Page 1

©Copyright 2017 Liberty Pumps Inc. All rights reserved. 1

Installation Manual 6850000A

TABLE OF CONTENTS

1. Safety Information

2. General Information

3. Installation Instructions

4. Maintenance and Troubleshooting

5. 3-Year Limited Warranty

XLSG200 & XLSGX200 Series

2 HP Grinder Pumps for Hazardous Locations

Models:

XLSG200 Series 2 HP, Single Stage

XLSGX200 Series 2 HP, Dual Stage

Approved Hazardous Locations:

Class 1, Div. 1, Groups C & D

Class 1, Zone 1, Groups IIA & IIB

7000 Apple Tree Avenue

Bergen, NY, USA 14416

Phone: +1 (800) 543-2550

Fax: +1 (585) 494-1839

www.libertypumps.com

Keep manual nearby for future reference. If manual becomes lost or damaged,

get a replacement at http://www.libertypumps.com/ under installation manuals, or contact Liberty Pumps.

Read every supplied manual before using pump sys-

tem. Follow all the safety instructions in manual(s)

and on the pump. Failure to do so could result in serious injury or death.

Installer: Please leave this manual with the own-

er/operator for future reference.

Prior to installation, duplicate the information from pump nameplate below and

keep nearby for future reference.

Model #:

Serial #:

Manufacture

(MFG) Date:

Installation

Date:

NOTICE

WARNING

Page 2

©Copyright 2017 Liberty Pumps Inc. All rights reserved. 2

1. Safety Information

This safety alert symbol in your manual and on the pump is intended to alert you

to a potential risk for injury or death.

This is a safety alert symbol identifying risk of electric shock. It will be accompa-

nied with an instruction intended to minimize your potential risk of electric shock.

This is a safety alert symbol identifying risk of fire. It will be accompanied with an

instruction intended to minimize your potential risk of fire.

This is a safety alert symbol identifying risk of injury or death. It will be accompa-

nied with an instruction intended to minimize your potential risk of injury or death.

Warns of hazards that will cause serious injury or death.

Warns of hazards that can or will cause minor or moderate injury.

Warns of hazards that can cause personal injury, death, or property damage.

Signals an important instruction related to the pump. Failure to follow these instructions could result in pump component failure, or improper operation of the

unit, possibly resulting in property damage .

ALWAYS disconnect the supplied pump(s) from their power sources before handling or making any

adjustments to either the pump(s), the pump system, or the control panel.

Only qualified personnel should complete fixed wiring and electrical connections, according to all

local and national electrical codes, during a pump system installation.

After installation, be certain that the pump is properly grounded, using its supplied grounding con-

ductor. Failure to properly ground the pump system can cause all metal portions of the pump and its

surroundings to become energized.

During flood conditions, submerged electrical connections can energize the water. Always wear

dielectric rubber boots and other applicable Personal Protective Equipment (PPE) when water is on

the floor and you must service an energized pump system. DO NOT ENTER THE WATER if the

water level is higher than that of the protection your PPE offers or if your PPE is not watertight.

NEVER lift or carry a pump or a float assembly by its power cord. This will damage the power cord,

and could expose the electrically live wires inside the power cord.

DO NOT bypass grounding wires.

The electrical power supply shall be located within the length limitations of the pump power cord,

and for below grade installations it shall be at least 1.22 m (4 ft) above the floor level.

NEVER use this product in applications where human contact with the pumped fluid is common

(such as swimming pools, fountains, marine areas, etc.).

NOTICE

DANGER

WARNING

CAUTION

RISK OF ELECTRIC SHOCK - Accidental contact

with electrically live parts, items, fluid, or water can cause

serious injury or death.

WARNING

NOTICE

DANGER

WARNING

CAUTION

Page 3

©Copyright 2017 Liberty Pumps Inc. All rights reserved. 3

During construction, if the pump system is installed before its power cord can be plugged in or direct

wired, all power cords must be protected from the environment to prevent water from wicking

through the cord end into the pump or switch housings. If water enters these housings, an electrical

short can occur from the pump or switch to its surroundings, which will energize the surroundings.

DO NOT use an extension cord to power the product. Extension cords can overload both the

product and extension cord supply wires. Overloaded wires will get very hot and can catch on fire.

