Page 1

7000 Apple Tree Avenue

Bergen, NY 14416

Phone: (800) 543-2550

Fax: (585) 494-1839

www.libertypumps.com

Contents

1.) General Information

2.) General operation – On primary Power (115Vac or 230Vac)

3.) Alarm Operation

4.) Front-Panel Indicators

5.) Pumping Alarm Condition – On Primary Power

6.) Operator Controls – On Primary Power

7.) General operation – On Alarm Backup Power

8.) Alarm Operation – On Alarm Backup power

9.) Operator Controls – On Alarm Backup Power

10.) Front-Panel Indicators – On Alarm Backup Power (9 volt battery)

Installation Manual 8338000D

ProVore

®

Duplex Control

Indoor Models:

PDC-115 – 115 Volt

PDC-230 – 230 Volt

Outdoor Models:

PDCW-115 – 115 Volt

PDCW-230 – 230 Volt

Designed for use with Liberty Pumps

ProVore® 1 hp. residential grinder pumps

©Copyright 2013 Liberty Pumps Inc. All rights reserved

Page 2

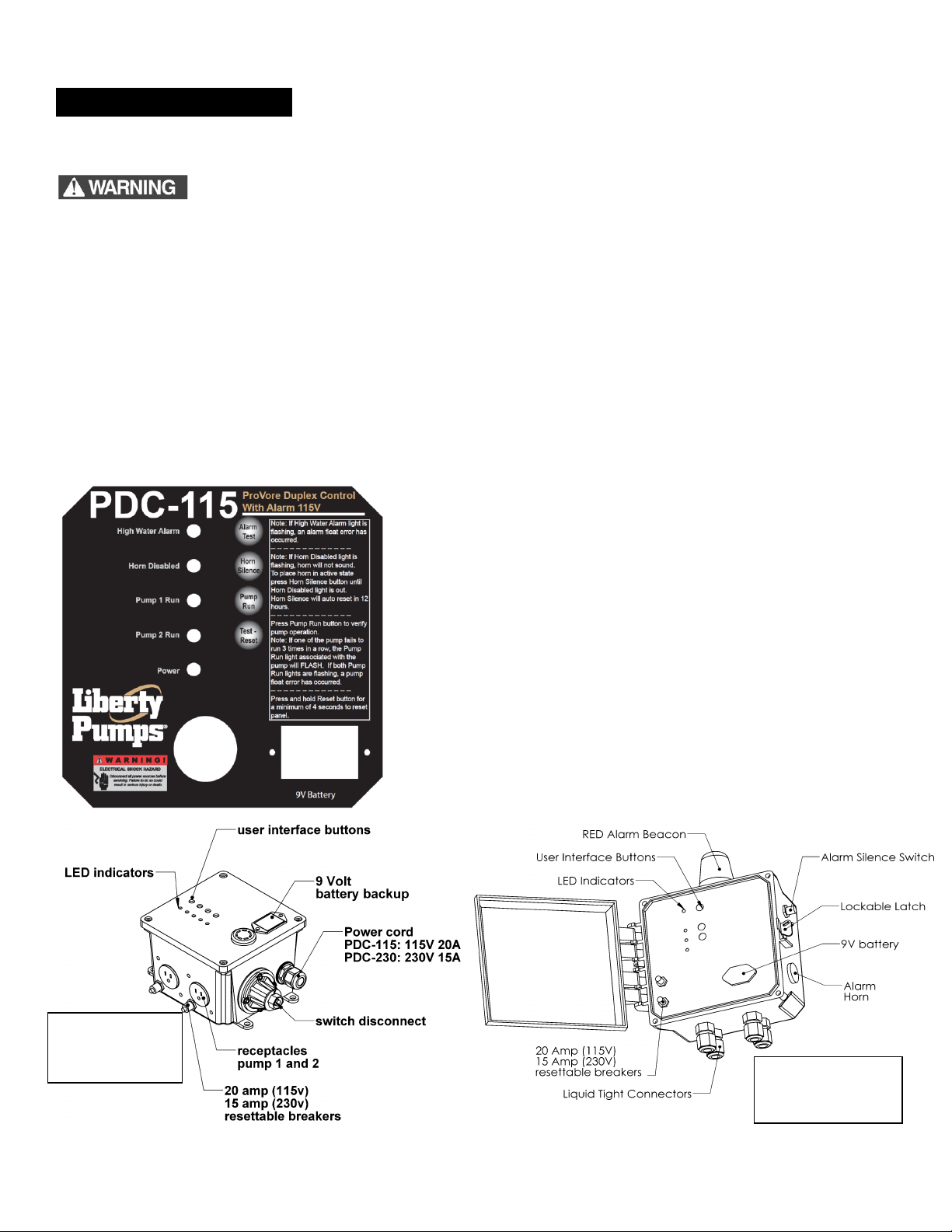

Indoor Models:

PDC-115

PDC-230

Outdoor Models:

PDCW-115

PDCW-230

General Information

Before installation, read the following instructions carefully. Each Liberty pump is individually factory tested to insure proper

performance. Closely following these instructions will eliminate potential operating problems, assuring years of trouble-free service.

Risk of electric shock. Always disconnect the controller from the power source before opening the enclosure.

This controller is supplied with a grounding conductor and grounding-type attachment plug. To reduce the risk of

electric shock, be certain that it is connected only to a properly grounded, grounding-type receptacle.

DO NOT bypass grounding wires or remove ground prong from attachment plugs.

This controller requires a separate, properly fused and grounded branch circuit. Make sure the power source is

properly sized for the voltage and amperage requirements of the pumps, as noted on the nameplate.

The electrical outlet shall be within the length limitations of the power cord, and at least 4 feet above floor level to

minimize possible hazards from flood conditions. DO NOT use an extension cord.

The installation must be in accordance with the National Electric Code, Uniform Plumbing Code, International

Plumbing Code, as well as all applicable local codes and ordinances.

DO NOT use this product for flammable or corrosive liquid.

DO NOT use this product in applications where human contact with the pumped fluid is common (such as swimming

pools, fountains, etc.)

The ProVore® Duplex Control system (PDC-series) monitors the

operation of two ProVore® grinder pumps. The control system comes in

two parts, the controller with user interface and the float switches

mounted inside the basin. The P680 system includes two ProVore®

pumps and two float ball switches. The two float ball switches are

connected such that only three cords exit the cover. All three cords, two

pump power cords and control cord, must be plugged into the controller

box for the indoor models, PDC-115 and PDC-230. The outdoor units

require hard wiring, the plug ends of the pumps and switch must be cut

off and stripped appropriately. The control box monitors the liquid level

in the basin and alternates the two grinder pumps each cycle such that

both pumps receive equal wear. In the event one pump should fail, the

system will automatically switch to the other pump. On the face of the

controller are a number of LED lights and push buttons that allow the

user to monitor and control the system. Both controllers require a

dedicated circuit of the proper ampacity. The PDC(W)-115 requires

115V, 20 amp service while the PDC(W)-230 is 230V, 15 amp service.

©Copyright 2013 Liberty Pumps Inc. All rights reserved 2

Page 3

Indoor Models:

