©Copyright 2012 Liberty Pumps Inc. All rights reserved 1

Installation Manual

5824000F

SumpJet® - Water Powered Backup System

IMPORTANT:

Prior to installation, record Model, Serial Number, and

Code Number from pump nameplate for future

reference.

MODEL ________________________

SERIAL ______________________

CODE ______________________

INSTALLATION

DATE _______________________

©Copyright 2012 Liberty Pumps Inc. All rights reserved 2

MODEL SJ10

No Alarm

MODEL SJ10A

With Alarm

7000 Apple Tree Avenue

Bergen, NY 14416

Phone: (800) 543-2550

Fax: (585) 494-1839

www.libertypumps.com

©Copyright 2012 Liberty Pumps Inc. All rights reserved 3

TABLE OF CONTENTS

SECTION

1

GENERAL INFORMATION------------------------------------------------------------------------------ 3

SECTION

2

INTRODUCTION-------------------------------------------------------------------------------------------- 4

SECTION

3

MECHANICAL INSTALLATION ----------------------------------------------------------------------- 5-7

SECTION

4

WARRANTY STATEMENT------------------------------------------------------------------------------ 7

SECTION

5

TEMPLATE ------------------------------------------------------------------------------------------------ 9

1

Before installation, read the following instructions carefully. Each Liberty Pump is individually factory tested to ensure proper performance.

Closely following these instructions will eliminate potential operating problems, assuring years of trouble-free service.

NOTE: As per the Uniform Plumbing Code and per the Plumbing Codes of some states, including the State of Michigan, installation

of this product requires the use of an RPZ backflow protection device. Contact your local plumbing or water authority for more

information regarding the requirements for your specific area.

• Risk of electric shock. When installing the SumpJet®, Always disconnect any electric pumps from the power

source before handling or making adjustments.

• The SumpJet® is designed for use with municipal water supply, and is intended to be used as an emergency

backup to your existing pump system.

General Information

©Copyright 2012 Liberty Pumps Inc. All rights reserved 4

• The SumpJet® comes with a foot valve installed and therefore does not require a check valve on the discharge.

The foot valve has a removable poppet. Where freezing discharge pipes are a problem, simply unscrew the

strainer screen, remove the poppet and spring, and replace the strainer. The SumpJet® will now allow water to

flow back into the pit, eliminating discharge pipe freezing.

• Maximum water pressure = 100 psi with the valve closed.

• Minimum water pressure = 30 psi with the valve open. (less pressure may not eject water from your basement)

• This unit must have a shut-off valve installed on the water supply line. (Refer to figure 1)

• For nominal backflow protection SumpJet® is pre-equipped with an internal check valve certified to ASME

A112.18.3-2002 and ASME A112.18.1/CSA B125.1.2005.

• Additional backflow protection must be provided by the installer to meet the requirements of the local

plumbing code or the requirements of the local water authority. As per the Uniform Plumbing Code and per

the Plumbing Codes of some states, including the State of Michigan, installation of this product requires the use

of an RPZ backflow protection device. Contact your local plumbing or water authority for more information

regarding the requirements for your specific area.

• The discharge of the water-powered sump pump should not to be connected to the primary sump pump. Also,

the discharge of the water-powered sump pump is not to be directly connected to the municipal drain. An air gap

with a minimum 1” gap should be used, or the discharge should be directed onto the yard.

• The inlet of the SumpJet® is pre-equipped with a push-type pipe connector, SharkBite®, and can be used with

PEX, CPVC, or copper pipe.

• Do not use pipe dope on inlet threads, and do not sweat copper fittings within 18” of SumpJet® body. Use PTFE

(Teflon®) sealing tape only when assembling threaded fittings into SumpJet® inlet. Do not over tighten threaded

inlet fitting, and do not hold onto float plunger shroud when tightening.

• Purge water line prior to connection to SumpJet® to insure debris does not enter unit and clog the operating

valve.

