LG PQCPA11A0E User guide

ACP

Advanced Control Platform

(PQCPA11A0E, PQCPB11A0E)

Installation/Owner's Manual

LG

Caution

• Read this manual thoroughly before installing the product.

• Only the certified professional should install this product.

• Keep this manual for referring during the operation later.

2

ACP

Advanced Control Platform

Contents

1. ACP FUNCTIONS & SPECIFICATION .............1-1

Functions of ACP ............................................................................................................1-1

Denomination of ACP .....................................................................................................1-4

Components of ACP .......................................................................................................1-6

Hardware specification of ACP......................................................................................1-7

2. INSTALLING ACP.............................................2-1

Before installing the ACP ...............................................................................................2-2

• Using the single ACP as web server ........................................................................2-3

• Connecting the single ACP to the AC Manager ......................................................2-5

• Connecting more than on ACPs to the AC Manager ..............................................2-7

Setting the indoor unit address .....................................................................................2-8

• Setting the address by the wired remote controller ...............................................2-9

• Setting the address by the wireless remote controller.........................................2-10

Setting the PI485 and Connecting the cable .............................................................2-12

• Setting the PI485 DIP switch ...................................................................................2-12

• Connecting the 2PIN connector..............................................................................2-14

• Connceting RS485 cable to PI485...........................................................................2-16

Installing the ACP and Connecting the cable.............................................................2-19

• Fixing the ACP at the installation site ....................................................................2-19

• Connecting RS485 cable to ACP ............................................................................2-20

• Connecting Ethernet cable to ACP.........................................................................2-23

• Connecting Power adaptor to ACP.........................................................................2-24

Configuring the ACP network ......................................................................................2-25

• Before configuring the ACP environment..............................................................2-25

• Setting the IP address..............................................................................................2-29

• Setting the gateway address...................................................................................2-30

• Setting the net mask address .................................................................................2-31

• Checking the network environment .......................................................................2-32

Installation/Owner's Manual

3

3.

ACP OPERATION BY USING THE LG ACCS

.............3-1

Setting the functions of the ACP .................................................................................2-33

• Before setting the functions of the ACP ................................................................2-33

• Selecting Peak or Demand ......................................................................................2-34

• Selecting the ACCS display language....................................................................2-36

• Setting whether to use the schedule function or not ...........................................2-38

• Setting whether to use the wattage display function or not ................................2-40

• Setting error history display ..................................................................................2-42

Configuring the ACCS access .....................................................................................2-43

• Chceking the MS JAVA VM installation .................................................................2-43

• Checking the MS Explorer security setting ...........................................................2-45

Entering the indoor unit & ventilator information......................................................2-49

• If the ACP is connected to the AC Manager ..........................................................2-49

• If the ACP is not connected to the AC Manager....................................................2-50

Making sure and checking the ACP installation ........................................................2-67

Accessing the ACCS.......................................................................................................3-1

Reviewing the initial ACCS screen................................................................................3-4

Controlling the air conditioner.......................................................................................3-7

Controlling the ventilator .............................................................................................3-14

Setting the schedule .....................................................................................................3-21

• Reviewing the schedule setup screen ...................................................................3-21

• Example for setting the schedule ...........................................................................3-32

Controlling the peak operation rate ............................................................................3-44

Controlling the demand electric power.......................................................................3-51

Monitoring the air conditioner status..........................................................................3-56

Reviewing the error history..........................................................................................3-58

Reviewing the power consumption (interconnecting with the power display).......3-61

Setting the system ........................................................................................................3-66

4. REFERENCE ....................................................4-1

Troubleshooting..............................................................................................................4-1

Guide for the open source software..............................................................................4-2

UTP cable connection chart...........................................................................................4-3

ACP

4

Note for safety

Note for safety

In order to prevent the user's injury or the damage of the product, keep the followings to use the

product.

■ The service center or the professional installation agency cettified by our company should

perform the installation because the professional technique is required to install.

■ The installer should be responsible for all problems related the installation occurred by the

installation work without the installation certification, for which our company does not offer the

free-of-charge service.

■ Using the product ignoring the note for safety may cause the misoperation of the product,

which may cause the body's injury or the damage of the product. The note for safety is

classified into two following items:

■ The symbols used at this manual have the following meanings:

For causing the critical injury to the body.

For the body's injury or the damage of the product.

It should not be followed.

It should be carefully kept to perform.

WARNING

CAUTION

Installation/Owner's Manual

5

Note for safety

Any question about the

product should be asked to

the service center or the

professional installation

agency.

• The non-professional may

cause accident, electric

shock, explosion or injury.

Consult the service center

or the professional

installation agency about

reinstalling the installed

product.

• The non-professional may

cause accident, electric

shock, explosion or injury.

The standardized part.

• The non-standard part

may cause electric shock,

explosion, injury or failure.

LG-NET 1

MENU/

SELECT

TX

RX

LG-NET 2

TX

RX

LG-NET 3

TX

RX

LG-NET 4

TX

RX

Ethernet 1

ACT

LNK

Ethernet 2

ACT

LNK

Console

Run

Power

TX

RX

FDD

TX

RX

Ext.

TX

RX

DI

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

DO

1

2

3

4

Consult the service center

or the professional

installation agency about

reinstalling the installed

product

• The non-professional may

cause electric shock,

explosion or injury.

The flammable gas or the

combustible substance

such as gasoline, benzene

and thinner should not be

used near the power cord.

• It may cause explosion or

fire.

Do not disassemble, repair

or modify the product at

random.

• It may cause electric

shock or fire.

WARNING

■ When installing

TX

LG-NET 1

RX

TX

LG-NET 2

1

DI

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

1

DO

2

3

4

RX

TX

LG-NET 3

RX

TX

LG-NET 4

RX

TX

FDD

RX

TX

Ext.

RX

ACT

Ethernet 1

LNK

MENU/

ACT

Ethernet 2

SELECT

LNK

TX

Console

RX

Run

Power

TX

LG-NET 1

RX

TX

LG-NET 2

1

DI

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

1

DO

2

3

4

RX

TX

LG-NET 3

RX

TX

LG-NET 4

RX

TX

FDD

RX

TX

Ext.

RX

ACT

Ethernet 1

LNK

MENU/

ACT

Ethernet 2

SELECT

LNK

TX

Console

RX

Run

Power

TX

LG-NET 1

RX

TX

LG-NET 2

1

DI

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

1

DO

2

3

4

RX

TX

LG-NET 3

RX

TX

LG-NET 4

RX

TX

FDD

RX

TX

Ext.

RX

ACT

Ethernet 1

LNK

MENU/

ACT

Ethernet 2

SELECT

LNK

TX

Console

RX

Run

Power

Thinner

Wax

TX

LG-NET 1

RX

TX

LG-NET 2

1

DI

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

1

DO

2

3

4

RX

TX

LG-NET 3

RX

TX

LG-NET 4

RX

TX

FDD

RX

TX

Ext.

RX

ACT

Ethernet 1

LNK

MENU/

ACT

Ethernet 2

SELECT

LNK

TX

Console

RX

Run

Power

TX

LG-NET 1

RX

TX

LG-NET 2

1

DI

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

1

DO

2

3

4

RX

TX

LG-NET 3

RX

TX

LG-NET 4

RX

TX

FDD

RX

TX

Ext.

RX

ACT

Ethernet 1

LNK

MENU/

ACT

Ethernet 2

SELECT

LNK

TX

Console

RX

Run

Power

ACP

6

Note for safety

Do not install the product at the wet place.

• It may cause to degrade the insulating ability and may cause fire.

Do not change or extend the

power cord.

• It may cause fire or

electric shock.

Do not place any heating

device near the product.

• It may cause fire.

Do not use any heating

device near the power cord.

• It may cause fire or

electric shock.