PDC-115

PDC-230

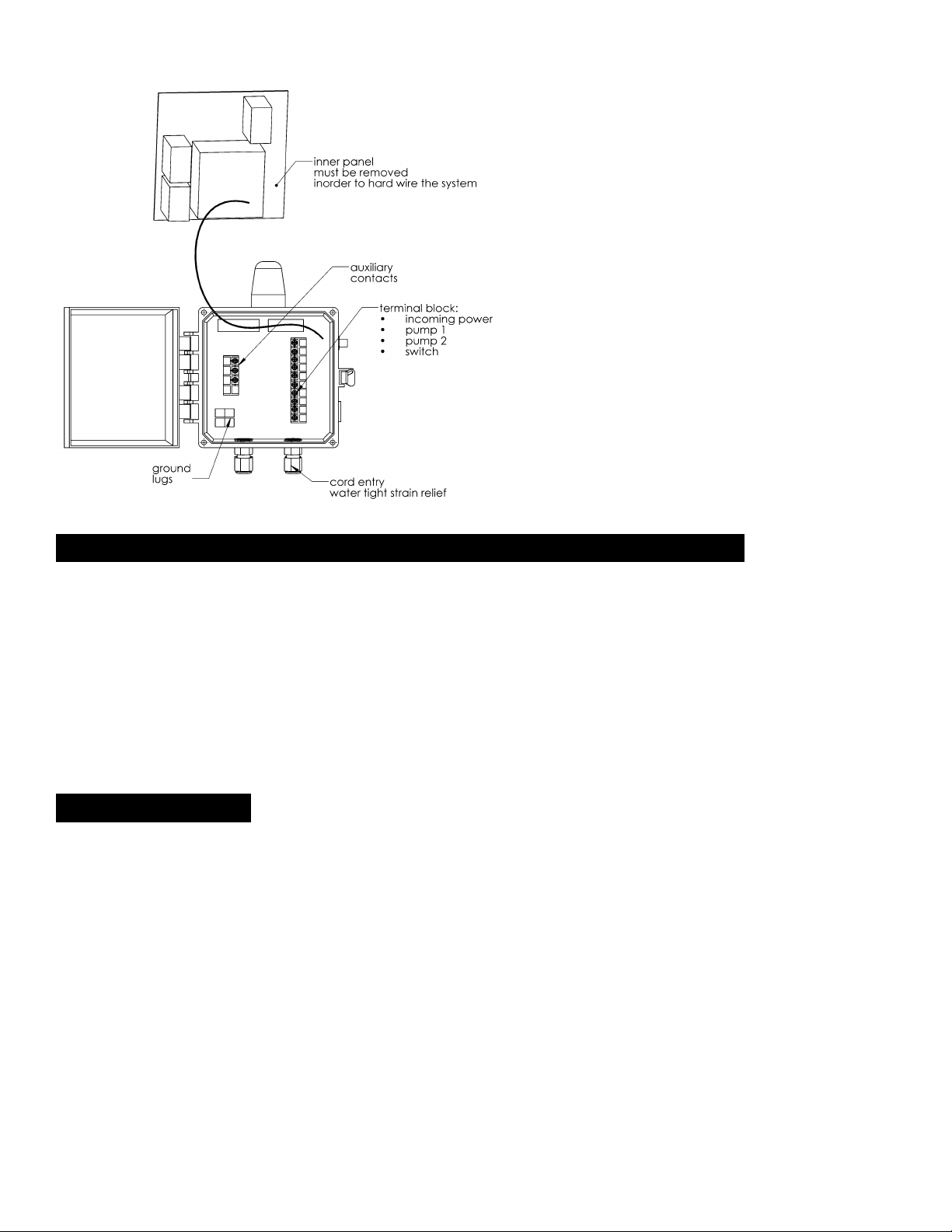

Models: PDCW-115 and PDCW-230 require hard

wiring, the inner panel must be removed to provide

access to the terminal block(s) inside the panel. The

plug of the pumps and switch must be cut off and wires

stripped. Feed the cords, along with the incoming

power, through the water tight strain relief bushings

and wire into the terminal block mounted in the PDC

panel. A wiring schematic is provided beside the

terminal block. The panel has a secondary terminal

block for auxiliary contacts if required.

The controller normally operates on primary power

(115Vac or 230Vac), but if that power fails, an internal

9 volt battery allows the controller to monitor liquid

level and to activate the alarm if required.

On alarm backup power ( 9 volt ), the controller cannot

run the pumps. Pumps will only operate when primary

power is supplied to the control panel.

On alarm backup power, the operator can test the

alarm circuits and can change the horn enable/disable

status. Since pumps do not operate while the controller

is on alarm backup power, the manual run feature will

not be functional.

General operation – On primary Power (115Vac or 230Vac)

The PDC panel controls the operation of two ProVore® grinder pumps in a pump-down application. Two floats are

mounted to the quick tree: a primary pump control float switch and an alarm float switch. On the front panel of the

controller are indicators that show various operating conditions such as pump run status, alarm status, horn

enable/disable status, and other conditions. Operator push-button controls are available to manually run the pumps, to

manually test the alarm, and to disable or enable the alarm horn, as well as reset the system. Both pumps are individually

protected with a manual reset fuse to isolate a failed pump.

When the incoming water activates the primary pump switch, the controller will energize one of the pumps. Normally the

water level in the sump will recede as the pump operates; the pump will turn off when the primary pump switch drops to

the off position. Upon the next pumping cycle the controller will activate the next pump in sequence from the one that ran

previously, providing a pumping redundancy for the system. The controller will continue to alternate pumps on each cycle.

Alarm Operation

In the event water fills the tank faster than it can be pumped out, or if a pump fails to operate, the level can reach an alarm

point by flipping the alarm float switch. The following occurs when an alarm condition activates:

1) The pump that is (or should be) running is turned OFF and the next pump in sequence is turned ON.

2) If the Alarm float remains closed (up position) for 4 sec. the alarm indicator on the front panel of the controller will

illuminate solid

3) The auxiliary relay will activate, closing its normally open contacts and opening its normally closed contacts.

4) If the horn is enabled (i.e. its indicator is NOT flashing) the horn will sound.

Note, an alarm condition will remain active until the liquid level drops below the Pump Float switch. When that occurs, the

following things will take place:

1) The running pump will turn OFF.

2) The front panel alarm indicator will turn OFF.

3) The auxiliary relay will de-activate.

4) The horn (if on) will turn OFF.

If the alarm float remains closed (up position) for 6 hours but the primary float switch is open (down position) the alarm

light will flash and the pump is turned off. This feature prevents the pump from running indefinitely.

