P/NO : MFL42540232

www.lg.com

INSTALLATION MANUAL

• Please read this installation manual completely before installing the product.

• Installation work must be performed in accordance with the national wiring

standards by authorized personnel only.

• Please retain this installation manual for future reference after reading it

thoroughly.

MODEL : PWFCKN000

Variable Water Flow Control Kit

ENGLISH ITALIANO ESPAÑOL FRANÇAIS

DEUTSCH

ΕΛΛΗΝΙΚΆ

NEDERLANDS

POLSKI ČEŠTINA

LIMBA ROMÂNĂ

Variable Water Flow Control Kit Installation manual

TABLE OF CONTENTS

n Safety Precautions................................................................................3

n Accessory Parts ....................................................................................5

n Name of each Part ................................................................................6

n Variable Water Flow Control kit – Functions summary .........................7

n Installation Method................................................................................8

Variable Water Flow Control kit Installation Method.............................8

n Setting and Using Method ..................................................................11

1. Wiring Diagram ..............................................................................11

2. Wiring for Variable Water Flow Control kit......................................12

3. Series Installation(more than 2 unit)...............................................13

4. Power Source Input .......................................................................14

5.

Variable Water Flow Control Kit Functions

...............................................16

6. Setting of Outside Unit DIP Switch.................................................22

7. Setting Example .............................................................................23

2 Variable Water Flow Controller Kit

Installation manual 3

Safety Precautions

ENGLISH

n During installation

Safety Precautions

To prevent injury to the user or other people and property damage, the following instructions

must be followed.

n Incorrect operation due to ignoring instruction will cause harm or damage. The seriousness is

classified by the following indications.

n Meanings of symbols used in this manual are as shown below.

WARNING

CAUTION

This symbol indicates the possibility of death or serious injury.

This symbol indicates the possibility of injury or damage.

Be sure not to do.

Be sure to follow the instruction.

WARNING

Be sure to turn off

Outside unit power

Before installation.

Please install the

designated location in the

Control box.

• It can cause the breakdown

or accident.

Do not touch the board

when the power is

connected .

•

It can cause a fire, electric

shock, explosion, injury and

problem to the product.

Always request for installation of the

product to the service center or the

installation service provider.

•

It can cause a fire, electric shock, explosion

and injury.

When reinstalling the previously

installed product, request for service to

the service center or the installation

service provider.

•

It can cause a fire, electric shock, explosion and

injury.

4 Variable Water Flow Controller Kit

Safety Precautions

n During use

Do not modify or extend the

Provided wires.

• It can cause a fire and

electric shock.

Do not pour water inside the

product.

• It can cause an electric

shock and problem to the

product.

When the product is submersed

in water, always request for

service to the service center or

the installation service provider.

• It can cause a fire and

electric shock.

Make the children and the

elderly use the product with

the help of a guardian.

• It can cause a safety

accident and problems to

the product.

Do not give impact to the

product.

• It can cause problem to the

product.

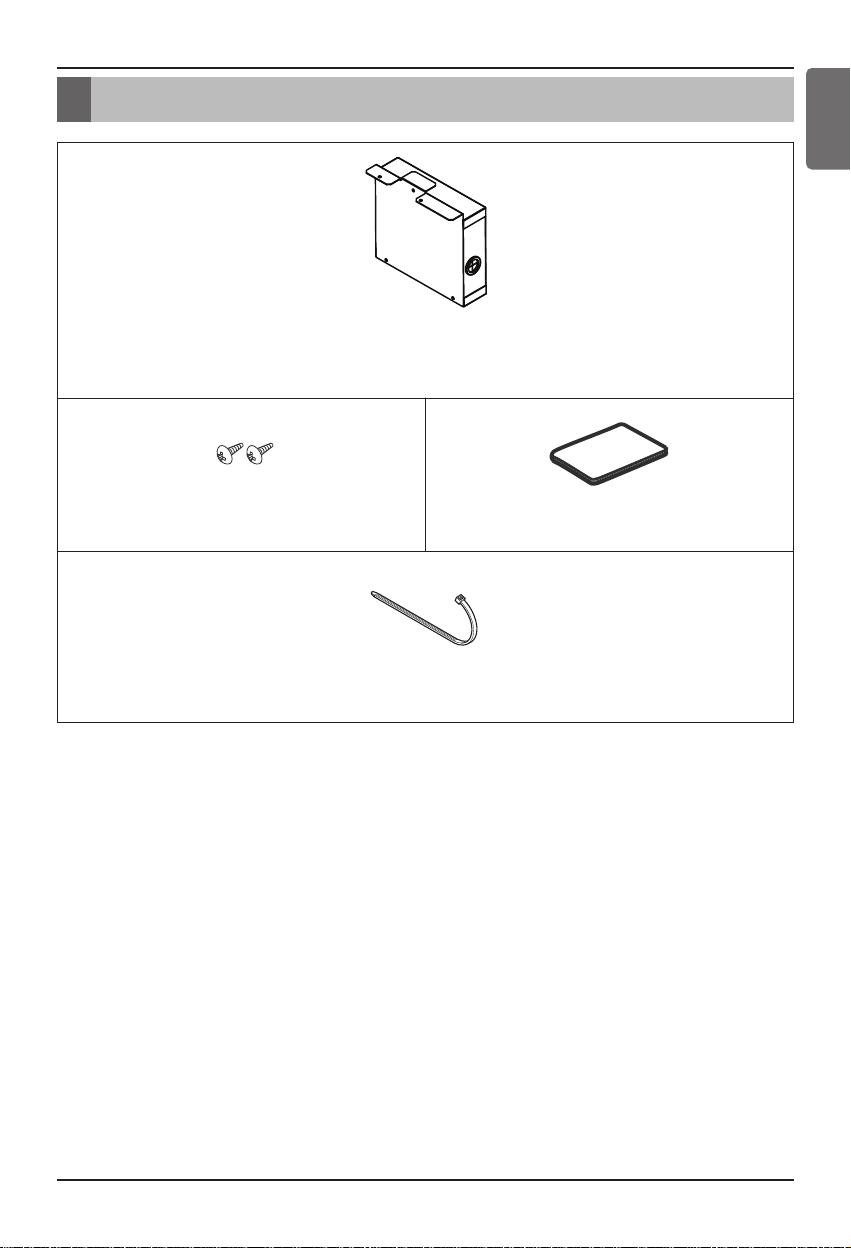

Accessory Parts

Installation manual 5

ENGLISH

Accessory Parts

Controller Assy

(Variable Water Flow Control Board,

Transformer, Terminal Block, Harness Single)