Do not let water flow into the

product.

• It may cause electric

shock and failure.

Do not put heavy weight on

the power cord.

• It may cause fire or

electric shock.

Do not put heavy weight on

the product.

• It may cause the failure of

the product.

■ When using

TX

LG-NET 1

RX

TX

LG-NET 2

RX

1

DI

TX

LG-NET 3

2

RX

3

TX

4

LG-NET 4

RX

5

6

7

TX

8

FDD

RX

9

TX

10

Ext.

RX

11

12

13

14

ACT

Ethernet 1

15

LNK

16

MENU/

17

ACT

Ethernet 2

18

LNK

SELECT

19

20

TX

Console

RX

1

Run

DO

2

3

Power

4

TX

LG-NET 1

RX

TX

LG-NET 2

1

DI

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

1

DO

2

3

4

RX

TX

LG-NET 3

RX

TX

LG-NET 4

RX

TX

FDD

RX

TX

Ext.

RX

ACT

Ethernet 1

LNK

MENU/

ACT

Ethernet 2

SELECT

LNK

TX

Console

RX

Run

Power

TX

LG-NET 1

RX

TX

LG-NET 2

RX

1

DI

TX

LG-NET 3

2

RX

3

TX

4

LG-NET 4

RX

5

6

7

TX

8

FDD

RX

9

TX

10

Ext.

RX

11

12

13

14

ACT

Ethernet 1

15

LNK

16

MENU/

17

ACT

Ethernet 2

SELECT

18

LNK

19

20

TX

Console

RX

1

Run

DO

2

3

Power

4

TX

LG-NET 1

RX

TX

LG-NET 2

1

DI

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

1

DO

2

3

4

RX

TX

LG-NET 3

RX

TX

LG-NET 4

RX

TX

FDD

RX

TX

Ext.

RX

ACT

Ethernet 1

LNK

MENU/

ACT

Ethernet 2

SELECT

LNK

TX

Console

RX

Run

Power

TX

LG-NET 1

RX

TX

LG-NET 2

RX

1

DI

TX

LG-NET 3

2

RX

3

TX

4

LG-NET 4

RX

5

6

7

TX

8

FDD

RX

9

TX

10

Ext.

RX

11

12

13

14

ACT

Ethernet 1

15

LNK

16

MENU/

17

ACT

Ethernet 2

SELECT

18

LNK

19

20

TX

Console

RX

1

Run

DO

2

3

Power

4

TX

LG-NET 1

RX

TX

LG-NET 2

1

DI

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

1

DO

2

3

4

RX

TX

LG-NET 3

RX

TX

LG-NET 4

RX

TX

FDD

RX

TX

Ext.

RX

ACT

Ethernet 1

LNK

MENU/

ACT

Ethernet 2

SELECT

LNK

TX

Console

RX

Run

Power

Installation/Owner's Manual

7

Note for safety

CAUTION

If the product is flooded,

consult the service centre or

the professional installation

agency.

• It may cause fire or

electric shock.

Let the children or the old

and the weak be controlled

by the guardian to use.

• It may cause accident or

failure.

Do not give any shock to the

product.

• Any shock to the product

may cause failure.

Do not use strong detergent such as

solvent, but a soft cloth.

• It may cause fire or to deform the product.

Grab the head of the plug of the power cord

to pull when disconnecting the plug, and do

not touch the plug with wet hands.

• It may cause fire or electric shock.

■ When using

1

DI

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

MENU/

17

SELECT

18

19

20

1

DO

2

3

4

TX

LG-NET 1

RX

TX

LG-NET 2

RX

TX

LG-NET 3

RX

TX

LG-NET 4

RX

TX

FDD

RX

TX

Ext.

RX

ACT

Ethernet 1

LNK

ACT

Ethernet 2

LNK

TX

Console

RX

Run

Power

TX

LG-NET 1

RX

TX

LG-NET 2

RX

1

DI

TX

LG-NET 3

2

RX

3

TX

4

LG-NET 4

RX

5

6

7

TX

8

FDD

RX

9

TX

10

Ext.

RX

11

12

13

14

ACT

Ethernet 1

15

LNK

16

MENU/

17

ACT

Ethernet 2

SELECT

18

LNK

19

20

TX

Console

RX

1

Run

DO

2

3

Power

4

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

1

2

3

4

TX

LG-NET 1

RX

TX

LG-NET 2

RX

DI

TX

LG-NET 3

RX

TX

LG-NET 4

RX

TX

FDD

RX

TX

Ext.

RX

ACT

Ethernet 1

LNK

MENU/

ACT

Ethernet 2

SELECT

LNK

TX

Console

RX

Run

DO

Power

TX

LG-NET 1

RX

TX

LG-NET 2

RX

TX

LG-NET 3

RX

TX

LG-NET 4

RX

TX

FDD

RX

TX

Ext.