©Copyright 2013 Liberty Pumps Inc. All rights reserved 3

Page 4

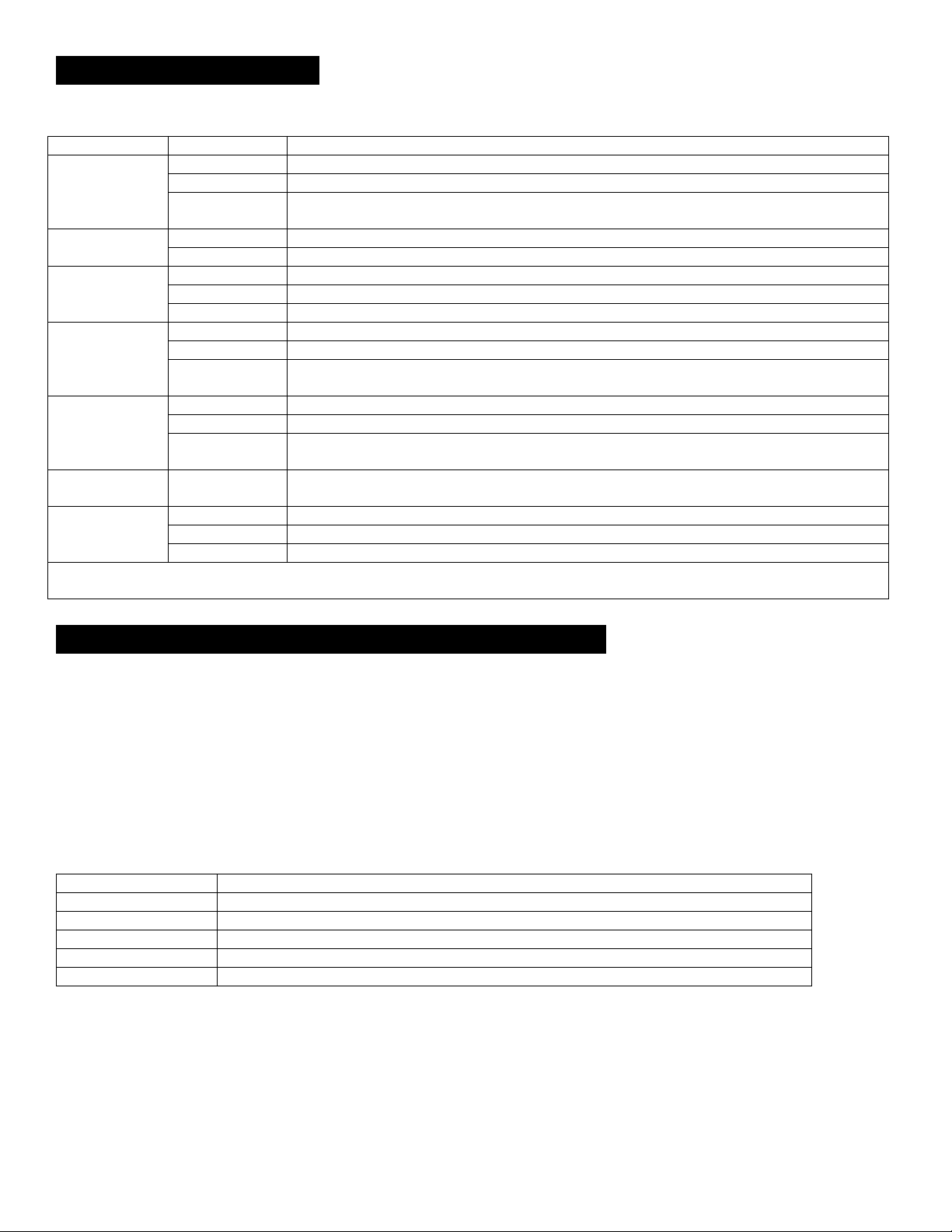

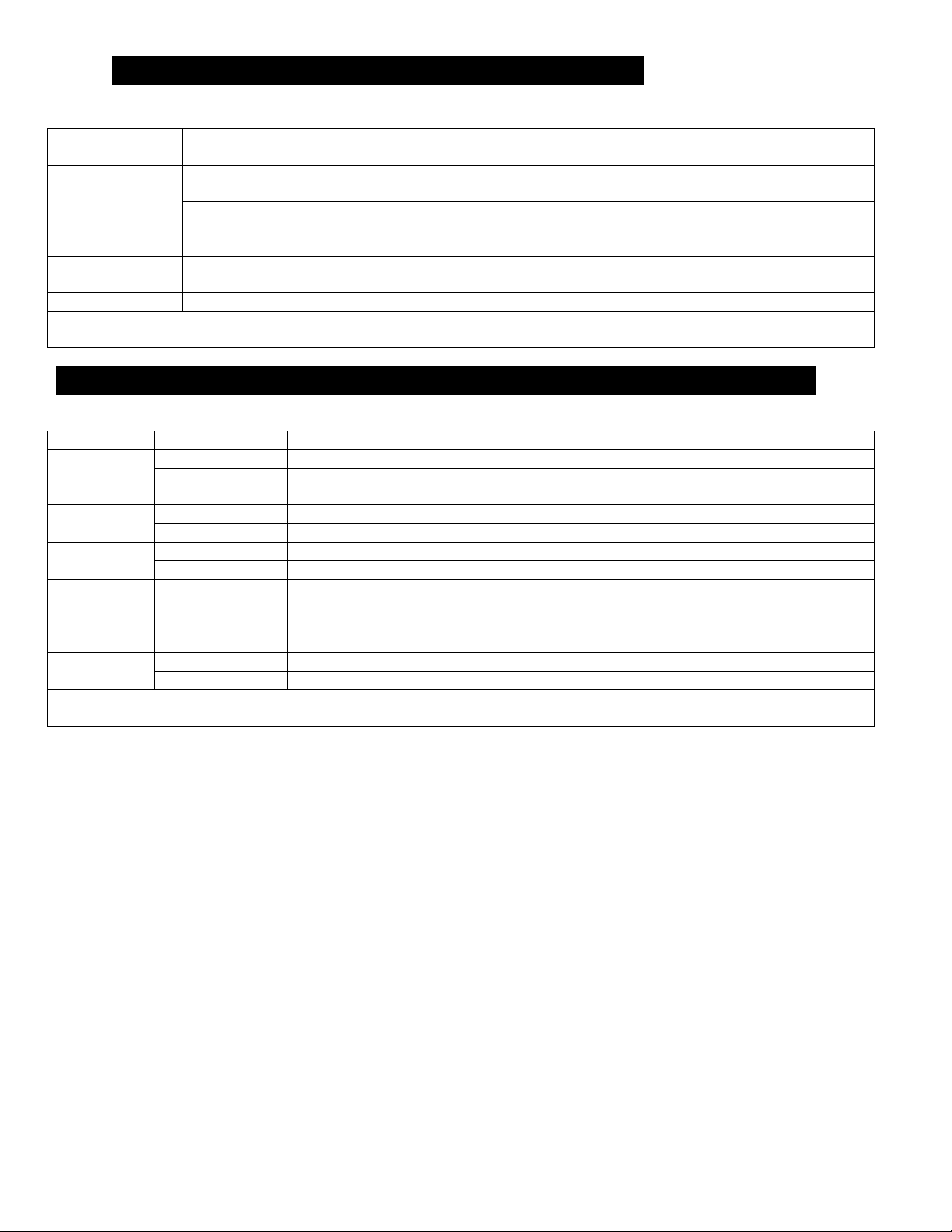

Front-Panel Indicators

Indicator

Indicator state

Description

Power led

OFF

Power is off to the panel and the battery is dead

On constantly

Primary power to the panel is ON

Blinking

Primary power to the panel is OFF; the panel is on alarm backup power. Pumps will

NOT run. See Front-Panel indicators – On Alarm backup power.

*Horn disable

LED

Blinking

Horn operation is DISABLED. The horn will NOT sound in an alarm condition.

OFF

Horn operation is ENABLED. The horn WILL sound in an alarm condition

Alarm LED

OFF

There is no alarm condition

On constantly

An alarm condition is active

Blinking

The Alarm Float switch is not working properly

Pump 1 LED

OFF

The pump is not being called to run

On constantly

The pump is being called to run

Blinking

A pumping alarm condition occurred multiple times; see the section Pumping Alarm

Condition below

Pump 2 LED

OFF

The pump is not being called to run

On constantly

The pump is being called to run

Blinking

A pumping alarm condition occurred multiple times; see the section Pumping Alarm

Condition below

Both pump 1 &

Pump 2 LED

Blinking

The primary float switch is not working properly.

Horn

OFF

No alarm condition is present, and the alarm backup battery is in good condition

ON

An alarm condition is present

Chirping

The voltage of the alarm backup battery is low and the battery should be replaced

*Horn disable LED is on PDC-115 and PDC230 units only. Outdoor units, PDCW-115 and PDCW-230, have an alarm

silence switch on the exterior of the unit.

Blinking LED

Related problem

Power light

No AC power, main breaker has tripped or power outage

Pump 1

Pump failed to operate; fuse tripped, jammed impeller, unplugged, short circuit…

Pump 2

Pump failed to operate; fuse tripped, jammed impeller, unplugged, short circuit…

Pump 1 and pump 2

Primary float switch; mechanically stuck open or tangled in an open condition.

Alarm light

Alarm float switch; mechanically stuck closed or tangled in a closed condition.

The horn and LED indicators on the front panel are used to show various conditions of the controller. Each indicator is

described below.

Pumping Alarm Condition – On Primary Power

The controller monitors a “pumping alarm condition” where a pump is called to run and the liquid level continues to rise

and goes above the Alarm Float switch. If a pumping alarm condition occurs three or more of the last five times a pump is

called to run, the pump indicator will blink indicating system components should be checked. Any of the following

conditions could cause a pumping alarm condition:

1) A pump fails to operate

2) The Alarm Float switch stays (mechanically stuck) in the closed (on, or up) position.

3) There is a problem (blocked or leak) in the out-flow plumbing

4) The water in-flow rate is greater than the pump-out rate

5) The Primary Float switch stays (mechanically stuck) in the open (off, or down) position.

A blinking light indicates a component failed and service is required. To assist the service technician the controller will

indicate which component has failed.

©Copyright 2013 Liberty Pumps Inc. All rights reserved 4

Page 5

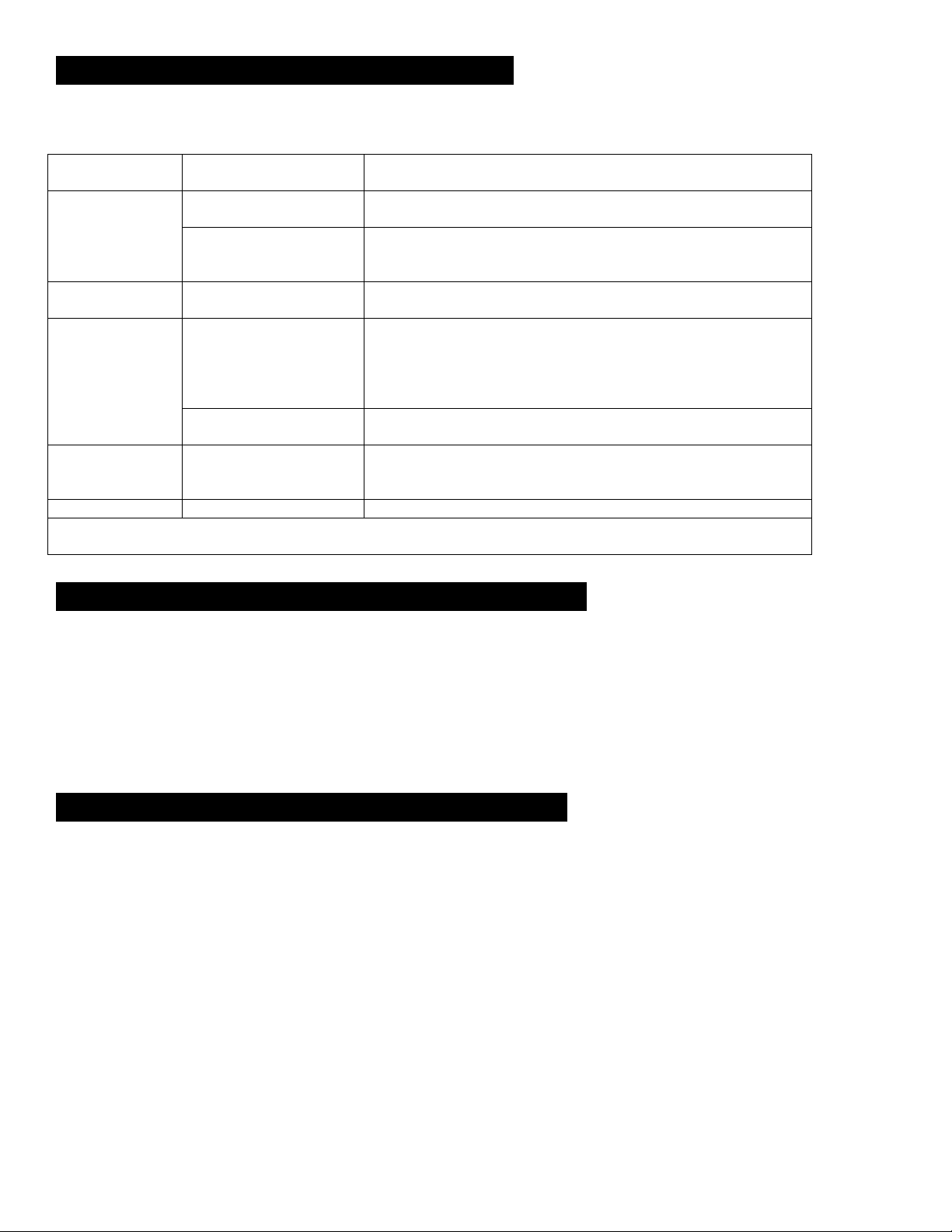

Operator Controls – On Primary Power

Control Pushbutton

Existing Conditions(s)

Action When Pressed

*HORN ENABLE

/ DISABLE

HORN DISABLED

indicator is blinking

Horn Disable indicator will turn OFF and the horn be Enabled

HORN DISABLE

indicator is OFF.

Horn Disable indicator will start blinking and the horn will be

disabled for 12 hours. After 12 hours, the indicator will turn

OFF automatically and the horn will then be Enabled.

ALARM TEST

Alarm indicator, auxiliary relay, and horn (if enabled) turn On.

These actions remain until the button is released.

MANUAL RUN

A pump is running

The pump that is running will be turned OFF; the next pump in

sequence will be turned ON. That pump will remain on as long

as the button is held. When the button is released, that pump

will turn off if the condition calling for a pump to run is no

longer present.

Neither pump is running

The next pump in sequence will be turned ON and will remain

on Until the button is released.

