Page 1

Installation manual

PV Solar

MODULE

Please read this manual carefully before operating

your set and retain it for future reference.

N-TYPE MODELS

LGXXXQ1C-V5

LGXXXQ1K-V5

www.lg.com/global/business/solar

Page 2

TABLE OF CONTENTS

SAFETY ..................................................................03

BEFORE & AFTER INSTALLATION ......................05

Before Installation ................................................................................05

After Installation ...................................................................................05

ELECTRICAL INSTALLATION ...............................06

Danger .................................................................................................06

Electrical Connections .........................................................................06

Diodes .................................................................................................06

Series Connection ...............................................................................06

Parallel Connection .............................................................................07

General Wiring.....................................................................................07

Earth Grounding ..................................................................................07

MECHANICAL INSTALLATION ..............................08

Module Mounting .................................................................................08

Site Consideration ...............................................................................08

Mounting Methods ...............................................................................08

DISCLAIMER OF LIABILITY / DISPOSAL .............10

TRANSPORTING AND STORAGE ........................10

REVISIONS TABLE ................................................10

PRODUCT SPECIFICATIONS ................................11

Electrical & Mechanical Properties ......................................................11

Dimensions of Modules .......................................................................12

APPENDIX ..............................................................13

Mechanical Installation methods

Bolting & Clamp Information

Unloading Flow Guide

..........................................................................15

..........................................................13

................................................................14

Page 3

SAFETY

The instructions related to the safety indicated in the

following are for preventing unexpected danger or

damage in advance by safely and exactly using the product.