Screw(2EA)

Manual

Tie (1EA)

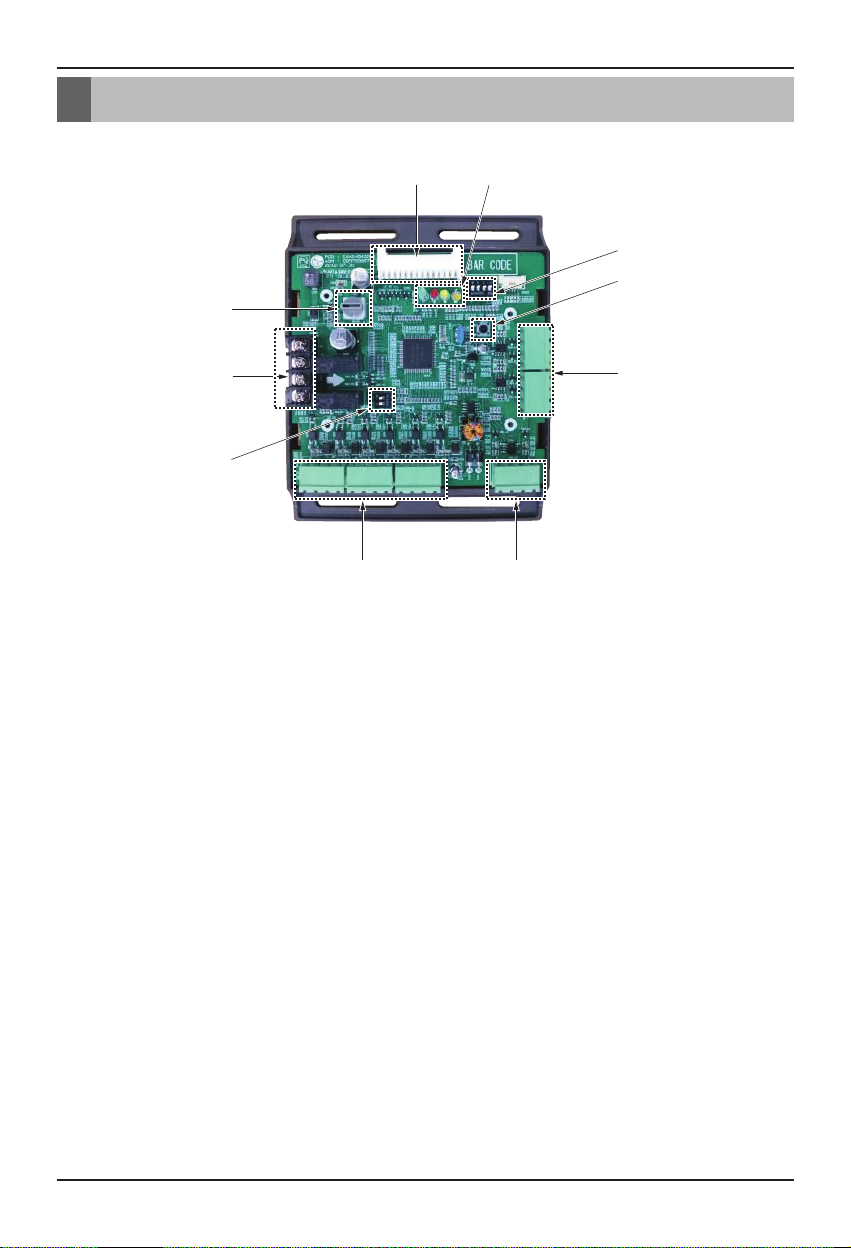

Name of each Part

6 Variable Water Flow Controller Kit

Name of each Part

① Main connector : Power input and communication connector with Outside Unit

② SW104 : Rotary Switch for setting capacity control step

③ Digital Output : Operating & Error status Relay output (DDC output AC 1A at 250V source)

④ SW102 : Switch for setting internal function

⑤ Digital Input : Dry contact input

⑥ Analog Input : DC 0~10V Analog signal input

⑦ Analog Output : DC 0~10V Analog signal output

⑧ SW103 : Reset Switch

⑨ SW101 : DIP Switch for setting operating function

⑩ LED : Indicate VWFC*(board) status

- LED1C(Green) : communication status (receive)

- LED2C(Red) : communication status (transfer)

- LED3C(Yellow) : Communication error status

- LED4C(Orange) : Power status

* Variable Water Flow Control Kit

ڹ

ڸہ

ۀ

ڿ

ں

ڻ

ڼڽ

ھ

Variable Water Flow Control kit – Functions summary

Installation manual 7

ENGLISH

Variable Water Flow Control kit – Functions summary

Variable Water Flow Control

This function can be applied to save pump operation power by optimizing water flow rate by

interlocking between electric valve and MULTI V WATER IV operation. Depends on MULTI V

WATER IV operation cycle, Variable Water Flow Control Kit(Board) outputs analog signal

(0~10V) to electric valve.

CAUTION

Please keep water flow rate more than 40% of rated water flow indicated MULTI V WATER

IV PDB

Demand control

- This function is to reduce Outside Unit power consumption by using input signal. This manual

provides variable setting to control outside unit capacity according to input method. This function

supports 2 types of input signal : AI(0~10V) and contact signal(3 Step).

Output Outside or Indoor Unit Operation status

- This function displays outside or indoor unit’s operation status. Depends on DIP switch setting,

either outside or indoor unit operation status is reflected through output signal.