RX

ACT

Ethernet 1

LNK

MENU/

ACT

Ethernet 2

SELECT

LNK

TX

Console

RX

Run

Power

Wax

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

1

2

3

4

Thinner

DI

DO

ACP

1-1

1. ACP Functions & Specification

Functions of ACP

1. ACP Functions & Specification

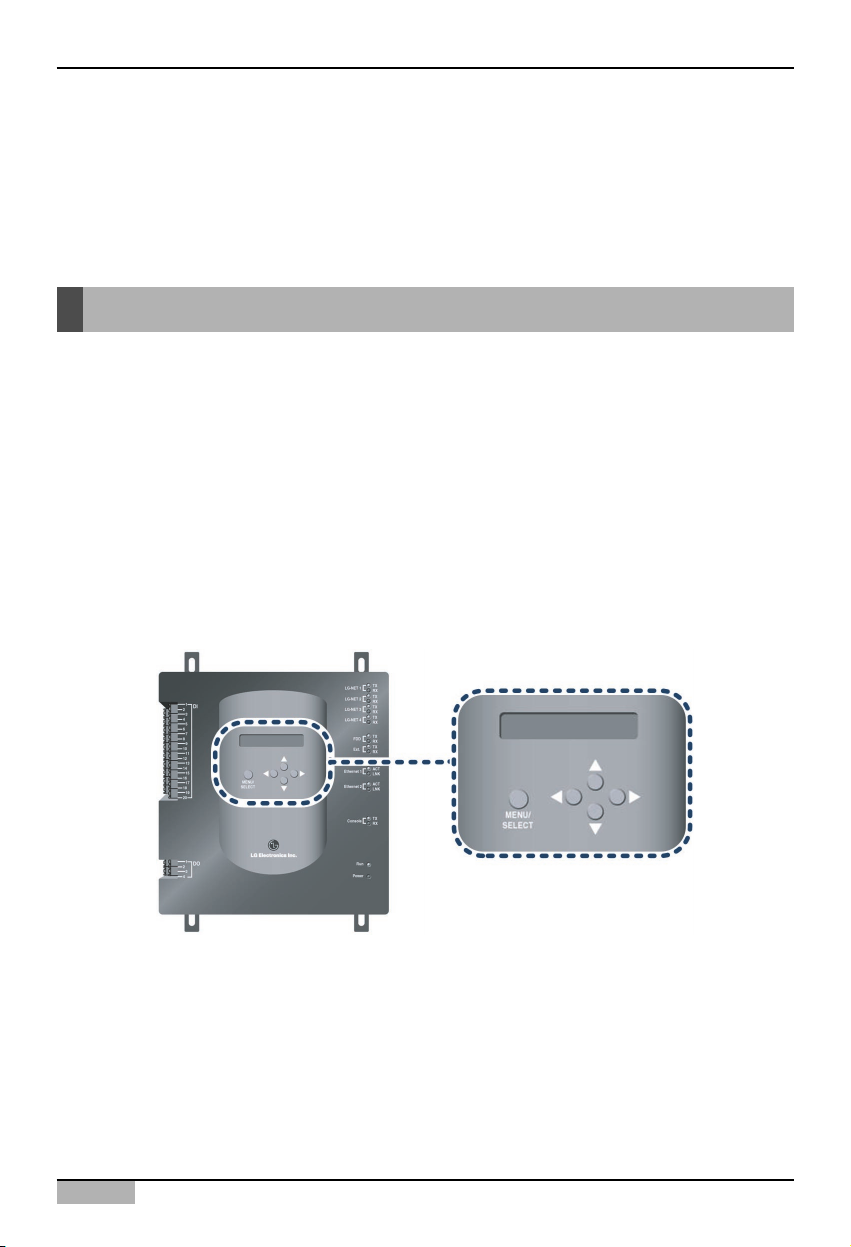

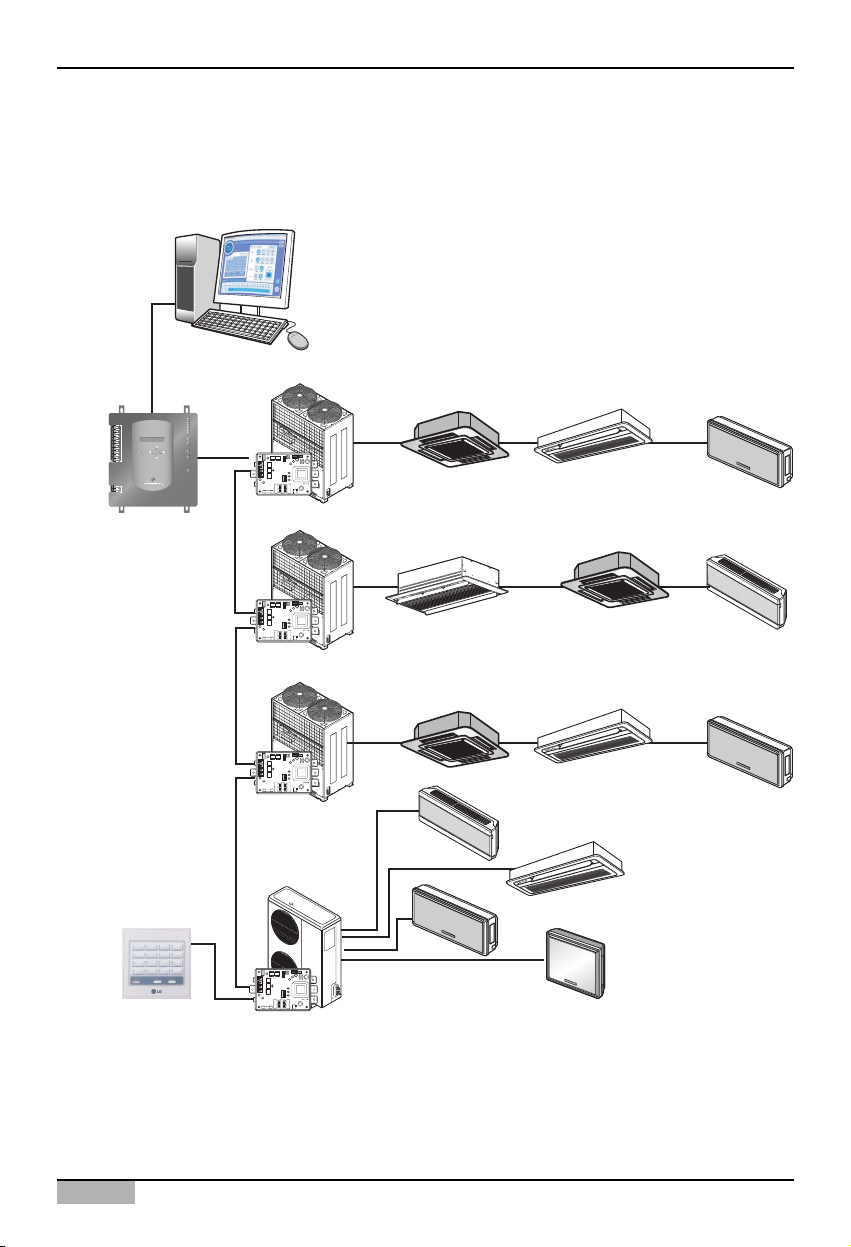

The ACP(Advanced Control Platform) is the central controller which can control up to 256 indoor units

of the airconditioner at one place individually or totally. The ACP can monitor or control to operate the

airconditioner and the ventilator installed at each room of the building from the place such as the

control room of a building, the administrative room of a school.

Main functions of the ACP are as follows:

Using the external button of the ACP to set the environment

The following functions can be set by using the external buttons of the ACP.

• Set the network environment (IP address, net mask, gateway)

• Set one of Peak/Demand function to use

• Set the language displayed on the LG ACCS screen

• Set whether to use the schedule feature or not

• Set whether to use the watthour meter feature or not.

Installation/Owner's Manual

1-2

1. ACP Functions & Specification

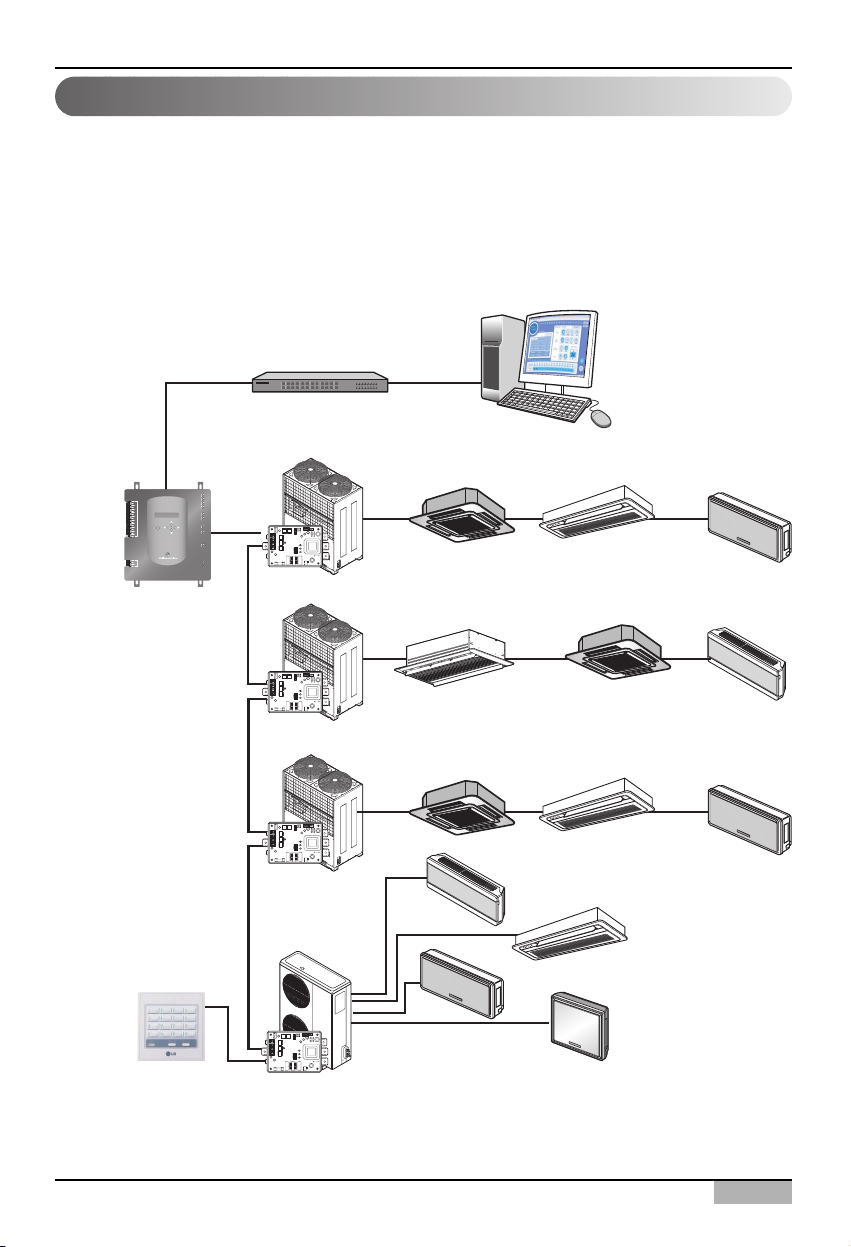

Built-in Web server

Various functions of contents can be used when the IP address of the ACP is entered at the address

window by using the Internet Explorer without installing a separate PC program to automatically

execute the central control program at the ACP web server.

