Page 1

Wheeled Excavator

A 900 C

Operating Weight: 17,400 - 19,600 kg

Engine Output: 95 kW / 129 HP

Bucket Capacity: 0.32 - 0.95 m³

Page 2

2

A 900 C

Operating Weight: 17,400 - 19,600 kg

Engine Output: 95 kW / 129 HP

Bucket Capacity: 0.32 - 0.95 m³

A 900 C Litronic

Page 3

3

Reliability

Liebherr hydraulic excavators have been designed and

built to withstand the toughest of conditions at the building site. Their rugged design, high-tensile materials and

individual components ensure maximum availability and

long life-expectancy.

Performance

Liebherr wheel excavators have been designed for maximum productivity. Maximum digging performances, high

lift capacities and quick working cycles are prerequisite

for effi cient building site operation, and a wide variety of

attachments optimize every excavator application.

Comfort

Largely dimensioned and ergonomically designed, the

Liebherr excavator cab features an operator’s seat which

can be individually adjusted, as well as clearly arranged

control instruments and ideal all-round view. Automatic

air-conditioning guarantees an optimum temperature in

the Liebherr Feel-Good cab at all times.

Economy

The Liebherr-Litronic-System increases machine performance, reduces fuel consumption and minimises service

and maintenance costs. Due to Liebherr’s well- balanced

range, the ideal machine can always be selected to suit

every application.

A 900 C Litronic

Page 4

4

A 900 C Litronic

Features

• High-tensile steel plates in highstress areas for the toughest of

applications

• Well-thought-out and secure bearings

for attachments and cylinders

• Maximum resistance, even when

lifting heavy loads

Page 5

5

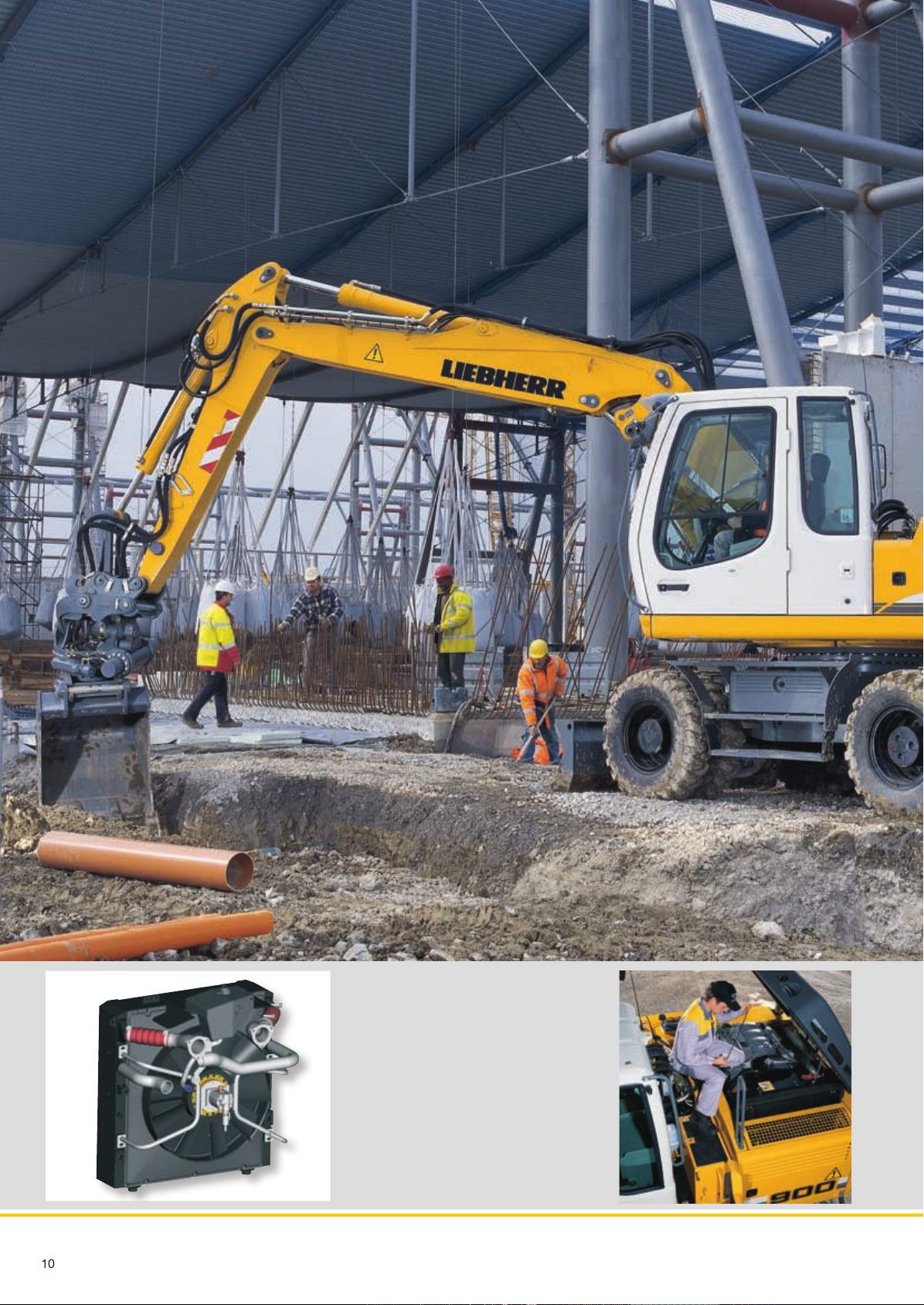

Reliability

Liebherr construction machinery is proven all over the world every day on the

most diverse of building sites. Many years of experience as the world’s largest

manufacturer of rubber-tyre excavators, continuous development and the introduction of the latest technology are evident in every machine, guaranteeing absolute safety during applications. With its rugged design, and featuring

Liebherr components, the Liebherr hydraulic excavators have been designed

for extremely long life-expectancy.

Quality in detail

Liebherr components

Functional safety

Rugged attachments

Working attachment

Components such as engine, hydraulic cylinders,

swing gear and electric parts have been specially

designed, tested and manufactured by Liebherr

for construction machinery. Parts including engines and pumps for example, are already being

synchronized with each other as early as the

construction phase, yielding a constant standard

of quality.

Safety-orientated components, fi tted as standard,

allow high availability.

The operator can thus concentrate fully on the

task at hand, due to the integrated on-board electronics performing a constant balancing of predefi ned set data.

Filtering of metallic fi lings by the magnetic rod, fi tted in the hydraulic system as standard, increases

life-expectancy of the hydraulic components and

the oil.

The durable attachments have been designed for

the toughest of applications. All components are

optimised to the FEM methods and the hoist cylinders feature bearings on both sides.

Liebherr hydraulic cylinders

• Specifi c size for each machine

• High-grade surface coating of

the piston rods

• All Liebherr cylinders feature

special long-life sealing systems

• Shock absorption at both sides

in the working cylinders

Piping

The hydraulic lines are arranged optimally to safeguard against damage. The electric cabling is

made with high-grade materials, thus guaranteeing a reliable supply to the consumer.

Functional safety

• Essential operating data is stored and can

be recalled at any time.

• Control and monitoring functions increase

functional safety of the machine.

• Four fi xed working modes for output discharge

facilitate an effective and effi cient operation:

– Eco-Mode: for high output at big fuel savings

– Power-Mode: for heavy-duty digging-and loading

performance under severe conditions

– Lift-Mode: for precise handling of heavy loads

– Fine-Mode: for fi ne control at precision work

A 900 C Litronic

Page 6

6

A 900 C Litronic

Liebherr diesel engine

• Long life-expectancy, expansive cylinder

capacity and increased weight

• According to level IIIA / Tier 3

• Specially designed for construction

machinery operation

• Oil supply even with extreme tilt angle

Page 7

7

Performance

Liebherr wheel excavators have been designed for maximum productivity. Perfectly harmonized, the Liebherr-developed and Liebherr-manufactured components including diesel engine, hydraulic pump and motor, as well as swing

gear and cylinders, guarantee maximum performance. Tremendous digging

and breakout forces, extensive lifting capacities and quick working and travel

movements are thus resulted.

Innovative solutions

Intelligent

undercarriage

Multitude of

attachments

Extensive lifting

capacities

High productivity

Quick working cycles

The entire travel drive unit is integrated in the sturdy

undercarriage. Intelligently built and robust in service, the undercarriage offers the travel drive unit

the best possible protection from debris, stones

and soil. Its advantages are perfect all-terrain compatibility and extremely high ground clearance.

Liebherr provide an individual, application-related

range of diverse attachments. Hydraulic booms,

adjustable both in height and offset positions, as

well as standard and offset-adjustable goosenecks,

can be combined with different sticks.

Canalization and the lifting of pipes are everyday

tasks for rubber-tyre excavators. These requirements are endorsed via an intelligent concept of

uppercarriage sectioning together with the positioning of the Liebherr engine, mounted at a transversal angle directly in front of the counterweight.

Separate hoist cylinder bearing points at the upper end of the basic boom also increase the lifting

capacities considerably.

High swing torque – attained as a result of the

Liebherr swing ring featuring internal teeth and

swing drive, specially designed to increase the

torque.

Rugged undercarriage

• Various undercarriage designs featuring welded, durable outriggers

allow safe positioning, optimum stability, and long life-expectancy of the

machine for every application.

• Prop-up blade / dozing blade in

box-type design – only two bearing

points for high torsional resistance

• Optional protection system for blade

cylinders

Performance without

compromise

Maximum performance and maximum forces are

available to the operator at all times.

Litronic

• Increases productivity of the

excavator

• Reduces fuel consumption

• Reduces service costs and eases

operation

• Allows maximum sensitivity and as

many overlapping movements as are

required

A 900 C Litronic

Page 8

8

A 900 C Litronic

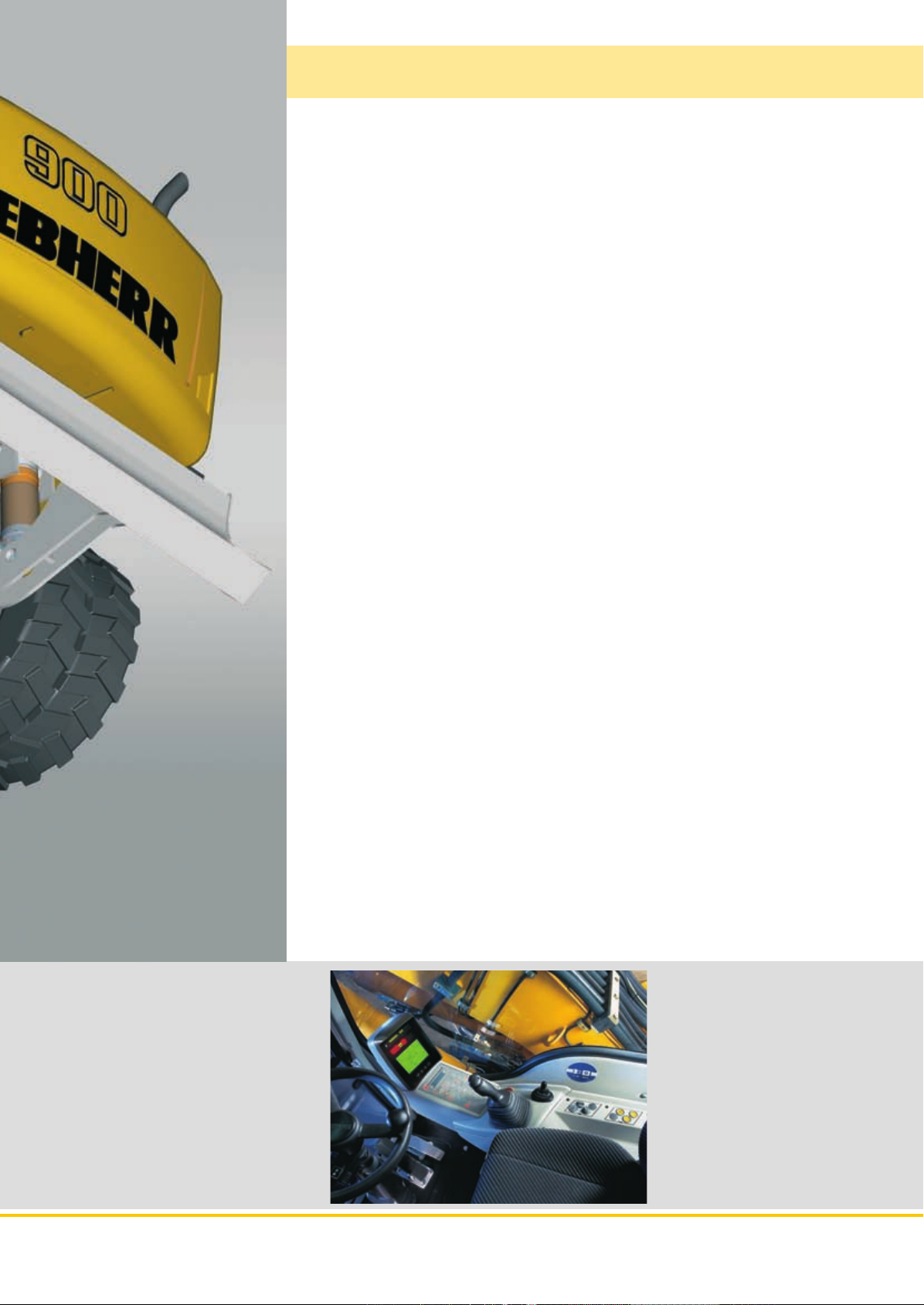

Large-sized cab

• Adjustable steering column

• Operator’s seat, adjustable in height and

can also be adapted to the individual weight

of the operator.

