Page 1

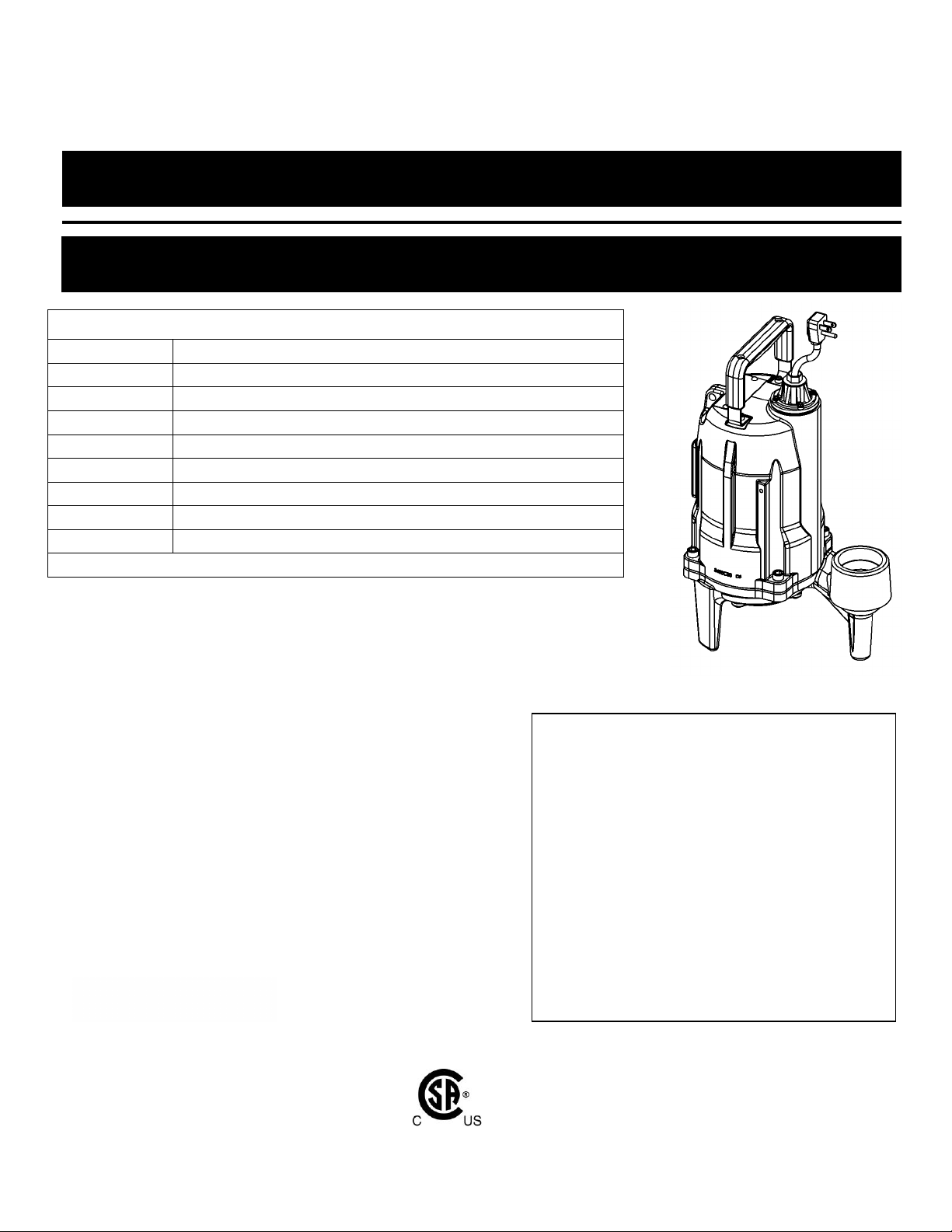

Models:

PRG101A

1 hp, 115V, 1 phase, Automatic Switch, 10’ Power cord

PRG101A-2

1 hp, 115V, 1 phase, Automatic Switch, 25’ Power cord

PRG101M

1 hp, 115V, 1 phase, 10’ Power cord

PRG101M-2

1 hp, 115V, 1 phase, 25’ Power cord

PRG102A

1 hp, 230V, 1 phase, Automatic Switch, 10’ Power cord

PRG102A-2

1 hp, 230V, 1 phase, Automatic Switch, 25’ Power cord

PRG102M

1 hp, 230V, 1 phase, 10’ Power cord

PRG102M-2

1 hp, 230V, 1 phase, 25’ Power cord

*Do not throw away or lose this manual.

Contents

General Information

Introduction

Mechanical Installation

Electrical Connection

Operation

Troubleshooting

Warranty

Installation Manual 2399000B

ProVore® Residential Grinder Pumps

IMPORTANT:

Prior to installation, record Model, Serial

Number, and Code Number from pump

nameplate for future reference.

MODEL _____________________

SERIAL _____________________

CODE _____________________

INSTALLATION

DATE _____________________

7000 Apple Tree Avenue

Bergen, NY 14416

Phone: (800) 543-2550

Fax: (585) 494-1839

www.libertypumps.com

©Copyright 2013 Liberty Pumps Inc. All rights reserved

Page 2

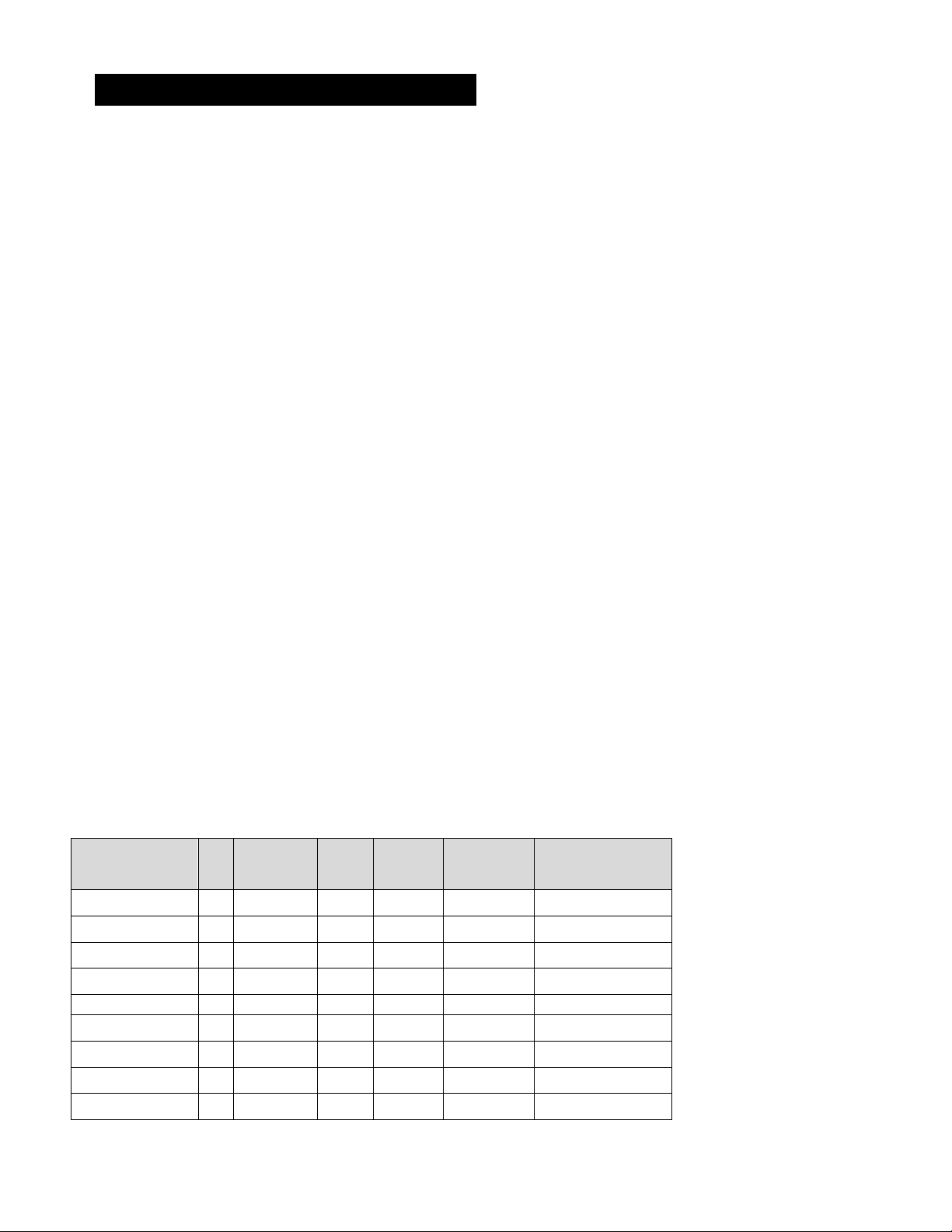

Model

HP

Volts

Phase

Full

Load

Amps

FNPT

Discharge

Automatic or

Manual*

PRG101A

1

115

1

12

2”

Automatic

PRG101A-2

1

115

1

12

2”

Automatic

PRG101M

1

115

1

12

2”

Manual

PRG101M-2

1

115

1

12

2”

Manual

PRG102A

1

230

1 6 2”

Automatic

PRG102A-2

1

230

1 6 2”

Automatic

PRG102M

1

230

1 6 2”

Manual

PRG102M-2

1

230

1 6 2”

Manual

1. X General Information X

Before installation, read the following instructions carefully. Each Liberty pump is individually factory tested to insure proper

performance. Closely following these instructions will eliminate potential operating problems, assuring years of trouble-free

service.

Risk of electric shock. Always disconnect the pump from the power source before handling or making

The electrical connections and wiring for a pump installation should only be made by qualified personnel.

This pump is supplied with a grounding conductor and grounding-type attachment plug. To reduce the risk of

DO NOT bypass grounding wires or remove ground prong from attachment plugs.

DO NOT use an extension cord.

This pump requires a separate, properly fused and grounded branch circuit. Make sure the power source is

The electrical outlet shall be within the length limitations of the pump power cord, and at least 4 feet above floor

The installation must be in accordance with the National Electric Code, Uniform Plumbing Code, International

Sump and sewage pumps often handle materials which could cause illness or disease. Wear adequate protective

Never enter a pump basin after it has been used. Sewage and effluent can emit several gases which are

Keep clear of suction and discharge openings. To prevent injury, never insert fingers into pump while it is

DO NOT use this product for flammable or corrosive liquid.

DO NOT use this product in applications where human contact with the pumped fluid is common (such as

NEVER dispose of materials such as paint thinner or other chemicals down drains, as they can chemically attack

DO NOT run pump dry, this product is intended to be partway submerged when operating.

Do not use these pumps in water over 140 F.

The Uniform Plumbing Code (UPC) states that sewage systems shall have an audio and visual alarm that signals

A 20 amp breaker is recommended for 115V pumps.

adjustments.

electric shock, be certain that it is connected only to a properly grounded, grounding-type receptacle.

properly sized for the voltage and amperage requirements of the pump, as noted on the nameplate.

level to minimize possible hazards from flood conditions.

Plumbing Code, as well as all applicable local codes and ordinances.

clothing when working on a used pump or piping.

poisonous.

plugged in.

swimming pools, fountains, etc.)

and damage pump components, potentially causing product malfunction or failure.

a malfunction of the system, to reduce the potential for property damage.

Note: Manual models (“M”

suffix), require a separate

approved pump control device or

panel for automatic operation.

Operation of these models will be

according to the control selected.

