Page 1

IMPORTANT:

Prior to installation, record Model, Serial

Number, and Code Number from pump

nameplate for future reference.

MODEL ________________________

SERIAL ______________________

CODE ______________________

INSTALLATION

DATE _______________________

Models

S35M Manual Pump, No Switch

S37 Automatic Pump,

Vertical Switch

S37-P Automatic Pump, Piggy-Back

Vertical Switch

S38 Automatic Pump,

Wide Angle Switch

Installation Manual

7175000G

S30 - Series Builders Series Sump Pump

Contents

1.) General Information

2.) Sump Pit

3.) Installation

4.) Operation

5.) Maintenance and Troubleshooting

7000 Apple Tree Avenue

Bergen, NY 14416

Phone: (800) 543-2550

Fax: (585) 494-1839

www.libertypumps.com

*Do not throw away or lose this manual.

©Copyright 2016 Liberty Pumps Inc. All rights reserved

Page 2

2. Sump Pit

1. General Information

Before Installation, read the following instructions carefully. Each Liberty pump is individually factory tested to assure proper

performance. By closely following these instructions, potential operating problems should be eliminated, providing years of

trouble-free service.

Risk of electric shock. Always disconnect the pump from the power source before handling or making adjustments.

The electrical connections and wiring for a pump installation should only be made by qualified personnel.

This pump is supplied with a grounding conductor and grounding-type attachment plug. To reduce the risk of electric

shock, be certain that it is connected only to a properly grounded, grounding-type 15 Amp receptacle.

Always wear rubber boots when water is on the floor and you must unplug the pump.

DO NOT bypass grounding wires or remove ground prong from attachment plugs.

DO NOT use an extension cord.

This pump requires a separate, properly fused and grounded branch circuit. Make sure the power source is properly sized

for the voltage and amperage requirements of the pump, as noted on the nameplate.

The electrical outlet shall be within the length limitations of the pump power cord, and at least 4 feet above floor level to

minimize possible hazards from flood conditions.

The installation must be in accordance with the National Electric Code, Uniform Plumbing Code, International Plumbing

Code, as well as all applicable local codes and ordinances.

Sump and sewage pumps often handle materials which could cause illness or disease. Wear adequate protective clothing

when working on a used pump or piping.

Keep clear of suction and discharge openings. To prevent injury, never insert fingers into pump while it is plugged in.

DO NOT use this product for flammable or corrosive liquid.

DO NOT use this product in applications where human contact with the pumped fluid is common (such as swimming pools,

fountains, etc.)

NEVER dispose of materials such as paint thinner or other chemicals down drains, as they can chemically attack and

damage pump components, potentially causing product malfunction or failure.

DO NOT use pumps in water over 140F (60C).

DO NOT use pumps in mud, sand, cement, oil or chemicals.

DO NOT modify the pump in any way.

DO NOT lift or carry pump by power cord.

DO NOT remove any tags from pump or cords.

If pump is installed during construction before power is available, it must be protected from the environment to prevent

water from entering through the cord plug end, etc.

A sump pit not less than 14” in diameter is recommended. A larger diameter pit is preferred as it allows for longer pump cycling

and reduced switch cycling. The minimum depth of the pit should be 18”.

The bottom of the pit should be a solid level of bricks or concrete. DO NOT place the pump directly on earth, gravel or debris

since this can cause excessive wear of the impeller and possible jamming. “The Brick” (sold by Liberty Pumps as part #

4445000) is a pre-molded stable platform designed to fit your submersible pump. It raises the pump 2.75” off the bottom of the

pit, reducing the potential for jamming from rocks and debris. Contact your local distributor to order. Remove all debris from the

bottom of the sump pit before installation of the pump. A sump pit cover is suggested for safety and to prevent foreign objects

from entering the pit.

©Copyright 2016 Liberty Pumps Inc. All rights reserved 2

Page 3

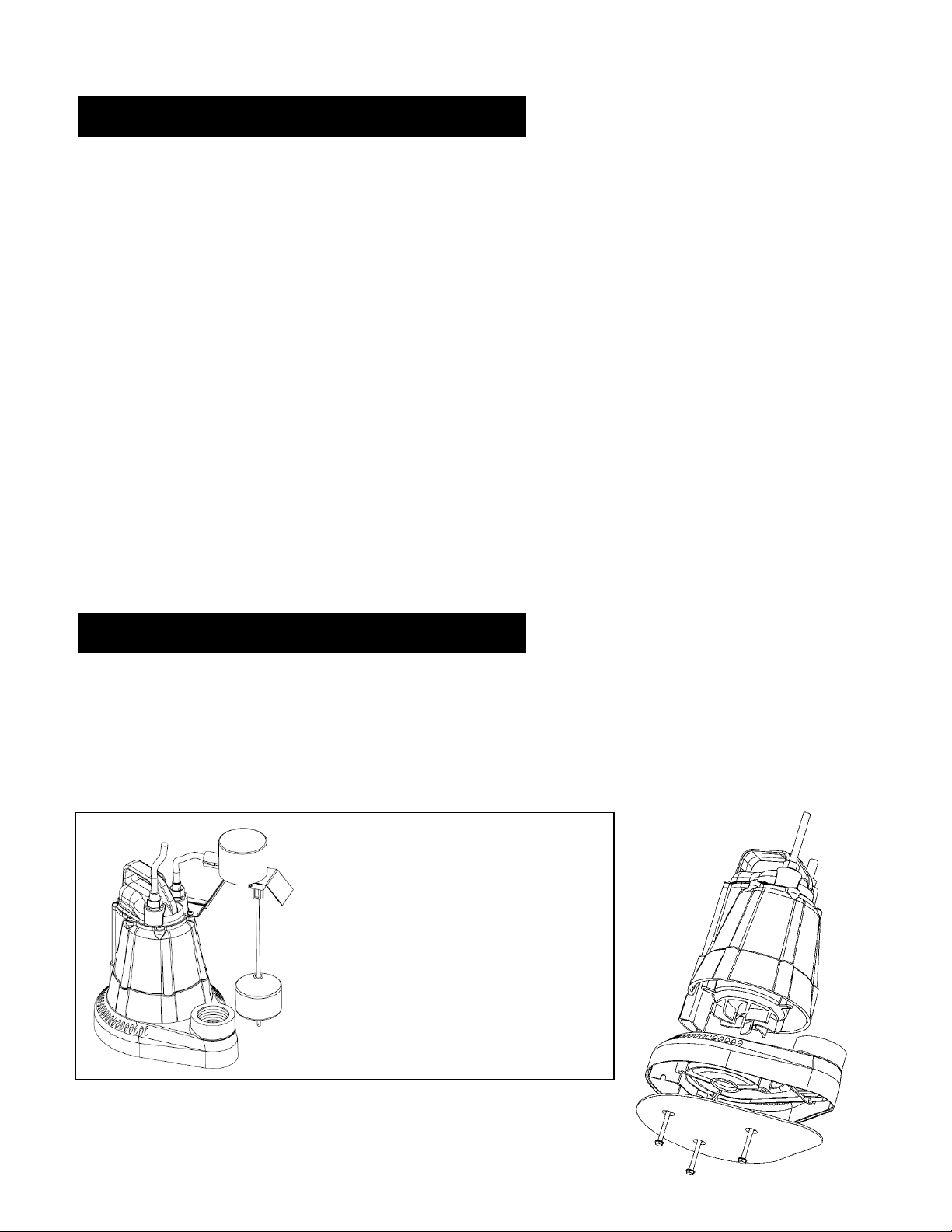

Models S37 and S37-P have an

integrated vertical float switch. The turn

off position can be adjusted by sliding

a rubber grommet up or down the

length of the float rod.