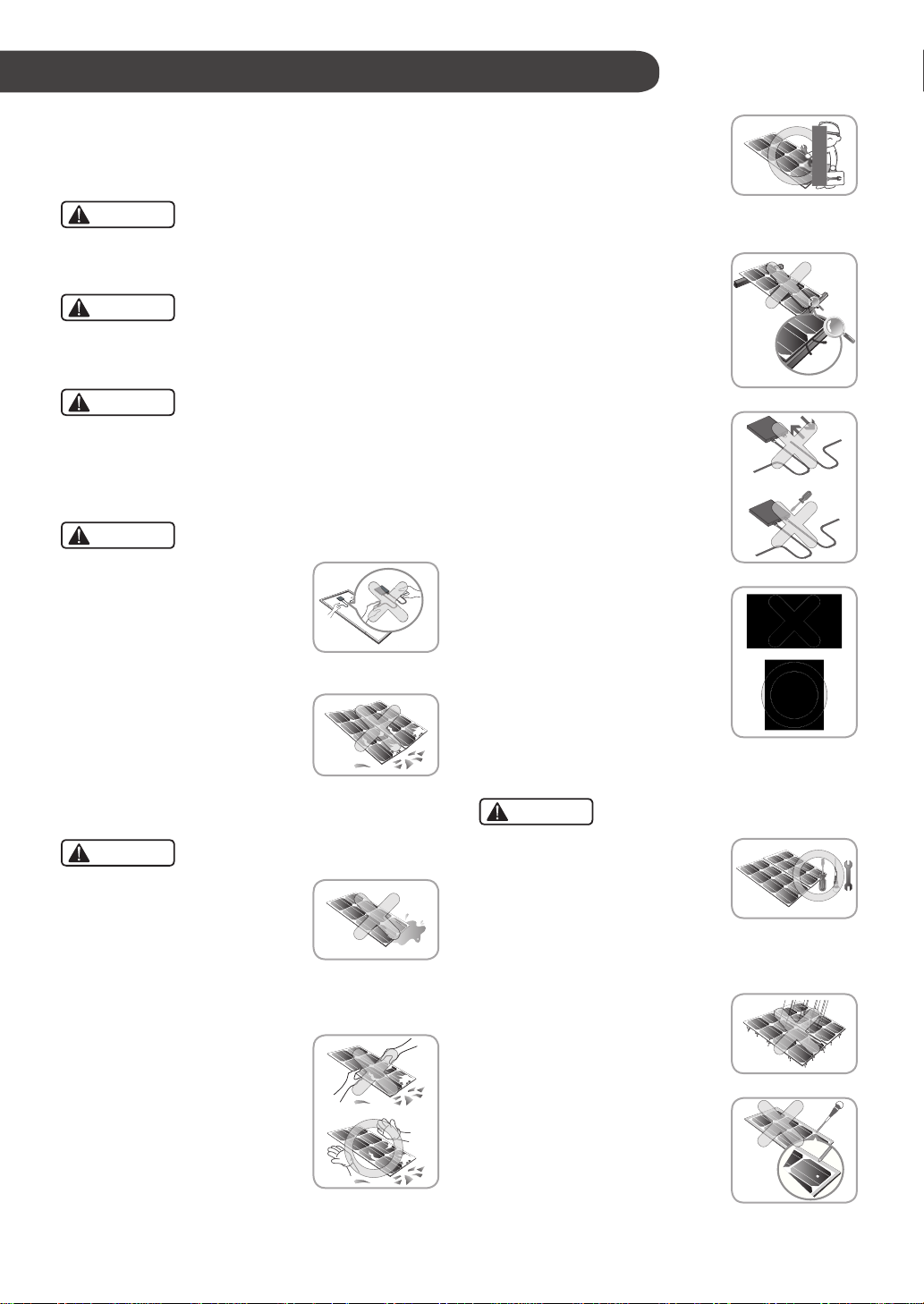

DANGER

Non-compliance of the instructions may immediately

cause serious injury or death.

WARNING

Non-compliance of the instructions may cause death or

serious injury to the user.

CAUTION

Non-compliance of the instructions may cause injury or

property damage to the user.

DANGER

Do not contact electrically active

parts of the panel, such as

terminals, without appropriate

safety gear. Contact may result in

lethal spark or electric shock.

Do not use or install if the module

is broken or torn. Failure to

comply may result in electric

shock.

Do not approach the damaged

or broken module unless you are

an authorized or qualified expert.

Failure to comply may result in

serious bodily injury or death.

No electrical parts like cables are

located after installation between

laminate and mounting structure.

Do Not reconnect or repair

junction box cable. It may occur

spark or electric shock.

Do not bending junction box's

cable. While under stress, it may

occur module damage. Cable

bending radius should be more

than 4 times the cable diameter,

at least.

WARNING

Perform all work in dry conditions

and use only dry tools. Do

not handle wet panels without

appropriate protection equipment.

Failure to comply may result in

accident or death.

Damaged modules must be

treated with safety protection

equipment. Failure to comply

may result in serious bodily injury

or death.

CAUTION

Use proper equipment,

connectors, wires and buttresses

for the installation of the module.

Failure to comply may result in

product damage, product failure

or bodily injury.

Installation during rain, heavy

wind or snowy day may result in

bodily injury or death.

Holes in the frame or glass of

the module may decrease the

strength of the frame or break the

glass.