• The SumpJet®

utilizes a quick acting valve which, per UPC, requires the use of an approved water pressure

absorbing device to prevent water hammer. DO NOT use SumpJet® in hot water.

• The SumpJet® is designed for use in clear water only. It is not designed to remove waste water, sewage,

effluent, or water with debris in it.

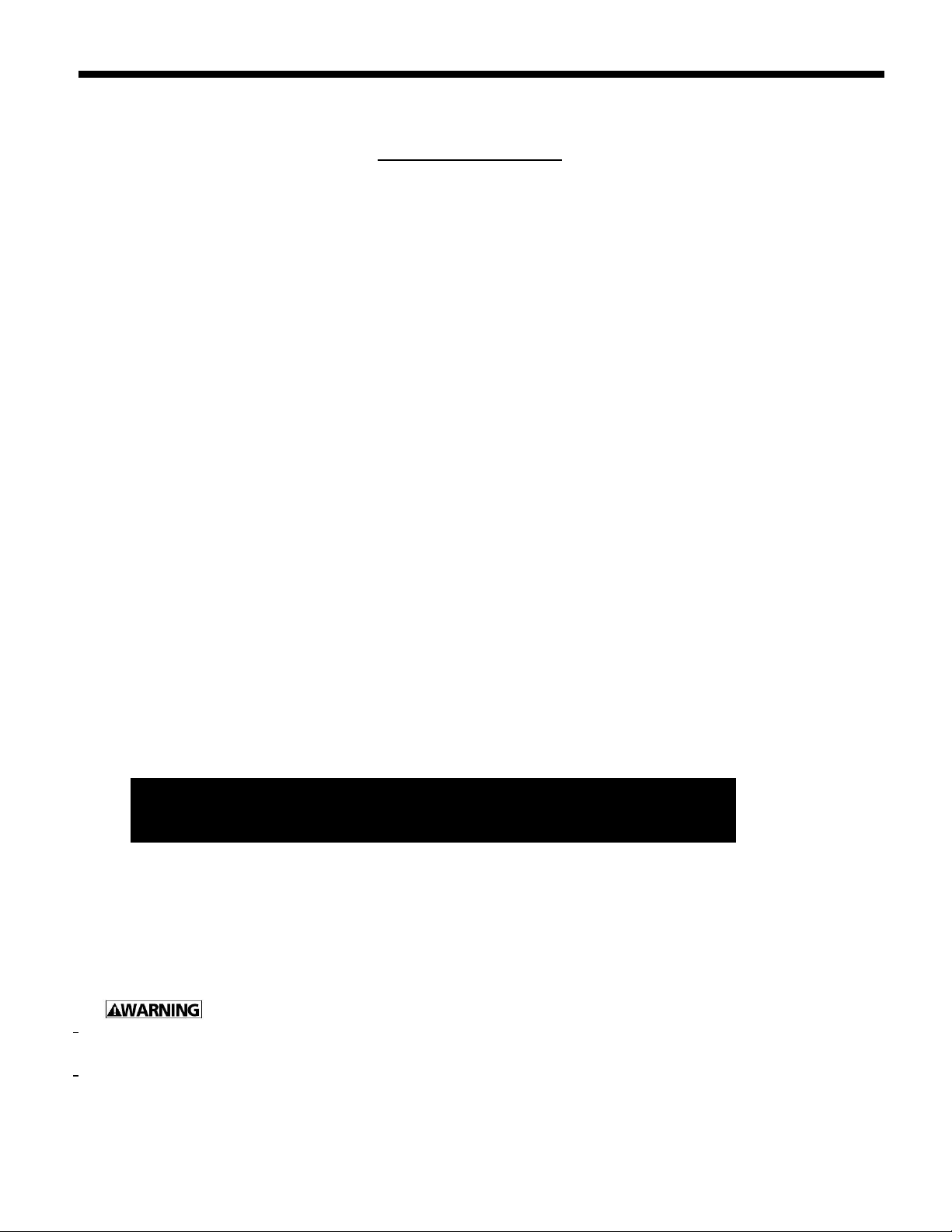

WATER PRESSURE AT

INLET OF SumpJet® WITH

VALVE OPEN AND WATER

FLOWING

SUMP WATER REMOVAL AT VARIOUS HEADS.