Output Outside or Indoor Unit Error Status Signal

- This function displays error signal by digital output when either outside or indoor unit has an

error

Installation Method

8 Variable Water Flow Controller Kit

Variable Water Flow Control kit Installation Method

Installation Method

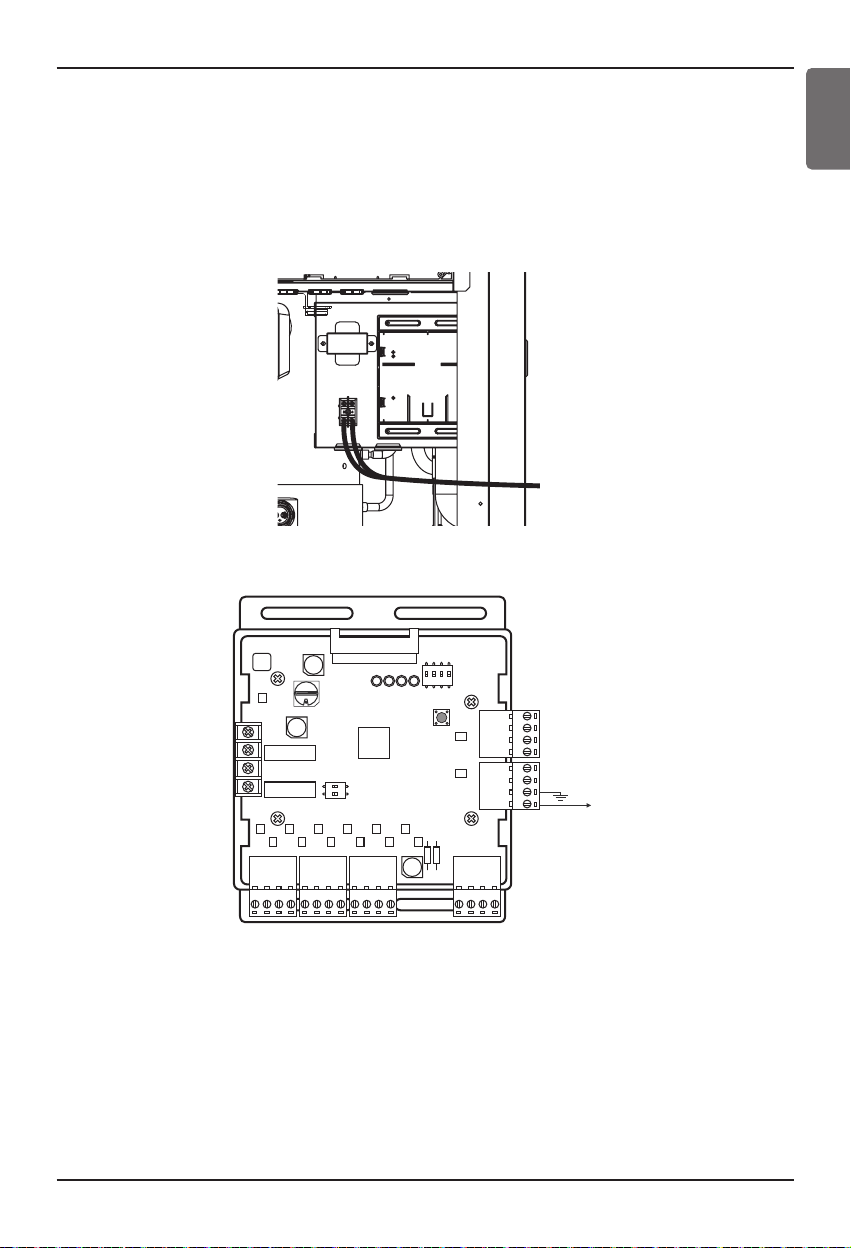

① Be sure to turn off outside unit power before installaion.

② Separate front panel from outside unit

③ Separate front cover of control box.

④ Separate Oil_Level Harness(3Pin Yellow) in External PCB(CN28).

⑤ Sepatate VWFC* Cover in VWFC Assy.

⑥ Install the VWFC Assy to the C/Box by using screws.

* VWFC : Variable Water Flow Control kit

ڹ

ں

* Separate of Oil_Level harness

* Tighten the screw from bottom to

the top direction.

ڻ

ڽ

ڼ

CAUTION

Be sure to turn off outside unit power before installation.

Installation Method

Installation manual 9

ENGLISH

⑦ Connect a power cable (AC 24V) of water flow control valve to the terminal block

(2Pin Terminal block, Max current 0.42A).

⑧ Connect a signal cable (DC 0~10V) of water flow control valve to CN1_A0(A0_1(A+), GND(A-))

of VWFC.

⑨ Set up the main function DIP Switch of VWFC PCB. (Refer to 16page)

⑩ Pull out put through the cover hole.

⑪ Install the VWFC Cover by using screws.

ھ

AO_1

ڿ

Setting and Using Method

10 Variable Water Flow Controller Kit

⑫ Connect the blue cable of transformer to the Main PCB(CN_JIG_N,CN_JIG_L).

⑬ Connect the black cable of VWFC PCB to the Main PCB(CN10).

⑭ Connect the Oil_Level harness(3Pin Yellow) to the External PCB(CN28).

⑮ Fix and fasten components and cables.

⑯Turn on the main power line of outside unit.

1. Install the product on flat surface and screw at least 2 places. Otherwise the VWFC PCB may not be

anchored properly.

2. Do not deform the case at random. It may cause malfunction of the Variable Water Flow Control PCB

3. This is a class A product. In a non-industrial environment, this product may cause radio interference, in

which case the user may be required to take adequate measures.

4.

It must be installed variable flow valve on water circulation system in advance.

5. The internal resistance of variable water flow control valve must be above 100kΩ. The resistance of

signal cable(CN1_A0) must be below 10Ω.