03

Page 4

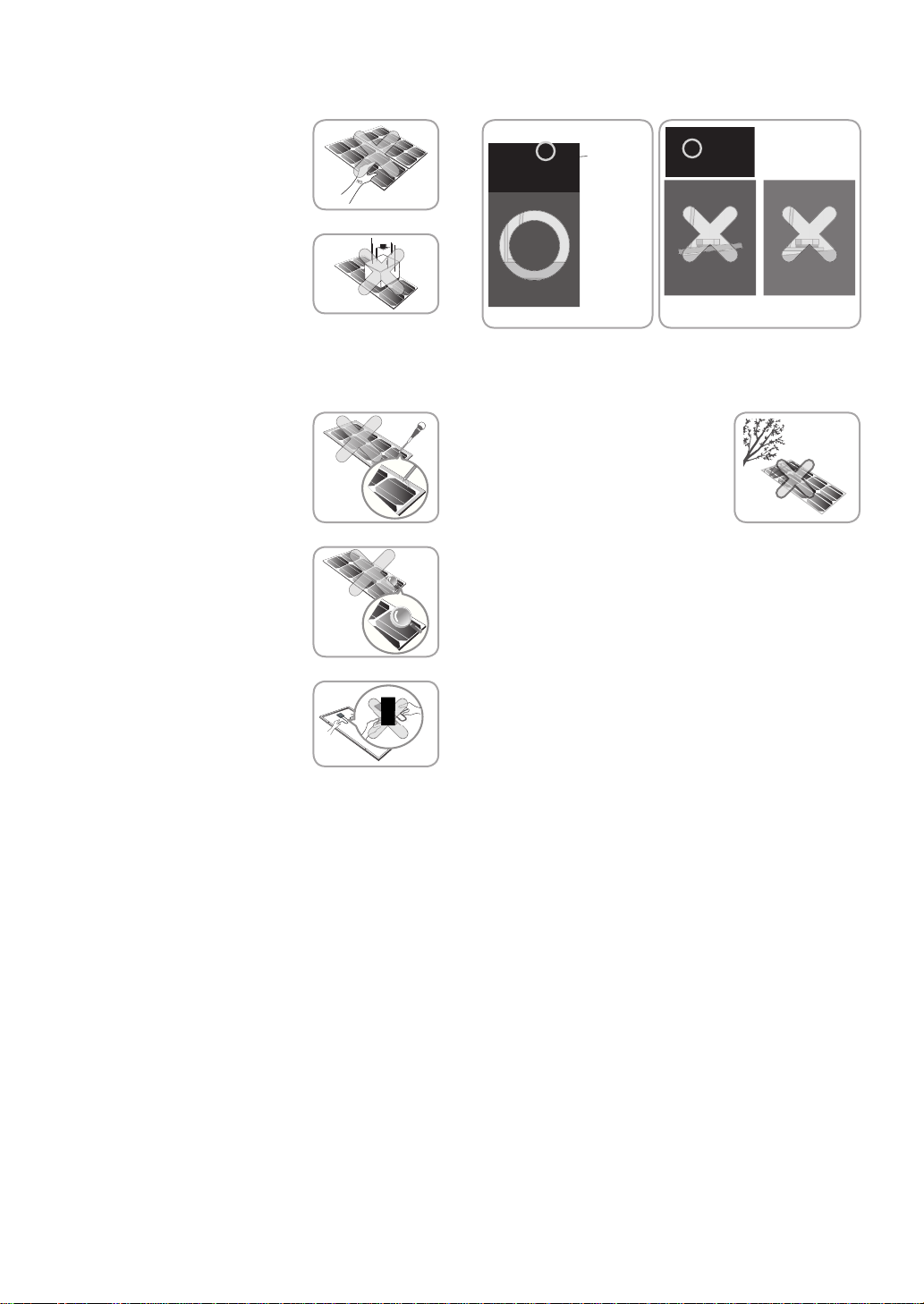

Do not touch the glass surface or

frame of the solar module after

installation of the module. It may

result in injury or death.

Heavy objects must be kept off of

the solar module.

Do not stand on or step on the

module. Do not drop the module.

Failure to comply may result in

product damage, product failure

or bodily injury.

Module

Installing structure

(bent type)

Product

Deformation

Module

Installing structure

(Stralght type)

Occurrence

of space

Do not scratch the coating

surface of the frame.

Scratches may decrease the total

solar output due to corrosion of

the frame.

Do not artificially concentrate

sunlight on the solar module

surface. Failure to comply may

result in product damage or

failure.

Do not apply a shock to the

junction box of the module or

pull the cable. Do not remove the

labels attached to the module.

Failure to comply may result in

damage of the product.

If the installing modules on curved surface, (e. g. arch

type), as shown in the below picture, do not forcefully

modify the module in the installation when connecting

it with the structure. Only install the module in the place

where the structure for the panels has been properly

set up. An improper structure may cause deformation

of the panels. Panels may also be damaged by

unapproved installation methods such as the use of a

crane.

Partial shadow must be removed

from solar module because it can

cause severe problems of solar

module.

04

Page 5

BEFORE & AFTER INSTALLATION

Before Installation

Please carefully read this manual before installation.

Solar module installation and maintenance must be

•

performed by qualified and authorized installer.

All installation instructions should be read and

•

understood before performing any installation.

Do not touch the solar module with bare hands.

•

It may result in a burn or injury.

Do not disassemble the solar module.

•

After installation or repair, check that the solar module

•

are operating properly.

In the event that the currently used solar module or

•

parts have been replaced the newly replaced module

and parts must have the same model name and parts

as the previously installed solar module.

Do not let anyone approach the solar module who has

•

little knowledge of solar modules or on the measures to

take when solar modules are damaged in order to avoid

the risk of injury or electrical shock.

Secure all necessary permits and licenses to install

•

the solar modules.

Do not locate the solar module horizontally, as this may

•

cause dirt or white efflorescence(glass deformation).

Panels are not intended for use indoors or on moving

•

vehicles of any kind.

Industry standard rated specifications are made at

•

conditions of 1000W/m irradiance and 25°C (77°F)

solar cell temperature. Colder temperatures may

substantially increase voltage and power.

Keep the solar module and system away from children

•

at all times.

Keep the module packed in the carton until the time of

•

installation.

Keep flammable gasses away from the installation

•

site.

Do not work alone. Please work as part of a team of

•

two or more people.

Safety harness use is strongly recommended for

•

installation.

Be careful not to damage the cable when using a tool

•

such as a knife to remove the cable tie that fixes the

junction box cable.

2

Partial shadowing may substantially reduce panel and

•

system output and may be the reason for the damage

of solar module.