This product requires a separate, properly fused and grounded branch circuit, sized for the voltage

and amperage requirements of the pump, as noted on the nameplate. Overloaded branch circuit

wires will get very hot and can catch on fire.

NEVER use this product with or near flammable liquids. If the rotating elements inside this pump

strike any foreign object, sparks may occur. Sparks could ignite flammable liquids.

This pump system must be installed in accordance with all applicable codes and ordinances.

DO NOT allow children to play with the pump system.

DO NOT allow children, or any person who is unqualified, to use this pump system. Any person

who is unaware of the dangers of this pump system, or whom has not read this manual, can easily

be injured by the pump system.

Wear adequate PPE when working on pumps or piping that have been exposed to wastewater.

Sump and sewage pumps often handle materials which can transmit illness or disease upon

contact with your skin and other tissues.

NEVER dispose of materials such as paint thinner or other chemicals down drains. Doing so could

chemically attack and damage pump system components and cause product malfunction or failure.

DO NOT use pumps with fluid over 40°C. Operating the pump in fluid above this temperature can

overheat the pump, resulting in pump failure.

DO NOT use pump system with mud, sand, cement, oil or chemicals. Pump and system

components can be damaged from these items causing product malfunction or failure. Additionally,

flooding can occur if these items jam the impeller or piping.

DO NOT modify the pump system in any way. Modifications may affect seals, change the electrical

loading of the pump, or damage the pump and its components. Modifications can void your warranty

on this product.

DO NOT run this pump system dry.

NOTICE

RISK OF ELECTRIC SHOCK - continued

WARNING

RISK OF FIRE

WARNING

WARNING

RISK OF SERIOUS INJURY OR DEATH

Page 4

©Copyright 2017 Liberty Pumps Inc. All rights reserved. 4

2. General Information

Notes:

