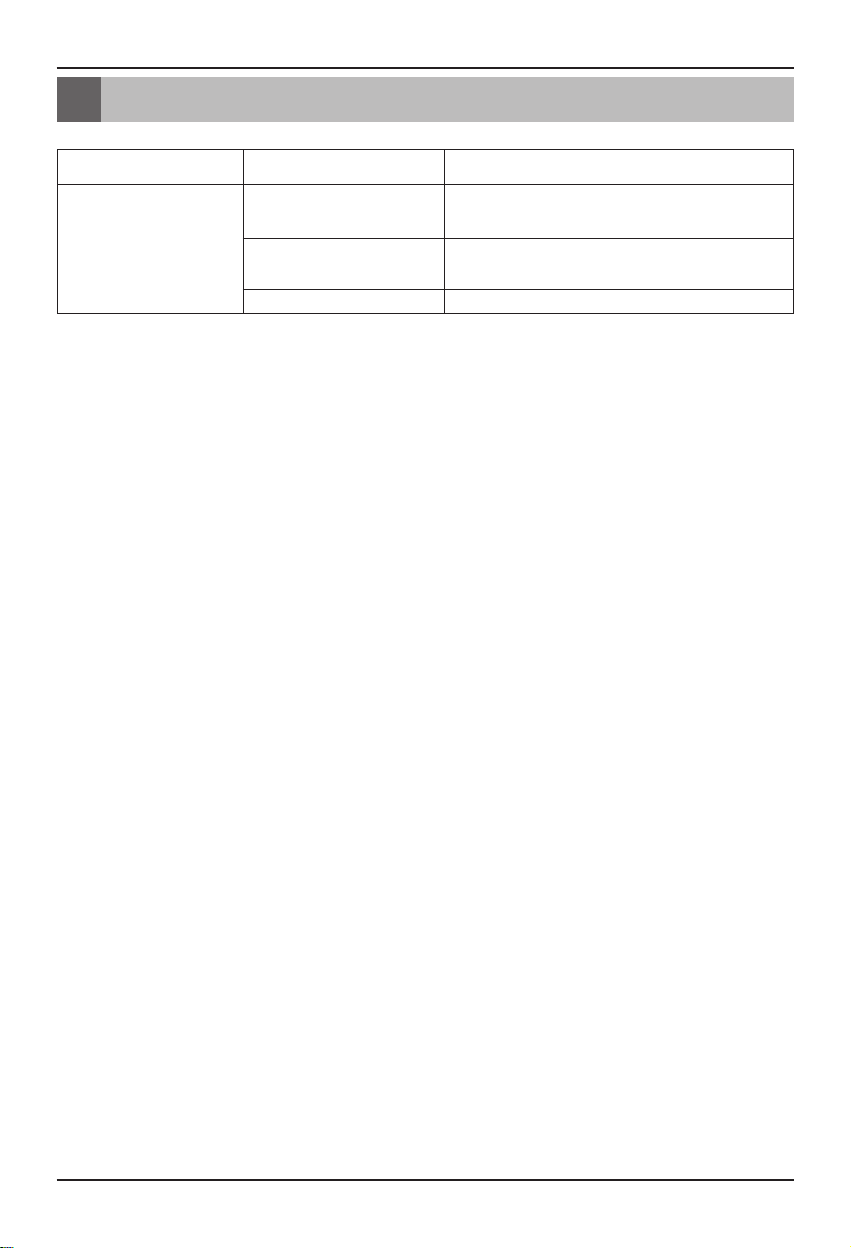

개정일자 :

QA 요청사항 :

예

바코드와 P/No.가 일치하는가? (바코드 확인)

예

언어표시띠의 위치(누락여부)는 바른가?

예

약물(기호)이 깨지거나 위치가 어긋 난 곳은 없는가?

예

그림이 가려지거나 잘려나간 곳은 없는가?

KUKJE-130

문서번호

CWROM-1606-00193

Order No.

MFL50024802

P/No.

최종 컨펌일자 :

작업자

연구실 담당자

희령

김동겸

예

작업원고와 수정내용이 일치하는가?

* 필수확인 - QA요구사항

*최종 확인후 본 체크리스트는 삭제됩니다.

1. 원고에 지시된 대로 작업한 후 이상없이 작업 되었는지 재차 검토 후 PDF 파일을 생성한다.

2. 작업완료 후 담당 연구원에게 수정부분에 대한 검증요청한다.

(*** 반드시 필요 – 의뢰자가 요청한 의도대로 작업이 정확히 되었는지 반드시 확인이

필요함)

3. 아래 체크리스트에 따라 놓치기 쉬운 사항을 우선으로 한번 더 확인한다.

2016-6-1

INSTALLATION MANUAL

AIR

CONDITIONER

ENGLISH

Please read this installation manual completely before installing the product.

Installation work must be performed in accordance with the national wiring

standards by authorized personnel only.

Please retain this installation manual for future reference after reading it

thoroughly.

