Page 1

Pump Specifications

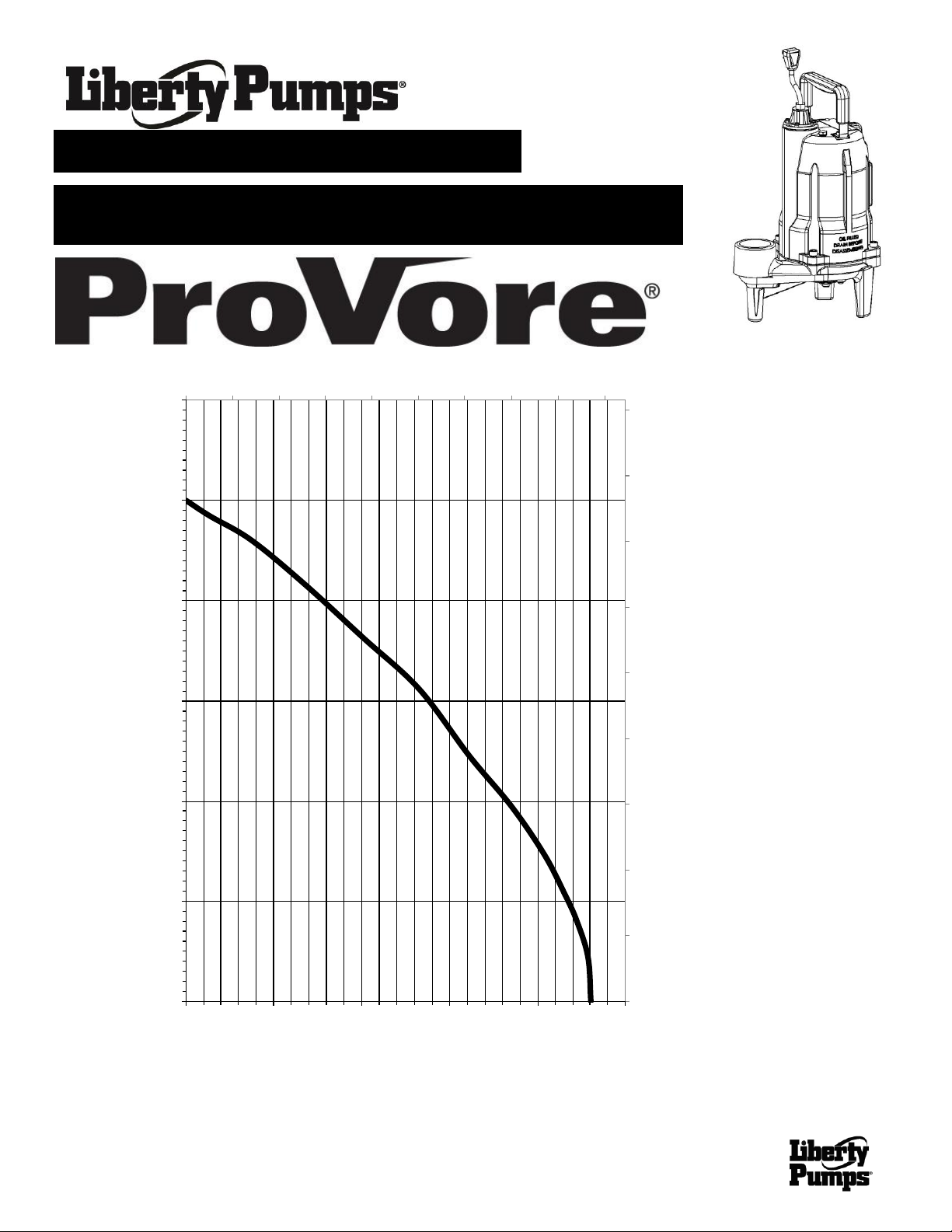

PRG - SERIES Residential Grinder Pump

0

2

4

6

8

10

12

14

16

18

0 20 40 60 80 100 120 140 160 180

0

10

20

30

40

50

60

0 10 20 30 40 50

TOTAL HEAD IN METERS

LITERS PER MINUTE

TOTAL HEAD IN FEET

GALLONS PER MINUTE

PRG100_ R11/16/2015 ©Copyright 2015 Liberty Pumps Inc. All rights reserved. Specifications subject to change without notice.