ۃ

ۄ

Setting and Using Method

Installation manual 11

ENGLISH

1. Wiring Diagram

Setting and Using Method

Setting and Using Method

12 Variable Water Flow Controller Kit

AO_1

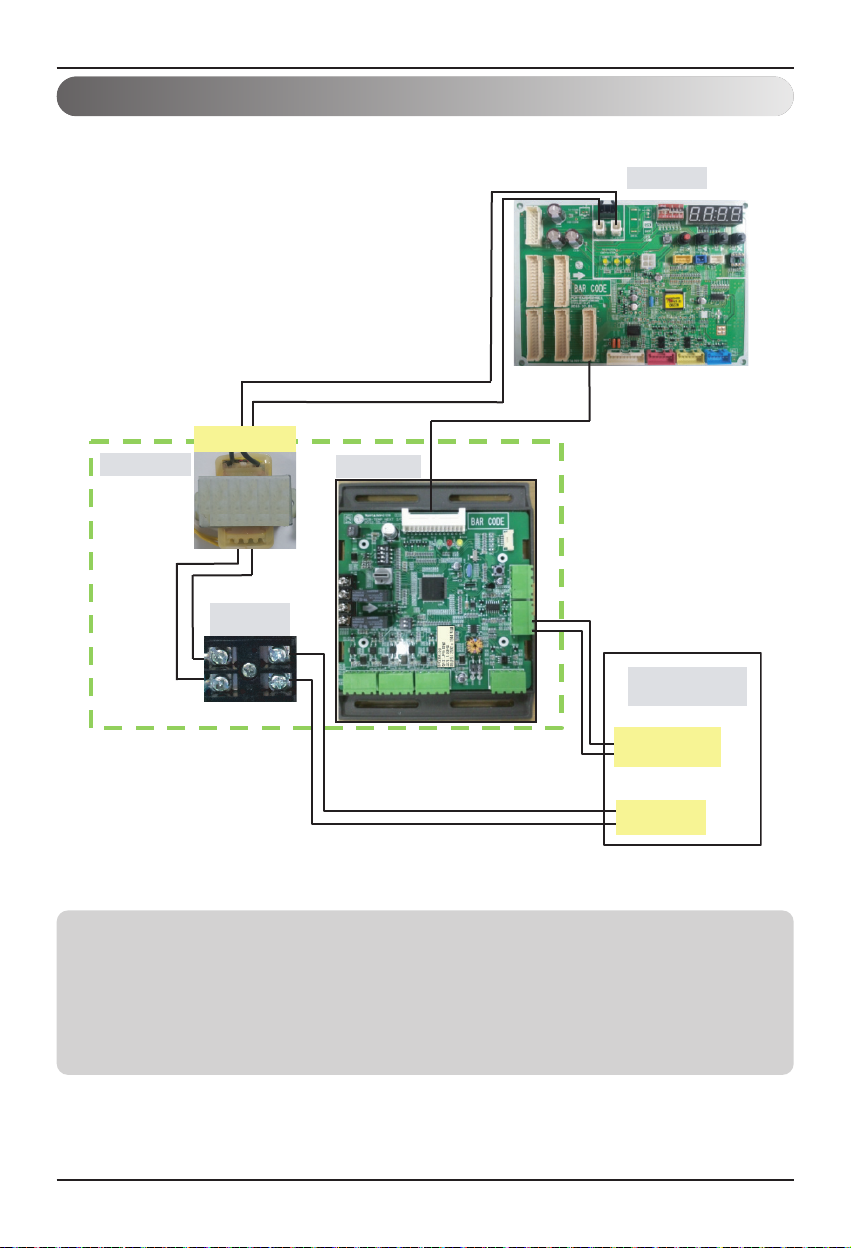

2. Wiring for Variable Water Flow Control kit

Notes

Transformer can supply only AC 24V to the terminal block

Do not input external power into Main PCB. Otherwise it will cause a serious damage.

The Variable Water Flow Control Kit controls only 1 valve actuator.

The power (AC 24V) and signal(DC 0~10V) line is recommended by AWG22(1/32 in, (0.644 mm),

0.016 Ω/ft (0.053 Ω/m)).

Please refer to the variable water flow control valve installation manual for wiring.

1 Unit

h BL : Blue, RD : Red, BK : Black

BL

Transformer

BL

AC 220-240V

VWFC Board

BK

Main PCB

RD

RD

Terminal

Block

AO_1

AO_1

Variable Water

Flow Valve

DC 0~10V

Control Signal

AC 24V

Setting and Using Method

Installation manual 13

ENGLISH

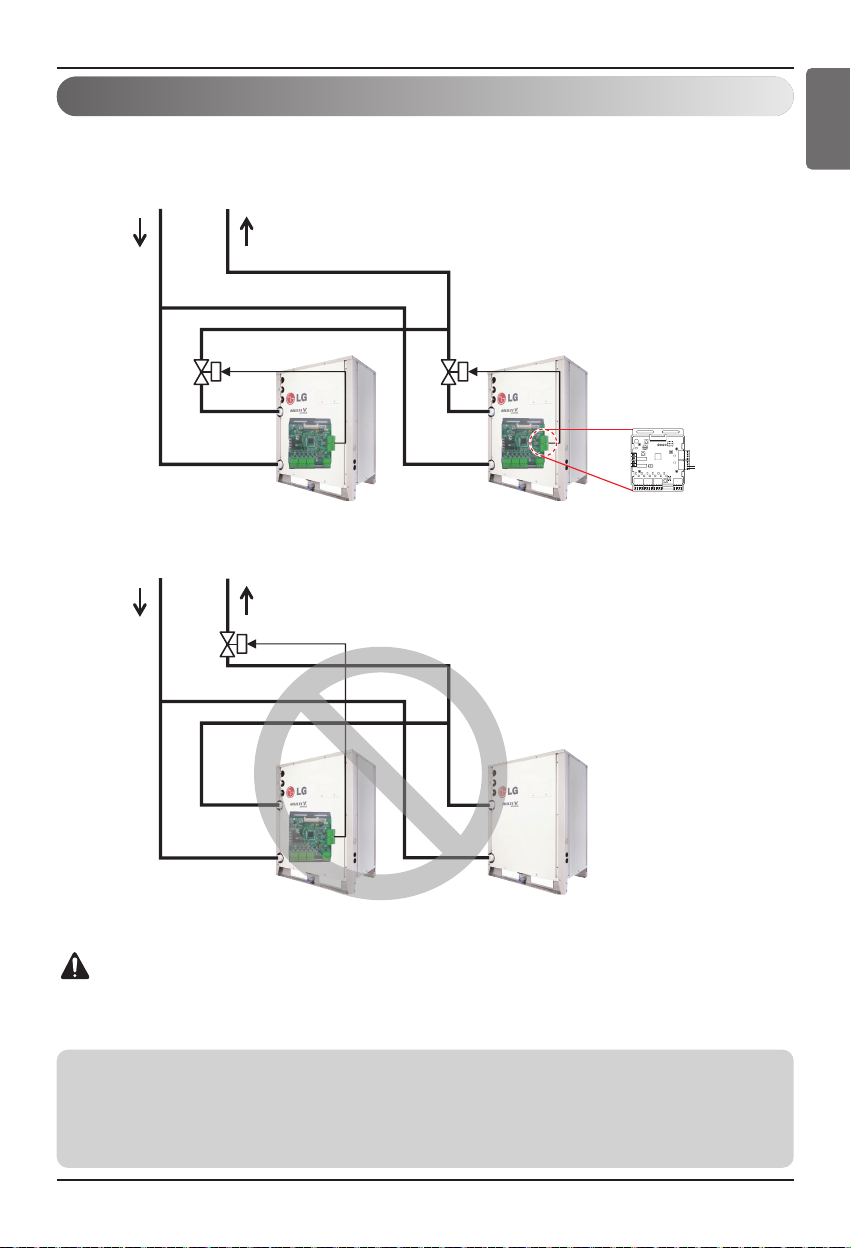

3. Series Installation(more than 2 unit)

For Variable Water Flow Control

Please apply an individual PWFCKN000 model for each MULTI V WATER IV unit

CAUTION

Variable Water Flow Control Kit only can control 1 unit of MULTI V WATER IV and electric

valve.