Applied(AHU)

Comm.kit

www.lg.com

P/NO : MFL50024802

AHU Control Kit Installation Manual

TABLE OF CONTENTS

n Safety Precautions............................................................3

n Installation Scene..............................................................4

n Supplies.............................................................................5

n Optional Accessories ........................................................5

n Part Description.................................................................6

n Before Installation .............................................................7

n Control Kit Installation........................................................9

Mechanical installation...................................................................................9

Electric wiring work .................................................................................10-12

Dip switch setting .........................................................................................12

Dry contact connection_optional accessory................................................13

n Thermistors Installation....................................................14

Pipe thermistors installation....................................................................14-16

Room thermistor...........................................................................................17

n Test Operation..................................................................18

n Troubleshooting ...............................................................19

2 AHU Control Kit

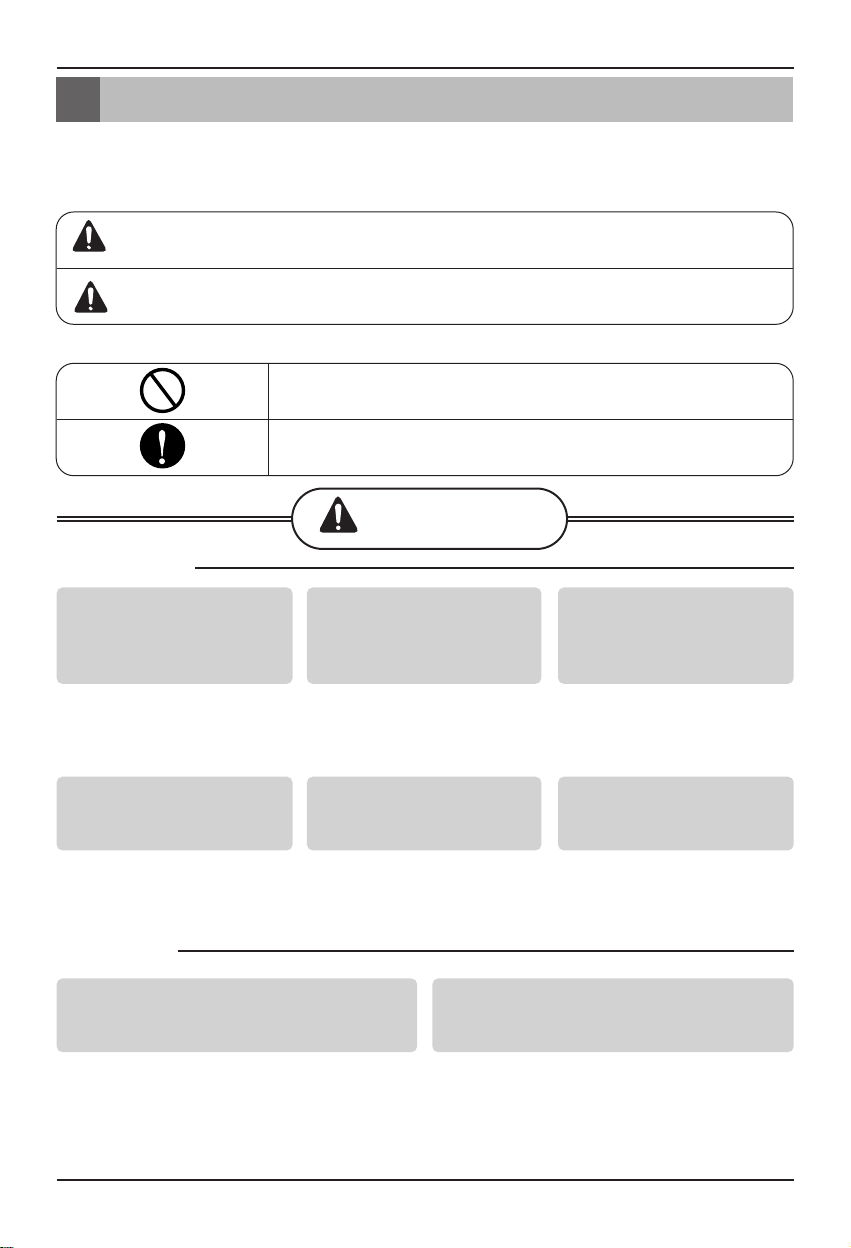

Safety Precautions

WARNING

WARNING

CAUTION

WARNING

Safety Precautions

To prevent injury to the user or other people and property damage, the following instructions must be followed.

n Incorrect operation due to ignoring instruction will cause harm or damage. The seriousness is

classified by the following indications.

This symbol indicates the possibility of death or serious injury.

This symbol indicates the possibility of injury or damage.

n Meanings of symbols used in this manual are as shown below.

Be sure not to do.

Be sure to follow the instruction.

n

Installation

Don't touch with the

hands while the power is

on

•

There is risk of fire or electric

shock.

Use the correctly rated

breaker or fuse.

• There is risk of fire or electric

shock.

n

Operation

When the product is soaked (flooded or

submerged), contact an Authorized Service

Center.

• There is risk of fire or electric shock.

Use standard

parts(connector).

•

Do not install, remove, or reinstall the unit by yourself

(customer).

• There is risk of fire, electric

Do not disassemble or repair

the product. There is risk of fire

or electric shock.

shock, explosion, or injury.

Be cautious that water could not enter the

product.

• There is risk of fire, electric shock, or product

damage.

For electrical work, contact

the dealer, seller, a qualified

electrician, or an Authorized

Service Center.

•

Do not disassemble or repair

the product. There is risk of fire

or electric shock.

For installation, always

contact the dealer or an

Authorized Service Center.

• There is risk of fire, electric

shock, explosion, or injury.