• Consoles with or without possibility

of horizontal adjustment.

• Large roof window

• Sun blinds

Page 9

9

Comfort

The excavator operator is provided with an ergonomically-arranged working

area within Liebherr hydraulic excavator cabs. All switches and functions are

logically laid out, and operator’s seat, steering column and consoles can be

adjusted individually. Conditioning and concentration can thus be maintained

throughout the entire working day, guaranteeing constant, maximum productivity of the operator.

Mobile comfort

Easy access

Optimum visibility

Pleasant surroundings

Maintenance features

Easy maintenance

Ease of operation

Easy access

Wide steps, ergonomically-positioned handles

and adjustable steering column allow an easy access into the Liebherr operator’s cab.

A well-thought-out design of the uppercarriage,

featuring large glass panels and rounded edges,

increase overall visibility and guarantees a safe

overview of the entire working area.

Reduced engine speed together with elaborate

sound insulation, as well as optimised hydraulic

components, allow a comfortable noise level both

inside and out. The noise level is comparable with

that of a diesel car.

Semi-Automatical Central lubrication for swing

gear and main parts of the attachment.

A shut-off valve, fi tted to the hydraulic tank as

standard, disconnects the system and guarantees

ease of maintenance to the hydraulic system.

Large maintenance fl aps allow comfortable and

safe access to all maintenance points.

Storage compartment –

Everything has its place

• Suffi cient storage space for a commercially-approved cooler box behind the

operator’s seat

• Drinks holder and storage compartment in operator’s cab

• Large storage box behind the

operator’s cab

• Two standard tool boxes in the

undercarriage

Fully-automatic air-conditioning system

• The air-conditioning system, fi tted as

standard, offers the same comfort as that

of a regular car

• Two sensors for precise temperature

regulation

• Ventilation fl aps are controlled via keys

• Reheat function for quick dehumidifying /

defrosting of the windshield

A 900 C Litronic

Page 10

10

A 900 C Litronic

Hydrostatic fan drive

• Accelerated warm-up period

• Guaranteed constant oil quality as a

result of constant oil temperature

• Increased life-expectancy of drive

components

• The fan only runs at the output required, thus conserving fuel and reducing the noise level considerably

Page 11

11

Economy

Liebherr offer a wide range of models, guaranteeing optimum suitability for

every application. Easy access to components, as well as the proven service

offer allows maintenance tasks to be performed in the shortest of times, thus

reducing operating costs considerably.

Low operating costs

Solid Liebherr Engine

Maximum power of the engine is generated even

when running at minimum speed. This allows the

necessary output without limitation, whereby the

torque which is available is ample for the level required, resulting in high productivity with low consumption.

Automatic idle

If no working or travel movements are being performed, the shiftable function reduces the engine

speed to idle, which in turn reduces fuel consumption and emission levels.

Intelligent hydraulic

management

The state-of-the-art hydraulic system allows conversion of the maximum engine output into high

force or speed, as required. The maximum possible forces are available at all times.

Investment for the future

Extensive service offer

Proven service offers assured by our service personnel trained directly at the manufacturing plants,

and endorsed by our tight-knit network of dealers, provide services in all required areas. Direct

contact to Liebherr is guaranteed via complete integration of all service points in our own Liebherr

logistics system. Electronic access to our global

spare-parts management allows a 98% availability of spare-parts 24 hours a day.

Service-orientated

• Service points of the engine – such

as fi lter or fi lling amount displays

are easily accessible and can be

easily reached from the maintenance platform

• The magnetic rod on the hydraulic

oil return fl ow increases life-expectancy of the oil

• semi-Automatical Central lubrication for swing gear and main parts

of the attachment allowing quicker

maintenance

High resale values

Liebherr excavators are built with high-grade materials and quality production to provide a longterm operational life-span, thus guaranteeing maximum resale values.

Modular quick-change system

made by Liebherr

• Likufi x – connects all hydraulically

mounted tools without having to leave

the operator’s cab, maximum productivity due to tool change being performed in a matter of seconds

• The suitable digging tool for every

application. Your machine is a multifunctional tool carrier and will pay for

itself very quickly indeed.

• Mechanic and hydraulic Liebherr

quick-change adapter

A 900 C Litronic

Page 12

Technical Data

Engine

Rating per ISO 9249

������������������������������

Model

�������������������������������

Type

Bore/Stroke

Displacement

Engine operation

Cooling system

Air cleaner

Fuel tank

�����������������������

�������������������������

Engine idling

Electrical system

Voltage

����������������������

Batteries

Alternator

���������

����������������

�������������

��������������

����������������

��������������������

��������������������

�������������������

Hydraulic System

Hydraulic pump

Max. flow

Max. hydr. pressure

Hydraulic pump

regulation and control

Hydraulic tank capacity

Hydraulic

Filtration

Cooling system

�����������������������������

Modes

LIFT

FINE

ECO

POWER

Super-Finish

RPM adjustment

����������������

�������������������

system capacity

��������������������������

����������������

���������������������������

��������������������������

��������������������������

���������������������

��������������������

���������������

Hydraulic Controls

Power distribution

Control type

Attachment and

swing

Travel

Additional functions

Option

������������������������

������������������������

�����������������������������

������������

����������

95 kW (129 HP) at 1,800 RPM

Liebherr D 934 S according to level IIIA / Tier 3

4 cylinder in-line

122/136 mm

6.4 l

4-stroke diesel

unit pump system

turbo-charged and after-cooled

reduced emissions

water-cooled and integrated motor oil

cooler

dry-type air cleaner with pre-cleaner,

primary and safety elements

290 l

sensor controlled

24 V

2 x 110 Ah/12 V

three phase current 28 V/80 A

Liebherr, variable displacement, swash-

plate pump

300 l/min.

����

350 bar

�������

Liebherr-Synchron-Comfort-system (LSC)

with electronic horsepower regulation,

pressure cut-off, load sensing and torque

controlled swing drive priority

�����

175 l

��

max. 290 l

one main return filter with integrated partial

micro filtration (5 µm)

compact cooler, consisting of a water

cooler, sandwiched with hydraulic oil

cooler, fuel cooler and after-cooler cores

and hydrostatically driven fan

can also be adjusted by the operator to

adjust engine and hydraulic performance to

match job conditions (Note: All modes pro-

vide full max. power)

for precise lifting tasks

for precision work at high speed i.e.

grading

for most economic performance at best

environmental conditions

for max. output

additional operator adjustable work speed

function for further increased feathering.

Applies to all modes and all control func-

tions

stepless adjustment of engine output via

rpm

via control valve with integrated safety

valves, simultaneous and independent

operation of travel drive, swing drive and

work

proportional via joystick levers

proportional via foot pedal

via switch and/or proportional foot pedals

Liebherr-Proportional-Controls, propor-

tionally acting transmitters on the joysticks

for additional hydraulic functions

Swing Drive

�������������������������������

Drive

Transmission

Swing ring

�����������������������

Swing speed

Swing torque

Holding brake

�����������������������������

Option

�������������������

��������������������

�������������������

������������������

Liebherr swashplate motor with torque

control and integrated brake valve

Liebherr compact planetary reduction gear

Liebherr sealed single race ball bearing

swing ring, internal teeth

0 – 9.0 RPM

42 kNm

wet discs (spring applied – pressure

released)

pedal controlled positioning brake

Operator’s Cab

���������������������������������

Cab

resiliently mounted, sound insulated, tinted

windows, front window stores overhead,

door with sliding window, large roof win-

Operator’s seat

����������������

dow, sun visor

fully adjustable, shockabsorbing suspen-

sion, adjustable to operator’s weight and

Joysticks

Monitoring

�������������������������

�����������������������

size, 6-way adjustable Liebherr seat

integrated into adjustable seat consoles

menu driven query of current operating

conditions via the LCD display. Automatic

monitoring, display, warning (acoustical

and optical signal) and saving machine

data, for example, engine overheating, low

Air conditioning

����������������

engine oil pressure or low hydraulic oil level

standard air conditioning, combined cooler/

heater, additional dust filter in fresh air/

recirculated

Noise emission

ISO 6396

2000/14/EC

�������������������������

���������������������

LpA (inside cab) = 72 dB(A)

LWA (surround noise) = 99 dB(A)

Sound level in correspondence with “Blue Angel” guidelines.

Undercarriage

�������������������������������

Drive

Transmission

Travel speed

�������������������

��������������������

variable flow swashplate motor with auto-

matic brake valve

oversized two speed power shift trans-

mission with additional creeper speed

0 – 2.5 km/h (creeper speed off road)

0 – 5.0 km/h (off road)

0 – 9.0 km/h (creeper speed on road)

0 – 20.0 km/h (road travel)

�������������������������������

Axles

����������������������������

Brakes

0 – 30.0 km/h Speeder (Option)

32 t excavator axles; automatic or operator

controlled front axle oscillation lock

steering and rigid axle with wet, mainte-

nance-free multi disc brakes with minimized

backlash. Spring applied/pressure released

Stabilization

���������������������

parking brake integrated into gear box

stabilizing blade (adjustable during travel

for dozing)

2-point outriggers

stabilizing blade, front + 2 pt. outriggers,

rear

�����������������������������

Option

4-point outriggers

EW (extra wide gauge) undercarriage

Attachment

Hydraulic cylinders

������������������������������

Pivots

Lubrication

�����������

����������������������

Liebherr cylinders with special seal system.

Shock absorption

sealed, low maintenance

Liebherr semi-automatic central lubrication

system

12 A 900 C Litronic

Page 13

Dimensions

E

D

W

U2

T2

M

L

U1

V

X

I2 J2

B

B2

T1

I3J3

T3

H

K

T1

U3

A

C

Q

B

B1

B

B3

B1

mm

A 2,550

B 2,550

1)

B

2,750

B1 3,690

B2 2,550

1)

B2

2,750

B3 2,550

C 3,160

D 2,260

E 2,330

H 2,465

I2 425

I3 380

J2 605

J3 585

K 1,235

L 2,540

M 1,100

Q 360

T1 1,050

T2 1,225

T3 1,155

U1 4,390

U2 4,575

U3 4,740

1)

= EW-Undercarriage

E = Tail radius

Tires 10.00-20

Stick Hydr. Adjustable Gooseneck Boom

Boom 3.60 m 5.00 m

stabil. 2 pt. blade 4 pt. stabil. 2 pt. blade 4 pt.

blade outr. + 2 pt. outr. blade outr. + 2 pt. outr.

outr. outr.

m mm mm mm mm mm mm mm mm

V 2.25 6,250 6,200 6,200 6,200 5,850 5,800 5,800 5,800

2.45 5,950 5,900 5,900 5,900 5,450 5,400 5,400 5,400

2.65 5,850 5,800 5,800 5,800 5,350 5,250 5,650 5,550*

W 2.25 3,050 3,050 3,050 3,050 3,150 3,150 3,150 3,150

2.45 3,050 3,050 3,050 3,050 3,050 3,050 3,050 3,050

2.65 3,100 3,100 3,100 3,100 3,100 3,100 3,100 3,100*

X 2.25 8,700 8,650 8,650 8,650 8,500 8,400 8,400 8,400

2.45 8,700 8,650 8,650 8,650 8,450 8,400 8,400 8,400

2.65 8,700 8,650 8,650 8,650 8,500 8,400 8,800 8,700*

Stick Adjustable Up/Down Adjustable Offset

Plus Offset Boom Boom 4.90 m

3.60 m

stabil. 2 pt. blade 4 pt. stabil. 2 pt. blade 4 pt.

