Page 1

Installation

Instructions

For BioFresh, NoFrost, Combined

Refrigerator-Freezers and

Side-By-Side Units

Instructions

de montage

Pour combinés réfrigérateur-

congélateurs anti-givre BioFresh et

les appareils côte à côte

Instrucciones

de instalación

Para frigoríficos-congeladores

combinados BioFresh, NoFrost y

unidades lado a lado

BFI/BF1051 / BGEN/es 2956

7082 248-00

Page 2

IMPORTANT

PLEASE READ AND FOLLOW

THESE INSTRUCTIONS

These instructions contain Warning and Caution

statements. This information is important for safe

and efficient installation.

Always read and follow all Warning and Caution

statements!

WARNING

!

States a hazard that may cause serious

injury or death if precautions are not

followed.

CAUTION

!

Signals a situation where minor injury of

product damage may occur if you do not

follow instructions.

IMPORTANT

This highlights information that is especially

relevant to a problem-free installation.

Make sure incoming voltage is the same as the unit

rating.

To reduce the risk of fire, electric shock, or

personal injury, installation work and electrical

wiring must be done by a qualified electrician in

accordance with all applicable codes and

standards, including fire-rated construction.

A delight in freshness

BFI/BF1051 / BGEN/es 2956

Page 3

TO THE INSTALLER

It is very important that the guidelines and

instructions are followed in the manual to ensure

proper installation and operation of the unit. The

Installation Guidelines section contains important

information for making sure the installation is

correct. Read and understand all the information in

Installation Guidelines, and in this manual before

the unit is installed.

IMPORTANT

BFI/BF1051 / BGEN/es 2956

A delight in freshness

1

Page 4

TABLE OF

Contents Page

Installation Guidelines.................................................................................. 3

Area Requirements................................................................................ 3

Electrical Requirement........................................................................... 3

Customer’s Responsibility...................................................................... 3

Blocking For Safety................................................................................ 3

Unit Venting............................................................................................ 3

Planning Information.................................................................................... 4

Cabinet Opening Dimensions................................................................ 4

Assembling Decorative Panels .................................................................... 7

Integrating Cabinetry.................................................................................... 8

Framed Panels ....................................................................................... 8

Overlay Panels....................................................................................... 9

Reversing Door Hinges.............................................................................. 14

Door Opening Angle ............................................................................ 17

Installation .................................................................................................. 19

Blocking For Safety.................................................................................... 22

IceMaker..................................................................................................... 23

Water Connection................................................................................ 23

Connection to the Water Supply.......................................................... 24

Side-By-Side Installation............................................................................ 25

CONTENTS

A delight in freshness

2

BFI/BF1051 / BGEN/es 2956

Page 5

INSTALLATION

GUIDELINES

Area Requirements

Verify the following:

• Floors can support refrigerator’s weight plus

approximately 1200 pounds (544 kg) of food

weight.

• Finish kitchen floor height is level. Refrigerator

must be shimmed to the floor level if the floor

heights are not equal to make sure air vents are

not obstructed.

• Remove anything attached to rear or side walls

that can obstruct refrigerator opening.

• Cutout dimensions are accurate.

• Electrical outlet is in correct location.

Do not install this unit next to another refrigerator or

freezer. This is important to prevent condensation

or consequential damage from another unit.

Electrical Requirement

If codes require a separate grounding circuit to be

used, have a qualified electrician install the circuit.

WARNING

!

Do not ground to a gas pipe. Check with a

qualified electrician if you are not sure the

appliance is properly grounded. Do not

have a fuse in the neutral or grounding

circuit.

WARNING

!

ELECTROCUTION HAZARD

Electrical Grounding Required.This

appliance is equipped with a three-prong

(grounding) polarized plug for your

protection against possible shock hazards.

DO NOT remove the round grounding

•

prong from the plug.

DO NOT use a two-prong grounding

•

adapter.

DO NOT use an extension cord to

•

connect power to the unit.

Customer’s Responsibility

A 115 Volt, 60 Hz, 15 Amp (20 Amp for side-by-side

installation) fused electrical supply is required. We

recommend using a dedicated circuit for this

appliance to prevent electrical overload. Follow the

National Electrical Code and local codes and

ordinances when installing the receptacle.

Blocking For Safety

The anti-tip brackets must be installed to prevent

the unit from tipping after it is installed. Refer to

Blocking For Safety.

Unit Venting

DO NOT restrict the air flow. Air flow must be

provided for the unit to operate. The factory air

vents provide 31 square inches (200 cm

flow per unit. If you are replacing the factory air

vents with an overlay, the air flow must be the same

or greater than the factory air vents.

2

) of air

WARNING

!

ELECTRICAL SHOCK HAZARD

• Electrically ground refrigerator.

• Do not use an extension cord.

• Failure to follow these instructions

could result in fire or electrical shock.

BFI/BF1051 / BGEN/es 2956

A delight in freshness

3

Page 6

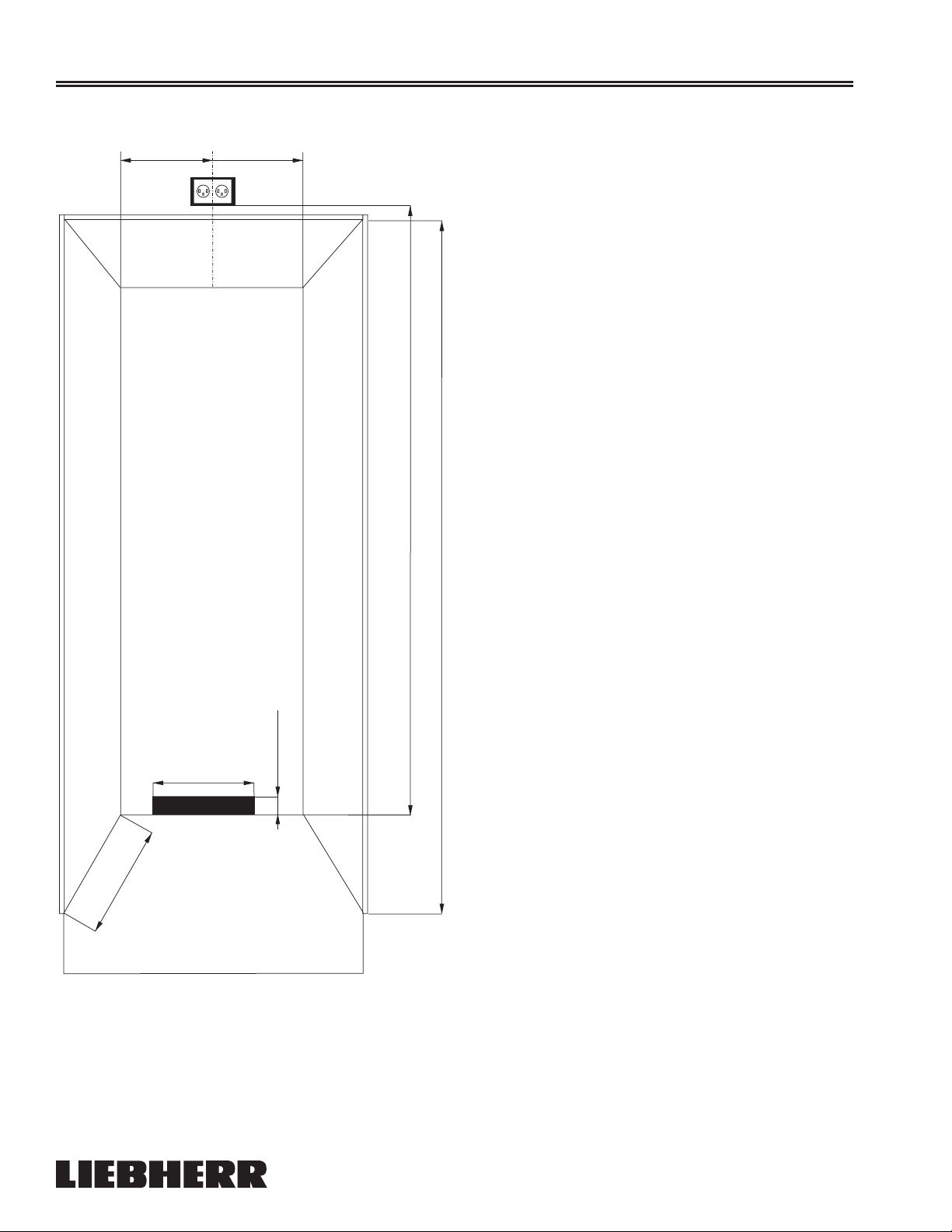

PLANNING

Electrical outlet

location

Locate water supply

within bottom

shaded area

NFORMATION

I

Cabinet Opening Dimensions

= =

Electrical outlet

location

- Figure 1

Allow units to open a minimum of 90° to prevent

problems removing drawers. With the door opening

90°, you may have to move drawers slightly to

clear the door interior.

Refer to the minimum door clearances in the PreInstallation Specifications chart.

•Allow for a minimum 3-3/4" (95 mm) filler, for

corner installations, so the door can open to 90°.

If you’re using raised panels, consider using a

wider filler.

IMPORTANT

Refer to the full scale illustrations at the end of

this section for specifics on door openings and

filler size alternatives.

Locate water supply

within bottom

shaded area

3" (7.6cm)

24" (61cm)

Single: 24" (610mm) / SBS: 48" (1219mm)

Figure 1

85" (2159mm)

79.3/4" (2025.7mm)

LBR022

A delight in freshness

4

BFI/BF1051 / BGEN/es 2956

Page 7

PLANNING

NFORMATION

I

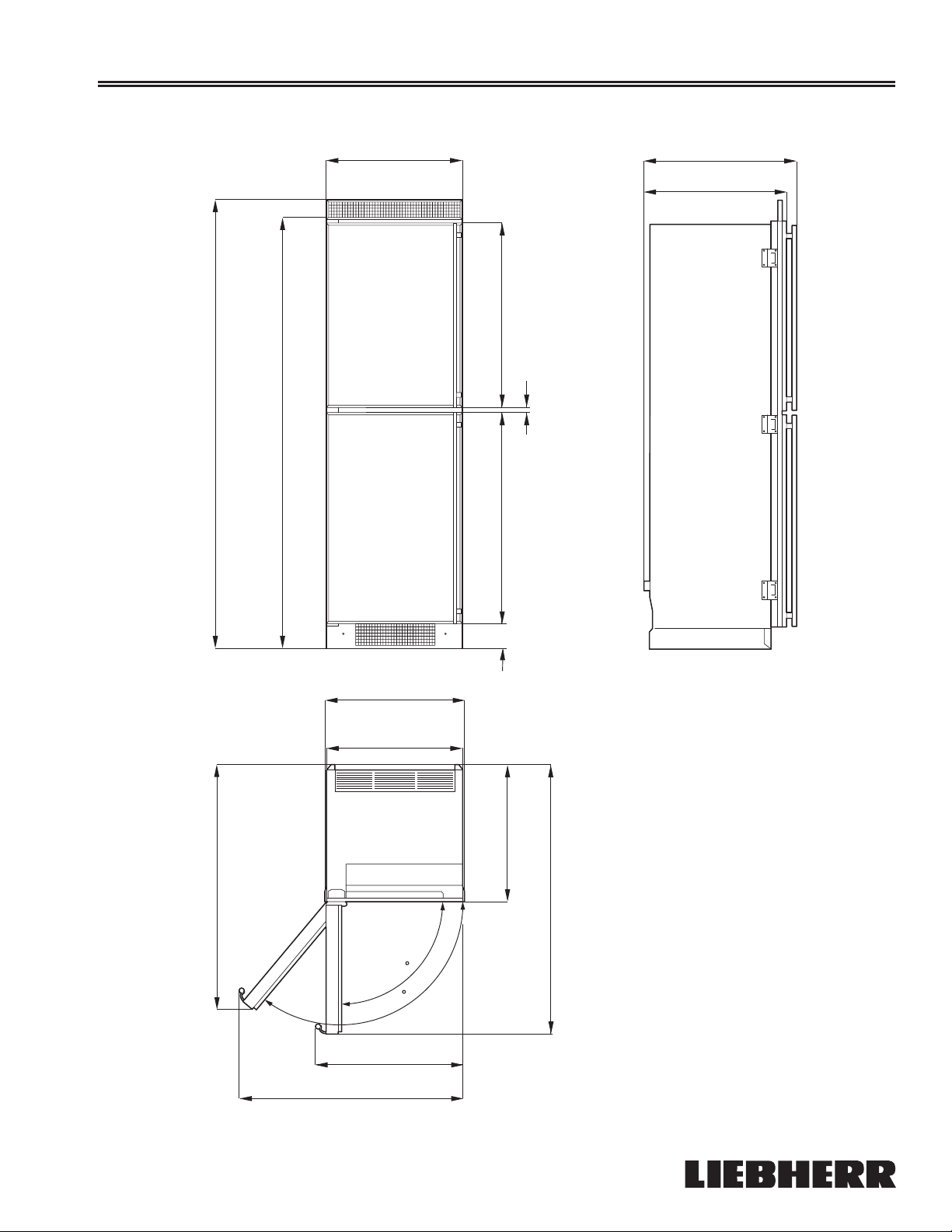

BFI 1051

- Figure 2

79-15/16" (2030 mm)

76-49/64" (1950 mm)

24" (610 mm)

32-25/32" (832 mm)

55/64"

(22 mm)

37-31/64" (952 mm)

26-57/64" (683 mm)

25-3/16" (640 mm)

43-33/64" (1105 mm)

39-29/64" (1002 mm)

24" (610 mm)

23-55/64" (606 mm)

90

130

25-25/32" (655 mm)

4-19/64" + 19/32"

(109 + 15 mm)

23-3/4"

(603 mm)

47-53/64" (1215 mm)

Figure 2

BFI/BF1051 / BGEN/es 2956

A delight in freshness

5

Page 8

PLANNING

NFORMATION

I

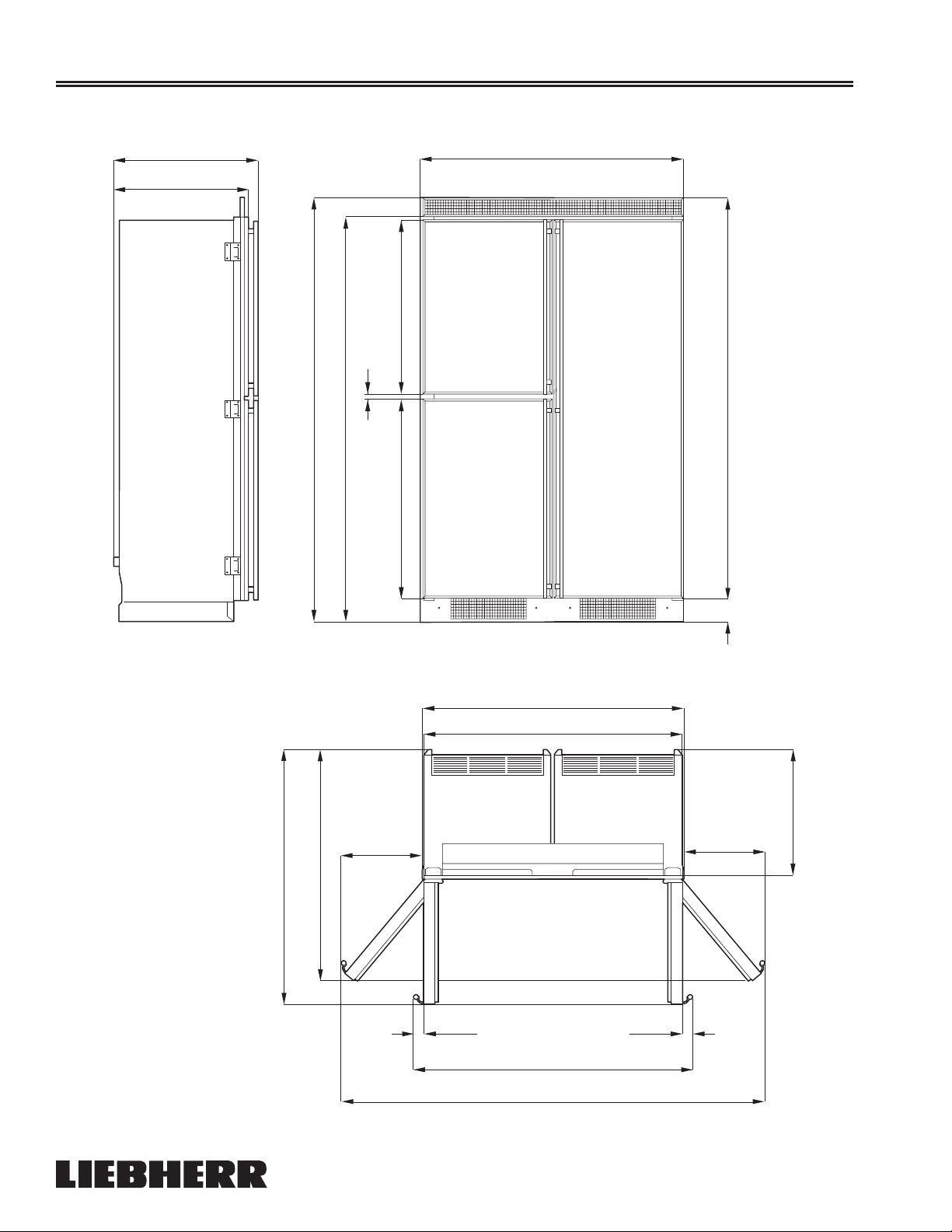

Side-By-Side BFI 1051

26-57/64" (683 mm)

25-3/16" (640 mm)

- Figure 3

32-25/32" (832 mm)

55/64"

(22 mm)

76-49/64" (1950 mm)

79-15/16" (2030 mm)

37-31/64" (952 mm)

48" (1219 mm)

71-1/8" (1807 mm)

15-13/32"

(391 mm)

43-33/64" (1105 mm)

47-53/64" (1215 mm)

1-23/32"

(44 mm)

48" (1219 mm)

47-3/4" (1213 mm)

51-29/64" (1307 mm)

4-19/64" + 19/32"

(109 +15 mm)

15-13/32"

(391 mm)

1-23/32"

(44 mm)

23-3/4"

(603 mm)

78-51/64" (2001 mm)