Care must be taken to avoid low tilt angles which may

•

cause dirt to buildup on the glass against the frame

edge.

Dirt build-up on the surface of the panel may

•

cause active solar cells to be shaded and electrical

performance to be impaired.

After Installation

Plug in the connector tightly and ensure that the wiring

•

properly works.

Conduct periodic inspection of the panels for damage

•

to front glass, back sheet, frame, junction box, or

external electrical connections.

Check electrical connections for loose connections

•

and corrosion.

PV panels can operate effectively without ever being washed,

•

although removal of dirt from the front glass can increase

output.

Water, ethanol or a conventional glass cleanser with

•

a micro-fiber cloth can be used for regular washing or

rinsing of the front glass to remove dust, dirt or other

deposits.

•

Do not use ground water containing calcium carbonate

components when cleaning glass.

Aggressive and abrasive cleansers or chemicals such

•

as alkali chemicals including ammonia based solution

should not be used on cleaning the module.

Always keep the back surface of the panel free from

•

any foreign objects or structural elements which could

come into contact with the panel, especially when the

panel is under mechanical load.

Deposits of foreign material on the frame surface can

•

be cleaned by using a wet sponge or cloth and dried

in air or by using a clean chamois.

Perform the wiring work by connecting the connector

•

and wires to the stand away from the roof or ground.

Do not use any kind of oil or lubricant on the module's

•

any parts, It can defect the PV Module.

05

Page 6

ELECTRICAL INSTALLATION

1

2 3 4

Caution

Avoid all electrical hazards when installing, wiring,

•

operating and maintaining all panels.

Do not connect panels that have different electrical

•

properties or physical configurations in the same

system.

Match the polarities of cables and terminals when

•

making the connections; failure to do so may result in

damage to the panel.

When reverse currents can exceed the value marked

•

on the name plate, a properly rated and certified

over-current device(fuse or circuit breaker) must be

connected in series with each panel or string of panels.

The rating of the over-current device shall not exceed

•

the maximum series fuse rating marked on the name

plate.

The panel contains factory installed bypass diodes

•

located inside the junction box.

When installing the system, it is recommended to

•

install a lightning rod to protect the system.

The induced overvoltage by lightning can cause the

•

system damage, you should design conductor loop

connection as minimum as possible.

The junction box should not be opened. Opening the

•

junction box will void the warranty.

Panels with a suspected electrical problem should be

•

returned to LG Electronics for inspection and possible

repair or replacement as per the warranty conditions

provided by LG Electronics.

When the module installing in series or in parallel (e.g.

•

using for extension cables, etc.), the connector of each

module should be the same products. (mated with its

original female or male connector of the same supplier)

Diodes

All LG modules are equipped with factory installed

•

bypass diodes. The factory-installed diodes provide

proper circuit protection for the module from

unexpected shadows.

IF (AV) 25A

V

F (max) 0.6V

V

RRM 50V

T

j (max)

R

TH 2.0°C/W

Diode specification and configuration

200°C

D1 D2 D3

+-

Series Connection

The solar modules may be wired in series to produce

•

the desired voltage output.

The current of each module connected in series

•

should be the same.

The maximum number of series connected modules

•

can be determined by basis on maximum system

voltage, the 125% safety factor, and the module Voc

which can be checked in “Product Specifications” in

this document.

The maximum solar module configuration can be

•

found in “Product Specifications”.

Electrical Connections

Shock hazard may occur near the solar modules

•

electrical connections.

Modules may be connected in series and/or parallel

•

to achieve the desired electrical output as long as it

is within the guidelines on the product specification

sheet.

Please use only the same type of modules in a

•

combined source circuit.

Do not disconnect the module under when it is

•

operating. Shock hazard may occur near the solar

modules connection means.

06

………….

Series connection for more voltage

Page 7

Parallel Connection

General Wiring

The solar modules may be combined in parallel to

•

produce the desired current output.

When modules are combined in parallel, the total

•

current is equal to the sum of currents from each

module.

The voltage of each module connected in parallel

•

should be the same.

When connecting plural strings of modules in parallel

•

every series string or solar module must be fused prior

to combining with other strings.

Abide with all applicable federal, state, and local codes

•

for additional fusing requirements and limitations on

the maximum number of solar modules in parallel.

Maximum series fuse rating is refer to “Product

•

Specifications; page 11”.

Parallel configuration is not limited if proper measures

•

are taken to block the reverse current flow, e.g. fuses

for the protection of the module and cables from overcurrent for prevention of unbalanced string voltage.