3. Installation

4. Operation

A.) Removal of the old pump (NOTE: Disconnect pump from power source before handling): Separate the discharge pipe

at either the check valve or at the union. If neither a check valve nor a union is part of the existing discharge pipe, cut the

pipe with a hacksaw and remove the pump (A union or check valve will need to be installed at this cut).

B.) The discharge size is 1-1/2” NPT Do not reduce the discharge size to less than 1-1/4”, as this will affect pump flow and

performance. Schedule 40 PVC pipe is recommended; however, flexible discharge hose kits may be used for temporary

installations.

C.) Connect the pipe or the discharge hose to the discharge of the pump. HAND TIGHTEN ONLY, over-tightening can damage

the pump discharge.

D.) Install a union or other means of separating the discharge pipe just above the floor to facilitate removal of the pump if

necessary. A check valve is recommended just above or in place of the union to prevent the back-flow of water

after each pump cycle.

E.) Connect additional pipe as necessary to direct the discharge to the desired location. Discharge should be kept

as short as possible with a minimum number of turns.

F.) Model S37, S37-P and S38: When placing the pump in the basin assure that float switch has adequate

clearance in pit and will not interfere with side wall.

G.) For added protection, consider the addition of a back-up pump such as Liberty’s SJ10 SumpJet, as well as an

alarm such as Liberty’s ALM-2 in applications where loss of pump function could result in property damage. If

an alarm is used, it must be connected to a separate electrical circuit.

A separate branch circuit, properly fused and grounded, should be provided to the pump. Make sure the power

source is properly sized for the voltage and amperage requirements of the motor as noted on the pump nameplate.

If electrical receptacle is corroded or worn it should be replaced to ensure reliable operation of the pump. The

electrical outlet or panel shall be within the length limitations of the pump power cord and at least 4 feet above floor

level to minimize possible hazards from flood conditions. Check to make sure installation is in accordance with the

National Electric Code and all applicable local codes and ordinances. Wiring extended over greater distances must

be in accordance with NEC requirements. DO NOT USE AN EXTENSION CORD.

©Copyright 2016 Liberty Pumps Inc. All rights reserved 3

Page 4

5. Maintenance and Troubleshooting

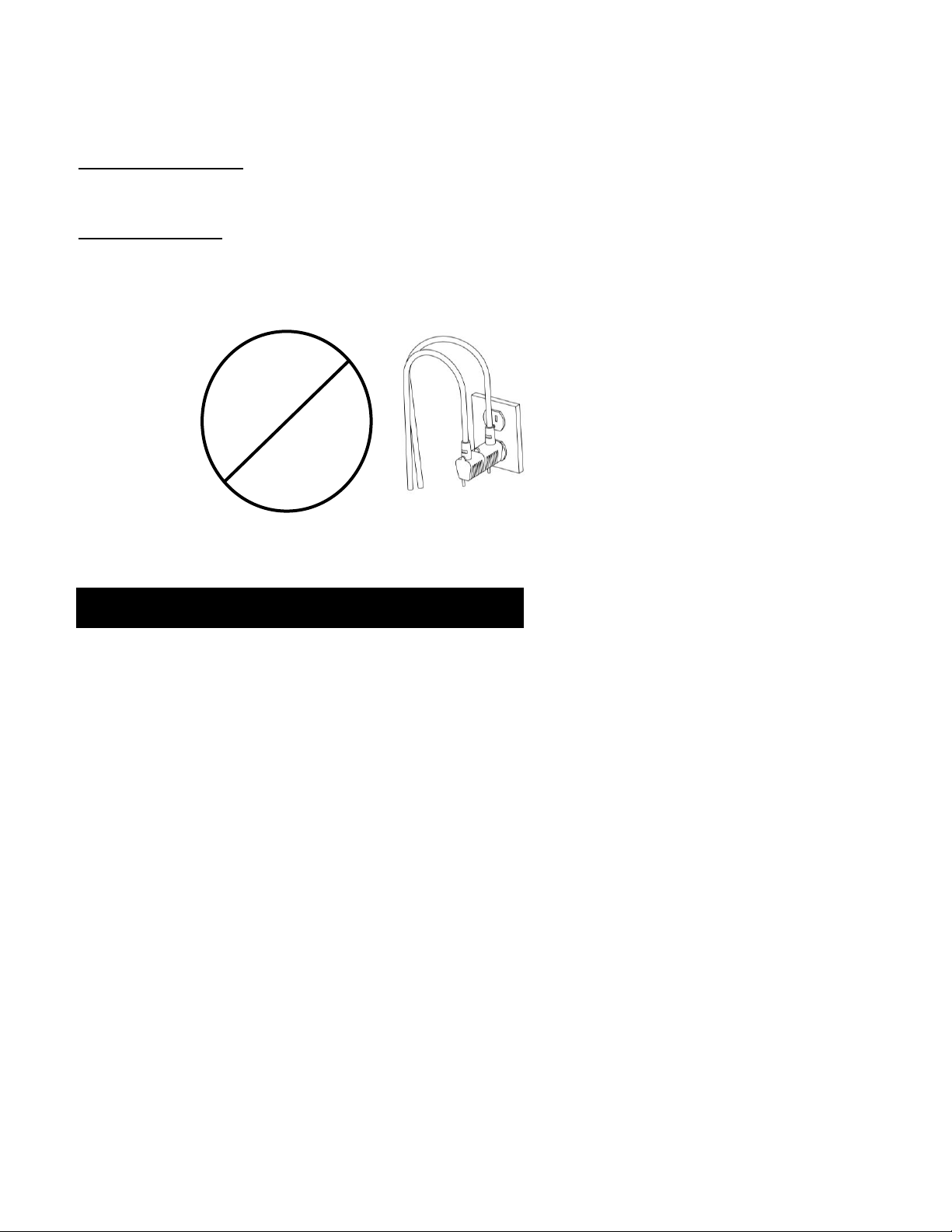

Models S37-P and S38 are automatic pumps which come with two cords - one for the switch and the other for the pump motor.

DON’T

DO

TEMPORARY

MANUAL OPERATION

The switch cord has a series (piggyback) plug enabling the pump (motor) cord to be plugged into the back of it. The purpose of

this design is to allow manual operation of the pump separate from the switch if necessary.

For automatic operation using the supplied switch, the two cords should be interconnected and plugged into a separately

fused, grounded outlet of proper amp capacity for your pump model. Both cords are equipped with 3-prong plugs and must be

properly plugged into a properly grounded 3-wire receptacle. DO NOT REMOVE THE GROUND PRONGS.

For manual operation, or in the event of switch failure, the pump cord can be separated and plugged directly into the electrical

outlet, bypassing the switch. The unit can be operated by directly plugging the pump cord (from the motor) into an approved

electrical outlet. To prevent excessive seal wear and overheating, the pump should not be run dry for extended periods of time.

A minimum 2-1/2” water level is recommended.

WARNING: ALWAYS DISCONNECT THE PUMP FROM THE POWER SOURCE BEFORE HANDLING. The

guide on the following page is designed to help identify reasons for potential operating problems. It is not a service guide.