Figure 3

A delight in freshness

6

BFI/BF1051 / BGEN/es 2956

Page 9

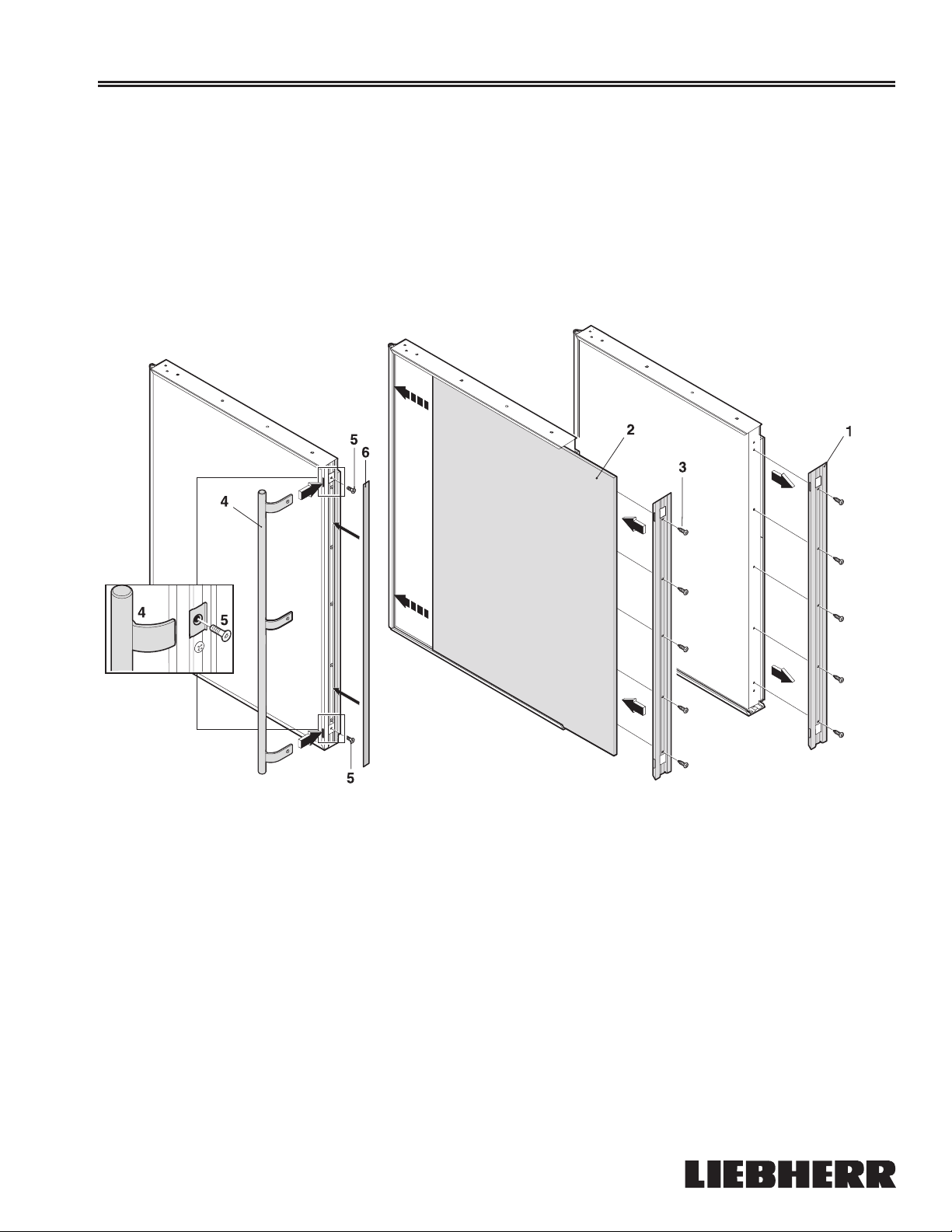

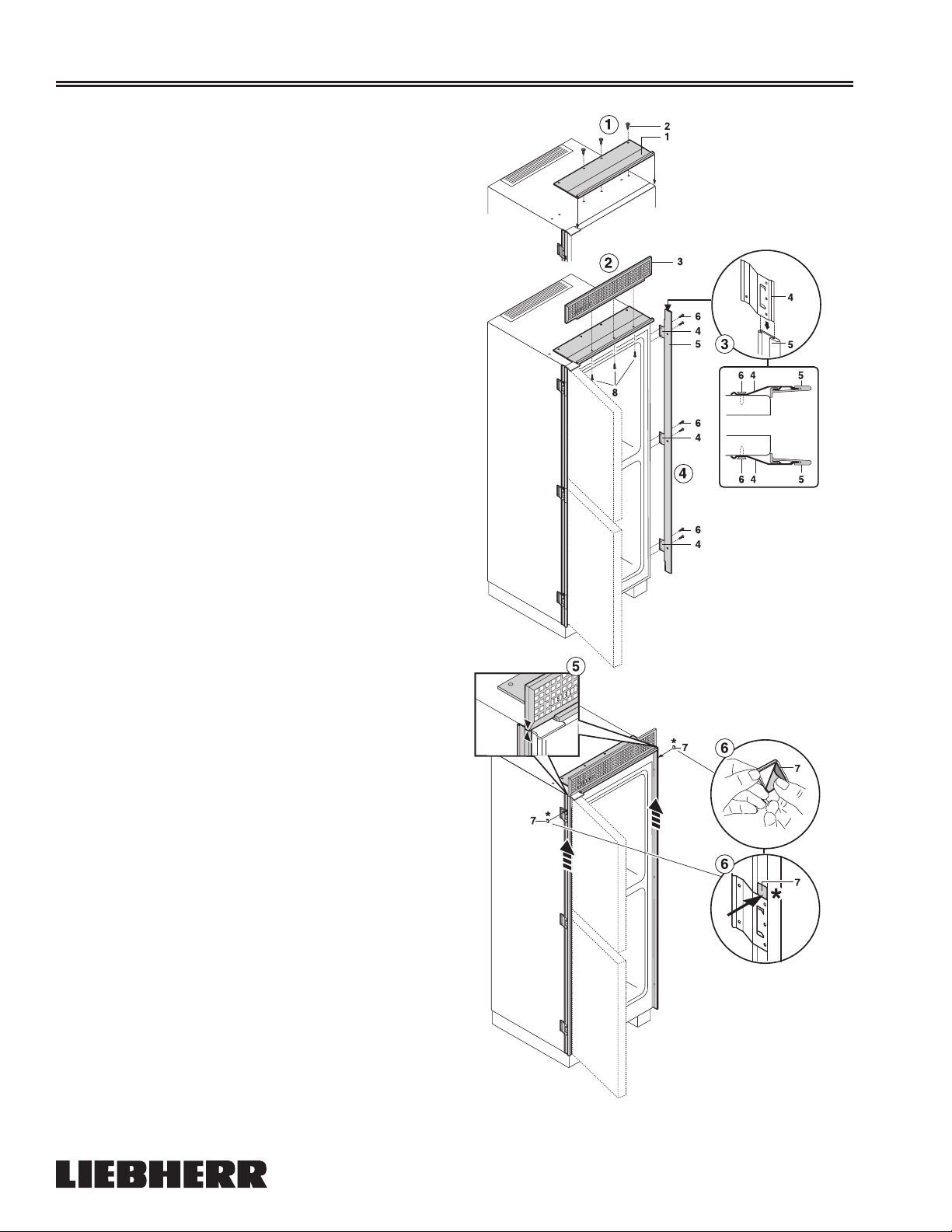

ASSEMBLING

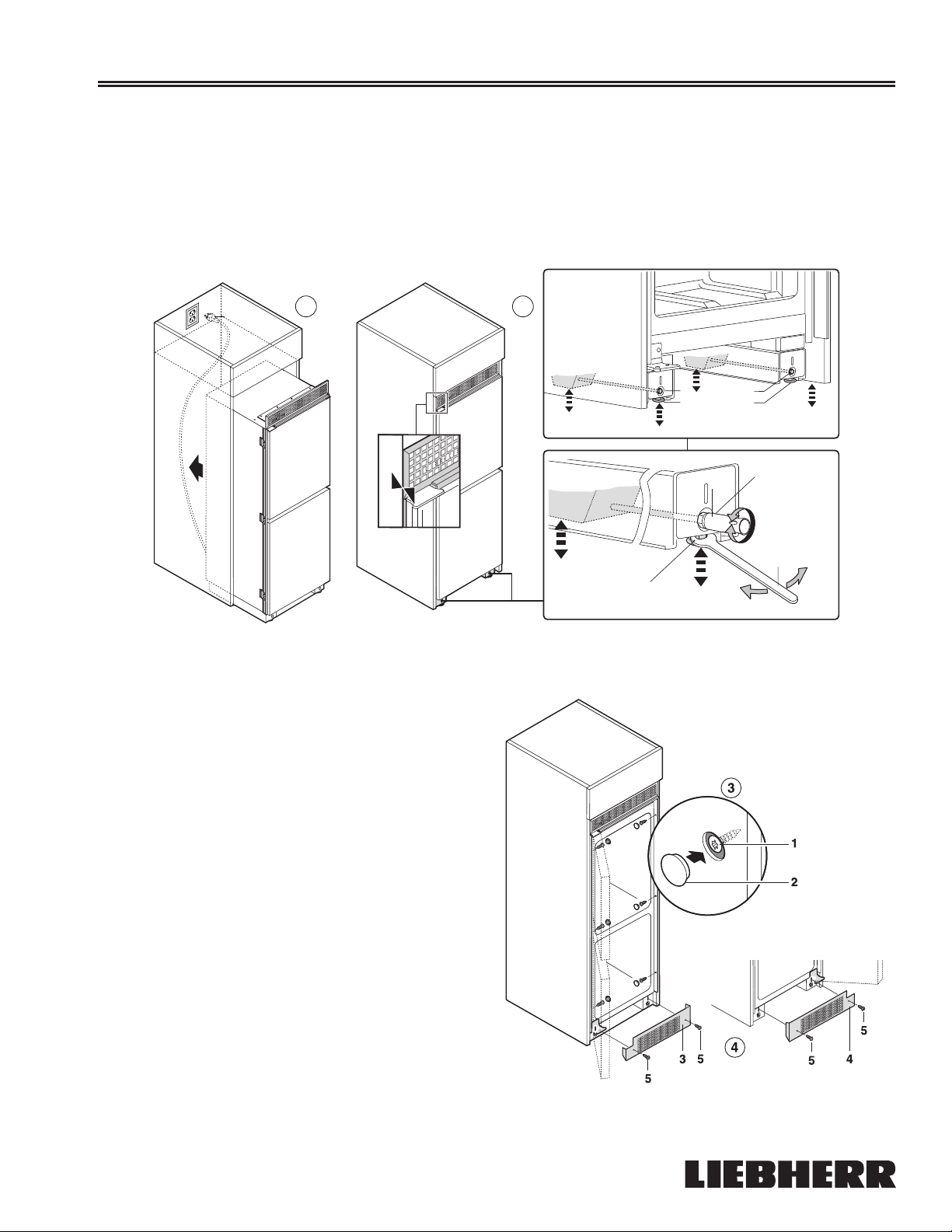

Figure 4

Proceed as shown in the illustration:

(1) Door change frames

(2) Decorative panel

(3) Screws for door change frames

(4) Handle, depending on model

(5) M4 x 10 screws for handle

(6) Filler strip

ECORATIVE PANELS

D

BFI/BF1051 / BGEN/es 2956

LBR048

Figure 4

A delight in freshness

7

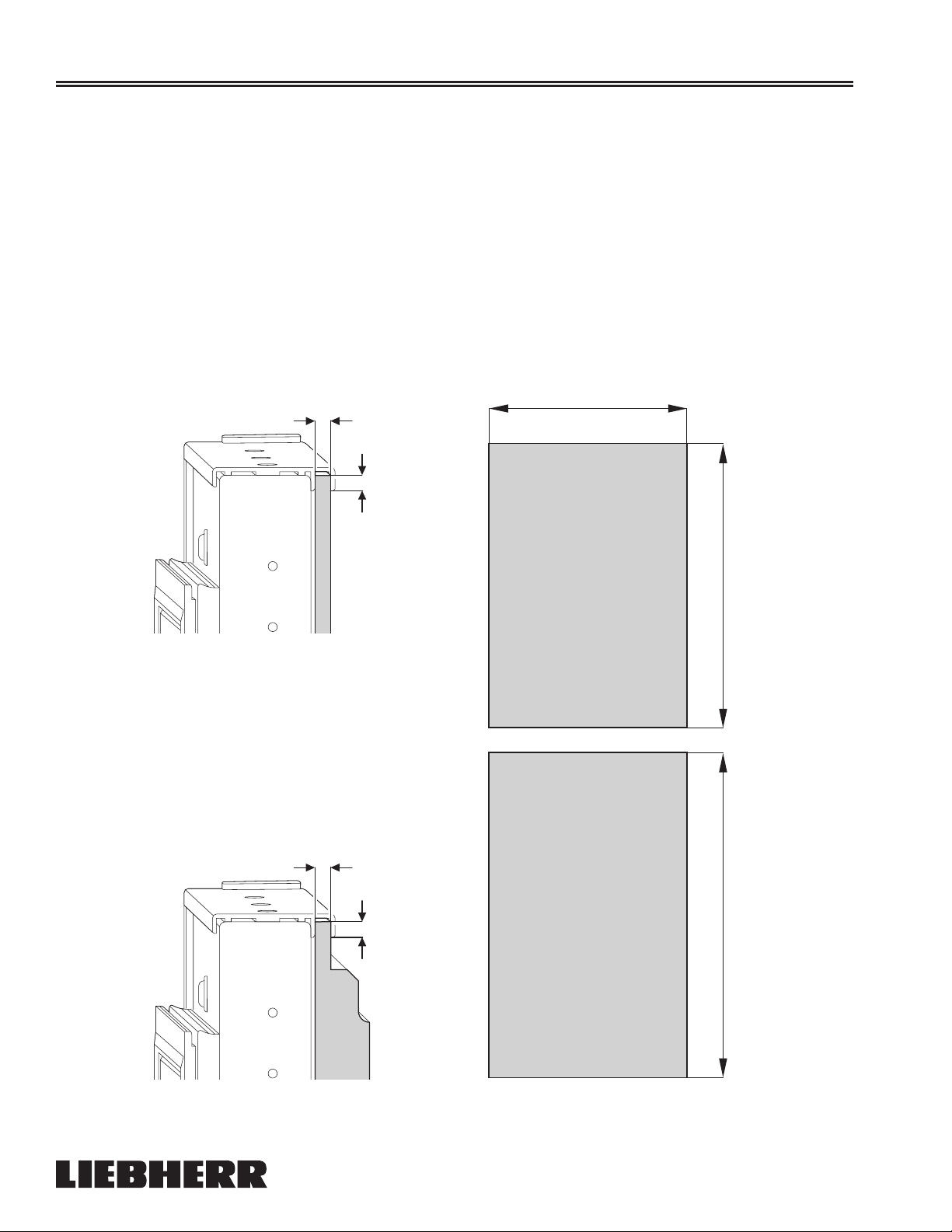

Page 10

INTEGRATING

3

CABINETRY

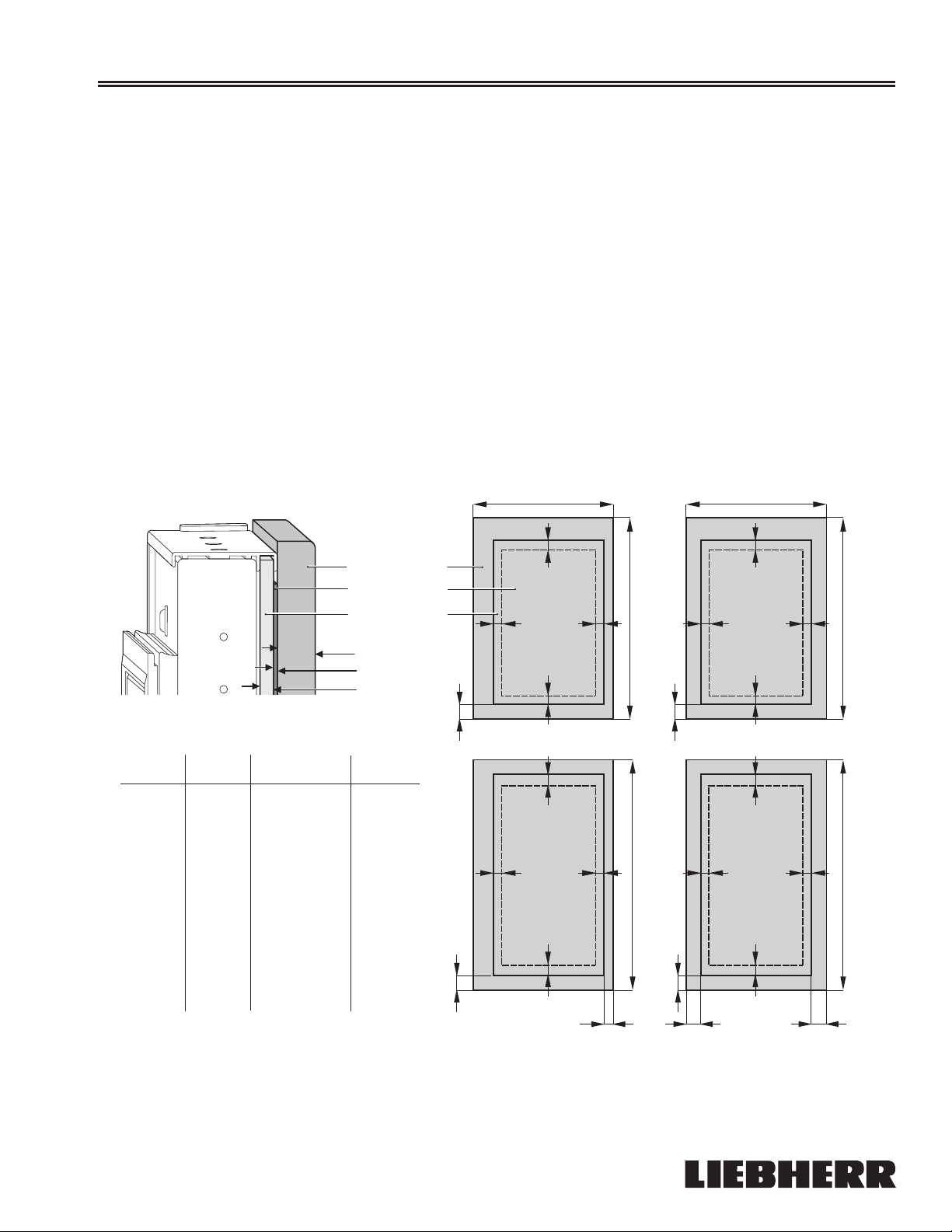

Framed Panels

If the thickness of the custom panels is less than

1/4" (0.635 cm), they must be backed up with a

sheet of shim material to build the total thickness to

1/4" (0.635 cm). If the panel is thicker than 1/4"

(0.635 cm), an edge must be routed around the

panel to ensure a proper fit.