A multiplying factor is required for increased output

•

of the PV modules. Under normal conditions, a PV

module is likely to experience conditions that produce

more current and/or voltage than reported at standard

test conditions. The requirements of the National

Electrical Code (NEC) in Article 690 shall be followed

to address these increased outputs. In installations

not under the requirements of the NEC, the values

of Isc and Voc marked on this PV module should

be multiplied by a factor of 125% when determining

component voltage ratings, conductor ampacities,

fuse sizes, and size of controls to the PV output.

Depending on national directives, additional safety

•

factors might be applicable for over current protection.

-

+

-

+

-

+

-

+

…………

-+

Parallel connection for more current

LG Electronics recommends that all wiring be double

•

insulated with a minimum rating of 90°C (194°F).

All wiring should use a flexible copper (Cu) conductor.

•

The minimum size should be determined by the

•

applicable codes.

LG Electronics recommends a size no smaller than

•

2

4mm .

Earth Grounding

All work must be conducted in conformance with all

•

Federal, State, and local codes and standards.

Grounding works should be performed by an

•

authorized installer for the safety and maintenance of

the system in accordance with all national, state and

local electrical codes and regulations and standards.

Specific information on the solar module dimensions

•

and location of grounding holes is provided in “Product

Specifications”.

One M4 stainless steel bolt, one nut, one spring

•

washer, two flat washers, one cup washer, one star

washer and 12 AWG Cu wires are recommended per

mounting hole.

Where common grounding hardware (nut, bolts,

•

washers) is used to attach a listed grounding device,

the attachment must be made in conformance with the

grounding device manufacturer’s instructions.

All hardware should be consist of corrosion resistant

•

material such as stainless steel.

There is an earth hole on the edge of the module

•

frame. Using this hole, an earth conductor and the

solar module frame may be recommended to be

connected and earthed as the below drawing.

All screws and nuts shall be tightened to a torque of

•

4~5 N∙m.

To prevent electric shock and fire, a protective ground

•

must be done on the frames of solar modules and arrays

although the solar modules from LG meet the conditions of

safety class II. The national directives must be respected.

Module frame

Bolt

Flat washer

Star washer

Cup washer

Grounding wire

Flat washer

Spring washer

Nut

07

Page 8

MECHANICAL INSTALLATION

Module Mounting

The LG Electronics’ (LGE) Limited Warranty for solar

•

modules is contingent upon modules being mounted

in accordance with the requirements described in this

section.

The solar modules are in Application Class A and

•

have the Safety Class II. Therefore they can be

operated in systems with 120V DC and higher.

General access is not restricted.

We recommend to use mounting device(bolt, nut,

•

washer) made by corrosion resistant material like

stainless steel.

Site Consideration

LGE solar modules should be mounted in a location that

meets the following requirements.

Operating Temperature

Maximum Operating Temperature: +90°C (194°F)

•

Minimum Operating Temperature: -40°C (-40°F)

•

Excluded Operating Environments

The solar modules from LG Electronics can not be

•

operated in a location where they could come in direct

contact with salt water or ammonia.

Module Strength(Basic Load) ; IEC61215-2:2016

①

②

Force

Direction

Rear Side

No. of Cell

60Cell

Y is a safety factor of 1.5

•

m

Detail of mounting distance is below.

•

②

①

※ This mounting method is by using frame bolt holes.

※ The mounting rails must run perpendicularly to the module

long side.

Design Load : A

②

①

3600 PascalFront Side

2650 Pascal

①

②

60Cell

Shadow

LGE solar module should be installed in a proper site

•

that there is no shadowing affected by building,

chimney, tree, and neighboring module, etc.

Test Load : B

(B = A x Y )

5400 Pascal

4000 Pascal

①

: 200mm

②

: 300mm

m

•

•

•

•

Mounting Methods

General Information

•

•

•

•

•

•

•

•

Mounting

Rails

Use corrosion resistant material mounting rails and

hardware.

Use appropriate bolted connections as per

manufacturer’s instructions.

No electrical parts like cables are located after

installation between laminate and mounting structure.

LGE solar module is qualified up to a altitude of 4000m.

Select the appropriate orientation to maximize sunlight

exposure.

Module should not be mounted or stored in a way that

the front/top glass faces downward in order to prevent

water from entering the junction box, which could

cause a safety hazard.

Clearance between the solar module frames and

structures such as roofs or ground is required to

prevent wiring damage and to allow air to circulate

behind the solar module. The recommended standoff

height is a minimum of 100mm.

When installed on a roof, the solar module must be

mounted over a fire-resistant roof covering rated for

the application. The fire resistance of the solar module

is class C after ANSI/UL790 Edition 2004.