( STATIC HEAD IN 1-1/2 PIPE OR LARGER)

LIFT

4FT

1.21 M

8FT

2.4 M

12 FT

3.6 M

15 FT

4.5 M

PSI

KPA

GPM GPH M 3 / HR

GPM GPH M 3 / HR

GPM GPH M 3 / HR

GPM GPH M 3 / HR

20

138

11.0

660

2.5

5.8

348

1.3

30

207

12.8

765

2.9

9

540

2.0

5.5

330

1.2

40

276

15.4

924

3.5

12.5

750

2.8

9.3

558

2.1

7.2

432

1.6

50

345

17.2

1032

3.9

14.5

870

3.3

12

720

2.7

10

600

2.3

60

414

19.8

1185

4.5

17

1020

3.9

15.2

912

3.5

13.5

810

3.1

Note: For optimal performance minimum recommended operating pressure is 30 psi. Use of an RPZ may lower operating pressure.

2

Introduction

©Copyright 2012 Liberty Pumps Inc. All rights reserved 5

2-1 INTRODUCTION

This manual was prepared to assist you in the correct installation, operation, and maintenance of your Liberty Pumps SumpJet®.

Please read it completely before installing the pump. Make certain that you are familiar with the contents, and the chapters on

installation and operation are fully understood before running the pump.

Liberty products are designed for minimal maintenance. However, regular checks will ensure longer life and greater operating

reliability.

WARRANTY: No repair work should be carried out during the warranty period without prior factory approval. To do so may render

the warranty void.

SERIAL #: In all correspondence and reports, make certain that the pump serial number is given.

2-2 DESIGN OF PUMP

The Liberty SumpJet® is designed for emergency backup to your existing pump system. It uses the municipal water supply to evacuate

water from the sump. It is not intended to be used as the main sump water removal pump. It is intended to remove clear sump

water only. Liberty Pumps recommends the use of an audible high water alarm. The model SJ10A features an alarm system

to warn when the SumpJet® is activated. If you purchased the model SJ10 (without alarm) and wish to add the alarm feature,

order part number ALM-P1 from you local distributor or contact the factory for more information. Prolonged use of the SumpJet®

will result in increased municipal water consumption. The SumpJet® will use approximately 1 gallon of water to remove 2 gallons

of sump water, depending on elevation.

2-3 INSPECTION UPON RECEIPT

The shipping container should be immediately inspected for damage that may have occurred in shipment. Exercise care in opening

the shipping container to avoid damage to the pump. Remove any blocking and cushioning from within the container.

Check all cushioning for spare parts before discarding. Visually check the pump and any spare parts for damage. Report any

damage or shortage of parts.

2-4 STORAGE BEFORE USE

Liberty pumps are shipped from the factory ready for installation and use. They should be held in storage if the pump station is

not complete. If storage is necessary, the pump should remain in its shipping container. It should be stored in a warehouse or

storage shed that has a clean, dry temperature-stable area where the pump and its container should be covered to protect it from

water, dirt, dust, etc.

AT NO TIME SHOULD THE PUMP BE STORED WITHIN AN INCOMPLETE WET PIT. THE PUMP SHOULD

NOT BE PLACED INTO THE PIT UNTIL IT CAN BE FULLY OPERATED.

2-5 LONG TERM STORAGE

If it is necessary to store a pump for a long period of time, it should be stored indoors in a clean, dry temperature-stable environment. The

pump should be covered to protect it from dust, dirt and water.

Do not allow the pump to freeze.