Dismantling of the pump voids the warranty. Servicing of the pump other than simple cleaning of the pump inlet or impeller

should be referred to the factory or its authorized service centers. NOTE: The manufacturer assumes no responsibility

for damage or injury due to disassembly in the field.

©Copyright 2016 Liberty Pumps Inc. All rights reserved 4

Page 5

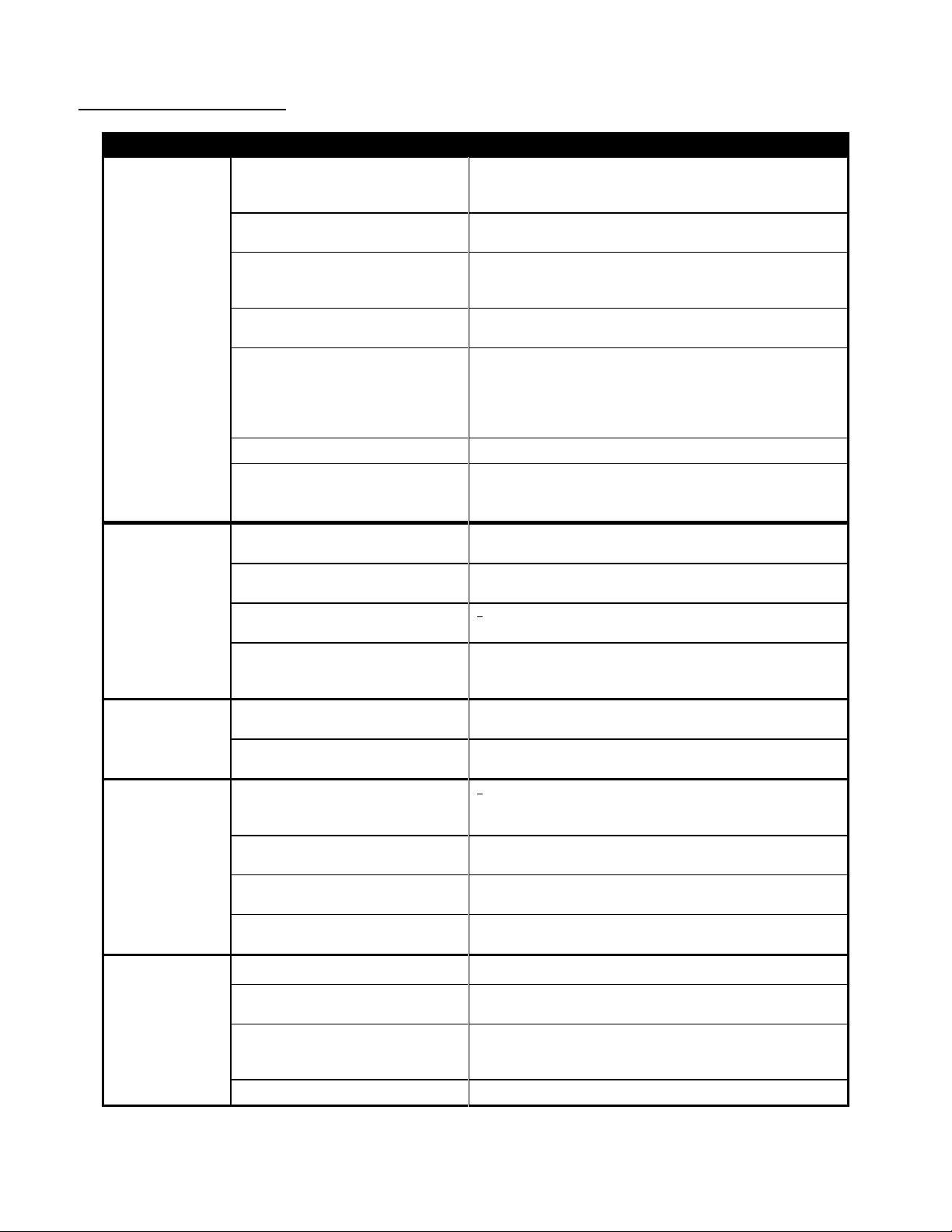

Troubleshooting Table:

Problem

Cause

Correction

Pump will not run

or hum.

Blown fuse or other

interruption of power; improper

voltage.

If blown, replace with properly sized fuse or reset

breaker; if voltage is under 108V, check wiring size.

Remove extension cord if connected.

Water level in pit may be too

low to activate switch.

Add more water to the pit.

Plug on power cord may not

be making contact in

receptacle.

Check security and connection. If receptacle is

corroded, have it replaced by a certified electrician.

Piggyback plugs may not be

connected tightly together.

Tighten connection of plugs.

Switch is defective Model S38

only.

Verify that water level is at least 4” above pump. To

test the switch, plug the power cord directly in to the

electrical receptacle bypassing the piggyback plug. If

pump operates, then the switch needs replacement.

(See Switch-Servicing procedures on page 5).

Motor winding may be open.

Consult factory.

Float switch obstructed Models

S37 and S38.

The float must be free to move unobstructed – if

bound remove debris or position pump to prevent

float from rubbing on side wall of sump.

Pump runs or

hums but does

not remove

water.

Check valve may be installed

backwards or is defective.

Make sure it’s installed properly and flapper in valve

is free to move.

Discharge line may be blocked

or frozen.

Make sure line doesn’t pass through cold areas or

isn’t blocked.

Vertical lift is beyond pump’s

capability.

If possible, try to reduce the discharge head to a

lower height.

Inlet screen of pump is

plugged or the impeller is

jammed.

Remove the pump screen and clean inlet and

impeller.

Pump runs and

removes water

but does not shut

off.

Switch is defective or

obstructed.

Make sure switch is free from obstruction or replace

switch.

Pump has met or exceeded its

maximum lift.

Route discharge piping to a lower level. If this isn’t

possible then a larger pump may be required.

Pump runs but

removes very

little water.

Vertical lift is approaching

pump’s maximum lift capability

of 27’.

If possible, try to reduce the discharge head to a

lower height.

Pump’s inlet is partially

blocked.

Remove volute and make sure inlet is clear of debris.

Discharge line is partially

blocked.

Remove blockage.

Check valve is not opening all

the way.

Remove blockage or make sure check valve is not

defective.

Circuit breaker

trips or fuse

blows when

pump starts.

Fuse or breaker is too small.

A 15-amp breaker should be used.

Other major appliance is on

the same circuit.

Pump should be on its own circuit.

Pump is connected to an

extension cord or wiring is

inadequate.

Have an electrician check for proper wiring.

Defective motor or switch.

Consult factory.

©Copyright 2016 Liberty Pumps Inc. All rights reserved 5

Page 6

6. 3 Year Limited Warranty

7000 Apple Tree Avenue

Bergen, NY 14416

Phone: (800) 543-2550

Fax: (585) 494-1839

www.libertypumps.com

Liberty Pumps, Inc. warrants that pumps of its manufacture are free from all factory defects in material and

workmanship for a period of 3 years from the date of purchase. The date of purchase shall be determined by a

dated sales receipt noting the model and serial number of the pump. The dated sales receipt must accompany the

returned pump if the date of return is more than 3 years from the "CODE" (date of manufacture) number noted on

the pump nameplate.

The manufacturer's obligation under this Warranty shall be limited to the repair or replacement of any parts found

by the manufacturer to be defective, provided the part or assembly is returned freight prepaid to the manufacturer

or its authorized service center, and provided that none of the following warranty-voiding characteristics are

evident.

