Page 1

Horizontal mixing

plants in the

Betomix range

Page 2

Betomix, a concept with

many advantages.

Modular construction

The Betomix modular system permits a range of variants and arrangement options in

different output capacities, all of which are

1

derived from one basic system.

3

2

Well-engineered in every

detail

The Betomix is defined by high quality and a long

service lifetime. The entire plant is easy to operate

and is extremely user-friendly.

State-of-the-art concrete

production

The plant’s high-quality components together afford high-performance concrete production for

the most demanding quality requirements.

4

Equipment and

accessories

For specific customer requirements, the

extensive options available for the Betomix

satisfy every need.

2

Page 3

3

Page 4

Modular

1

The mixing plants in the Betomix range are based on a sophisticated modular system. The basic module

and various adaptation modules can be combined to provide a multitude of variants and outputs. Ring pan

mixers or double-shaft mixers in various sizes can be integrated into the system for complete flexibility.

The aggregate and sand is stored in either an inline silo, star-pattern silo or circular silo. For loading the

mixer, there is a choice of a loading elevator or a loading conveyor.

construction

Conveyor loading of the mixer The star-pattern silo with scraper

4

Page 5

Storage of the aggregates and sand in a circular silo 90-degree configuration of the inline silo

5

Page 6

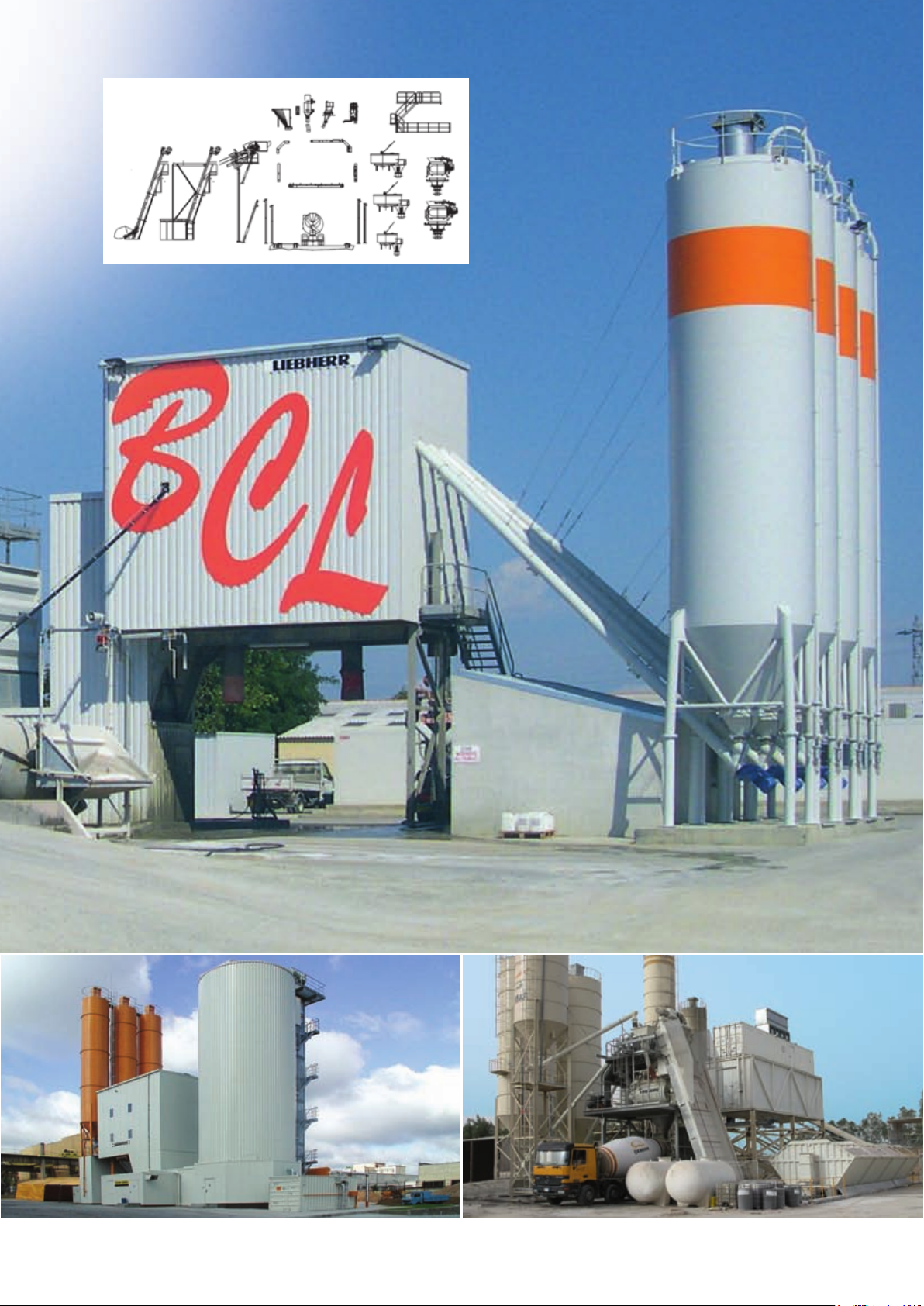

Tailor-made solutions

A state-of-the-art plant using a modular system meets every requirement profile to provide the optimal solution for the

operator. Betomix plants are also exceptionally well-suited to

particularly complex plant systems. For large-scale projects,

for instance the construction of embankment dams, Liebherr

can plan and realise entire systems with temporary storage

chambers and cooling units. The parallel operation of several

Betomix plants offers hourly outputs of more than 500 cu. m

of set concrete.

The many options mean that Betomix plants can be integrated with existing buildings and site restrictions. As a result,

the Betomix is also very popular in the concrete product and

prefabricated unit industries.