SYSTEM

RESET

Alarm, Pump 1 and / or

Pump 2 LED’s are

blinking

The system will reset and the Alarm, Pump 1 and / or Pump 2

LED’s will stop blinking.

FUSE

Blown fuse

Manual resettable fuse

*Horn disable LED is on PDC-115 and PDC230 units only. Outdoor units, PDCW-115 and PDCW-230, have

an alarm silence switch on the exterior of the unit.

An operator has access to front – panel push-button controls to change the horn enable status, to test the alarm circuits,

and to manually run the pumps. Each pump is protected by a manual resettable fuse; the fuses are located on the side

panel.

General operation – On Alarm Backup Power

On alarm backup power, the controller CANNOT run the pumps. Pumps will ONLY operate when primary (115Vac or

230Vac) is supplied to the control panel.

The Alarm Float switch mounted in the tank is used to monitor liquid level to possibly indicate when an alarm level might

be reached. The Pump Float switch is not used when the panel is on alarm backup power, since pumps cannot operate.

Front panel indicator show various operating conditions like alarm status, horn disable status, and other conditions.

Operator push-button controls are available to manually test the alarm circuits, and to disable the alarm horn.

When the liquid level drops below the Alarm Float, the switch will be open and there is no alarm condition; when the liquid

level rises above the ALARM Float, the switch will be CLOSED and an alarm condition will be indicated.

Alarm Operation – On Alarm Backup power

While on alarm backup power, if water fills the tank and the liquid level rises above the Alarm Float, the float switch will be

ON and an alarm condition is activated. The following occurs when an alarm condition activates:

1) The alarm indicator on the front panel of the controller will blink.

2) The auxiliary relay will activate once for one minute, closing its normally open contacts and opening its normally

closed contacts, then will de-activate.

3) If the horn is enabled (i.e. its indicator is NOT blinking) the horn will beep.

©Copyright 2013 Liberty Pumps Inc. All rights reserved 5

Page 6

Operator Controls – On Alarm Backup Power

Control Pushbutton

Existing Condition(s)

Action When Pressed

*HORN ENABLE

/ DISABLE

HORN DISABLE

indicator is blinking

Horn Disable indicator will stop blinking and the horn will be enabled.

HORN DISABLE

indicator is OFF

Horn disabled indicator will start blinking and the horn will be disabled for

12 hours. After 12 hours, the indicator will turn off automatically and the

horn will then be enabled

ALARM TEST

Horn, alarm indicator, and auxiliary relay will turn on. They will remain in

that state until the button is released

MANUAL RUN

The button press is ignored due to lack of primary power.

*Horn disable LED is on PDC-115 and PDC230 units only. Outdoor units, PDCW-115 and PDCW-230, have an alarm

silence switch on the exterior of the unit.

Indicator

Indicator State

Description

POWER

LED

Off

Power is off to the panel and the backup alarm battery is dead.

Blinking

Primary power to the panel is Off; the panel is on alarm backup power. Pumps will

NOT run. See the section on Alarm Backup Power.

*Horn

Disable LED

Off

Horn operation is Enabled. The horn Will beep on and off in an alarm condition.

Blinking

Horn operation is Disabled.

Alarm LED

Off

There is no alarm condition.

Blinking

An alarm condition is active.

PUMP 1

LED

OFF

The Pump 1 indicator will always be OFF when on alarm backup power.

PUMP 2

LED

OFF

The Pump 2 indicator will always be OFF when on alarm backup power.

HORN

OFF

No alarm condition is present.

BEEPING

An alarm condition is present.

*Horn disable LED is on PDC-115 and PDC230 units only. Outdoor units, PDCW-115 and PDCW-230, have an alarm

silence switch on the exterior of the unit.

The operator has access to front – panel push – button controls to change the horn enable status, to test the alarm

circuits, and to manually run the pumps.

Front-Panel Indicators – On Alarm Backup Power (9 volt battery)

The horn and LED indicators on the front panel, are used to show various conditions in the controller. Each indicator is

described below.

©Copyright 2013 Liberty Pumps Inc. All rights reserved 6

Page 7

Manual de instalación 8338000D

ProVore

®

Duplex Control

Modelos para interiores:

PDC-115 – 115 Voltios

PDC-230 – 230 Voltios

Modelos para exteriores:

PDCW-115 – 115 Voltios

PDCW-230 – 230 Voltios

7000 Apple Tree Avenue

Bergen, NY 14416

Teléfono: (800) 543-2550

Fax: (585) 494-1839

www.libertypumps.com

Índice

0.) Información general

1.) Operación general - Con energía primaria (115 VCA o 230 VCA)

2.) Operación de la alarma

3.) Indicadores del panel delantero

4.) Condición de alarma al bombear - Con energía primaria

5.) Controles del operador - Con energía primaria

6.) Operación general - Con energía de alarma de respaldo

7.) Operación de la alarma - Con energía de alarma de respaldo

8.) Controles del operador - Con energía de alarma de respaldo

9.) Indicadores del panel delantero - Con energía de alarma de respaldo (batería de 9 voltios)

Diseñados para usarse con las bombas Liberty

Bombas trituradoras residenciales ProVore® de 1 hp

©Copyright 2013 Liberty Pumps Inc. Todos los derechos reservados

Page 8

ADVERTENCIA

Modelos para

interiores:

PDC-115

PDC-230

Respaldo de

batería de 9 voltios

Botones de la interfaz

del usuario

Indicadores LED

desconexión del

interruptor

receptáculos

bomba 1 y 2

20 Amp (115 V)

15 Amp (230 V)

disyuntores de restablecimiento

Cable de

alimentación

PDC-115: 115 V 20 A

PDF-230: 230 V 15 A

Modelos para exteriores:

PDCW-115

PDCW-230

Indicadores LED

Faro de alarma ROJO

Interruptor para

silenciar alarma

Pestillo

asegurable

Batería de 9 V

Sirena de la

alarma

Conectores estancos

Botones de la interfaz del usuario

20 Amp (115 V)

15 Amp (230 V)

disyuntores de restablecimiento

Información general

Lea con atención estas instrucciones antes de instalar la unidad. Todas las bombas de Liberty se someten individualmente a pruebas en

fábrica para garantizar un funcionamiento adecuado. Siga estas instrucciones al pie de la letra para prevenir problemas de funcionamiento

y asegurar años de servicio satisfactorio.

Riesgo de descarga eléctrica. Desconecte siempre el controlador de la fuente de alimentación antes de abrir el chasis.

Este controlador viene con un conductor de conexión a tierra y un enchufe de toma a tierra. Conecte la bomba a un

tomacorriente a tierra debidamente conectado a tierra para evitar el riesgo de descargas eléctricas.

NO derive los cables de puesta a tierra ni retire las clavijas a tierra de los enchufes.

Con este controlador hay que utilizar un circuito derivado independiente, debidamente conectado tierra y con fusibles

adecuados. Asegúrese que la fuente de potencia tenga suficiente capacidad para cumplir los requisitos de voltaje y

amperaje indicados en la placa de las bombas.

El tomacorriente deberá encontrarse al alcance del cable de alimentación y a 1.2 m (4 pies) como mínimo por encima

del nivel del piso para evitar riesgos en caso de inundación. NO use cables de extensión.

Se deberá instalar la unidad según las disposiciones del Código eléctrico nacional (NEC, por sus siglas en inglés), el Código

unificado de plomería, el Código internacional de plomería, y todos los códigos y regulaciones locales que correspondan.

NO use este producto para líquidos inflamables o corrosivos.

NO use este producto en aplicaciones en las que el contacto humano con el fluido bombeado sea común (por ejemplo,

piscinas, fuentes, etc.).

El sistema ProVore® de control doble (serie PDC) monitorea la operación

de dos bombas trituradoras ProVore®. El sistema de control viene en

dos partes, el controlador con interfaz de usuario y los interruptores del

flotador montados dentro de la cubeta. El sistema P680 incluye dos

bombas ProVore® y dos interruptores para la esfera del flotador. Los

dos interruptores para la esfera del flotador están conectados de tal

manera que solamente tres cables salen de la tapa. Los tres cables,

dos cables de alimentación de la bomba y el cable de control deben

conectarse dentro de la caja del controlador para los modelos interiores,

PDC-115 y PDC-230. Las unidades exteriores requieren cableado, los

extremos de tapón de las bombas y el interruptor debe estar apagado y

desforrados adecuadamente. La caja de control monitorea el nivel de

líquido en la cubeta y alterna las dos bombas trituradoras en cada ciclo,

de tal manera que ambas mantengan un nivel de desgaste equitativo.

En caso de que falle una bomba, el sistema cambiará automáticamente a

la otra bomba. En la cara del controlador encontrará diversas luces LED

y pulsadores que permiten al usuario monitorear y controlar el sistema.

Ambos controladores requieren un circuito dedicado con la capacidad

de amperaje adecuada. El modelo PDC(W)-115 requiere 115 V, 20 amp

de servicio, mientras que el modelo PDC(W)-230 es de 230 V, 15 amp.

©Copyright 2013 Liberty Pumps Inc. Todos los derechos reservados 2

Page 9

El panel interior debe

quitarse para poder

cablear el sistema

contactos

auxiliares

Bloque de

terminales:

Entrante

Bomba 1

Bomba 2

interruptor

orejas de

puesta a tierra

entrada del cable

protección hermética

contra tirones

Modelos: Los modelos PDCW-115 Y PDCW-230

requieren cableado, el panel interior debe retirarse

para brindar acceso a los bloques de terminales dentro

del panel. El tapón de las bombas y el interruptor

deben estar desconectados y los cables desforrados.