Make sure the electrical

specifications of the control

selected properly match the

electrical specifications of the

pump. Always refer to control

panel instructions for proper

installation.

©Copyright 2013 Liberty Pumps Inc. All rights reserved - 2 -

Page 3

2. x Introduction x

INTRODUCTION

This manual was prepared to assist you in the correct installation, operation, and maintenance of your Liberty

pump. Please read it completely before installing the pump. Make certain that you are familiar with the contents,

and the chapters on installation and operation are fully understood before running the pump.

Liberty Pumps are designed for minimal maintenance. However, regular checks will ensure longer life and

greater operating reliability.

WARRANTY: No repair work should be carried out during the warranty period without prior factory approval. To

do so may render the warranty void.

SERIAL #: In all correspondence and reports, make certain that the pump serial number is given.

DESIGN OF PUMP

The grinder pump contains metal parts that rotate at high speeds. Be careful around

pump base while power is connected. Make sure that the pump is either in the tank or

clear from people and wires when in operation.

1. Liberty ProVore® Series grinder pumps are designed for continuous underwater operation. The motor and

pump form a close coupled, watertight unit. The induction motor is insulated against heat and moisture, Class

B insulation.

2. A thermal overload protector is imbedded in the stator windings. This is connected in series and wired to shut

down the pump if overheating occurs. The overload switch resets automatically when the motor cools.

3. The motor is protected against damage from water entry by a mechanical type cartridge seal with two siliconcarbide faces.

4. The impeller and volute are designed for efficient flow characteristics and clog-free operation. The hardened

cutters grind solids and fibrous matter into small particles that can be safely pumped through small diameter

piping.

5. For sewage systems, consult local plumbing codes on requirements for venting the tank. The pump shall not

be installed in locations classified as hazardous in accordance with the National Electrical Code, ANSI/

NFPA70.

NOTE: The primary material of the Liberty PRG Series Pumps is cast iron, elastomers are Buna-N. They

should not be used to pump corrosive liquids.

3. X Mechanical Installation x

INSPECTION UPON RECEIPT

The shipping container should be immediately inspected for damage that may have occurred in shipment.

Exercise care in opening the shipping container to avoid damage to the pump. Remove any blocking and

cushioning from within the container.

Check all cushioning for spare parts before discarding. Visually check the pump and any spare parts for damage.

Check for damaged electrical wires, especially where they exit the motor housing. Contact the Liberty Pumps

Customer Service Department to report any damage or shortage of parts. The cutter located on the bottom of the

unit should be turned several rotations with the use of a 6 mm hex wrench, it should rotate freely without rubbing

on the cutter plate. This will insure that the impeller and cutter are free of any seizure due to prolonged storage.

If the impeller is not rotated manually prior to installation, the pump may fail to activate. If the impeller’s rotation is

difficult or completely resistant, contact the Liberty Pumps Customer Service Department.

©Copyright 2013 Liberty Pumps Inc. All rights reserved - 3 -

Page 4

STORAGE BEFORE USE

Liberty pumps are shipped from the factory ready for installation and use. They should be held in storage if the

pump station is not complete. If storage is necessary, the pump should remain in its shipping container. It should

be stored in a warehouse or storage shed that has a clean, dry temperature-stable area where the pump and its

container should be covered to protect it from water, dirt, dust, etc. The ends of the cables - (plugs) must be

protected against moisture.

AT NO TIME SHOULD THE PUMP BE STORED WITHIN AN INCOMPLETE WET PIT. THE PUMP

SHOULD NOT BE PLACED INTO THE PIT UNTIL IT CAN BE FULLY OPERATED.

LONG TERM STORAGE

1. If it is necessary to store a pump for a long period of time, it should be stored indoors in a clean, dry

temperature-stable environment. The pump should be covered to protect it from dust, dirt and water. The

plug end of the cable must be protected against moisture.

2. Do not allow the pump to freeze.

3. Prior to installation, the pump motor should be rotated to ensure the seals and cutters are free spinning.

4. Installed pumps which are idle for long periods of time should be manually operated through the breaker

panel once a month to lubricate the seals. Turn off the breaker, unplug the piggyback switch, and plug the

pump directly into the wall socket. Turn the breaker on for 30 seconds. Turn the breaker off, and then plug

the piggyback switch back in.

4. x The Basin x

The basin required for both effluent and sewage applications must be sealed and vented to meet health and

plumbing code requirements. These pumps are not to be installed in locations classified as hazardous in

accordance with the National Electric Code, ANSI/NFPA 70. The diameter should be a minimum of 18" and the

depth a minimum of 24". (These are minimum requirements. A larger basin may be required in both effluent and

sewage applications depending on local codes and the number of fixture units entering the system. Check with the

local authorities or contact Liberty Pumps if you are unsure of the proper basin size.) Installation should be at a

sufficient depth to ensure that all plumbing is below the frost line. If this is not feasible, remove the check valve and

size the basin and/or adjust pump differential to accommodate the additional backflow volume.

A. Excavation: Excavate the hole as small as possible, with a minimum recommended 8" diametrical clearance

around the tank. Never place the basin directly in contact with rocks or other sharp objects. Place only fine,

1/8" to 3/4" pea gravel or 1/8" to 1/2" washed, crushed stone as bedding between the basin and the hole

walls. Do not use sand or native soil as backfill. Properly compact underneath the basin to provide a solid,

level base that can support the weight of the filled basin.

B. Inlet Connection & Initial Backfill: Only fine, 1/8" to 3/4" pea gravel or 1/8" to 1/2" washed, crushed stone

should be used around the bottom of the basin to hold it in place. Do not use sand or native soil as backfill.

Make the inlet connection as required for your basin.

Liberty P380, & P680: The Liberty Pro Series basins have a 4" inlet molded to the side of the tank. This inlet

is sized to accept a 4" no-hub type coupling. Connect the gravity drainage line from

the fixtures to this hub.

Other Basins: Other Liberty basins provide a 4" caulking hub or pipe grommet inlet. Hubs utilize

caulking material or rubber donuts; grommets are a simple slip-fit. Connect the

gravity drainage line from the fixtures to this opening. (Other inlet sizes available –

consult factory.)

C. Final Backfill: Large rocks, clods, and foreign objects should be kept out of the backfill material. Only fine,

1/4" to 3/4" pea gravel, or 1/8" to 1/2" washed, crushed stone is recommended. Do not use sand or native

soil as backfill. Mound the backfill slightly and allow for natural settling. Provide access to the basin cover for

maintenance and service.

Do not exert heavy pressure or run heavy equipment on the backfill material as this could cause

the tank to collapse.

©Copyright 2013 Liberty Pumps Inc. All rights reserved - 4 -

Page 5

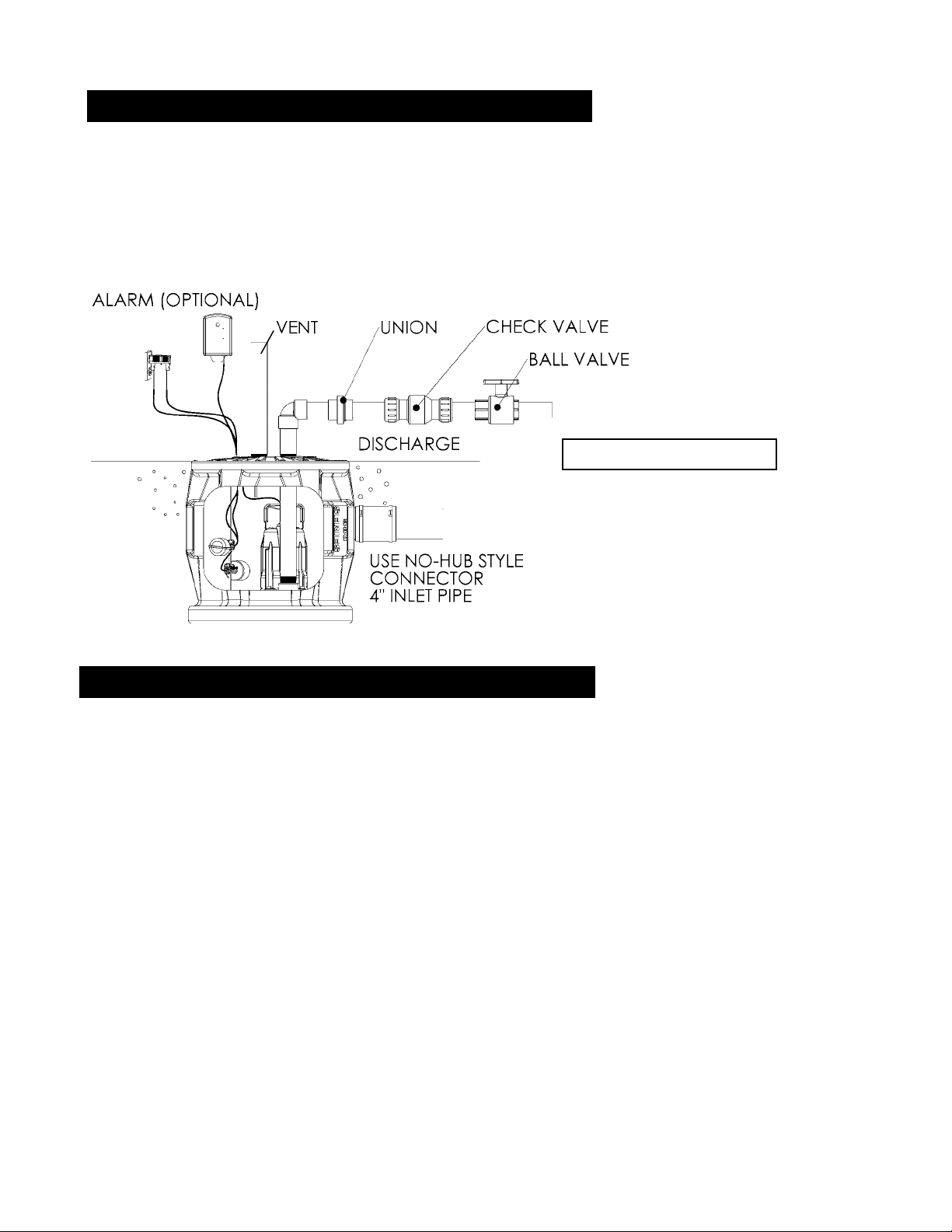

Typical simplex installation

5. X Installation of the Pump x

THIS PUMP IS NOT TO BE INSTALLED IN LOCATIONS CLASSIFIED AS HAZARDOUS IN

ACCORDANCE WITH THE NATIONAL ELECTRICAL CODE,ANSI/NFPA 70.

Grinder pumps must be installed in a tank that is vented in accordance with local plumbing codes.

Installation should be at a sufficient depth to ensure that all plumbing is below the frost line. If this is not feasible,

remove the check valve and size the basin and/or adjust pump differential to accommodate the additional

backflow volume. Consult the factory for details on how this should be done.

6.x Electrical Service & Operation x

Risk of electric shock. Always disconnect the pump from the power source before handling or making

adjustments.

The electrical connections and wiring for a pump installation should only be made by qualified personnel.

This pump is supplied with a grounding conductor or a grounding type attachment plug. To reduce the risk of

electric shock, be certain that the grounding conductor is connected only to a properly grounded control panel

or, if equipped with a grounding type plug that it is connected to a properly grounded, grounding type

receptacle.

DO NOT bypass grounding wires or remove ground prongs from attachment plugs.

DO NOT remove cord and strain relief and DO NOT connect conduit to pump.