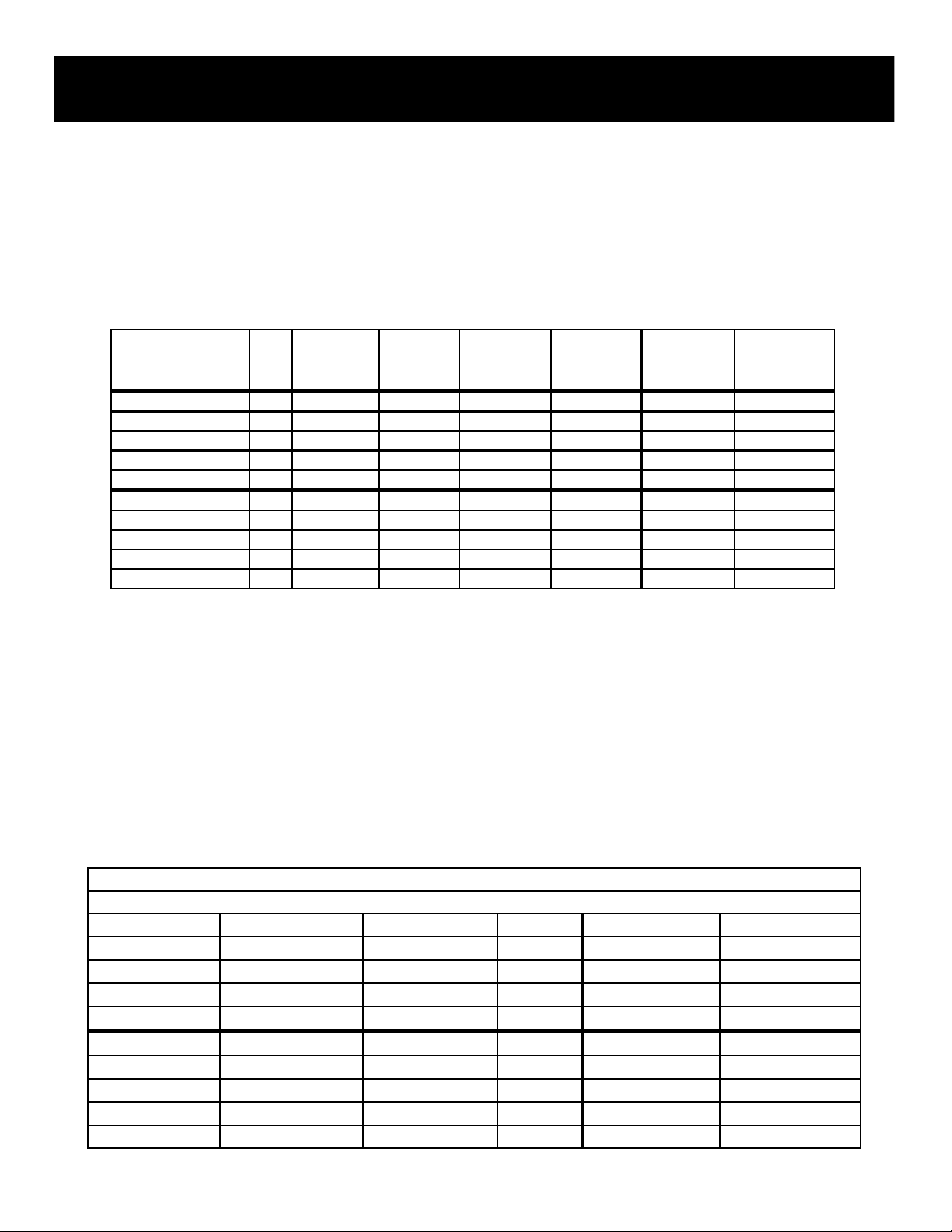

X-Series Grinder pumps require the use of a separate control panel. Panels designed for use with the X-Series pumps

are available from Liberty Pumps, and standard models are outlined below.

Single phase pumps require the use of a panel-mounted start circuit consisting of a start and run capacitor and a motor

start relay. These components are available as kits from Liberty Pumps. Please see the table below to identify the

correct kit for the pump being controlled.

All models have a surface temperature (T) class rating of T4; if thermostat is not connected on three phase units, the

temperature rating drops to T3. The float switches must be connected to an intrinsically safe circuit in the control panel.

The minimum water depth for proper motor cooling shall be set at 13”.

The use of Non-Liberty panels on 3-phase pumps must have provisions for the thermostat that open the motor

contactors in order to maintain the T4 temperature class. Do not exceed voltage / current combinations for the

thermostat: 16 VDC / 20 Amps, 115 VAC / 22 Amps, 277 VAC / 8 Amps, and 600 VAC / 4 Amps.

These pumps are to be used for handling septic tank effluent, sewage, and drain (storm) water. X-Series pumps are

CSA Certified to UL778 and CSA C22.2 no. 108, and tested to FM standards for Hazardous (Classified) Locations.

Improper installation, use, or operation of products in a Hazardous (classified) Locations can result in explosion and fire.

All components must be installed in accordance with best practices to minimize the possibility of ignition. All wiring and

electrical installation shall be in accordance with Federal, State, and Local codes by trained professionals.

The pump must be serviced at a qualified hazardous motor enclosure repair facility approved by Liberty Pumps. Any

unauthorized field repairs voids warranty and hazardous location ratings. Contact Liberty Pumps at 1-800-543-2550 to

locate the closest repair facility.

Model HP Voltage Phase

Full

Load

Amps

Locked

Rotor

Amps

Thermal

Overload

Temp.

Dis-

charge

XLSG208M 2 200 1 18.1 66.5 135° C 1-1/4 "

XLSG202M 2 230 1 15 64.3 135° C 1-1/4 "

XLSG203M 2 200/230 3 12 39.2 120° C 1-1/4 "

XLSG204M 2 460 3 6.2 19.6 120° C 1-1/4 "

XLSG205M 2 575 3 5 16.3 120° C 1-1/4 "

XLSGX208M 2 200 1 20 66.5 135° C 1-1/4 "

XLSGX202M 2 230 1 20 64.3 135° C 1-1/4 "

XLSGX203M 2 200/230 3 13.5 39.2 120° C 1-1/4 "

XLSGX204M 2 460 3 6.7 19.6 120° C 1-1/4 "

XLSGX205M 2 575 3 5.3 16.3 120° C 1-1/4 "