Notes

Communication line from controller such as DDC must be installed only with VWFC of master outside unit.

- Demand control

- Output outside or indoor unit operation status

- Output outside or indoor unit error status signal

Water

Inlet

Water

Inlet

Water

Outlet

Water

Outlet

Master Slave

AO_1

Master Slave

Setting and Using Method

14 Variable Water Flow Controller Kit

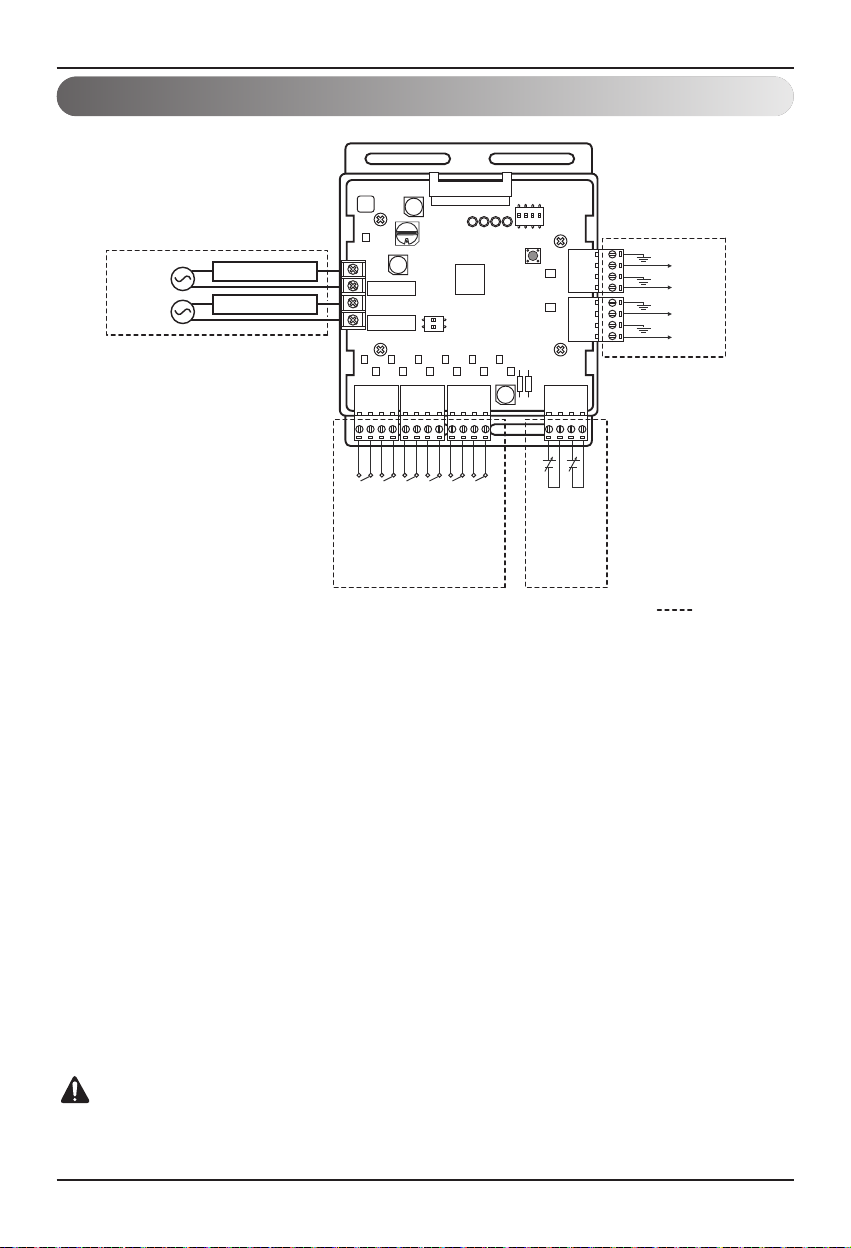

4. Power source input

① Dry contact input part

• Input_1,2,3 : Demand control by contact input(3 Step)

• Input_LNO : Low Noise Operation

• Priority setting

Using ‘Priority setting’ contact signal the priority of command.

(Demand control for external command from DDC vs peak control by LG Centrol controller.)

- Close : Central controller has priority to external signal

- Open : External signal has priority to central controller(default setting)

② Analog input part (AI : DC 0 ~ 10V)

• AI_1 : Demand control by analog input (10 Step)

③ Analog output part(AO : DC 0 – 10V, Max 20 mA)

• AO_1 : Connect analog output signal for variable water flow valve.

④ Digital Output (DDC output AC 1A at 250V source)

• Output error status

• Output operation status

CAUTION

Power must be turned on after the product is wired completely.

AO_4

AO_3

AO_2

AO_1

Field Wiring

ڻ

Power

AC or DC

Power

AC or DC

Error Status

Operating Status

Input_1

Input_2

Input_3

Input_LNO

Reserved

ڸ

Priority setting

AI_1

Reserved

ڹ

ں

Setting and Using Method

Installation manual 15

ENGLISH

n

Communication and Power Line

- If communication and power lines are run alongside each other then there is a strong likelihood of

operational faults developing due to interference in the signal wiring caused by electrostatic and

electromagnetic coupling. The tables below indicates our recommendation as to appropriate spacing

of communication and power lines where these are to be run side by side.