The manufacturer shall not be liable under this Warranty if the product has not been properly installed; if it has been

disassembled, modified, abused or tampered with; if the electrical cord has been cut, damaged or spliced; if the

pump discharge has been reduced in size; if the pump has been used in water temperatures above the advertised

rating, or water containing sand, lime, cement, gravel or other abrasives; if the product has been used to pump

chemicals or hydrocarbons; if a non-submersible motor has been subjected to excessive moisture; or if the label

bearing the serial, model and code number has been removed. Liberty Pumps, Inc. shall not be liable for any loss,

damage or expenses resulting from installation or use of its products, or for consequential damages, including costs

of removal, reinstallation or transportation.

There is no other express warranty. All implied warranties, including those of merchantability and fitness for a

particular purpose, are limited to three years from the date of purchase.

This Warranty contains the exclusive remedy of the purchaser, and, where permitted, liability for consequential or

incidental damages under any and all warranties are excluded.

©Copyright 2016 Liberty Pumps Inc. All rights reserved 6

Page 7

IMPORTANTE:

Antes de instalar la bomba, apunte el modelo,

el número de serie y el código que aparecen en

la placa de identificación de la bomba para

que le sirvan de referencia en el futuro.

MODELO ________________________

SERIE ______________________

CÓDIGO ______________________

FECHA DE

INSTALACIÓN _______________________

Modelos

S35M Bomba manual, sin interruptor

S37 Bomba automática,

Interruptor vertical

S37-P Bomba automática,

Interruptor vertical

S38 Bomba automática,

Interruptor de nivel

Manual de instalación

7175000G

Serie S30 -

Serie de bomba de sumidero para constructores

Índice

1.) Información general

2.) Sumidero de agua

3.) Instalación

4.) Operación

5.) Mantenimiento y diagnóstico

de problemas

7000 Apple Tree Avenue

Bergen, NY 14416a

Teléfono: +1-800-543-2550 (Solo EE.UU.)

Fax: +1-585-494-1839

www.libertypumps.com

*No tire ni pierda este manual.

©Copyright 2016 Liberty Pumps Inc. Todos los derechos reservados

Page 8

1. Información general

ADVERTENCIA

PELIGRO

Lea con atención las siguientes instrucciones antes de instalar la bomba. Todas las bombas de Liberty se someten

individualmente a pruebas en fábrica para garantizar un funcionamiento adecuado. Si se siguen estas instrucciones al pie de

la letra, se eliminará la posibilidad de problemas potenciales de funcionamiento, proporcionando años de servicio satisfactorio.

Riesgo de descarga eléctrica. Desconecte la bomba de la fuente de alimentación siempre que vaya a manipularla o a

realizar algún ajuste.

Solo personal cualificado deberá encargarse de instalar las conexiones y cables eléctricos necesarios para montar

la bomba.

Esta unidad viene con un conductor de conexión a tierra y un enchufe de toma a tierra. Para reducir el riesgo de

descargas eléctricas, asegúrese de conectar la bomba únicamente a un tomacorriente de toma a tierra de 15 amperios

debidamente conectado a tierra.

Cuando haya agua en el piso y deba desenchufar la bomba siempre use botas de hule.

NO derive los cables de puesta a tierra ni retire las clavijas a tierra de los enchufes.

NO use cables de extensión.

Con esta bomba hay que utilizar un circuito derivado independiente, debidamente conectado a tierra y con fusibles

adecuados. Asegúrese que la fuente de potencia tenga suficiente capacidad para cumplir los requisitos de voltaje y

amperaje indicados en la placa de la bomba.

El tomacorriente deberá estar ubicado al alcance del cable de electricidad de la bomba y a un mínimo de 1.21 m (4 pies)

por encima del piso para evitar peligros en caso de inundación.

Se deberá instalar la unidad según las disposiciones del Código eléctrico nacional (NEC, por sus siglas en inglés),

el Código unificado de plomería, el Código internacional de plomería, y todos los códigos y regulaciones locales que

correspondan.

Las bombas de drenaje y de alcantarillado a menudo manejan materiales capaces de provocar enfermedades. Use ropa

protectora adecuada cuando trabaje en una bomba o una tubería usada.

Manténgase alejado de la entrada de succión y de la salida de descarga. Para evitar lesiones, nunca introduzca los dedos

en la bomba mientras ésta se encuentre conectada.

NO use este producto para líquidos inflamables o corrosivos.

NO use este producto en aplicaciones en las que el contacto humano con el fluido bombeado sea común (por ejemplo,

piscinas, fuentes, etc.).

NUNCA deseche por el drenaje materiales como solvente para pintura u otros químicos, ya que pueden llegar a atacar y

dañar los componentes de la bomba y potencialmente causar que el equipo no funcione bien o deje de funcionar.

NO utilice las bombas en agua con temperatura superior a los 60C (140F).

NO utilice las bombas en lodo, arena, cemento, aceite o químicos.

NO modifique la bomba de ninguna manera.

NO levante ni transporte la bomba halando el cable eléctrico.

NO retire ninguna etiqueta de la bomba ni los cables.

Si la bomba se instala durante la construcción, antes de que haya energía eléctrica disponible, se deberá proteger de

la intemperie para evitar que el agua ingrese a través del enchufe, etc.

© Copyright 2016 Liberty Pumps Inc. Todos los derechos reservados 2

Page 9

2. Sumidero de agua

3. Instalación

No es recomendable que el sumidero de agua tenga un diámetro menor de 35.5 cm (14 pulg). Es preferible que el diámetro

sea más grande, ya que de esta manera los ciclos de bombeo podrán ser más largos y se reducirá el número de veces que

el interruptor tiene que entrar en funcionamiento. La profundidad mínima del sumidero deberá ser 45.72 cm (18 pulg).

El fondo del sumidero debe consistir en un nivel sólido de ladrillos o concreto. NO instale la bomba directamente sobre tierra,

grava o escombros, ya que el rotor se puede desgastar en exceso y atascarse. “The Brick” (vendida por Liberty Pumps como

pieza núm. 4445000) es una plataforma estable premoldeada, diseñada para sostener su bomba sumergible. La plataforma

eleva la bomba 6.5 cm (2.75 pulg) sobre el fondo del sumidero, lo cual reduce la posibilidad de atascamiento por rocas o

escombros. Para pedir el producto, contacte a su distribuidor local. Antes de instalar la bomba, quite todo escombro del fondo

del sumidero. Es conveniente instalar una cubierta para el sumidero por motivos de seguridad y para evitar la entrada de

objetos foráneos.

A.) Retiro de la bomba antigua (NOTA: Desconecte la bomba de la fuente de alimentación antes de manipularla): Separe

el tubo de descarga bien sea a nivel de la válvula de retención o a nivel de la unión. Si ni la válvula de retención ni la unión

son parte del tubo de descarga existente, corte el tubo con una sierra para metales y quite la bomba. (Se necesitará

instalar una unión o una válvula de retención a nivel de este corte.)

B.) El tamaño de la descarga es de 3.8 cm (1.5 pulg) conforme al NPT (National Pipe Thread). No reduzca el tamaño de

la descarga a menos de 3.2 cm (1.25 pulg), ya que el hacerlo afectará el flujo y el funcionamiento de la bomba. Se

recomienda una tubería de PVC 40, aunque se pueden usar mangueras flexibles de forma provisional.