Table 1

Liberty Pumps Control Information

Pump Models Start Capacitor Run Capacitor Cap Kit Simplex Panel Duplex Panel

XLSG208M 325 µF 65 µF K001640 ISS24HS1=3-5 ISD24HS1=3-5

XLSG202M 275 µF 50 µF K001641 ISS24HS1=3-5 ISD24HS1=3-5

XLSG203M N/A N/A N/A ISS34=3-511-5 ISD34=3-511-5

XLSG204M N/A N/A N/A ISS34=3-191-5 ISD34=3-191-5

XLSG205M N/A N/A N/A ISS54=3-171-5 ISD54=3-171-5

XLSGX208M 325 µF 65 µF K001640 ISS24HS1=3-5 ISD24HS1=3-5

XLSGX202M 275 µF 50 µF K001641 ISS24HS1=3-5 ISD24HS1=3-5

XLSGX203M N/A N/A N/A ISS34=3-511-5 ISD34=3-511-5

XLSGX204M N/A N/A N/A ISS34=3-191-5 ISD34=3-191-5

XLSGX205M N/A N/A N/A ISS54=3-171-5 ISD54=3-171-5

Table 2

Page 5

©Copyright 2017 Liberty Pumps Inc. All rights reserved. 5

Seal Leak Detection:

All X-Series Grinder pumps are equipped with two mechanical face seals with an intermediate oil chamber between

them. This ensures lubrication for the seals, shaft flame path, and as a barrier to the motor chamber in the event the

lower seal should become compromised. A seal fail or moisture sensing device is located in the mid oil chamber and

continuously monitors for leakage. In the event of a seal failure, moisture mixes with the oil tripping the seal leak circuit.

In a failure condition, a fault light will illuminate and the pump will continue to run; service should be scheduled as soon

as possible.

The ISS and ISD panels by Liberty Pumps have a seal leak test button that tests the integrity of the seal leak circuit

continuity. When pressed, the light should illuminate. If it does not, either the light is burned out or the circuitry is open.

The seal leak module is located inside the panel and requires adjustment upon installation. The seal leak relay

adjustment dial should be set to 75; for best results turn the dial until the light turns on around 125 then turn it back to

75.

Thermal Protection:

The X-Series Grinder pumps are protected from overheating by means of thermal switches located in the motors. For

single phase (1ph) models, a hermetically sealed thermal overload device is mounted on the motor windings and wired

directly in series with the motor’s winding, interrupting power in a high heat condition. Three phase (3ph) models utilize

two thermostats mounted in series directly on the motor windings. The thermostat circuit must be connected to a control

panel which will stop power to the pump in a high temperature condition. Both single and three phase (1ph & 3ph)

pumps are constructed with class F materials, with a maximum operation temperature of 311°F or 155°C. Failure to use

the proper circuitry and connection of the thermostat will drop temperature class from T4 to T3 on three phase units.

Note: when connecting a X-Series Grinder pump to an existing control panel, make certain the panel is correctly sized

for the pump. Many panels have a manual reset button for the thermostats on three phase units; this button must be

pressed to reset the system after the pump has cooled. Single phase units automatically reset after the pump has

cooled.

Control Panels:

All X-Series grinders shall be installed with controls equipped with correctly sized and adjusted overload protection

devices. The control panel must be installed outside the hazardous area and appropriately isolated and sealed to

prevent any potential ignition or explosion. Only approved controls that have intrinsically safe float switch connections

may be used for X-Series Grinder pumps. The control and power cables cannot be spliced; a junction box may be used

providing it is rated for hazardous locations and has approved cord connectors.

Pump Installation:

When connecting an explosion-proof pump in hazardous locations using a rail system, it must be of a non-sparking type

design. Contact Liberty Pumps for available models such as GR20NS.

The water level in the sump is determined by the placement of the control floats and should be positioned such that the

pump is completely submerged; if submersion isn’t possible, the minimum water depth shall be no less than the depth

defined from the bottom of the pump legs. The upper water level should be positioned to minimize pump starts. The

alarm float shall be above the turn on float switch but below any inlets. No control should be set above the inlet to the

sump.

After the pump(s) have been mounted and the cover sealed, install the remaining discharge line. Piping above the cover

should include a union to facilitate pump removal. A check valve is recommended after the union to prevent the backflow

of liquid after each pumping cycle. A gate valve should follow the check valve to allow periodic cleaning of the check

valve or removal of the pump. The remainder of the discharge line should be as short as possible with a minimum

number of turns, to minimize friction head loss. Do not restrict the discharge to anything smaller than the discharge

connection of the pump. Larger pipe sizes may be required to eliminate friction head loss over long runs. Contact Liberty

Pumps or other qualified person if there are questions regarding proper pipe size and flow rates.