Installation Manual 3

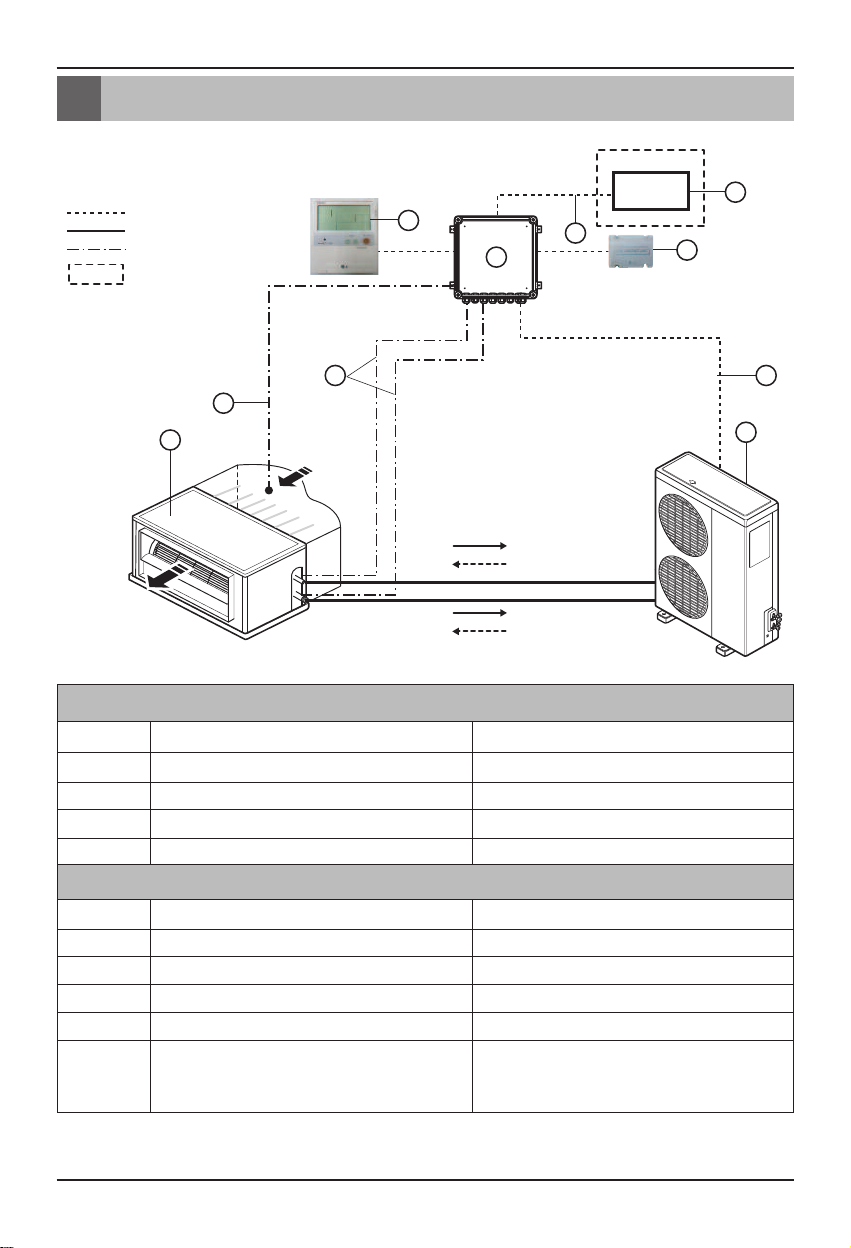

Installation Scene

Signal

Pipe

Thermistor

9

4

10

5

7

8

6

2

3

1

Field supply

DDC

A

i

r

f

l

o

w

Cooling

Heating

Cooling

Heating

Installation Scene

Parts and components

No. Name Remarks

1

2

3

4

Wiring connections

5

6

7

8

9

10

4 AHU Control Kit

Air Handling Unit

Outdoor Unit

AHU Control Kit(PUCKA0)

Control kit wiring

Pipe thermistors

Room thermistor

Remote controller(PQRCUSA0/1)

Dry contact (PQDSBC)

DDC

Signal

Field supply

Universal

Field supply(Central control Device)

(Power supply and communication between control kit and outdoor unit)

Evaporator (In/Out) control of Air Handling Unit

Return air control

Optional accessory

Optional accessory

• Fan signal(Low / Middle / High)