C.) Conecte la tubería o la manguera de descarga al extremo de descarga de la bomba. APRIETE LAS CONEXIONES CON

LA MANO SOLAMENTE. Apretar de más puede dañar la descarga de la bomba.

D.) Instale una unión u otro medio para separar la línea de descarga justo encima del nivel del piso para facilitar el desmonte

de la bomba, en caso de ser necesario. Encima de la unión o en su lugar, se recomienda instalar una válvula de

retención para evitar el contraflujo de agua después de cada ciclo de bombeo.

E.) Conecte extensiones de tubería adicionales según sea necesario para canalizar la descarga al punto deseado.

La descarga debe ser lo más corta posible con un número de giros mínimo.

F.) Modelos S37, S37-P y S38: Cuando coloque la bomba en la cubeta, asegúrese de que el interruptor de

flotador tenga suficiente espacio dentro del sumidero de manera que no interfiera con la pared lateral.

G.) Para mayor protección, considere agregar una bomba de respaldo como la SJ10 SumpJet de Liberty,

además de un sistema de alarma como el ALM-2 de Liberty en aplicaciones donde la pérdida de

funcionamiento de la bomba pueda resultar en daños a la propiedad. Si se utiliza una alarma, se deberá

conectar a un circuito eléctrico separado.

© Copyright 2016 Liberty Pumps Inc. Todos los derechos reservados 3

Page 10

El Modelos S37 y S37-P ofrece un

flotador vertical integrado. La posición

de apagado se puede ajustar

deslizando un ojal de caucho hacia

arriba o hacia abajo a lo largo de la

longitud de la barra del flotador.

4. Operación

Con esta bomba hay que utilizar un circuito derivado independiente, debidamente conectado a tierra y con fusibles

adecuados. La fuente de alimentación tendrá que tener suficiente capacidad para cumplir los requisitos de voltaje

y amperaje del motor, indicados en la placa de la bomba. El tomacorriente debe ser reemplazado si está corroído o

desgastado para garantizar la operación debida de la bomba. El tomacorriente o panel deberá encontrarse al

alcance del cable de alimentación de la bomba y a 1.22 metros (4 pies) como mínimo por encima del piso para

evitar problemas en caso de inundación. La instalación debe respetar las disposiciones del Código eléctrico

nacional (NEC) y los códigos y ordenanzas locales. Todo cableado extendido a distancias extensas debe cumplir

con los requisitos del Código eléctrico nacional (NEC). NO USE EXTENSIONES ELÉCTRICAS.

Modelos S37-P y S38 es bombas automáticas. Este modelo viene con dos cables: uno para operar el interruptor y el otro al

motor de la bomba. El cable del interruptor viene con un interruptor en serie, o cascada, en el que puede enchufar el cable del

motor en la parte posterior del mismo. Este diseño permite la operación manual de la bomba por separado del interruptor en

caso de ser necesario.

Si se quiere activar la operación automática con el interruptor suministrado, se deberán interconectar los dos cables y

enchufarse a un tomacorriente con toma a tierra y fusibles independientes y el amperaje apropiado para su modelo. Ambos

cables cuentan con enchufes de 3 patas y se deben enchufar en un tomacorriente trifilar con toma a tierra. NO DESMONTE

LAS CLAVIJAS A TIERRA.

© Copyright 2016 Liberty Pumps Inc. Todos los derechos reservados 4

Page 11

5. Mantenimiento y diagnóstico de

Si se prefiere la operación manual, o si falla el interruptor, el cable de la bomba se puede separar y enchufar directamente en

¡NO!

¡SÍ!

FUNCIONAMIENTO

MANUAL TEMPORAL

un tomacorriente, evitando de esta manera el interruptor. Esta unidad se puede operar conectando directamente el cable de

la bomba (del motor) a un tomacorriente eléctrico aprobado. Para evitar el desgaste excesivo y sobrecalentamiento de

los sellos, no se deberá hacer funcionar la bomba en seco por períodos prolongados. Se recomienda un nivel de agua mínimo

de 6.4 cm (1.5 pulg).

ADVERTENCIA: SIEMPRE DESCONECTE LA BOMBA DE LA FUENTE DE ALIMENTACIÓN ANTES DE

MANIPULARLA. La guía en la siguiente página está diseñada para ayudar a identificar las causas de posibles problemas de

operación. No es una guía de servicio. Desmantelar la bomba anulará la garantía. Cualquier otro tipo de servicio a la bomba,

aparte de la simple limpieza de la entrada o del impulsor, deberá referirse al fabricante o a sus centros de servicio autorizados.

NOTA: El fabricante no asume ninguna responsabilidad por daños o lesiones resultantes por desarmar

la bomba en el sitio.

© Copyright 2016 Liberty Pumps Inc. Todos los derechos reservados 5

Page 12

Tabla de diagnóstico de problemas:

Problema

Causa

Solución

La bomba no

funciona ni

zumba.

Se ha fundido un fusible o

el flujo eléctrico se ha

interrumpido de algún otro

modo; voltaje incorrecto.

Si se fundió un fusible, remplácelo con uno de

tamaño adecuado o restablezca el disyuntor; si

el voltaje es inferior a 108V, verifique el tamaño de

los cables. Retire el cable de extensión si se ha

conectado uno.

El nivel del agua en

el sumidero puede estar

demasiado bajo para activar

el interruptor.

Agregue más agua al sumidero.

El enchufe del cable eléctrico

puede no estar haciendo

contacto en el tomacorriente.

Verifique la seguridad y la conexión. Si

el tomacorriente está corroído, pida a un electricista

certificado que lo reemplace.

Los enchufes en cascada

podrían no estar debidamente

apretados.

Apriete la conexión de los enchufes.

El interruptor está defectuoso

(Modelo S38 solamente).

Verifique que el nivel del agua se encuentre a por lo

menos 10 cm (4 pulg) por encima de la bomba. Para

probar el interruptor, enchufe el cable de alimentación

directamente al tomacorriente evitando el enchufe en

cascada. Si la bomba funciona, entonces se debe

reemplazar el interruptor. (Vea los procedimientos de

servicio del interruptor en la página 5).

El devanado del motor podría

estar abierto.

Consulte al fabricante.

El interruptor de flotador está

obstruido (Modelos S37 y

S38).

El flotador debe moverse libremente sin

obstrucciones. Si está obstruido, quite los escombros

o coloque la bomba en una posición en que evite que

el flotador frote contra las paredes laterales del

sumidero.

La bomba

funciona o

zumba, pero no

extrae agua.

La válvula de retención

puede estar instalada al

revés o puede estar

defectuosa.

Asegúrese de que la válvula esté instalada de

manera adecuada y que la chapaleta de la válvula

pueda moverse libremente.

La línea de descarga puede

estar bloqueada o congelada.

Asegúrese de que la línea no pase por áreas frías ni

se encuentre bloqueada.

La elevación vertical está más

allá de la capacidad de

la bomba.

Si es posible, trate de reducir la altura de la línea de

descarga.

La malla de entrada de

la bomba está obstruida o

el rotor está atascado.

Extraiga la malla de la bomba y limpie la entrada y

el rotor.

La bomba

funciona y extrae

agua, pero no se

apaga.

El interruptor está defectuoso

u obstruido.

Asegúrese de que el interruptor no se encuentre

obstruido o reemplácelo.

La bomba ha cumplido o

superado la máxima

capacidad de elevación.

Canalice el tubo de descarga a un nivel más bajo.