DO NOT use an extension cord.

This pump requires separate, properly fused and grounded branch circuit. Make sure the power source is

properly sized for the voltage and amperage requirements of the motor, as noted on the pump nameplate.

The electrical outlet or panel shall be within the length limitations of the pump power cord, and at least 4 feet

above floor level to minimize possible hazards from flood conditions.

The installation must be in accordance with the National Electric Code and all applicable local codes and

ordinances.

When the risk of property damage from high water levels exists, an independent high water

alarm should be installed. A duplex pumping system is recommended for critical installations.

©Copyright 2013 Liberty Pumps Inc. All rights reserved - 5 -

Page 6

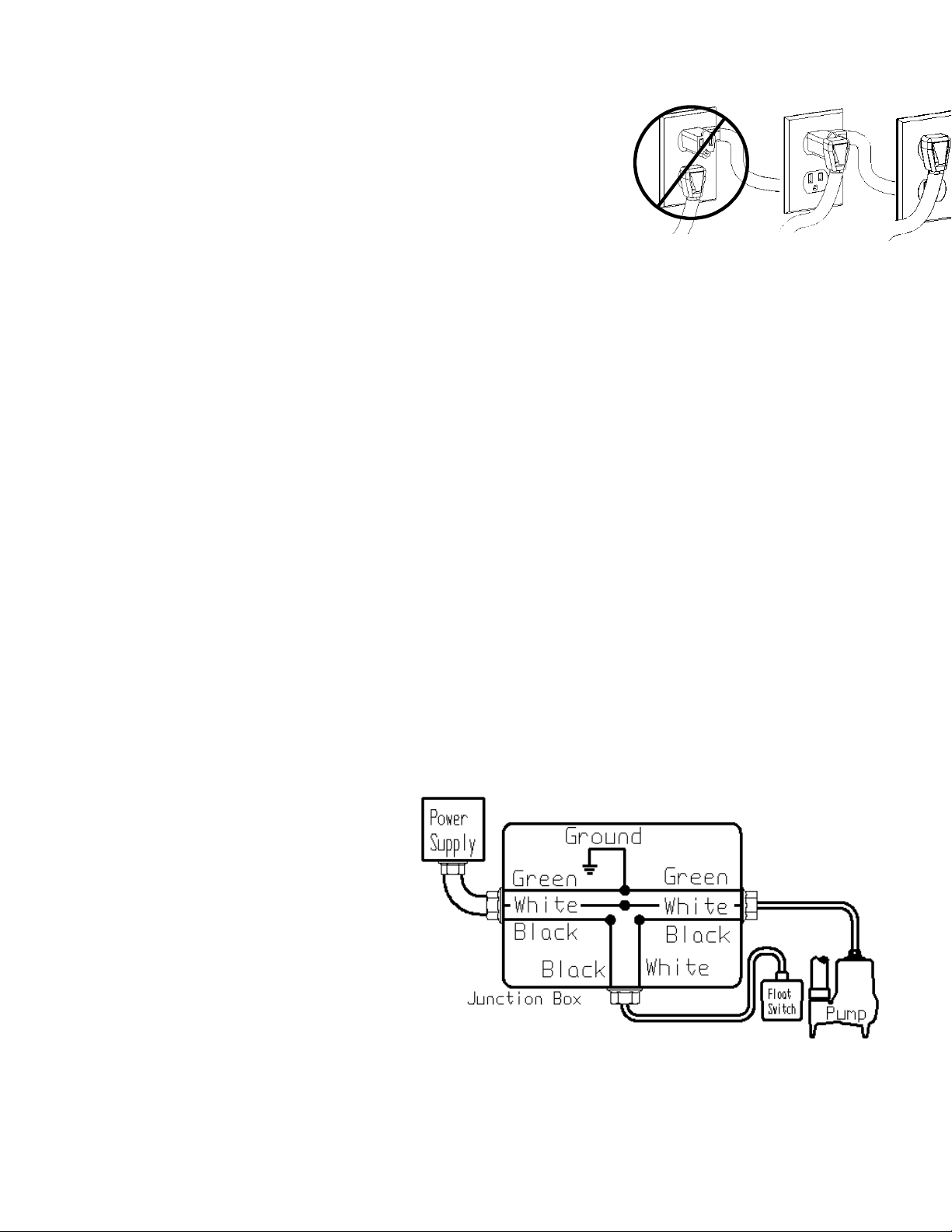

Direct Wiring of 115V or 230V,

Single Phase, Automatic Pumps

TEMPORARY

MANUAL

OPERATION

DO!

DON’T!

Fig. 4 Piggyback plug installation.

Figure C – Direct wiring of 115V or 208-230V, single

phase, automatic pumps.

All "A" models (automatic pumps) come factory-equipped with a

float switch mounted to the pump. These models come with two

cords - one to the float switch and the other to the pump motor.

The switch cord has a series (piggyback) plug enabling the pump

(motor) cord to be plugged into the back of it (see Fig. 4). The

purpose of this design is to allow manual operation of the pump.

Note, on / off operation of the pump must be controlled by the

circuit breaker.

For automatic operation using Liberty's supplied switch, the two cords should be interconnected and plugged

into a separately fused, grounded outlet of proper amp capacity for your selected pump model. (See Section 1,

General Information, or the pump nameplate for electrical specifications of your model.) Both cords are equipped

with 3-prong plugs and must be plugged into a properly grounded 3-wire receptacle. DO NOT REMOVE THE

GROUND PRONGS.

In the event of switch failure, the pump cord can be separated and plugged into the electrical outlet, directly

bypassing the switch. For 115V and 230V single phase pumps should only be operated without the float switch by

using the circuit breaker or panel disconnect. Do not let the pump run dry.

The turn-on level of automatic "A" models is approximately 12" to 16" above the bottom of the basin. The turn-off

level is approximately 6" above the bottom of the basin. Other pumping differentials may be obtained by tethering

the switch cord to the discharge pipe. NOTE: A minimum cord length of 3.5" from the tether point to the top

surface of the float is required for proper switch operation. If using a differential other than the factory setting, be

sure when the pump shuts off at least 6" of fluid is left in the basin so the impeller remains submerged.

PRG Series pump models with an "M" designation are manual models with no switch. They are intended to

be run using an approved liquid level control or approved motor control with correct rating that matches motor

input in full load amperes. 3-phase models require the use of an approved motor control that matches motor input

in full load amperes with overload element(s) selected or adjusted in accordance with control instructions.

Automatic operation with optional control devices: If the pump(s) are to be operated by either a simplex or

duplex control panel, or other optional control device, follow the installation instructions provided with your specific

control and make the power connections per those instructions. If necessary, certain models may be run without

a separate control. 230V single-phase pumps should only be operated without the float switch by using the circuit

breaker or panel disconnect. Do not let the pump run dry.

ProVore® "A" and "M" models: If the pump is to be wired directly into a control device or junction box, and it is

necessary to remove the plugs, have a certified electrician do the wiring in accordance with the National Electric

Code and applicable local codes. See Fig. 5 for direct wire installation of single phase, automatic pumps.

In 230V installations,

one side on the line

going to the pump is

always “hot”, whether

the float switch is on or

off. To avoid hazards,

install a double pole

disconnect near the

pump installation.

©Copyright 2013 Liberty Pumps Inc. All rights reserved - 6 -

Page 7

STEPS TO BE TAKEN BEFORE ENERGIZING

1. Retighten all field-made connections. Retighten all factory-made connections. These may have loosened

due to shipping and handling vibrations.

2. Check the security of mounting hardware.

3. Check the enclosure to see that it has not been damaged in such a manner as to reduce electrical spacing.

4. Rotate the cutter wheel with the hex socket head cap screw to verify movement and lubricate the seals.

5. Ensure that no wires or other obstacles are in the way of the pump cutter.

6. MOTOR OVERLOAD PROTECTION: The pump motor is protected from locked rotor and running overloads

by a thermal overload integrally mounted to the motor. No adjustments are required.

7. Check to determine that all grounding connections are made properly

If a panel is used, remove all debris, scrap wire, etc., from the control panel interior before closing the

doors. Install covers, close doors making certain that no wires are pinched and that all enclosure parts

are properly aligned and tightened.

ENERGIZING THE CONTROL PANEL OR BREAKER FOR THE FIRST TIME IS

POTENTIALLY DANGEROUS. LICENSED ELECTRICAL PERSONNEL SHOULD BE

PRESENT WHEN THE PANEL OR BREAKER IS ENERGIZED FOR THE FIRST TIME. IF

FAULTS CAUSED BY DAMAGE OR POOR INSTALLATION PRACTICES HAVE NOT BEEN

DETECTED, SERIOUS DAMAGE CAN RESULT WHEN POWER IS APPLIED (REFER TO

SECTION 5).

FLOAT SWITCHES

1. The pump's on and off cycles are normally controlled by a "piggy back" float switch attached to the side of the

pump, or by hanging switches in the wet well. Refer to panel or switch instructions for proper electrical

connection

FLOAT SEQUENCE- PIGGY BACK SWITCH (AUTOMATIC MODELS)

1. As the liquid level in the wet well rises, the float tilts, closing the switch. This starts the pump.

2. The pump runs until the liquid level falls to the “PUMP OFF” level of the float (Factory set - 6" minimum).

FLOAT SEQUENCE- SIMPLEX CONTROL PANEL (MANUAL MODELS)

1. As the liquid level in the wet well rises, the “PUMP OFF” float tilts, closing the switch (This level must be set at

a minimum of 6"). As the liquid level continues to rise, the “PUMP ON” float tilts. This switch closes, starting

the pump.

2. The pump runs until the liquid level falls below the “PUMP OFF” float, emptying the wet well.

3. In the event of a malfunctioning float switch, control relay or pump, the liquid level rises and tilts the “HIGH

LEVEL ALARM” float. The alarm system will activate.

FLOAT SEQUENCE-DUPLEX CONTROL PANEL (MANUAL MODELS)

1. As the liquid level in the wet well rises, the “PUMP OFF” tilts, closing the switch. As the liquid level continues

to rise, the “LEAD PUMP ON” float tilts. This switch closes, starting the lead pump. The pump runs until the

liquid level falls below the “PUMP OFF” float (6” minimum), emptying the wet well.

2. On the next rise of the liquid level, the other pump will start on the “LEAD PUMP ON” signal. The pumps will

continue to alternate their cycles.

NOTE: The ON/OFF float switch differential should be set as to not exceed 12 starts per hour.

3. If the liquid level rises to the “LAG PUMP ON" float, the second pump will start. Both pumps will run until the

liquid falls below the “PUMP OFF” float, emptying the wet well.

4. In the event of a malfunctioning float switch, control relay or pump, the liquid level rises and tilts the “HIGH

LEVEL ALARM” float. The alarm system will activate.

©Copyright 2013 Liberty Pumps Inc. All rights reserved - 7 -

Page 8

FLOAT SWITCH INSTALLATION

The engineering drawings will normally specify the levels for pump start and stop and high level alarm. If

they are not specified, these guidelines should be used to determine float switch locations.

PIGGY BACK SWITCH

(1-Float System)

Pump Off: Factory set. (Float tether 3.5")

Pump On: Factory set. (Float tether 3.5")

SIMPLEX PUMP STATION

(3-Float System)

Pump Off: Level to top of motor housing.

Pump On: Minimum 1-1/2 ft. above Pump Off Level.

High Level Alarm: Minimum 1 ft. above pump ON level. Below influent pipe.