• Defrost / Heating / Cooling signal

• Themal On/Off

-

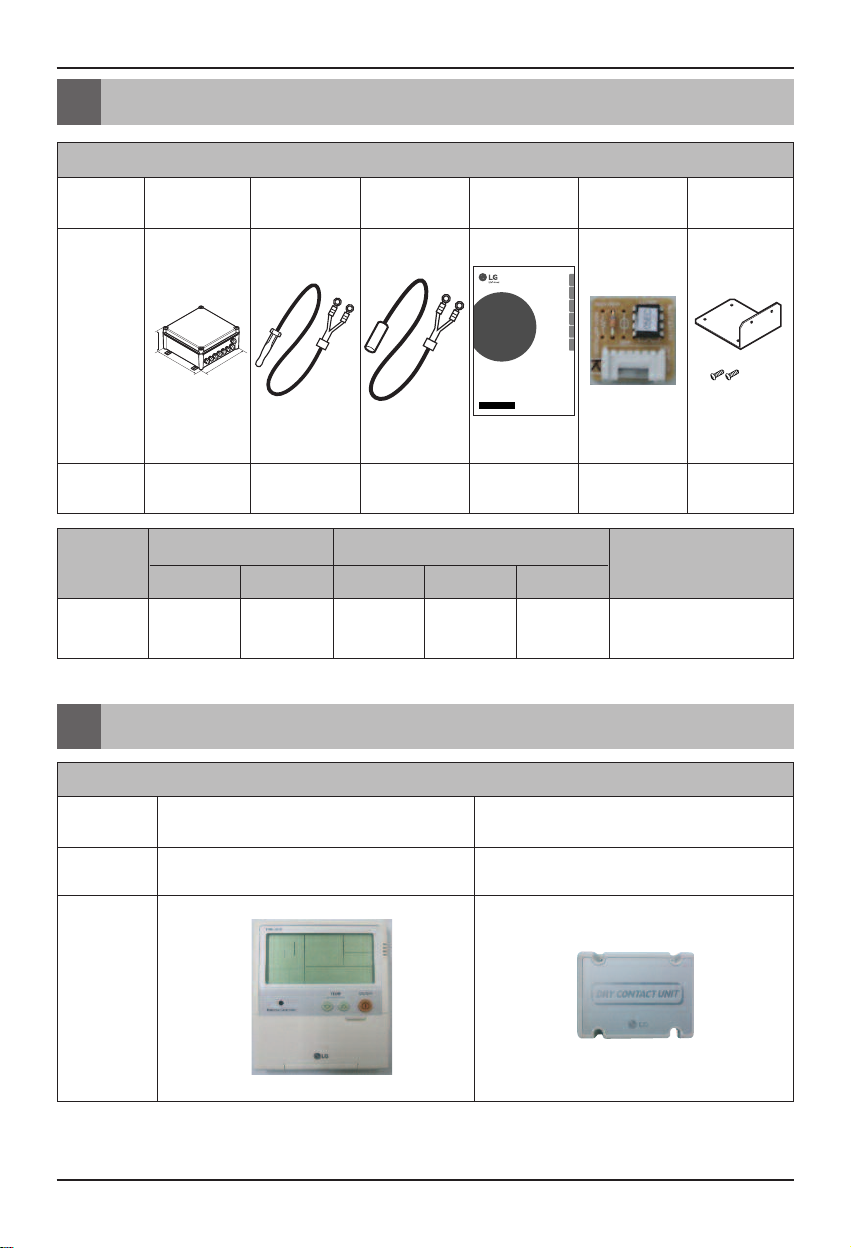

Supplies

W

D

H

P/NO : MFL50024802

I

NSTALLATION MANUAL

AIR

C

ONDITIONER

www.lg.com

Applied(AHU)

Comm.kit

P

lease read this installation manual completely before installing the product.

Installation work must be performed in accordance with the national wiring

s

tandards by authorized personnel only.

Please retain this installation manual for future reference after reading it

thoroughly.

PUCKA0

Components

Shape

Supplies / Optional Accessories

AHU Control Kit Room thermistor Pipe thermistors Installation manual

Capacity setting

option PCB

Panel(Dry contact

support)

Quantity(EA)

112(Pipe In/Out) 1 10(Each 1)

Weight(kg) Dimension(mm)

Model Name

NET Gross WHD

PUCKA0 2.5 4 280 135 280

1Phase, 220~240V,

Optional Accessories

Accessories

Components Remote controller Dry contact

Model name

Shape

PQRCUSA0/1 PQDSBC

1(Panel)

2(Screw)

POWER

50/60Hz

* For further details of the accessories, refer to the manual provided at the time of purchasing the

accessories.