2-6 MAINTENANCE

Installed pumps which are idle for long periods of time should be manually operated once a month to ensure proper operation. Check

for proper operation of the float and clean any debris that may be on the float or the suction screen. Make sure that the float

operates freely without any restrictions.

2-7 OPTIONAL ALARM

The SJ10A pump comes supplied with a pre-mounted alarm probe. If you would like to add an alarm to the SJ10 system, Liberty

Pumps offers a model, ALM-P1, which is suitable for this installation.

©Copyright 2012 Liberty Pumps Inc. All rights reserved 6

3

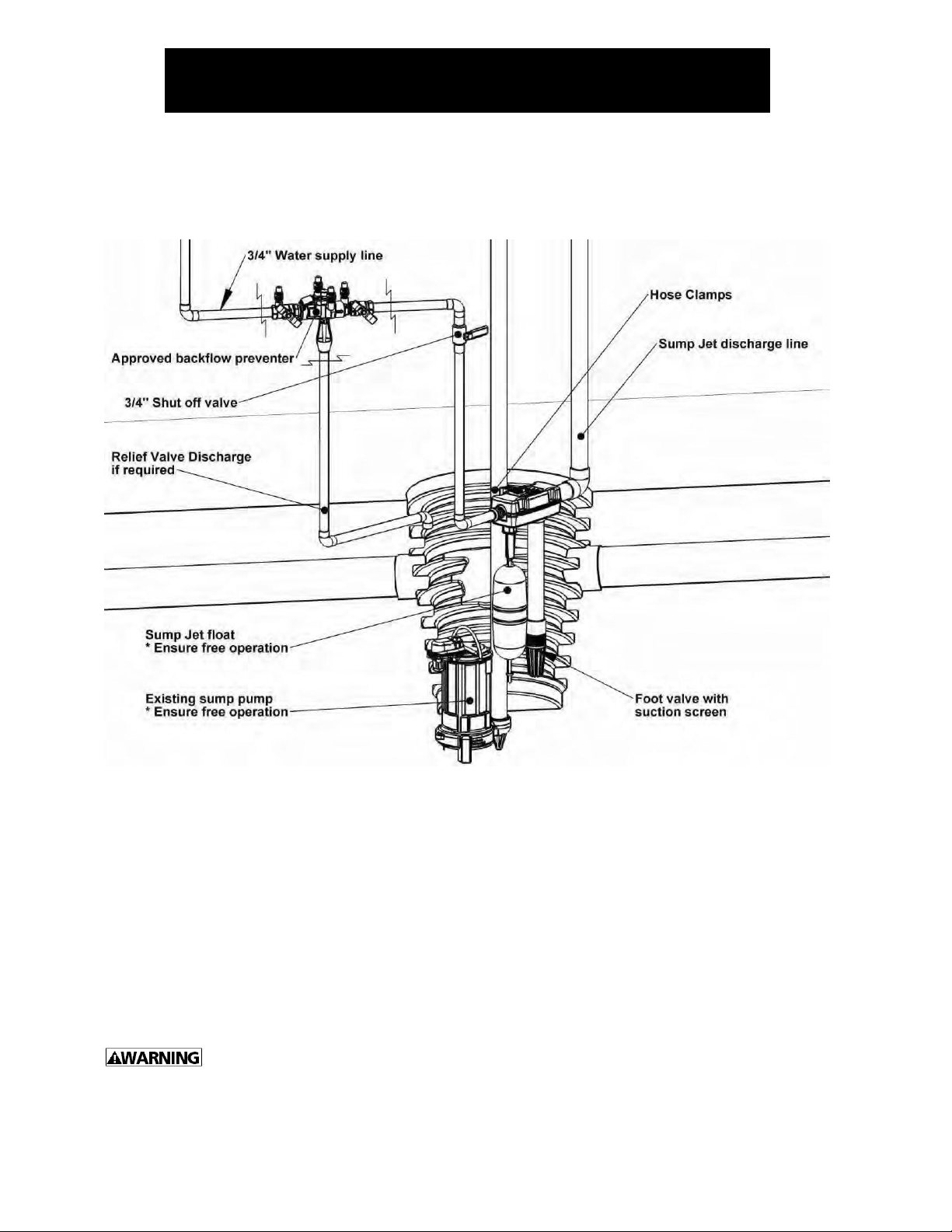

Figure 1 Typical installation

Note- The SumpJet® comes fully assembled. Only placement and connection is required.