blade outr. + 2 pt. outr. blade outr. + 2 pt. outr.

outr. outr.

m mm mm mm mm mm mm mm mm

V 2.25 6,250 6,150 6,100 6,150 6,250 6,150 6,150 6,150

2.45 6,000 5,900 5,900 5,900 5,700 5,650 5,650 5,650

2.65 5,900 5,800 5,800 5,800 5,300 5,250 5,650 5,500

W 2.25 3,050 3,050 3,050 3,050 3,150 3,150 3,150 3,150

2.45 3,050 3,050 3,050 3,050 3,050 3,050 3,050 3,050

2.65 3,150 3,150 3,150 3,150 3,000 3,000 3,000 3,000

X 2.25 8,700 8,650 8,650 8,650 8,350 8,300 8,300 8,300

2.45 8,700 8,650 8,650 8,650 8,400 8,300 8,300 8,300

2.65 8,700 8,650 8,650 8,650 8,400 8,300 8,750 8,600*

Dimensions are with attachment over steering axle

* Attachment over digging axle for shorter transport dimensions

A 900 C Litronic 13

Page 14

Backhoe Attachment

with Hydr. Adjustable Boom 3.60 m

ft m

35

30

25

20

15

10

5

0

-5

-10

-15

11

Digging Envelope

with Quick Change Adapter 1 2 3

10

Stick length m 2.25 2.45 2.65

9

8

7

6

5

Max. digging depth m 5.65 5.80 6.05

Max. reach at ground level m 9.10 9.30 9.50

Max. dumping height m 7.20 7.40 7.55

Max. teeth height m 10.30 10.45 10.65

Min. attachment radius m 2.85 2.75 2.80

Digging Forces

4

3

2

1

0

-1

-2

-3

-4

-5

-6

1

2

3

2345678910

1

0

0mft51015202530

without Quick Change Adapter 1 2 3

Max. digging force (ISO 6015) kN 81.0 76.0 71.6

t 8.3 7.7 7.3

Max. breakout force (ISO 6015) kN 98.4 98.4 98.4

t 10.0 10.0 10.0

Max. breakout force with ripper bucket 125.7 kN (12.8 t)

Max. possible digging force (stick 1.70 m) 99.4 kN (10.1 t)

Operating Weight

The operating weight includes the basic machine with 8 tires plus

spacer rings, hydr. adjustable boom 3.60 m, stick 2.25 m, quick

change adapter 48 and bucket 1,050 mm/0.80 m

Undercarriage versions Weight

A 900 C

A 900 C

A 900 C

A 900 C

li tr on ic

li tr on ic

li tr on ic

li tr on ic

A 900 C EW

A 900 C EW

`

with stabilizer blade 17,700 kg

`

with 2 pt. outriggers 18,000 kg

`

with stabilizer blade + 2 pt. outriggers 18,800 kg

`

with 4 pt. outriggers 18,900 kg

li tr on ic

li tr on ic

`

with stabilizer blade 17,800 kg

`

with 2 pt. outriggers 18,100 kg

3

.

Buckets Machine stability per ISO 10567* (75 % of tipping capacity)

Stabilizers Stabilizer 2 point

raised blade down outriggers + 2 pt. outr. outriggers raised blade down outriggers

down down down down

2.25 2.45 2.65 2.25 2.45 2.65 2.25 2.45 2.65 2.25 2.45 2.65 2.25 2.45 2.65 2.25 2.45 2.65 2.25 2.45 2.65 2.25 2.45 2.65

Cutting width

Capacity

mm m

5002) 0.32 290

650

850

1,050

1,250

500

650

850

1,050

1,250

500

650

850

1,050

1,250

3

kg

2)

0.45 400

2)

0.60 430

2)

0.80 510

2)

0.95 560

3)

0.32 330

3)

0.45 440

3)

0.60 480

3)

0.80 570

3)

0.95 630

4)

0.34 280

4)

0.45 380

4)

0.65 410

4)

0.85 490

4)

1.05 530

Stick length (m) Stick length (m) Stick length (m) Stick length (m) Stick length (m) Stick length (m) Stick length (m) Stick length (m)

ISO 74511)Weight

Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y

Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y

Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y

V V y Y V Y Y Y Y Y Y Y Y Y Y Y V Y Y Y Y Y Y Y

y y v V y V Y V V Y V V Y V V V y V Y V V Y V V

Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y

Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y

Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y

V y y Y V V Y Y V Y Y V Y Y V Y V V Y Y V Y Y V

y y v y y y Y V y Y V y Y V y y y y Y V y Y V y

Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y

Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y

Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y

V y y V V V Y Y V Y Y V Y Y V V V V Y Y V Y Y V

y v v y y y V V y V V y V V y y y y V V y V V y

* Indicated loads are based on ISO 10567 and do not exceed 75 % of tipping or 87 % of hydraulic capacity, max. stick length without quick

change adapter, lifted 360° on firm with blocked oscillating axle

1)

comparable with SAE (heaped)

2)

Bucket with teeth 3) Bucket with teeth in HD-version 4) Bucket with cutting lip (also available in HD-version)