Si no es posible, entonces podría ser necesario usar

una bomba más grande.

La bomba

funciona pero

extrae muy poca

agua.

La elevación vertical se

aproxima a la máxima

capacidad de elevación de

la bomba de 8.2 m (27 pies).

Si es posible, trate de reducir la altura de la línea de

descarga.

La entrada de la bomba se

encuentra parcialmente

bloqueada.

Retire la voluta y asegúrese de que la entrada esté

libre de escombros.

La línea de descarga está

parcialmente bloqueada.

Quite las obstrucciones.

La válvula de retención no se

abre completamente.

Quite las obstrucciones o asegúrese de que

la válvula de retención no esté defectuosa.

© Copyright 2016 Liberty Pumps Inc. Todos los derechos reservados 6

Page 13

El disyuntor se

dispara o el

fusible se funde

cuando la bomba

se enciende.

El tamaño del fusible o del

disyuntor es demasiado

pequeño.

Se debe utilizar un disyuntor de 15 amperios.

Hay otros electrodomésticos

importantes conectados al

mismo circuito.

La bomba debe estar conectada a un circuito

exclusivo.

La bomba está conectada a

una extensión eléctrica o el

cableado es inadecuado.

Llame a un electricista para que verifique que

el cableado esté correcto.

Motor o interruptor defectuoso.

Consulte al fabricante.

7000 Apple Tree Avenue

Bergen, NY 14416

Teléfono: +1-800-543-2550 (Solo EE.UU.)

Fax: +1-585-494-1839

www.libertypumps.com

6. Garantía limitada por 3 años

Liberty Pumps, Inc. garantiza que las bombas que fabrica están libres de defectos en los materiales y la mano

de obra por un período de 3 años a partir de la fecha de compra. La fecha de compra se determinará con el recibo

de compra fechado, que incluya el modelo y el número de serie de la bomba. Este recibo deberá acompañar a

la bomba si la fecha de devolución ocurre más de 3 años después de la fecha de fabricación (código-CODE)

indicada en la placa de identificación de la unidad.

Las obligaciones del fabricante bajo esta garantía se limitan a la reparación o el reemplazo de las piezas que

el fabricante determine defectuosas, siempre que la pieza o el ensamblaje se devuelva al fabricante o a uno de sus

centros de servicio autorizados con el porte pagado y que no se evidencie ninguna de las siguientes

características, lo que supondría la anulación de la garantía.

El fabricante no tendrá obligación alguna bajo esta garantía si el producto no ha sido instalado correctamente; si

ha sido desmontado, modificado, abusado o forzado; si el cable eléctrico se ha cortado, dañado o empalmado; si

se redujo el tamaño de la descarga de la bomba; si la bomba se usó con agua más caliente de la temperatura

nominal, o agua con arena, cal, cemento, grava u otros elementos abrasivos; si la bomba ha sido utilizada para

bombear químicos o hidrocarburos; si un motor no sumergible ha sido sometido a un exceso de humedad; o si se

ha retirado la etiqueta con el número de serie y de código. Liberty Pumps, Inc. no se hace responsable de

pérdidas, daños o gastos causados por la instalación o uso de sus productos, o por daños consiguientes, incluidos

los costos de desmontaje, reinstalación o transporte de la unidad.

No se ofrece ninguna otra garantía expresa. Todas las garantías implícitas, incluidas las de comerciabilidad y

adecuación para un propósito determinado, están limitadas a un plazo de tres años a partir de la fecha de compra.

Esta garantía contiene el resarcimiento exclusivo del comprador y, donde sea permitido, se excluye toda

responsabilidad por daños secundarios y consiguientes bajo cualquier otra garantía.

© Copyright 2016 Liberty Pumps Inc. Todos los derechos reservados 7

Page 14

IMPORTANT :

Avant l’installation, noter les numéros de

modèle, de série et de code qui figurent sur

la plaque signalétique pour éventuellement

s’y référer.

Nº de MODÈLE ____________

Nº de SÉRIE ____________

Nº de CODE ___________

DATE D'INSTALLATION ____________

Modèles

S35M Pompe manuelle, aucun

interrupteur

S37 Pompe automatique,

interrupteur vertical

S37-P Pompe automatique,

interrupteur vertical d’un connecteur

en série

S38 Pompe automatique,

Interrupteur à flotteur à grand angle

Manuel d'installation

7175000G

Série S-30

Pompe d'assèchement, gamme constructeurs

Table des matières

1.) Renseignements généraux

2.) Puisard

3.) Installation

4.) Fonctionnement

5.) Entretien et dépannage

*Ne pas jeter ni perdre ce manuel.

7000 Apple Tree Avenue

Bergen (NY) 14416a

Téléphone : (800) 543-2550

Télécopieur : (585) 494-1839

www.libertypumps.com

© Copyright 2016 Liberty Pumps Inc. Tous droits réservés

Page 15

1. Renseignements généraux

AVERTISSEMENT

MISE EN GARDE

Lire attentivement les directives avant d’effectuer l’installation. Chaque pompe de marque Liberty est testée individuellement en

usine pour assurer son bon fonctionnement. Le fait de suivre ces directives à la lettre éliminera les risques de problèmes de

fonctionnement et assurera des années de service sans soucis.

Danger d’électrocution. Toujours débrancher la pompe de l'alimentation électrique avant de la manipuler ou d'y effectuer

des réglages.

Les raccords électriques et le câblage pour l’installation de la pompe ne devraient être effectués que par des professionnels

qualifiés.

Cette pompe est fournie avec un conducteur de mise à la terre et une fiche de branchement de type mise à la terre. Afin de

réduire les dangers d'électrocution, s’assurer que celle-ci est raccordée seulement à une prise de 15 ampères correctement

mise à la terre.

Toujours porter des bottes de caoutchouc lorsqu'il y a de l'eau sur le plancher et qu'il est nécessaire de débrancher

la pompe.

NE PAS dévier les fils de mise à la terre ou retirer la broche de mise à la terre des fiches de branchement.

NE PAS utiliser de rallonge électrique.

Cette pompe nécessite un circuit de dérivation dédié correctement protégé par un fusible et mis à la terre. S’assurer que

la tension et l’intensité du courant électrique de la source d’alimentation électrique sont suffisantes pour répondre aux

exigences de la pompe, telles qu’indiquées sur la plaque signalétique.

La prise électrique doit se trouver à la portée du cordon d’alimentation de la pompe et à au moins 1,2 m (4 pi) au-dessus du

niveau du plancher pour minimiser les dangers liés à une inondation.

L’installation doit être faite en respectant le Code national de l’électricité, le Uniform Plumbing Code, le Code international

de plomberie ainsi que tous les codes locaux et règlements en vigueur.

Les pompes d'assèchement et de système d'égout traitent souvent des matières pouvant causer des maladies. Porter des

vêtements protecteurs adéquats pour manipuler une pompe ou de la tuyauterie ayant déjà servi.

Demeurer à l'écart des orifices d'aspiration et d'évacuation. Afin de prévenir les blessures, ne jamais insérer les doigts dans

la pompe alors qu'elle est branchée.

NE PAS utiliser ce produit pour pomper des liquides inflammables ou corrosifs.

NE PAS utiliser ce produit pour les installations où le contact humain avec les liquides pompés est fréquent (piscines,

fontaines, etc.)