Page 6

©Copyright 2017 Liberty Pumps Inc. All rights reserved. 6

RISK OF ELECTRIC SHOCK - Accidental contact

with electrically live parts, items, fluid, or water can cause

serious injury or death.

WARNING

Always disconnect the pump from its power source before handling.

All electrical connections must be wired and grounded in accordance with the National Electrical

Code and all applicable local codes and ordinances.

Risk of electrical shock – Do not remove the power supply cord. All repairs and service must be

performed by a repair facility approved by Liberty Pumps and certified to work on explosion proof

motor enclosures.

If power or control cord are damaged, or in need of replacement, contact Liberty Pumps for closest

approved repair facility.

All installations of pumps, controls, protection devices and general wiring should be done by a

qualified licensed electrician. All electrical and safety codes should be followed for the National

Electrical Code (NEC), the Occupational Safety and Health Administration (OSHA) and applicable

local codes.

Refer to articles 500 through 503 of the National Electric Code (NEC) for all electrical and wiring

requirements in hazardous locations.

3. Installation Instructions

Electrical Installation Procedure

1. Verify that the pump model and control panel are the correct configuration and voltage. If using Liberty control panel,

confirm that the panel is sized appropriately for the pump being controlled. See Table 2.

2. Terminate the leads for the power and control cords from the pump to the appropriate terminal blocks in the control

panel. Reference wiring diagrams on the following page and control panel schematics provided with panel.

3. Install and wire the start relay and capacitors in the control panel. Refer to panel schematics for the proper

connections.

RISK OF FIRE

WARNING

Risk of explosion or fire—hazardous locations contain explosive gases which can be detonated by

sparking or electric shock.

All terminations and penetrations of conduit or cable shall be done using approved materials and

methods intended for use to mitigate the potential for explosion.

All personnel shall be trained for safe work practices and procedures.

All installations shall be in compliance with all applicable Federal, State, and Local codes for

hazardous locations.

Page 7

©Copyright 2017 Liberty Pumps Inc. All rights reserved. 7

CAUTION - Check 3-phase pumps for proper rotation prior to in-

stalling pump(s) in basin. To change rotation, reverse any two of the

three power leads to the pump. Code the wires for reconnection after

installation.

CAUTION

Figure 1

4. Connect the leads for the seal leak detection and the thermal overloads (3-phase models) to the panel. Proceed to

set the seal leak relay by rotating adjustment clockwise until LED turns red, then turn adjustment counter clockwise

slightly until LED has just changed back to green.

5. Route float wires and terminate to the corresponding terminals on the intrinsically safe (IS) barrier.

6. With main power disconnected, connect the pump power and control power to the panel according to schematics

provided. Be certain that the power available will work with the power required by the controls and the pump.

7. With all electrical connections complete and secure, turn on power and verify operation of the pump, floats, and

alarm circuits.

8. Verify that the rotation of the pump is in the correct direction as shown in figure 1. If correct, proceed to step 9.

9. If rotation is incorrect for a 3-phase pump, switch two power leads to the motor to reverse direction; for a single

phase product please contact the factory.

10. Proceed with mechanical installation.

11. Route float wires and terminate to the corresponding terminals on the intrinsically safe (IS) barrier.

12. With main power disconnected, connect the pump power and control power to the panel according to schematics

provided. Be certain that the power available will work with the power required by the controls and the pump.

13. With all electrical connections complete and secure, turn on power and verify operation of the pump, floats, and

alarm circuits.

14. Verify that the rotation of the pump is in the correct direction as shown in figure 1. If correct, proceed to step 9.

Page 8

©Copyright 2017 Liberty Pumps Inc. All rights reserved. 8

Figure 2

Figure 3

Page 9

©Copyright 2017 Liberty Pumps Inc. All rights reserved. 9

RISK OF ELECTRIC SHOCK - Always disco nnect the p ump from

power source prior to handling, set-up, or maintenance.