Buckets with 500 mm cutting width with limited digging depth

Max. material weight

Y

= ≤ 1.8 t/m3,

V

= ≤ 1.5 t/m3,

Stabilizer blade

y

= ≤ 1.2 t/m3,

4 point EW stabilizers EW stabilizer EW 2 point

v

= not authorized

14 A 900 C Litronic

Page 15

Lift Capacities

with Hydr. Adjustable Boom 3.60 m

Stick 2.25 m

3.0 m 4.5 m 6.0 m 7.5 m

m Undercarriage m

Stabilizers raised

Stabilizer blade down

2 pt. outriggers down

9.0

Blade + 2 pt. down

4 pt. outriggers down

Stabilizers raised

Stabilizer blade down

2 pt. outriggers down

7.5

Blade + 2 pt. down

4 pt. outriggers down

Stabilizers raised

Stabilizer blade down

2 pt. outriggers down

6.0

Blade + 2 pt. down

4 pt. outriggers down

Stabilizers raised

Stabilizer blade down

2 pt. outriggers down

4.5

Blade + 2 pt. down

4 pt. outriggers down

Stabilizers raised

Stabilizer blade down

2 pt. outriggers down

3.0

Blade + 2 pt. down

4 pt. outriggers down

Stabilizers raised

Stabilizer blade down

2 pt. outriggers down

1.5

Blade + 2 pt. down

4 pt. outriggers down

Stabilizers raised

Stabilizer blade down

2 pt. outriggers down

0

Blade + 2 pt. down

4 pt. outriggers down

Stabilizers raised

Stabilizer blade down

2 pt. outriggers down

– 1.5

Blade + 2 pt. down

4 pt. outriggers down

Stabilizers raised

Stabilizer blade down

2 pt. outriggers down

– 3.0

Blade + 2 pt. down

4 pt. outriggers down

Stabilizers raised

Stabilizer blade down

2 pt. outriggers down

– 4.5

Blade + 2 pt. down

4 pt. outriggers down

4.0* 4.0* 2.3* 2.3*

4.0* 4.0* 2.3* 2.3*

4.0* 4.0* 2.3* 2.3*

4.0* 4.0* 2.3* 2.3*

4.0* 4.0* 2.3* 2.3*

4.6 4.7* 2.9 3.9* 2.1* 2.1*

4.7* 4.7* 3.1 3.9* 2.1* 2.1*

4.7* 4.7* 3.8 3.9* 2.1* 2.1*

4.7* 4.7* 3.9* 3.9* 2.1* 2.1*

4.7* 4.7* 3.9* 3.9* 2.1* 2.1*

6.6* 6.6* 4.5 6.2* 2.9 4.5 1.8 2.0* 1.8 2.0*

6.6* 6.6* 4.9 6.2* 3.2 5.2* 2.0* 2.0* 2.0* 2.0*

6.6* 6.6* 5.9 6.2* 3.9 5.2* 2.0* 2.0* 2.0* 2.0*

6.6* 6.6* 6.2* 6.2* 4.7 5.2* 2.0* 2.0* 2.0* 2.0*

6.6* 6.6* 6.2* 6.2* 5.2* 5.2* 2.0* 2.0* 2.0* 2.0*

7.8 11.4* 4.3 6.7 2.9 4.4 1.8 3.0 1.6 2.0*

8.6 11.4* 4.7 7.4* 3.1 5.6* 2.0 3.9* 1.8 2.0*

10.6 11.4* 5.7 7.4* 3.8* 5.6* 2.5 3.9* 2.0* 2.0*

11.4* 11.4* 7.0* 7.4* 4.6 5.6* 3.2 3.9* 2.0* 2.0*

11.4* 11.4* 7.4* 7.4* 5.5 5.6* 3.9* 3.9* 2.0* 2.0*

7.6 11.3* 4.3 6.6 2.8 4.4 1.8 2.9 1.5 2.2*

8.4 11.3* 4.7 8.3* 3.0 6.0* 2.0 4.7* 1.7 2.2*

10.4 11.3* 5.7 8.3* 3.7 6.0* 2.5 4.7* 2.2* 2.2*

11.3* 11.3* 6.9 8.3* 4.6 6.0* 3.1 4.7* 2.2* 2.2*

11.3* 11.3* 8.3* 8.3* 5.5 6.0* 3.8 4.7* 2.2* 2.2*

7.4 12.6* 4.1 6.6 2.6 4.2 1.7 2.8 1.5 2.5*

8.3 12.6* 4.5 8.4* 2.9 6.1* 1.9 4.6* 1.7 2.5*

10.5 12.6* 5.7 8.4* 3.6 6.1* 2.4 4.6* 2.2 2.5*

12.6* 12.6* 6.9 8.4* 4.4 6.1* 3.0 4.6* 2.5* 2.5*

12.6* 12.6* 8.3 8.4* 5.5* 6.1* 3.8* 4.6* 2.5* 2.5*

7.0 13.1* 3.9 6.6 2.4 4.0 1.7 2.9

7.9 13.8* 4.3 8.5* 2.7 6.1* 1.9 3.0*

10.4 13.8* 5.5 8.5* 3.4 6.1* 2.4 3.0*

13.5 13.8* 6.9 8.5* 4.3 6.1* 3.0* 3.0*

13.8* 13.8* 8.5* 8.5* 5.3 6.1* 3.0* 3.0*

7.0 13.1 3.6 6.2 2.3 3.9 2.1 3.6*

7.8 14.2* 4.0 8.3* 2.6 4.5* 2.4 3.6*

10.3 14.2* 5.1 8.3* 3.3 4.5* 3.0 3.6*

13.8 14.2* 6.6 8.3* 4.1 4.5* 3.6* 3.6*

14.2* 14.2* 8.3* 8.3* 4.5* 4.5* 3.6* 3.6*

5.41

6.73

7.50

7.91

8.00

7.80

7.27

6.33

Stick 2.45 m

3.0 m 4.5 m 6.0 m 7.5 m

m Undercarriage m

Stabilizers raised

Stabilizer blade down

2 pt. outriggers down

9.0

Blade + 2 pt. down

4 pt. outriggers down

Stabilizers raised

Stabilizer blade down

2 pt. outriggers down

7.5

Blade + 2 pt. down

4 pt. outriggers down

Stabilizers raised

Stabilizer blade down

2 pt. outriggers down

6.0

Blade + 2 pt. down

4 pt. outriggers down

Stabilizers raised

Stabilizer blade down

2 pt. outriggers down

4.5

Blade + 2 pt. down

4 pt. outriggers down

Stabilizers raised

Stabilizer blade down

2 pt. outriggers down

3.0

Blade + 2 pt. down

4 pt. outriggers down

Stabilizers raised

Stabilizer blade down

2 pt. outriggers down

1.5

Blade + 2 pt. down

4 pt. outriggers down

Stabilizers raised

Stabilizer blade down

2 pt. outriggers down

0

Blade + 2 pt. down

4 pt. outriggers down

Stabilizers raised

Stabilizer blade down

2 pt. outriggers down

– 1.5

Blade + 2 pt. down

4 pt. outriggers down

Stabilizers raised

Stabilizer blade down

2 pt. outriggers down

– 3.0

Blade + 2 pt. down

4 pt. outriggers down

Stabilizers raised

Stabilizer blade down

2 pt. outriggers down

– 4.5

Blade + 2 pt. down

4 pt. outriggers down

2.9* 2.9*

2.9* 2.9*

2.9* 2.9*

2.9* 2.9*

2.9* 2.9*

3.9* 3.9* 2.1* 2.1*

3.9* 3.9* 2.1* 2.1*

3.9* 3.9* 2.1* 2.1*

3.9* 3.9* 2.1* 2.1*

3.9* 3.9* 2.1* 2.1*

4.3* 4.3* 2.9 3.8* 1.9* 1.9*

4.3* 4.3* 3.2 3.8* 1.9* 1.9*

4.3* 4.3* 3.8* 3.8* 1.9* 1.9*

4.3* 4.3* 3.8* 3.8* 1.9* 1.9*

4.3* 4.3* 3.8* 3.8* 1.9* 1.9*

5.4* 5.4* 4.5 5.5* 2.9 4.5 1.9 2.6* 1.7 1.8*

5.4* 5.4* 4.9 5.5* 3.2 4.9* 2.1 2.6* 1.8* 1.8*

5.4* 5.4* 5.5* 5.5* 3.9 4.9* 2.6 2.6* 1.8* 1.8*

5.4* 5.4* 5.5* 5.5* 4.7* 4.9* 2.6* 2.6* 1.8* 1.8*

5.4* 5.4* 5.5* 5.5* 4.9* 4.9* 2.6* 2.6* 1.8* 1.8*

7.8 11.5* 4.3 6.7 2.9 4.4 1.8 3.0* 1.5 1.8*

8.5 11.5* 4.8 7.2* 3.2 5.5* 2.0 4.0* 1.7 1.8*

10.6 11.5* 5.7 7.2* 3.8 5.5* 2.5 4.0* 1.8* 1.8*

11.5* 11.5* 7.0* 7.2* 4.6 5.5* 3.2 4.0* 1.8* 1.8*

11.5* 11.5* 7.2* 7.2* 5.5* 5.5* 3.9 4.0* 1.8* 1.8*

7.5 11.2* 4.3 6.6 2.8 4.4 1.8 2.9 1.5 2.0*

8.3 11.2* 4.6 8.2* 3.1 5.9* 2.0 4.7* 1.6 2.0*

10.3* 11.2* 5.6 8.2* 3.8 5.9* 2.5 4.7* 2.0* 2.0*

11.2* 11.2* 6.8 8.2* 4.6 5.9* 3.1 4.7* 2.0* 2.0*

11.2* 11.2* 8.2* 8.2* 5.5 5.9* 3.8 4.7* 2.0* 2.0*

7.5 12.4* 4.1 6.6 2.6* 4.2 1.7 2.8 1.5 2.2*

8.4 12.4* 4.6 8.4* 2.9 6.0* 1.9 4.6* 1.7 2.2*

10.5 12.4* 5.7 8.4* 3.6 6.0* 2.4 4.6* 2.1 2.2*

12.4* 12.4* 6.9* 8.4* 4.5 6.0* 3.0 4.6* 2.2* 2.2*

12.4* 12.4* 8.3 8.4* 5.5 6.0* 3.8 4.6* 2.2* 2.2*

7.0 12.9 3.9 6.6 2.4 4.0 1.6 2.7*

7.9 13.7* 4.3 8.5* 2.7 6.1* 1.8 2.7*

10.4 13.7* 5.5 8.5* 3.4 6.1* 2.3 2.7*

13.4 13.7* 6.9 8.5* 4.3 6.1* 2.7* 2.7*

13.7* 13.7* 8.4* 8.5* 5.3 6.1* 2.7* 2.7*

6.9 13.1 3.6 6.3 2.3 3.9 2.0 3.4

7.8 14.2* 4.1 8.6* 2.6 5.0* 2.2 3.5*

10.3 14.2* 5.2 8.6* 3.3 5.0* 2.8 3.5*

13.8 14.2* 6.6 8.6* 4.1 5.0* 3.5* 3.5*

14.2* 14.2* 8.5 8.6* 5.0* 5.0* 3.5* 3.5*

6.7 9.4* 4.7 6.5*

7.6 9.4* 5.2 6.5*

9.4* 9.4* 6.5* 6.5*

9.4* 9.4* 6.5* 6.5*

9.4* 9.4* 6.5* 6.5*

3.36

5.70

6.96

7.71

8.10

8.20

8.00

7.48

6.57

3.76

Stick 2.65 m

3.0 m 4.5 m 6.0 m 7.5 m

m Undercarriage m

Stabilizers raised

Stabilizer blade down

2 pt. outriggers down

9.0

Blade + 2 pt. down

4 pt. outriggers down

Stabilizers raised

Stabilizer blade down

2 pt. outriggers down

7.5

Blade + 2 pt. down

4 pt. outriggers down

Stabilizers raised

Stabilizer blade down

2 pt. outriggers down

6.0

Blade + 2 pt. down

4 pt. outriggers down

Stabilizers raised

Stabilizer blade down

2 pt. outriggers down

4.5

Blade + 2 pt. down

4 pt. outriggers down

Stabilizers raised

Stabilizer blade down

2 pt. outriggers down

3.0

Blade + 2 pt. down

4 pt. outriggers down

Stabilizers raised

Stabilizer blade down

2 pt. outriggers down

1.5

Blade + 2 pt. down

4 pt. outriggers down

Stabilizers raised

Stabilizer blade down

2 pt. outriggers down

0

Blade + 2 pt. down

4 pt. outriggers down

Stabilizers raised

Stabilizer blade down

2 pt. outriggers down

– 1.5

Blade + 2 pt. down

4 pt. outriggers down

Stabilizers raised

Stabilizer blade down

2 pt. outriggers down

– 3.0

Blade + 2 pt. down

4 pt. outriggers down

Stabilizers raised

Stabilizer blade down

2 pt. outriggers down

– 4.5

Blade + 2 pt. down

4 pt. outriggers down

2.5* 2.5*

2.5* 2.5*

2.5* 2.5*

2.5* 2.5*

2.5* 2.5*

3.7* 3.7* 1.9* 1.9*

3.7* 3.7* 1.9* 1.9*

3.7* 3.7* 1.9* 1.9*

3.7* 3.7* 1.9* 1.9*

3.7* 3.7* 1.9* 1.9*

4.0* 4.0* 2.9 3.7* 1.7* 1.7*

4.0* 4.0* 3.2 3.7* 1.7* 1.7*

4.0* 4.0* 3.7* 3.7* 1.7* 1.7*

4.0* 4.0* 3.7* 3.7* 1.7* 1.7*

4.0* 4.0* 3.7* 3.7* 1.7* 1.7*

4.5 4.9* 2.9 4.4 1.9 2.9* 1.6* 1.6*

4.8* 4.9* 3.2 4.5* 2.1 2.9* 1.6* 1.6*

4.9* 4.9* 3.9 4.5* 2.6 2.9* 1.6* 1.6*

4.9* 4.9* 4.5* 4.5* 2.9* 2.9* 1.6* 1.6*

4.9* 4.9* 4.5* 4.5* 2.9* 2.9* 1.6* 1.6*

7.8 11.0* 4.3 6.7 2.9 4.4 1.9 3.0 1.5 1.7*

8.6* 11.0* 4.7 7.0* 3.2* 5.4* 2.1 4.0* 1.6 1.7*

10.6 11.0* 5.7 7.0* 3.8 5.4* 2.6 4.0* 1.7* 1.7*

11.0* 11.0* 7.0* 7.0* 4.6 5.4* 3.2 4.0* 1.7* 1.7*

11.0* 11.0* 7.0* 7.0* 5.4* 5.4* 3.9* 4.0* 1.7* 1.7*

7.6 11.1* 4.2 6.6 2.8 4.4 1.8 2.9 1.4 1.8*

8.3 11.1* 4.6* 8.0* 3.1 5.8* 2.0 4.6* 1.6 1.8*

10.3 11.1* 5.6 8.0* 3.8 5.8* 2.5 4.6* 1.8* 1.8*

11.1* 11.1* 6.8 8.0* 4.5 5.8* 3.1 4.6* 1.8* 1.8*

11.1* 11.1* 8.0* 8.0* 5.4 5.8* 3.8 4.6* 1.8* 1.8*

7.5 12.1* 4.1 6.6 2.7 4.3 1.7 2.8 1.4 2.0*

8.4 12.1* 4.6 8.3* 2.9 6.0* 1.9 4.6* 1.6 2.0*

10.4* 12.1* 5.6* 8.3* 3.6 6.0* 2.4 4.6* 2.0* 2.0*

12.1* 12.1* 6.8* 8.3* 4.5 6.0* 3.0 4.6* 2.0* 2.0*

12.1* 12.1* 8.2* 8.3* 5.5 6.0* 3.8 4.6* 2.0* 2.0*

7.0 12.9* 3.9 6.6 2.4 4.0 1.6 2.8 1.5 2.4*

7.9 13.5* 4.3 8.4* 2.7 6.1* 1.8 3.8* 1.7 2.4*

10.4 13.5* 5.4 8.4* 3.4 6.1* 2.3 3.8* 2.2 2.4*

13.3 13.5* 6.9 8.4* 4.3 6.1* 2.9 3.8* 2.4* 2.4*

13.5* 13.5* 8.3 8.4* 5.3 6.1* 3.7 3.8* 2.4* 2.4*

6.9 13.0 3.6 6.3 2.3 3.9 1.8 3.2

7.8 14.0* 4.1 8.6* 2.5 5.3* 2.1 3.2*

10.2 14.0* 5.2 8.6* 3.2 5.3* 2.6 3.2*

13.8 14.0* 6.6 8.6* 4.1 5.3* 3.2* 3.2*

14.0* 14.0* 8.5 8.6* 5.2 5.3* 3.2* 3.2*

6.7 10.6* 3.5 5.2* 3.5 5.1*

7.5 10.6* 3.9 5.2* 3.9 5.1*

9.9 10.6* 5.0 5.2* 5.0 5.1*

10.6* 10.6* 5.2* 5.2* 5.1* 5.1*

10.6* 10.6* 5.2* 5.2* 5.1* 5.1*

3.84

5.99

7.19

7.92

8.30

8.39

8.20

7.70

6.82

4.53

Height Can be slewed through 360° In longitudinal position of undercarriage Max. reach * Limited by hydr. capacity

The lift capacities on the load hook of the Liebherr quick-change adapter 48 without grab attachment are stated in metric tons (t) and are valid on a firm, level supporting surface with blocked

oscillating axle. These capacities can be slewed through 360° with the undercarriage in the transverse position. Capacities in the longitudinal position of the undercarriage (+/– 15°) are specified

over the steering axle with the stabilisers raised and over the rigid axle with the stabilisers down. The values apply when the adjusting cylinder is in the optimal position. Indicated loads comply

with the ISO 10567 standard and do not exceed 75 % of tipping or 87 % of hydraulic capacity, or are limited by the permissible load of the load hook on the quick-change adapter (max. 12 t).

Without the quick-change adapter, lift capacities will increase by up to 226 kg.

In accordance with the harmonised EU Standard EN 474-5, hydraulic excavators used for lifting operations must be equipped with pipe rupture protection devices on the hoist cylinders and an

overload warning device.