Current capacity of power line Spacing

100V or more

10A 11-13/16 in (300 mm)

50A 19-11/16 in (500 mm)

100A 39-3/8 in (1,000 mm)

Exceed 100A 59-3/64 in (1,500 mm)

Notes

If the power supply waveform continues to exhibit some distortion the recommended spacing in the

table should be increased.

• If the lines are laid inside conduits then the following point must also be taken into account when

grouping various lines together for introduction into the conduits.

• Power lines (including power supply to air conditioner) and signal lines must not be laid inside the

same.

• In the same way, when grouping the lines power and signal lines should not be bunched together.

Setting and Using Method

16 Variable Water Flow Controller Kit

CAUTION

After change ‘DIP Switch’ setting, then you must press reset switch to reflect the setting.

Before operating the outside unit, check the flow rate of water and voltage signal of PCB.

Minimum flow rate of water is recommended 40% of rated flow rate. Otherwise, the outside unit

get damage.

Position Function

Control signal : DC 0V(OFF), DC 8~10V(ON)

Control signal : DC 0V(OFF), DC 6~10V(ON)

Control signal : DC 0V(OFF), DC 4~10V(ON)

Default status

Control signal : DC 0V(OFF), DC 2~10V(ON)

ON

L1 2 3 4

ON

L1 2 3 4

ON

L1 2 3 4

ON

L1 2 3 4

• Output signal setting : SW101 L1, L2

5. Variable Water Flow Control Kit Functions

Setting of DIP Switch

Using 'SW101', select the minimum analog output value as described below to meet the

requirement of applied valve or to keep minimum flow rate.

L1

ON

2

3

4

Notes

Default status is all off.

SW101

Setting and Using Method

Installation manual 17

ENGLISH

Position Function Wiring

ON

L1 2 3 4

ON : Activate Digital Output according to Indoor Unit status

OFF : Activate Digital Output according to Outside Unit status

Operation

status

Using ‘SW101’, Select the option of control function as described below.

- Operation Status output

• Operation status output : SW101 L4

Depends on SW101 L4 position(ON/OFF), VWCK(Board) is operated as below

L1

ON

2

3

4

Notes

Default status is all off.

SW101

Dip Switch VWCK(Board) operation

SW101 L4 ON

When even one of indoor unit (Remote controller) is turned on → Relay on

All Indoor are turned off → Relay off

SW101 L4 OFF

When even one of compressor is turned on → Relay on

All compressor are turned off → Relay off

CAUTION

After change DIP SW setting, press reset switch to reflect the setting.

Setting and Using Method

18 Variable Water Flow Controller Kit

L1

ON

2

Notes

Default status is all off.

CAUTION

Do not operate the DIP SW except authorized person.

After change DIP SW setting, press reset switch to reflect the setting.

Position Function

ON

L1 2

ON : Ignore minimum Analog output value setting

(L1,L2 setting value of 4pin DIP SW)

OFF : Follow minimum Analog output value setting

(L1,L2 setting value of 4pin DIP SW)

• Set Analog output Range : SW102 L2

Basically this module keeps a minimum Analog output voltage refer to L1,L2 setting of SW101 to

prevent unexpected accident. When you need to use 0~10V full range, L2 should be set as ON.

When communication error happened, LED3C(yellow) will truned ON

The setting method makes to open the valve using output signal when occur communication error.

• Set analog output default value in case that communication error between VWFC and outside

unit PCB is occurred : SW102 L1

Using ‘SW102’, Select the option of control function as described below.

- Set analog output optional function

SW102

Position Function Wiring

ON

L1 2

ON : Analog output 0V

OFF : Analog output 10V

AO_1 ~ 4

Setting and Using Method

Installation manual 19

ENGLISH

Setting For Demand control

Use the Rotary Switch to set a control step for contact signal input : The type of input signal and

control step can be set using ‘SW104’

This function is for Demand control to reduce power consumption.

Set the control mode what you want according to the table as below.

CAUTION

Do not change a command too quickly.

Keep the command 30 seconds at least, otherwise it will cause a damage to outside unit.

• Operation rate condition :

- Cooling : Outside 35 °C, Indoor 27 °C

- Heating : Outside 7 °C, Indoor 20 °C

• The tolerance of the operation rate can be cause by combination of outside unit, operating

condition, installation circumstance.

• When operation rate is 100%, Target Evaporating Temp. and Target Condensing Temp. can be

changed by installation option.

