Page 1

Flexible Robot Systems

Intelligent Work Piece Handling:

Bin Picking

Page 2

Liebherr Robot System for Bin Picking

Bin picking is one of the most challenging industry automation applications. The foundation of this system is the

automatic unload of randomly arranged work pieces out of

dunnage. To date there are very few robot designs that meet

both the sturdiness and cycle time requirements. Liebherr

offers flexible robot systems with which bin picking can be

economically automated. Liebherr has designed and created

robot systems that help automate manufacturing processes

to increase capacity thereby lowering costs. Many tasks can

be solved with the long established tried and tested work

piece handling components from the Liebherr automation

systems area.

Process Description

Unloading the work piece out of dunnage is a complex interaction between a vision system, software and robot. According

to the part spectrum all process-relevant steps need to be synchronized to reach an optimum grip and positioning result.

Visual Data Acquisition

Robot Path Planning

Data Analysis

Collision Detection

Object Identification

Object Removal

Object Selection

Object Positioning

Flexible Robot Systems

2

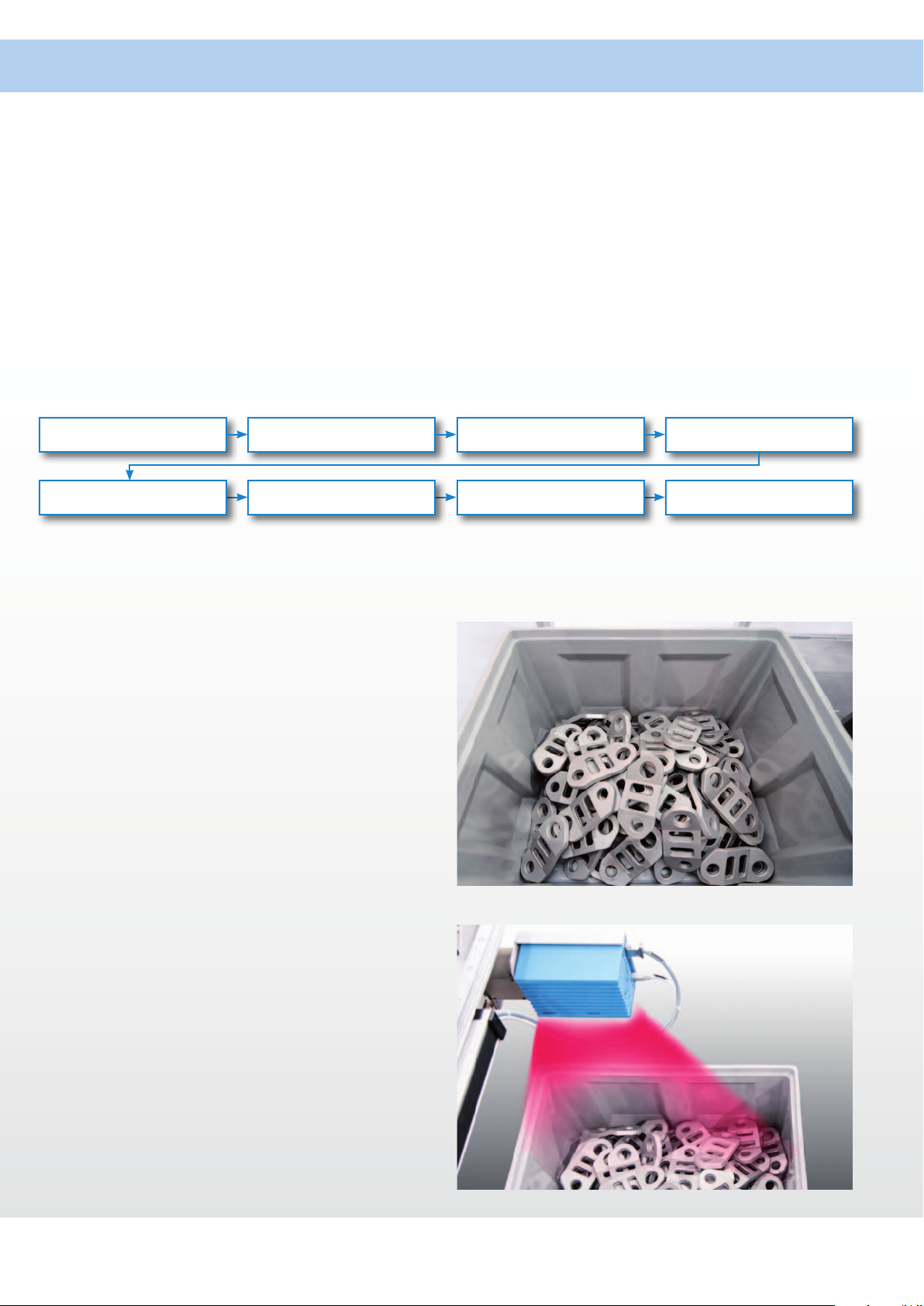

Requirement

Randomly arranged parts should be

removed from a transport container.