DUPLEX PUMP STATION

(4-Float System)

Pump Off: Level to top of motor housing.

Lead Pump On: Minimum 1-1/2 ft. above Pump Off level.

Lag Pump On: Minimum 1 ft. above Lead Pump On level.

High Level Alarm: Minimum 1 ft. above Lag Pump On level. Below influent pipe.

©Copyright 2013 Liberty Pumps Inc. All rights reserved - 8 -

Page 9

5

Operation

7. x Operation x

OPERATION

After the electrical and mechanical installations have been performed, the pump is ready for operation. No

operational procedures are required except to apply rated power to the pump. There are no specific shutdown

procedures beyond disconnecting the power supply.

IF THE ROTATION OF A SINGLE PHASE PUMP IS INCORRECT, NOTIFY THE LIBERTY PRODUCT

SERVICE DEPARTMENT IMMEDIATELY. DO NOT SWITCH THE POWER SUPPLY LEADS. DO NOT

OPERATE THE PUMP.

ALWAYS ENSURE THAT THE PUMP IS FREE OF WIRES OR OTHER OBSTRUCTIONS THAT MAY CAUSE

HARM OR INJURY.

PERIODIC MAINTENANCE & LUBRICATION

Liberty pumps are designed for long lasting, efficient and reliable service with a minimum of preventive

maintenance checks. These checks are few but will add years of satisfactory service to the life of the pump

LUBRICATION

Pump is permanently lubricated and cooled by turbine oil. If replacement oil is required, use ISO-10 turbine oil.

Capacity .5 gallons.

©Copyright 2013 Liberty Pumps Inc. All rights reserved - 9 -

Page 10

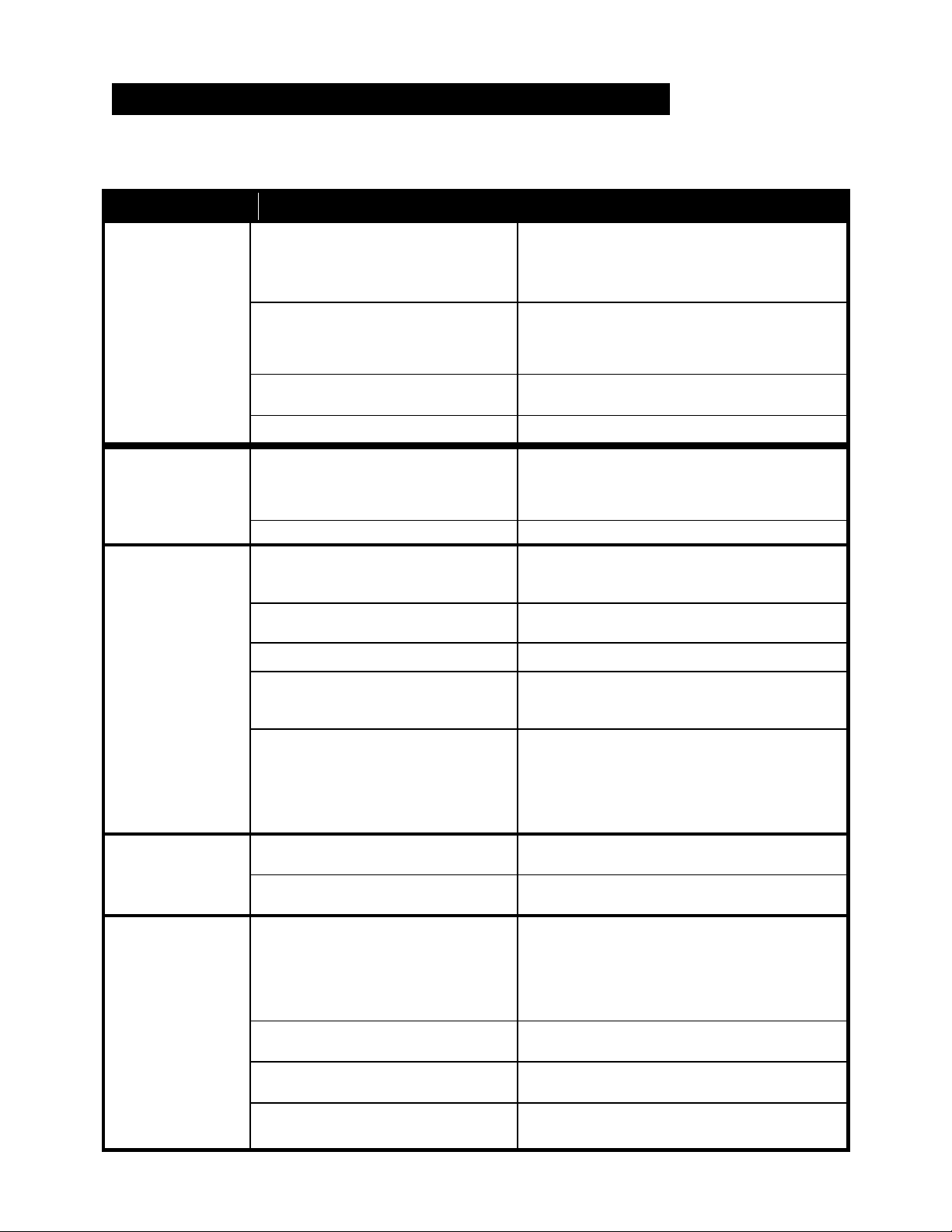

Problem

Cause

Correction

Pump will not run.

Blown fuse or other interruption of

power; improper voltage.

Check that the unit is securely plugged in.

Have an electrician check all wiring for proper

connections and adequate voltage and

capacity.

Switch is unable to move to the

“turn on” position due to

interference with the side of basin

or other obstruction

Position the pump or switch so that it has

adequate clearance for free operation.

Insufficient liquid level.

Make sure the liquid level is allowed to rise

enough to activate switch(s).

Defective switch.

Remove and replace switch.

Pump will not turn

off.

Switch(s) unable to move to the

“turn off” position due to

interference with the side of basin

or other obstacle.

Position the pump or switch so that it has

adequate clearance for free operation.

Defective switch.

Remove and replace switch.

Pump runs or hums,

but does not pump.

Discharge is blocked or restricted.

Check the discharge line for foreign material,

including ice if the discharge line passes

through or into cold areas.

Check valve is stuck closed or

installed backwards.

Remove check valve(s) and examine for

freedom of operation and proper installation.

Gate or ball valve is closed.

Open gate or ball valve.

Total lift is beyond pump's

capability.

Try to route piping to a lower level. If not

possible, a larger pump may be required.

Consult the factory.

Pump impeller is jammed or volute

casing is plugged.

Remove the pump from the basin, remove

cutter and cutter plate clean the area around

the impeller. Reassemble and reinstall. The

center screw uses a 6mm hex drive. The screw

can be heated to remove thread locking

compound

Pump runs

periodically when

fixtures are not in

use.

Check valve was not installed, is

stuck open or is leaking.

Remove check valve(s) and examine for

freedom of operation and proper installation.

Fixtures are leaking.

Repair fixtures as required to eliminate leakage.

Pump operates

noisily.

Foreign objects in the impeller

cavity.

Remove the pump from the basin, remove

cutter and cutter plate clean the area around

the impeller. Reassemble and reinstall. The

center screw uses a 6mm hex drive. The screw

can be heated to remove thread locking

compound

Broken impeller.

Consult the factory for information regarding

replacement of impeller.

Worn bearings.

Return pump to the factory or authorized repair

station for repair.

Piping attachments to building are

too rigid.

Replace a portion of the discharge line with

rubber hose or connector.

8. X Maintenance and Troubleshooting x

Risk of electric shock. Always disconnect the pump from the power source before handling or making

adjustments.

This pump has an oil filled motor enclosure, drain oil before removing the four cover screws.

©Copyright 2013 Liberty Pumps Inc. All rights reserved - 10 -

Page 11

7000 Apple Tree Avenue

Bergen, NY 14416

Phone: (800) 543-2550

Fax: (585) 494-1839

www.libertypumps.com

9. x 3 Year Limited Warranty x

Liberty Pumps, Inc. warrants that pumps of its manufacture are free from all factory defects in material and

workmanship for a period of 3 years from the date of purchase. The date of purchase shall be determined by a

dated sales receipt noting the model and serial number of the pump. The dated sales receipt must accompany

the returned pump if the date of return is more than 3 years from the "CODE" (date of manufacture) number noted

on the pump nameplate.

The manufacturer's obligation under this Warranty shall be limited to the repair or replacement of any parts found

by the manufacturer to be defective, provided the part or assembly is returned freight prepaid to the manufacturer

or its authorized service center, and provided that none of the following warranty-voiding characteristics are

evident.

The manufacturer shall not be liable under this Warranty if the product has not been properly installed; if it has

been disassembled, modified, abused or tampered with; if the electrical cord has been cut, damaged or spliced;

if the pump discharge has been reduced in size; if the pump has been used in water temperatures above the

advertised rating, or water containing sand, lime, cement, gravel or other abrasives; if the product has been used

to pump chemicals or hydrocarbons; if a non-submersible motor has been subjected to excessive moisture; or if

the label bearing the serial, model and code number has been removed. Liberty Pumps, Inc. shall not be liable

for any loss, damage or expenses resulting from installation or use of its products, or for consequential damages,

including costs of removal, reinstallation or transportation.

There is no other express warranty. All implied warranties, including those of merchantability and fitness for a

particular purpose, are limited to three years from the date of purchase.

This Warranty contains the exclusive remedy of the purchaser, and, where permitted, liability for consequential or

incidental damages under any and all warranties are excluded.

©Copyright 2013 Liberty Pumps Inc. All rights reserved - 11 -

Page 12

Modelos:

PRG101A

1 hp, 115 V, monofásica, interruptor automático,

cordón eléctrico de 10 pies (3 m)

PRG101A-2

1 hp, 115 V, monofásica, interruptor automático,

cordón eléctrico de 25 pies (3 m)

PRG101M

1 hp, 115 V, monofásica, cordón eléctrico de 10 pies (3 m)

PRG101M-2

1 hp, 115 V, monofásica, cordón eléctrico de 25 pies (8.3 m)

PRG102A

1 hp, 230V, monofásica, interruptor automático,

cordón eléctrico de 10 pies (3 m)

PRG102A-2

1 hp, 230 V, monofásica, interruptor automático,

cordón eléctrico de 25 pies (8.3 m)

PRG102M

1 hp, 230 V, monofásica, cordón eléctrico de 10 pies (3 m)

PRG102M-2

1 hp, 230 V, monofásica, cordón eléctrico de 25 pies (8.3 m)

*No tire ni pierda este manual.

Manual de instalación 2399000B

Bombas trituradoras residenciales ProVore®

IMPORTANTE:

Antes de instalar la bomba, apunte el modelo,

el número de serie y el código que aparecen

en la placa de identificación de la bomba para

que le sirvan de referencia en el futuro.

MODELO _______________________

No. SERIE _______________________

CÓDIGO _______________________

FECHA DE

INSTALACIÓN _______________________

7000 Apple Tree Avenue

Bergen, NY 14416

Teléfono: +1-800-543-2550

(Solo EE.UU.)

Fax: +1-585-494-1839

www.libertypumps.com

Índice

Información general

Introducción

Instalación mecánica

Conexión eléctrica

Operación

Diagnóstico de problemas

Garantía

©Copyright 2013 Liberty Pumps Inc. Todos los derechos reservados

Page 13

1. X Información general X

Modelo

HP

Voltios

Fase

Amperios a

carga total

Descarga de la rosca

hembra FNPT

Automático o

manual*

PRG101A

1

115

1

12

5.08 cm (2 pulg.)