The solar module is only IEC listed for use when its

factory frame is fully intact.

Removal or alteration must be done by an authorized

and qualified individual.

Creating additional mounting holes may damage the

solar module and reduce the strength of the frame.

We recommend a 6mm gap between module frames

to avoid tension from thermal expansion.

08

Page 9

The solar module may be mounted by using the

•

following methods: (*Torque:8~12N∙m)

When installing modules in heavy snow areas,

•

it is recommended to be taken an appropriate

countermeasure to prevent possible damages to the

lower side frame by slipping snow.

We recommend to use corrosion resistant material

•

for these supporting part. (A snow guard should be

installed in accordance with the manufacturer’s

instructions.)

Roof

Mounting by using frame bolts holes

Secure the solar module to the structure by using the

•

factory mounting holes.

Four M8 stainless steel bolts, four nuts, four spring

•

washers, and eight flat washers are recommended

per solar module.

The module may be fastened to a support by using

•

both the outer and inner bolt holes of the frame.

Each module should be securely fastened at a

•

minimum 4 points on two opposite sides.

•

and location of mounting holes is provided in ‘Product

Solar module

Supporting part

Mounting by using clamps

The module may be fastened to a support by using

•

clamps on both the long edge and the short edge of

the modules.

•

provided in ‘Mechanical Installation Scene’. (Refer to

Appendix.)

→ If you use a special clamp, it needs to test for

If the installation is likely to be affected by

•

heavy(extreme) snow, further suitable panel support is

recommended on the lower row of panels.

compatibility by LGE.

Tighten the bolt securely by using the combination.

•

Place the spring washer between the Flat washer

and Nut.

Module frame

Nut

Spring washer

Flat washer

Mounting Rail

Flat washer

Bolt

* Mounting Rails Material : Aluminum, Stainless steel, etc.

→ We recommend more than 40x40mm mounting rails.

09

Page 10

DISCLAIMER OF LIABILITY / DISPOSAL

Disclaimer of Liability

By beginning to installation process, the installer has to read and completely understand this Installation Manual.

•

If installer had any questions regarding this installation manual, the installer would have contacted LG with any

•

questions or concerns.

•

lunteer and employees, other participants in any activity

connected to installation, operation, or service of LG Solar Modules, and if applicable, from all liabilities, claims,

demands, losses, or damages on my account caused or alleged to be caused in whole or in part by the negligence

and employees.

Disposal

Disposal of your old appliance

1. This crossed-out wheeled bin symbol indicates that waste electrical and electronic products(WEEE)

should be disposed of eparately from the municipal waste stream.

2. Old electrical products can contain hazardous substances so correct disposal of your old appliance

will help prevent potential negative consequences for the environment and human health. Your old

appliance may contain reusable parts that could be used to repair other products, and other valuable

materials that can be recycled to conserve limited resources.

3. You can take your appliance either to the shop where you purchased the product, or contact your local government

waste office for details of your nearest authorized WEEE collection point. For the most up to date information for your

country please see www.lg.com/global/recycling materials that can be recycled to conserve limited resources.

TRANSPORTING AND STORAGE

Do not loosen the banding, when the module is transported by truck, ship and etc.

•

In case of loose banding, the module will be shaken, which may cause damage.

Do not stack on more than one pallet. Maximum height is two pallets. Severe stacking can cause stress to the

•

module and may cause product damage.

Do not transport only one side of the module when transporting the module. Damage to the frame or cable may occur.

•

REVISIONS TABLE

Date Version Description of change Remark

2018.10.10 1.0 (1

2019.02.13 2.0 Adding a new model (Q1K-V5)

2019.04.15 3.0

10

st

edition) Publish Installation Manual

Adding a new model (Q1C-V5)

Adding a new model (Q1C-V5)2020.02.03 4.0

Page 11

PRODUCT SPECIFICATIONS

Rated electrical characteristic except power rating within -0/+3 percent are within 5 percent of measured.