3-1 For nominal backflow protection SumpJet® is pre-equipped with an internal check valve certified to ASME A112.18.3-2002 and ASME

A112.18.1/CSA B125.1.2005. Additional backflow protection must be provided by the installer to meet the requirements of the

local plumbing code or the requirements of the local water authority. As per the Uniform Plumbing Code and per the Plumbing

Codes of some states, including the State of Michigan, installation of this product requires the use of an RPZ backflow protection

device. Contact your local plumbing or water authority for more information regarding the requirements for your specific area.

The discharge of the water-powered sump pump should not to be connected to the primary sump pump. Also, the discharge of

the water-powered sump pump is not to be directly connected to the municipal drain. An air gap with a minimum 1” gap should

be used, or the discharge should be directed onto the yard.

3-2

Disconnect the existing sump pump from the electrical supply before installation of the SumpJet®.

Mechanical Installation

©Copyright 2012 Liberty Pumps Inc. All rights reserved 7

3-3 DO NOT USE A GARDEN HOSE. Garden hose is not designed to hold municipal pressure indefinitely. It could leak

or burst and cause flooding. The SumpJet® requires permanent piping methods such as copper, PEX, or CPVC, or any other

permanent plumbing method, be used for installation. To achieve maximum performance from the SumpJet® it is recommended

that the unit is plumbed with 3/4” pipe.

3-4 The inlet of the SumpJet® is factory equipped with a SharkBite® push-type fitting. This fitting can be used with various approved

3/4-inch potable water tubing and pipe, such as PEX tubing (ASTM F876, CSA B137.5), copper pipe (ASTM B 88), or Copper

Tube Size (CTS) CPVC pipe (ASTM D 2846, CSA B137.6). Follow the instructions below for connecting the municipal water line

to the SharkBite®. For more details on using the SharkBite® go to www.cashacme.com.

3-5 Using the Hose clamps provided, mount the SumpJet® to the existing discharge pipe. Place the unit so that the float level will operate

a few inches above the turn on level of the existing sump pump.

(Refer to figure 2). Tighten hose clamps on discharge pipe. NOTE:

If this type of installation will not work refer to alternate installation

3-17.

3-6 After mounting the SumpJet®, you are ready to hook into the existing

municipal water supply line. Shut off the municipal water supply,

and plumb the tubing or piping into the municipal water supply line.

Use the appropriate backflow prevention for your jurisdiction.

3-7 Prior to connecting water line to the SumpJet® purge the water line to

insure it is free from debris, solder, pie sealant, etc.

3-8 To connect the water line to the SharkBite® cut the pipe or tubing end

square. Ensure that there are no burrs or scratches 1” from the

cut end. Mark the pipe or tubing 1” from the cut end to indicate

proper insertion depth. If using PEX tubing the tube liner in the

end of the SharkBite® must be used. For copper and CPVC piping

the tube liner must be removed by using your fingers or pliers.

Insert the tubing or pipe into the SharkBite® through the release

collar to rest against the grab ring. Then push the tube or pipe

firmly until it reaches the tube stop. To insure the tube or pipe is

correctly inserted, check that the depth mark is up to the end of the

release collar.

3-9 If the Shark fitting is removed for connection to other types of 3/4” NPT

threaded fittings, make sure all sealing tape is removed from the

threaded inlet of the SumpJet®. Use a small picktype tool if

necessary. Do not allow any debris to enter the valve body.

3-10 If reconnecting the SharkBite® or other

threaded fitting use PTFE (Teflon®) sealing tape only when assembling

threaded fittings into SumpJet® inlet.