- Figure 5

1/4"

1/4"

IMPORTANT

If you are replacing the factory air vents with

an overlay, DO NOT restrict the air flow. The air

flow must be the same or greater than the

factory air vents of 31 square inches (200 cm

2

The door handles must be installed before the

screw covers are installed. If you fail to install

the handles before the screw covers, you can

damage the covers.The screw covers are

taped to the unit doors during shipping. Use

care when removing covers.

The door panel weight must not exceed

25 lb (11,3 kg).

22-11/16" (576 mm)

).

1/4"

32-37/64" (828 mm)37-9/32" (947 mm)

1/4"

Figure 5

A delight in freshness

8

LBR02

BFI/BF1051 / BGEN/es 2956

Page 11

INTEGRATING

CABINETRY

Overlay Panels

- Figure 6

The overlay design line allows decorative panels to

cover the door trim for a more seamless

appearance that blends with the design of the

room. To achieve this look, the most common way

is to work with three panels, the decorative overlay

panel, a 0.10" (0.25 cm) spacer panel and a 1/4"

(0.635 cm) backer panel.

1 Overlay Panel

2 Spacer Panel

3 Backer Panel

Approx. 3/4"

(19.1mm)

0.1” (25.4mm)

1/4” (6.4mm)

Depending on your cabinet manufacturer, this could

be one panel routed for different dimensions or,

more likely, three different panels.

IMPORTANT

If you are replacing the factory air vents with

an overlay, DO NOT restrict the air flow. The air

flow must be the same or greater than the

factory air vents of 31 square inches (200 cm

2

).

The door handles must be installed before the

screw covers are installed. If you fail to install

the handles before the screw covers, you can

damage the covers.The screw covers are

taped to the unit doors during shipping. Use

care when removing covers.

The door panel weight must not exceed

25 lb (11,3 kg).

W

=

=

=

=

H

Refrigerator

W

=

=

=

=

H

Refrigerator

1 Overlay

Panel

2 Spacer

Panel

3 Backer

Panel

W

23-5/16”

(592 mm)

21-3/4”

(553 mm)

22-11/16”

(576 mm)

H - Refrigerator H - Freezer

33-5/8”

(854 mm)

31-1/2”

(800 mm)

32-37/64”

(828 mm)

38”

(965 mm)

36-1/4”

(921 mm)

37-9/32

(947 mm)

A delight in freshness

3/8”

3/8”

(9mm)

(9mm)

=

Handle Side

48”

Side-by-Side

Figure 6

3/8”

(9mm)

=

=

=

=

3/8”

(9 mm)

H

Hinge Side

Freezer

3/8”

(9mm)

=

=

=

=

24”

Stand alone

=

H

Freezer

=

LBR024

BFI/BF1051 / BGEN/es 2956

9

Page 12

INTEGRATING

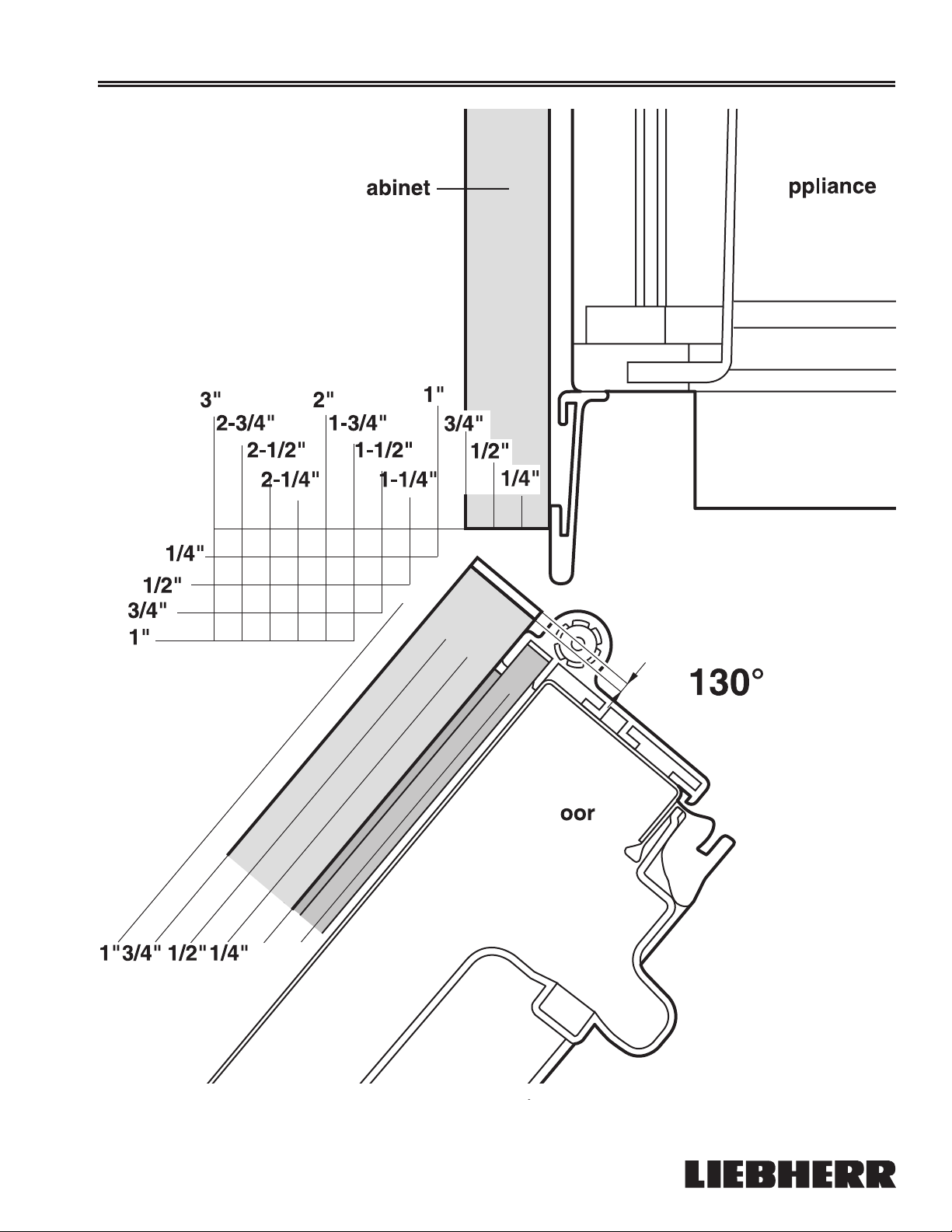

Figure 7

The factory setting for the door to swing open is

130°. Use this illustration to ensure other cabinets

or counters do not interfere with the door opening.

Frameless cabinets:The casing trim overlaps the

cabinets at the side and top. Cabinets may require

filler strips to prevent interference with the cabinet

door swing. The door opening must allow for filler

strips.

CABINETRY

A delight in freshness

10

BFI/BF1051 / BGEN/es 2956

Page 13

INTEGRATING

CABINETRY

C

A

2

4

”

4

8

”

BFI/BF1051 / BGEN/es 2956

3/32”

D

LBR026

Figure 7

(Scale 1:1)

A delight in freshness

11

Page 14

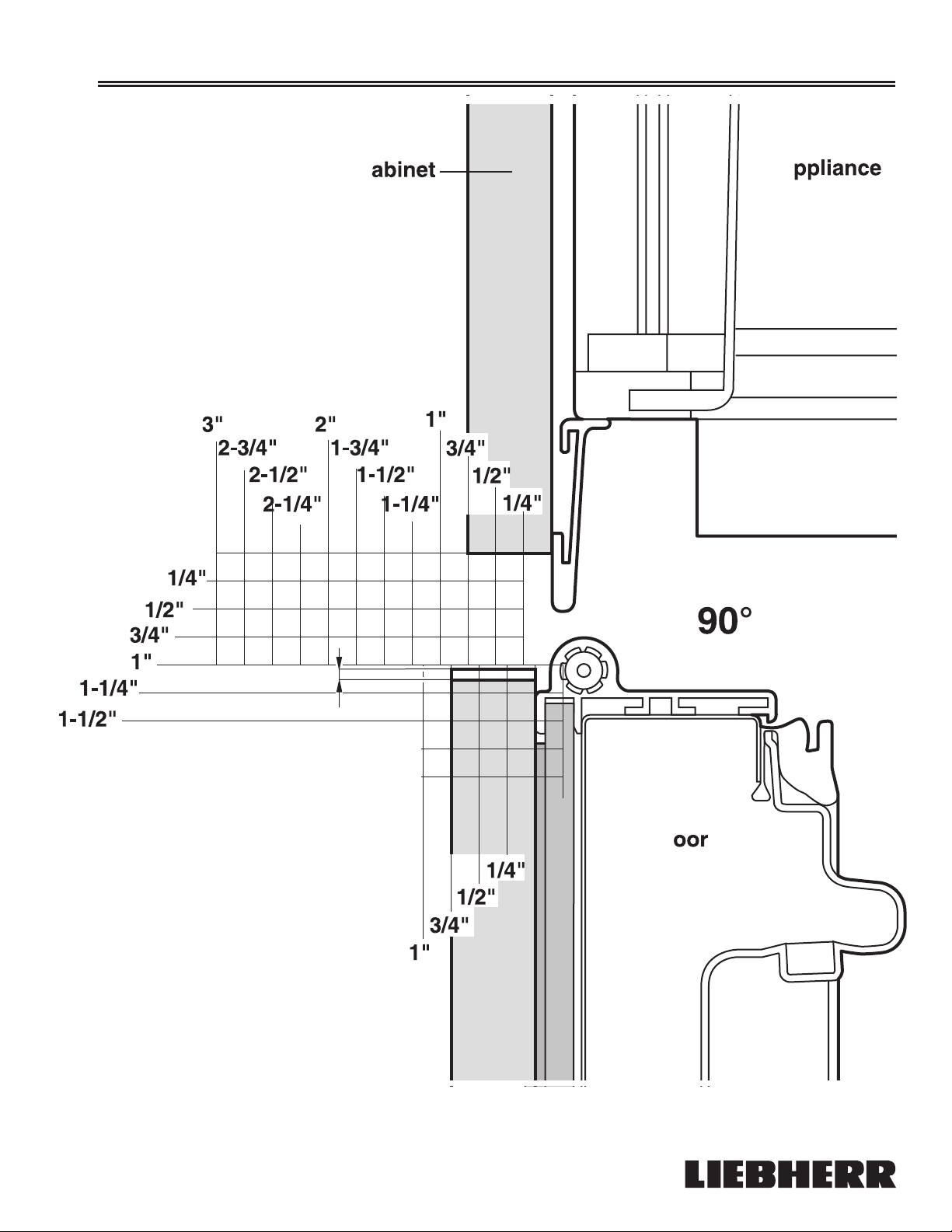

INTEGRATING CABINETRY

Figure 8

The optional setting for the door to swing open is

90°. Use this illustration to ensure other cabinets or

counters do not interfere with the door opening.

Frameless cabinets:The casing trim overlaps the

cabinets at the side and top. Cabinets may require

filler strips to prevent interference with the cabinet

door swing. The door opening must allow for filler

strips.

A delight in freshness

12

BFI/BF1051 / BGEN/es 2956

Page 15

INTEGRATING

CABINETRY

C

A

3/32”

24”

48”

D

LBR025

Figure 8

(Scale 1:1)

BFI/BF1051 / BGEN/es 2956

A delight in freshness

13

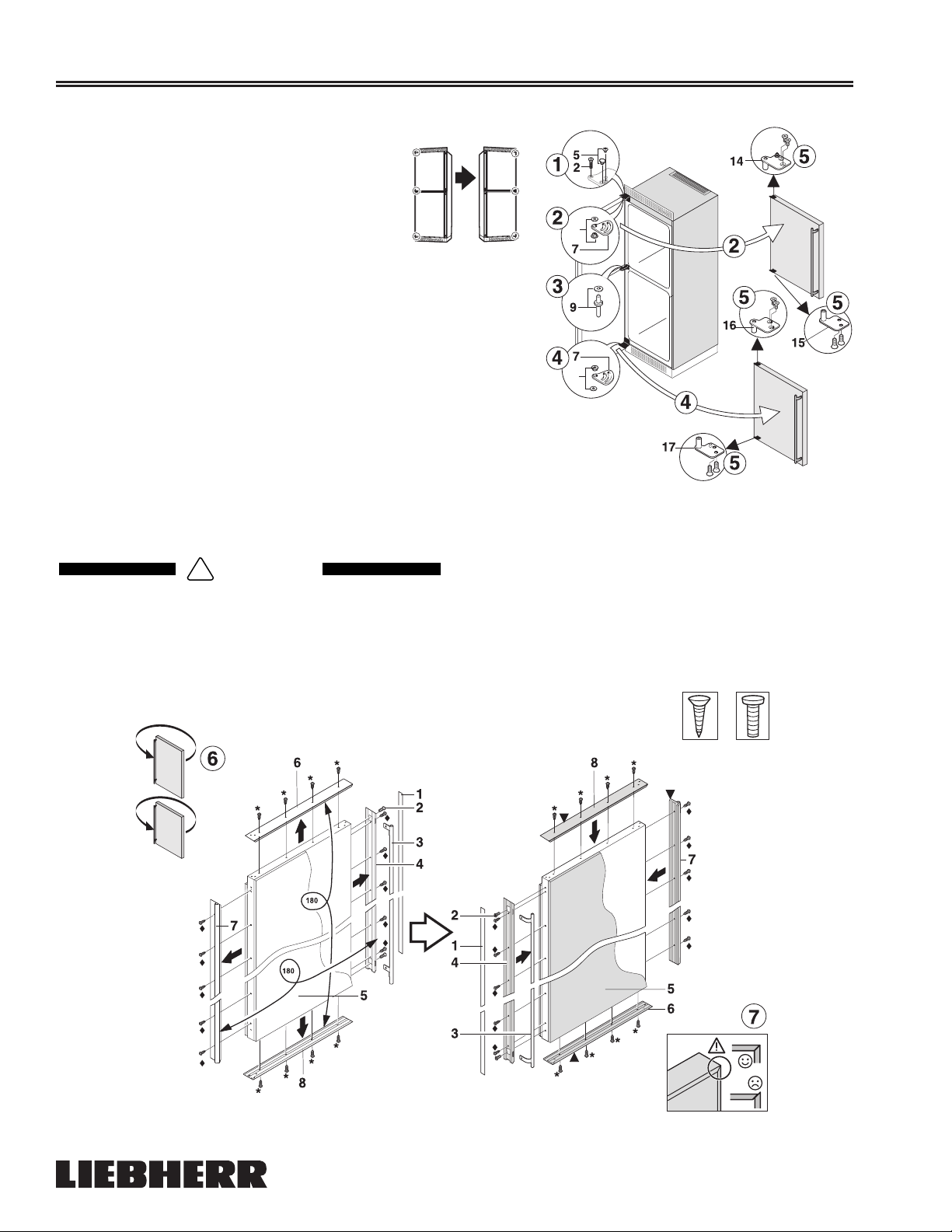

Page 16

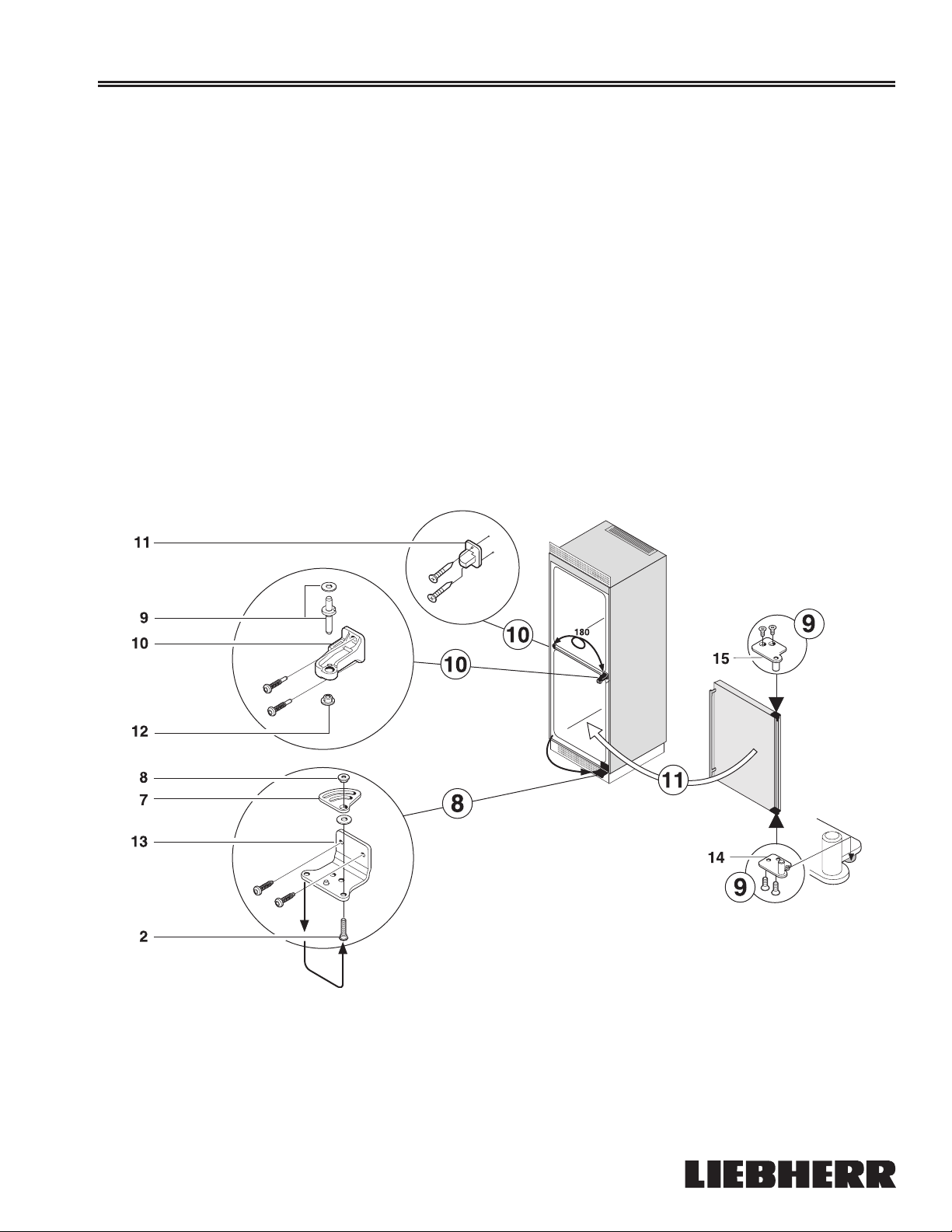

OOR HINGES

7

REVERSING

The door hinges can be changed from one

side to the other if required.

1. Figure 10: Top: Unscrew the hinge pin (2)

and remove the screw (5) with the

eccentric.