A 900 C Litronic 15

Page 16

Lift Capacities

with Hydr. Adjustable Boom 3.60 m EW-Undercarriage

Stick 2.25 m

3.0 m 4.5 m 6.0 m 7.5 m

m Undercarriage m

Stabilizers raised

Stabilizer blade down

9.0

2 pt. outriggers down

Stabilizers raised

Stabilizer blade down

7.5

2 pt. outriggers down

Stabilizers raised

Stabilizer blade down

6.0

2 pt. outriggers down

Stabilizers raised

Stabilizer blade down

4.5

2 pt. outriggers down

Stabilizers raised

Stabilizer blade down

3.0

2 pt. outriggers down

Stabilizers raised

Stabilizer blade down

1.5

2 pt. outriggers down

Stabilizers raised

Stabilizer blade down

0

2 pt. outriggers down

Stabilizers raised

Stabilizer blade down

– 1.5

2 pt. outriggers down

Stabilizers raised

Stabilizer blade down

– 3.0

2 pt. outriggers down

Stabilizers raised

Stabilizer blade down

– 4.5

2 pt. outriggers down

4.0* 4.0* 2.3* 2.3*

4.0* 4.0* 2.3* 2.3*

4.0* 4.0* 2.3* 2.3*

4.7* 4.7* 3.1 3.9* 2.1* 2.1*

4.7* 4.7* 3.4 3.9* 2.1* 2.1*

4.7* 4.7* 3.9* 3.9* 2.1* 2.1*

6.6* 6.6* 4.9 6.2* 3.2 4.5 2.0* 2.0* 2.0* 2.0*

6.6* 6.6* 5.3 6.2* 3.4 5.2* 2.0* 2.0* 2.0* 2.0*

6.6* 6.6* 6.1 6.2* 3.9 5.2* 2.0* 2.0* 2.0* 2.0*

8.5 11.0* 4.7 6.7 3.1 4.4 2.0 3.0 1.8 2.0*

9.2 11.0* 5.1 7.4* 3.4 5.6* 2.2 3.9* 2.0 2.0*

11.0 11.0* 5.8 7.4* 3.9 5.6* 2.6 3.9* 2.0* 2.0*

8.3 10.4* 4.6 6.6 3.0 4.4 2.0 2.9 1.7 2.2*

9.0 10.4* 5.1 8.3* 3.3 6.0* 2.2 4.7* 1.9 2.2*

10.4* 10.4* 5.8 8.3* 3.8 6.0* 2.5 4.7* 2.2* 2.2*

8.3 12.6* 4.5 6.6* 2.9 4.2 1.9 2.9* 1.7 2.5*

9.4* 12.6* 5.0 8.4* 3.1 6.1* 2.1 4.5* 1.9 2.5*

10.8* 12.6* 5.9 8.4* 3.6 6.1* 2.5 4.5* 2.3 2.5*

7.9 13.0 4.3 6.6 2.7 4.0 1.9 2.9

9.0 13.8* 4.8 8.5* 3.0 6.1* 2.1 3.0*

10.9 13.8* 5.6 8.5* 3.5 6.1* 2.5 3.0*

7.8 13.2 4.0 6.3 2.6 3.9 2.4 3.6*

8.9 14.2* 4.5 8.3* 2.9 4.5* 2.6 3.6*

10.8 14.2* 5.3 8.3* 3.4 4.5* 3.1 3.6*

5.41

6.73

7.50

7.91

8.00

7.80

7.27

6.33

Stick 2.45 m

3.0 m 4.5 m 6.0 m 7.5 m

m Undercarriage m

Stabilizers raised

Stabilizer blade down

9.0

2 pt. outriggers down

Stabilizers raised

Stabilizer blade down

7.5

2 pt. outriggers down

Stabilizers raised

Stabilizer blade down

6.0

2 pt. outriggers down

Stabilizers raised

Stabilizer blade down

4.5

2 pt. outriggers down

Stabilizers raised

Stabilizer blade down

3.0

2 pt. outriggers down

Stabilizers raised

Stabilizer blade down

1.5

2 pt. outriggers down

Stabilizers raised

Stabilizer blade down

0

2 pt. outriggers down

Stabilizers raised

Stabilizer blade down

– 1.5

2 pt. outriggers down

Stabilizers raised

Stabilizer blade down

– 3.0

2 pt. outriggers down

Stabilizers raised

Stabilizer blade down

– 4.5

2 pt. outriggers down

2.9* 2.9*

2.9* 2.9*

2.9* 2.9*

3.9* 3.9* 2.1* 2.1*

3.9* 3.9* 2.1* 2.1*

3.9* 3.9* 2.1* 2.1*

4.3* 4.3* 3.2 3.8* 1.9* 1.9*

4.3* 4.3* 3.4 3.8* 1.9* 1.9*

4.3* 4.3* 3.8* 3.8* 1.9* 1.9*

5.4* 5.4* 4.9 5.5* 3.2* 4.5 2.1 2.6* 1.8* 1.8*

5.4* 5.4* 5.3* 5.5* 3.5 4.9* 2.3 2.6* 1.8* 1.8*

5.4* 5.4* 5.5* 5.5* 4.0 4.9* 2.6 2.6* 1.8* 1.8*

8.5 11.5* 4.8 6.7 3.1 4.4 2.0 3.0 1.7 1.8*

9.3 11.5* 5.2 7.2* 3.4 5.5* 2.2* 4.0* 1.8* 1.8*

11.0* 11.5* 5.9 7.2* 3.9 5.5* 2.6 4.0* 1.8* 1.8*

8.3 10.4* 4.6 6.5 3.1 4.4 2.0 2.9 1.6 2.0*

9.1 10.4* 5.0 8.2* 3.4 5.9* 2.2 4.7* 1.8 2.0*

10.4* 10.4* 5.8* 8.2* 3.8 5.9* 2.5 4.7* 2.0* 2.0*

8.4 12.4* 4.6 6.6 2.8 4.2 1.9 2.9 1.7 2.2*

9.1 12.4* 5.0 8.4* 3.2 6.0* 2.1 4.6* 1.9 2.2*

10.7 12.4* 5.8 8.4* 3.7 6.0* 2.5 4.6* 2.2 2.2*

7.9 13.0 4.3 6.6 2.7 4.0 1.8 2.7*

9.0 13.7* 4.8 8.5* 3.0 6.1* 2.0 2.7*

10.9 13.7* 5.6 8.5* 3.5 6.1* 2.4 2.7*

7.8 13.1 4.1 6.3 2.5 3.9 2.2 3.4

8.9 14.2* 4.5 8.6* 2.8 5.0* 2.5 3.5*

10.7 14.2* 5.3 8.6* 3.3 5.0* 2.9 3.5*

7.6 9.4* 5.2 6.5*

8.6 9.4* 5.9 6.5*

9.4* 9.4* 6.5* 6.5*

3.36

5.70

6.96

7.71

8.10

8.20

8.00

7.48

6.57

3.76

Stick 2.65 m

3.0 m 4.5 m 6.0 m 7.5 m

m Undercarriage m

Stabilizers raised

Stabilizer blade down

9.0

2 pt. outriggers down

Stabilizers raised

Stabilizer blade down

7.5

2 pt. outriggers down

Stabilizers raised

Stabilizer blade down

6.0

2 pt. outriggers down

Stabilizers raised

Stabilizer blade down

4.5

2 pt. outriggers down

Stabilizers raised

Stabilizer blade down

3.0

2 pt. outriggers down

Stabilizers raised

Stabilizer blade down

1.5

2 pt. outriggers down

Stabilizers raised

Stabilizer blade down

0

2 pt. outriggers down

Stabilizers raised

Stabilizer blade down

– 1.5

2 pt. outriggers down

Stabilizers raised

Stabilizer blade down

– 3.0

2 pt. outriggers down

Stabilizers raised

Stabilizer blade down

– 4.5

2 pt. outriggers down

2.5* 2.5*

2.5* 2.5*

2.5* 2.5*

3.7* 3.7* 1.9* 1.9*

3.7* 3.7* 1.9* 1.9*

3.7* 3.7* 1.9* 1.9*

4.0* 4.0* 3.2 3.7* 1.7* 1.7*

4.0* 4.0* 3.5 3.7* 1.7* 1.7*

4.0* 4.0* 3.7* 3.7* 1.7* 1.7*

4.8* 4.9* 3.2 4.5 2.1 2.9* 1.6* 1.6*

4.9* 4.9* 3.5 4.5* 2.3 2.9* 1.6* 1.6*

4.9* 4.9* 4.0 4.5* 2.6 2.9* 1.6* 1.6*

8.4* 11.0* 4.7 6.7* 3.2* 4.4* 2.0 3.0 1.6 1.7*

9.4 11.0* 5.1 7.0* 3.4 5.4* 2.3 4.0* 1.7* 1.7*

11.0* 11.0* 5.8 7.0* 3.9 5.4* 2.6 4.0* 1.7* 1.7*

8.2* 10.9* 4.5* 6.5 3.1 4.3 2.0 2.9 1.6 1.8*

9.1 10.9* 5.0 8.0* 3.4 5.8* 2.2 4.6* 1.7 1.8*

10.6 10.9* 5.7 8.0* 3.8 5.8* 2.5 4.6* 1.8* 1.8*

8.3 12.0* 4.6 6.6 2.9 4.2 1.9 2.9 1.6 2.0*

9.2 12.0* 5.1 8.3* 3.2 6.0* 2.1 4.6* 1.8 2.0*

10.8 12.0* 5.8 8.3* 3.7 6.0* 2.5 4.6* 2.0* 2.0*

7.9 12.7 4.3 6.6 2.7 4.0 1.8 2.8 1.7 2.4*

9.0 13.5* 4.8 8.4* 3.0 6.1* 2.0 3.8* 1.9 2.4*

10.9 13.5* 5.6 8.4* 3.5 6.1* 2.4 3.8* 2.3 2.4*

7.8 13.1 4.1 6.3 2.5 3.9 2.1 3.2*

8.8 14.0* 4.5 8.6* 2.8 5.3* 2.3 3.2*

10.7 14.0* 5.4 8.6* 3.3 5.3* 2.7 3.2*

7.5 10.6* 3.9 5.2* 3.9 5.1*

8.5 10.6* 4.4 5.2* 4.4 5.1*

10.4 10.6* 5.2* 5.2* 5.1* 5.1*

3.84

5.99

7.19

7.92

8.30

8.39

8.20

7.70

6.82

4.53

Height Can be slewed through 360° In longitudinal position of undercarriage Max. reach * Limited by hydr. capacity

The lift capacities on the load hook of the Liebherr quick-change adapter 48 without grab attachment are stated in metric tons (t) and are valid on a firm, level supporting surface with blocked

oscillating axle. These capacities can be slewed through 360° with the undercarriage in the transverse position. Capacities in the longitudinal position of the undercarriage (+/– 15°) are specified

over the steering axle with the stabilisers raised and over the rigid axle with the stabilisers down. The values apply when the adjusting cylinder is in the optimal position. Indicated loads comply

with the ISO 10567 standard and do not exceed 75 % of tipping or 87 % of hydraulic capacity, or are limited by the permissible load of the load hook on the quick-change adapter (max. 12 t).

Without the quick-change adapter, lift capacities will increase by up to 226 kg.

In accordance with the harmonised EU Standard EN 474-5, hydraulic excavators used for lifting operations must be equipped with pipe rupture protection devices on the hoist cylinders and an

overload warning device.

16 A 900 C Litronic

Page 17

Backhoe Attachment

with Gooseneck Boom 5.00 m

ft m

30

25

20

15

10

5

0

-5

-10

-15

10

Digging Envelope

with Quick Change Adapter 1 2 3

9

Stick length m 2.25 2.45 2.65

8

7

6

5

4

Max. digging depth m 5.50 5.70 5.90

Max. reach at ground level m 8.80 9.00 9.20

Max. dumping height m 6.15 6.25 6.40

Max. teeth height m 9.00 9.10 9.25

Min. attachment radius m 3.30 3.05 3.05

Digging Forces

3

2

1

0

-1

-2

-3

-4

-5

-6

1

2

3

1

2345678910

0

0mft51015202530

without Quick Change Adapter 1 2 3

Max. digging force (ISO 6015) kN 81.0 76.0 71.6

t 8.3 7.7 7.3

Max. breakout force (ISO 6015) kN 98.4 98.4 98.4

t 10.0 10.0 10.0

Max. breakout force with ripper bucket 125.7 kN (12.8 t)

Max. possible digging force (stick 1.70 m) 99.4 kN (10.1 t)

Operating Weight

The operating weight includes the basic machine with 8 tires plus

spacer rings, gooseneck boom 5.00 m, stick 2.25 m, quick change

adapter 48 and bucket 1,050 mm/0.80 m

Undercarriage versions Weight

A 900 C

A 900 C

A 900 C

A 900 C

li tr on ic

li tr on ic

li tr on ic

li tr on ic

A 900 C EW

A 900 C EW

`

with stabilizer blade 17,400 kg

`

with 2 pt. outriggers 17,700 kg

`

with stabilizer blade + 2 pt. outriggers 18,500 kg

`

with 4 pt. outriggers 18,600 kg

li tr on ic

li tr on ic

`

with stabilizer blade 17,500 kg

`

with 2 pt. outriggers 17,800 kg

3

.