NE JAMAIS disposer de matériaux comme du solvant à peinture ou d'autres produits chimiques en les vidant dans l'avaloir,

car ils peuvent attaquer chimiquement et endommager les composants de la pompe, causant éventuellement son mauvais

fonctionnement ou sa défaillance.

NE PAS utiliser ces pompes dans de l'eau dont la température est supérieure à 60 C (140 F)

NE PAS utiliser de pompes avec de la boue, du sable, du ciment, du pétrole ou des produits chimiques.

NE PAS modifier la pompe, de quelque manière que ce soit.

NE PAS soulever ou transporter la pompe par son cordon d'alimentation.

NE PAS retirer les étiquettes de la pompe ou des cordons.

Si la pompe est installée durant la construction, avant que l'alimentation électrique ne soit disponible, il est important de

la garder à l'abri afin d'empêcher que de l'eau ne pénètre par l'extrémité du cordon, etc.

© Copyright 2016 Liberty Pumps Inc. Tous droits réservés 2

Page 16

2. Puisard

3. Installation de la pompe

On recommande l'utilisation d'un puisard dont le diamètre est d'au moins 35,6 cm (14 po). Un diamètre supérieur est

recommandé, car il permet de plus longs cycles de fonctionnement de la pompe et réduit le fonctionnement de l'interrupteur.

Le puisard devrait avoir une profondeur d’au moins 45,7 cm (18 po).

Le fond du puisard doit être constitué d'une couche solide et bien au niveau de briques ou de béton. NE PAS placer la pompe

directement sur de la terre, du gravier ou des débris susceptibles de causer une usure prématurée du rotor et même de

le bloquer. « The Brick » (vendu par Liberty Pumps, pièce nº 4445000) est une plateforme prémoulée stable conçue pour

l'installation de votre pompe submersible. Elle soulève la pompe de 6,35 cm (2,75 po) du fond du puisard, réduisant ainsi

les risques d'obstruction causée par les cailloux et les débris. Communiquer avec le distributeur local pour commander. Retirer

tous les débris du fond du puisard avant l'installation de la pompe. On suggère l’installation d’un couvercle de puisard pour plus

de sécurité et empêcher que des corps étrangers ne tombent dans le puits.

A.) Retrait de l'ancienne pompe (REMARQUE : débrancher la pompe de sa source d’alimentation électrique avant d’en

effectuer la manipulation) : séparer le tuyau d’évacuation vis-à-vis du clapet antiretour ou du raccord union. Si le tuyau

d'évacuation en place ne comprend ni clapet antiretour ni raccord union, couper le tuyau avec une scie à métaux et retirer

la pompe (il sera nécessaire d'installer un clapet antiretour ou un raccord union à l'endroit de cette coupure).

B.) La taille du tuyau d'évacuation est de 1½ po NPT. Ne pas installer de tuyau d’évacuation d’un diamètre inférieur à 1½ po,

car cela risque de nuire au débit et au rendement de la pompe. Il est recommandé d’utiliser du tuyau de PVC de

nomenclature 40; cependant, on peut utiliser un ensemble de tuyau d’évacuation souple pour les installations temporaires.

C.) Raccorder le tuyau d’évacuation temporaire ou permanent à la sortie filetée de la pompe. RESSERRER À LA MAIN

SEULEMENT; trop serrer peut endommager le tuyau d'évacuation de la pompe.

D.) Installer un raccord union ou autre dispositif permettant de séparer la canalisation d’évacuation juste au-dessus du

plancher, pour faciliter le retrait de la pompe si nécessaire. On recommande l’installation d’un clapet antiretour après le

raccord union ou à sa place afin de prévenir le refoulement du liquide après chaque cycle de la pompe.

E.) Raccorder, au besoin, un tuyau supplémentaire pour diriger l'évacuation à l'endroit désiré. La conduite

d’évacuation devrait être la plus courte possible et comporter un nombre minimum de virages.

F.) Modèles S37, S37-P et S38 : lors de l'installation de la pompe dans le bassin, s'assurer que l'interrupteur à

flotteur dispose d'un dégagement suffisant dans le puisard et qu'il n'entrera pas en contact avec la paroi

latérale.

G.) Pour plus de protection, envisager l'ajout d'une pompe de secours, comme une pompe d'assèchement

Liberty SJ10 SumpJet, ainsi que d'une alarme, comme le modèle Liberty ALM-2, pour les installations où

une panne de la pompe risque de causer des dommages matériels. Lorsqu'une alarme est utilisée, elle doit

être raccordée à un circuit électrique distinct.

© Copyright 2016 Liberty Pumps Inc. Tous droits réservés 3

Page 17

Le modèles S37 et S37-P possède

un interrupteur à flotteur vertical

intégré. La position d'arrêt peut être

réglée en glissant un œillet de

caoutchouc vers le haut ou vers

le bas le long de la tige du flotteur.

4. Fonctionnement

Cette pompe nécessite un circuit de dérivation dédié correctement protégé par un fusible et mis à la terre.

S’assurer que la source d’alimentation électrique est suffisante pour répondre aux exigences de tension et

d’intensité du courant électrique du moteur, tel qu’indiqué sur la plaque signalétique de la pompe. Tout réceptacle

d’alimentation électrique corrodé ou usé doit être remplacé afin d'assurer le bon fonctionnement de la pompe.

La prise électrique ou le panneau doivent se trouver à la portée du cordon d’alimentation de la pompe et à au

moins 1,2 m (4 pieds) au-dessus du niveau du plancher pour minimiser les dangers possibles pouvant être causés

par une inondation. S’assurer que l’installation est conforme au code national de l’électricité et aux codes et

règlements locaux en vigueur. Tout câblage effectué sur de plus grandes distances doit être effectué

conformément aux normes du code national de l’électricité (NEC). NE PAS UTILISER DE RALLONGE.

© Copyright 2016 Liberty Pumps Inc. Tous droits réservés 4

Page 18

5. Entretien et dépannage

Le modèle S37-P ou S38 est une pompe automatique. Ce modèle est muni de deux cordons : un qui actionne l’interrupteur à

NON!

OUI!

FONCTIONNEMENT

MANUEL TEMPORAIRE

flotteur et l’autre le moteur de la pompe. Le cordon de l’interrupteur est muni d’un connecteur en série (siamois) permettant de

brancher le cordon de la pompe (moteur) sur son dos. Ce système a pour but de permettre le fonctionnement manuel de la

pompe indépendamment de l'interrupteur au besoin.

Pour un fonctionnement automatique, les deux cordons doivent être interconnectés et branchés dans une prise d’une

intensité en ampères suffisante pour le modèle de pompe, avec fusibles indépendants et mise à la terre. Les deux cordons sont

munis de fiches à trois broches et doivent être adéquatement branchés dans une prise à trois broches avec mise à la terre

adéquate. NE PAS RETIRER LA BROCHE DE MISE À LA TERRE.

Pour permettre le fonctionnement manuel, ou en cas de défaillance de l’interrupteur, le cordon de la pompe peut être séparé

et branché directement dans la prise électrique, en contournant l’interrupteur. La pompe peut être mise en marche en

raccordant directement son cordon d'alimentation (à partir du moteur) dans une prise de courant approuvée. Afin de prévenir

l'usure excessive des joints d'étanchéité et la surchauffe, la pompe ne doit pas fonctionner à vide pendant de longues périodes.

Un minimum de 6,4 cm (2½ po) d'eau est recommandé.