3-11 Do not over tighten threaded inlet fitting, and

do not hold onto float plunger shroud when tightening.

3-12 DO NOT SWEAT PIPES OR FITTINGS

DIRECTLY CONNECTED TO THE SumpJet® . HEAT

TRANSFERRED FROM THE COPPER WILL DAMAGE

PLASTIC PARTS!

3-13 Determine the length of discharge pipe required to the discharge exit

point. Using schedule 40 PVC pipe, glue the discharge pipe into

the socket elbow of the SumpJet®. Complete all discharge

piping. Discharge piping should be routed to the yard outside the

building.

NOTE: The SumpJet® comes complete with a foot valve. There is no need to

install a check valve on the discharge pipe.

Figure

2

The bottom of the

grey pump housing

should be

approximately 12”

above the water

level at which the

normal sump pump

turns on.

©Copyright 2012 Liberty Pumps Inc. All rights reserved 8

NOTE: If the discharge is emptying to a municipal drain then this unit must

be used in conjunction with an "air gap". The "air gap" must be at

least 1".

NOTE: The foot valve has a removable poppet. Where freezing discharge

pipes are a problem, simply unscrew the strainer screen, remove

the poppet and spring, and replace the strainer. The SumpJet®

will now allow water to flow back into the pit, eliminating discharge

pipe freezing.

3-14 Turn the municipal water supply back on and open the shutoff valve. Check

for leaks. Test the SumpJet® to ensure that it is

operational. You will need to fill the sump pit with water by garden

hose or bucket.

3-15 Re-connect primary electric sump pump to power supply.