Also, the demand control feature to control the demand power is controlled by directly connecting the

ACP to the demand controller without installing a separate PC program.

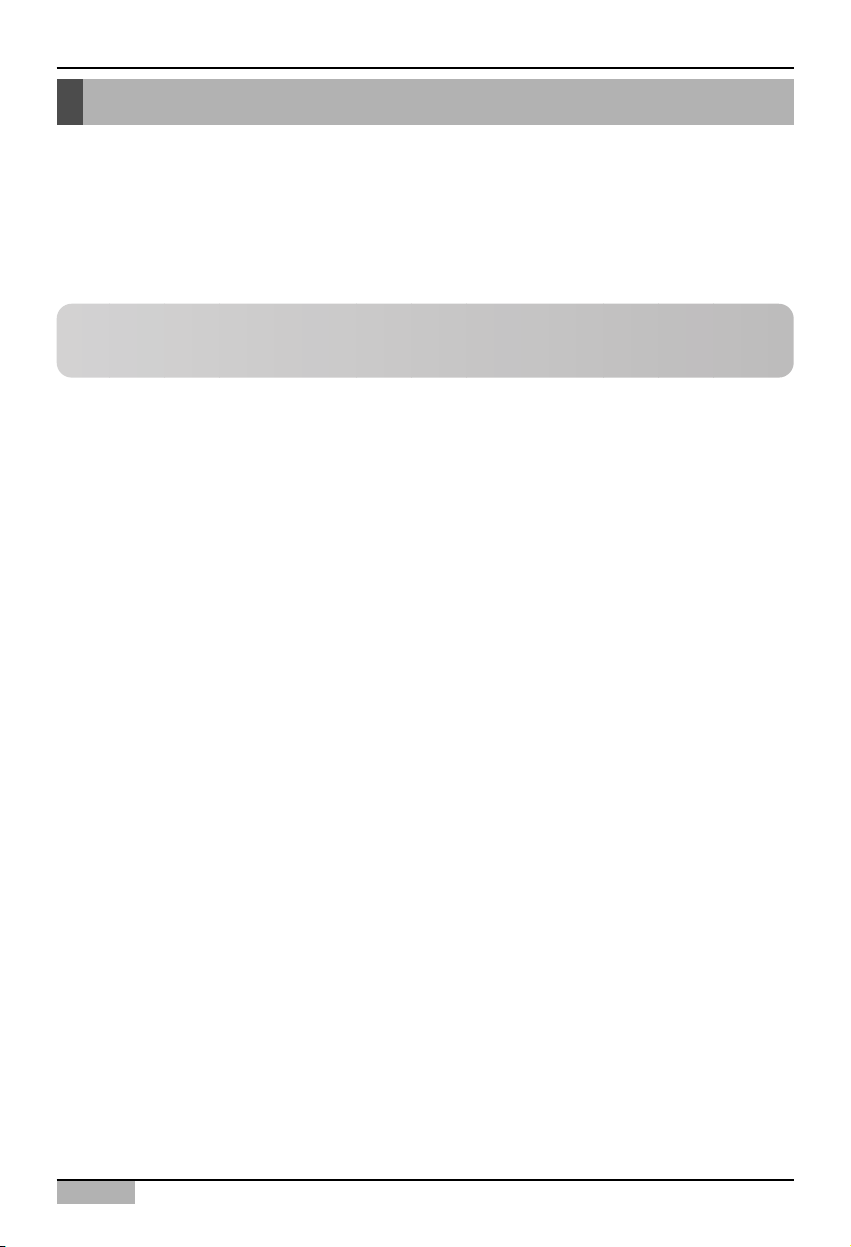

Interconnecting with the AC Manager

Various features offered by the AC Manager are offered by connecting the AC Manager program

installed at the PC to the ACP. Especially, when using the schedule feature of the AC Manager,

because the ACP has its own engine, even though the user turns off the PC where the AC Manager is

installed, the ACP can perform the schedule featre by itself.

➲ Control 256 indoor units of the airconditioner at

maximum

➲ Monitoring the error and operation state

➲ Controlling the peak/demand electric power

➲ Setting the system

TX

LG-NET 1

RX

TX

LG-NET 2

RX

TX

LG-NET 3

RX

TX

LG-NET 4

RX

TX

FDD

RX

TX

Ext.

RX

ACT

Ethernet 1

LNK

ACT

Ethernet 2

LNK

TX

Console

RX

Run

Power

Internet

Explorer

1

DI

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

MENU/

17

SELECT

Internet

18

19

20

1

DO

2

3

4

ACP

TX

LG-NET 1

RX

TX

LG-NET 2

RX

TX

LG-NET 3

RX

TX

LG-NET 4

RX

TX

FDD

RX

TX

Ext.