Automática

PRG101A-2

1

115

1

12

5.08 cm (2 pulg.)

Automática

PRG101M

1

115

1

12

5.08 cm (2 pulg.)

Manual

PRG101M-2

1

115

1

12

5.08 cm (2 pulg.)

Manual

PRG102A

1

230

1 6 5.08 cm (2 pulg.)

Automática

PRG102A-2

1

230

1 6 5.08 cm (2 pulg.)

Automática

PRG102M

1

230

1 6 5.08 cm (2 pulg.)

Manual

PRG102M-2

1

230

1 6 5.08 cm (2 pulg.)

Manual

PRECAUCIÓN

ADVERTENCIA

Lea con atención estas instrucciones antes de instalar la unidad. Todas las bombas de Liberty se someten individualmente a

pruebas en fábrica para garantizar un funcionamiento adecuado. Siga estas instrucciones al pie de la letra para prevenir

problemas de funcionamiento y asegurar años de servicio satisfactorio.

Riesgo de descarga eléctrica. Desconecte la bomba de la fuente de alimentación siempre que vaya a manipularla

o a realizar algún ajuste.

Solo personal cualificado deberá encargarse de instalar las conexiones y cables eléctricos necesarios para montar

la bomba.

Esta unidad viene con un conductor de conexión a tierra y un enchufe de toma a tierra. Conecte la bomba a un

tomacorriente a tierra debidamente conectado a tierra para evitar el riesgo de descargas eléctricas.

NO derive los cables de puesta a tierra ni retire las clavijas a tierra de los enchufes.

NO use cables de extensión.

Con esta bomba hay que utilizar un circuito derivado independiente, debidamente conectado tierra y con fusibles

adecuados. Asegúrese que la fuente de potencia tenga suficiente capacidad para cumplir los requisitos de voltaje y

amperaje indicados en la placa de la bomba.

El tomacorriente deberá encontrarse al alcance del cable de alimentación de la bomba y a 1.2 metros como mínimo

por encima del piso para evitar problemas en caso de inundación.

Se deberá instalar la unidad según las disposiciones del Código eléctrico nacional (NEC, por sus siglas en inglés),

el Código unificado de plomería, el Código internacional de plomería, y todos los códigos y regulaciones locales que

correspondan.

Las bombas de drenaje y de alcantarillado a menudo manejan materiales capaces de provocar enfermedades. Use

ropa protectora adecuada cuando trabaje en una bomba o una tubería usada.

Nunca ingrese a una cubeta de bomba después que haya sido usada. Los sistemas de efluentes y de alcantarillado

pueden emitir diferentes tipos de gases tóxicos.

Manténgase alejado de la entrada de succión y de la salida de descarga. Para evitar lesiones, nunca introduzca los

dedos en la bomba mientras ésta se encuentre conectada.

NO use este producto para líquidos inflamables o corrosivos.

NO use este producto en aplicaciones en las que el contacto humano con el fluido bombeado sea común (por

ejemplo, piscinas, fuentes, etc.).

NUNCA deseche por el drenaje materiales como solvente para pintura u otros químicos, ya que pueden llegar a

atacar y dañar los componentes de la bomba y potencialmente causar que el equipo no funcione bien o deje de

funcionar.

NO haga funcionar la bomba seca; este producto está diseñado para estar parcialmente sumergido al operar.

La bomba no se debe utilizar con agua por encima de los 60 C (140 ° F).

El Código uniforme de plomería (UPC) de Estados Unidos exige que todos los sistemas de saneamiento dispongan

de una alarma visual y sonora que indique averías del sistema con el fin de evitar daños a la propiedad.

Para las bombas de 115 V se recomienda un disyuntor de 20 A.

Nota: Los modelos manuales

(con el sufijo "M") requieren un

dispositivo o panel de control

por separado, aprobado para

funcionar automáticamente.

El funcionamiento de estos

modelos dependerá del control

seleccionado. Asegúrese que

las especificaciones eléctricas

del control seleccionado

correspondan con las

especificaciones eléctricas de la

bomba. Instale el panel de

control según las instrucciones

correspondientes.

©Copyright 2013 Liberty Pumps Inc. Todos los derechos reservados - 2 -

Page 14

2. X Introducción X

ADVERTENCIA

INTRODUCCIÓN

El propósito de este manual es ayudarle a instalar, operar y mantener la bomba Liberty de manera correcta.

Léalo completamente antes de instalar el sistema. Antes de poner la bomba en funcionamiento, asegúrese de

entender todo el contenido, incluidos los capítulos sobre instalación y operación.

Las bombas Liberty requieren un mantenimiento mínimo. Sin embargo, para que duren el mayor tiempo posible y

funcionen sin problemas es importante revisarlos con regularidad.

GARANTÍA: Durante el período de garantía no se podrá llevar a cabo ninguna reparación sin la aprobación de la

fábrica. De lo contrario, la garantía podría resultar nula.

NÚMERO DE SERIE: Incluya el número de serie de la bomba en los informes y demás correspondencia.

DISEÑO DE LA BOMBA

La bomba trituradora contiene piezas de metal que giran a gran velocidad.

Tenga cuidado con la base de la máquina cuando la electricidad esté conectada.

Cuando esté en funcionamiento, la bomba deberá encontrarse dentro del tanque

o alejada de personas y cables.

1. La serie de bombas trituradoras Liberty ProVore® ha sido diseñada para funcionar continuamente bajo el

agua. El motor y la bomba forman una unidad perfectamente acoplada y estanca. El motor de inducción está

aislado contra calor y humedad con un aislamiento Clase B.

2. El devanado estatórico lleva un protector de sobrecarga térmica. Está conectado en serie y cableado de

forma que se apague cuando se sobre calienta. El interruptor de sobrecarga se restablece automáticamente

cuando se enfría el motor.

3. El motor está protegido contra la entrada de agua mediante un sello de cartucho mecánico con dos caras de

carburo de silicio.

4. El rotor y la voluta están diseñados para producir un caudal óptimo y funcionar sin obstrucciones. Los discos

endurecidos trituran la materia sólida y fibrosa hasta convertirla en partículas pequeñas que pueden pasar

con el reducido diámetro de las tuberías.

5. Consulte los códigos de plomería locales para informarse de los requisitos de ventilación del tanque en

sistemas de saneamiento. La bomba no se deberá instalar en un lugar clasificado como peligroso por el

Código eléctrico nacional (NEC) de Estados Unidos, ANSI/NFPA 70.

NOTA: El material básico de las bombas Liberty Serie PRG es hierro vaciado, elastómeros y Buna-N. No

deben usarse para bombear líquidos corrosivos.

3. X Instalación mecánica X

INSPECCIÓN AL RECIBIR

Inspeccione inmediatamente la caja para comprobar si se ha producido algún daño durante el transporte. Tenga

cuidado al abrir la caja para no dañar la bomba. Saque todo el embalaje de protección del interior de la caja.

Revise bien este embalaje antes de desecharlo para asegurarse de que no haya ninguna pieza de repuesto en

él. Haga una inspección visual de la bomba y de las piezas de repuesto. Compruebe que no haya ningún cable

dañado, especialmente a la salida del chasis del motor. Comuníquese con el Departamento de Servicio al Cliente

de Liberty Pumps para informar de cualquier daño en un producto o en caso de faltar alguna pieza. La cortadora

que se encuentra en la parte inferior de la unidad debe girarse varias veces con una llave hexagonal de 6 mm;

debe girar libremente sin rozar la placa cortadora. Si el rotor y los discos están agarrotados debido a un

prolongado período de almacenamiento, esta operación los soltará. Si no se rota manualmente el rotor antes de

la instalación, es probable que no arranque la bomba. Si le es imposible o muy difícil girar el rotor, comuníquese

con el Departamento de Servicio al Cliente de Liberty Pumps.

©Copyright 2013 Liberty Pumps Inc. Todos los derechos reservados - 3 -

Page 15

ALMACENAMIENTO ANTES DE USAR

PRECAUCIÓN

PRECAUCIÓN

Las bombas Liberty vienen ya listas de fábrica para su instalación y uso. Si la estación de bombeo no está

terminada, tendrá que almacenar la bomba. Si necesita almacenar la bomba, no la saque de la caja en que se

transportó. Guárdela en un almacén o caseta limpio y seco a temperatura estable y cubra la caja y el recipiente

para protegerlos contra el agua, el polvo, etc. Proteja los extremos de los cables (enchufes) contra la humedad.

LA BOMBA NUNCA SE DEBERÁ ALMACENAR EN UN SUMIDERO INUNDADO SIN

TERMINAR. SÓLO SE DEBERÁ COLOCAR EN EL SUMIDERO CUANDO SE PUEDA

OPERAR CORRECTAMENTE.

ALMACENAMIENTO A LARGO PLAZO

1. Si hiciera falta almacenar la bomba durante un período prolongado, hágalo en un recinto cerrado limpio y

seco a temperatura estable. Cubra la bomba para protegerla del polvo, la suciedad y el agua. También los

enchufes se deberán proteger contra la humedad.

2. No deje que la unidad se congele.

3. Gire los sellos y los discos antes de instalar la bomba para verificar que giran sin dificultad.

4. Si la bomba está instalada y permanece inactiva durante un período de tiempo prolongado, se deberá poner en

marcha una vez al mes a través del panel disyuntor para lubricar los sellos. Apague el disyuntor, desenchufe el

interruptor en cascada y enchufe la bomba directamente en el tomacorriente de la pared. Encienda el disyuntor

durante 30 segundos. Apague el disyuntor y vuelva a enchufar el interruptor en cascada.

4. X La cubeta X

La cubeta que se usa con sistemas efluentes y de saneamiento tiene que estar sellada y ventilada de acuerdo a los

códigos de sanidad y fontanería. Estas bombas no se deberán instalar en un lugar clasificado como peligroso según el

Código Eléctrico Nacional de Estados Unidos, ANSI/NFPA 70. El diámetro mínimo es de 5.48 m (18 pies) y la

profundidad de 60.96 cm (24 pulg.). (Estos son los requisitos mínimos. Los códigos locales y el número de accesorios

instalados en el sistema deberán servir de guía para decidir si se necesita una cubeta mayor en ambos tipos de

aplicaciones. Si no está seguro del tamaño adecuado de la cubeta, compruebe con las autoridades locales o llame a

Liberty Pumps.) La instalación se deberá realizar a una profundidad suficiente como para que todas las cañerías

queden por debajo de la línea de penetración de la helada. Si esto no fuera posible, desmonte la válvula de retención y

modifique el tamaño de la cubeta o ajuste el diferencial de la bomba para acomodar el contraflujo adicional.

A. Excavación: Excave un hoyo tan pequeño como sea posible, dejando un espacio libre de alrededor de

20.32 cm (8 pulg.) como mínimo alrededor del tanque. No coloque la cubeta en contacto directo con rocas ni

objetos cortantes. Instale gravilla fina de 0.33-1.90 cm (1/8-3/4 pulg.) o piedra pulverizada fina y lavada de

0.33-1.27 cm (1/8-1/2 pulg.) entre la cubeta y las paredes del hoyo. No utilice arena ni tierra del suelo como

relleno. Compacte la superficie sobre la que se asentará la cubeta para que quede sólida y nivelada y pueda

soportar el peso de la misma.

