Members of Liebherr-MCCtec GmbH (Offshore Division):

Liebherr-Werk Nenzing GmbH

Dr. Hans Liebherr Strasse 1

6710 Nenzing

Austria

Tel.: +43 50809 41-481

Fax: +43 50809 41-625

info.lwn@liebherr.com

Liebherr-MCCtec Rostock GmbH

Liebherrstrasse 1

18147 Rostock

Germany

Tel.: +49 381 60 06 0

Fax: +49 381 60 06 100

info.mcr@liebherr.com

Liebherr Sunderland Works Ltd.

Ayres Quay, Deptford Terrace

Sunderland

Tyne and Wear, SR4 6DD

Great Britain

Tel.: +44 191 51 43 001

Fax: +44 191 51 44 191

info.lsw@liebherr.com

Sales Stations:

Liebherr Brasil Ltda.

Av. Marechal Câmara, 271, Sala 301

Rio de Janeiro - RJ-Brasil

20020-080

Tel.: +55 21 2220 8469

Fax: +55 21 2240 3563

Liebherr Russland OOO

1 Borodinskaya Str. 5

121 059 Moscow

Russia

Tel.: +7 495 502 17 34

Fax: +7 495 933 72 23

Liebherr-Maritime Benelux B.V.

Beeldschermweg 2

0/¬"OX¬

3821 AH Amersfoort

Netherlands

Tel.: +31 33 450 0850

Fax: +31 33 450 0899

Sales Headquarters:

Liebherr-Werk Nenzing GmbH

Dr. Hans Liebherr Strasse 1

6710 Nenzing

Austria

Tel.: +43 50809 41-481

Fax: +43 50809 41-625

offshore.crane@liebherr.com

Liebherr Nenzing Crane Co.

Offshore Cranes

7075 Bennington Street

Houston, Texas 77028

USA

Tel.: +001 713 636 4070 (24 h)

Fax: +001 713 636 4073

Service Stations:

Liebherr-Nenzing Service GmbH

Am Neuländer Baggerteich 1

210 Hamburg

Germany

Tel.: +49 40 76702 200

Fax: +49 40 76587 79

Liebherr Brasil Ltda.

Rua Dr. Hans Liebherr, 1

30¬¬'UARANTIGUETA

Brazil

Tel.: +55 12 3128 4282

Fax: +55 12 3128 4322

Liebherr (HKG) Limited

¬0ING¬#HE¬2OAD

Fanling

New Territories

Hong Kong

Tel.: +852 3142 3113

Fax: +852 3142 3119

Liebherr-Werk Nenzing GmbH

0/¬"OX¬¬!¬.ENZING!USTRIA

Tel.: +43 50809 41-0

Fax: +43 50809 41-500

info.lwn@liebherr.com

www.liebherr.com

Liebherr Sunderland Works Ltd.

Ayres Quay, Deptford Terrace

Sunderland

Tyne and Wear, SR4 6DD

Great Britain

Tel.: +44 191 567 9977

Fax: +44 191 567 2723

Liebherr-Canada Ltd.

3UITE¬¬!TLANTIC¬0LACE

215 Water Street

St. John´s, NL A1C 6C9

Canada

Tel.: +001 709 748 7829

Fax: +001 709 368 6494

Liebherr-Singapore Pte. Ltd.

.O¬¬0ANADAN¬!VENUE

Singapore 609384

Tel.: +65 6265 2305 264

Fax: +65 6261 6485

Liebherr-Maritime Benelux B.V.

Beeldschermweg 2

0/¬"OX¬

3821 AH Amersfoort

Netherlands

Tel.: +31 33 450 0880

Fax: +31 33 450 0897

Liebherr Nenzing Crane Co.

Offshore Cranes

11801 NW 100th Road, Suite 17

Miami, FL 33178

USA

Tel.: +001 305 889 0176

Fax: +001 305 889 0655

Liebherr-Africa (Pty.) Ltd.

Vlakfontein Road

Fulcrum Ind. Township

0/¬"OX¬

Springs/Trasnvaal 1560

Tel.: +27 11 365 2000

Fax: +27 11 817 3884

Liebherr Russland OOO

1-aya Borodinskaya UL., 5

Floor 3

121 059 Moscow

Russia

Tel.: +7 495 710 7602

Fax: +7 495 933 0771

Liebherr (HKG) Limited

Shanghai Representive Office

Suite 709

7/F. Jin Zhong Building

Shanghai, China 200031

Tel.: +86 21 6415 2148

Fax: +86 21 6473 6786

Liebherr Middle East FZE

Liebherr-Werk Nenzing Division

Jebel Ali Free Zone (South)

0/¬"OX¬

Dubai/U.A.E

Tel.: +971 4 8860199 107

Fax: +971 4 8860324

Liebherr Offshore Cranes – 10597542 – 04/2012 – Subject to change without notice.

Loading...

Loading...