Buckets Machine stability per ISO 10567* (75 % of tipping capacity)

Stabilizers Stabilizer 2 point

raised blade down outriggers + 2 pt. outr. outriggers raised blade down outriggers

down down down down

2.25 2.45 2.65 2.25 2.45 2.65 2.25 2.45 2.65 2.25 2.45 2.65 2.25 2.45 2.65 2.25 2.45 2.65 2.25 2.45 2.65 2.25 2.45 2.65

Cutting width

Capacity

mm m

5002) 0.32 290

650

850

1,050

1,250

500

650

850

1,050

1,250

500

650

850

1,050

1,250

3

kg

2)

0.45 400

2)

0.60 430

2)

0.80 510

2)

0.95 560

3)

0.32 330

3)

0.45 440

3)

0.60 480

3)

0.80 570

3)

0.95 630

4)

0.34 280

4)

0.45 380

4)

0.65 410

4)

0.85 490

4)

1.05 530

Stick length (m) Stick length (m) Stick length (m) Stick length (m) Stick length (m) Stick length (m) Stick length (m) Stick length (m)

ISO 74511)Weight

Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y

Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y

Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y

V V V Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y

y y y V V V Y V V Y V V Y V V V V V Y V V Y V V

Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y

Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y

Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y

V V V Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y

y y y V V y Y V y Y V y Y V y V V y Y V y Y V y

Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y

Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y

Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y

V V V Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y

y y v V V y Y V y Y V y Y V y V V y Y V y Y V y

* Indicated loads are based on ISO 10567 and do not exceed 75 % of tipping or 87 % of hydraulic capacity, max. stick length without quick

change adapter, lifted 360° on firm with blocked oscillating axle

1)

comparable with SAE (heaped)

2)

Bucket with teeth 3) Bucket with teeth in HD-version 4) Bucket with cutting lip (also available in HD-version)