Installation Manual 5

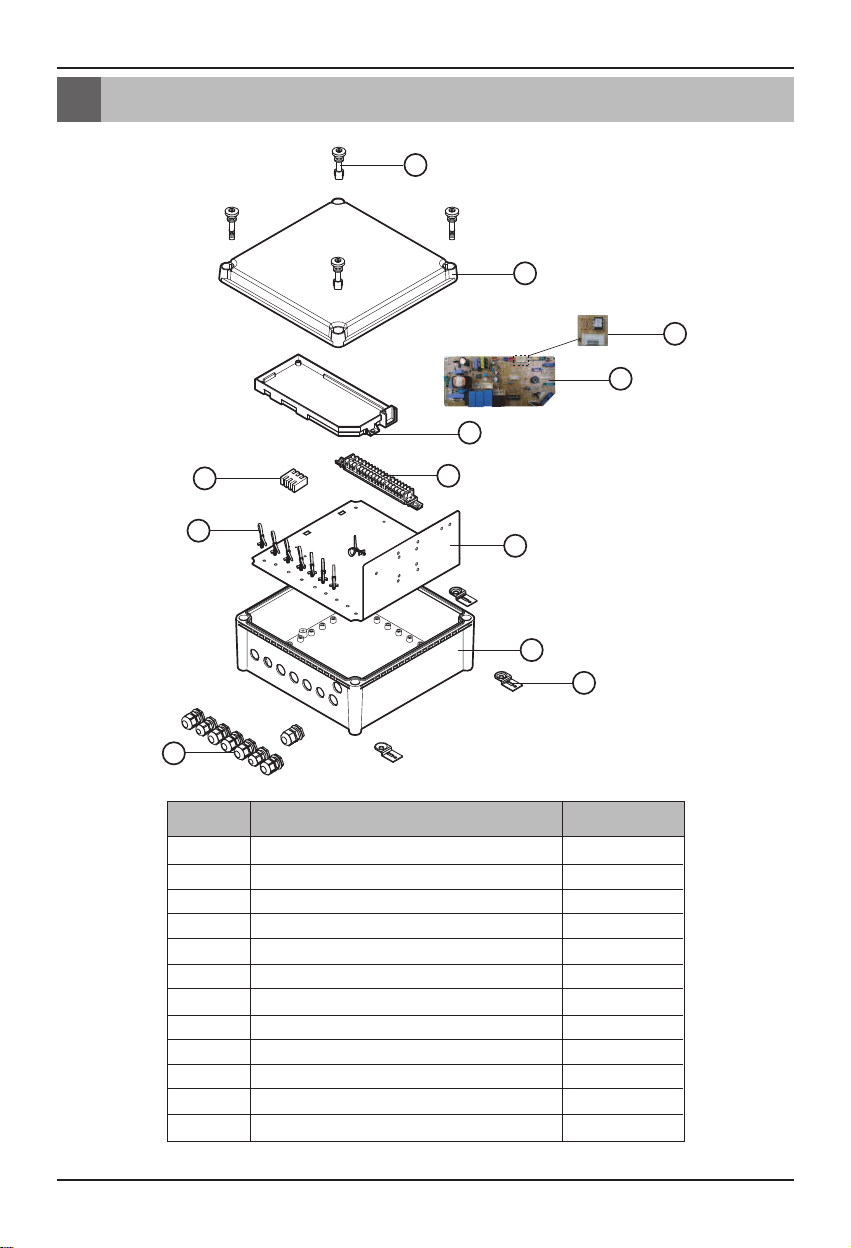

Part Description

1

2

3

4

5

7

11

9

8

10

12

6

CN-OPTION

Part Description

6 AHU Control Kit

No. Part Name Quantity(EA)

1

2

3

4

5

6

7

8

9

10

11

12

Plastic (+) bolt

Control box cover

Terminal block (communication)

Terminal block (POWER Supply)

Main PCB

Option PCB(24k)

Main PCB case

Panel

Support Tie wrap

Control box case

Cable gland(2type)

Bracket

4

1

1

1

1

1

1

1

8

1

8

4

Before Installation

WARNING

CAUTION

Before Installation

n Don't install or operate the unit in rooms mentioned below.

①

Where mineral oil, like cutting oil is present.

②

Where the air contains high levels of salt such as air near the ocean.

③

Where sulphurous gas is present such as that in areas of hot spring.

④

In vehicles or vessels.

⑤

Where voltage fluctuates a lot such as that in factories.

⑥

Where high concentration of vapor spray are present.

⑦

Where machines generating electromagnetic waves are present.

⑧

Where acidic or alkaline vapor is present.

⑨

The option boxes must be installed with entrances downward.

⑩

If you want to install the product outdoors, it should be installed with outdoor casing.

n Check the mentioned below, when you apply the AHU(Field supply).

①

If the AHU (Field supply) provided in the field is exclusively for heating, you must not

change the operating mode to cooling on the remote controller. If not, it can cause electric

shock, injury or death. If you want to operate in cooling mode, AHU (Field supply) must

comply with the following details.

(Following)

- The insulation level of AHU (Field supply) motor must be ‘F’ or above, and the protection

level must satisfy ‘IP 54’.

- AHU (Field supply) must have the drain pan installed.

②

For refrigerant piping of outdoor unit, refer to the installation manual supplied with the

outdoor unit.

③

For installation of the wired remote controller(PQRCUSA0/1), refer to the manual supplied

with the wired remote controller.

④

For connection of the Dry contact (PQDSBC), refer to the manual supplied with the Dry

contact (PQDSBC).

n AHU Control Kit

①

Thermistor cable and remote controller wire should be located at least 50mm away from

power supply wires and from wires to the controller. Not following this guideline may result

in malfunction due to electrical noise.

②

Use only specified wires, and tightly connect wires to the terminals. Keep wiring in neat

order so that it does not obstruct other equipment. Incomplete connections could result in

overheating, and in worse case electric shock or fire.

