Liberty Pumps PC237-441, PC257-441, PC457-441, PCS37-441, PC237-442-10A Installation Manual

...

Installation Manual 4428000F

PC SERIES

Sump Pump Combo Series with 12V Battery Backup

441 Series:

PC237-441

PC257-441

PC457-441

PCS37-441

442 Series:

PC237-442-10A

PC237-442-10A-EYE

PC257-442-10A

PC257-442-10A-EYE

PC457-442-10A

PC457-442-10A-EYE

PCS37-442-10A

PCS37-442-10A-EYE

Contents

1) General Information / Safety Guidelines

Installer: Please leave this manual

with the owner/operator for future

reference.

2) Installation

3) Exploded View

PUMPS

7000 Apple Tree Avenue

Bergen, NY 14416

Phone: (800) 543-2550

Fax: (585) 494-1839

www.libertypumps.com

©Copyright 2016 Liberty Pumps Inc. All rights reserved. 1

Read manual before using pump. Follow all safety instructions in

manual and on the pump. Failure to do so could result in serious

injury or death.

Keep manual nearby for future reference. If manual becomes lost

or damaged, get a replacement at http://www.libertypumps.com/

Service/Manuals/ or contact Liberty Pumps.

1. General Information and Safety Guidelines

Before installation, read the following instructions carefully. Each Liberty pump is individually factory tested to ensure

proper performance. Closely following these instructions will eliminate potential operating problems, assuring years of

trouble-free service.

RISK OF ELECTRIC SHOCK

NEVER enter a flooded space without proper

Personal Protective Equipment. Always wear

dielectric rubber boots and other applicable

protective equipment when water is on the

floor and you must service an energized

pump or alarm system.

DO NOT enter the water if the water level is

higher than that of the protection your PPE

offers or if your PPE is not watertight.

DISCONNECT POWER before installing or

servicing this product. A qualified service

person must install and service this product

according to applicable electrical and

plumbing codes.

The electrical outlet shall be within the length limitations of the pump power cord, and at least 4 feet above

floor level to minimize possible hazards from flood conditions.

Failure to follow the above precautions could result in serious injury or death. Replace product

immediately if sensor or power cable becomes damaged or severed. Keep these instructions in a safe

place for future reference. This product must be installed in accordance with National Electric Code,

ANSI/NFPA 70 so as to prevent moisture from entering or accumulating within junction boxes, conduit

bodies, fittings, float housing, alarm enclosure, or cable.

DO NOT bypass grounding wires or remove ground prong

from attachment plugs.

DO NOT use an extension cord.

This pump requires a separate, properly fused and ground-

ed branch circuit. Make sure the power source is properly

sized for the voltage and amperage requirements of the

pump, as noted on the nameplate.

RISK OF FIRE

NEVER use this product with or near

flammable liquids.

DO NOT install this product in locations

classified as hazardous or in explosive

atmospheres as defined by any

applicable electrical safety code.