B. Conexión de la tubería de admisión y relleno inicial: Instale gravilla fina de 0.33-1.90 cm (1/8-3/4 pulg.) o

piedra pulverizada fina y lavada de 0.33-1.27 cm (1/8-1/2 pulg.) alrededor del fondo de la cubeta para

sujetarla en su sitio. No utilice arena ni tierra del suelo como relleno. Instale las tuberías de admisión que

necesite su modelo de cubeta.

Liberty P380 y P680: Las cubetas de la serie Liberty Pro tienen una conexión de admisión de 10.16 cm

(4 pulg.) moldeada sobre el costado del tanque. Está hecha para conectar un

manguito (no para bocas de admisión) de 10.16 cm. Conecte la línea de drenaje por

gravedad de los accesorios a esta boca.

Otras cubetas: Otras cubetas Liberty llevan una boca de calafateo o un arandela para tuberías de

10.16 cm (4 pulg.). Con las bocas de admisión se utiliza material de calafateo o

guarniciones de caucho, mientras que la tubería se conecta directamente en el caso

de la arandela. Conecte la línea de drenaje por gravedad de los accesorios a esta

admisión. (Existen otros tamaños de admisión. Consulte con la fábrica.)

C. Relleno final: El relleno no debe contener rocas, terrones y otros objetos foráneos. Sólo se recomienda usar

gravilla fina de 0.33-1.90 cm (1/4-3/4 pulg) o piedra pulverizada fina y lavada de 0.33-1.27 (1/8-1/2 pulg.). No

utilice arena ni tierra del suelo como relleno. Forme un ligero montículo con el relleno y deje que se asiente

naturalmente. Deberá dejarse acceso a la tapa para tareas de mantenimiento y servicio.

No ejerza una presión excesiva ni trabaje con equipo pesado encima del material de

relleno, ya que esto podría hacer colapsar el tanque.

©Copyright 2013 Liberty Pumps Inc. Todos los derechos reservados - 4 -

Page 16

5. X Instalación de la bomba X

Instalación simple típica

ALARMA (OPCIONAL)

VENTILACIÓN

JUNTA

VÁLVULA DE

RETENCIÓN

VÁLVULA

DE BOLA

DESAGÜE

USE UNA TUBERÍA DE ADMISIÓN

CON CONECTOR SIN BOCA DE

10.16 CM (4 PULG.)

ADVERTENCIA

ADVERTENCIA

PRECAUCIÓN

LA BOMBA NO SE DEBERÁ INSTALAR EN UN LUGAR CLASIFICADO COMO

PELIGROSO POR EL CÓDIGO ELÉCTRICO NACIONAL (NEC) DE ESTADOS

UNIDOS, ANSI/NFPA 70.

Las bombas trituradoras se deberán instalar en un tanque ventilado según los códigos de plomería locales.

La instalación se deberá realizar a una profundidad suficiente como para que todas las cañerías queden por

debajo de la línea de penetración de la helada. Si esto no fuera posible, desmonte la válvula de retención y

modifique el tamaño de la cubeta o ajuste el diferencial de la bomba para acomodar el contraflujo adicional.

Consulte la información de fábrica sobre este procedimiento.

6. X Servicio eléctrico y operación X

Riesgo de descarga eléctrica. Desconecte la bomba de la fuente de alimentación siempre que vaya a

manipularla o a realizar algún ajuste.

Solo personal cualificado deberá encargarse de instalar las conexiones y cables eléctricos necesarios para

montar la bomba.

Esta unidad viene con un conector a tierra y un enchufe con conexión a tierra. Para reducir el riesgo de

electrocución, el conector de puesta a tierra tiene que estar conectado debidamente a un panel de control a

tierra, o si cuenta con un enchufe a tierra tendrá que enchufarse a un tomacorriente conectado a tierra.

NO derive los cables de puesta a tierra ni retire las espigas a tierra de los enchufes.

NO quite el cordón ni la protección contra tirones, y no conecte canal para cables a la bomba.

NO use cables de extensión.

Con esta bomba, hay que utilizar un circuito derivado independiente conectado a tierra y con fusibles.

La fuente de alimentación tendrá que tener suficiente capacidad para cumplir los requisitos de voltaje y

amperaje del motor, indicados en la placa de la bomba.

El tomacorriente o panel deberá encontrarse al alcance del cable de alimentación de la bomba y a

1.22 metros (4 pies) como mínimo por encima del piso para evitar problemas en caso de inundación.

Se deberá instalar la unidad según las disposiciones del Código Eléctrico Nacional de Estados Unidos y

todos los códigos y reglamentos locales que correspondan.

Si la propiedad está expuesta a niveles altos de inundación, se debe instalar una

alarma independiente que notifique niveles altos de agua. Para instalaciones vitales

se recomienda un sistema de bombeo doble.

©Copyright 2013 Liberty Pumps Inc. Todos los derechos reservados - 5 -

Page 17

TEMPORARY

MANUAL

OPERATION

Cableado directo de las bombas monofásicas

automáticas de 115 V o 230 V

Figura C – Cableado directo de una bomba

automática monofásica de 115 V o 208-230 V

¡NO!

¡SÍ!

Fuente

de

alimen-

tación

Tierra

Verde

Verde

Blanco

Blanco

Negro

Negro

Negro

Blanco

Caja de conexión

Bomba

Interruptor

de flotador

Figura 4 Instalación del

enchufe en cascada

ADVERTENCIA

Todos los modelos “A” (bombas automáticas) vienen equipados

con un interruptor de flotador montado en la bomba misma. Estos

modelos vienen con dos cables: uno al interruptor de flotador y el

otro al motor. El cable del interruptor cuenta con un interruptor en

serie, o cascada, en el que se puede conectar el cable del motor

(vea la figura 4). Esto permite la operación manual de la bomba.

Tome en cuenta que la operación de encendido/apagado de la

bomba se debe controlar con el disyuntor.

Si se quiere activar la operación automática con el interruptor de Liberty, se deberán interconectar los dos

cables y enchufarse a un tomacorriente con conexión a tierra, con fusible independiente y el amperaje apropiado

para el modelo. (Para conocer las especificaciones eléctricas de su modelo, consulte la Sección 1, información

general, o la placa de identificación de la bomba.) Ambos cables cuentan con enchufes de 3 patas y se deben

enchufar en un tomacorriente trifilar con toma a tierra. NO DESMONTE LAS CLAVIJAS A TIERRA.

Si falla el interruptor, el cable de la bomba se puede separar y enchufar en un tomacorriente, evitando de esta

manera el interruptor. Las bombas monofásicas de 115 y 230 V se deben operar solamente sin el flotador por

medio de un disyuntor o panel de desconexión. No deje que la bomba funcione en seco.

El nivel de encendido de los modelos A es de entre 30.48 y 40.64 cm. (12 a 16 pulg.) por encima del fondo de la

cubeta. El nivel de apagado es de 15.24 cm ( 6 pulg.) por encima del fondo de la cubeta. Para obtener otros

diferenciales de bombeo se puede amarrar el cable del interruptor a la tubería de desagüe. NOTA: Se requiere

un cable de 8.89 cm (3.5 pulg.) desde el punto de amarre hasta la superficie superior del flotador para que el

interruptor funcione correctamente. Si se va a utilizar un diferencial distinto al de fábrica, se deberá ajustar de

forma que la bomba se apague cuando queden 15.24 cm (6 pulg.) como mínimo de líquido en la cubeta para que

el rotor permanezca sumergido en todo momento.

Las bombas de la Serie PRG con la designación “M” son modelos manuales sin interruptor. Funcionan con

un control de nivel de líquido o control de motor aprobado con el valor nominal correcto que corresponda con la

entrada del motor en amperios a carga total. Los modelos trifásicos requieren un control de motor aprobado que

corresponda con la entrada del motor en amperios a carga total con elementos de sobrecarga seleccionados o

ajustados según las instrucciones del control.

Operación automática con dispositivos de control opcionales: Si la bomba va a funcionar con un panel de

control simple o doble u otro dispositivo de control opcional, siga las instrucciones de instalación incluidas con su

control específico y establezca las conexiones eléctricas indicadas. Algunos modelos pueden funcionar sin un

control independiente. Las bombas monofásicas de 230 V sólo se deben operar sin el flotador con un disyuntor o

panel de desconexión. No deje que la bomba funcione en seco.

Modelos ProVore® “A” y “M”: Si la bomba va a estar cableada directamente a un dispositivo de control o caja

de conexión y se hace necesario retirar los enchufes, la labor la deberá llevar a cabo un electricista certificado

según el Código eléctrico nacional de Estados Unidos y los códigos locales. Vea la figura 5 para encontrar

instrucciones para cablear directamente una bomba automática monofásica.

En instalaciones de 230 V, uno de los

extremos de la línea que va a la bomba

está siempre activo mientras que el

flotador se encenderá y se apagará.

Instale un desconectador bipolar cerca de

la bomba para no correr riesgos.

©Copyright 2013 Liberty Pumps Inc. Todos los derechos reservados - 6 -

Page 18

ANTES DE ENERGIZAR LA UNIDAD

ADVERTENCIA

1. Apriete todas las conexiones realizadas sobre el terreno. Apriete todas las conexiones de fábrica. Existe la

posibilidad de que se hayan aflojado durante el transporte.

2. Compruebe que la tornillería de montaje esté segura.

3. Compruebe que el chasis no haya sufrido desperfectos que pudieran reducir el espacio eléctrico.

4. Gire la moleta con el tornillo de cabeza hexagonal para verificar el movimiento y lubricar los sellos.

5. Compruebe que no haya cables ni ningún otro obstáculo en la carrera de la moleta.

6. PROTECCIÓN CONTRA SOBRECARGA DEL MOTOR: El motor viene con un protector de sobrecarga térmica

que lo protege en caso de que se bloquee el rotor o se produzca una sobrecarga. No se necesita ningún ajuste.

7. Compruebe que todas las conexiones a tierra estén correctamente establecidas.

Si se va a usar un panel, retire del interior los trozos de cable y otros restos que hubiera antes de cerrar

las puertas. Instale las cubiertas y cierre las puertas después de revisar que no haya cables pillados y

que todas las piezas estén bien apretadas y alineadas.

EL PROCESO DE ENERGIZAR UN PANEL O DISYUNTOR POR PRIMERA VEZ

PUEDE SER PELIGROSO. A LA HORA DE LLEVAR A CABO ESTA OPERACIÓN

POR PRIMERA VEZ DEBERÁ HABER UN ELECTRICISTA CALIFICADO

PRESENTE. SI EXISTE UNA FALLA DEBIDO A UN DESPERFECTO O A UNA

INSTALACIÓN INCORRECTA Y NO SE DETECTA A TIEMPO, SE PUEDEN

PRODUCIR DAÑOS GRAVES AL APLICAR LA ELECTRICIDAD (CONSULTE LA

SECCIÓN 5).

INTERRUPTOR DE FLOTADOR

1. Los ciclos de la bomba suelen estar controlados por un interruptor de flotador en cascada instalado en el

lateral de la bomba o por un interruptor colgante en el sumidero inundado. Consulte las instrucciones del

panel o interruptor antes de realizar las conexiones eléctricas.

SECUENCIA DEL FLOTADOR-INTERRUPTOR EN CASCADA (MODELOS AUTOMÁTICOS)

1. El flotador se va inclinando a medida que sube el nivel del sumidero inundado, con lo que cierra el

interruptor. Esto hace arrancar la bomba.