Installation Manual 7

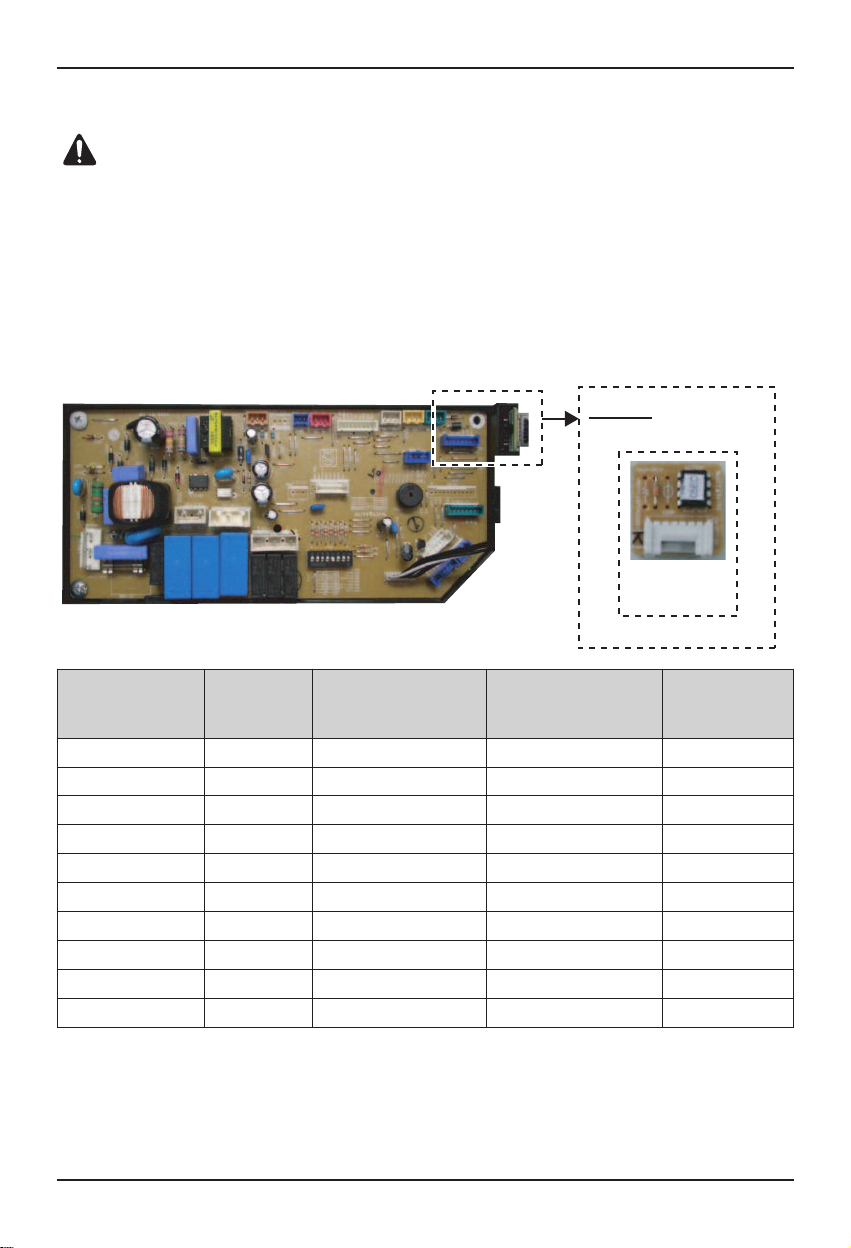

Before Installation

WARNING

CAUTION

Capacity setting

'Option PCB'

Detail

(Main PCB)

Selection of Evaporator(Air Handling Unit)

See table below for applicable units

Selecting the capacity setting 'Option PCB'(Accessory) according to the capacity mentioned below.

-

The corresponding capacity setting '

capacity.

- After checking the need capacity, remove the 24k

and set up the

Option

(Main PCB)

PCB fitted the need capacity in the main PCB.

Option

PCB' needs to be selected depending on the need

Option

PCB equipped in the main PCB,

Option PCB

P/NO

EBR65102901 12 k 2.2 3.5 9~10

EBR65102902 18 k 2.4 5.0 13~16.5

EBR65102903 24 k 2.6 7.1 14~18

EBR65102904 30 k 2.9 8.0 20~26.5

EBR65102905 36 k 3.1 10.0 26.5~32

EBR65102906 42 k 3.4 12.5 28~36

EBR65102907 48 k 4.0 14.0 30~40

EBR65102908 60 k 4.7 15.0 40~50

EBR52358920 70 k 5.2 20.0 60~70

EBR52358921 85 k 5.9 23.0 64~80

Saturated Suction Temperature (SST) = 6°C, SH (Superheat) = 5K, Air Temperature = 27°C DB / 19°C WB.

Capacity

(Btu/h)

Standard heat

exchanger volume

(103× m3)

Maximum heat

exchanger capacity

(kW)

Air Flow rate

(CMM)

8 AHU Control Kit

Control Kit Installation

298 mm

Provided holes

Ø4.5 mm (4EA)

189 mm

Control Kit Installation

Mechanical installation

1. Remove the Control Kit box cover by unscrewing the plastic (+) bolt(4EA).

2. Drill 4 holes on correct position and fix the Control Kit box securely with 4 screws(Field supply)

through the provided holes Ø4.5 mm(Reference the length of the holes Ø4.5)

Installation Manual 9

Control Kit Installation

Electric Wiring Work

n

Circuit diagram

1. For electric wiring, refer to figure 'Circuit diagram' mentioned below.

CONNECTOR

NUMBER

CN-POWER AC POWER SUPPLY

CN-D/PUMP FIELD WIRING THERMOSTAT ON/OFF SIGNAL

CN-MOTOR FAN MOTOR CONTROLLER FAN SPEED CONTROLL OUTPUT

CN-OUT FIELD WIRING

CN-OPTION OPTION PCB

CN-FLOAT FLOAT SWITCH INPUT FLOAT SWITCH SENSING

CN-REMO REMOTE CONTROLLER REMOTE CONTROL LINE

CN-ROOM ROOM SENSOR ROOM AIR THERMISTOR

CN-PIPE/IN SUCTION PIPE SENSOR PIPE IN THERMISTOR

CN-CC DRY CONTACT DRY CONTACT LINE

CN-PIPE/OUT DISCHARGE PIPE SENSOR PIPE OUT THERMISTOR

10 AHU Control Kit

LOCATION POINT FUNCTION

AC POWER LINE INPUT FOR INDOOR CONTROLLER

DEFROST, HEATING, COOLING SIGNAL OUTPUT

COMMUNICATION BETWEEN MAIN AND OPTION

1 2 3 4 5 6 7

8

Control Kit Installation

Support

tie wrap

Nut of cable

gland

(Side view)

Detail

Cable insert

Electric Wiring Work

n

Connection of the wires

2. For connection to outdoor unit and to controller (Field supply) :

Pull the wires inside through the cable gland and close that's nut firmly in order to ensure a

good pull relieve and water protection.