2. Installation

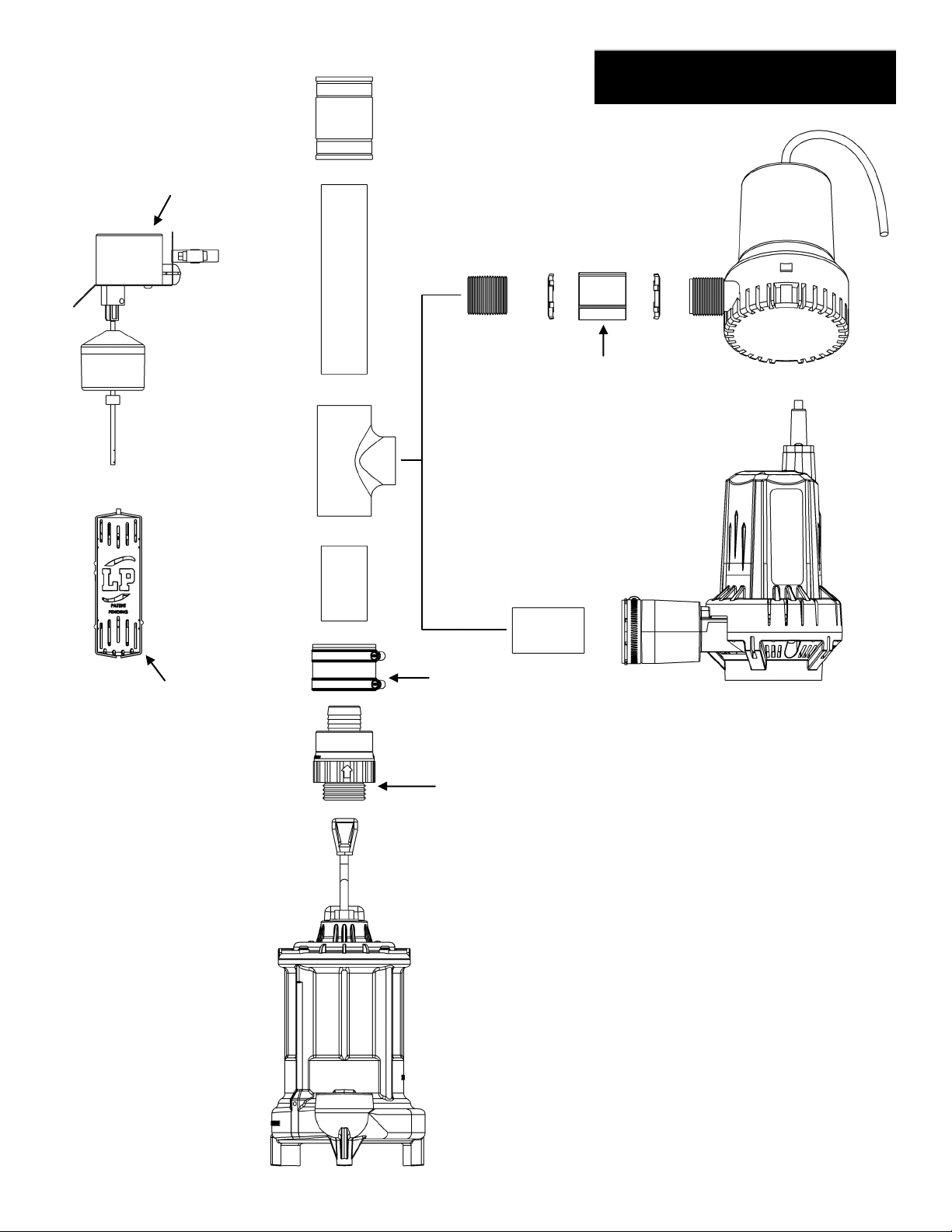

The PC Series includes a primary sump pump preassembled with a DC powered battery backup pump. An exploded

view of the system can be seen on page 3 (Figure 1). PC series with a 441 DC pump have the pump angled at approximately 30° to help prevent airlock.

1. This system should not be installed in a sump pit less than 15” in diameter. A larger diameter pit is preferred as it

allows for longer pump cycling and reduced switch cycling. The depth of the pit should be at least 18” above the

surface that the pump is resting on. If the pit is not already enclosed on the bottom, provide a hard level bottom

of bricks or concrete. DO NOT place the pump directly on earth, gravel or debris since this can cause excessive

wear of the impeller and possible jamming. “The Brick” (sold by Liberty Pumps, PN: 4445000) is a pre-molded

stable platform designed to fit your submersible pump. It raises the pump 2.5” off the bottom of the pit, reducing

the potential for jamming from rocks and debris (contact your local distributor to order). Remove all debris from

the bottom of the sump pit before installation of the pump. A sump pit cover is suggested for safety and to prevent foreign objects from entering the pit.

2. Set the complete system in place by lowering the pump by the handle on the primary pump. Confirm that both

the primary float switch and the backup float switch have adequate clearance and will not hang-up on the pit

wall. The float must be free to move throughout its travel, without contacting the pump body, piping, or other

objects.

3. The uppermost rubber coupling will connect to 1-1/2” PVC pipe. Tighten clamps to prevent leaking. Do not reduce the discharge size to less than 1-1/4”, as this will affect pump flow and performance.

4. Check valves come pre-installed on both the primary and backup pumps. Please refer to the proper installation

manual for instruction on the battery backup system.

©Copyright 2016 Liberty Pumps Inc. All rights reserved. 2

VERTICAL FLOAT SWITCH

(441)

3. Exploded View

1 1/2” RUBBER COUPLING

WITH CLAMPS

441, ROTATED TO 30°

TO PREVENT AIRLOCK

CHECK VALVE

SNAP-ON FLOAT SWITCH

(442)

PRIMARY PUMP

(257 SHOWN)

442, WITH INTEGRATED

CHECK VALVE

COUPLING

1 1/2” THREADED CHECK VALVE, 2” OUTER

DIAMETER. HAND TIGHTEN ONLY

Figure 1. Exploded view of PC series

combination system showing 257 primary

pump and what is included for systems with

either a 441 or 442 DC backup pump.

©Copyright 2016 Liberty Pumps Inc. All rights reserved. 3

4. Warranty

Liberty Pumps, Inc. warrants that its products are free from all factory defects in material and workmanship for a period

of 3 years from the date of purchase. The date of purchase shall be determined by a dated sales receipt noting the

model and serial number of the pump. The dated sales receipt must accompany the returned pump if the date of return

is more than 3 years from the "CODE" (date of manufacture) number noted on the pump nameplate.

The manufacturer's sole obligation under this Warranty shall be limited to the repair or replacement of any parts found by

the manufacturer to be defective, provided the part or assembly is returned freight prepaid to the manufacturer or its authorized service center, and provided that none of the following warranty-voiding events have taken place.

The manufacturer shall not be liable under this Warranty if the product has not been properly installed; if it has been disassembled, modified, abused or tampered with; if the electrical cord has been cut, damaged or spliced; if the pump discharge has been reduced in size; if the pump has been used in water temperatures above the advertised rating, or in

water containing sand, lime, cement, gravel or other abrasives; if the product has been used to pump chemicals or hydrocarbons; if a non-submersible motor has been subjected to excessive moisture; or if the label bearing the serial,

model and code number has been removed. Liberty Pumps, Inc. shall not be liable for any loss, damage or expenses

resulting from installation or use of its products, or for indirect, incidental, and consequential damages, including costs of

removal, reinstallation or transportation.

THE WARRANTIES SET FORTH ABOVE ARE IN LIEU OF ALL OTHER WARANTIES, EXPRESSED OR IMPLIED,

INCLUDING WITHOUT LIMITATION, ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE, AND ALL SUCH OTHER WARRANTIES ARE HEREBY DISCLAIMED AND EXCLUDED BY LIBERTY

PUMPS, INC.

©Copyright 2016 Liberty Pumps Inc. All rights reserved. 4

Loading...

Loading...