• Input_1 : 0 OFF, Input_1 : 1 ON

- Setting of Demand control by type of input signal

Input signal

SW_STEP

Wiring

Demand control by contact input 0, 1, 2, 3, 4, 5, 6, 7 Input 1,2,3

Demand control by analog input(0~10V) C, D, E AI_1

Setting and Using Method

20 Variable Water Flow Controller Kit

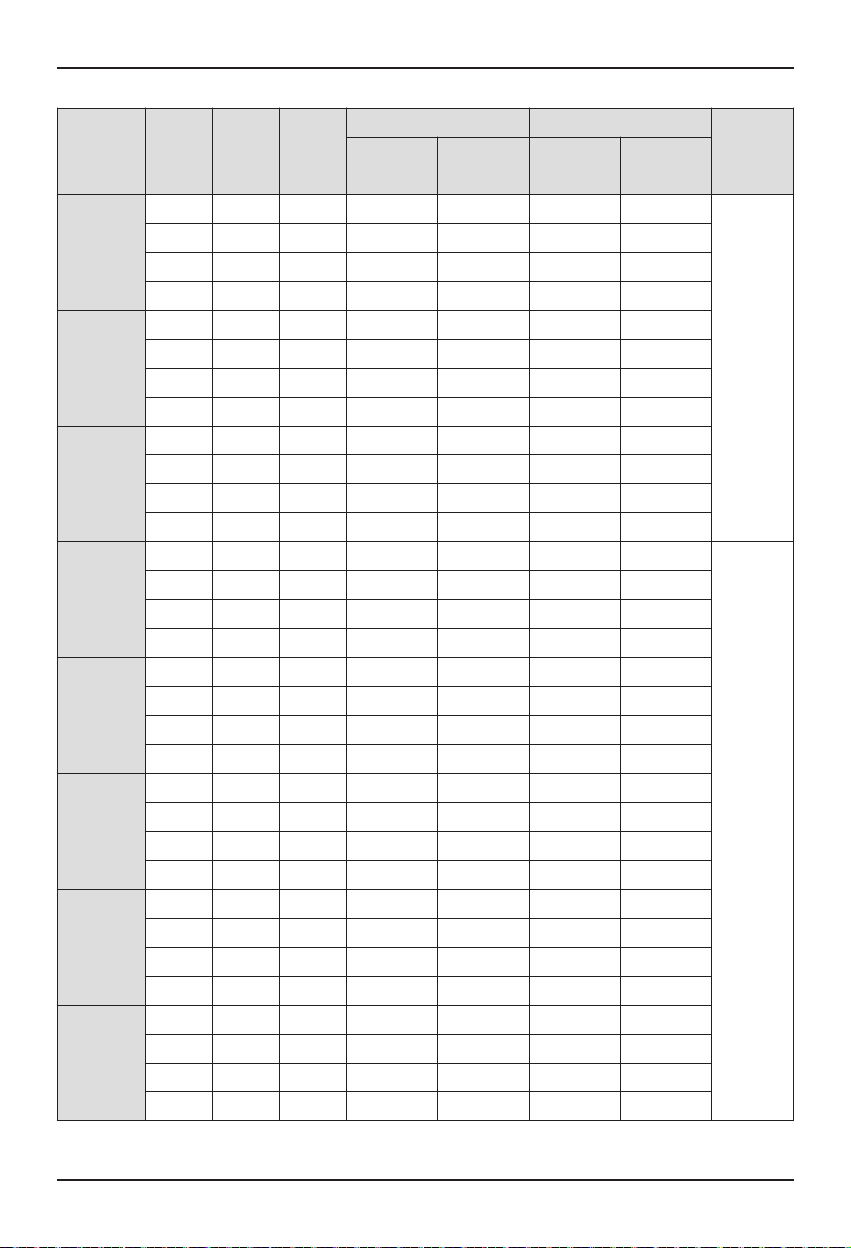

• Demand control by contact input control (3 Step)

3

0 0 0 No control -

No control -

Contact

signal

1 0 0 5.9 70% 40.4 70%

0

1 0 11.0 40% 31.3 40%

00

1 All off 0% All off 0%

4

0 0 0 No control -

No control -

1 0 0 5.9 70% 40.4 70%

0

1 0 9.0 50% 34.5 50%

00

1 All off 0% All off 0%

5

0 0 0 No control - No control -

1 0 0 5.0 80% 43.1 80%

0 1 0 9.0 50% 34.5 50%

0 0 1 All off 0% All off 0%

6

0 0 0 No control - No control -

1 0 0 9.0 50% 34.5 50%

0 1 0 Comp off 0% Comp off 0%

0 0 1 All off 0% All off 0%

7

0 0 0 No control - No control -

1 0 0 5.5 75% 41.8 75%

0 1 0 9.0 50% 34.5 50%

0 0 1 All off 0% All off 0%

SW_ STEP Input_1 Input_2 Input_3

Cooling Heating

Type of

input

Evaporating

Temp. [°C]

Operation

rate

Condensing

Temp. [°C]

Operation

rate

0

0 0 0 No control -

No control -

Contact

signal

1 0 0 5.9 70% 40.4 70%

0

1 0 11.0 40% 31.3 40%

00

1 Comp off 0% Comp off 0%

1

0 0 0 No control -

No control -

1 0 0 5.9 70% 40.4 70%

0

1 0 9.0 50% 34.5 50%

00

1 Comp off 0% Comp off 0%

2

0 0 0 No control - No control -

1 0 0 5.0 80% 43.1 80%

0 1 0 9.0 50% 34.5 50%

0 0 1 Comp off 0% Comp off 0%

Setting and Using Method

Installation manual 21

ENGLISH

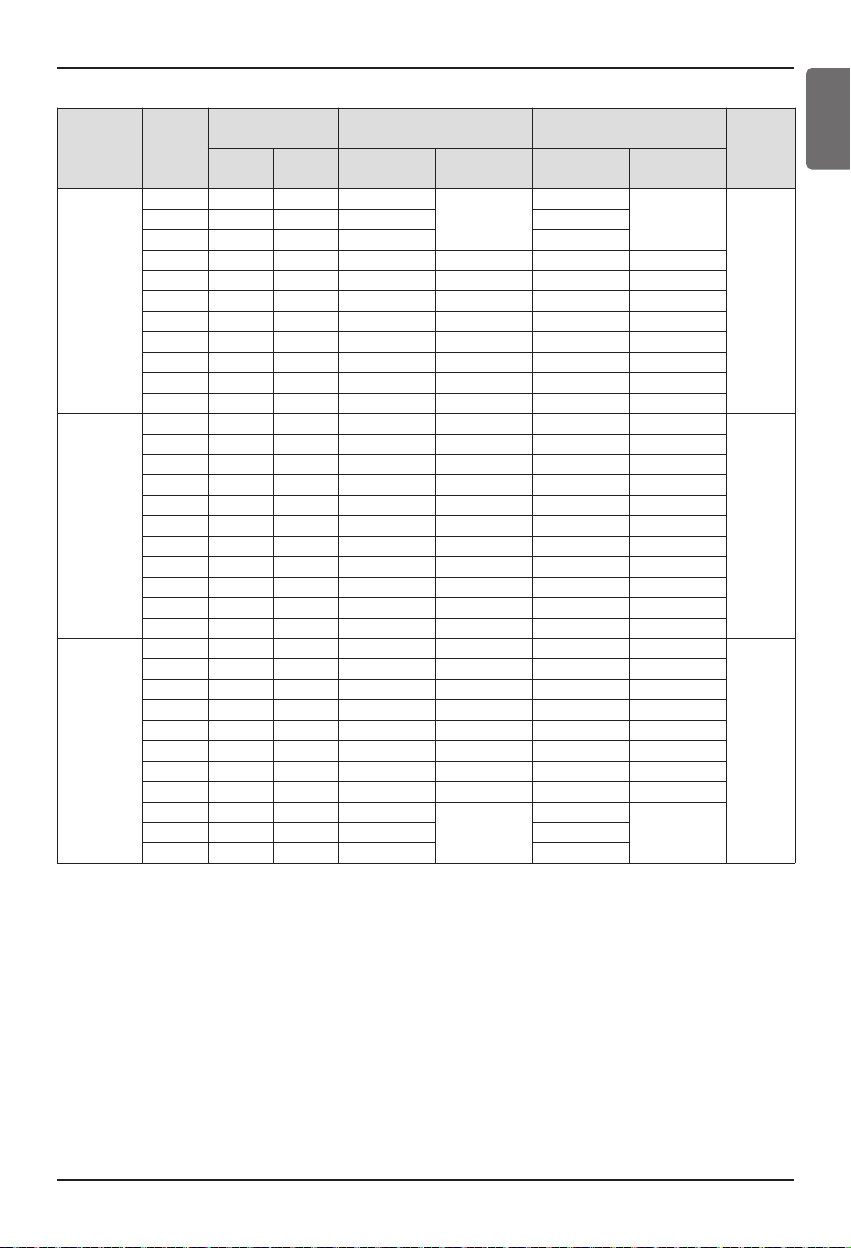

• Demand control by analog input control (10 Step)