Buckets with 500 mm cutting width with limited digging depth

Max. material weight

Y

= ≤ 1.8 t/m3,

V

= ≤ 1.5 t/m3,

Stabilizer blade

y

= ≤ 1.2 t/m3,

4 point EW stabilizers EW stabilizer EW 2 point

v

= not authorized

A 900 C Litronic 17

Page 18

Lift Capacities

with Gooseneck Boom 5.00 m

Stick 2.25 m

3.0 m 4.5 m 6.0 m 7.5 m

m Undercarriage m

Stabilizers raised

Stabilizer blade down

2 pt. outriggers down

9.0

Blade + 2 pt. down

4 pt. outriggers down

Stabilizers raised

Stabilizer blade down

2 pt. outriggers down

7.5

Blade + 2 pt. down

4 pt. outriggers down

Stabilizers raised

Stabilizer blade down

2 pt. outriggers down

6.0

Blade + 2 pt. down

4 pt. outriggers down

Stabilizers raised

Stabilizer blade down

2 pt. outriggers down

4.5

Blade + 2 pt. down

4 pt. outriggers down

Stabilizers raised

Stabilizer blade down

2 pt. outriggers down

3.0

Blade + 2 pt. down

4 pt. outriggers down

Stabilizers raised

Stabilizer blade down

2 pt. outriggers down

1.5

Blade + 2 pt. down

4 pt. outriggers down

Stabilizers raised

Stabilizer blade down

2 pt. outriggers down

0

Blade + 2 pt. down

4 pt. outriggers down

Stabilizers raised

Stabilizer blade down

2 pt. outriggers down

– 1.5

Blade + 2 pt. down

4 pt. outriggers down

Stabilizers raised

Stabilizer blade down

2 pt. outriggers down

– 3.0

Blade + 2 pt. down

4 pt. outriggers down

Stabilizers raised

Stabilizer blade down

2 pt. outriggers down

– 4.5

Blade + 2 pt. down

4 pt. outriggers down

2.3* 2.3*

2.3* 2.3*

2.3* 2.3*

2.3* 2.3*

2.3* 2.3*

2.8 3.0* 2.0* 2.0*

3.0 3.0* 2.0* 2.0*

3.0* 3.0* 2.0* 2.0*

3.0* 3.0* 2.0* 2.0*

3.0* 3.0* 2.0* 2.0*

4.3 4.6* 2.7 4.2* 2.0 2.0*

4.6* 4.6* 3.0 4.2* 2.0* 2.0*

4.6* 4.6* 3.7 4.2* 2.0* 2.0*

4.6* 4.6* 4.2* 4.2* 2.0* 2.0*

4.6* 4.6* 4.2* 4.2* 2.0* 2.0*

7.0 9.5* 3.9 6.0* 2.5 4.2 1.8 2.4* 1.7 2.1*

7.9 9.5* 4.3 6.0* 2.8 4.8* 2.0 2.4* 1.9 2.1*

9.5* 9.5* 5.4 6.0* 3.5 4.8* 2.4* 2.4* 2.1* 2.1*

9.5* 9.5* 6.0* 6.0* 4.4 4.8* 2.4* 2.4* 2.1* 2.1*

9.5* 9.5* 6.0* 6.0* 4.8* 4.8* 2.4* 2.4* 2.1* 2.1*

3.5 6.1 2.4 4.0 1.7 2.9 1.6 2.2*

4.0 7.4* 2.6 5.5* 1.9 3.2* 1.8 2.2*

5.0 7.4* 3.3 5.5* 2.4 3.2* 2.2* 2.2*

6.5 7.4* 4.2 5.5* 3.0 3.2* 2.2* 2.2*

7.4* 7.4* 5.3 5.5* 3.2* 3.2* 2.2* 2.2*

5.9* 5.9* 3.3 5.9 2.3 3.9 1.7 2.6*

5.9* 5.9* 3.7 8.3* 2.5 5.9* 1.9 2.6*

5.9* 5.9* 4.8 8.3* 3.2 5.9* 2.4 2.6*

5.9* 5.9* 6.2 8.3* 4.1 5.9* 2.6* 2.6*

5.9* 5.9* 8.1 8.3* 5.2 5.9* 2.6* 2.6*

6.0 9.0* 3.3 5.8 2.2 3.8 1.9 3.2

6.9 9.0* 3.7 8.3* 2.5 6.0* 2.1 3.3*

9.0* 9.0* 4.8 8.3* 3.2 6.0* 2.6 3.3*

9.0* 9.0* 6.2 8.3* 4.0 6.0* 3.3* 3.3*

9.0* 9.0* 8.0 8.3* 5.1 6.0* 3.3* 3.3*

6.2 10.9* 3.4 5.9 2.4 4.0

7.1 10.9* 3.8 7.4* 2.6 5.2*

9.4 10.9* 4.9 7.4* 3.3 5.2*

10.9* 10.9* 6.3 7.4* 4.2 5.2*

10.9* 10.9* 7.4* 7.4* 5.2* 5.2*

4.89

6.32

7.14

7.57

7.67

7.45

6.90

5.89

Stick 2.45 m

3.0 m 4.5 m 6.0 m 7.5 m

m Undercarriage m

Stabilizers raised

Stabilizer blade down

2 pt. outriggers down

9.0

Blade + 2 pt. down

4 pt. outriggers down

Stabilizers raised

Stabilizer blade down

2 pt. outriggers down

7.5

Blade + 2 pt. down

4 pt. outriggers down

Stabilizers raised

Stabilizer blade down

2 pt. outriggers down

6.0

Blade + 2 pt. down

4 pt. outriggers down

Stabilizers raised

Stabilizer blade down

2 pt. outriggers down

4.5

Blade + 2 pt. down

4 pt. outriggers down

Stabilizers raised

Stabilizer blade down

2 pt. outriggers down

3.0

Blade + 2 pt. down

4 pt. outriggers down

Stabilizers raised

Stabilizer blade down

2 pt. outriggers down

1.5

Blade + 2 pt. down

4 pt. outriggers down

Stabilizers raised

Stabilizer blade down

2 pt. outriggers down

0

Blade + 2 pt. down

4 pt. outriggers down

Stabilizers raised

Stabilizer blade down

2 pt. outriggers down

– 1.5

Blade + 2 pt. down

4 pt. outriggers down

Stabilizers raised

Stabilizer blade down

2 pt. outriggers down

– 3.0

Blade + 2 pt. down

4 pt. outriggers down

Stabilizers raised

Stabilizer blade down

2 pt. outriggers down

– 4.5

Blade + 2 pt. down

4 pt. outriggers down

2.1* 2.1*

2.1* 2.1*

2.1* 2.1*

2.1* 2.1*

2.1* 2.1*

2.8 3.2* 1.9* 1.9*

3.1 3.2* 1.9* 1.9*

3.2* 3.2* 1.9* 1.9*

3.2* 3.2* 1.9* 1.9*

3.2* 3.2* 1.9* 1.9*

2.7 4.0* 1.8* 1.8*

3.0 4.0* 1.8* 1.8*

3.7 4.0* 1.8* 1.8*

4.0* 4.0* 1.8* 1.8*

4.0* 4.0* 1.8* 1.8*

7.2 8.8* 3.9 5.7* 2.5 4.2 1.8 2.9 1.7 1.9*

8.1 8.8* 4.4 5.7* 2.8 4.7* 2.0 2.9* 1.8 1.9*

8.8* 8.8* 5.5 5.7* 3.5 4.7* 2.5 2.9* 1.9* 1.9*

8.8* 8.8* 5.7* 5.7* 4.4 4.7* 2.9* 2.9* 1.9* 1.9*

8.8* 8.8* 5.7* 5.7* 4.7* 4.7* 2.9* 2.9* 1.9* 1.9*

5.2* 5.2* 3.6 6.1 2.4 4.0 1.7 2.8 1.6 2.0*

5.2* 5.2* 4.0 7.2* 2.6 5.4* 1.9 3.7* 1.7 2.0*

5.2* 5.2* 5.1 7.2* 3.3 5.4* 2.4 3.7* 2.0* 2.0*

5.2* 5.2* 6.5 7.2* 4.2 5.4* 3.0 3.7* 2.0* 2.0*

5.2* 5.2* 7.2* 7.2* 5.3 5.4* 3.7* 3.7* 2.0* 2.0*

5.9* 5.9* 3.3 5.9 2.2 3.8 1.6 2.8 1.6 2.3*

5.9* 5.9* 3.7 8.2* 2.5 5.9* 1.8 3.3* 1.8 2.3*

5.9* 5.9* 4.8 8.2* 3.2 5.9* 2.3 3.3* 2.3 2.3*

5.9* 5.9* 6.2 8.2* 4.1 5.9* 3.0 3.3* 2.3* 2.3*

5.9* 5.9* 8.1 8.2* 5.1 5.9* 3.3* 3.3* 2.3* 2.3*

6.0 8.6* 3.3 5.8 2.2 3.8 1.7 2.9*

6.8 8.6* 3.7 8.3* 2.5 6.0* 2.0 2.9*

8.6* 8.6* 4.7 8.3* 3.1 6.0* 2.5 2.9*

8.6* 8.6* 6.1 8.3* 4.0 6.0* 2.9* 2.9*

8.6* 8.6* 8.0 8.3* 5.1 6.0* 2.9* 2.9*

6.1 11.2* 3.3 5.9 2.3 3.8 2.2 3.7

7.0 11.2* 3.7 7.6* 2.5 5.3* 2.4 4.3*

9.3 11.2* 4.8 7.6* 3.2 5.3* 3.1 4.3*

11.2* 11.2* 6.2 7.6* 4.1 5.3* 4.0 4.3*

11.2* 11.2* 7.6* 7.6* 5.2 5.3* 4.3* 4.3*

3.6 5.3*

4.0 5.3*

5.1 5.3*

5.3* 5.3*

5.3* 5.3*

5.20

6.56

7.35

7.76

7.86

7.65

7.11

6.14

4.46

Stick 2.65 m

3.0 m 4.5 m 6.0 m 7.5 m

m Undercarriage m

Stabilizers raised

Stabilizer blade down

2 pt. outriggers down

9.0

Blade + 2 pt. down

4 pt. outriggers down

Stabilizers raised

Stabilizer blade down

2 pt. outriggers down

7.5

Blade + 2 pt. down

4 pt. outriggers down

Stabilizers raised

Stabilizer blade down

2 pt. outriggers down

6.0

Blade + 2 pt. down

4 pt. outriggers down

Stabilizers raised

Stabilizer blade down

2 pt. outriggers down

4.5

Blade + 2 pt. down

4 pt. outriggers down

Stabilizers raised

Stabilizer blade down

2 pt. outriggers down

3.0

Blade + 2 pt. down

4 pt. outriggers down

Stabilizers raised

Stabilizer blade down

2 pt. outriggers down

1.5

Blade + 2 pt. down

4 pt. outriggers down

Stabilizers raised

Stabilizer blade down

2 pt. outriggers down

0

Blade + 2 pt. down

4 pt. outriggers down

Stabilizers raised

Stabilizer blade down

2 pt. outriggers down

– 1.5

Blade + 2 pt. down

4 pt. outriggers down

Stabilizers raised

Stabilizer blade down

2 pt. outriggers down

– 3.0

Blade + 2 pt. down

4 pt. outriggers down

Stabilizers raised

Stabilizer blade down

2 pt. outriggers down

– 4.5

Blade + 2 pt. down

4 pt. outriggers down

1.9* 1.9*

1.9* 1.9*

1.9* 1.9*

1.9* 1.9*

1.9* 1.9*

2.8 3.2* 1.7* 1.7*

3.1 3.2* 1.7* 1.7*

3.2* 3.2* 1.7* 1.7*

3.2* 3.2* 1.7* 1.7*

3.2* 3.2* 1.7* 1.7*

2.7 3.9* 1.8 1.9* 1.6* 1.6*

3.0 3.9* 1.9* 1.9* 1.6* 1.6*

3.7 3.9* 1.9* 1.9* 1.6* 1.6*

3.9* 3.9* 1.9* 1.9* 1.6* 1.6*

3.9* 3.9* 1.9* 1.9* 1.6* 1.6*

7.3 8.1* 4.0 5.5* 2.5 4.2 1.8 2.9 1.6 1.7*

8.1* 8.1* 4.4 5.5* 2.8 4.5* 1.9 3.2* 1.7* 1.7*

8.1* 8.1* 5.5* 5.5* 3.5 4.5* 2.5 3.2* 1.7* 1.7*

8.1* 8.1* 5.5* 5.5* 4.4 4.5* 3.1 3.2* 1.7* 1.7*

8.1* 8.1* 5.5* 5.5* 4.5* 4.5* 3.2* 3.2* 1.7* 1.7*

6.1* 6.1* 3.6 6.1 2.4 4.0 1.7 2.8 1.5 1.8*

6.1* 6.1* 4.0 7.0* 2.6 5.2* 1.9 4.0* 1.7 1.8*

6.1* 6.1* 5.1 7.0* 3.3 5.2* 2.4 4.0* 1.8* 1.8*

6.1* 6.1* 6.5 7.0* 4.2 5.2* 3.0 4.0* 1.8* 1.8*

6.1* 6.1* 7.0* 7.0* 5.2* 5.2* 3.8 4.0* 1.8* 1.8*

5.9 6.0* 3.3 5.9 2.2 3.8 1.6 2.8 1.5 2.1*

6.0* 6.0* 3.7 8.0* 2.5 5.8* 1.8 3.9* 1.7 2.1*

6.0* 6.0* 4.8 8.0* 3.2 5.8* 2.3 3.9* 2.1* 2.1*

6.0* 6.0* 6.2 8.0* 4.1 5.8* 2.9 3.9* 2.1* 2.1*

6.0* 6.0* 8.0* 8.0* 5.1 5.8* 3.7 3.9* 2.1* 2.1*

5.9 8.3* 3.2 5.8 2.2 3.8 1.6 2.6*

6.7 8.3* 3.6 8.3* 2.4 6.0* 1.8 2.6*

8.3* 8.3* 4.7 8.3* 3.1 6.0* 2.4 2.6*

8.3* 8.3* 6.1 8.3* 4.0 6.0* 2.6* 2.6*

8.3* 8.3* 7.9 8.3* 5.1 6.0* 2.6* 2.6*

6.0 11.5* 3.3 5.8 2.2 3.8 2.0 3.5

6.9 11.5* 3.7 7.7* 2.5 5.5* 2.3 3.7*

9.2 11.5* 4.7 7.7* 3.2 5.5* 2.9 3.7*

11.5* 11.5* 6.2 7.7* 4.0 5.5* 3.7 3.7*

11.5* 11.5* 7.7* 7.7* 5.1 5.5* 3.7* 3.7*

6.4 8.6* 3.5 5.7* 3.2 5.2*

7.2 8.6* 3.9 5.7* 3.6 5.2*

8.6* 8.6* 5.0 5.7* 4.5 5.2*

8.6* 8.6* 5.7* 5.7* 5.2* 5.2*

8.6* 8.6* 5.7* 5.7* 5.2* 5.2*

5.49

6.79

7.56

7.96

8.05

7.85

7.32

6.39

4.80

Height Can be slewed through 360° In longitudinal position of undercarriage Max. reach * Limited by hydr. capacity

The lift capacities on the load hook of the Liebherr quick-change adapter 48 without grab attachment are stated in metric tons (t) and are valid on a firm, level supporting surface with blocked

oscillating axle. These capacities can be slewed through 360° with the undercarriage in the transverse position. Capacities in the longitudinal position of the undercarriage (+/– 15°) are specified

over the steering axle with the stabilisers raised and over the rigid axle with the stabilisers down. Indicated loads comply with the ISO 10567 standard and do not exceed 75 % of tipping or 87 % of

hydraulic capacity, or are limited by the permissible load of the load hook on the quick-change adapter (max. 12 t). Without the quick-change adapter, lift capacities will increase by up to 226 kg.

In accordance with the harmonised EU Standard EN 474-5, hydraulic excavators used for lifting operations must be equipped with pipe rupture protection devices on the hoist cylinders and an

overload warning device.

18 A 900 C Litronic

Page 19

Lift Capacities

with Gooseneck Boom 5.00 m EW-Undercarriage

Stick 2.25 m

3.0 m 4.5 m 6.0 m 7.5 m

m Undercarriage m

Stabilizers raised

Stabilizer blade down

9.0

2 pt. outriggers down

Stabilizers raised

Stabilizer blade down

7.5

2 pt. outriggers down

Stabilizers raised

Stabilizer blade down

6.0

2 pt. outriggers down

Stabilizers raised

Stabilizer blade down

4.5

2 pt. outriggers down

Stabilizers raised

Stabilizer blade down

3.0

2 pt. outriggers down

Stabilizers raised

Stabilizer blade down

1.5

2 pt. outriggers down

Stabilizers raised

Stabilizer blade down

0

2 pt. outriggers down

Stabilizers raised

Stabilizer blade down

– 1.5

2 pt. outriggers down

Stabilizers raised

Stabilizer blade down

– 3.0

2 pt. outriggers down

Stabilizers raised

Stabilizer blade down

– 4.5

2 pt. outriggers down

2.3* 2.3*

2.3* 2.3*

2.3* 2.3*

3.0 3.0* 2.0* 2.0*

3.0* 3.0* 2.0* 2.0*

3.0* 3.0* 2.0* 2.0*

4.6* 4.6* 3.0 4.2* 2.0* 2.0*

4.6* 4.6* 3.3 4.2* 2.0* 2.0*

4.6* 4.6* 3.8 4.2* 2.0* 2.0*

7.9 9.5* 4.3 6.0* 2.8 4.2 2.0 2.4* 1.9 2.1*

9.0 9.5* 4.8 6.0* 3.1 4.8* 2.2 2.4* 2.1* 2.1*

9.5* 9.5* 5.6 6.0* 3.6 4.8* 2.4* 2.4* 2.1* 2.1*

4.0 6.1 2.6 4.0 1.9 2.9 1.8 2.2*

4.4 7.4* 2.9 5.5* 2.1 3.2* 2.0 2.2*

5.2 7.4* 3.4 5.5* 2.5 3.2* 2.2* 2.2*

5.9* 5.9* 3.7 5.9 2.5 3.9 1.9 2.6*

5.9* 5.9* 4.2 8.3* 2.8 5.9* 2.1 2.6*

5.9* 5.9* 5.0 8.3* 3.3 5.9* 2.4 2.6*

6.9 9.0* 3.7 5.9 2.5 3.8 2.1 3.2

7.9 9.0* 4.2 8.3* 2.8 6.0* 2.3 3.3*

9.0* 9.0* 4.9 8.3* 3.3 6.0* 2.7 3.3*

7.1 10.9* 3.8 5.9 2.6 4.0

8.0 10.9* 4.2 7.4* 2.9 5.2*

9.8 10.9* 5.0 7.4* 3.4 5.2*

4.89

6.32

7.14

7.57

7.67

7.45

6.90

5.89

Stick 2.45 m

3.0 m 4.5 m 6.0 m 7.5 m

m Undercarriage m

Stabilizers raised

Stabilizer blade down

9.0

2 pt. outriggers down

Stabilizers raised

Stabilizer blade down

7.5

2 pt. outriggers down

Stabilizers raised

Stabilizer blade down

6.0

2 pt. outriggers down

Stabilizers raised

Stabilizer blade down

4.5

2 pt. outriggers down

Stabilizers raised

Stabilizer blade down

3.0

2 pt. outriggers down

Stabilizers raised

Stabilizer blade down

1.5

2 pt. outriggers down

Stabilizers raised

Stabilizer blade down

0

2 pt. outriggers down

Stabilizers raised

Stabilizer blade down

– 1.5

2 pt. outriggers down

Stabilizers raised

Stabilizer blade down

– 3.0

2 pt. outriggers down

Stabilizers raised

Stabilizer blade down

– 4.5

2 pt. outriggers down

2.1* 2.1*

2.1* 2.1*

2.1* 2.1*

3.1 3.2* 1.9* 1.9*

3.2* 3.2* 1.9* 1.9*

3.2* 3.2* 1.9* 1.9*

3.0 4.0* 1.8* 1.8*

3.3 4.0* 1.8* 1.8*

3.8 4.0* 1.8* 1.8*

8.1 8.8* 4.4 5.7* 2.8 4.2 2.0 2.9 1.8 1.9*

8.8* 8.8* 4.8 5.7* 3.1 4.7* 2.2 2.9* 1.9* 1.9*

8.8* 8.8* 5.6 5.7* 3.6 4.7* 2.5 2.9* 1.9* 1.9*

5.2* 5.2* 4.0 6.2 2.6 4.0 1.9 2.9 1.7 2.0*

5.2* 5.2* 4.4 7.2* 2.9 5.4* 2.1 3.7* 1.9 2.0*

5.2* 5.2* 5.2 7.2* 3.4 5.4* 2.4 3.7* 2.0* 2.0*

5.9* 5.9* 3.7 5.9 2.5 3.9 1.8 2.8 1.8 2.3*

5.9* 5.9* 4.2 8.2* 2.8 5.9* 2.0 3.3* 2.0 2.3*

5.9* 5.9* 5.0 8.2* 3.3 5.9* 2.4 3.3* 2.3* 2.3*

6.8 8.6* 3.7 5.8 2.5 3.8 2.0 2.9*

7.8 8.6* 4.1 8.3* 2.7 6.0* 2.2 2.9*

8.6* 8.6* 4.9 8.3* 3.2 6.0* 2.6 2.9*

7.0 11.2* 3.7 5.9 2.5 3.9 2.4 3.7

8.0 11.2* 4.2 7.6* 2.8 5.3* 2.7 4.3*

9.7 11.2* 5.0 7.6* 3.3 5.3* 3.2 4.3*

4.0 5.3*

4.5 5.3*

5.3* 5.3*

5.20

6.56

7.35

7.76

7.86

7.65

7.11

6.14

4.46

Stick 2.65 m

3.0 m 4.5 m 6.0 m 7.5 m

m Undercarriage m

Stabilizers raised

Stabilizer blade down

9.0

2 pt. outriggers down

Stabilizers raised

Stabilizer blade down

7.5

2 pt. outriggers down

Stabilizers raised

Stabilizer blade down

6.0

2 pt. outriggers down

Stabilizers raised

Stabilizer blade down

4.5

2 pt. outriggers down

Stabilizers raised

Stabilizer blade down

3.0

2 pt. outriggers down

Stabilizers raised

Stabilizer blade down

1.5

2 pt. outriggers down

Stabilizers raised

Stabilizer blade down

0

2 pt. outriggers down

Stabilizers raised

Stabilizer blade down

– 1.5

2 pt. outriggers down

Stabilizers raised

Stabilizer blade down

– 3.0

2 pt. outriggers down

Stabilizers raised

Stabilizer blade down

– 4.5

2 pt. outriggers down

1.9* 1.9*

1.9* 1.9*

1.9* 1.9*

3.1 3.2* 1.7* 1.7*

3.2* 3.2* 1.7* 1.7*

3.2* 3.2* 1.7* 1.7*

3.0 3.9* 1.9* 1.9* 1.6* 1.6*

3.3 3.9* 1.9* 1.9* 1.6* 1.6*

3.8 3.9* 1.9* 1.9* 1.6* 1.6*

8.1* 8.1* 4.4 5.5* 2.8 4.2 1.9 2.9 1.7* 1.7*

8.1* 8.1* 4.9 5.5* 3.1 4.5* 2.2 3.2* 1.7* 1.7*

8.1* 8.1* 5.5* 5.5* 3.6 4.5* 2.5 3.2* 1.7* 1.7*

6.1* 6.1* 4.0 6.2 2.6 4.0 1.9 2.8 1.7 1.8*

6.1* 6.1* 4.4 7.0* 2.9 5.2* 2.1 4.0* 1.8* 1.8*

6.1* 6.1* 5.2 7.0* 3.4 5.2* 2.4 4.0* 1.8* 1.8*

6.0* 6.0* 3.7 5.9 2.5 3.8 1.8 2.8 1.7 2.1*

6.0* 6.0* 4.2 8.0* 2.8 5.8* 2.0 3.9* 1.9 2.1*

6.0* 6.0* 5.0 8.0* 3.3 5.8* 2.4 3.9* 2.1* 2.1*

6.7 8.3* 3.6 5.8 2.4 3.8 1.8 2.6*

7.7 8.3* 4.1 8.3* 2.7 6.0* 2.1 2.6*

8.3* 8.3* 4.9 8.3* 3.2 6.0* 2.4 2.6*

6.9 11.5* 3.7 5.8 2.5 3.8 2.3 3.5

7.9 11.5* 4.1 7.7* 2.8 5.5* 2.5 3.7*

9.6 11.5* 4.9 7.7* 3.2 5.5* 3.0 3.7*

7.2 8.6* 3.9 5.7* 3.6 5.2*

8.2 8.6* 4.4 5.7* 4.0 5.2*

8.6* 8.6* 5.1 5.7* 4.7 5.2*

5.49

6.79

7.56

7.96

8.05

7.85

7.32

6.39

4.80

Height Can be slewed through 360° In longitudinal position of undercarriage Max. reach * Limited by hydr. capacity