2. Swivel out the door at the top, ensuring

that you do not lose the stop (7) and

bushing (8); lift off the door and place it on

the floor.

3. Center: Pull out the hinge pin (9) with its

washer.

4. Swivel out the lower door, lift it out and

place it on the floor.Take care not to lose

the stop (7) and washers (8).

5. Unscrew all the door fittings (14, 15, 16,

17).

6. Figure 11: Unscrew all the door change

frames and exchange them with one

another (6 with 8, 4 with 7 and handle remove cover 1). Secure them in position

using the same screws.

7. Ensure that the door change frames are correctly

positioned and mitered.

D

8

8

LBR02

Figure 10

WARNING

!

Make sure the corners of the door change

frames are positioned correctly. Sharp

edges will be exposed if they are not

mitered or positioned correctly.

Figure 11

A delight in freshness

14

LBRP28

BFI/BF1051 / BGEN/es 2956

Page 17

REVERSING

OOR HINGES

D

8. Figure 12: Unscrew the lower hinge (13).

- Remove the stops, bushing and washer (7, 8, 6).

- Transfer hinge pin (2) to the opposite side.

- Turn the stop (7) through 180° and position

bushing (8) and washer as shown in the

detailed drawing.

- Screw on hinge (13) on the new hinge side.

9. On the lower door: Reinstall the door fittings (14,

15). Pay special attention to the part (14) with

the stop.

10. Unscrew the center hinge (10) and cover (11),

pull them off to the side and after turning them

through 180°, slide them on again on the

opposite side and secure them.

11. Place the lower door on the hinge pin (2) at the

bottom.

- Swivel in the door.

- Pay special attention to the bushing (12) in the

center hinge (10).

- Insert hinge pin (9) and add the washer.

BFI/BF1051 / BGEN/es 2956

LBR029

Figure 12

A delight in freshness

15

Page 18

REVERSING

180

°

OOR HINGES

D

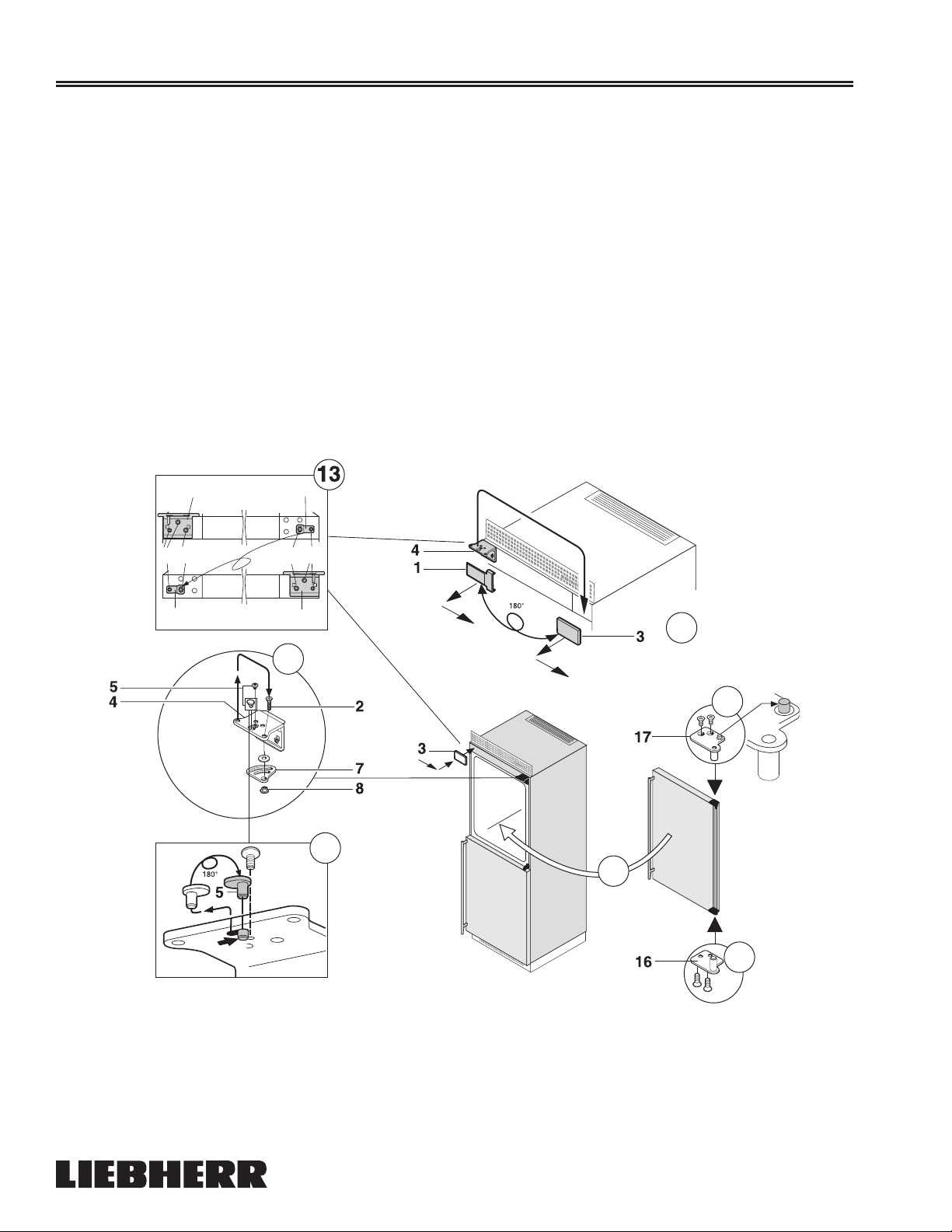

12. Figure 13: Lift up cover (3) on handle side,

push outward; lift up cover (1) on hinge side

and pull off.

13. Unscrew mounting plate (21): first mounting

screw (20), then inner retaining screw (25).

- Unscrew hinge (4): first remove the mounting

screw (20), then retaining screws (25). Fit

hinge (4) to opposite side: for easy assembly,

fit hinge from above and first tighten with the

upper retaining screw (25) M5, then screw

(25) and finally mounting screw M4 (20).

- Turn mounting plate (21) through 180° and

screw tight again on the new handle side: first

retaining screw (25), then mounting screw

(20).

20

25

4

180°

25

21

20

14. Remove the eccentric (5) with the retaining

screw and screw (6) in the hinge (4).

15. On the upper door: Reinstall the door fittings

(16, 17). Pay special attention to the fitting (17)

with the stop.

16. Place the upper door on the center hinge, fit the

bushing (8), stop (7) and washer on the door,

swivel in the door at the top and insert and

secure the hinge pin (2) from above through the

hinge and stop.

17. Re-insert the eccentric (5) with the retaining

screw as shown in the detailed drawing.

Check for proper alignment of all doors. Adjust

them if necessary using the slots on the hinge.

21

4

12

14

15

17

16

15

LBR030

Figure 13

A delight in freshness

16

BFI/BF1051 / BGEN/es 2956

Page 19

REVERSING

OOR HINGES

D

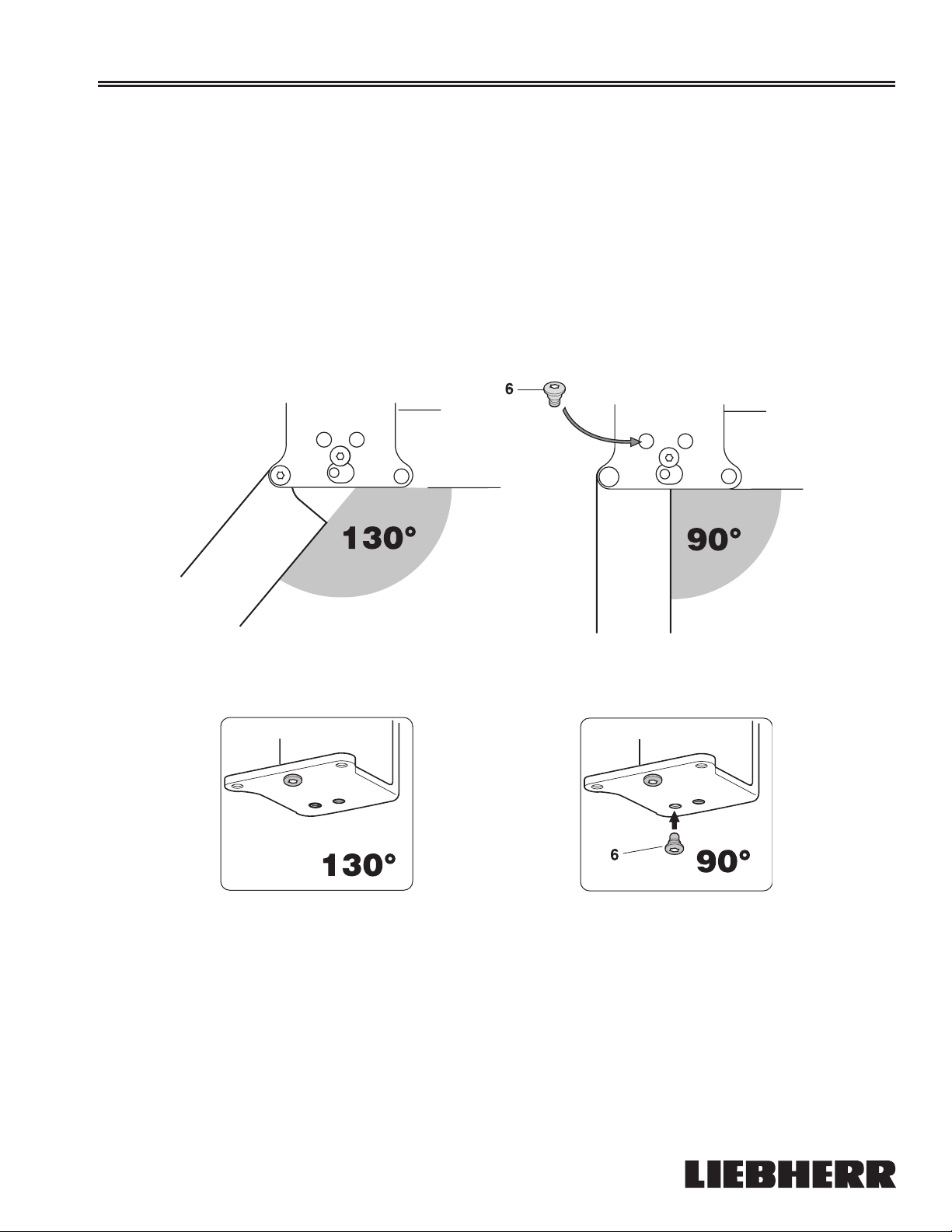

Door Opening Angle

The appliance is delivered with a door opening

angle of 130°.

If the angle is to be decreased to 90°, proceed as

follows:

• Insert attached screw (6) in the upper hinge as

shown in

• Insert attached screw (6) in the lower hinge as

shown in

Figure 14

Figure 15

.

.

- Figures 14, 15

Figure 14

Figure 15

LBR031

LBR032

BFI/BF1051 / BGEN/es 2956

A delight in freshness

17

Page 20

EVERSING DOOR H

R

Only install the refrigerator/freezer in a stable

kitchen cabinet that has been properly aligned.

- Mount and fix the handles, depending on your

model and choice.

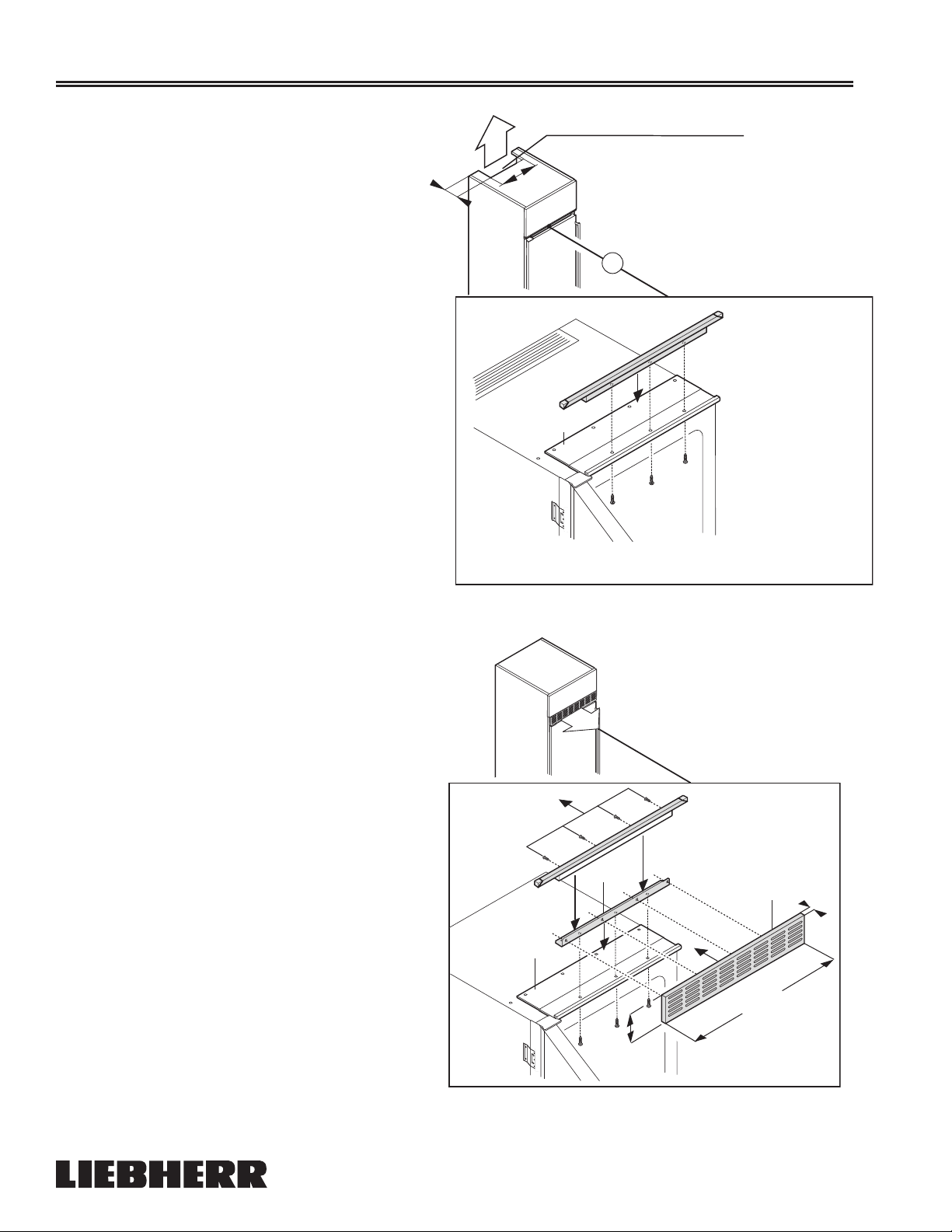

Figure 16: Installation with Ventilation Grille Set:

1. Screw the installation frame at the top (1) onto

the appliance (2).

2. Place the ventilation grille (3) on this, align it in

the center and secure at the front from

underneath.

3. Slide brackets (4) onto the side installation

frames (5) from above and below.

4. Using the frame (5), screw the brackets onto

the side wall*.

5. Slide the side installation frames (5) upwards

until they are in contact with the underside of

the ventilation grille.

INGES

6. Secure the side frames with the adhesive

section (7) to prevent them from sliding down.

Remove the protective film and affix the

adhesive sections over the upper brackets on

the handle and hinge sides.

A delight in freshness

18

LBR034

Figure 16

BFI/BF1051 / BGEN/es 2956

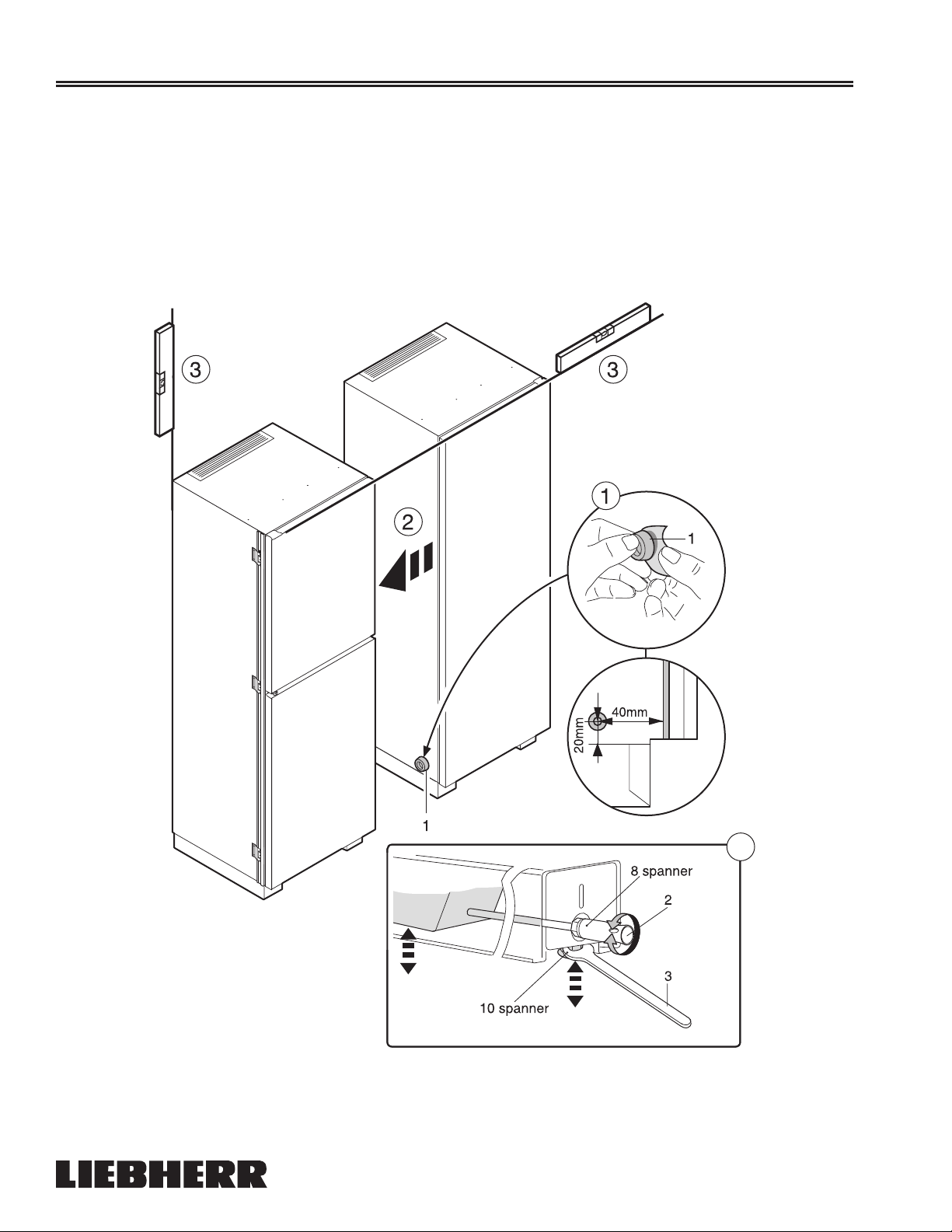

Page 21

INSTALLATION

6

- Figure 17: Connect the appliance to the

main power supply.