SW_ STEP

Normal

(V)

Input voltage

range(V)

Cooling Heating

Type of

input

Min Max

Evaporating

Temp. [°C]

Operation

rate

Condensing

Temp. [°C]

Operation

rate

C

0 0 0.4 Comp off

0%

Comp off

0%

Analog

input

1 0.6 1.4 Comp off Comp off

2 1.6 2.4 Comp off Comp off

3 2.6 3.4 11.0 40% 31.3 40%

4 3.6 4.4 9.8 45% 33.3 45%

5 4.6 5.4 9.0 50% 34.5 50%

6 5.6 6.4 7.2 60% 37.5 60%

7 6.6 7.4 5.9 70% 40.4 70%

8 7.6 8.4 5.0 80% 43.1 80%

9 8.6 9.4 4.1 90% 45.6 90%

10 9.6 10 3.1 100% 48.1 100%

D

0 0 0.4 No control - No control -

Analog

input

1 0.6 1.4 3.1 100% 48.1 100%

2 1.6 2.4 4.1 90% 45.6 90%

3 2.6 3.4 5.0 80% 43.1 80%

4 3.6 4.4 5.9 70% 40.4 70%

5 4.6 5.4 7.2 60% 37.5 60%

6 5.6 6.4 9.0 50% 34.5 50%

7 6.6 7.4 9.8 45% 33.3 45%

8 7.6 8.4 11.0 40% 31.3 40%

9 8.6 9.4 Comp off 0% Comp off 0%

10 9.6 10 All off 0% All off 0%

E

0 0 0.4 Comp off 0% Comp off 0%

Analog

input

1 0.6 1.4 11.0 40% 31.3 40%

2 1.6 2.4 9.8 45% 33.3 45%

3 2.6 3.4 9.0 50% 34.5 50%

4 3.6 4.4 7.2 60% 37.5 60%

5 4.6 5.4 5.9 70% 40.4 70%

6 5.6 6.4 5.0 80% 43.1 80%

7 6.6 7.4 4.1 90% 45.6 90%

8 7.6 8.4 3.1

100%

48.1

100%9 8.6 9.4 3.1 48.1

10 9.6 10 3.1 48.1

Setting and Using Method

22 Variable Water Flow Controller Kit

6. Setting of Outside Unit DIP Switch

Variable Water flow Control Kit Mode

• Steps for setting of Variable water flow control mode

Set the switch No.5 of outside unit ON

Select the “Func” mode using ‘▶’ and ‘◀’

button, and then press the confirm button '●'

Select the “Fn4” using ‘▶’ and ‘◀’ button,

and then press the confirm button '●'

Press reset button to reflect the setting

Setting of variable water flow control kit is

finished

h If you want to stop the variable water flow control mode, follow the same step and make “Fn4” “Off”

Select the “On” using ‘▶’ and ‘◀’ button,

and then press the confirm button '●'

CAUTION

After change ‘DIP Switch’ setting, then you must press reset switch to reflect the setting.

Before operating the outside unit, check the flow rate of water and voltage signal of PCB.

Minimum flow rate of water is recommended 40% of rated flow rate. Otherwise, the outside unit

get damage.

DIP SWITCH 7-Segment

SW04C

( X : cancel)

SW03C (

SW02C ( : backward)

SW01C ( : confirm)

SW01D (reset)

: forward)

ȯ

ȭ

Ɨ

Setting and Using Method

Installation manual 23

ENGLISH

7. Setting Example

Using

Demand control

Using Demand control function with 3-Non Voltage contact.

LG does not supply this section

(Field supply)

With this function comp capacity of outside unit can be controlled.

Ex) Demand control by 3-contact signal

SW_ STEP Input_1 Input_2 Input_3

Comp capacity Of outside

unit(%)

Type of input

0

0 0 0 No control

Contact signal

100 70

0

10 40

00

1 Comp off

CAUTION

• This input can accept only non voltage contact.

Do not input external power source. Otherwise it will cause a serious damage.

Input_1

Input_2

Input_3

Input_LNO

Reserved

Reserved

Setting and Using Method

24 Variable Water Flow Controller Kit

With this function compressor capacity of outside unit can be controlled by Building Management

System.

Ex) Demand control by Analog input signal Refer to Detail of the control step for analog input

signal.

CAUTION

• This function is sensitive to voltage level.

So when using analog input, make a signal cable as short as possible.

• Do not change a command too quickly.

Keep the command 30 seconds at least, otherwise it will cause a damage to outside unit.

Using Demand control function with 0~10V DC voltage signal

LG does not supply this section

(Field supply)

DC 0~10V

input

Direct Digital

Controller

GND

Setting and Using Method

Installation manual 25

ENGLISH

CAUTION

When using high voltage over than AC24V, make sure to use H07RNF wire.

① Error Display

: This function displays error signal by digital output when either outside or indoor unit has an

error

② Operating Display

: This function is depend on 4th DIP SW setting of ‘SW101’.

- L4 is ON : Display indoor unit operating status (Include FAN mode only)

- L4 is OFF : Display outside unit operating status (Compressor operating on/off status)

Operation Status

LG does not supply this

section (Field supply)

Status output Relay can

endure 250VAC, 1A.

Position Function

ON

L1 2 3 4

ON : Activate Digital Output according to indoor unit status

OFF : Activate Digital Output according to outside unit status

• L4 : Set Operating status output

Power

AC or DC

Power

AC or DC

Error Status

Operating Status

26 Variable Water Flow Controller Kit

Loading...

Loading...