WARNING

RISK OF FIRE - When working in a hazardous location, all precautions

to minimize ignition sources such as spark and flame should be

minimized to limit the potential for fire or explosion.

WARNING

Mechanical Installation Procedure

1. Record the pump model, serial number, manufacture date, and installation date on the front page of this manual.

2. Complete a visual inspection of the pump prior to installation. Address any loose fasteners and missing or damaged

parts. Contact Liberty Pumps with any concerns.

3. Complete an inspection of the tank or basin where the pump will be installed. Remove any construction debris or

foreign material from the vessel.

4. If the pump is to be installed using a guide rail and base, verify the installation is correct and that all mounting hard-

ware is tight.

5. Mount the guide rail claw components to the pump, being certain to tighten all fasteners as specified. Be sure all

gaskets and components are present.

6. For installations not using a guide rail, complete all pump mounted plumbing at this time being sure to use all neces-

sary sealants and hardware.

7. Place pump in basin, being sure the mounting interface (guide rail, torque stop, etc.) is engaged correctly.

8. Verify that all plumbing components in the tank or basin are installed correctly and that they are functional. Validate

that any valves are open and ready for pump use.

9. Set the floats heights to control pump operation. The minimum process fluid level for safe pump operation shall not

be less than 13 inches.

10. Complete any final connections to the pump.

11. Engage power to panel and pump

12. Run several cycles of water through the system to verify correct control operation for the installation. Be certain to

complete adequate testing, especially on systems with multiple pumps or custom control configurations.

Use non-sparking components to mitigate the risk of spark and explosion in hazardous locations.

All electrical terminations shall be made according to Federal, State, and Local codes for hazardous

or classified locations.

All mechanical penetrations to the basin by cables or conduit shall be made according to

specification and best practices associated with hazardous locations.

Conduit, junction boxes, and associated components shall be approved for use with hazardous

locations and installed according to specifications.

Page 10

©Copyright 2017 Liberty Pumps Inc. All rights reserved. 10

4. Maintenance and Troubleshooting

Troubleshooting:

Many common operation issues are outlined in the troubleshooting matrix at the end of this section. Use this resource

to diagnose and solve common problems which may occur with the pump or system. If problems persist, please

contact your Liberty Pumps authorized representative.

Maintenance:

The pump must be serviced at a qualified hazardous motor enclosure repair facility approved by Liberty Pumps. Any

unauthorized field repairs voids warranty and hazardous location ratings. Contact Liberty Pumps at 1-800-543-2550 to

locate the closest repair facility.

The pump must be pulled from the sump; prior to any service - disengage electrical power to the pump prior to

performing any work.

In the event the pump becomes clogged, the inlet screen can be removed to gain access to the pump’s impeller. Once

the obstruction is removed the anti air lock hole should be cleaned.

The lower shaft seal is field serviceable; a certified repair shop should perform this task because they have the

capability to clean and flush the mid oil chamber.

This is the only work or maintenance that can be performed. All other maintenance or service such as cord

replacement requires a certified repair shop. Contact Liberty Pumps at 1-800-543-2550 to locate the closest authorized

hazardous duty motor repair shop.

*NOTE: Liberty Pump s, Inc. assumes n o respons ibility for damage or injury due to di sassembly in the field.

Disassembly, other than at Liberty Pumps or its authorized service centers, automatically voids warranty.

Power cord and control cord replacement:

The power cord and control cord are not field replaceable. If either cord is compromised the entire pump must be

brought to a qualified hazardous motor enclosure repair facility approved by Liberty Pumps. Any unauthorized field

repairs voids warranty and hazardous location ratings. Contact Liberty Pumps at 1-800-543-2550 to locate the closest

repair facility.

CAUTION - Sewage water gives off methane and hydrogen sulfide

gases which are poisonous. Proper personal protection equipment

should be worn.

CAUTION

RISK OF ELECTRIC SHOCK - Acc idental cont act with elect ricall y

live parts, items, fluid, or water can cause serious injury or death.

WARNING

Page 11

©Copyright 2017 Liberty Pumps Inc. All rights reserved. 11

Problem Cause Correction

Pump will not run.

Tripped breaker or other interruption of

power; improper voltage.

Reset breaker by pushing completely

down on the handle then back to the on

position.

Have an electrician check all wiring for

proper connections and adequate voltage

and capacity.