- If the appliance is equipped with an

IceMaker, establish the connection for the

water supply. See “IceMaker, Water

Connection”.

1

1 2

1. Carefully slide the appliance into the cabinet

until the ventilation grille touches the

surrounding kitchen cabinet.

2. Align the appliance until it is parallel with the

surrounding kitchen cabinet: at the front using

the leveling wheels (3) – take a 10 mm wrench;

at the rear using the adjusting bolt (2).

Maximum adjustment: 19/32” (15 mm).

2

3

2

2

3

8 spanner

3

3. Figure 18: Align the appliance at the side

with the cabinet side panel and attach it

with screws (1).

- Cover the screws with cover caps (2).

4. Fit the ventilation grille at the bottom [(3)

if the door is hinged on the left, (4) if it is

on the right]: Secure the ventilation grille

so that it touches the floor and then

adjust it using the slots.

10 spanner

LBR035

Figure 17

BFI/BF1051 / BGEN/es 2956

LBR03

Figure 18

A delight in freshness

19

Page 22

INSTALLATION

The following ventilation cross-section

and distances must be observed:

- There must be a ventilation space of

at least 31 square inches

(200 cm

2

) per appliance in the

cabinet plinth and under the cabinet

top panel.

- The depth of the ventilation duct at

the rear of the cabinet must be at

least 1-1/2" (38 mm).

Alternatively:

1. For built-in appliances without

ventilation grilles and only with an

installation frame, ventilation must take

place through the ventilation duct at the

rear of the cabinet.

Built-in appliances with an installation

frame:

• Figure 19:

- Screw the complete installation

frame (2) to the appliance.

1 1/2”

(38mm)

At least 31 square inches (200cm2)

”

/4

)

3

m

0

m

2

7

2

5

(

1

2

1

2. Built-in appliances with a wooden

ventilation grille:

Figure 20: Cut out the wooden trim for

use as a ventilation grille using the

enclosed template.

- The required ventilation cross-

section must be at least 31 square

inches (200 cm

2

) when a single

appliance is installed, which

corresponds to template “small” (If

you install two appliances sidebyside, the cross-section must be at

least 62 square inches, 400 cm

2

,

which corresponds to template

“double-size;” for more information

see “Side-by-Side Installation”).

• Remove the attachment bracket (2)

from the installation frame and screw it

to the appliance (1) from underneath.

Place the wooden ventilation grille (5)

on the appliance, align it in the center

and secure it from the rear using the

attachment bracket (2).

LBR037

Figure 19

2

1

(609,6 mm)

3-11/16"

(93,7 mm)

5

24"

1/2"

(13 mm)

A delight in freshness

20

LBR038

Figure 20

BFI/BF1051 / BGEN/es 2956

Page 23

NOTES

BFI/BF1051 / BGEN/es 2956

A delight in freshness

21

Page 24

BLOCKING

FOR SAFETY

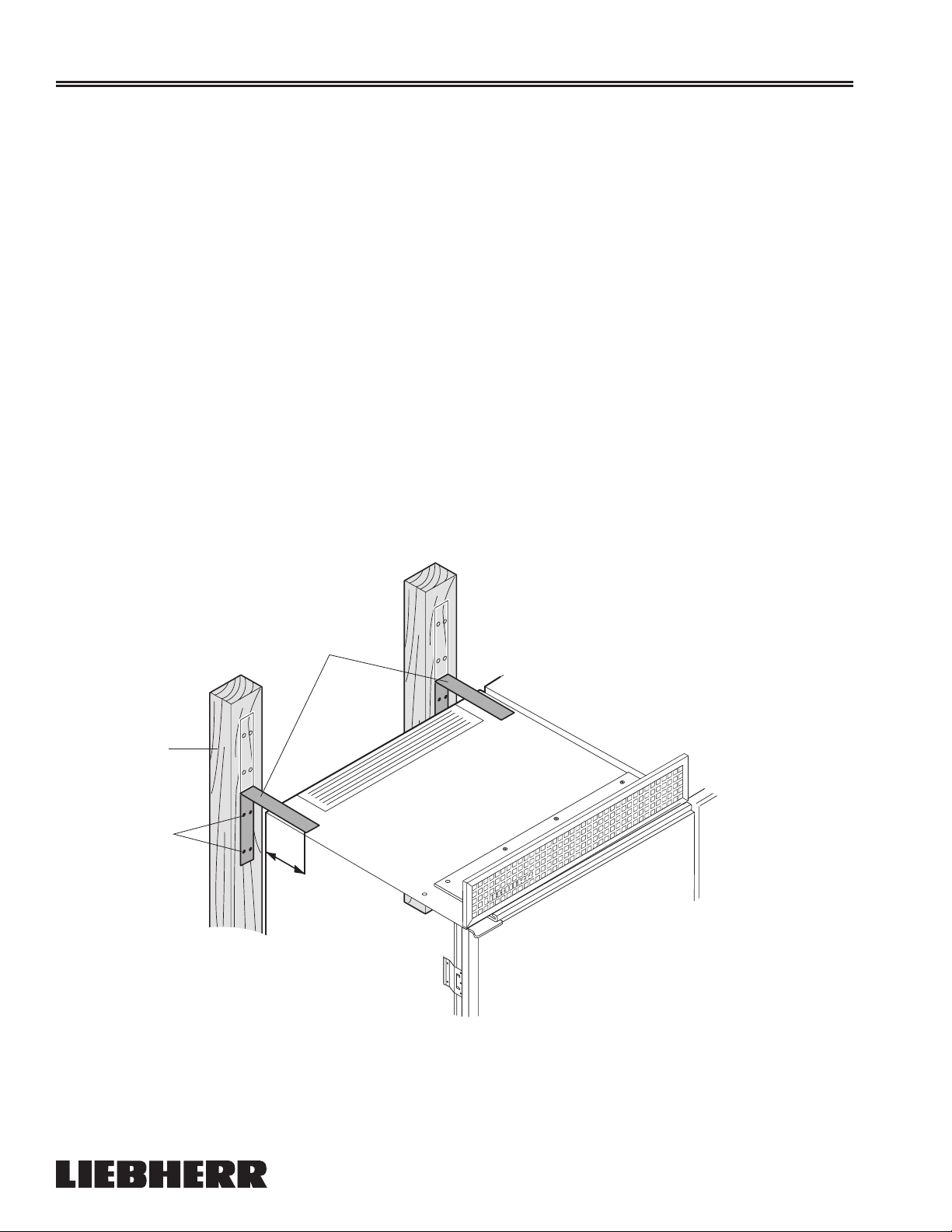

Figure 21: Secure the refrigerator in place so it

does not tip forward when the fully stocked door

is opened.

2. Measure the distance from the floor to the

upper edge of the unit.

3. Locate and mark two wall studs (1) against the

wall where the refrigerator will be located. The

space between the unit top and the bottom

of the brackets must not be more than

1/4" (0.635 cm).

4. Make sure the screws (2) extend a minimum of

1" (2.54 cm) into each of the wall studs.

5. Make sure the anti-tip brackets (3) extend at

least 3" (7.62 cm) over the unit and are

securely in place.

IMPORTANT

The anti-tip brackets can be installed in either

direction or closer together. Always position

the anti-tip brackets as wide apart as

possible, but make sure they are anchored to

two studs.

6. Using the adjustable roller base, raise the unit

until it makes contact with the brackets. Make

sure the front levelers are firmly on the floor to

prevent appliance from tipping forward.

IMPORTANT

If your unit is positioned in between the wall

studs, a board can be secured to the wall.

Make sure the board is secured to the studs

with screws that will penetrate into the studs a

minimum of 1" (2.54 cm). The board should

be a minimum of 1" x 6" (2.54 cm x 15.24 cm)

and long enough to secure both ends to the

wall studs.

3

1

min 3"

Figure 21

A delight in freshness

22

BFI/BF1051 / BGEN/es 2956

Page 25

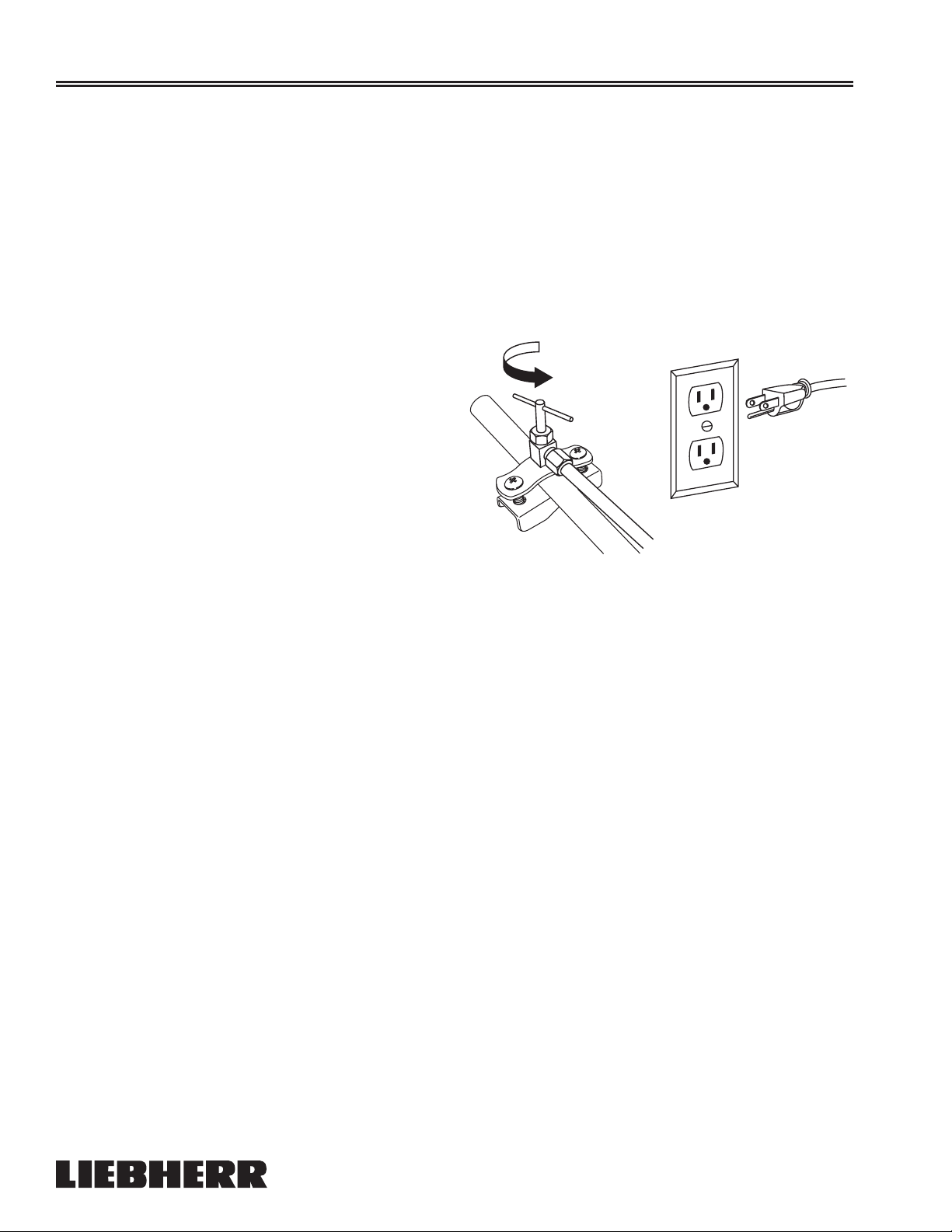

ICE

M

AKER

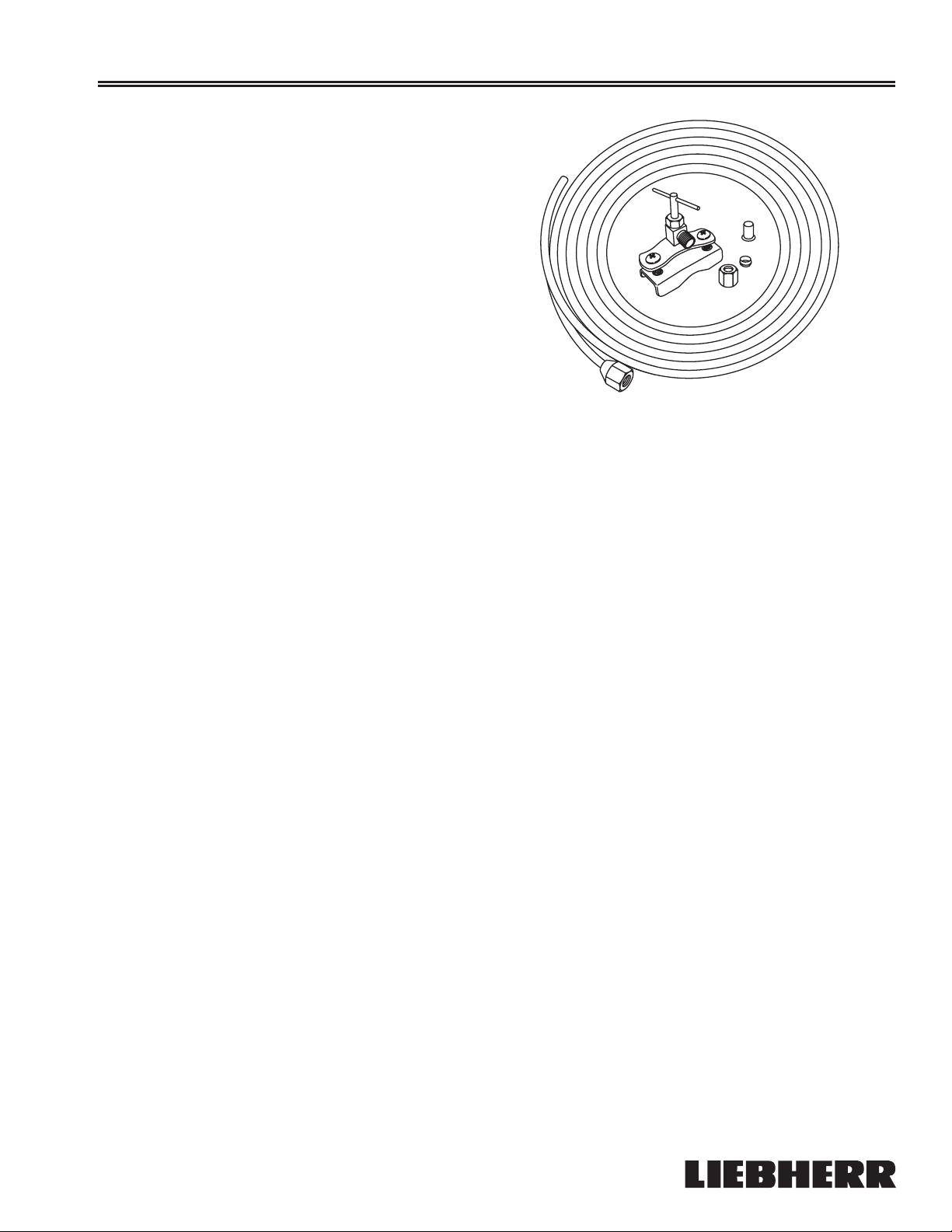

Water Connection

Please read the first three points of the safety

instructions and warnings before connecting the

appliance to the main water supply.

• The water pressure must be between 21.8-87.0

psi (1.5-6 bar).

• Use a 1/4" OD copper line to connect the water

supply to the solenoid valve.

supplied with the refrigerator (Figure 22).

• A shut-off valve, such as the saddle valve

illustration here, must be installed between the

hose line and the main water supply so the

water supply can be stopped if necessary.

Do not install the shut-off valve behind the

refrigeration unit.

- Figure 22

This is not

Figure 22

• If you have hard water, we recommend you install

a water softener. Also, a filter must be installed if

the water contains solids such as sand.

• All equipment and devices used to supply the

water to the appliance must comply with the

current regulations for your geographical area.

BFI/BF1051 / BGEN/es 2956

A delight in freshness

23

Page 26

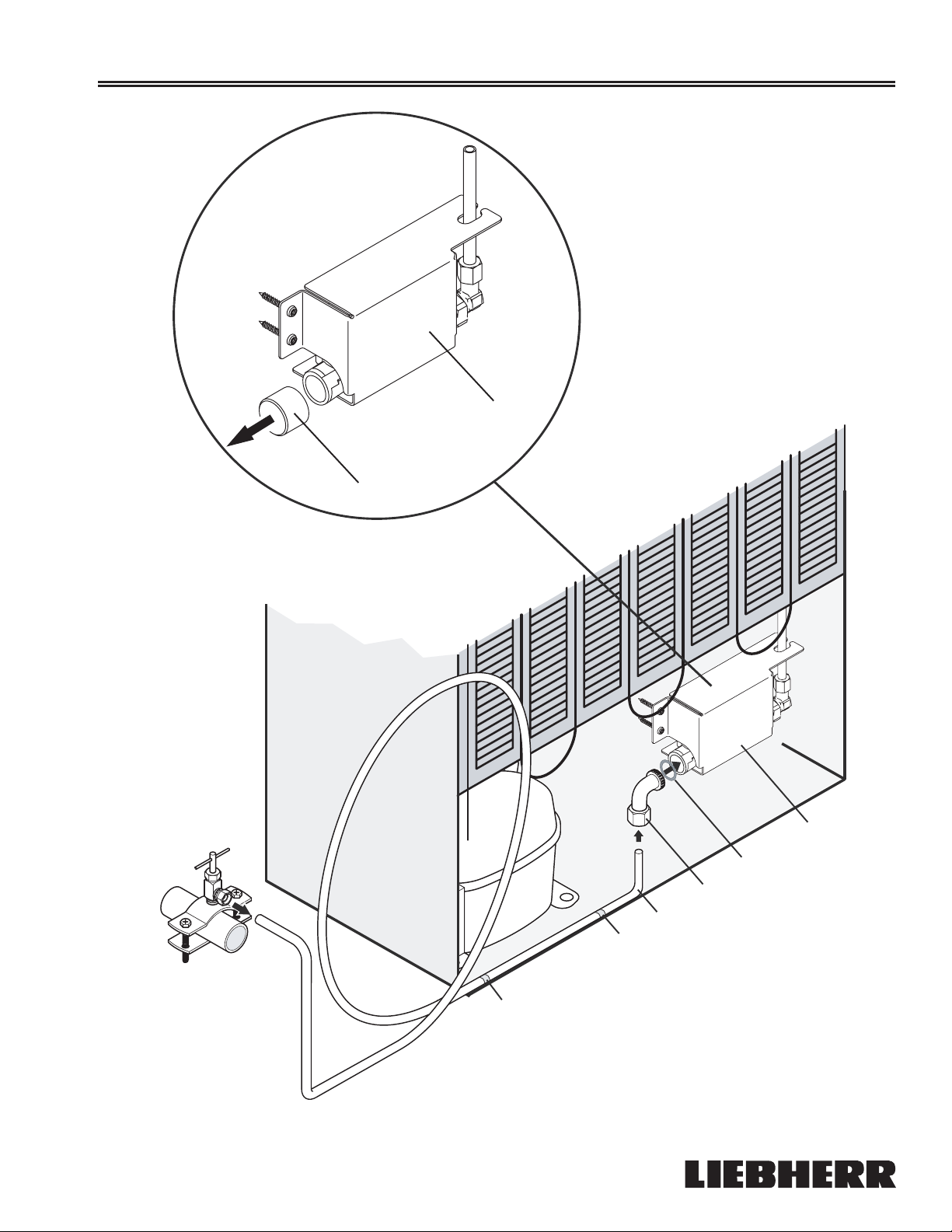

ICE

M

AKER

Connection to the Water Supply

Figures 23, 24

1. Install the shut-off valve, water filter and

automatic shut-off device as required.