Page 2

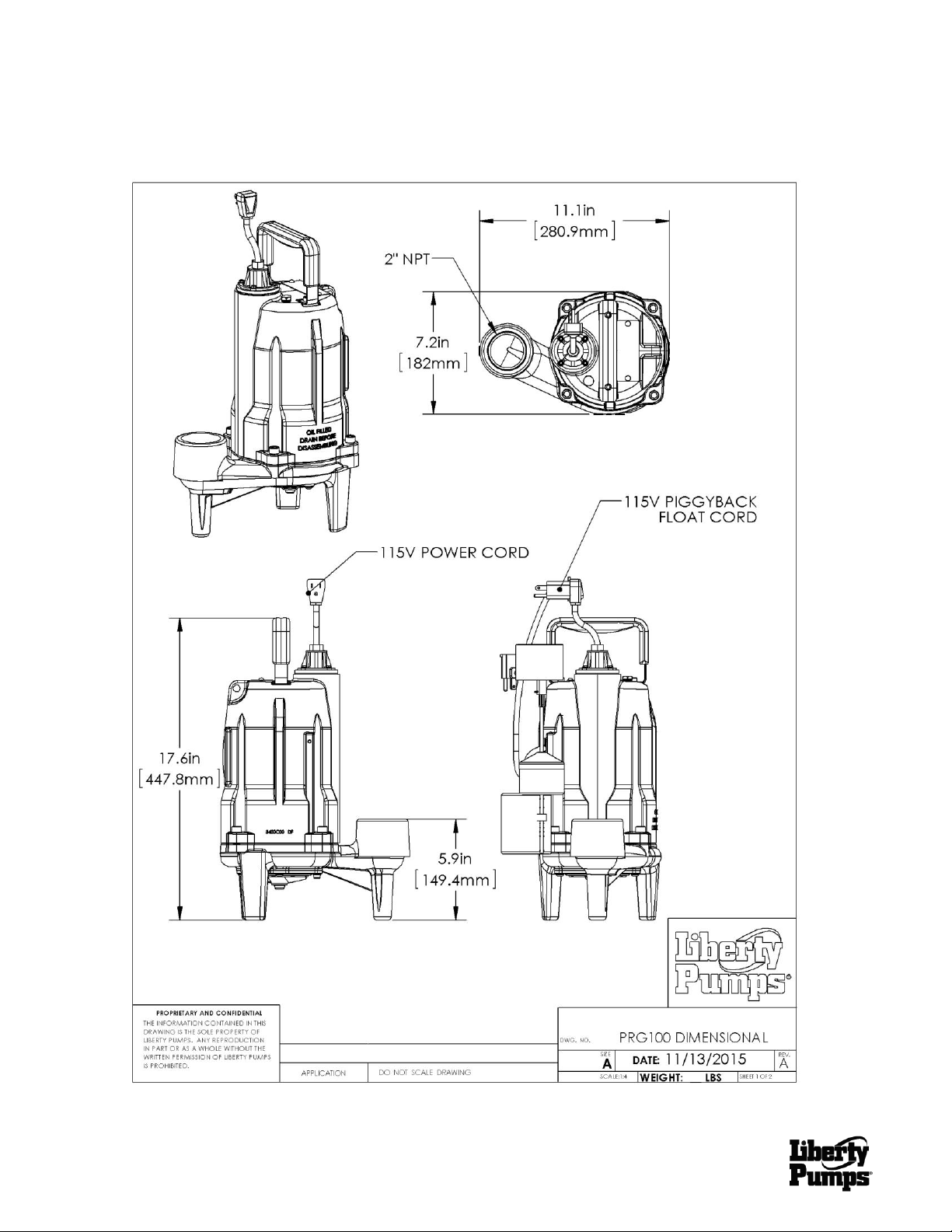

ProVore® PRG100 - Series Dimensional data

PRG100_ R11/16/2015 ©Copyright 2015 Liberty Pumps Inc. All rights reserved. Specifications subject to change without notice.

Page 3

PRG100_ R11/16/2015 ©Copyright 2015 Liberty Pumps Inc. All rights reserved. Specifications subject to change without notice.