Values at Standard Test Condition(STC) : Irradiance 1000W/m

Electrical Properties Mechanical Properties

Pmax

Module

Series

LGXXXQ1C-V5LGXXXQ1K-V5

Model Name

LG330Q1C-V5

LG335Q1C-V5

LG340Q1C-V5

LG345Q1C-V5

LG350Q1C-V5

LG355Q1C-V5

LG360Q1C-V5

LG365Q1C-V5

LG370Q1C-V5

LG375Q1C-V5

LG380Q1C-V5

LG350Q1K-V5

LG355Q1K-V5

LG360Q1K-V5

LG365Q1K-V5

LG370Q1K-V5

Power

at STC

Tolerance

W % V A V A A V mm mm mm kg

330 0~3% 42.5 10.73 35.2 9.38 18 20 1000 MC4/JM608 1700 1016 40 17.5

335 0~3% 42.6 10.74 35.4 9.47 18 20 1000 MC4/JM608 1700 1016 40 17.5

340 0~3% 42.6 10.75 35.6 9.56 18 20 1000 MC4/JM608 1700 1016 40 17.5

345 0~3% 42.6 10.76 35.8 9.64

350 0~3% 42.7 10.77 36.1 9.70 18

355 0~3% 42.7 10.78 36.3 9.79 18

360 0~3% 42.7 10.79 36.5 9.87 18

365 0~3% 42.8 10.80 36.7 9.95 18

370 0~3% 42.8 10.82 37.0 10.01 18

375 0~3% 42.8 10.83 37.2 10.09 18

380 0~3% 42.9 10.84 37.4 10.17

350 0~3% 42.9 10.39 36.2 9.68 18

355 0~3% 43.1 10.44 36.4 9.76 18

360 0~3% 43.3 10.50 36.7 9.82 18

365 0~3% 43.5 10.55 36.9 9.90

370 0~3% 43.7 10.61 37.2 9.97 18

Voc at

STC

Isc at

STC

Vmpp

at STC

2

, Cell temp. 25℃, 1.5AM

Max.

Max.

Impp at

STC

No. of

module

in series

18

Series

Fuse

Rating

20 1000 MC4/JM608 1700 1016 40 17.5

20 1000 MC4/JM608 1700 1016 40 17.5

20 1000 MC4/JM608 1700 1016 40 17.5

20 1000 MC4/JM608 1700 1016 40 17.5

20 1000 MC4/JM608 1700 1016 40 17.5

20 1000 MC4/JM608 1700 1016 40 17.5

20 1000 MC4/JM608 1700 1016 40 17.5

18

20 1000 MC4/JM608 1700 1016 40 17.5

20 1000 MC4/JM608 1700 1016 40 17.5

20 1000 MC4/JM608 1700 1016 40 17.5

20 1000 MC4/JM608 1700 1016 40 17.5

18

20 1000 MC4/JM608 1700 1016 40 17.5

20 1000 MC4/JM608 1700 1016 40 17.5

Max.

System

Voltage

Connector Length Width Height Weight

Note) MC4 formal name : PV-KST4 / 6II-UR, PV-KBT4 / 6II-UR

→ Plus (+) Connector : Male MC4 coupler (PV-KST4/6II-UR)

→ Negative (-) Connector : Female MC4 coupler (PV-KBT4/6II-UR)

Note) The Typical change in module efficiency at 200W/m in relation to 1000W/m

◇ Female and male cable couplers ◇

Female cable coupler

Ø AØ A

Male cable coupler

2 2

Model Cable Cross Section

MC4

JM608

※ See more information >> http://www.multi-contact.com/

“Max. No. of modules in series” is considering 125% of Voc. Actual number of connections

should be selected according to the installation site conditions and local code.

is -6.0% (Min. -8.0%)

4mm²

12AWG

4mm²

12AWG

Electrical Properties(NMOT*)

Model

Maximum Power (Pmax) [W] 256.0

MPP Voltage (Vmpp) [V] 35.5

MPP Current (Impp) [A] 7.21

Open Circuit Voltage (Voc) [V] 40.1

Short Circuit Current (Isc) [A] 8.66

*

NMOT (Nominal Module Operating Temperature) : Irradiance 800W/m , ambient temperature 20℃, wind speed 1m/s

330

248.4

35.0

7.11

40.0

8.65

335

252.2

35.3

7.17

40.1

8.66

340

259.8

35.7

7.27

40.1

8.67

LGXXXQ1C-V5 LGXXXQ1K-V5

360

365

274.7

36.6

7.51

40.2

8.70

370

278.7

36.9

7.55

40.3

8.71

345

350

355

267.2

36.2

7.39

40.2

8.68

271.1

36.4

7.45

40.2

8.69

263.5

36.0

7.32

40.1

8.67

2

Temperature Characteristics

Model

NMOT [ °C ]

Pmax [%/°C] -0.30

Voc [%/°C] -0.24

Isc [%/°C] 0.037

LGXXXQ1C-V5

44 ± 3

LGXXXQ1K-V5

44 ± 3

-0.30

-0.24

0.037

A (Cable outer diameter)

Ø

5.5 ~ 9mm

5.4 ~ 7.2mm

375

380

350

282.4

286.2

263.6

37.1

37.3

36.1

7.61

7.67

7.30

40.3

40.3

40.4

8.72

8.73

8.37

R

ated current

30A

30A

or http://www.jmthy.com/

355

360

365

267.3

271.2

274.9

36.3

36.6

36.8

7.36

7.41

7.47

40.6

40.8

41.0

8.41

8.46

8.50

370

278.7

37.1

7.53

41.2

8.55

11

Page 12

Dimensions of Modules

LGXXXQ1C(K)-V5

60Cell Module

Unit: mm / in.