Note

The solenoid valve is located at the rear of your

unit.

2. The 1/4" copper tubing between the shut-off

valve and solenoid valve has a 3/4" male

connector

approximately 27" (70 cm) of excess tubing

behind the unit for easy connection.

A 3/4" to a 1/4" adapter and cable clip are

supplied with the icemaker.

Remove the cover cap (4) from the solenoid

valve (1). Install the connection bracket (2) with

sealing ring (6) on the solenoid valve (1). Attach

the copper tube to the connection bracket (2).

Secure the copper tube (3) to the appliance

using the cable clip (5).

(Figure 24)

Note

. Make sure there is

3. Open the shut-off valve for the water supply

-

and check the entire water system for leaks.

Before the appliance is used for the first time a

licensed plumber should bleed air from the

system.

4. Insert the electrical plug for the combined

refrigerator/freezer into the electrical outlet

(Figure 23)

5. Move the combined refrigerator-freezer into

final position in the room.

.

Figure 23

A delight in freshness

24

BFI/BF1051 / BGEN/es 2956

Page 27

SIDE

4

-B

Y-SIDE INSTALLATION

1

BFI/BF1051 / BGEN/es 2956

1

6

2

3

5

5

Figure 24

A delight in freshness

25

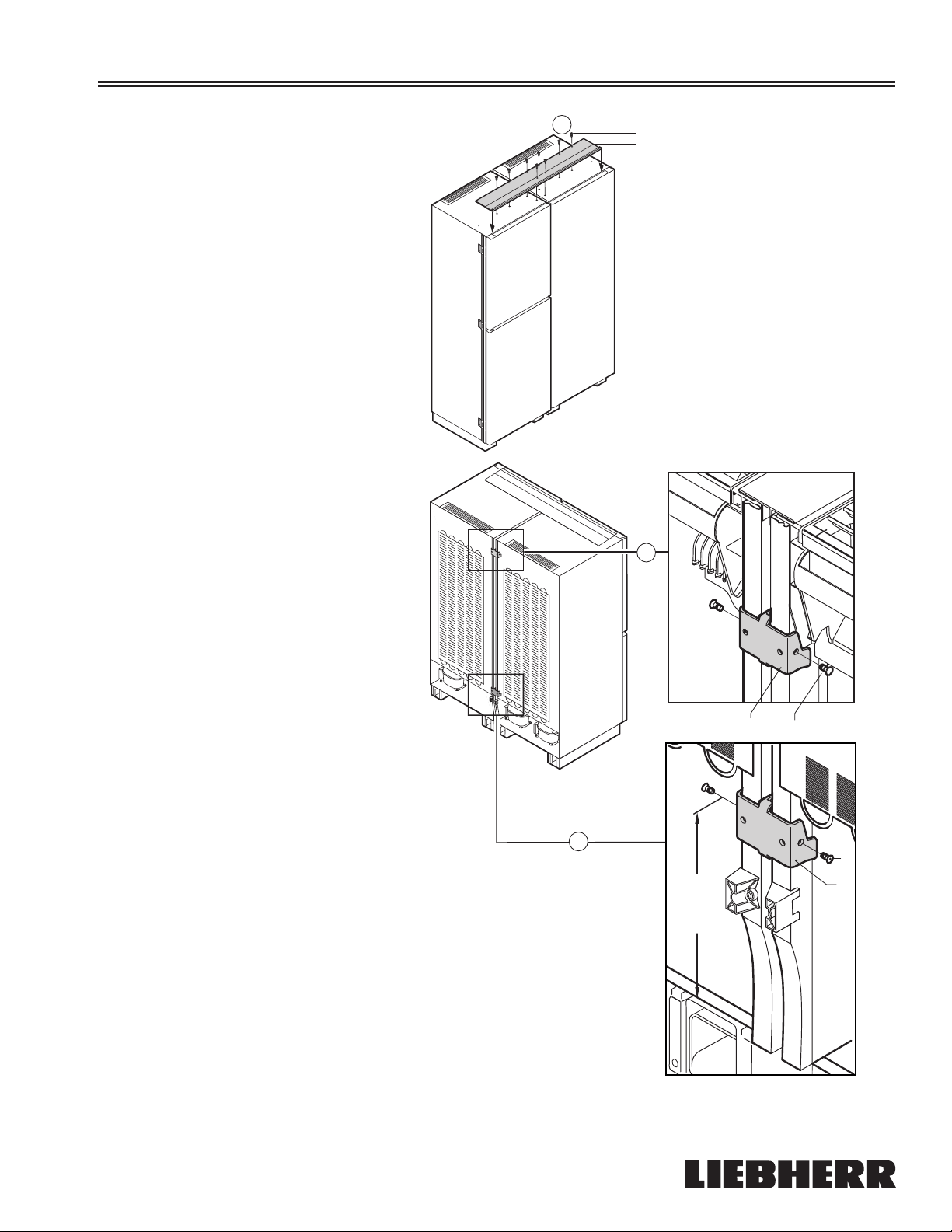

Page 28

SIDE

-B

Y-SIDE INSTALLATION

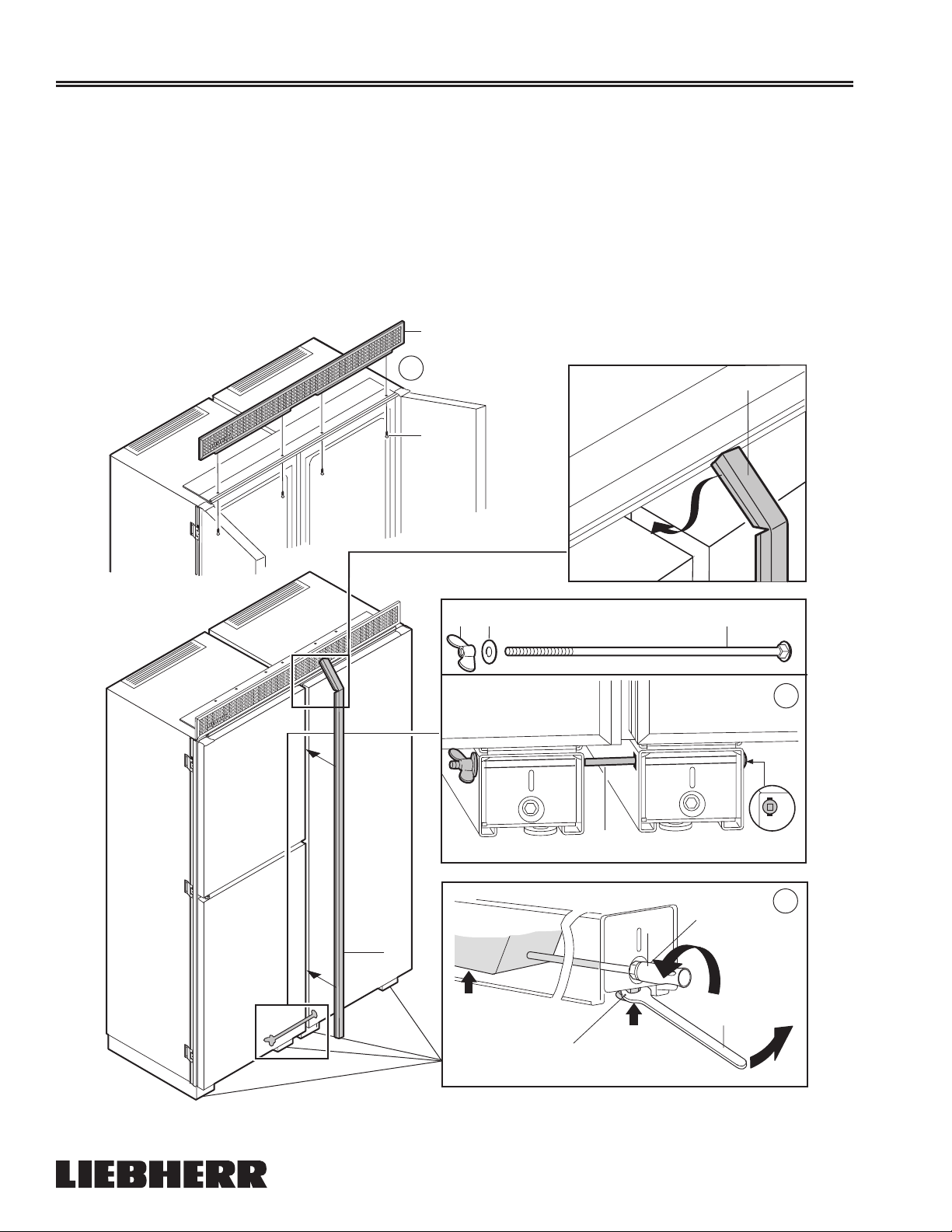

Figure 25: To install the BFI 1051 appliances sideby-side, proceed as follows:

- Always place the BF/BFI 1051 with the hinges

on the left-hand side (looking from the front).

Installation with SBS Ventilation Grille Set:

1. Affix the spacer (1) on the side wall of the

appliance – remove the protective film.

2. Push the appliances together,

- align them

3. Use a level on the top to align them

same height

4. Use the adjustable roller base (2, 3) and

adjusting bolt (2) at the rear.

parallel

:

to each other.

to the

Figure 25

A delight in freshness

26

4

LBR039

BFI/BF1051 / BGEN/es 2956

Page 29

SIDE

-B

Y-SIDE INSTALLATION

5. Secure the installation frame (3) at

the

top to the appliances (2).

Align the appliance at the front

bottom.

6. Figure 26: Position the attachment

brackets (6) at the rear of the

appliances at the top and bottom.

Slide the upper attachment bracket

upwards as far as possible. Secure it

at the side using the screws provided

(5).

5

2

3

6

6

A delight in freshness

Figure 26

8-1/4"

ca. (210)

6

5

5

6

LBR040

BFI/BF1051 / BGEN/es 2956

27

Page 30

SIDE

7. Figure 27: Push the long carriage bolt M5x260

(7) through the leveling wheels as shown. Fit in a

washer (8). Screw on the wing nut (9) and tighten

it

manually

-B

Y-SIDE INSTALLATION

. Do not overtighten.

Screw in all the leveling wheels

8.

will damage the floor when you push in the

appliances.

9. Secure the ventilation grille (10) to the appliance

(11). Push in the sealing strip (4) as shown.

. Otherwise you

10

9

11

4

9 8 7

4

Figure 27

10 spanner

7

7

8 spanner

2

3

8

LBR041

A delight in freshness

28

BFI/BF1051 / BGEN/es 2956

Page 31

SIDE

-B

Y-SIDE INSTALLATION

10. Figures 28, 29: Slide the side

installation

frames (15) upward until they are in

contact with the underside of the

ventilation grille,

11. Secure the side frames with the

adhesive section (17) to prevent them

from sliding down. Remove the

protective film and place the adhesive

sections over the upper brackets on

the handle and hinge sides.

12. Install anti-tip brackets for each

appliance. Refer to “Blocking For

Safety.”

Figure 28

.

10

17

15

17

11

15

11

17

min 3"

Figure 30

A delight in freshness

Figure 28

BFI/BF1051 / BGEN/es 2956

29

Page 32

SIDE

13. Figure 30, 31: Connect the appliances:

- to the main power supply and

- to the water supply if the appliance is equipped

with an IceMaker. See “IceMaker, Water

Connection,”

14. Carefully slide the connected appliances into the

recess until the ventilation grille touches the top,

Figure 31

-B

Y-SIDE INSTALLATION

Figure 30

.

.

15. Align the appliances by using only the outer

leveling wheels at the front (3) and rear (2).

13

Figure 30

14

10 spanner

Figure 31

A delight in freshness

30

15

2

8 spanner

3

LBR042

BFI/BF1051 / BGEN/es 2956

Page 33

SIDE

-B

Y-SIDE INSTALLATION

16. Figure 32: Attach the

aligned

combination to

the surrounding kitchen cabinet. Secure it

through the side frames using the screws (20)

provided.

- Cover the screws with cover caps (21).

17. Now adjust the center adjustable roller bases

(22) so that they make slight contact with the

floor.

18. Install the lower ventilation grille (23): Secure

the ventilation grille so that it touches the floor

and adjust it using the slots.

20

21

22

16

24

17

23

18

24

10 spanner

24

24

2

8 spanner

3

LBR043

BFI/BF1051 / BGEN/es 2956

Figure 32

A delight in freshness

31

Page 34

SIDE

-BY-SIDE INSTALLATION

1. For built-in appliances without ventilation

grilles and only with installation frame (2),

ventilation must take place through the

ventilation duct at the rear of the cabinet.

Ensure that the ventilation cross-section is at

least 31 square inches (200 cm

At least 62 square inches (400 cm

2

)

per appliance

2

) for side-byside installation of two appliances. Built-in

appliances with an installation frame:

- Figure 33: Screw the installation frame (2) to

the appliance through the attachment

brackets.

At least 31 square inches (200cm2)

"

/4

)

3

m

0

2

m

7

2

"

5

(

/4

)

3

0

m

2

1 1/2"

(38mm)

m

7

2

5

(

.

1

2

6

Figure 33

A delight in freshness

32

LBR033

BFI/BF1051 / BGEN/es 2956

Page 35

SIDE

-BY-SIDE INSTALLATION

Built-in appliances with a wooden ventilation

grille:

2. Figure 34: Cut out the wooden trim for use as

a ventilation grille using the attached template.

- The required ventilation cross-section must

be at least 62 square inches (400 cm

side-by-side installation of two appliances,

which corresponds to the attached template

“double-size.”

2

) for

- Remove the attachment brackets from the

installation frame (2) and screw them to the

appliance from underneath.

- Place the wooden ventilation grille (5) on the

appliance, align it in the center and secure it

from the rear using the attachment brackets.

2

BFI/BF1051 / BGEN/es 2956

3-11/16"

(93,7 mm)

X

Figure 34

A delight in freshness

33

5

48"

(1219,2 mm)

1/2"

(13 mm)

LBR044

Page 36

NOTES

A delight in freshness

34

BFI/BF1051 / BGEN/es 2956

Page 37

Instructions

de montage

Pour combinés réfrigérateur-

congélateurs anti-givre BioFresh et

les appareils côte à côte

BFI/BF1051 / BGEN/es 2956

7082 248-00

Page 38

IMPORTANT

VEUILLEZ LIRE ET SUIVRE CES

INSTRUCTIONS

Ces informations contiennent des avertissements et des

mises en garde. Elles sont importantes pour une

installation sûre et efficace.

Lisez et respectez toujours les avertissements et les

mises en garde !

AVERTISSEMENT

!

Indique un danger qui peut provoquer des

blessures graves voire la mort si les

précautions ne sont pas respectées.

PRECAUCIÓN

!

Indique une situation pouvant induire de

légères blessures ou des dommages matériels

si les instructions ne sont pas suivies.

IMPORTANT

Souligne des informations particulièrement

importantes pour réaliser une installation

sans problème.

Assurez-vous que la tension secteur correspond à la

tension nominale de l’appareil.

Pour réduire le risque d’incendie, d’électrochoc ou de

blessures, les travaux d’installation et le câblage

électrique doivent être confiés à un électricien qualifié

selon les codes et normes applicables, y compris à la

construction résistante au feu.

Un délice de fraîcheur

BFI/BF1051 / BGEN/es 2956

Page 39

IMPORTANT

À L’ATTENTION DE L’INSTALLATEUR

Il est très important de suivre toutes les directives et

instructions contenues dans ce manuel afin de garantir

l’installation et le fonctionnement adéquats de l’appareil.

La section des consignes d’installation contient des

renseignements importants relatifs à une bonne

installation. Assurez-vous de lire attentivement et de bien

comprendre toutes les informations contenues dans les

consignes d’installation et dans ce manuel avant

d’installer l’appareil.

BFI/BF1051 / BGEN/es 2956

Un délice de fraîcheur

37

Page 40

TABLE DES MATIÈRES

Sommaire Page

Consignes d’installation ......................................................................................... 39

Encombrement ................................................................................................ 39

Exigences électriques ..................................................................................... 39

Responsabilité du client .................................................................................. 39

Fixation de sécurité ......................................................................................... 39

Ventilation de l’appareil ................................................................................... 39

Préparatifs .............................................................................................................. 40

Dimensions d’ouverture de l’élément de cuisine............................................ 40

Assemblage des panneaux décoratifs .................................................................. 43

Intégration aux éléments de cuisine...................................................................... 44

Panneaux décoratifs encadrés........................................................................ 44

Panneaux décoratifs superposés.................................................................... 45

Inversion des charnières de porte ......................................................................... 50

Angle d’ouverture de la porte ......................................................................... 53

Installation .............................................................................................................. 55

Fixation de sécurité................................................................................................ 58

Machine à glaçons................................................................................................. 59

Raccordement à l’arrivée d’eau ...................................................................... 59

Raccordement au réseau d’eau...................................................................... 60

Installation côte à côte ........................................................................................... 61

Un délice de fraîcheur

38

BFI/BF1051 / BGEN/es 2956

Page 41

CONSIGNES D

’INSTALLATION

Encombrement

Vérifiez les points suivants :

• Les planchers peuvent supporter le poids de

l’appareil augmenté d’un poids d’environ 1200 livres

(544 kg) correspondant aux aliments.