Pase los cables junto con la energía entrante, a través

de los bujes de alivio de la protección contra tirones de

agua y cablee en el bloque de terminales montado en

el panel PDC. Se incluye un plano esquemático del

cableado a un lado del bloque de terminales. El panel

tiene un bloque de terminales secundario para

contactos auxiliares, si se requiere.

Por lo general, el controlador opera con energía

primaria (115 VCA o 230 VCA), pero si falla esa

energía, una batería interna de 9 V permite al

controlador monitorear el nivel de líquido y activar la

alarma, en caso de ser necesario.

Cuando se utiliza la energía de la alarma de respaldo

(9 V), el controlador no puede operar las bombas. Las

bombas solamente operarán cuando se suministre

energía primaria al panel de control.

Cuando se utiliza la energía de la alarma de respaldo,

el operador puede probar los circuitos de la alarma y

cambiar el estado de habilitar/inhabilitar la sirena.

Como las bombas no funcionan cuando el controlador

está funcionando con la energía de la alarma de

respaldo, la función de operación manual no va a

funcionar.

Operación general - Con energía primaria (115 VCA o 230 VCA)

El panel PDC controla la operación de dos bombas trituradoras ProVore® en una aplicación de fase de descenso en vacío.

Se montan dos flotadores a una barra: un interruptor del flotador de control de la bomba principal y un interruptor del flotador

de la alarma. En el panel delantero del controlador se encuentran indicadores que muestran diversas condiciones de

operación, como estado de funcionamiento de la bomba, estado de la alarma, estado para habilitar/inhabilitar la sirena y

otras condiciones. El operador tiene disponibles controles de botones para hacer funcionar las bombas manualmente,

probar la alarma manualmente, e inhabilitar o habilitar la sirena de la alarma, así como para reiniciar el sistema. Las dos

bombas tienen protección individual con un fusible de reinicio manual para aislar una bomba que falle.

Cuando el agua que entra activa el interruptor de la bomba principal, el controlador energizará una de las bombas.

Normalmente, el nivel de agua en el drenaje bajará mientras la bomba esté funcionando; la bomba se apagará cuando el

interruptor de la bomba principal se mueva a la posición de apagado. En el siguiente ciclo de bombeo, el controlador

activará la siguiente bomba en secuencia empezando por la que funcionaba anteriormente, generando una redundancia

de bombeo en el sistema. El controlador seguirá alternando las bombas en cada ciclo.

Operación de la alarma

En caso de que el agua llene el tanque con más rapidez de lo que puede bombear, o si una bomba falla, el nivel puede

llegar a un punto de activación de la alarma al activar el interruptor del flotador de alarma. Cuando se activa una

condición de alarma ocurre lo siguiente:

1) La bomba que funciona (o que debería funcionar) se apaga y la siguiente bomba en la secuencia se enciende.

2) Si el flotador de la alarma se mantiene cerrado (en la posición hacia arriba) por 4 segundos, el indicador de la

alarma en el panel delantero del controlador se encenderá sin destellar.

3) Se activará el relevo auxiliar, cerrando sus contactos normalmente abiertos y abriendo sus contactos normalmente

cerrados.

4) Si se habilita la sirena (es decir, su indicador NO destella), sonará la sirena.

Nota: una condición de alarma se mantendrá activa hasta que el nivel del líquido quede por debajo del interruptor del

flotador de la bomba. Cuando eso pase, ocurrirá lo siguiente:

©Copyright 2013 Liberty Pumps Inc. Todos los derechos reservados 3

Page 10

1) La bomba en funcionamiento se apagará.

Indicador

Estado del

indicador

Descripción

LED de

energía

Apagada

La energía al panel está desconectada y la batería está descargada

Encendido

continuamente

La energía principal al panel está activada

Intermitente

La energía primaria hacia el panel está apagada; el panel funciona con energía de la

alarma de respaldo. Las bombas NO funcionarán. Vea los indicadores del panel

delantero - Con energía de la alarma de respaldo.

*LED para

inhabilitar la

sirena

Intermitente

Se INHABILITA la operación de la sirena. La sirena NO sonará en una condición de

alarma.

Apagada

Se HABILITA la operación de la sirena. La sirena SONARÁ en una condición de

alarma

LED de

alarma

Apagada

No hay condición de alarma

Encendido

continuamente

Una condición de alarma está activa

Intermitente

El interruptor del flotador de la alarma no funciona adecuadamente

LED de la

bomba 1

Apagada

No se manda señal a la bomba para que funcione

Encendido

continuamente

Se manda señal a la bomba para que funcione

Intermitente

Ocurrió varias veces una condición de alarma en el bombeo; vea más adelante la

sección de Condiciones de alarma en el bombeo

LED de la

bomba 2

Apagada

No se manda señal a la bomba para que funcione

Encendido

continuamente

Se manda señal a la bomba para que funcione

Intermitente

Ocurrió varias veces una condición de alarma en el bombeo; vea más adelante la

sección de Condiciones de alarma en el bombeo

LED de la

bomba 1 y de

la bomba 2

Intermitente

El interruptor del flotador principal no funciona adecuadamente.

Sirena

Apagada

No hay condiciones de alarma presentes, y la batería de respaldo de la alarma está

en buenas condiciones

Encendida

Existe una condición de alarma

Chirrido

El voltaje de la batería de respaldo de la alarma está bajo y debe cambiarse la batería

*El LED para inhabilitar la sirena está solamente en las unidades PDC-115 y PDC230. Las unidades exteriores,

PDCW-115 y PDCW-230, tienen un interruptor para silenciar la alarma en la parte exterior de la unidad.

2) El indicador de alarma del panel delantero se apagará.

3) El relevo auxiliar se desactivará.

4) La sirena (si está encendida) se apagará.

Si el flotador de la alarma se mantiene cerrado (en la posición hacia arriba) durante 6 horas, pero el interruptor del flotador

primario está abierto (en la posición hacia abajo), la luz de la alarma destellará y la bomba se apagará. Esta función

impide que la bomba funcione de manera indefinida.

Indicadores del panel delantero

La sirena y los indicadores de LED del panel delantero se usan para mostrar diversas condiciones del controlador.

Cada indicador se describe a continuación.

©Copyright 2013 Liberty Pumps Inc. Todos los derechos reservados 4

Page 11

Condición de alarma al bombear - Con energía primaria

LED intermitente

Problema relacionado

Luz de energía

No hay energía de CA, el disyuntor se ha disparado o se interrumpió la electricidad

Bomba 1

La bomba no operó, el fusible de desconectó, el impulsor se trabó, desconectó,

hubo un corto circuito...

Bomba 2

La bomba no operó, el fusible de desconectó, el impulsor se trabó, desconectó,

hubo un corto circuito...

Bomba 1 y bomba 2

Interruptor del flotador primario; se quedó mecánicamente abierto o se enredó en

una condición de abierto.

Luz de alarma

Interruptor del flotador de alarma; se quedó mecánicamente cerrado o se enredó

en una condición de cerrado.

Botón de control

Condiciones existentes

Acción al presionar

*HABILITAR/INHABILITAR

SIRENA

El indicador SIRENA

INHABILITADA está

destellando

El indicador para inhabilitar sirena se apagará y se habilitará

la sirena

El indicador

INHABILITAR SIRENA

está APAGADO.

El indicador Inhabilitar sirena comenzará a destellar y la sirena

estará inhabilitada 12 horas. Después de 12 horas, el indicador

se apagará AUTOMÁTICAMENTE y se habilitará la sirena.

PRUEBA DE LA ALARMA

Se encienden el indicador de alarma, el relevo auxiliar y la

sirena (si está habilitada). Estas acciones continuarán hasta

soltar el botón.

OPERACIÓN MANUAL

Una bomba está

funcionando

La bomba que funcione se apaga y la siguiente bomba en la

secuencia se enciende. La bomba se mantendrá encendida

mientras se mantenga presionado el botón. Cuando se suelta

el botón, esa bomba se apagará si la condición que solicita

que funcione la bomba ya no está presente.

Ninguna bomba

funciona

La siguiente bomba en la secuencia se encenderá y se

mantendrá encendida hasta que se suelte el botón.

REINICIO DEL SISTEMA

LED intermitente de

alarma, bomba 1 y/o

bomba 2.

El sistema se reinicia y dejarán de destellar los LED de alarma,

bomba 1 y/o bomba 2.

FUSIBLE

Fusible fundido

Fusible reiniciable manualmente

*El LED para inhabilitar la sirena está solamente en las unidades PDC-115 y PDC230. Las unidades exteriores,

PDCW-115 y PDCW-230, tienen un interruptor para silenciar la alarma en la parte exterior de la unidad.

El controlador monitorea una "condición de alarma en el bombeo", donde se pide que funcione una bomba y el nivel de

líquido sigue subiendo y sobrepasa el interruptor del flotador de alarma. Si ocurre una condición de alarma en el bombeo

tres o más de las últimas cinco veces que se pidió que funcionara la bomba, el indicador de la bomba destellará indicando

que se deben comprobar los componentes del sistema. Cualquiera de las siguientes condiciones puede provocar una

condición de alarma en el bombeo:

1) Una bomba no funciona

2) El interruptor del flotador de alarma se queda (pegado mecánicamente) en la posición cerrada (encendido,

o arriba).

3) Existe un problema (bloqueo o fuga) en la plomería de flujo saliente

4) El caudal de agua entrante es mayor que la tasa de bombeo saliente.

5) El interruptor del flotador primario se queda (pegado mecánicamente) en la posición de abierto (apagado,

o abajo).