RX

ACT

Ethernet 1

LNK

ACT

Ethernet 2

LNK

TX

Console

RX

Run

Power

AC Manager

HUB

1

DI

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

MENU/

17

SELECT

18

19

20

1

DO

2

3

4

ACP

ACP

1-3

1. ACP Functions & Specification

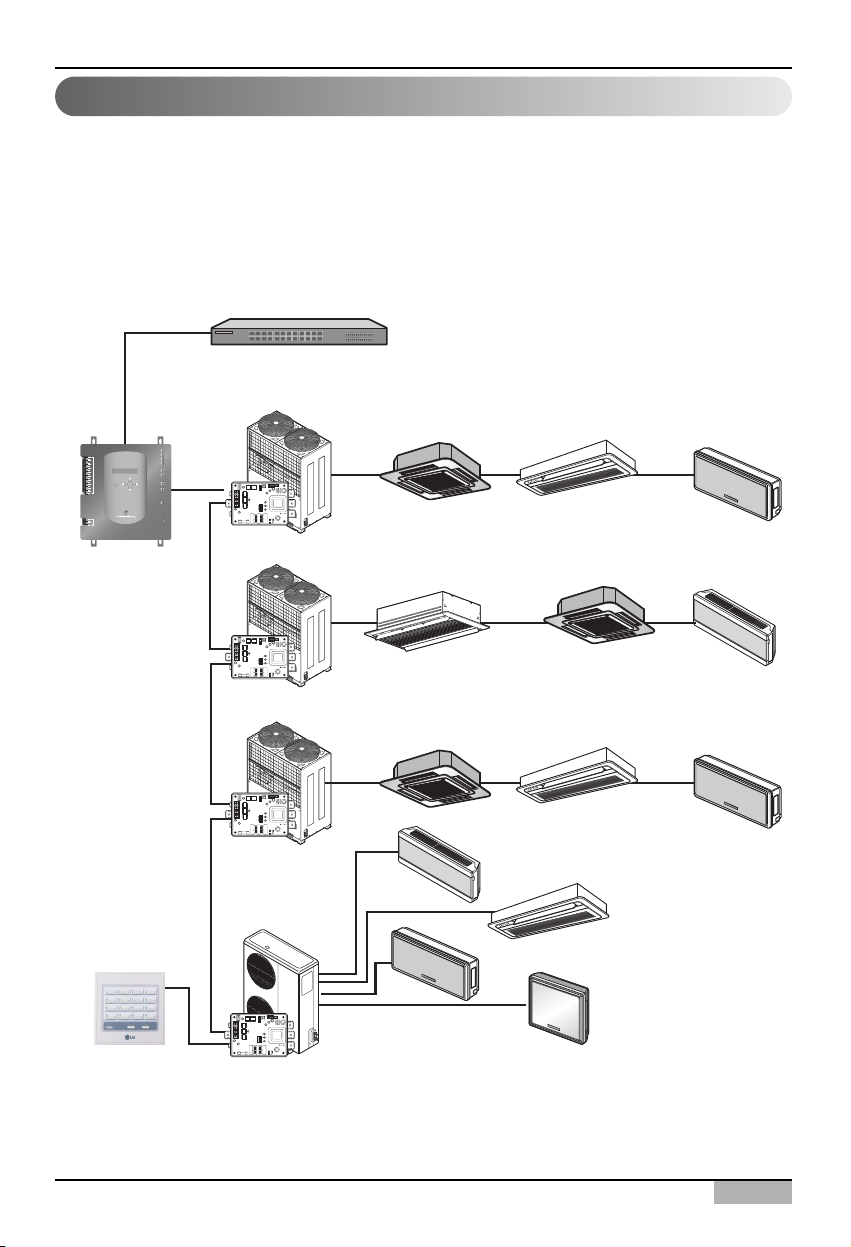

Interconnecting with the simple central controller

The 16-room simple central controller can be interconnected with the ACP. When the ACP centrally

controlling all airconditioners and the simple central controller at each floor of the building are used

together, the airconditioner can be controlled more easily.

TX

LG-NET 1

RX

TX

LG-NET 2

1

DI

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

1

DO

2

3

4

RX

TX

LG-NET 3

RX

TX

LG-NET 4

RX

TX

FDD

RX

TX

Ext.

RX

ACT

Ethernet 1

LNK

MENU/

ACT

SELECT

Ethernet 2

LNK

TX

Console

RX

Run

Power

ACP

Simple central controller

PI485

PI485

ON

L1 2 3 4

KSDO4H

ON

L1 2 3 4

KSDO4H

Multi V

Multi V

00

Central control

address

Central control

address

(0.0) (0.1) (0.F)

(0.0) (0.1) (0.F)

Installation/Owner's Manual

1-4

1. ACP Functions & Specification

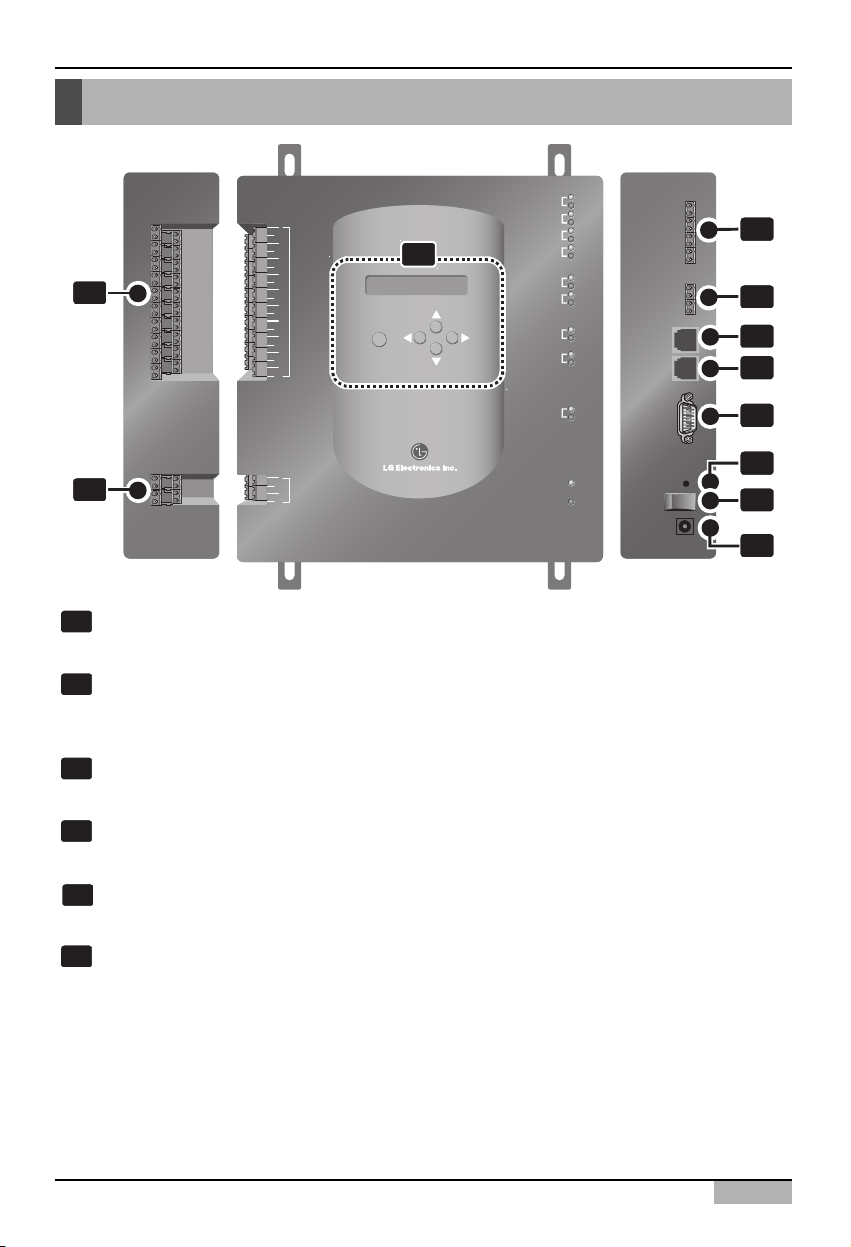

Denomination of ACP

1

6

Buttons and LCD

Buttons and the LCD to display the network environment setting and other information

RS485 communication port (for PI485 connection)

RS485 communication port connecting to the PI485 to connect the airconditioner and the

ventilator (4EA in total)

RS485 communication port (for external extension)

RS485 communication port spar for exter extension (2EA in total)

Ethernet port (for connecting the Internet and the AC Manager)

The Ethernet port for connecting the Internet and the AC Manager

Ethernet port (spare)

Ethernet port spare for the function extension of the ACP

RS232 port

RS232 port for updating the software of the ACP

6

5

4

3

2

1

1

DI

2

3

4

5

6

7

8

9

10

10

11

12

13

14

15

16

17

18

19

20

MENU/

SELECT

TX

LG-NET 1

RX

TX

LG-NET 2

RX

LG-NET 3

LG-NET 4

FDD

Ext.

Ethernet 1

Ethernet 2

Console

TX

RX

TX

RX

TX

RX

TX

RX

ACT

LNK

ACT

LNK

TX

RX

2

3

4

5

11

1

DO

2

3

4

Run

Power

7

8

9

ACP

1-5

Note: External input/output signal terminal

9 external input signal terminal and 10 external output signal terminal are configured at the

PQCPB11A0E only. These terminals are used to connect the AC Manager to set the fire control

function. These terminal are used to set the indoor unit to operate or stop for responding High or Low

signal of each external input signal.

In case of PQCPA11A0E model, a separate IO Kit (Model: PQCPE11A0E) can be purchased and

installed to use for connecting the external signal.