Note) Cable length with connector (JM608)

12

Page 13

APPENDIX

Mechanical Installation : 60Cell Model

Fig.1 Bolting Type Fig.2 Clamping Type

①

②

①

②

②

①

A

B

B

A

① : 200mm

② : 300mm

A : 200mm

B : 400mm

②

①

Front : 5400Pa

Rear : 4000Pa

A : 200mm

B : 400mm

A : 0mm

B : 650mm

Front : 5400Pa

Rear : 4000Pa

Front : 2400Pa

Rear : 2400Pa

Fig.3 Clamping Type Fig.4 Clamping Type

A

B

B

A

Front : 4000Pa

Rear : 4000Pa

A : 200mm

B : 200mm

B

A

Front : 1800Pa

Rear : 1800Pa

Front : 2400Pa

Rear : 2400Pa

Fig.5 Clamping Type Fig.6 Clamping Type

C

A

B

②

①

A

B

A

①

B

B

A

C

A : 200mm

B : 400mm

C : 120mm

Front : 5400Pa

Rear : 4000Pa

Front : 5400Pa

Rear : 1800Pa

All mechanical installation methods(Fig.1 to Fig.6) and bolting method in this appendix were not tested by VDE.Note)

It is evaluated by LG internal test.

①

A : 120mm

A : 120mm

B : 843 ±100mm

*4point(①)

6point(①+②)

②

①

Front : 1800Pa

Rear : 1800Pa

Front : 5400Pa

Rear : 4000Pa

13

Page 14

Bolting Method

Module frame

Bolt

Flat washer

Mounting Rail

Flat washer

Spring washer

Nut

•Four M8(5/16inch) stainless steel bolts, four nuts, four spring washers, and eight flat washers are recommended

per solar module.

Clamp system requirements

•The clamp should not be touched with the module’s glass.

•

•

Use corrosion resistant material clamps and hardware.

→ .EGL yb ytilibitapmoc rof tset ot sdeen ti ,pmalc laiceps a esu uoy fI

•Use appropriate bolted connections as per clamp manufacturer’s instructions.

•

•Follow the clamp manufacturer’s recommended applied torque to fasten the clamps.

•

Width

Height

Depth

<Middle Clamp>

Width

Height

Depth

<Edge Clamp>

14

Page 15

Unloading Flow Guide

If you are unloading using heavy equipment such as a crane, please follow the procedure below.

[ Step 1 ] [ Step 2 ] [ Step 3 ] [ Step 4 ]

Step 1. Place the packaging on a flat surface.

Step 2. Put the safety timber bar on the packaging and fasten a rope as shown Fig. [ Step 2 ]

- To prevent module breakage, you should use safety timber bar bigger than packaging length.

- The position of rope have to be between block 1 and block 2 when you fasten a rope to pallet.

- Detailed view of the rope position is below.

Rope

Standard Line

Block ①

- If you have not timber bar, you can use a pallet which is longer than module size.

Step 3. Loading & unloading packaging.

- The crane hook have to be placed center of packaging.

- For the balance of packaging, the rope between the packaging and crane must be the same length.

Step 4. Landing packaging on a floor.

- A minimum of two operator is required to ensure that all four corners are seated at the same

time when the packaging is unloaded.

▶ If you need some question or advice of this, please contact our sales manager.

Block ② Block ② Block ①

15

Page 16

LG Electronics Deutschland GmbH

Alfred-Herrhausen-Allee 3-5, 65760 Eschborn, Germany

Contact : service-solar@lge.de

LG Electronics Inc. (Global HQ)

LG Twin Towers, 128, Yeoui-daero, Yeongdeungpo-gu,

Seoul 07336, Korea

Contact: solar-svc@lge.com

http://www.lg-solar.com

This document is subject to change without notice.

LG, LG logo and Life's Good are trademarks of LG Electronics, Inc. worldwide. Trademarks and

intellectual properties of LG Electronics, Inc. are protected by international copyright laws.

Loading...

Loading...