Una luz intermitente indica que falló un componente y que requiere mantenimiento. Para asistir al técnico de servicio,

el controlador indicará el componente que ha fallado.

Controles del operador - Con energía primaria

Un operador tiene acceso a los controles de botón del panel delantero para cambiar el estado de habilitar la sirena, para

probar los circuitos de la alarma y para activar manualmente las bombas. Cada bomba está protegida por un fusible

reiniciable manualmente; los fusibles se encuentran en el panel lateral.

©Copyright 2013 Liberty Pumps Inc. Todos los derechos reservados 5

Page 12

Operación general - Con energía de alarma de respaldo

Botón de control

Condiciones

existentes

Acción al presionar

*HABILITAR/INHABILITAR

SIRENA

El indicador

SIRENA

INHABILITADA está

destellando.

El indicador de inhabilitar sirena dejará de destellar y la sirena se

habilitará.

El indicador

INHABILITAR

SIRENA está

apagado.

El indicador de sirena inhabilitada dejará de destellar y la sirena

estará inhabilitada 12 horas. Después de 12 horas, el indicador se

apagará automáticamente y la sirena quedará habilitada.

PRUEBA DE LA ALARMA

La sirena, el indicador de alarma y el relevo auxiliar se encenderán.

Se mantendrán en ese estado hasta que se suelte el botón.

OPERACIÓN MANUAL

Se ignora la presión del botón debido a la falta de energía primaria.

*El LED para inhabilitar la sirena está solamente en las unidades PDC-115 y PDC230. Las unidades exteriores, PDCW-115

y PDCW-230, tienen un interruptor para silenciar la alarma en la parte exterior de la unidad.

Con la energía de alarma de respaldo, el controlador NO PUEDE hacer funcionar las bombas. Las bombas funcionarán

SOLAMENTE cuando se suministre energía primaria (115 VCA o 230 VCA) al panel de control.

El interruptor del flotador de alarma montado en el tanque se usa para monitorear el nivel de líquido, para indicar

posiblemente cuando se pudiera alcanzar un nivel de alarma. El interruptor del flotador de alarma no se usa cuando el

panel está con potencia de respaldo de alarma, puesto que las bombas no pueden operar.

El indicador del panel delantero muestra diversas condiciones de operación, como estado de alarma, estado de

inhabilitar sirena y otras condiciones. Los controles de botón del operador están disponibles para realizar pruebas

manuales a los circuitos de alarma y para inhabilitar la sirena de la alarma.

Cuando el nivel de líquido cae por debajo del flotador de la alarma, el interruptor se abrirá y ya no habrá condición de

alarma; cuando el nivel de líquido sube por encima del flotador de ALARMA, el interruptor se CERRARÁ y se indicará

una condición de alarma.

Operación de la alarma - Con energía de alarma de respaldo

Con energía de alarma de respaldo, si el tanque se llena de agua y el nivel de líquido sube por encima del flotador de

alarma, el interruptor del flotador se encenderá y se activará una condición de alarma. Cuando se activa una condición de

alarma ocurre lo siguiente:

1) El indicador de alarma en el panel delantero del controlador va a destellar.

2) El relevo auxiliar se activará una vez por un minuto, cerrando sus contactos normalmente abiertos y abriendo sus

contactos normalmente cerrados, y luego se desactivará.

3) Si la sirena está habilitada (es decir, su indicador NO destella), la sirena va a emitir un sonido.

Controles del operador – Con energía de alarma de respaldo

El operador tiene acceso a los controles de botones delanteros (del panel) para cambiar el estado de habilitar sirena,

para probar los circuitos de la alarma y para operar manualmente las bombas.

©Copyright 2013 Liberty Pumps Inc. Todos los derechos reservados 6

Page 13

Indicadores del panel delantero - Con energía de alarma de respaldo

Indicador

Estado del

indicador

Descripción

LED DE

ENERGÍA

Apagada

No hay potencia en el panel y la batería de respaldo de la alarma está descargada.

Intermitente

La energía primaria hacia el panel está apagada; el panel funciona con energía de

la alarma de respaldo. Las bombas NO funcionarán. Consulte la sección sobre

energía de respaldo de la alarma.

*LED de

sirena

inhabilitada

Apagada

La operación de la sirena está habilitada. La sirena emitirá un sonido intermitente

en condición de alarma.

Intermitente

La operación de la sirena está inhabilitada.

LED de

alarma

Apagada

No hay condición de alarma

Intermitente

Una condición de alarma está activa.

LED DE LA

BOMBA 1

Apagada

El indicador de la bomba 1 siempre estará apagado al funcionar con energía de

respaldo de la alarma.

LED DE LA

BOMBA 2

Apagada

El indicador de la bomba 2 siempre estará apagado al funcionar con energía de

respaldo de la alarma.

SIRENA

Apagada

No existe una condición de alarma.

EMITE

SONIDOS

Existe una condición de alarma

*El LED para inhabilitar la sirena está solamente en las unidades PDC-115 y PDC230. Las unidades exteriores,

PDCW-115 y PDCW-230, tienen un interruptor para silenciar la alarma en la parte exterior de la unidad.

(batería de 9 voltios)

Los indicadores de sirena y de LED en el panel delantero se usan para mostrar diversas condiciones en el controlador.

Cada indicador se describe a continuación.

©Copyright 2013 Liberty Pumps Inc. Todos los derechos reservados 7

Page 14

Manuel d’installation 8338000D

Commande de ProVoreMD double

Modèles intérieurs :

PDC-115, 115 volts

PDC-230, 230 volts

Modèles extérieurs :

PDCW-115, 115 volts

PDCW-230, 230 volts

7000 Apple Tree Avenue

Bergen, NY 14416, USA

Téléphone : 1 800 543-2550

Télécopieur : 585 494-1839

www.libertypumps.com

Table des matières

0.) Renseignements généraux

1.) Fonctionnement, avec source principale d'alimentation électrique (120 V CA ou 230 V CA)

2.) Fonctionnement de l'alarme

3.) Indicateurs du panneau avant

4.) Situation d'alarme pendant le pompage, avec source principale d'alimentation électrique

5.) Commandes de l'opérateur, avec source principale d'alimentation électrique

6.) Fonctionnement, avec alimentation de secours de l'alarme

7.) Fonctionnement de l'alarme, avec alimentation de secours de l'alarme

8.) Commandes de l'opérateur, avec alimentation de secours de l'alarme

9.) Indicateurs du panneau avant, avec alimentation de secours de l'alarme (pile de 9 volts)

Conçus pour fonctionner avec les pompes broyeuses

résidentielles ProvoreMD 1 HP de Liberty Pumps

©Copyright 2013 Liberty Pumps Inc. Tous droits réservés

Page 15

Modèles

intérieurs :

PDC-115

PDC-230

Modèles extérieurs :

PDCW-115

PDCW-230

Indicateurs DEL

Boutons d'interface utilisateur

Boutons d'interface

utilisateur

Interrupteur de

l'alarme sonore

Loquet

verrouillable

Pile de 9 V

Alarme

sonore

20 A (115 V)

15 A (230 V)

disjoncteurs réarmables

Connecteurs étanches

Pile auxiliaire

de 9 volts

Voyant ROUGE de l'alarme

Indicateurs DEL

Cordon

d'alimentation

PDC-115 : 115V 20A

PDF-230: 230V 15A

Prises,

pompe 1 et 2

20 A (115 V)

15 A (230 V)

disjoncteurs réarmables

AVERTISSEMENT

Sectionneurinterrupteur

Renseignements généraux

Lire attentivement les directives avant d’effectuer l’installation. Chaque pompe de marque Liberty est testée individuellement en usine

pour assurer un bon fonctionnement. Le fait de suivre ces directives à la lettre éliminera les risques de dysfonctionnement et assurera

des années de fonctionnement sans soucis.

Danger d’électrocution. Toujours débrancher le régulateur de la source d'alimentation avant d'ouvrir l'enceinte.

Ce régulateur est fourni avec un conducteur de mise à la terre et une fiche de branchement de type mise à la terre. Afin de

réduire les dangers d'électrocution, s’assurer que la pompe est raccordée seulement à une prise correctement mise à la terre.

NE PAS dévier les fils de mise à la terre ou retirer la broche de mise à la terre des fiches de branchement.

Ce régulateur nécessite un circuit de dérivation dédié correctement protégé par un fusible et mis à la terre. S’assurer

que la source d’alimentation électrique est suffisante pour répondre aux exigences de tension et d’intensité du courant

électrique des pompes, tel qu’indiqué sur la plaque signalétique.

La prise électrique doit se trouver à la portée du cordon d’alimentation et à au moins 1,2 m (4 pi) au-dessus du niveau

du plancher pour minimiser les dangers liés à une inondation. NE PAS utiliser de rallonge électrique.

L’installation doit être faite en respectant le Code national de l’électricité, le Uniform Plumbing Code, le Code international

de plomberie ainsi que tous les codes locaux et règlements en vigueur.

NE PAS utiliser ce produit pour pomper des liquides inflammables ou corrosifs.

NE PAS utiliser ce produit pour les installations où le contact humain avec les liquides pompés est fréquent (piscines,

fontaines, etc.)

Le système de commande double ProVoreMD (série PDC) contrôle le

fonctionnement de deux pompes broyeuses ProVoreMD. Le système de

commande est composé de deux pièces, le régulateur avec interface

utilisateur et les interrupteurs à flotteur installés à l'intérieur du bassin.