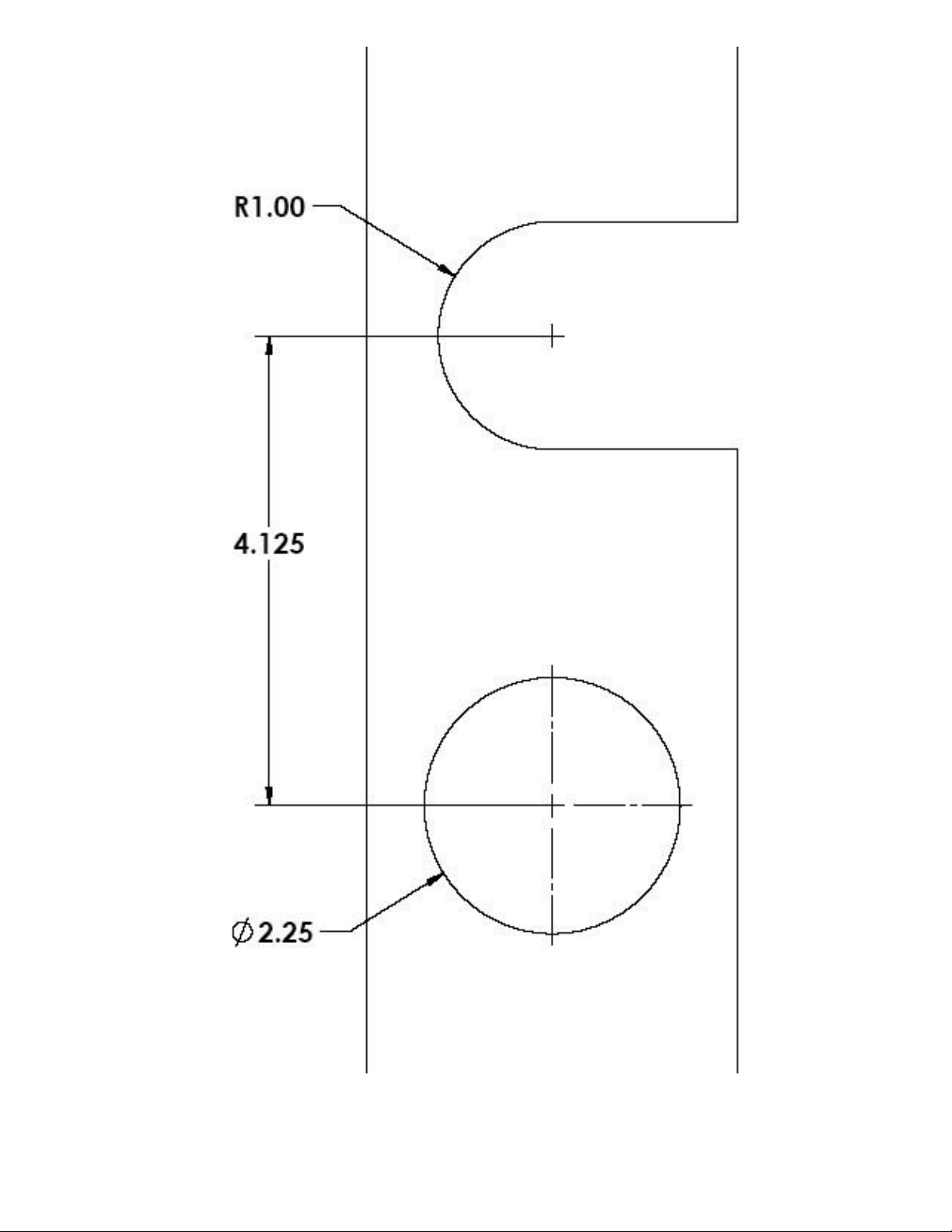

3-16 If you want to replace the sump cover it will be necessary to add additional

holes and slots to make access for the SumpJet® suction pipe and

float rod. Refer to template provided in Figure (4) at the end of the

manual.