MISE EN GARDE : TOUJOURS DÉBRANCHER LA POMPE DE LA SOURCE D’ALIMENTATION ÉLECTRIQUE

AVANT DE LA MANIPULER. Le guide à la page suivante sert à aider à identifier les causes d'éventuels problèmes de

fonctionnement. Ce n'est pas un guide d'entretien. Le démontage de la pompe annulera la garantie. L'entretien de la pompe

pour effectuer des travaux autres que d'en nettoyer l'entrée ou le rotor doit être confié au fabricant ou à ses centres d'entretien

autorisés. REMARQUE : Liberty Pumps, Inc. n’est pas responsable des dommages ou blessures résultant d’un

démontage sur le terrain.

© Copyright 2016 Liberty Pumps Inc. Tous droits réservés 5

Page 19

Tableau de dépannage :

Problème

Cause

Solution

La pompe ne

fonctionne pas et

ne gronde pas.

Fusible brûlé ou autre

interruption d'alimentation,

tension inadéquate.

Si le fusible est brûlé, remplacer par un fusible de

la bonne intensité ou réarmer le disjoncteur; si la tension

est inférieure à 108 V, vérifier la grosseur des câbles.

Retirer la rallonge, le cas échéant.

Le niveau de l'eau du

puisard est trop bas pour

activer l'interrupteur.

Ajouter de l'eau dans le puisard.

Le contact ne se fait peut-

être pas entre le cordon

d'alimentation et la prise.

Vérifier la sécurité et les raccords. Si le réceptacle

d’alimentation électrique est corrodé, le faire remplacer

par un électricien agréé.

Les connecteurs siamois ne

sont peut-être pas bien

branchés.

Resserrer les connecteurs.

L'interrupteur est

défectueux (modèle S38

seulement).

Vérifier que le niveau d'eau est d'au moins 10,2 cm

(4 po) au-dessus de la pompe. Pour vérifier le

fonctionnement de l'interrupteur, brancher le cordon

d’alimentation électrique directement dans la prise

électrique en contournant le connecteur siamois. Si

la pompe fonctionne, il faut remplacer l'interrupteur.

(Consulter les procédures d'entretien de l'interrupteur à

la page 5).

Le bobinage du moteur peut

être ouvert.

Consulter le fabricant.

Obstruction de l'interrupteur

à flotteur (modèles S37 et

S38).

Le flotteur doit bouger librement. S'il est bloqué, retirer

les débris ou déplacer la pompe pour éviter la friction sur

les parois latérales du puisard.

La pompe tourne

ou gronde, mais

ne pompe pas

d'eau.

Le clapet antiretour est

peut-être installé à l'envers

ou défectueux.

S’assurer que la pompe est bien installée et que

le clapet de la soupape bouge librement.

La canalisation d’évacuation

peut être bloquée ou gelée.

S’assurer que la canalisation d’évacuation ne traverse

pas de zones froides et qu'elle n'est pas bloquée.

La charge ascensionnelle

dépasse la capacité de

la pompe.

Si possible, essayer d'abaisser la hauteur de

refoulement.

Le tamis d'entrée de

la pompe est bouché ou

le rotor est bloqué.

Retirer le filtre d'aspiration de la pompe et nettoyer

l'entrée et le rotor.

La pompe tourne

et pompe l'eau,

mais elle ne

s'éteint pas.

L'interrupteur est

défectueux ou obstrué.

S'assurer que l'interrupteur n'est pas bloqué ou

le remplacer au besoin.

La pompe a atteint ou

dépassé sa charge

ascensionnelle maximum.

Rediriger le tuyau à un niveau inférieur. Si c’est

impossible, il faut probablement se procurer une pompe

plus puissante.

La pompe tourne,

mais ne pompe

que très peu

d'eau.

La charge ascensionnelle

est près de la limite

maximum de la pompe, qui

est de 8,3 m (27 pi).

Si possible, essayer d'abaisser la hauteur de

refoulement.

L'entrée de la pompe est

partiellement obstruée.

Retirer la volute et vérifier que l'entrée ne contient pas

de débris.

La canalisation d'évacuation

est partiellement obstruée.

Retirer ce qui obstrue.

Le clapet antiretour ne

s'ouvre pas complètement.

Retirer ce qui obstrue ou s'assurer que le clapet

antiretour n'est pas défectueux.

© Copyright 2016 Liberty Pumps Inc. Tous droits réservés 6

Page 20

Le disjoncteur se

déclenche ou

le fusible saute

lorsque la pompe

se met en

marche.

La puissance du disjoncteur

ou du fusible n'est pas

suffisante.

Un disjoncteur de 15 ampères est nécessaire.

D'autres appareils

énergivores sont raccordés

au même circuit.

La pompe devrait avoir son circuit dédié.

La pompe est raccordée à

une rallonge, ou le câblage

est inadéquat.

Demander à un électricien de vérifier le câblage.

Interrupteur ou moteur

défectueux

Consulter le fabricant.

7000 Apple Tree Avenue

Bergen, NY 14416, É.-U.

Téléphone : (800) 543-2550

Télécopieur : (585) 494-1839

www.libertypumps.com

6. Garantie limitée de 3 ans

Liberty Pumps, Inc. garantit que les pompes sortant de son usine sont exemptes de tout défaut de matériau et de

fabrication pour une période de 3 ans à partir de la date d’achat. La date d'achat sera établie par une facture

d’achat datée indiquant les numéros de modèle et de série de la pompe. La pompe retournée doit être

accompagnée de la facture d’achat datée si la date de retour se situe à plus de 3 ans du numéro de « CODE »

(date de fabrication) indiqué sur la plaque signalétique de la pompe.

L’obligation de garantie du fabricant se limite à la réparation ou au remplacement de toute pièce jugée défectueuse

par le fabricant, à condition que la pièce ou l’appareil soit retourné franco de port au fabricant ou à son centre de

service autorisé et à condition qu’il n’y ait aucune preuve que les critères suivants annulant la garantie sont en

cause.

Le fabricant ne peut en aucun cas être tenu responsable, selon les dispositions de cette garantie, si le produit n’a

pas été correctement installé; s’il a été démonté, modifié, soumis à un usage abusif ou endommagé; si le cordon

électrique a été coupé, endommagé ou ligaturé; si la taille du tuyau d’évacuation de la pompe a été réduite; si

la pompe a été utilisée pour pomper de l’eau d'une température supérieure aux recommandations ci-dessus ou de

l’eau contenant du sable, de la chaux, du ciment, du gravier ou autres matières abrasives; si le produit a été utilisé

pour pomper des produits chimiques ou des hydrocarbures; si un moteur non submersible a été exposé à de

l’humidité excessive; ou si l’étiquette portant le numéro de série, de modèle et de code a été retirée. Liberty Pumps,

Inc. ne pourra être tenue responsable des pertes, dommages, frais attribuables à l’installation ou l’utilisation de ses

produits ni pour les dommages accessoires ou consécutifs, y compris les coûts de retrait, de réinstallation ou de

transport.

Il n’y a aucune autre garantie expresse. Toute garantie implicite, y compris celles de qualité marchande et

d'aptitude à une fin particulière est limitée à trois ans à partir de la date d’achat.

Cette garantie contient le recours exclusif de l’acheteur et exclut, lorsque permis par la loi, toute responsabilité pour

dommages consécutifs ou accessoires en vertu de toutes autres garanties.

© Copyright 2016 Liberty Pumps Inc. Tous droits réservés 7

Loading...

Loading...