Switch is unable to move to the “turn on”

position due to interference with the side

of basin or other obstruction.

Position the pump or switch so that it has

adequate clearance for free operation.

Insufficient liquid level.

Make sure the liquid level is allowed to

rise enough to activate switch(s).

Defective switch. Remove and replace switch.

Internal motor short. Requires an authorized service center.

Pump will not turn off.

Switch(s) unable to move to the “turn off”

position due to interference with the side

of basin or other obstacle.

Position the pump or switch so that it has

adequate clearance for free operation.

Defective switch. Remove and replace switch.

Pump runs or hums, but does

not pump.

Stuck / defective motor contactor. Replace motor contactor in panel.

Discharge is blocked or restricted.

Check the discharge line for foreign mate-

rial, including ice if the discharge line

passes through or into cold areas.

Check valve is stuck closed or installed

backwards.

Remove check valve(s) and examine for

freedom of operation and proper installation.

Gate or ball valve is closed. Open gate or ball valve.

Total lift is beyond pump's capability.

Try to route piping to a lower level. If not

possible, a larger pump may be required.

Consult the factory.

Pump impeller is jammed or volute casing

is plugged.

Remove the pump from the basin. De-

tach the pump base and clean the area

around the impeller. Reassemble and

reinstall.

Pump is air locked.

Clear anti-air lock hole.

Add baffle to reduce entrained air bub-

bles.

Capacitor failure. Check caps and replace if needed.

Pump runs periodically when

fixtures are not in use.

Check valve was not installed, is stuck

open or is leaking.

Remove check valve(s) and examine for

freedom of operation and proper installation.

Fixtures are leaking.

Repair fixtures as required to eliminate

leakage.

Pump operates noisily.

Foreign objects in the impeller cavity.

Remove the pump from the basin. De-

tach the pump base and clean the area

around the impeller. Reassemble and

reinstall.

Broken impeller.

Consult the factory for information regard-

ing replacement of impeller.

Worn bearings.

Return pump to the factory or authorized

repair station for repair.

Piping attachments to building are too

rigid.

Replace a portion of the discharge line

with rubber hose or connector.

Seal fail light is illuminated.

Lower seal has been compromised. Replace lower seal.

Relay sensitivity is incorrect.

Decrease sensitivity by turning the dial.

Proper range is 75 to 125.

Page 12

©Copyright 2017 Liberty Pumps Inc. All rights reserved. 12

5. 3-Year Limited Warranty

Liberty Pumps, Inc. warrants that its products are free from all factory defects in material and workmanship for a period

of 3 years from the date of purchase. The date of purchase shall be determined by a dated sales receipt noting the

model and serial number of the pump. The dated sales receipt must accompany the returned pump if the date of return

is more than 3 years from the "CODE" (date of manufacture) number noted on the pump nameplate.

The manufacturer's sole obligation under this warranty shall be limited to the repair or replacement of any parts found by

the manufacturer to be defective, provided the part or assembly is returned freight prepaid to the manufacturer or its

authorized service center, and provided that none of the following warranty-voiding events have taken place.

The manufacturer shall not be liable under this warranty if the product has not been properly installed; if it has been

disassembled, modified, abused or tampered with; if the electrical cord has been cut, damaged or spliced; if the pump

discharge has been reduced in size; if the pump has been used in water temperatures above the advertised rating, or in

water containing sand, lime, cement, gravel or other abrasives; if the product has been used to pump chemicals or

hydrocarbons; if a non-submersible motor has been subjected to excessive moisture; or if the label bearing the serial,

model and code number has been removed. Liberty Pumps, Inc. shall not be liable for any loss, damage or expenses

resulting from installation or use of its products, or for indirect, incidental, and consequential damages, including costs of

removal, reinstallation or transportation.

THE WARRANTIES SET FORTH ABOVE ARE IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED,

INCLUDING WITHOUT LIMITATION, ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE, AND ALL SUCH OTHER WARRANTIES ARE HEREBY DISCLAIMED AND EXCLUDED BY LIBERTY

PUMPS, INC.

7000 Apple Tree Avenue

Bergen, NY 14416

Phone: (800) 543-2550

Fax: (585) 494-1839

www.libertypumps.com

Loading...

Loading...