3. The wires require an additional pull-relief. Strap the wire with the support tie wrap.

4. For the wired remote controller wire and outdoor unit communication wire, remove the coating

at the end of the wire to connect and use the ring type (Ø3) to connect to the terminal block.

Ring type (Ø 3)

5. Each wire have to pass the number of the cable gland mentioned below.

No. Electric wire

(Side view)

①

②

③

④

⑤

⑥

⑦

⑧

Defrost / Heating / Cooling signal

Power supply

Outdoor com.

Thermal Signal(On/Off)

Fan signal(Low / Middle / High)

Room / Pipe thermistor(In/Out)

Remote controller

DRY contact

Installation Manual 11

Control Kit Installation

WARNING

CAUTION

Detail

(Main PCB)

1

ON

OFF

2345678

Electric Wiring Work

n All field supplied parts and materials and electric works must be conform to local codes.

n Use copper wire only.

n All wiring must be performed by an authorized electrician.

n

A main switch or other means for disconnection, having a contact separation in all poles, must

be incorporated in the fixed wiring in accordance with relevant local and national legislation.

n Refer to the installation manual attached to the outdoor unit for the size of power supply

electric wire connected to the outdoor unit, the capacity of the circuit breaker and switch,

wiring and wiring instructions.

Dip switch setting

If you want to run the Fan(L/M/H) in Heating Mode - defrosting condition, you should set the dip

switch 4 to "On"(As shown below)

n

PCB output signal(According to the dip switch 4 setting)

Thermal On/Off Fan L/M/H Defrost Heating Mode

On Off Off On

On Off On On

On On Off On

On On On On

Dip switch Off

Dip switch On

Condition

Off Off Off Off Off

Cooling Mode Off or On On Off Off

Fan Mode Off On Off Off

Heating Mode Off or On Off or On Off On

Heating Mode – Preheating

Heating Mode – Defrosting

Auto Mode The Same as Cooling or Heating Mode

Off Off Off Off Off

Cooling Mode Off or On On Off Off

Fan Mode Off On Off Off

Heating Mode Off or On On Off On

Heating Mode – Preheating

Heating Mode – Defrosting

Auto Mode The Same as Cooling or Heating Mode

12 AHU Control Kit

Output Signal

Dry contact connection_optional accessory

Signal

Field work

Local controller

1. Using screw(4EA), fix the dry contact on the bracket.

h Applicable dry contact model

- PQDSBC

2. Using cable, connect the dry contact to main PCB.

For more information, please refer to dry contact installation manual.

Control Kit Installation

3. Using screw(4EA), fix the dry contact upper cover to bottom cover.

4. Combine the dry contact upper cover to bottom cover with screw(2EA).

Installation Manual 13

Thermistors Installation

1

2

Thermistors Installation

Pipe thermistors Installation

Location of the pipe thermistors

A correct installation of the thermistors is required to ensure a good operation :

1. Pipe_In

: Install the thermistor behind the distributor on the coldest pass the heat exchanger

(contact your heat exchanger dealer).

2. Pipe_Out

: Install the thermistor at the outlet of the heat exchanger as close as possible to the

heat exchanger.

Evaluation must be done to check if the evaporator is protected against freeze-up.

Execute test operation and check for freeze-up.

1 Pipe_In(Suction pipe)

2 Pipe_Out(Discharge pipe)

14 AHU Control Kit

(Air Handling Unit)

Thermistors Installation

2

45°

1

1234

Pipe thermistors Installation

Installation of the pipe thermistor cable

1. Put the thermistor cable in a separate protective tube.

2. Always add a pull-relief to the thermistor cable to avoid atrain on the thermistor cable and

loosening of the thermistor. Strain on the thermistor cable or loosening of the thermistor

may result in bad contact and incorrect temperature measurement.

Fixation of the pipe thermistors (Field work)

1. Fix the thermistor with insulating aluminum tape (Field supply) in order to ensure a good

heat transference.

2. Put the supplied piece of rubber around the thermistor in order to avoid loosening of the

thermistor after some years.

3. Fasten the thermistor with 2 tie wraps.

4. Insulate the thermistor with the supplied insulation sheet.

Installation Manual 15

Thermistors Installation

45°

2

1

Pipe thermistors Installation

INSTRUCTION

n Put the thermistor wire slightly top to avoid water accumulation on down of the thermistor.

n Make good between thermistor and evaporator. Put the top of the thermistors on the

evaporator, this is the most sensitive point of the thermistor.

1 Most sensitive point of the thermistor

2 Maximize the contact

16 AHU Control Kit

Thermistors Installation

Thermistor

A

ir

fl

o

w

Room thermistor

Installation of the Room thermistor

1. The room thermistor have to be installed in the return air part of the AHU(Field supply)

mentioned below.