Le système P680 comprend deux pompes ProVoreMD et deux interrupteurs

flotteurs à boule. Les interrupteurs flotteurs à boule sont raccordés de façon

à ce que seulement trois cordons sortent du couvercle. Les trois cordons,

deux pour l'alimentation de la pompe et le troisième pour la commande,

doivent être branchés dans le boîtier du régulateur pour les modèles

intérieurs, PDC-115 et PDC-230. Les modèles extérieurs nécessitent un

câblage direct; il est nécessaire de couper les extrémités des fiches de la

pompe et de l'interrupteur et de dénuder adéquatement les fils. Le boîtier

de commande contrôle le niveau de liquide dans le bassin et fait fonctionner

les deux pompes broyeuses en alternance de façon à garantir l'uniformité

de l'usure des deux pompes. En cas de défaillance d'une pompe, le système

bascule automatiquement vers l'autre pompe. Le devant du régulateur

comporte un certain nombre de voyants DEL et de boutons poussoirs qui

permettent à l'utilisateur de surveiller et contrôler le système. Les deux

régulateurs requièrent un circuit dédié ayant l'intensité admissible adéquate.

Le modèle PDC(W)-115 exige un circuit de 115 V et 20 ampères alors que

le PDC(W)-230 requiert 230 V et 15 ampères alors que le.

©Copyright 2013 Liberty Pumps Inc. Tous droits réservés 2

Page 16

il est nécessaire de retirer

le panneau intérieur afin

d'effectuer le câblage

direct du système

contacts auxiliaires

Plaque à bornes :

Entrée

Pompe nº 1

Pompe nº 2

interrupteur

chevilles de

mise à la terre

entrée du cordon

réducteur de tension étanche

Modèles : Les modèles PDCW-115 et PDCW-230

nécessitent un câblage direct; il est nécessaire de retirer

le panneau intérieur afin d'avoir accès à la plaque à

bornes située à l'intérieur. Il faut également couper les

extrémités des fiches de la pompe et de l'interrupteur et

dénuder les fils. Enfiler ensuite les cordons, ainsi que

l'alimentation électrique, à travers les raccordements du

réducteur de tension étanche jusqu'à la plaque à bornes

fixée à l'intérieur du panneau PDC. Un schéma du câblage

est fourni à côté de la plaque à bornes. Le panneau

possède une plaque à bornes secondaire pour les

raccordements secondaires, au besoin.

Le régulateur est normalement alimenté par la source

électrique principale (115 V CA ou 230 V CA), mais en

cas de panne électrique, une pile interne de 9 volts

permet au régulateur de surveiller le niveau de liquide

et d'activer l'alarme au besoin.

Le régulateur ne peut pas activer les pompes lorsqu'il

est alimenté par la pile de secours de l'alarme (9 volts).

Les pompes fonctionneront uniquement lorsqu'une

source principale d'alimentation électrique est

raccordée au panneau de commande.

L'opérateur peut vérifier les circuits d'alarme et peut modifier

l'état d'activation ou de désactivation de l'alarme sonore

lorsqu'alimentée par la source de secours. Puisque les

pompes ne fonctionnent pas quand le régulateur est

alimenté par la source d'alimentation de secours de

l'alarme, la caractéristique d'activation manuelle ne sera

pas fonctionnelle.

Fonctionnement, avec source principale d'alimentation électrique

(120 V CA ou 230 V CA)

Le panneau PDC commande le fonctionnement de deux pompes broyeuses ProVoreMD lorsqu'utilisées pour la vidange.

Deux flotteurs sont installés au Quicktree : un interrupteur à flotteur qui commande la pompe principale et un interrupteur

à flotteur d'alarme. Sur le panneau avant du régulateur, on retrouve des indicateurs qui affichent les diverses situations de

fonctionnement comme l'état de fonctionnement de la pompe, l'état de l'alarme sonore (activée/désactivée) et d'autres

situations. Des commandes à bouton-poussoir sont présentes afin que l'opérateur active manuellement les pompes,

vérifie manuellement l'alarme, active ou désactive l'alarme sonore, réinitialise le système. Les deux pompes sont

protégées individuellement grâce à un fusible de réinitialisation manuelle qui isole une pompe défectueuse.

Lorsque de l'eau qui entre active l'interrupteur de la pompe principale, le régulateur met l'une des pompes sous tension.

Normalement le niveau d'eau dans le puisard diminue au fur et à mesure que la pompe fonctionne; la pompe s'arrête

lorsque l'interrupteur de la pompe principale descend à la position Arrêt. Lors du prochain cycle de pompage, le

régulateur activera la pompe de la séquence qui suit celle qui fonctionnait précédemment, assurant le pompage continu

du système. Le régulateur continuera d'activer les pompes en alternance à chaque cycle.

Fonctionnement de l'alarme

Advenant que l'eau remplisse le réservoir plus rapidement qu'il ne peut être vidangé, ou si une pompe est défectueuse, le

niveau peut atteindre un seuil d'alerte en basculant l'interrupteur à flotteur de l'alarme. La situation suivante se produit

lorsqu'une alarme se déclenche :

1) La pompe qui est (ou devrait être) sous tension est mise hors tension et la pompe suivante dans la séquence est

mise sous tension.

2) Lorsque le flotteur de l'alarme demeure fermé (vers le haut) pendant 4 secondes, l'indicateur d'alarme du

panneau avant du régulateur s'allumera.

3) Le relais auxiliaire s'active alors, fermant ainsi ses contacts normalement ouverts et ouvrant ses contacts

normalement fermés.

4) Si l'alarme sonore est activée (c.-à-d. que son indicateur NE clignote PAS), on entend la sonnerie.

©Copyright 2013 Liberty Pumps Inc. Tous droits réservés 3

Page 17

Remarque : une situation d'alarme demeurera active jusqu'à ce que le niveau de liquide redescende sous l'interrupteur à

Indicateur

État de

l'indicateur

Description

Del de mise

sous tension

Éteint

Le courant n'alimente pas le panneau et la pile est morte

Constamment

allumé

Le panneau est alimenté par la source principale d'alimentation électrique

Clignotant

Le panneau n'est pas alimenté par la source principale d'alimentation électrique;

le panneau est alimenté par la source d'alimentation de secours de l'alarme. La pompe

NE fonctionnera PAS. Voir les indicateurs du panneau avant : l'alimentation de

secours de l'alarme.

DEL de

désactivation

de la sonnerie

Clignotant

La sonnerie est DÉSACTIVÉE. La sonnerie NE retentira PAS dans une situation

d'alarme.

Éteint

La sonnerie est ACTIVÉE. La sonnerie RETENTIRA dans une situation d'alarme

DEL d'alarme

Éteint

Aucune situation d'alarme

Constamment

allumé

Une situation d'alarme est en cours

Clignotant

L'interrupteur à flotteur de l'alarme ne fonctionne pas bien

DEL de la

pompe 1

Éteint

La pompe ne reçoit pas de signal de mise sous tension

Constamment

allumé

La pompe REÇOIT un signal de mise sous tension

Clignotant

Une situation d'alarme de pompage est survenue à plusieurs reprises; consulter la

rubrique Situations d'alarme de pompage ci-dessous

DEL de la

pompe 2

Éteint

La pompe ne reçoit pas de signal de mise sous tension

Constamment

allumé

La pompe REÇOIT un signal de mise sous tension

Clignotant

Une situation d'alarme de pompage est survenue à plusieurs reprises; consulter la

rubrique Situations d'alarme de pompage ci-dessous

DEL de la

pompe 1 et de

la pompe 2

Clignotant

L'interrupteur à flotteur principal ne fonctionne pas bien

Sonnerie

Hors tension

Absence de situation d'alarme, et la pile de secours de l'alarme est en bon état

Sous tension

En présence d'une situation d'alarme

Bruit strident

La tension de la pile de secours de l'alarme est faible et la pile devrait être

remplacée.

*Le DEL de désactivation de la sonnerie est présent sur les modèles PDC-115 et PDC230 seulement. Les modèles

extérieurs PDCW-115 et PDCW-230 sont munis d'un interrupteur de l'alarme sonore à l'extérieur de l'appareil.

flotteur de la pompe. Dans une telle situation, les actions suivantes se dérouleront :

1) La pompe qui fonctionne se mettra hors tension.

2) L'indicateur d'alarme du panneau avant s'éteindra.

3) Le relais auxiliaire se désactivera.

4) La sonnerie (si elle est activée) s'arrêtera.

Si le flotteur de l'alarme demeure fermé (vers le haut) pendant 6 heures, mais que l'interrupteur à flotteur principal est

ouvert (vers le bas), le voyant de l'alarme clignotera et la pompe sera mise hors tension. Cette fonction permet d'éviter

que la pompe fonctionne indéfiniment.

Indicateurs du panneau avant

On utilise la sonnerie et les indicateurs DEL du panneau avant pour montrer divers états du régulateur. Chaque indicateur

est décrit ci-dessous.

©Copyright 2013 Liberty Pumps Inc. Tous droits réservés 4

Page 18

Situation d'alarme pendant le pompage, – avec source principale

DEL clignotant

Problème associé

Voyant de mise

sous tension

Aucune alimentation en CA, disjoncteur principal sauté ou panne de courant

Pompe nº 1

La pompe ne fonctionne pas; fusible sauté, rotor obstrué, cordon débranché, court-circuit…

Pompe nº 2

La pompe ne fonctionne pas; fusible sauté, rotor obstrué, cordon débranché, court-circuit…

Pompe 1 et

pompe 2

Interrupteur à flotteur principal; coincé mécaniquement en position ouverte ou

enchevêtré en position ouverte.