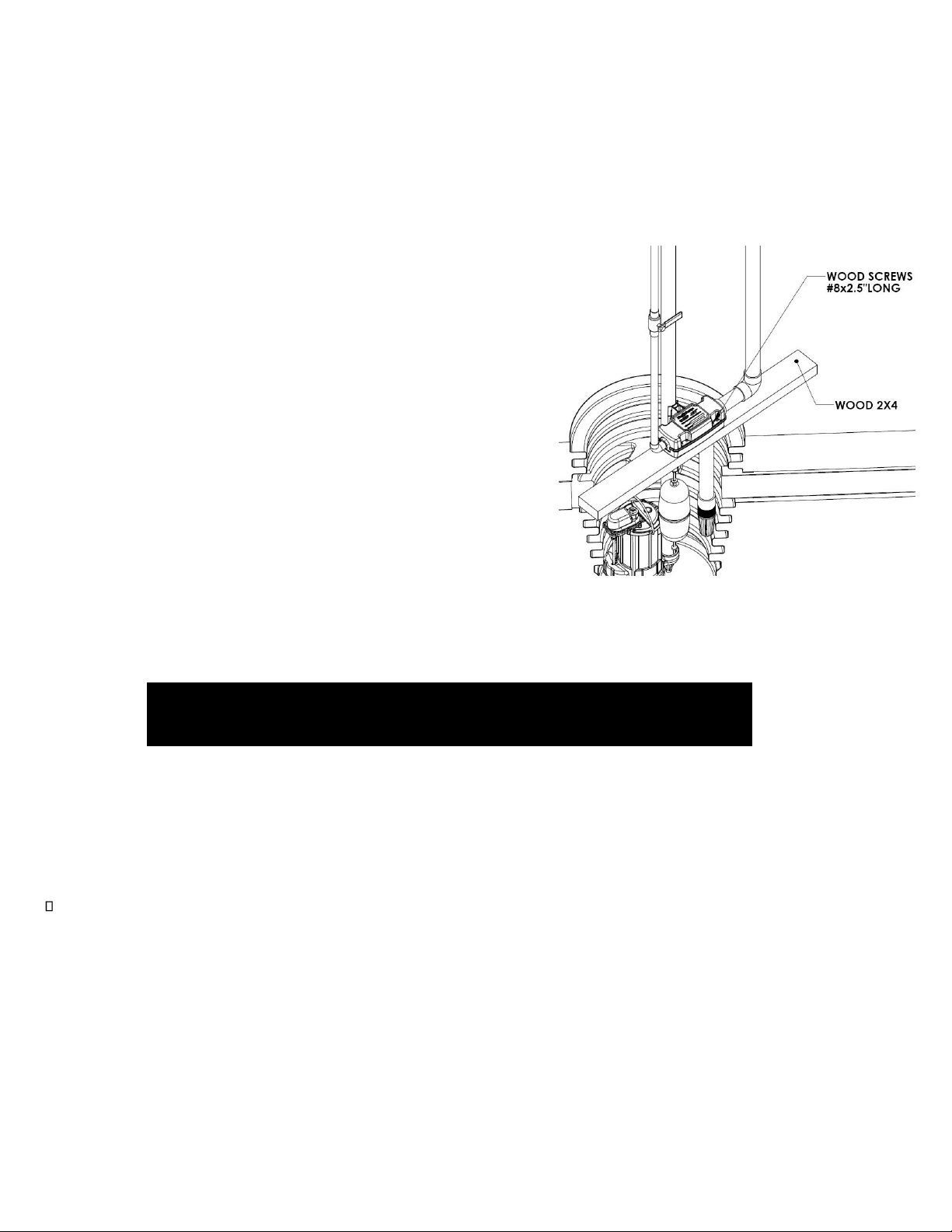

3-17 If you cannot mount the SumpJet® to the pump discharge pipe you may

use a piece of wood to mount the SumpJet®. Cut holes as per figure

(4) at the end of the manual. There are 4 screw holes that you can use

to fasten the SumpJet® to the wood. Use #8x2.5" long wood screws.

Refer to Figure ( 3 )

4

NOTE: Liberty Pumps, Inc. assumes no responsibility for damage or injury due to disassembly in the field. Disassembly, other than at

Liberty Pumps or its authorized service centers, automatically voids warranty.

Liberty Pumps, Inc. warrants that pumps of its manufacture are free from all factory defects in material and workmanship for a period of 3

years from the date of purchase. The date of purchase shall be determined by a dated sales receipt noting the model and serial number

of the pump. The dated sales receipt must accompany the returned pump if the date of return is more than 3 years from the "CODE" (date

of manufacture) number noted on the pump nameplate.

The manufacturer's obligation under this Warranty shall be limited to the repair or replacement of any parts found by the manufacturer to

be defective, provided the part or assembly is returned freight prepaid to the manufacturer or its authorized service center, and provided

that none of the following warranty-voiding characteristics are evident.

Warranty

Figure 3

©Copyright 2012 Liberty Pumps Inc. All rights reserved 9

The manufacturer shall not be liable under this Warranty if the product has not been properly installed; if it has been disassembled, modified,

abused or tampered with; if the electrical cord has been cut, damaged or spliced; if the pump discharge has been reduced in size; if the

pump has been used in water temperatures above the advertised rating, or water containing sand, lime, cement, gravel or other abrasives;

if the product has been used to pump chemicals or hydrocarbons; if a non-submersible motor has been subjected to excessive moisture;

or if the label bearing the serial, model and code number has been removed. Liberty Pumps, Inc. shall not be liable for any loss, damage

or expenses resulting from installation or use of its products, or for consequential damages, including costs of removal, reinstallation or

transportation.

There is no other express warranty. All implied warranties, including those of merchantability and fitness for a particular purpose, are limited

to three years from the date of purchase.

This Warranty contains the exclusive remedy of the purchaser, and, where permitted, liability for consequential or incidental damages under

any and all warranties are excluded.

©Copyright 2012 Liberty Pumps Inc. All rights reserved 10

5

Hole Template

©Copyright 2012 Liberty Pumps Inc. All rights reserved 11

Figure 7

Loading...

Loading...