2. La bomba seguirá funcionando hasta que el nivel de líquido caiga por debajo del nivel de apagado

establecido (fijado en fábrica a un mínimo de 17.77 cm/6 pulg.).

SECUENCIA DEL FLOTADOR-PANEL DE CONTROL SIMPLE (MODELOS MANUALES)

1. El flotador de apagado se va inclinando a medida que sube el nivel del sumidero inundado, con lo que cierra

el interruptor. (El nivel debe estar a 17.77 cm/6 pulg. como mínimo). A medida que va subiendo el líquido, el

flotador de encendido se empieza a inclinar. El interruptor se cierra y la bomba arranca.

2. La bomba sigue funcionando hasta que el nivel cae por debajo del flotador de apagado, con lo que se vacía

el sumidero.

3. Si falla el interruptor, el relevo de control o la bomba, la subida del nivel de líquido hará que el flotador de

alarma se incline y el sistema de alarma se activará.

SECUENCIA DEL FLOTADOR-PANEL DE CONTROL DOBLE (MODELOS MANUALES)

1. El flotador se va inclinando a medida que sube el nivel del sumidero inundado, con lo que cierra el

interruptor. A medida que va subiendo el líquido, el flotador de encendido principal se empieza a inclinar.

El interruptor se cierra y la bomba principal arranca. La bomba sigue funcionando hasta que el nivel cae por

debajo del flotador de apagado (17.77 cm/6 pulg. como mínimo), con lo que se vacía el sumidero.

2. Cuando vuelva a subir el nivel, la otra bomba arrancará con la señal de encendido principal. Las bombas

alternarán sus ciclos de esta manera.

NOTA: Nunca se debe configurar el diferencial del interruptor de flotador de encendido por

encima de los 12 arranques por hora.

3. Si el nivel sube por encima del flotador de encendido de retardo, arrancará la segunda bomba. Ambas

bombas funcionarán hasta que el nivel vuelva a caer por debajo del flotador de apagado, con lo que se

vaciará el sumidero.

4. Si falla el interruptor, el relevo de control o la bomba, la subida del nivel de líquido hará que el flotador de

alarma se incline y el sistema de alarma se activará.

©Copyright 2013 Liberty Pumps Inc. Todos los derechos reservados - 7 -

Page 19

INSTALACIÓN DEL INTERRUPTOR DEL FLOTADOR

Los dibujos técnicos suelen especificar los niveles a los que la bomba arranca y se detiene y el nivel de

alarma. Si no se especifica lo contrario, la información siguiente deberá servir para determinar la

ubicación de los interruptores de flotador.

INTERRUPTOR EN CASCADA

(sistema de 1 flotador)

Bomba apagada: Ajustado en fábrica. (varilla del flotador 10.16 cm /3.5 pulg.)

Bomba encendida: Ajustado en fábrica. (varilla del flotador 10.16 cm /3.5 pulg.)

ESTACIÓN DE BOMBA SIMPLE

(sistema de 3 flotadores)

Bomba apagada: Nivel hasta la parte superior del chasis.

Bomba encendida: Mínimo 45.72 cm (1.5 pies) por arriba del nivel de la bomba apagada.

Alarma de nivel alto: Mínimo de 30.48 cm (1 pie) por arriba del nivel de la bomba encendida.

Por debajo de tubería de entrada.

ESTACIÓN DE BOMBAS DÚPLEX

(sistema de 4 flotadores)

Bomba apagada: Nivel hasta la parte superior del chasis.

Bomba principal encendida: Mínimo 45.72 cm (1.5 pies) por arriba del nivel de la bomba apagada.

Segunda bomba encendida: Mínimo de 30.48 cm (1 pie) por arriba del nivel de la bomba principal

encendida.

Alarma de nivel alto: Mínimo de 30.48 cm (1 pie) por arriba del nivel de la segunda bomba

encendida. Por debajo de tubería de entrada.

©Copyright 2013 Liberty Pumps Inc. Todos los derechos reservados - 8 -

Page 20

7. X Operación X

ADVERTENCIA

PRECAUCIÓN

OPERACIÓN

Una vez se haya completado la instalación eléctrica y mecánica, la bomba estará lista para su uso. No se

requiere ningún procedimiento especial excepto aplicar la potencia nominal a la bomba. No existe ningún

procedimiento de apagado excepto desconectar la alimentación.

SI LA ROTACIÓN DE UNA FASE DE LA BOMBA ES INCORRECTA, NOTIFIQUE AL DEPARTAMENTO DE

SERVICIO DE LIBERTY INMEDIATAMENTE. NO CAMBIE LOS HILOS DE ALIMENTACIÓN. NO ENCIENDA

LA BOMBA.

COMPRUEBE SIEMPRE QUE NO HAYA CABLES SUELTOS Y OTRAS OBSTRUCCIONES QUE PUDIERAN

CAUSAR LESIONES PERSONALES O DESPERFECTOS.

MANTENIMIENTO Y LUBRICACIÓN PERIÓDICOS

Las bombas Liberty han sido diseñadas para ofrecer un servicio eficiente y confiable con un mínimo de

mantenimiento preventivo. Estas tareas de mantenimiento son pocas pero muy importantes para asegurar años

de servicio satisfactorio.

LUBRICACIÓN

La bomba tiene lubricación permanente y es enfriada por el aceite de la turbina. Si se requiere cambiar el aceite,

use aceite para turbina ISO-10. Capacidad: 1.9 litros (0.5 galones).

©Copyright 2013 Liberty Pumps Inc. Todos los derechos reservados - 9 -

Page 21

8. X Mantenimiento y diagnóstico de problemas X

Problema

Causa

Solución

La bomba no

funciona.

Se ha fundido un fusible o el flujo

eléctrico se ha interrumpido de

algún otro modo; voltaje incorrecto.

Compruebe que la unidad esté bien conectada. Pida a

un electricista que compruebe las conexiones

adecuadas del cableado, y la capacidad y el voltaje

adecuados.

El interruptor no puede cambiar a la

posición de encendido debido a una

interferencia con el lateral del

tanque u otra obstrucción.

Coloque la bomba o el interruptor de forma que cuente

con suficiente espacio para funcionar libremente.

Líquido insuficiente.

El líquido debe subir lo suficiente como para activar el

interruptor.

Interruptor defectuoso.

Reemplace el interruptor.

La bomba no se

apaga.

El interruptor no puede cambiar a la

posición de apagado debido a una

interferencia con el lateral del

tanque u otra obstrucción.

Coloque la bomba o el interruptor de forma que cuente

con suficiente espacio para funcionar libremente.

Interruptor defectuoso.

Reemplace el interruptor.

La bomba funciona o

zumba pero no

bombea.

La descarga está atascada.

Compruebe que no haya atascos en la línea de

descarga, como puede ser hielo si la línea pasa por

áreas frías.

Compruebe que la válvula no se

haya quedado cerrada o esté

instalada al revés.

Saque la válvula de retención y asegúrese de que

funciona sin impedimentos y que haya sido instalada

correctamente.

La válvula de compuerta o la de

bola está cerrada.

Abra la válvula de compuerta o la de bola.

La elevación total es superior a la

capacidad de la bomba.

Dirija las tuberías a una altura inferior. Si esto no es

posible, necesitará adquirir otra bomba de mayor

capacidad. Consulte a la fábrica.

El rotor de la bomba está atascado

o la cubierta de voluta está

taponada.

Quite la bomba de la cubeta, quite el cortador y la placa

del cortador; limpie la zona alrededor del rotor. Monte la

bomba y vuélvala a instalar. El tornillo central utiliza una

llave hexagonal de 6 mm. El tornillo se puede calentar

para quitar el compuesto que bloquea roscas

La bomba se activa

cuando la maquinaria

no está en uso.

No hay instalada una válvula de

retención, se queda abierta o tiene

una fuga.

Saque la válvula de retención y asegúrese de que

funciona sin impedimentos y que haya sido instalada

correctamente.

Las piezas gotean.

Repare las piezas para eliminar las fugas.

La bomba hace

demasiado ruido.

Material foráneo en la cavidad

del rotor.

Quite la bomba de la cubeta, quite el cortador y la placa

del cortador; limpie la zona alrededor del rotor. Monte la

bomba y vuélvala a instalar. El tornillo central utiliza una

llave hexagonal de 6 mm. El tornillo se puede calentar

para quitar el compuesto que bloquea roscas

Rotor roto.

La fábrica le puede informar sobre cómo reemplazar el

rotor.

Cojinetes desgastados.

Envíe la bomba a reparar a la fábrica o a un centro de

reparación autorizado.

Las conexiones de las tuberías al

edificio son demasiado rígidas.

Cambie una parte de la línea de descarga con una

manguera o conector de caucho.

ADVERTENCIA

Riesgo de descarga eléctrica. Desconecte la bomba de la fuente de alimentación siempre que

vaya a manipularla o a realizar algún ajuste.

La bomba tiene un chasis de motor lleno de aceite; drene el aceite antes de quitar los cuatro

tornillos de la cubierta.

©Copyright 2013 Liberty Pumps Inc. Todos los derechos reservados - 10 -

Page 22

9. X Garantía limitada de 3 años X

7000 Apple Tree Avenue

Bergen, NY 14416

Teléfono: +1-800-543-2550

(Solo EE.UU.)

Fax: +1-585-494-1839

www.libertypumps.com

Liberty Pumps, Inc. garantiza que las bombas que fabrica están libres de defectos en los materiales y la mano de

obra por un período de 3 años a partir de la fecha de compra. La fecha de compra se determinará con el recibo

de compra fechado, que incluya el modelo y el número de serie de la bomba. Este recibo deberá acompañar a la

bomba si la fecha de devolución ocurre más de 3 años después de la fecha de fabricación (código-CODE)

indicada en la placa de identificación de la unidad.

Las obligaciones del fabricante bajo esta garantía se limitan a la reparación o el reemplazo de las piezas que el

fabricante determine defectuosas, siempre que la pieza o el ensamblaje se devuelva al fabricante o a uno de sus

centros de servicio autorizados con el porte pagado y que no se evidencie ninguna de las siguientes

características, lo que supondría la anulación de la garantía.

El fabricante no tendrá obligación alguna bajo esta garantía si el producto no ha sido instalado correctamente; si

ha sido desmontado, modificado, abusado o forzado; si el cable eléctrico se ha cortado, dañado o empalmado; si

se redujo el tamaño de la descarga de la bomba; si la bomba se usó con agua más caliente de la temperatura

nominal, o agua con arena, cal, cemento, grava u otros elementos abrasivos; si la bomba ha sido utilizada para

bombear químicos o hidrocarburos; si un motor no sumergible ha sido sometido a un exceso de humedad; o si se

ha retirado la etiqueta con el número de serie y de código. Liberty Pumps, Inc. no se hace responsable de

pérdidas, daños o gastos causados por la instalación o uso de sus productos, o por daños consiguientes,

incluidos los costos de desmontaje, reinstalación o transporte de la unidad.

No se ofrece ninguna otra garantía expresa. Todas las garantías implícitas, incluidas las de comerciabilidad y

adecuación para un propósito determinado, están limitadas a un plazo de tres años a partir de la fecha de compra.

Esta garantía contiene el resarcimiento exclusivo del comprador y, donde sea permitido, se excluye toda

responsabilidad por daños secundarios y consiguientes bajo cualquier otra garantía.