1. ACP Functions & Specification

Reset switch

Switch for resetting the ACP by the software

Power switch

Switch for turning on/off the ACP

Adaptor connection port

Port for DC 12V to connect the adaptor supplying the power

External input signal terminal

Port for connecting the external input signal (20EA in total). Input terminal not requiring the

power.

External output signal terminal

Connection port spare for the function extension of the ACP (4EA in total)

11

10

9

8

7

Installation/Owner's Manual

1-6

1. ACP Functions & Specification

Components of ACP

The following components are contained within the packaging box of the ACP. Open the packaging

box of the ACP to make sure that all components are contained.

LG

ACP

(Advanced Control Platform)

Adaptor for Power supply

Input: 100~240V

AC 50/60Hz 1.5A

Output: DC 12V

3.33A, 40W MAX

Power Cord

International Standard

IEC320 C14 Type

ACP

Installation/Owner's Manual

Notice : In Australia, purchase the power code

In Australia, the power code from local area.

The power code is not included in the package

Caution: Using the standardized part

We are not responsible for any problem caused by using the adaptor other than the

standardized one offered by us, so using any non-standard part should be prohibited.

You can consult the LG System Air Conditioner Support Division about the applicable

product.

237mm

180mm

TX

LG-NET 1

RX

TX

LG-NET 2

1

DI

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

MENU/

17

SELECT

18

19

20

1

DO

2

3

4

RX

TX

LG-NET 3

RX

TX

LG-NET 4

RX

TX

FDD

RX

TX

Ext.

RX

250mm

273mm

ACT

Ethernet 1

LNK

ACT

Ethernet 2

LNK

TX

Console

RX

Run

Power

57mm

ACP

1-7

1. ACP Functions & Specification

Hardware Specification of ACP

Item Description

CPU PXA255-400MHz Xscale

RAM 128MB (32x4) SDRAM

ROM • 512KB NOR Flash – Boot image

• 128MB (64x2) NAND Flash – Program image, Database, others

RS-232 Console For updating the program (for developing)

Communication port

• RS485 port: PI485 communication port 4EA, External device

connection port 2EA

• RS-232 communication port: Port for updating the program 1EA

• Ethernet port: for Internet connectioin 1EA (10Base-T) Spare 1EA

For the PQCPB11A0E model, the following ports are supplied as default.

• External input port: 20EA (Pulse contable, DC 12V)

• External output port: 4EA (Relay output, 5V)

For the PQCPA11A0E model, the IO Kit (PQCPE11A0E) should be

separately purchased for connecting the above port

LED

20EA (for displaying RS communication status, Ethernet communication

status, RS232 communication status, Power operation status)

LCD

16x2 Character, displaying Network environment setting and information

Note: License policy

This product follows the GPL(General Public License) for using the embedded Linux.

Installation/Owner's Manual

2-1

2. Installing ACP

This chapter describes how to install the ACP to use.

In order to use the ACP, the environment for the ACP, the indoor unit and the ventilator to

communicate should be built and the indoor unit should be registered.

In order to use the ACP, the installation should be performed by the following order.

STEP 1. Check the environment before installing the ACP

Before installing the ACP, check the network configuration according to the

interconnection between the ACP and the external device.

STEP 2. Set the indoor unit address and Connecting the PI485

Set the address of the ACP not overlapped with the connecting indoor unit and connect

the PI485.

STEP 3. Install the ACP and set the environment and the function

Install the ACP and set the network environment and the function.

STEP 4. ACCS access and Information input

Set the access environment at the LG ACCS, the ACP operation program and enter the

air conditioner information.

STEP 5. Make sure and check the ACP installation

Make sure and check that the ACP is normally installed.

2. Installing ACP

Caution: Installing the ACP

The ACP installation work needs the professional technique. Therefore, the

installation described at this chapter should be performed by the certified

installation professional.

Consult the service center or the professional installation agency certified by us about

any question or request related to the installation.

ACP

2-2

2. Installing ACP

Before installing the ACP

ACP provides 4 RS485 ports to connect the indoor unit. Maximum of 16 units can be connected to

PI485 for outdoor unit in 1 RS385 port, and maximum of 31 units for SINGLE/Ventilator PI485.

256 indoor units at maximum can be connected to one ACP. All of 256 indoor units may be connected

to one RS485 port, which is the maximum number of units for the ACP to connect. But, in order to

improve the communication performce of the RS485, we recommend to distribute them to four ports.

By considering three following cases using the ACP, perform the installation after carefully considering

how to use.

• Install the single ACP to use as web server

• Connect the single ACP to the AC Manager to use

• Connect more than one ACP to the AC Manager via the hub to use

Note: Change the number of connections of RS485

If it is inevitable to change the above specification, call the system air conditioner support division

Installation/Owner's Manual

2-3

2. Installing ACP

When one ACP is used as web server, the ACP should be connected with the network structure as

shown at the following examples.

Using the hub

If it is connected via the hub, the network can be configured as shown at the following example.

Using the single ACP as web server

LAN

(Direct Cable)

Hub

Multi V

TX

LG-NET 1

RX

TX

LG-NET 2

MENU/

SELECT

ACP

RX

TX

LG-NET 3

RX

TX

LG-NET 4

RX

TX

FDD

RX

TX

Ext.

RX

ACT

Ethernet 1

LNK

ACT

Ethernet 2

LNK

TX

Console

RX

Run

Power

PI485

ON

L1 2 3 4

KSDO4H

Multi V

1

DI

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

1

DO

2

3

4

00 01 02

10

11 12

Simple central controller

(possible to connect

when necessary)

PI485

PI485

PI485

ON

L1 2 3 4

KSDO4H

Multi V

ON

L1 2 3 4

KSDO4H

Multi

ON

L1 2 3 4

KSDO4H

20 21 22

30

31

32

33

ACP

2-4

2. Installing ACP

Not using the hub

If it is connected without the hub, the network can be configured as shown at the following example.

Multi V

00 01 02

TX

LG-NET 1

RX

TX

LG-NET 2

MENU/

SELECT

ACP

RX

TX

LG-NET 3

RX

TX

LG-NET 4

RX

TX

FDD

RX

TX

Ext.

RX

ACT

Ethernet 1

LNK

ACT

Ethernet 2

LNK

TX

Console

RX

Run

Power

PI485

ON

L1 2 3 4

KSDO4H

Multi V

10

ON

L1 2 3 4

KSDO4H

11 12

1

DI

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

1

DO

2

3

4

PI485

Multi V

20 21 22

Simple central controller

(possible to connect

when necessary)

PI485

PI485

ON

L1 2 3 4

KSDO4H

Multi

ON

L1 2 3 4

KSDO4H

30

31

32

33

Installation/Owner's Manual

2-5

2. Installing ACP

When one ACP is connected to the AC Manager without the hub, the ACP should be

connected with the network structure as shown at the following examples.

Using the hub

If it is connected via the hub, the network can be configured as shown at the following example.

Connecting the single ACP to the AC Manager

AC Manager

LAN

(Direct Cable)

1

DI

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

1

DO

2

3

4

MENU/

SELECT

ACP

Hub

Multi V

TX

LG-NET 1

RX

TX

LG-NET 2

RX

TX

LG-NET 3

RX

TX

LG-NET 4

RX

TX

FDD

RX

TX

Ext.

RX

ACT

Ethernet 1

LNK

ACT

Ethernet 2

LNK

TX

Console

RX

Run

Power

PI485

ON

L1 2 3 4

KSDO4H

00 01 02

Multi V

11 12

PI485

10

ON

L1 2 3 4

KSDO4H

Multi V

20 21 22

ON

L1 2 3 4

KSDO4H

PI485

Multi

30

31

32

Simple central controller

(possible to connect

when necessary)

PI485

33

ON

L1 2 3 4

KSDO4H

ACP

2-6

2. Installing ACP

Not using the hub

If it is connected without the hub, the network can be configured as shown at the following example.