Voyant d'alarme

Interrupteur à flotteur de l'alarme; coincé mécaniquement en position fermée ou

enchevêtré en position fermée

Bouton-poussoir de

commande

Conditions(s)

existante(s)

Action lorsqu'enfoncé

*ACTIVATION/

DÉSACTIVATION

DE LA SONNERIE

L'indicateur de la

DÉSACTIVATION

DE LA SONNERIE

clignote.

L'indicateur de désactivation de la sonnerie S'ÉTEINDRA et la

sonnerie sera activée.

L'indicateur de la

DÉSACTIVATION

DE LA SONNERIE

est éteint.

L'indicateur de désactivation de la sonnerie se met à clignoter

et la sonnerie est désactivée pendant 12 heures. Après 12

heures, l'indicateur s'éteindra automatiquement et la sonnerie

sera alors activée.

TEST D'ALARME

Indicateur d'alarme, relais auxiliaire et sonnerie (si activée)

mis sous tension. Ces actions demeurent inchangées tant que

le bouton est enfoncé.

ACTIVATION

MANUELLE

Une pompe

fonctionne

La pompe qui fonctionne sera mise hors tension; la pompe

suivante dans la séquence sera mise sous tension. Cette pompe

demeurera en fonction tant que le bouton est maintenu enfoncé.

Lorsque le bouton est relâché, la pompe s'arrêtera en l'absence

d'une situation exigeant qu'une pompe fonctionne.

Aucune des pompes

ne fonctionne

La pompe suivante dans la séquence sera mise sous tension

et le demeurera jusqu'à ce que le bouton soit relâché.

RÉINITIALISATION

DU SYSTÈME

Les DEL de l'alarme,

de la pompe 1 et/ou

de la pompe 2

clignotent

Le système se réinitialisera et les DEL de l'alarme, de la

pompe 1 et/ou de la pompe 2 cesseront de clignoter.

FUSIBLE

Fusible sauté

Fusible réarmable manuellement

*Le DEL de désactivation de la sonnerie est présent sur les modèles PDC-115 et PDC230 seulement. Les modèles

extérieurs PDCW-115 et PDCW-230 sont munis d'un interrupteur de l'alarme sonore à l'extérieur de l'appareil.

d'alimentation électrique

Le régulateur surveille une « situation d'alarme de pompage » lorsqu'une pompe reçoit un signal de mise sous tension et

que le niveau de liquide continue à monter et dépasse l'interrupteur à flotteur de l'alarme. Si une situation d'alarme de

pompage survient trois fois ou plus au cours des cinq derniers signaux de mise sous tension de la pompe, l'indicateur de

la pompe clignotera indiquant ainsi que l'on devrait vérifier certains composants du système. Une situation d'alarme de

pompage peut être occasionnée par l'une ou l'autre des conditions suivantes :

1) Une pompe ne fonctionne pas

2) L'interrupteur à flotteur de l'alarme demeure (mécaniquement coincé) en position fermée (en marche ou vers le haut).

3) Un problème est survenu (obstruction ou fuite) durant la vidange

4) Le débit de l'eau qui entre est supérieur à celui qui sort

5) L'interrupteur à flotteur principal demeure (mécaniquement coincé) en position ouverte (en arrêt ou vers le bas).

Un voyant clignotant indique la défaillance d'un composant et une réparation est nécessaire. Afin de faciliter la tâche du

technicien d'entretien, le régulateur indiquera quel composant a fait défaut.

Commandes de l'opérateur, avec source principale d'alimentation

électrique

L'opérateur a accès aux commandes à boutons-poussoirs du panneau avant pour changer l'état d'activation de la

sonnerie, pour tester les circuits de l'alarme et pour faire fonctionner manuellement les pompes. Chaque pompe est

protégée par un fusible réarmable manuellement situé sur le panneau latéral.

©Copyright 2013 Liberty Pumps Inc. Tous droits réservés 5

Page 19

Fonctionnement, avec alimentation de secours de l'alarme

Bouton-poussoir

de commande

Conditions(s)

existante(s)

Action lorsqu'enfoncé

*ACTIVATION/

DÉSACTIVATION

DE LA

SONNERIE

L'indicateur de la

DÉSACTIVATION

DE LA SONNERIE

clignote

L'indicateur de désactivation de la sonnerie cessera de clignoter et la

sonnerie sera activée

L'indicateur de la

DÉSACTIVATION

DE LA SONNERIE

est éteint

L'indicateur de désactivation de la sonnerie se mettra à clignoter et la

sonnerie sera désactivée pendant 12 heures. Après 12 heures, l'indicateur

s'éteindra automatiquement et la sonnerie sera alors activée.

TEST D'ALARME

La sonnerie, l'indicateur d'alarme et le relais auxiliaire se mettront en

marche. Ils demeureront dans cet état jusqu'à ce que le bouton soit relâché

ACTIVATION

MANUELLE

Il est inutile d'appuyer sur le bouton poussoir en raison de l'absence

d'alimentation électrique provenant de la source principale.

*Le DEL de désactivation de la sonnerie est présent sur les modèles PDC-115 et PDC230 seulement. Les modèles

extérieurs PDCW-115 et PDCW-230 sont munis d'un interrupteur de l'alarme sonore à l'extérieur de l'appareil.

Le régulateur NE PEUT PAS activer les pompes lorsqu'il est alimenté par la pile de secours de l'alarme. Les pompes

fonctionneront UNIQUEMENT lorsqu'une source principale d'alimentation électrique (115 V ca ou 230 V ca) est fournie au

panneau de commande.

L'interrupteur à flotteur de l'alarme installé dans le réservoir sert à surveiller le niveau de liquide et indiquer si le niveau

d'alarme a été atteint. L'interrupteur à flotteur de la pompe n'est pas utilisé lorsque le panneau est alimenté par la source

d'alimentation de secours de l'alarme, puisque les pompes ne peuvent pas fonctionner.

L'indicateur du panneau avant montre les diverses conditions de fonctionnement comme l'état de l'alarme, l'état d'activation

ou de désactivation de la sonnerie et d'autres conditions. Des commandes à bouton-poussoir sont disponibles afin que

l'opérateur teste manuellement les circuits de l'alarme et qu'il désactive la sonnerie de l'alarme.

Lorsque le niveau de liquide descend sous le flotteur d'alarme, l'interrupteur s'ouvre et aucune situation d'alarme n'est

présente; lorsque le niveau de liquide monte au-dessus du flotteur d'ALARME, l'interrupteur sera FERMÉ et la situation

d'alarme s'affichera.

Fonctionnement de l'alarme, avec alimentation de secours de l'alarme

Lorsqu'alimenté par la source d'alimentation de secours de l'alarme, si le réservoir se remplit d'eau et si le niveau de

liquide monte au-dessus du flotteur d'alarme, l'interrupteur à flotteur sera mis sous tension et une situation d'alarme sera

activée. La situation suivante se produit lorsqu'une alarme se déclenche :

1) L'indicateur d'alarme du panneau avant du régulateur clignotera.

2) Le relais auxiliaire s'activera pendant une minute, fermant ainsi ses contacts normalement ouverts et ouvrant ses

contacts normalement fermés, puis il se désactivera.

3) Si la sonnerie est activée (c.-à-d. que son indicateur NE clignote PAS) la sonnerie émettra un bip.

Commandes de l'opérateur : avec alimentation de secours de l'alarme

L'opérateur a accès aux commandes à boutons-poussoirs du panneau avant pour changer l'état d'activation de la

sonnerie, pour tester les circuits de l'alarme et pour faire fonctionner manuellement les pompes.

©Copyright 2013 Liberty Pumps Inc. Tous droits réservés 6

Page 20

Indicateurs du panneau avant, avec alimentation de secours de l'alarme

Indicateur

État de

l'indicateur

Description

DEL DE

MISE SOUS

TENSION

Éteint

Le courant n'alimente pas le panneau et la pile de secours de l'alarme est morte

Clignotant

Le panneau n'est pas alimenté par la source principale d'alimentation électrique;

le panneau est alimenté par la source d'alimentation de secours de l'alarme.

La pompe NE fonctionnera PAS. Consulter la rubrique portant sur l'alimentation de

secours de l'alarme.

*DEL de

désactivation

de la

sonnerie

Éteint

La sonnerie est activée. La sonnerie émettra un bip intermittent lors d'une situation

d'alarme.

Clignotant

La sonnerie est désactivée.

DEL

d'alarme

Éteint

Aucune situation d'alarme

Clignotant

Une situation d'alarme est en cours

DEL DE LA

POMPE 1

Éteint

L'indicateur de la pompe 1 sera toujours ÉTEINT lorsqu'alimenté par la source

d'alimentation de secours de l'alarme.

DEL DE LA

POMPE 2

Éteint

L'indicateur de la pompe 2 sera toujours ÉTEINT lorsqu'alimenté par la source

d'alimentation de secours de l'alarme.

SONNERIE

Hors tension

Aucune situation d'alarme

BIP SONORE

En présence d'une situation d'alarme

*Le DEL de désactivation de la sonnerie est présent sur les modèles PDC-115 et PDC230 seulement. Les modèles

extérieurs PDCW-115 et PDCW-230 sont munis d'un interrupteur de l'alarme sonore à l'extérieur de l'appareil.

(pile de 9 volts)

On utilise la sonnerie et les indicateurs DEL du panneau avant pour montrer divers états du régulateur. Chaque indicateur

est décrit ci-dessous.

©Copyright 2013 Liberty Pumps Inc. Tous droits réservés 7

Loading...

Loading...