©Copyright 2013 Liberty Pumps Inc. Todos los derechos reservados - 11 -

Page 23

Modèles :

PRG101A

1 hp, 115V, monophasée, interrupteur automatique, cordon

d’alimentation de 3 m (10 pi)

PRG101A-2

1 hp, 115V, monophasée, interrupteur automatique, cordon

d’alimentation de 3 m (25 pi)

PRG101M

1 hp, 115V, monophasée, cordon d’alimentation de 3 m (10 pi)

PRG101M-2

1 hp, 115V, monophasée, cordon d’alimentation de 3 m (25 pi)

PRG102A

1 hp, 230V, monophasée, interrupteur automatique, cordon

d’alimentation de 3 m (10 pi)

PRG102A-2

1 hp, 230V, monophasée, interrupteur automatique, cordon

d’alimentation de 3 m (25 pi)

PRG102M

1 hp, 230V, monophasée, cordon d’alimentation de 3 m (10 pi)

PRG102M-2

1 hp, 230V, monophasée, cordon d’alimentation de 3 m (25 pi)

*Ne pas jeter ni perdre ce manuel.

Table des matières

Renseignements généraux

Introduction

Installation mécanique

Raccordement électrique

Fonctionnement

Guide de dépannage

Garantie

Manuel d’installation 2399000B

Pompes broyeuses résidentielles ProVoreMD

IMPORTANT :

Avant l’installation, noter les numéros de

modèle, de série et de code qui figurent sur

la plaque signalétique pour éventuellement

s’y référer.

Nº de MODÈLE _____________________

Nº de SÉRIE _____________________

CODE _____________________

DATE

D’INSTALLATION _____________________

7000 Apple Tree Avenue

Bergen (NY) 14416, É.-U.

Téléphone : 1 800 543-2550

Télécopieur : 585 494-1839

www.libertypumps.com

©Copyright 2013 Liberty Pumps Inc.Tous droits réservés

Page 24

1. X Renseignements généraux X

Modèle

HP

Volts

Phase

Intensité

maximale

FNPT

d’évacuation

Automatique ou

manuel*

PRG101A

1

115

1

12

2 po

Automatique

PRG101A-2

1

115

1

12

2 po

Automatique

PRG101M

1

115

1

12

2 po

Manuel

PRG101M-2

1

115

1

12

2 po

Manuel

PRG102A

1

230

1 6 2 po

Automatique

PRG102A-2

1

230

1 6 2 po

Automatique

PRG102M

1

230

1 6 2 po

Manuel

PRG102M-2

1

230

1 6 2 po

Manuel

MISE EN GARDE

AVERTISSEMENT

Lire attentivement les directives avant d’effectuer l’installation. Chaque pompe de marque Liberty est testée individuellement en

usine pour assurer un bon fonctionnement. Le fait de suivre ces directives à la lettre éliminera les risques de dysfonctionnement et

assurera des années de fonctionnement sans soucis.

Danger d’électrocution. Toujours débrancher la pompe de l’alimentation électrique avant de la manipuler ou

d’y effectuer des réglages.

Les raccords électriques et le câblage pour l’installation de la pompe ne devraient être effectués que par des

professionnels qualifiés.

Cette pompe est fournie avec un conducteur de mise à la terre et une fiche de branchement de type mise à la

terre. Afin de réduire les dangers d’électrocution, s’assurer que la pompe est raccordée seulement à une prise

correctement mise à la terre.

NE PAS dévier les fils de mise à la terre ou retirer la broche de mise à la terre des fiches de branchement.

NE PAS utiliser de rallonge électrique.

Cette pompe nécessite un circuit de dérivation dédié correctement protégé par un fusible et mis à la terre.

S’assurer que la tension et l’intensité du courant électrique de la source d’alimentation électrique sont suffisantes

pour répondre aux exigences de la pompe, telles qu’indiquées sur la plaque signalétique.

La prise électrique doit se trouver à la portée du cordon d’alimentation de la pompe et à au moins 1,2 m (4 pi)

au-dessus du niveau du plancher pour minimiser les dangers liés à une inondation.

L’installation doit être faite en respectant le Code national de l’électricité, le Uniform Plumbing Code, le Code

international de plomberie ainsi que tous les codes locaux et règlements en vigueur.

Les pompes d’assèchement et de système d’égout traitent souvent des matières pouvant causer des maladies.

Porter des vêtements protecteurs adéquats pour manipuler une pompe ou de la tuyauterie ayant déjà servi.

Ne jamais pénétrer dans le réservoir de pompage après qu’il ait servi. Les égouts et effluents peuvent émettre

des gaz toxiques.

Demeurer à l’écart des orifices d’aspiration et d’évacuation. Afin de prévenir les blessures, ne jamais insérer les

doigts dans la pompe alors qu’elle est branchée.

NE PAS utiliser ce produit pour pomper des liquides inflammables ou corrosifs.

NE PAS utiliser ce produit pour les installations où le contact humain avec les liquides pompés est fréquent

(piscines, fontaines, etc.)

NE JAMAIS disposer de matériaux comme du solvant à peinture ou d’autres produits chimiques en les vidant

dans l’avaloir, car ils peuvent attaquer chimiquement et endommager les composants de la pompe, causant

éventuellement son mauvais fonctionnement ou sa défaillance.

NE PAS laisser la pompe fonctionner à sec, ce produit est destiné à être en partie submergé pendant son

fonctionnement.

Ne pas utiliser ces pompes dans de l’eau dont la température est supérieure à 60 °C (140 F)

Le Uniform Plumbing Code (UPC, Code de plomberie universel) indique que les systèmes d’égout doivent être

munis d’une d’alarme sonore et visuelle qui signale tout mauvais fonctionnement du système, afin de réduire les

risques de dommages à la propriété.

On recommande un disjoncteur de 20 ampères pour les pompes 115 V.

Remarque : Les modèles

manuels (suffixe « M ») nécessitent

un dispositif ou un panneau

indépendant de commande

de pompe approuvé pour

fonctionner automatiquement. Le

fonctionnement de ces modèles

variera en fonction du dispositif de

commande choisi. S’assurer que

les caractéristiques électriques

du dispositif de commande

choisi correspondent bien aux

caractéristiques de la pompe.

Toujours se référer aux directives

d’installation du panneau.

©Copyright 2013 Liberty Pumps Inc.Tous droits réservés - 2 -

Page 25

2. X Introduction X

MISE EN GARDE

INTRODUCTION

Ce manuel est destiné fournir les renseignements nécessaires à l’installation, l’utilisation et l’entretien de la

pompe Liberty. Il est recommandé de lire entièrement les directives avant d’installer la pompe. S’assurer d’être

familier avec le contenu et de bien comprendre les chapitres relatifs à l’installation et l’utilisation de la pompe

avant de la faire fonctionner.

Les pompes Liberty sont conçues pour ne nécessiter qu’un entretien minimal. Toutefois, des vérifications

régulières assureront une plus grande durabilité et une meilleure fiabilité d’utilisation.

GARANTIE : Aucun travail de réparation ne devrait être effectué au cours de la période de garantie avant d’avoir

obtenu l’autorisation préalable du fabricant. Une telle situation annulerait la garantie.

Nº DE SÉRIE : S’assurer que le numéro de série de la pompe figure dans toute la correspondance et les

rapports.

CONCEPTION DE LA POMPE

La pompe broyeuse contient des pièces de métal qui tournent à des vitesses

élevées. Faire preuve de prudence à proximité de la pompe lorsque celle-ci est

sous tension. S’assurer que la pompe est bien dans le réservoir ou qu’aucune

personne ni aucun câble ne se trouvent à proximité lorsque celle-ci fonctionne.

1. Les pompes broyeuses Liberty de série ProVoreMD sont conçues pour fonctionner de manière continue sous

l’eau. Le moteur et la pompe forment un appareil étanche à couplage direct. Le moteur à induction est isolé

contre la chaleur et l’humidité, conformément aux normes de classe B.

2. Un dispositif de protection thermique contre les surcharges est intégré aux enroulements du stator. Il est

raccordé en série et branché de manière à s’éteindre en cas de surchauffe. L’interrupteur de surcharge se

réinitialise automatiquement lorsque le moteur refroidit.

3. Le moteur est protégé contre les dommages causés par l’introduction d’eau par une cartouche d’étanchéité

mécanique comportant deux côtés en carbure de silicium.

4. Le compresseur et la sortie sont conçus pour une utilisation sans obstruction et comportent des

caractéristiques d’écoulement efficaces. Les lames solidifiées broient les matières solides et fibreuses en

petites particules pouvant être pompées de manière sécuritaire au travers des conduits de petit diamètre.

5. Pour les systèmes d’égout, consulter les codes de plomberie relativement aux exigences relatives à la

ventilation du réservoir. Cette pompe ne doit pas être installée dans un endroit classé dangereux selon la

norme ANSI/NFPA 70 du NEC.

REMARQUE : Les pompes Liberty de la série PRG sont principalement fabriquées de fonte, les

élastomères sont faits de caoutchouc nitrile. Elles ne doivent pas servir à pomper des liquides corrosifs.

3. X Installation mécanique X

INSPECTION À LA RÉCEPTION

Le contenant d’expédition devrait être inspecté immédiatement afin de s’assurer qu’aucun dommage ne s’est

produit au cours de l’expédition. Faire attention lors de l’ouverture du contenant d’expédition afin d’éviter

d’endommager la pompe. Retirer tout matériel de bourrage et de calage du contenant.

Avant de jeter le matériel de bourrage, vérifier s’il ne s’y trouve pas de petites pièces. Inspecter visuellement la

pompe et toute pièce de rechange afin de s’assurer que celles-ci ne comportent aucun dommage. Inspecter les

cordons électriques pour voir s’ils sont endommagés, particulièrement à l’endroit où ils sortent du caisson moteur.

Communiquer avec le service à la clientèle de Liberty Pumps pour signaler tout dommage ou toute pièce

manquante. À l’aide d’une clé hexagonale de 6 mm, faire faire plusieurs rotations au couteau situé au fond de

l’appareil pour vérifier s’il tourne librement sans frotter sur la plaque de coupe. Ceci assurera que le rotor et la

lame ne sont pas grippés en raison de l’entreposage prolongé. Si on néglige de faire tourner le rotor

manuellement avant son installation, la pompe pourrait ne pas démarrer. Si la rotation du rotor se fait difficilement

ou est complètement impossible, communiquer avec le service à la clientèle de Liberty Pumps.

©Copyright 2013 Liberty Pumps Inc.Tous droits réservés - 3 -

Page 26

ENTREPOSAGE AVANT UTILISATION

AVERTISSEMENT

AVERTISSEMENT

Les pompes Liberty sont expédiées de l’usine prêtes à être installées et utilisées. Elles devraient être

entreposées si la station de pompage n’est pas complète. S’il est nécessaire d’entreposer la pompe, celle-ci doit

demeurer dans son contenant d’expédition. Elle devrait être conservée dans un entrepôt ou une remise, dans un

endroit propre, sec et dont la température est stable. Il faut couvrir la pompe et son contenant pour les protéger

de l’eau, de la saleté, de la poussière, etc. L’extrémité des câbles (fiches) doit être protégée contre l’humidité.

LA POMPE NE DEVRAIT JAMAIS ÊTRE ENTREPOSÉE DANS UN PUISARD NON

ACHEVÉ. LA POMPE NE DOIT PAS ÊTRE DÉPOSÉE DANS LE PUISARD TANT

QU’ELLE N’EST PAS COMPLÈTEMENT OPÉRATIONNELLE.

ENTREPOSAGE PROLONGÉ

1. S’il est nécessaire d’entreposer une pompe pour une période prolongée, elle devrait être conservée à