• Le revêtement de sol dans la cuisine est à niveau.

L’appareil doit être calé si les hauteurs de plancher

ne sont pas égales pour garantir la non-obstruction

des grilles de ventilation.

• Retirez tout ce qui est attaché aux parois arrière ou

latérales et risque d’entraver l’ouverture de la porte.

• Les dimensions des découpes sont précises.

• La prise de courant est correctement placée.

N’installez pas cet appareil à côté d’un autre

réfrigérateur ou congélateur. Ceci est important pour

éviter tout dommage suite aux écoulements d’eau de

condensation et autres dégâts.

AVERTISSEMENT

!

RISQUE D’ÉLECTROCUTION

Mise à la terre nécessaire. Le cordon

d’alimentation de cet appareil est doté d’une

fiche à trois broches polarisée (avec mise à la

terre) pour vous protéger contre les risques

d’électrocution éventuels.

NE PAS ôter la broche ronde de mise à la

•

terre.

NE PAS utiliser un adaptateur de mise à la

•

terre à 2 broches.

NE PAS utiliser de rallonge pour raccorder

•

l’appareil au secteur.

Responsabilité du client

Une alimentation électrique à fusible de 15 A (20 A

pour une installation côte à côte), 60 Hz et 115 V est

nécessaire. Nous recommandons l’utilisation d’un

circuit dédié à cet appareil pour éviter une surcharge

électrique. Suivez le code national de l’électricité ou les

codes ou réglementations locaux lors de l’installation de

la prise.

Exigences électriques

Si les règlements exigent un circuit indépendant de mise

à la terre, demandez à un électricien qualifié d’installer le

circuit.

AVERTISSEMENT

!

Ne mettez pas à la terre sur un tuyau de gaz.

En cas de doute, assurez-vous avec un

électricien qualifié que l’appareil est

correctement mis à la terre. Ne mettez pas de

fusible dans le circuit du neutre ou le circuit de

mise à la terre.

AVERTISSEMENT

!

RISQUE D’ÉLECTROCHOC

• Mettre l’appareil à la terre.

• Ne pas utiliser de rallonge.

• Suivez ces instructions sous peine

d’incendie ou d’électrochoc.

Fixation de sécurité

Les équerres anti-basculement doivent être installées

afin d’empêcher que l’appareil ne bascule une fois

installé. Consultez « Fixation de sécurité ».

Ventilation de l’appareil

NE RÉDUISEZ PAS le débit d’air. Pour pouvoir

fonctionner, l’appareil doit recevoir un débit d’air. Les

grilles de ventilation de l’usine fournissent 31 pouces

carrés (200 cm2) de débit d’air par unité. Si vous

remplacez les grilles de l’usine par une grille décorative

personnalisée, le débit d’air doit être égal ou supérieur à

celui des grilles de l’usine.

BFI/BF1051 / BGEN/es 2956

Un délice de fraîcheur

39

Page 42

PRÉPARATIFS

Electrical outlet

location

Locate water supply

within bottom

shaded area

Dimensions de l’ouverture de l’élément de cuisine

= =

Les appareils doivent pouvoir être ouverts à 90°

minimum pour éviter des problèmes lors du retrait des

tiroirs et des bacs. Lorsque la porte est ouverte à 90°, il

Emplacement de

Electrical outlet

la prise électrique

location

est possible que vous ayez à déplacer légèrement les

bacs pour pouvoir les dégager.

Reportez-vous aux écarts minimum dans le tableau des

spécifications pré-installation.

• En cas d’installation en coin, prévoyez un bourrelet de

3-3/4 po (95 mm) afin que la porte puisse s’ouvrir à

90°. Si des panneaux surélevés sont utilisés, le

bourrelet devra être plus large.

IMPORTANT

Reportez-vous aux illustrations à l’échelle à la fin de

ce chapitre pour les spécifications concernant les

ouvertures de porte et les autres tailles de bourrage.

- Figure 1

Locate water supply

Arrivée d’eau dans la

within bottom

zone grise du bas

shaded area

3" (7.6cm)

24" (61cm)

Unique : 24" (610 mm) Côte à côte : 48" (1219 mm)

Single: 24" (610mm) / SBS: 48" (1219mm)

Figure 1

85" (2159mm)

79.3/4" (2025.7mm)

LBR022

Un délice de fraîcheur

40

BFI/BF1051 / BGEN/es 2956

Page 43

PRÉPARATIFS

BFI 1051

- Figure 2

79-15/16" (2030 mm)

76-49/64" (1950 mm)

24" (610 mm)

32-25/32" (832 mm)

55/64"

(22 mm)

37-31/64" (952 mm)

26-57/64" (683 mm)

25-3/16" (640 mm)

43-33/64" (1105 mm)

39-29/64" (1002 mm)

24" (610 mm)

23-55/64" (606 mm)

90

130

25-25/32" (655 mm)

4-19/64" + 19/32"

(109 + 15 mm)

23-3/4"

(603 mm)

47-53/64" (1215 mm)

Figure 2

BFI/BF1051 / BGEN/es 2956

Un délice de fraîcheur

41

Page 44

PRÉPARATIFS

BFI 1051 côte à côte

26-57/64" (683 mm)

25-3/16" (640 mm)

- Figure 3

32-25/32" (832 mm)

55/64"

(22 mm)

76-49/64" (1950 mm)

79-15/16" (2030 mm)

37-31/64" (952 mm)

48" (1219 mm)

71-1/8" (1807 mm)

15-13/32"

(391 mm)

43-33/64" (1105 mm)

47-53/64" (1215 mm)

1-23/32"

(44 mm)

48" (1219 mm)

47-3/4" (1213 mm)

51-29/64" (1307 mm)

4-19/64" + 19/32"

(109 +15 mm)

15-13/32"

(391 mm)

1-23/32"

(44 mm)

23-3/4"

(603 mm)

78-51/64" (2001 mm)

Figure 3

Un délice de fraîcheur

42

BFI/BF1051 / BGEN/es 2956

Page 45

ASSEMBLAGE DES PANNEAUX DÉCORATIFS

Figure 4

Procédez comme indiqué sur l’illustration :

(1) Cadres de changement de porte

(2) Panneau décoratif

(3) Vis pour cadres de changement de porte

(4) Poignée, selon le modèle

(5) Vis M4 x 10 pour la poignée

(6) Bourrelet

BFI/BF1051 / BGEN/es 2956

LBR048

Figure 4

Un délice de fraîcheur

43

Page 46

INTÉGRATION AUX ÉLÉMENTS DE CUISINE

Panneaux décoratifs encadrés

-

Figure 5

Si l’épaisseur des panneaux décoratifs est inférieure à

1/4 po (0,635 cm), ils doivent être renforcés au moyen

d’une feuille de matériau de calage pour obtenir

l’épaisseur totale de 1/4 po (0,635 cm). Si l’épaisseur du

panneau est supérieure à 1/4 po (0,635 cm), un bord

être chanfreiné sur son périmètre pour garantir un

ajustement approprié.

1/4"

(6.4 mm)

1/4"

(6.4 mm)

IMPORTANT

Si vous remplacez les grilles de ventilation de

l’usine par une grille décorative personnalisée,

N’ENTRAVEZ PAS le débit d’air. Le débit d’air doit

être égal ou supérieur à celui fourni par les grilles

de l’usine - 31 pouces carrés (200 cm2).

Les poignées de porte doivent être installées

avant la mise en place des cache-vis. Si vous

n’installez pas les poignées avant les cache-vis,

vous risquez d’endommager ces derniers. Les

cache-vis sont collés avec un ruban sur la porte

de l’appareil pour l’expédition. Faites attention

lorsque vous les retirez.

Le poids du panneau de porte ne doit pas être

supérieur à 25 livres (11,3 kg).

22-11/16" (576 mm)

1/4"

(6.4 mm)

32-37/64" (828 mm)37-9/32" (947 mm)

1/4"

(6.4 mm)

LBR023

Figure 5

Un délice de fraîcheur

44

BFI/BF1051 / BGEN/es 2956

Page 47

INTÉGRATION AUX ÉLÉMENTS DE CUISINE

Panneaux décoratifs superposés

- Figure 6

La conception superposée permet de recouvrir

l’intégralité de la porte pour donner une apparence plus

nette qui se fond dans le décor de la pièce. Pour ce faire,

il suffit d’utiliser trois panneaux - le panneau superposé

décoratif, un panneau intermédiaire de 0,10 po (0,25 cm)

et un panneau support de 1/4 po (0,635 cm).

1 Panneau

superposé

2 Panneau

intermédiaire

3 Panneau support

3/4" environ

(19,1mm)

0,1" (25,4mm)

1/4" (6,4mm)

Selon le fabricant de vos meubles de cuisine, il pourrait

s’agir d’un panneau chanfreiné pour des dimensions

différentes ou, plus vraisemblablement, de trois

panneaux différents.

IMPORTANT

Si vous remplacez les grilles de ventilation de

l’usine par une grille décorative personnalisée,

N’ENTRAVEZ PAS le débit d’air. Le débit d’air doit

être égal ou supérieur à celui fourni par les grilles

de l’usine - 31 pouces carrés (200 cm2).

Les poignées de porte doivent être installées

avant la mise en place des cache-vis. Si vous

n’installez pas les poignées avant les cache-vis,

vous risquez d’endommager ces derniers. Les

cache-vis sont collés avec un ruban sur la porte

de l’appareil pour l’expédition. Faites attention

lorsque vous les retirez.

Le poids du panneau de porte ne doit pas être

supérieur à 25 livres (11,3 kg).

W

=

=

=

=

H

Réfrigérateur

W

=

=

=

=

H

Réfrigérateur

1 Panneau

superposé

2 Panneau

intermédiaire

3 Panneau

support

W

23-5/16"

(592 mm)

21-3/4"

(553 mm)

22-11/16"

(576 mm)

H -

Réfrigérateur

33-5/8"

(854 mm)

31-1/2"

(800 mm)

32-37/64"

(828 mm)

3/8"

(9mm)

H -

Congélateur

38"

(965 mm)

36-1/4"

(921 mm)

Côté poignée

37-9/32"

(947 mm)

3/8"

(9mm)

Figure 6

Un délice de fraîcheur

=

=

=

48" (122 cm)

côte à côte

=

=

3/8"

(9 mm)

3/8"

H

Congélateur

Côté charnières

3/8"

(9mm)

(9mm)

=

=

=

=

24" (61 cm)

autonome

=

H

Congélateur

=

LBR024

BFI/BF1051 / BGEN/es 2956

45

Page 48

INTÉGRATION AUX ÉLÉMENTS DE CUISINE

Figure 7

Le réglage usine pour l’ouverture de la porte est de

130°. Utilisez cette illustration pour vous assurer

qu’aucun autre élément de cuisine ou comptoir

n’interfère avec l’ouverture de la porte. Éléments de

cuisine sans cadre : La bordure recouvre les éléments

de cuisine en haut et sur le côté. Les éléments de

cuisine auront éventuellement besoin de bourrelets pour

empêcher toute interférence avec l’ouverture de la porte.

Pour l’ouverture de la porte, tenez compte de l’utilisation

de bourrelets.

Un délice de fraîcheur

46

BFI/BF1051 / BGEN/es 2956

Page 49

INTÉGRATION AUX ÉLÉMENTS DE CUISINE

A

C

AppareilÉlément de cuisine

(12.7 mm)

(19.1 mm)

(25.4 mm)

(6.4 mm)

3/4"

1"

1/4"

1/2"

3"

(76.2 mm)

(69.9 mm)

2-3/4"

(63.5 mm)

2-1/2"

(57.2 mm)

(50.8 mm )

2-1/4"

2"

1-3/4"

(44.5 mm)

1-1/2"

(38.1 mm)

1-1/4"

(31.8 mm)

1"

(25.4 mm)

(19.1 mm)

3/4"

1/2"

(12.7 mm)

(6.4 mm)

24" (609.6 mm)

(1219.2 mm)

48"

1/4"

Porte

D

3/32"

(2.4 mm)

1"

(25.4 mm)

(19.1 mm)

(12.7 mm)

(6.4 mm)

1/4"

1/2"

3/4"

BFI/BF1051 / BGEN/es 2956

LBR026

Figure 7

(échelle 1:1)

Un délice de fraîcheur

47

Page 50

INTÉGRATION AUX ÉLÉMENTS DE CUISINE

Figure 8

Le réglage usine pour l’ouverture de la porte est de 90°.

Utilisez cette illustration pour vous assurer qu’aucun

autre élément de cuisine ou comptoir n’interfère avec

l’ouverture de la porte. Éléments de cuisine sans cadre :

La bordure recouvre les éléments de cuisine en haut et

sur le côté. Les éléments de cuisine auront

éventuellement besoin de bourrelets pour empêcher

toute interférence avec l’ouverture de la porte. Pour

l’ouverture de la porte, tenez compte de l’utilisation de

bourrelets.

Un délice de fraîcheur

48

BFI/BF1051 / BGEN/es 2956

Page 51

INTÉGRATION AUX ÉLÉMENTS DE CUISINE

A

C

AppareilÉlément de cuisine

(25.4 mm)

1-1/4"

(31.8 mm)

1-1/2"

(38.1 mm)

(12.7 mm)

3/4"

(19.1 mm)

1"

1/4"

(6.4 mm)

1/2"

3"

(76.2 mm)

2-3/4"

(69.9 mm)

2-1/2"

(63.5 mm)

2-1/4"

(57.2 mm)

(2.4 mm)

2"

(50.8 mm )

3/32”

1-3/4"

(44.5 mm)

1-1/2"

(38.1 mm)

(25.4 mm)

1-1/4"

(31.8 mm)

1"

(25.4 mm)

1"

3/4"

(19.1 mm)

(12.7 mm)

3/4"

(19.1 mm)

1/2"

(12.7 mm)

1/4"

(6.4 mm)

24”

(609.6 mm)

48”

(1219.2 mm)

1/4"

(6.4 mm)

1/2"

Porte

D

BFI/BF1051 / BGEN/es 2956

LBR025

Figure 8

(échelle 1:1)

Un délice de fraîcheur

49

Page 52

INVERSION DES CHARNIÈRES DE PORTE

7

Les charnières de porte peuvent être transférées

de l’autre côté au besoin.

1. Figure 10 : Haut : Dévissez l’axe de charnière

(2) et retirez la vis (5) avec l’excentrique.

2. Basculez le haut de la porte vers l’extérieur,

en veillant à ne pas perdre la butée (7) et la

douille (8) ; soulevez la porte et posez-la

par terre.

3. Centre : Retirez l’axe de charnière (9) avec sa

rondelle.

4. Basculez la porte inférieure vers l’extérieur,

soulevez pour la retirer et posez-la par terre.

Veillez à ne pas perdre la butée (7) et les

rondelles (8).

5. Dévissez tous les raccords de porte

(14, 56, 16, 17).

6. Figure 11 : Dévissez tous les cadres de

changement de porte et intervertissez-les

(6 avec 8, 4 avec 7 et poignée - retirez le

cache 1). Fixez-les en position à l’aide des

mêmes vis.

7. Assurez-vous que les cadres de changement

de porte sont correctement positionnés et à onglet.

AVERTISSEMENT

!

8

8

Figure 10

LBR02

Assurez-vous que les coins des cadres de

changement de porte sont correctement

positionnés. Leurs bords coupants seront

exposés s’ils ne sont pas correctement

positionnés ou n’ont pas d’onglet.

Figure 11

Un délice de fraîcheur

50

LBRP28

BFI/BF1051 / BGEN/es 2956

Page 53

INVERSION DES CHARNIÈRES DE PORTE

8. Figure 12 : Dévissez la charnière du bas (13).

- Retirez les butées, la douille et la rondelle (7, 8, 6).

- Transférez l’axe de goupille (2) du côté opposé.

- Tournez la butée (7) de 180° et positionnez la

douille (8) et la rondelle comme indiqué sur le

dessin détaillé.

- Vissez la charnière (13) sur le nouveau côté.

9. Sur la porte inférieure : Réinstallez tous les raccords

de porte (14, 15). Prêtez une attention particulière à

la pièce (14) à butée.

10. Dévissez la charnière centrale (10) et le cache (11),

tirez-les sur le côté et après les avoir tourné de 180°,

réinsérez-les de l’autre côté et fixez-les en position.

11. Placez la porte inférieure sur l’axe de charnière (2) en

bas.

- Basculez la porte.

- Prêtez une attention particulière à la douille (12) de la

charnière centrale (10).

- Insérez l’axe de charnière (9) et ajoutez la rondelle.

BFI/BF1051 / BGEN/es 2956

LBR029

Figure 12

Un délice de fraîcheur

51

Page 54

INVERSION DES CHARNIÈRES DE PORTE

180

°

12. Figure 13 : Soulevez le cache (3) côté poignée,

poussez vers l’extérieur ; soulevez le cache (1) côté

charnières et détachez en tirant.

13. Dévissez la plaque de fixation (21) : tout d’abord

la vis de fixation (20), puis la vis de retenue

interne (25).

- Dévissez la charnière (4) : retirez tout d’abord la

vis de fixation (20), puis les vis de retenue (25).

Installez la charnière (4) du côté opposé : pour

faciliter l’assemblage, installez la charnière par en

haut et commencez par serrer la vis de retenue

supérieure M5 (25), puis vissez (25) et enfin,

serrez la vis de fixation M4 (20).

- Tournez la plaque de fixation (21) de 180° et

vissez bien sur le nouveau côté poignée : tout

d’abord la vis de retenue (25), puis la vis de

fixation (20).

20

25

4

180°

25

21

20

14. Retirez l’excentrique (5) avec la vis de retenue et la

vis (6) de la charnière (4).

15. Sur la porte supérieure : Réinstallez tous les

raccords de porte (17, 16). Prêtez une attention

particulière au raccord (17) à butée.

16. Placez la porte supérieure sur la charnière centrale,

installez la douille (8), la butée (7) et la rondelle sur

la porte, basculez la porte vers l’intérieur en haut,

puis insérez et fixez l’axe de charnière (2) par en

haut, à travers la charnière et la butée.

17. Réinsérez l’excentrique (5) avec la vis de retenue,

comme illustré par le dessin détaillé.

Vérifiez l’alignement correct de toutes les portes.

Ajustez-les au besoin à l’aide des fentes de la charnière.

21

4

12

14

15

17

16

15

LBR030

Figure 13

Un délice de fraîcheur

52

BFI/BF1051 / BGEN/es 2956

Page 55

INVERSION DES CHARNIÈRES DE PORTE

Angle d’ouverture de la porte

Figures 14, 15

L’appareil a été livré avec un angle d’ouverture de porte

de 130°.

Pour diminuer l’angle à 90°, procédez comme suit :

• Insérez la vis attachée (6) dans la charnière

supérieure comme illustré à la

• Insérez la vis attachée (6) dans la charnière

inférieure comme illustré à la

Figure 14

Figure 15

.