The lift capacities on the load hook of the Liebherr quick-change adapter 48 without grab attachment are stated in metric tons (t) and are valid on a firm, level supporting surface with blocked

oscillating axle. These capacities can be slewed through 360° with the undercarriage in the transverse position. Capacities in the longitudinal position of the undercarriage (+/– 15°) are specified

over the steering axle with the stabilisers raised and over the rigid axle with the stabilisers down. Indicated loads comply with the ISO 10567 standard and do not exceed 75 % of tipping or 87 % of

hydraulic capacity, or are limited by the permissible load of the load hook on the quick-change adapter (max. 12 t). Without the quick-change adapter, lift capacities will increase by up to 226 kg.

In accordance with the harmonised EU Standard EN 474-5, hydraulic excavators used for lifting operations must be equipped with pipe rupture protection devices on the hoist cylinders and an

overload warning device.

A 900 C Litronic 19

Page 20

Backhoe Attachment

with Adjustable Up/Down Plus Offset Boom 3.60 m

ft m

35

30

25

20

15

10

-10

-15

11

10

9

8

7

6

5

4

3

2

5

1

0

0

-1

-5

-2

-3

-4

-5

-6

1

2

3

4

5

6

1

2345678910

0

0mft51015202530

Digging Envelope

with Quick Change Adapter 4 5 6

Stick length m 2.25 2.45 2.65

Max. digging depth m 5.65 5.85 6.05

Max. reach at ground level m 9.15 9.35 9.50

Max. dumping height m 7.20 7.40 7.55

Max. teeth height m 10.30 10.50 10.65

Min. attachment radius m 2.85 2.80 2.85

1 stick 2.25 m 4 stick 2.25 m

2 stick 2.45 m 5 stick 2.45 m

3 stick 2.65 m 6 stick 2.65 m

at max. attachment offset with set straight boom

with vertical ditch walls

Digging Forces

without Quick Change Adapter 4 5 6

Max. digging force (ISO 6015) kN 81.0 76.0 71.6

t 8.3 7.7 7.3

Max. breakout force (ISO 6015) kN 98.4 98.4 98.4

t 10.0 10.0 10.0

Max. breakout force with ripper bucket 125.7 kN (12.8 t)

Max. possible digging force (stick 1.70 m) 99.4 kN (10.1 t)

Operating Weight

44º

R=2885

The operating weight includes the basic machine with 8 tires plus

spacer rings, hydr. adjustable offset boom 3.60 m, stick 2.25 m, quick

change adapter 48 and bucket 1,050 mm/0.80 m

3

.

Undercarriage versions Weight

A 900 C

A 900 C

2450 2450

A 900 C

A 900 C

li tr on ic

li tr on ic

li tr on ic

li tr on ic

A 900 C EW

49º

A 900 C EW

`

with stabilizer blade 18,300 kg

`

with 2 pt. outriggers 18,600 kg

`

with stabilizer blade + 2 pt. outriggers 19,400 kg

`

with 4 pt. outriggers 19,600 kg

li tr on ic

li tr on ic

`

with stabilizer blade 18,400 kg

`

with 2 pt. outriggers 18,700 kg

Buckets Machine stability per ISO 10567* (75 % of tipping capacity)

Stabilizers Stabilizer 2 point

raised blade down outriggers + 2 pt. outr. outriggers raised blade down outriggers

down down down down

2.25 2.45 2.65 2.25 2.45 2.65 2.25 2.45 2.65 2.25 2.45 2.65 2.25 2.45 2.65 2.25 2.45 2.65 2.25 2.45 2.65 2.25 2.45 2.65

Cutting width

Capacity

mm m

8502) 0.60 430

1,050

1,250

850

1,050

1,250

850

1,050

1,250

3

kg

2)

0.80 510

2)

0.95 560

3)

0.60 480

3)

0.80 570

3)

0.95 630

4)

0.65 410

4)

0.85 490

4)

1.05 530

Stick length (m) Stick length (m) Stick length (m) Stick length (m) Stick length (m) Stick length (m) Stick length (m) Stick length (m)

ISO 74511)Weight

Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y

y y y V V V Y Y V Y Y V Y Y V V V V Y Y V Y Y V

v v v y y y Y V y Y V y Y V y y y y Y V y Y V y

Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y

y y y V V V Y Y V Y Y V Y Y V V V V Y Y V Y Y V

v v v y y y V V y V V y V V y y y y V V y V V y

Y Y V Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y

y y y V V V Y Y V Y Y V Y Y V V V V Y Y V Y Y V

v v v y y y V y y V y y V y y y y y V y y V y y

* Indicated loads are based on ISO 10567 and do not exceed 75 % of tipping or 87 % of hydraulic capacity, max. stick length without quick

change adapter, lifted 360° on firm with blocked oscillating axle

1)

comparable with SAE (heaped)

2)

Bucket with teeth 3) Bucket with teeth in HD-version 4) Bucket with cutting lip (also available in HD-version)

Max. material weight

Y

= ≤ 1.8 t/m3,

V

= ≤ 1.5 t/m3,

Stabilizer blade

y

= ≤ 1.2 t/m3,

4 point EW stabilizers EW stabilizer EW 2 point

v

= not authorized

20 A 900 C Litronic

Page 21

Lift Capacities

with Adjustable Up/Down Plus Offset Boom 3.60 m

Stick 2.25 m

3.0 m 4.5 m 6.0 m 7.5 m

m Undercarriage m

Stabilizers raised

Stabilizer blade down

2 pt. outriggers down

9.0

Blade + 2 pt. down

4 pt. outriggers down

Stabilizers raised

Stabilizer blade down

2 pt. outriggers down

7.5

Blade + 2 pt. down

4 pt. outriggers down

Stabilizers raised

Stabilizer blade down

2 pt. outriggers down

6.0

Blade + 2 pt. down

4 pt. outriggers down

Stabilizers raised

Stabilizer blade down

2 pt. outriggers down

4.5

Blade + 2 pt. down

4 pt. outriggers down

Stabilizers raised

Stabilizer blade down

2 pt. outriggers down

3.0

Blade + 2 pt. down

4 pt. outriggers down

Stabilizers raised

Stabilizer blade down

2 pt. outriggers down

1.5

Blade + 2 pt. down

4 pt. outriggers down

Stabilizers raised

Stabilizer blade down

2 pt. outriggers down

0

Blade + 2 pt. down

4 pt. outriggers down

Stabilizers raised

Stabilizer blade down

2 pt. outriggers down

– 1.5

Blade + 2 pt. down

4 pt. outriggers down

Stabilizers raised

Stabilizer blade down

2 pt. outriggers down

– 3.0

Blade + 2 pt. down

4 pt. outriggers down

Stabilizers raised

Stabilizer blade down

2 pt. outriggers down

– 4.5

Blade + 2 pt. down

4 pt. outriggers down

4.0* 4.0* 2.2* 2.2*

4.0* 4.0* 2.2* 2.2*

4.0* 4.0* 2.2* 2.2*

4.0* 4.0* 2.2* 2.2*

4.0* 4.0* 2.2* 2.2*

4.7* 4.7* 2.8 3.9* 2.0* 2.0*

4.7* 4.7* 3.1 3.9* 2.0* 2.0*

4.7* 4.7* 3.8 3.9* 2.0* 2.0*

4.7* 4.7* 3.9* 3.9* 2.0* 2.0*

4.7* 4.7* 3.9* 3.9* 2.0* 2.0*

6.6* 6.6* 4.5 6.1* 2.9 4.5 1.7 2.0* 1.7 1.9*

6.6* 6.6* 4.9* 6.1* 3.2 5.0* 1.9 2.0* 1.9* 1.9*

6.6* 6.6* 5.9 6.1* 3.9 5.0* 2.0* 2.0* 1.9* 1.9*

6.6* 6.6* 6.1* 6.1* 4.7 5.0* 2.0* 2.0* 1.9* 1.9*

6.6* 6.6* 6.1* 6.1* 5.0* 5.0* 2.0* 2.0* 1.9* 1.9*

7.6 11.2* 4.3 6.7 2.9 4.4 1.7 2.9 1.5 2.0*

8.5 11.2* 4.8 7.2* 3.2* 5.4* 1.9 3.8* 1.7 2.0*

10.5 11.2* 5.7 7.2* 3.9 5.4* 2.4 3.8* 2.0* 2.0*

11.2* 11.2* 6.9* 7.2* 4.6 5.4* 3.1 3.8* 2.0* 2.0*

11.2* 11.2* 7.2* 7.2* 5.4* 5.4* 3.8 3.8* 2.0* 2.0*

7.5 10.6* 4.2 6.6 2.7 4.4 1.7 2.8 1.4 2.1*

8.3 10.6* 4.6 8.0* 3.0 5.8* 1.9 4.5* 1.6 2.1*

10.1* 10.6* 5.6 8.0* 3.7 5.8* 2.4 4.5* 2.1 2.1*

10.6* 10.6* 6.8 8.0* 4.6 5.8* 3.0 4.5* 2.1* 2.1*

10.6* 10.6* 8.0* 8.0* 5.4 5.8* 3.8 4.5* 2.1* 2.1*

7.4 12.4* 4.1 6.5 2.5 4.2 1.5 2.7 1.4 2.3*

8.4 12.4* 4.6 8.1* 2.8* 5.8* 1.7 4.4* 1.6 2.3*

10.5 12.4* 5.7 8.1* 3.5 5.8* 2.3 4.4* 2.1 2.3*

12.4* 12.4* 6.9 8.1* 4.4 5.8* 2.9 4.4* 2.3* 2.3*

12.4* 12.4* 8.1* 8.1* 5.4 5.8* 3.7 4.4* 2.3* 2.3*

6.9 12.8 3.8 6.6 2.3 3.9 1.5 2.8

7.8 13.3* 4.3 8.3* 2.5 5.9* 1.8 2.9*

10.3 13.3* 5.4 8.3* 3.3 5.9* 2.3 2.9*

13.2 13.3* 6.9 8.3* 4.1 5.9* 2.9* 2.9*

13.3* 13.3* 8.3* 8.3* 5.2 5.9* 2.9* 2.9*

6.7 12.9 3.4 6.1 2.1 3.8 1.9 3.3*

7.6 13.9* 3.8 8.1* 2.4 4.3* 2.2 3.3*

10.1 13.9* 5.0 8.1* 3.1 4.3* 2.8 3.3*

13.7 13.9* 6.4 8.1* 4.0 4.3* 3.3* 3.3*

13.9* 13.9* 8.1* 8.1* 4.3* 4.3* 3.3* 3.3*

5.42

6.74

7.51

7.91

8.01

7.80

7.28

6.34

Stick 2.45 m

3.0 m 4.5 m 6.0 m 7.5 m

m Undercarriage m

Stabilizers raised

Stabilizer blade down

2 pt. outriggers down

9.0

Blade + 2 pt. down

4 pt. outriggers down

Stabilizers raised

Stabilizer blade down

2 pt. outriggers down

7.5