A Betomix plant adjoining an existing building Dry Batching Plant with upgrade to Betomix 2.25 Up to 6 cement grades can be processed

6

Page 7

Betomix 3.0 twin plant Betomix 2.25 for producing prefabricated units Betomix 1.0 container variant

7

Page 8

Litronic-MPS real-time control The weighing conveyor The skip

8

Page 9

State-of-the-art

2

concrete

production

High dosing accuracy when the materials are being weighed together with

moisture measurement during the ongoing process guarantee concrete of the

highest quality. Litronic-MPS, state-of-the-art real-time control, ensures the exact interaction of all components. As a result, the mixing plant yields maximum

output volumes and operates very economically. The quality of the components

and the long service lifetime of all moving parts guarantee operation with virtually

no downtime over a period of many years. The entire plant concept is extremely

user- and maintenance-friendly.

The large-scale, robust mixing platformThe cement weighing equipmentBetomix 3.0 twin plant

9

Page 10

The electrical system complies with international standards The loader drive with gears

10

Page 11

Well-engineered

3

Betomix plants owe their dependability to careful planning down to the very last detail. They have been developed with the support of more than 50 years of practical experience. All areas of the plant are extremely

easy to access. All cables, pipes and other elements are protected in mountings and ducts in order to prevent

malfunctions. Provision has also been made for the retrofitting of additional equipment. For example, weighing

equipment for silica or ice can be integrated into the plant at a later date. The steel construction is extensively

galvanised to ensure that the plant is resistant to corrosion and weathering.

in every detail

The installations beneath the weighing platform

Robust and corrosion-resistant weighing cells

11

Page 12

Equipment and

4

Liebherr provides a wealth of options and additional equipment to satisfy all customer requirements and demands. Depending on the geographical location of the plant, the Betomix

is available with an insulated cladding and heating for operation during the winter. For hot

regions, the Liebherr range includes all components for adding ice. Practical options, for

example high-pressure mixer cleaning, make day-to-day operation of the plant significantly

more straightforward. Depending on the mixer type, the Betomix is also available with

twin loading bays.

accessories

Cladding of the plant

12

Page 13

The ice weighing equipment

The micro silica weighing equipment

Inline silo heating

Discharge of dry material Dust filtering systems

Twin loading bays

There are various additive weighing

equipment options

High-pressure mixer cleaning Chutes for truck loading or for reclaiming water

13

Page 14

The right mixer for every application

Liebherr has been developing and building its own mixing systems for more than 50 years. Tests using the widest possible range of materials are carried out in the company’s mixing technology laboratory, where the systems are subject to

ongoing development and optimisation.

Based on the well-proven Type R ring-pan mixer, there are further versions with additional agitator tools for higher-quality

grades of concrete. Depending on the size, the Type RIM is available with one or two mechanical agitators (RIM-M /

RIM-D). The Type RIH has one or two hydraulically-driven agitators, with the advantage that the speed of agitator rotation

can be continuously varied (RIH-M / RIH-D). Ring-pan mixers are available with capacities from 0.5 to 3.0 cu.m.

Liebherr’s double-shaft mixers are extremely strong and are suitable for high output rates. The Type DW is available with

nominal volumes of between 2.25 and 6.0 cu. m. All mixer systems from Liebherr are particularly maintenance-friendly.

14

Page 15

Litronic-MPS microprocessor control

Litronic-MPS is based on an open system concept derived to a large extent from industrial standards, enabling the

latest hardware and software developments to be incorporated without difficulty. Screen displays allow all work sequences to be followed easily, and the necessary interfaces for connection to existing data processing systems are

provided. Extensive additional software packages are available and can be installed retrospectively.

Litronic-FMS moisture measurement

To ensure that aggregate moisture is measured accurately during the dosing operation, we use an intelligent Liebherr

capacitive-type sensor.

Litronic-TMS temperature measurement

Liebherr offers Litronic-TMS for non-contact temperature measurement of the material in the intensive mixer.

Litronic-FMS

Litronic-TMSInstalled moisture sensors

15

Page 16

Betomix plants

Basic data/type 1.0 1.5 2.25 2.5 3.0 4.5 6.0

Mixer size (cu. m) 1,0 1,5 2,25 2,5 3,0 4,5 6,0

Use of ring-pan mixer

Use of double-shaft mixer

Theoretical output rate for mixed concrete, compacted (cu. m/h)

Theoretical output rate for mixed concrete (cu. m/h)

2)

Version with loading elevator

Version with loading conveyor

Number of cement grades max. 6

Storage volume with inline silo (cu. m) 70 - 300 105 - 500

Mix constituents with inline silo 4 - 10

Storage volume with compartment-type silo (cu. m) 40 - - - - - Mix constituents with compartment-type silo 4 - - - - - Storage volume with circular silo (cu. m) 180 - 1010

Mix constituents with circular silo 4 - 12

Storage volume with star-pattern silo (cu. m) ca. 950 - - - Mix constituents with star-pattern silo 4 - 6 - - - -

1) 30-second mixing time

2) 30-second mixing time, compacting factor v = 1.25

3) With discharge from truck mixer

4) With discharge from truck

• • • •

•

1)

•

60 75 100 110 120 160 3) / 210 4)180 3) / 260

• • •

75 94 125 138 150 200 3) / 260 4)225

• • •

• • •

•

•

•

• • •

3)

/ 325

4)

4)

Printed in Germany by Eberl LMT-8203 042 05-12.12_enGB

Liebherr-Mischtechnik GmbH

Postfach 145, 88423 Bad Schussenried, Germany

+49 (0)7583 949-0, Fax: +49 (0)7583 949-3 99

www.liebherr.com, E-Mail: info.lmt@liebherr.com

Subject to technical modifications.

Loading...

Loading...