-

.

Figure 14

Figure 15

LBR031

LBR032

BFI/BF1051 / BGEN/es 2956

Un délice de fraîcheur

53

Page 56

NVERSION DES CHARNIÈRES DE PORTE

I

Installez le réfrigérateur/congélateur dans un élément de

cuisine stable qui a été correctement aligné.

- Montez et fixez les poignées, selon votre modèle

et votre préférence.

Figure 16 : Installation avec jeu de grilles

de ventilation :

1. Vissez le cadre d’installation en haut (1)

sur l’appareil (2).

2. Placez dessus la grille de ventilation (3), alignez-la

au centre et fixez-la sur l’avant par en dessous.

3. Glissez les équerres (4) sur les cadres d’installation

latéraux (5) par en haut et par en dessous.

4. À l’aide du cadre (5), vissez les équerres sur la paroi

latérale*.

5. Glissez les cadres d’installation latéraux (5) vers le

haut, jusqu’à ce qu’ils touchent le dessous de la

grille de ventilation.

6. Fixez les cadres latéraux avec la section adhésive

(7) pour les empêcher de glisser vers le bas. Retirez

le film de protection et fixez les sections adhésives

par-dessus les équerres du haut, côtés poignée et

charnières.

Un délice de fraîcheur

54

LBR034

Figure 16

BFI/BF1051 / BGEN/es 2956

Page 57

INSTALLATION

6

- Figure 17 : Branchez l’appareil sur secteur.

- Si l’appareil est équipé d’une machine à glaçons,

raccordez-le au réseau d’eau. Reportez-vous à

« Raccordement de la machine à glaçons au

réseau d’eau ».

1

1 2

1. Glissez avec précaution l’appareil dans l’élément de

cuisine jusqu’à ce que la grille de ventilation touche

l’élément.

2. Alignez l’appareil jusqu’à ce qu’il soit parallèle à

l’élément de cuisine dans lequel il est encastré :

sur l’avant, à l’aide des roulettes de mise à niveau

(3) – prenez une clé de 10 mm ; à l’arrière à l’aide

du boulon de réglage (2). Ajustement maximum :

19/32 po (15 mm).

2

3

2

2

3

Clé 8

8 spanner

3

3. Figure 18 : Alignez le côté de l’appareil sur le

panneau latéral de l’élément de cuisine et

fixez-le avec les vis (1).

- Couvrez les vis avec les capuchons-

caches (2).

4. Installez la grille de ventilation en bas [(3) si

la porte est articulée à gauche, (4) si elle est

articulée à droite] : Fixez la grille de

ventilation de manière à ce qu’elle touche

le sol, puis ajustez-la à l’aide des fentes.

Figure 17

10 spanner

Clé 10

LBR035

BFI/BF1051 / BGEN/es 2956

LBR03

Figure 18

Un délice de fraîcheur

55

Page 58

INSTALLATION

La coupe transversale de ventilation et les

distances suivantes doivent être observées :

- Il doit y avoir un espace de ventilation de

31 pouces carrés (200 cm2) minimum

par appareil au niveau de la plinthe de

l’élément de cuisine et sous son

panneau supérieur.

- La profondeur de la conduite de

ventilation à l’arrière de l’élément de

cuisine doit être de 1-1/2 po (38 mm)

minimum.

Autre solution :

1. Pour les appareils encastrés sans

grilles de ventilation et seulement avec

un cadre d’installation, la ventilation doit se

faire par la conduite de ventilation à

l’arrière de l’élément de cuisine.

Appareils encastrés avec un cadre

d’installation :

• Figure 19 :

- Vissez le cadre d’installation complet (2)

sur l’appareil.

1 1/2”

(38mm)

31 pouces carrés (200 cm2) minimum

At least 31 square inches (200cm2)

”

/4

)

3

m

0

m

2

7

2

5

(

1

2

1

2. Appareils encastrés avec une grille de

ventilation en bois :

Figure 20 : Découpez la garniture en bois

à l’aide du gabarit ci-joint pour l’utiliser

comme grille de ventilation.

- La coupe transversale de ventilation

requise doit être de 31 pouces carrés

(200 cm2) minimum pour un appareil

unique, ce qui correspond à « petit »

gabarit. (Si vous installez deux appareils

côte à côte, la coupe transversale doit

mesurer au moins 62 pouces carrés,

400 cm2, ce qui correspond à un gabarit

« double taille » ; pour plus

d’informations, reportez-vous à «

Installation côte à côte »).

• Retirez l’équerre de fixation (2) du cadre

d’installation et vissez-la sur l’appareil (1)

par en dessous. Placez la grille de

ventilation en bois (5) sur l’appareil,

alignez-la au centre et fixez-la par l’arrière

à l’aide de l’équerre de fixation (2).

LBR037

Figure 19

2

1

(609,6 mm)

3-11/16"

(93,7 mm)

5

24"

1/2"

(13 mm)

Un délice de fraîcheur

56

LBR038

Figure 20

BFI/BF1051 / BGEN/es 2956

Page 59

REMARQUES

BFI/BF1051 / BGEN/es 2956

Un délice de fraîcheur

57

Page 60

FIXATION DE SÉCURITÉ

Figure 21 : Fixez le réfrigérateur en place pour qu’il ne

bascule pas vers l’avant lorsque la porte remplie est

ouverte.

2. Mesurez la distance entre le sol et le bord supérieur

de l’appareil.

3. Localisez et marquez deux poteaux muraux (1) pour

fixer le réfrigérateur au mur. L’espace entre le haut

de l’appareil et le bas des équerres de fixation ne

doit pas être supérieur à 1/4 po (0,635 cm).

4. Assurez-vous que les vis (2) rentrent au minimum de

1 po (2,54 cm) dans chacun des poteaux muraux.

5. Assurez-vous que les équerres anti-basculement (3)

recouvrent au minimum l’appareil de 3 po (7,62 cm)

et sont bien vissées.

IMPORTANT

Les équerres anti-basculement peuvent être

installées dans n’importe quelle direction ou

rapprochées. Placez toujours les équerres antibasculement le plus loin possible l’une de l’autre

tout en vous assurant qu’elles sont ancrées dans

deux barres de fixation murale.

6. En utilisant le socle à roulettes ajustable, levez

l’appareil jusqu’à ce qu’il touche les équerres de

fixation. Assurez-vous que les pieds réglables avant

reposent fermement au sol pour empêcher l’appareil

de basculer vers l’avant.

IMPORTANT

Si votre appareil est placé entre les poteaux

muraux, vous pouvez fixer une planche au mur.

Assurez-vous que la planche est fixée sur les

poteaux muraux avec des vis qui pénètrent les

poteaux de 1 po (2,54 cm) minimum. La planche

doit mesurer au moins 1 po x 6 po (2,54 cm x

15,24 cm) et être suffisamment longue pour que

ses deux extrémités soient solidement fixées aux

poteaux muraux.

3

1

min 3"

Figure 21

Un délice de fraîcheur

58

BFI/BF1051 / BGEN/es 2956

Page 61

MACHINE À GLAÇONS

Raccordement à l’arrivée d’eau

Figure 22

Avant de procéder au raccordement, veuillez respecter

les trois premiers points des recommandations et

consignes de sécurité.

• La pression d’eau doit se situer entre 21,8 et 87 psi

(1,5 - 6 bars).

• Utilisez un tuyau de cuivre d’un diamètre extérieur de

1/4 po (6 mm) pour raccorder l’électrovanne à

l’arrivée d’eau.

livraison (Figure 22).

• Un robinet d’arrêt, comme le robinet auto-perforant

illustré ci-dessous, permettant en cas de besoin de

couper l’alimentation en eau doit être installé entre le

tuyau et le raccord de réseau d’eau.

N’installez pas le robinet d’arrêt derrière le groupe

frigorifique.

Ce tuyau n’est pas inclus dans la

-

Figure 22

• Si vous avez de l’eau calcaire, nous vous

recommandons d’installer un adoucisseur d’eau. Un

filtre doit également être installé si l’eau contient des

solides comme du sable par exemple.

• Tous les équipements et dispositifs utilisés pour

alimenter l’appareil en eau doivent être conformes

aux règlements en cours dans votre région.

BFI/BF1051 / BGEN/es 2956

Un délice de fraîcheur

59

Page 62

MACHINE À GLAÇONS

Raccordement au réseau d’eau

Figures 23, 24

1. Installez le robinet d’arrêt, le filtre à eau et le dispositif

d’arrêt automatique comme indiqué.

Remarque

L’électrovanne est située à l’arrière de votre appareil.

2. Le tuyau de cuivre de 1/4 po (6 mm) entre le robinet

d’arrêt et l’électrovanne est muni d’un connecteur

mâle de 3/4 po (18 mm)

qu’il y a environ 27 po (70 cm) de longueur de tube

derrière l’appareil pour assurer un raccordement

facile.

Un adaptateur 3/4 po/1/4 po (18 mm/6 mm) et une

pince à câble sont fournis avec la machine à

glaçons.

Retirez le capuchon de protection (4) de l’électrovanne

(1). Installez le raccord (2) avec l’anneau d’étanchéité

(6) sur l’électrovanne (1). Attachez le tuyau en cuivre

au raccord (2). Fixez le tuyau en cuivre (3) à l’appareil

à l’aide de la pince à câble (5).

(Figure 24)

Remarque

. Assurez-vous

-

3. Ouvrez le robinet de l’arrivée d’eau et assurez-vous

qu’il n’y a aucune fuite dans le circuit. Avant d’utiliser

l’appareil pour la première fois, un plombier agréé

doit purger l’air du système.

4. Enfichez la fiche secteur du combiné réfrigérateurcongélateur dans la prise électrique

5. Déplacez le combiné réfrigérateur-congélateur à

l’emplacement prévu.

Figure 23

(Figure 23)

.

Un délice de fraîcheur

60

BFI/BF1051 / BGEN/es 2956

Page 63

INSTALLATION CÔTE À CÔTE

1

4

BFI/BF1051 / BGEN/es 2956

1

6

2

3

5

5

Figure 24

Un délice de fraîcheur

61

Page 64

INSTALLATION CÔTE À CÔTE

Figure 25 : Pour installer les appareils BFI 1051 côte à

côte, procédez comme suit :

- Placez toujours le BF/BFI 1051 avec les

charnières à gauche (Vu de face).

Installation avec le jeu de grilles de ventilation :

1. Fixez l’entretoise (1) sur la paroi latérale de

l’appareil - retirez le film de protection.

2. Poussez les appareils l’un contre l’autre,

- alignez-les

3. Utilisez un niveau en haut pour les aligner

même hauteur

4. Utilisez le socle à roulettes ajustable (2, 3) et le

boulon de réglage (2) à l’arrière.

parallèlement

:

l’un à l’autre.

à la

Clé 10

Figure 25

Un délice de fraîcheur

62

4

Clé 8

LBR039

BFI/BF1051 / BGEN/es 2956

Page 65

INSTALLATION CÔTE À CÔTE

5. Fixez le cadre d’installation (3) en haut

des appareils (2). Alignez l’appareil sur

l’avant, en bas.

6. Figure 26 : Positionnez les équerres de

fixation (6) à l’arrière des appareils, en

haut et en bas. Glissez l’équerre de

fixation supérieure le plus haut possible.

Fixez-la sur le côté à l’aide des vis

fournies (5).

5

2

3

6

6

Un délice de fraîcheur

Figure 26

8-1/4"

ca. (210)

6

5

5

6

LBR040

BFI/BF1051 / BGEN/es 2956

63

Page 66

INSTALLATION CÔTE À CÔTE

7. Figure 27 : Poussez le long boulon ordinaire M5x260

(7) à travers les roues de mise à niveau, comme

illustré. Installez une rondelle (8).Vissez l’écrou à

oreilles (9) et serrez

8.

Vissez toutes les roues de mise à niveau

endommagerez le sol lorsque vous pousserez les

appareils en place.

9. Fixez la grille de ventilation (10) sur l’appareil (11).

Poussez la bande de calfeutrage (4) comme illustré.

à la main

. Ne serrez pas trop.

. Sinon, vous

10

9

11

9 8 7

4

7

4

10 spanner

Figure 27

Un délice de fraîcheur

64

Clé 10

7

8 spanner

2

Clé 8

3

BFI/BF1051 / BGEN/es 2956

8

LBR041

Page 67

INSTALLATION CÔTE À CÔTE

10. Figures 28, 29 : Glissez les cadres

d’installation latéraux (15) vers le haut,

jusqu’à ce qu’ils touchent le dessous de la

grille de ventilation,

11. Fixez les cadres latéraux avec la section

adhésive (17) pour les empêcher de

glisser vers le bas. Retirez le film de

protection et placez les sections

adhésives par-dessus les équerres

supérieures, côtés poignée et charnières.

12. Installez les équerres anti-basculement

pour chaque appareil. Consultez la

section « Fixation de sécurité ».

Figure 28

.

10

17

15

17

11

15

11

17

min 3"

Figure 30

Un délice de fraîcheur

Figure 28

BFI/BF1051 / BGEN/es 2956

65

Page 68

INSTALLATION CÔTE À CÔTE

13. Figures 30, 31 : Branchez les appareils :

- sur secteur et

- raccordez-les à l’arrivée d’eau si l’appareil est

équipé d’une machine à glaçons. Reportez-vous à

« Raccordement de la machine à glaçons au

réseau d’eau »,

14. Glissez avec précaution les appareils branchés dans

l’emplacement qui leur est réservé jusqu’à ce que la

grille de ventilation touche le haut,

15. Alignez les appareils en utilisant uniquement les

roues de mise à niveau extérieures avant (3) et

arrière (2).

Figure 30

.

Figure 31

.

13

14

10 spanner

Clé 10

15

2

Figure 30

Clé 8

8 spanner

3

Figure 31

Un délice de fraîcheur

66

LBR042

BFI/BF1051 / BGEN/es 2956

Page 69

INSTALLATION CÔTE À CÔTE

16. Figure 32 : Attachez l’ensemble

aligné

sur l’élément

de cuisine dans lequel il est encastré. Fixez-le à

travers les cadres latéraux à l’aide des vis fournies

(20).

- Couvrez les vis avec les capuchons-caches (21).

17. Maintenant, ajustez les socles à roulettes ajustables

centraux (22) de sorte qu’ils touchent légèrement

le sol.

18. Installez la grille de ventilation du bas (23) : Fixez la

grille de ventilation de manière à ce qu’elle touche le

sol, puis ajustez-la à l’aide des fentes.

20

21

22

16

24

17

23

18

24

10 spanner

Clé 10

24

24

2

Clé 8

8 spanner

3

LBR043

BFI/BF1051 / BGEN/es 2956

Figure 32

Un délice de fraîcheur

67

Page 70

INSTALLATION CÔTE À CÔTE

1. Pour les appareils encastrés sans grilles de

ventilation et seulement avec un cadre d’installation

(2), la ventilation doit se faire par la conduite de

ventilation à l’arrière de l’élément de cuisine.

Assurez-vous que la coupe transversale de

ventilation est de 31 pouces carrés (200 cm2)

minimum

côte, comptez au moins 62 pouces carrés (400 cm2).

Appareils encastrés avec un cadre d’installation :

- Figure 33 : Vissez le cadre d’installation (2) sur

l’appareil à travers les équerres de fixation.

par appareil

1 1/2"

(38mm)

. Pour deux appareils côte à

31 pouces carrés (200 cm2) minimum

At least 31 square inches (200cm2)

"

/4

)

3

m

0

2

m

7

2

"

5

(

/4

)

3

0

m

2

m

7

2

5

(

1

2

6

Figure 33

Un délice de fraîcheur

68

LBR033

BFI/BF1051 / BGEN/es 2956

Page 71

INSTALLATION CÔTE À CÔTE

Appareils encastrés avec une grille de ventilation

en bois :

2. Figure 34 : Découpez la garniture en bois à l’aide

du gabarit ci-joint pour l’utiliser comme grille de

ventilation.

- La coupe transversale de ventilation requise doit

être de 62 pouces carrés (400 cm2) minimum pour

l’installation côte à côte de deux appareils, ce qui

correspond au gabarit « double taille » ci-joint.

- Retirez les équerres de fixation du cadre

d’installation (2) et vissez-les sur l’appareil

par dessous.

- Placez la grille de ventilation en bois (5) sur

l’appareil, alignez-la au centre et fixez-la par

l’arrière à l’aide des équerres de fixation.

2

BFI/BF1051 / BGEN/es 2956

3-11/16"

(93,7 mm)

X

Figure 34

Un délice de fraîcheur

69

5

48"

(1219,2 mm)

1/2"

(13 mm)

LBR044

Page 72

REMARQUES

Un délice de fraîcheur

70

BFI/BF1051 / BGEN/es 2956

Page 73

Instrucciones

de instalación

Para frigoríficos-congeladores

combinados BioFresh, NoFrost y

unidades lado a lado

BFI/BF1051 / BGEN/es 2956

7082 248-00

Page 74

IMPORTANTE

POR FAVOR LEA Y SIGA ESTAS

INSTRUCCIONES

Estas instrucciones contienen indicaciones de

advertencia y precaución. Esta información es

importante para una instalación segura y eficiente.

¡Siempre debe leer y seguir todas las indicaciones de

advertencia y precaución!

AVERTISSEMENT

!

Indica un riesgo que puede provocar lesiones

graves o la muerte si no se tienen en cuenta

las prescripciones de seguridad.

PRECAUCIÓN

!

Señala una situación en la cual pueden

producirse lesiones menores o daños en el

producto si no se siguen las instrucciones.

IMPORTANTE

Aquí se destaca la información que es

especialmente relevante para una instalación

sin problemas.

Asegúrese de que el voltaje entrante sea el mismo que

el valor nominal del aparato.

Para reducir el riesgo de incendio, descarga

eléctrica, o lesiones personales, la tarea de instalación y

el cableado eléctrico debe llevarlo a cabo un electricista

competente de acuerdo con todos los códigos y

estándares aplicables, incluyendo la construcción con

protección contra incendios.

Un deleite de frescura

BFI/BF1051 / BGEN/es 2956

Page 75

IMPORTANTE

AL INSTALADOR

Es muy importante que se cumplan las normas e

instrucciones del manual para asegurar la instalación y

el funcionamiento correctos del aparato. La sección de

Normas para la instalación contiene información

importante para asegurar que la instalación se efectúe

correctamente. Lea atentamente toda la información de

estas normas y del manual, antes de instalar el aparato.

BFI/BF1051 / BGEN/es 2956

Un deleite de frescura

73

Page 76

CONTENIDO

Contenido Página

Normas para la instalación .................................................................................... 75

Requisitos de superficie.................................................................................. 75