Visual Data Acquisition

and Analysis

A reliable and dynamic 3D object recognition

system visually acquires and analyzes the data.

Page 3

Liebherr possesses years of experience with automation

systems in the most varied branches and fields of manufacturing. This produces proficiency in new technology development. Liebherr robot systems have a reliable and dynamic

3D object identification system based on powerful software

which separates, identifies, and part selection. This robot

system is also designed with a specially-developed gripper

with additional axes for collision-free gripping and removal

of the parts from dunnage.

Object Identification and Selection

Specially designed software segments identify and

select the tool information and technical conditions.

Collision-Free Work Piece Unload

The intelligent gripper has additional axes and enables

collision-free removal of parts from dunnage.

Object Positioning

Lastly, the tools are precisely positioned at the

defined location or in a machine.

Flexible Robot Systems

3

Page 4

Machine Tools and

Automation Systems by Liebherr

With around sixty years of experience in the field, Liebherr is one of the world‘s leading manufacturers of CNC gear

cutting machines, gear cutting tools and automation systems. These innovative products are the result of advanced

ideas, highly qualified employees and the latest manufacturing systems at each of their locations. They are characterised

by economy, ease of use, quality and reliability in combination with a high degree of flexibility.

Liebherr employs approximately 1,200 people in the field of machine tools and automation technology and has production

facilities in Kempten and Ettlingen (Germany), Collegno (Italy), Saline (Michigan, USA) and Bangalore (India). They are

supported by expert and reliable marketing and service specialists at a large number of locations worldwide.

System Solutions for

Gear Cutting Machines

The Liebherr range in the field of gear cutting machines

includes gear hobbing machines, gear shaping machines

and hobbing and profile grinding machines, all noted for

their high degree of stability and availability. Liebherr can

supply all technologies required for the manufacture of

high-quality gears and is continuously developing these

technologies. Particular importance is attached to the

energy efficiency of the machines.

Gear cutting machines from Liebherr are supplied to

renowned manufacturers of gears and gearboxes as well

as large-scale slewing rings worldwide. They are in demand

primarily from the automotive and construction machinery industries and also increasingly from the windpower

industry for the manufacture of gears for wind turbines.

High-Quality

Gear Cutting Tools

Liebherr manufactures high-quality precision tools for the

soft and hard machining of gears and all Liebherr gear

cutting machines are fitted with these tools. The range also

includes Lorenz stock tools and products customised for

specific applications.

Automation Systems for a Wide

Range of Applications

Liebherr has a wide range of products for linear portals,

pallet-handling systems, conveyor systems and robot

integration for projects in all areas of production and can

provide above-average availability of systems.

www.liebherr.com

Liebherr-Verzahntechnik GmbH

Werk Ettlingen

Gear cutting tools

He r tzs t r a ße 9 -15

76275 Ettlingen, Germany

+49 (0)7243 708-0

Fax +49 (0)7243 708-685

tools.lvt@liebherr.com

Liebherr-Verzahntechnik GmbH

Machine tools, automation systems

Kaufbeurer Straße 141, 87437 Kempten, Germany

+49 (0)831 786-0, Fax +49 (0)831 786-1279

www.liebherr.com, e-mail: info.lvt@liebherr.com

Liebherr-Utensili S.r.l.

Gear cutting tools

Via Nazioni Unite 18

10093 Collegno TO, Italy

+39 (0)114 24 8 7 11

Fax +39 (0)114 559964

info.lut@liebherr.com

Liebherr-Gear Technology Inc.

Machine tools

Liebherr Automation Systems Co.

Automation systems

1465 Woodland Drive

Saline, MI 48176-1259, USA

+1 7344 297225

Fax +1 7344 292294

info.lgt@liebherr.com

Liebherr-Machine Tools India Pvt. Ltd

Machine tools

353/354, 4th Main, 9th Cross, 4th Phase

Peenya Industrial Area

Bangalore - 560 058, India

+91 (0)80 41 273033

Fax +91 (0)80 41 272625

info.mti@liebherr.com

Subject to change without prior notice.Printed in Germany by Typodruck BK 08.12_enGB

Loading...

Loading...