AC Manager

LAN

Cross cable

1

DI

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

1

DO

2

3

4

MENU/

SELECT

ACP

TX

LG-NET 1

RX

TX

LG-NET 2

RX

TX

LG-NET 3

RX

TX

LG-NET 4

RX

TX

FDD

RX

TX

Ext.

RX

ACT

Ethernet 1

LNK

ACT

Ethernet 2

LNK

TX

Console

RX

Run

Power

PI485

PI485

Multi V

ON

L1 2 3 4

KSDO4H

Multi V

ON

L1 2 3 4

KSDO4H

Multi V

00 01 02

10

20 21 22

11 12

Simple central controller

(possible to connect

when necessary)

PI485

PI485

ON

L1 2 3 4

KSDO4H

Multi

ON

L1 2 3 4

KSDO4H

30

31

32

33

Installation/Owner's Manual

2-7

2. Installing ACP

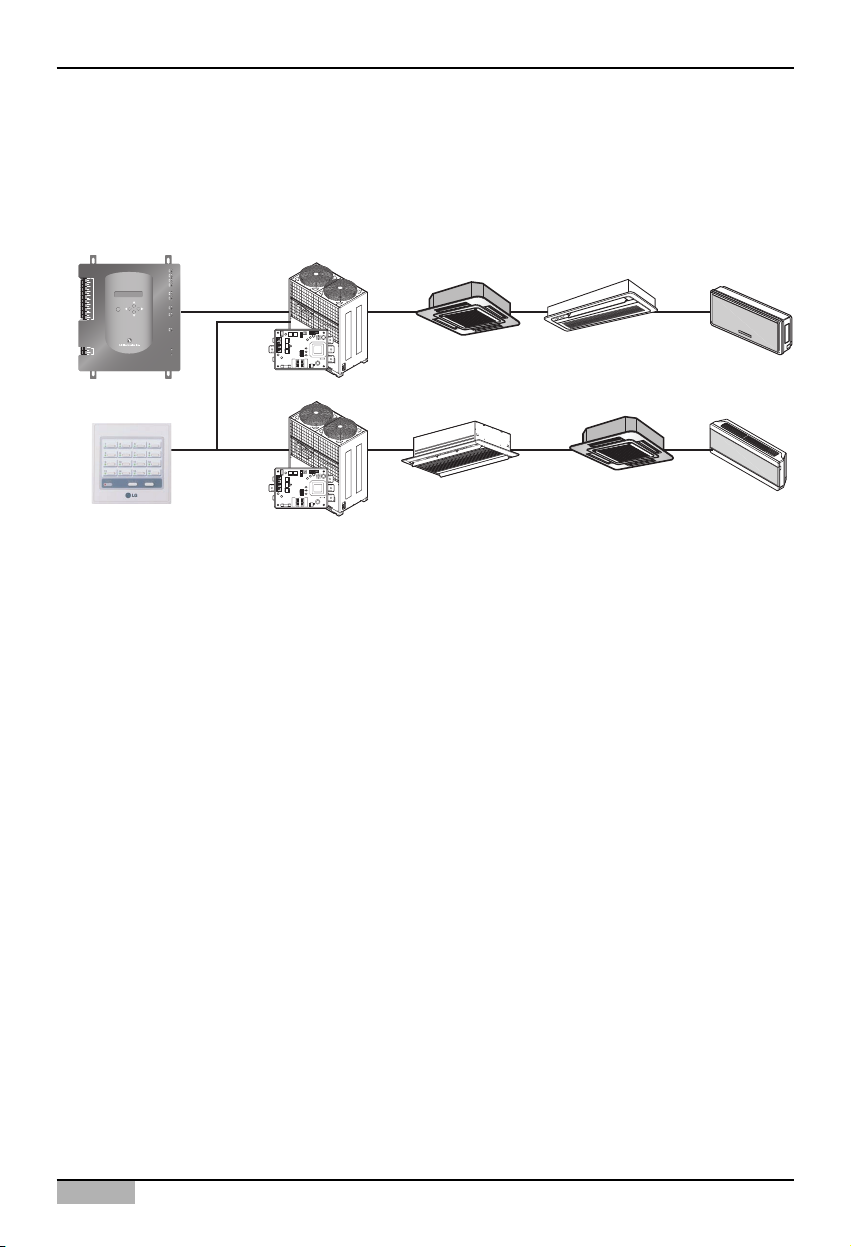

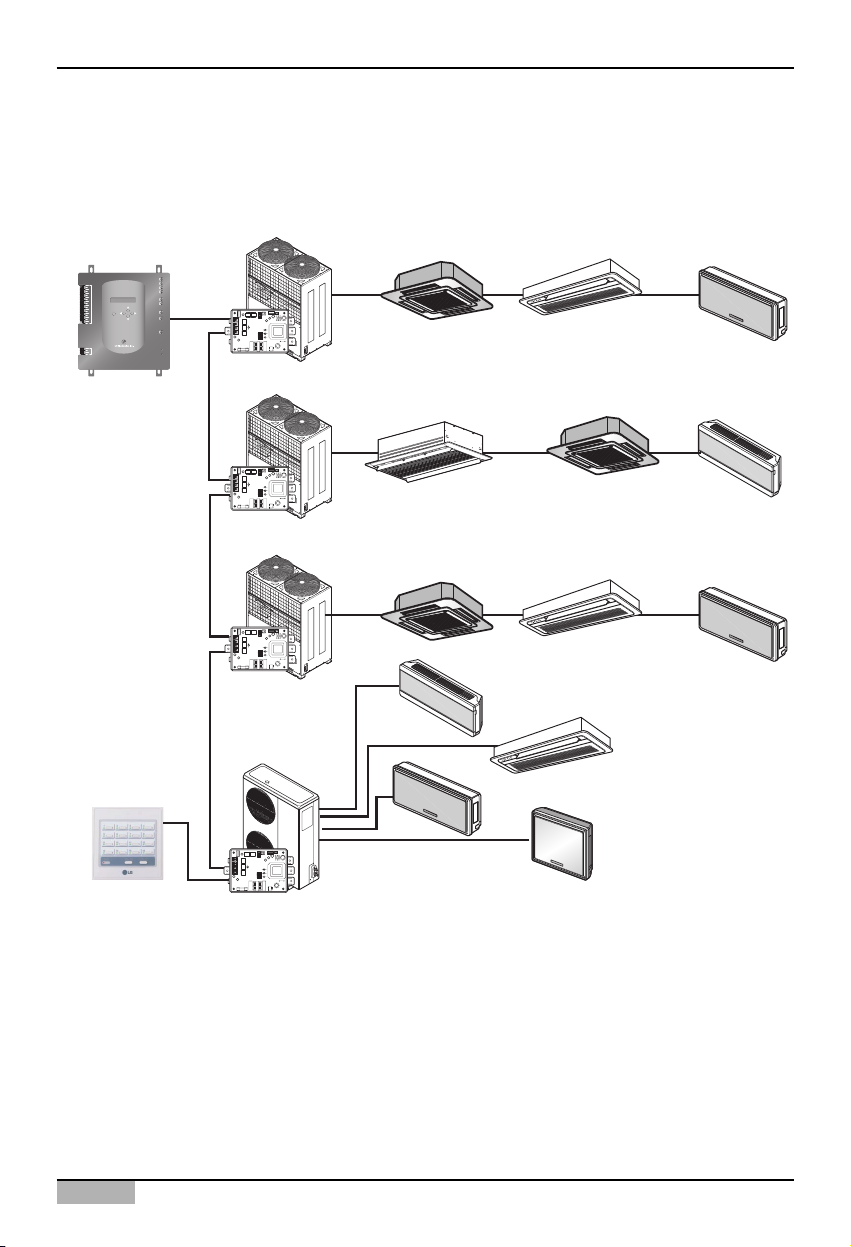