(AHU Control Kit)

(Air Handling Unit)

Installation Manual 17

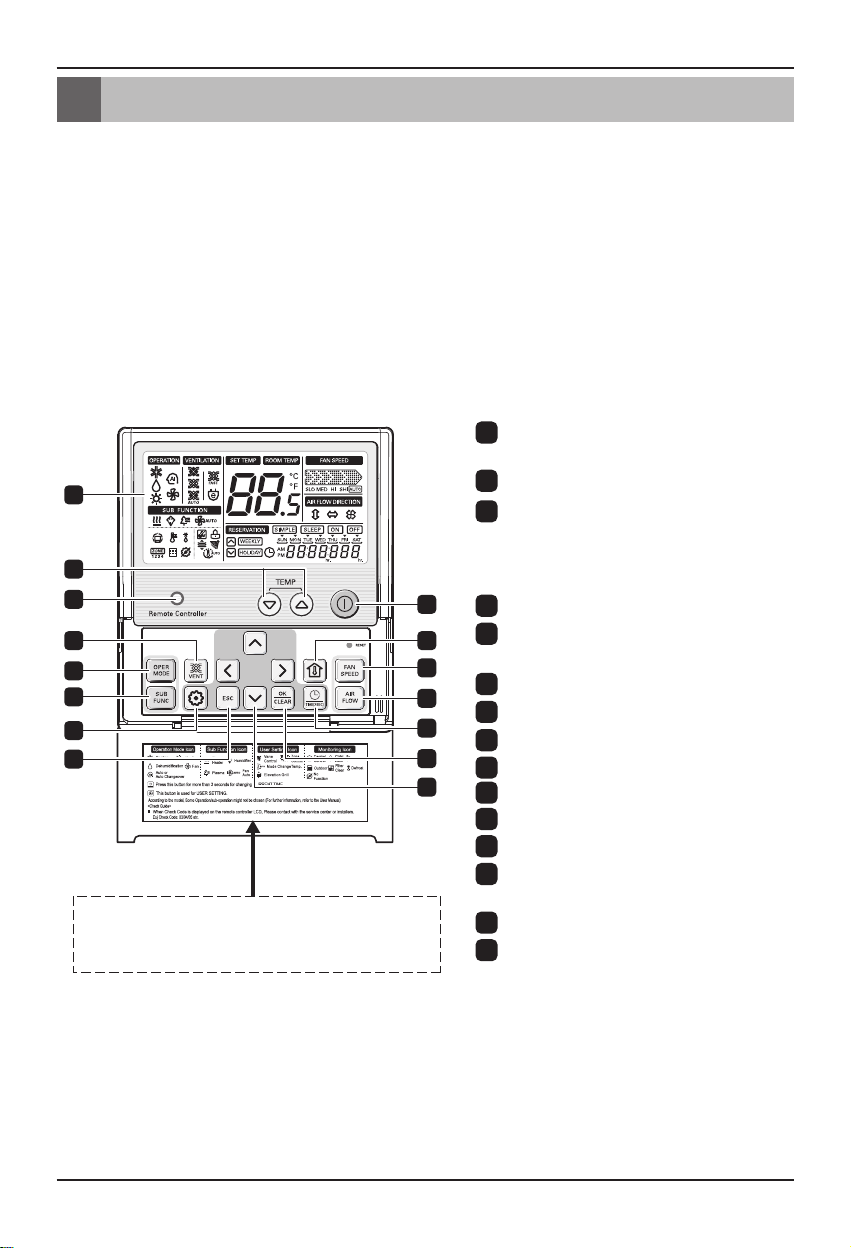

Test Operation

1

9

11

12

3

5

6

2

4 10

13

14

7

8

15

Please attach the inform label inside of the door.

Please choose proper language defend on your

country.

Test Operation

Before test operation, be sure all information is understood completely, and follow the

guideline of manual.

n Check the refrigerant piping of outdoor unit.

(Additional charging of the refrigerant ,the maximum allowed piping length and open the stop valve)

* For more detailed information of that, refer to the installation manual supplied with the

outdoor unit.

n Executing the test operation.

1. Connect the power and turn on with the wired remote controller(PQRCUSA0/1).

2. Check the AHU(Field supply) and outdoor unit operation when the wired remote

controller (PQRCUSA0/1) is controlled.

OPERATION INDICATION

1

SCREEN

2

SET TEMPERATURE Button

WIRELESS REMOTE

3

CONTROLLER RECEIVER

• Some products don't receive the

wireless signals.

4

VENTILATION Button

5

OPERATION MODE SELECTION

Button

6

SUBFUNCTION Button

7

FUNCTION SETTING Button

EXIT Button

* For more detailed function of the wired remote controller, refer to the Owner's &

Installation manual supplied with the wired remote controller.

* Button ③,④,,⑫ on the wired remote controller(PQRCUSA0/1) is not operated.

8

ON/ OFF Button

9

10

ROOM TEMPERATURE Button

11

FAN SPEED Button

12

AIR FLOW Button

13

RESERVATION/ TIME SETTING

Button

14

SETTING/ CANCEL Button

15

UP, DOWN, LEFT, RIGHT Button

(Do not operate)

(Do not operate)

(Do not operate)

18 AHU Control Kit

Troubleshooting

Problem Cause Remedy

No power supply Check the electrical connection and voltage of the

AHU Control Kit

does not work

Wiring is wrong Check the electrical connection of the Control kit

AHU Control Kit is broken Check the electrical and mechanical part.

power supply.

(Refer to the circuit diagram of the Control Kit)

Troubleshooting

Installation Manual 19

Loading...

Loading...