Page 4

ProVore® PRG100 - Series Electrical data

MODEL

HP

VOLTAGE

PHASE

SF

FULL

LOAD

AMPS

LOCKED

ROTOR

AMPS

THERMAL

OVERLOAD

TEMP

STATOR

WINDING

CLASS

CORD

LENGTH

FT

DISCHARGE

AUTOMATIC

PRG101A

1

115

1

1.0

12

47.5

105˚C 221°F

B

10

2” NPT

WIDE ANGLE

PRG101A-2

1

115

1

1.0

12

47.5

105˚C 221°F

B

25

2” NPT

WIDE ANGLE

PRG101M

1

115 1

1.0

12 47.5

105˚C 221°F

B

10

2” NPT

NO

PRG101M-2

1

115 1

1.0

12 47.5

105˚C 221°F

B

25

2” NPT

NO

PRG101AV

1

115

1

1.0

12

47.5

105˚C 221°F

B

10

2” NPT

VERTICAL SWITCH

PRG101AV-2

1

115 1

1.0

12 47.5

105˚C 221°F

B

25

2” NPT

VERTICAL SWITCH

PRG102A

1

230

1

1.0 6 23.7

105˚C 221°F

B

10

2” NPT

WIDE ANGLE

PRG102A-2

1

230

1

1.0 6 23.7

105˚C 221°F

B

25

2” NPT

WIDE ANGLE

PRG102M

1

230 1

1.0

6 23.7

105˚C 221°F

B

10

2” NPT

NO

PRG102M-2

1

230 1

1.0

6 23.7

105˚C 221°F

B

25

2” NPT

NO

IMPELLER

CAST IRON

PAINT

POWDER COAT

MAX LIQUID TEMP

60˚C 140˚F

MAX STATOR TEMP

105˚C

THERMAL OVERLOAD

105˚C 221°F

DISCHARGE SIZE

2” FNPT

POWER CORD TYPE

SJTW

MOTOR HOUSING

CLASS 25 CAST IRON

VOLUTE

CLASS 25 CAST IRON

SHAFT

303 SERIES S.S.

HARDWARE

STAINLESS

ORINGS

BUNA N

MECHANICAL SEAL

UNITIZED SILICON CARBIDE

MIN BEARING LIFE

50,000 HRS

CUTTER / CUTTER PLATE

V-SLICE® DESIGN, 440 STAINLESS

STEEL ROCKWELL 58 C

ProVore® PRG100 - Series Technical Data

PRG100_ R11/16/2015 ©Copyright 2015 Liberty Pumps Inc. All rights reserved. Specifications subject to change without notice.

Page 5

ProVore® PRG100 - Series Specifications

1.01 OPERATING CONDITIONS:

Each submersible pump shall be rated at 1 hp_____ volts _______ phase 60 Hz. 3450 RPM. The unit shall produce ______G.P.M. at ______

feet of total dynamic head.

The submersible pump shall be capable of handling residential sewage and grinding it to a fine slurry, enabling it to be pumped over long

distances in pipelines as small as 1.25" in diameter. The PRG series single stage submersible pump shall have a shut-off head of 45 feet and

a maximum flow of 28 GPM @ 30 feet of total dynamic head.

The pump shall be controlled with:

______A piggy back style on/off float switch (Single Phase Only).

______A NEMA 4X outdoor simplex control panel with three float switches and a high water alarm.

______A NEMA 1 indoor simplex control panel with three float switches and a high water alarm.

______A NEMA 4X outdoor duplex control panel with three float switches and a high water alarm.

______A NEMA 1 indoor duplex control panel with three float switches and a high water alarm.

______A NEMA 4X outdoor duplex control panel with four float switches and a high water alarm.

______A NEMA 1 indoor duplex control panel with four float switches and a high water alarm.

2.01 CONSTRUCTION:

Each centrifugal grinder pump shall be equal to the certified PRG Series Grinder pumps as manufactured by Liberty Pumps, Bergen

NY. The castings shall be constructed of class 25 cast iron. The motor housing shall be oil filled to dissipate heat. Air filled motors shall not be

considered equal since they do not properly dissipate heat from the motor. All mating parts shall be machined and sealed with a Buna-N oring. All fasteners exposed to the liquid shall be stainless steel. The motor shall be protected on the top side with sealed cord entry plate with

molded pins to conduct electricity eliminating the ability of water to enter internally through the cord. The motor shall be protected on the lower

side with a unitized hard face silicon carbide seal with stainless steel housings and spring.

The upper and lower bearing shall be capable of handling all radial thrust loads. The lower bearing shall have the additional ability to handle

the downward axial thrust produced by the impeller and cutters. The pump shall be furnished with stainless steel handle having a nitrile grip.

3.01 ELECTRICAL POWER CORD

The submersible pump shall be supplied with 10 feet of multi-conductor power cord (25ft for PRG101/102A-2 models). It shall be cord type

SJTW (1-phase). The power cord shall be sized for the rated full load amps of the pump in accordance with the National Electric Code. The

power cable shall not enter the motor housing directly but will conduct electricity to the motor by means of a water tight compression fitting

cord plate assembly, with molded pins to conduct electricity. This will eliminate the ability of water to enter internally through the cord, by

means of a damaged or wicking cord.

4.01 MOTORS

Single phase motors shall be oil filled, capacitor start / capacitor run, class B insulated NEMA B design, rated for continuous duty. At

maximum load the winding temperature shall not exceed 105 degrees C unsubmerged. Since air filled motors are not capable of dissipating

heat they shall not be considered equal. Single phase pump motors shall have an integral thermal overload switch in the windings for

protecting the motor. On all single phase models, the capacitor circuit shall be mounted internally and motors shall have an integral solid state

starting circuit switch for switching the start winding off.

5.01 SEALS

The pump shall have a unitized silicon carbide hard face seal with stainless steel housings and spring equal to Crane Type T-6a.

PRG100_ R11/16/2015 ©Copyright 2015 Liberty Pumps Inc. All rights reserved. Specifications subject to change without notice.

Page 6

6.01 IMPELLER

The impeller shall be class 25 gray cast iron with pump out vanes on the back shroud to keep debris away from the seal area. It shall be

keyed and bolted to the motor shaft.

7.01 CUTTER MECHANISM

The cutter and plate shall be of the V-Slice® design and consist of 440 stainless steel with a Rockwell C hardness of 55-60. The stationary

cutter plate shall have specially designed orifices through it, which enable the slurry to flow through the pump housing at an equalized

pressure and velocity. The stationary cutter shall consist of V shapes to maximize cutting action and arc shape exclusion slots to outwardly

eject debris from under the rotary cutter. The rotary cutter shall have (2) blades and be designed with a recessed area behind the cutting edge

to prevent the accumulation and binding of any material between rotary cutter and the stationary cutter. The cutting system must incorporate

close tolerances for optimum performance. Ring or radial cutters, or those that grind on the outside circumference of shall not be considered

equal.

8.01 CONTROLS

All single phase units can be supplied with CSA and UL approved automatic wide angle tilt float or pre-assembled HD vertical switches. The

switches shall be equipped with piggy back style plug that allows the pump to be operated manually without the removal of the pump in the

event that a switch becomes inoperable. Manual Pumps are operable by means of a pump control panel.

9.01 PAINT

The exterior of the casting shall be protected with Powder Coat paint.

10.01 SUPPORT

The pump shall have cast iron support legs, enabling it to be a free standing unit. The legs will be high enough to allow solids and long stringy

debris to enter the cutter assembly.

11.01 SERVICEABILTY

Components required for the repair of the pump shall be shipped within a period of 24 hours.

12.01 TESTING

The pump shall have a ground continuity check and the motor chamber shall be Hi-potted to test for electrical integrity, moisture content and

insulation defects. The motor and volute housing shall be pressurized, and an air leak decay test is performed to ensure integrity of the motor

housing. The pump shall be run, voltage current monitored, and the tester checks for noise or other malfunction.

13.01 QUALITY CONTROL

The pump shall be manufactured in an ISO 9001 certified Facility.

14.01 WARRANTY

Standard limited warranty shall be 3 years.

PRG100_ R11/16/2015 ©Copyright 2015 Liberty Pumps Inc. All rights reserved. Specifications subject to change without notice.

Loading...

Loading...