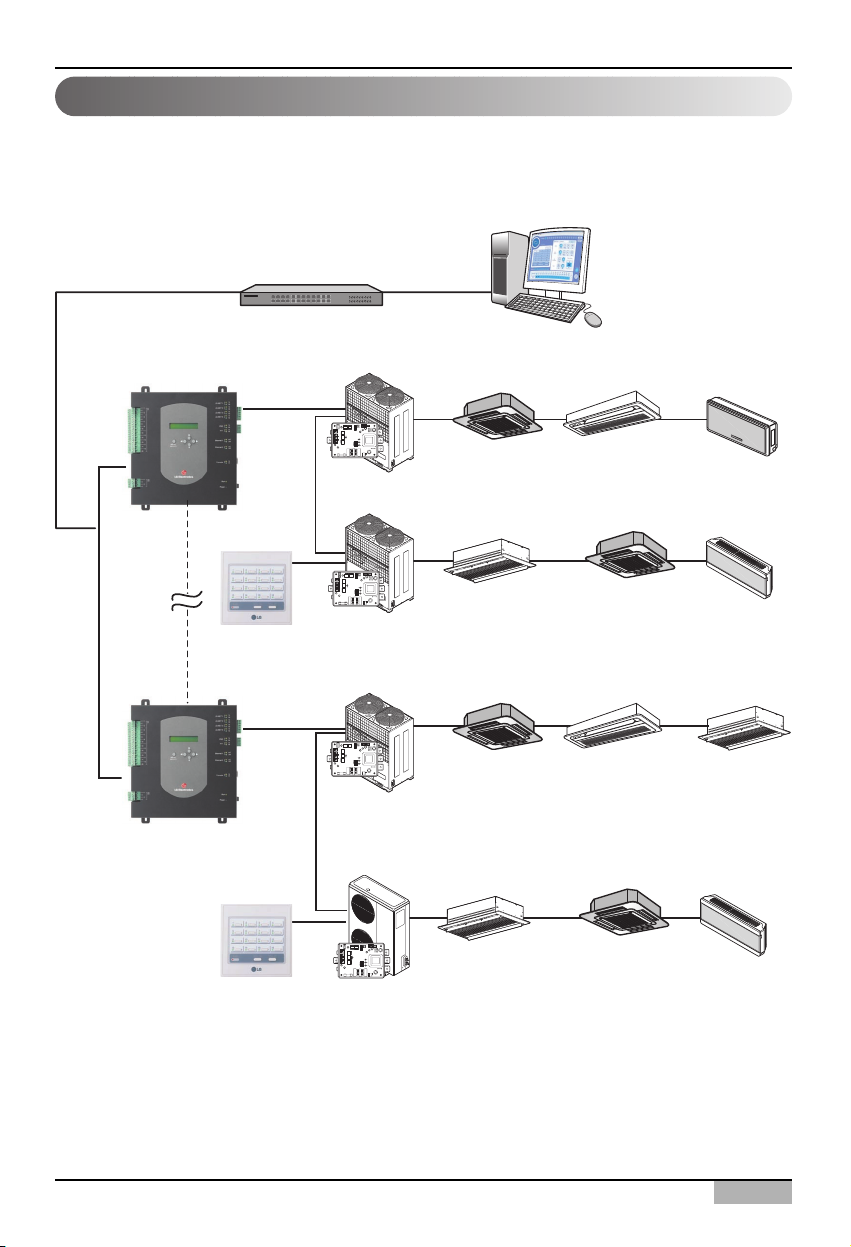

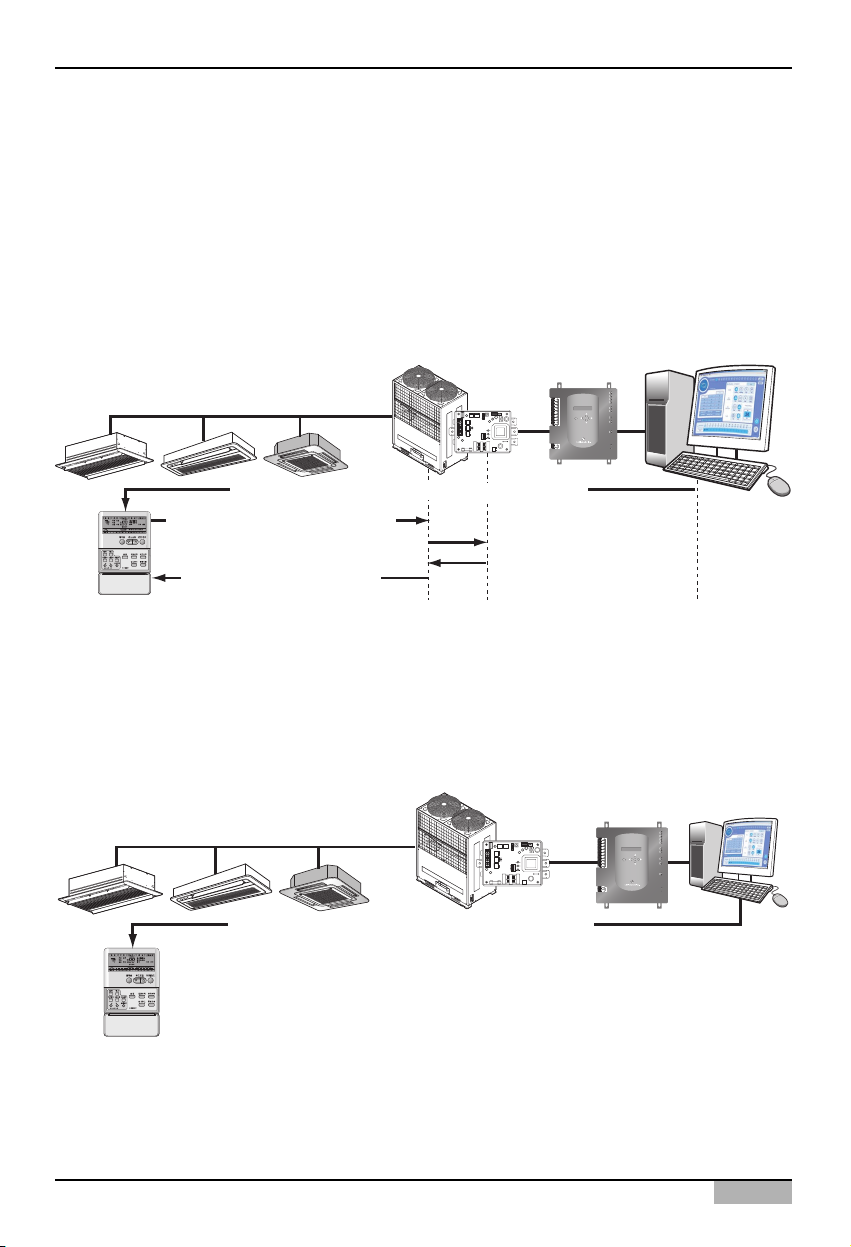

When more than one ACP are connected to the AC Manager via the hub, the ACP should be

connected with the network structure as shown at the following examples.

Connecting more than on ACPs to the AC Manager

LAN

Direct cable

ACP

ACP

Hub

PI485

PI485

Simple central controller

(possible to connect

when necessary)

PI485

Multi V

L1 2 3 4

KSDO4H

Multi V

ON

L1 2 3 4

KSDO4H

Multi V

ON

L1 2 3 4

KSDO4HON

Multi

AC Manager

00 01 02

10 11 12

20 21 22

30 31 32

Simple central controller

(possible to connect

when necessary)

PI485

ON

L1 2 3 4

KSDO4H

ACP

2-8

2. Installing ACP

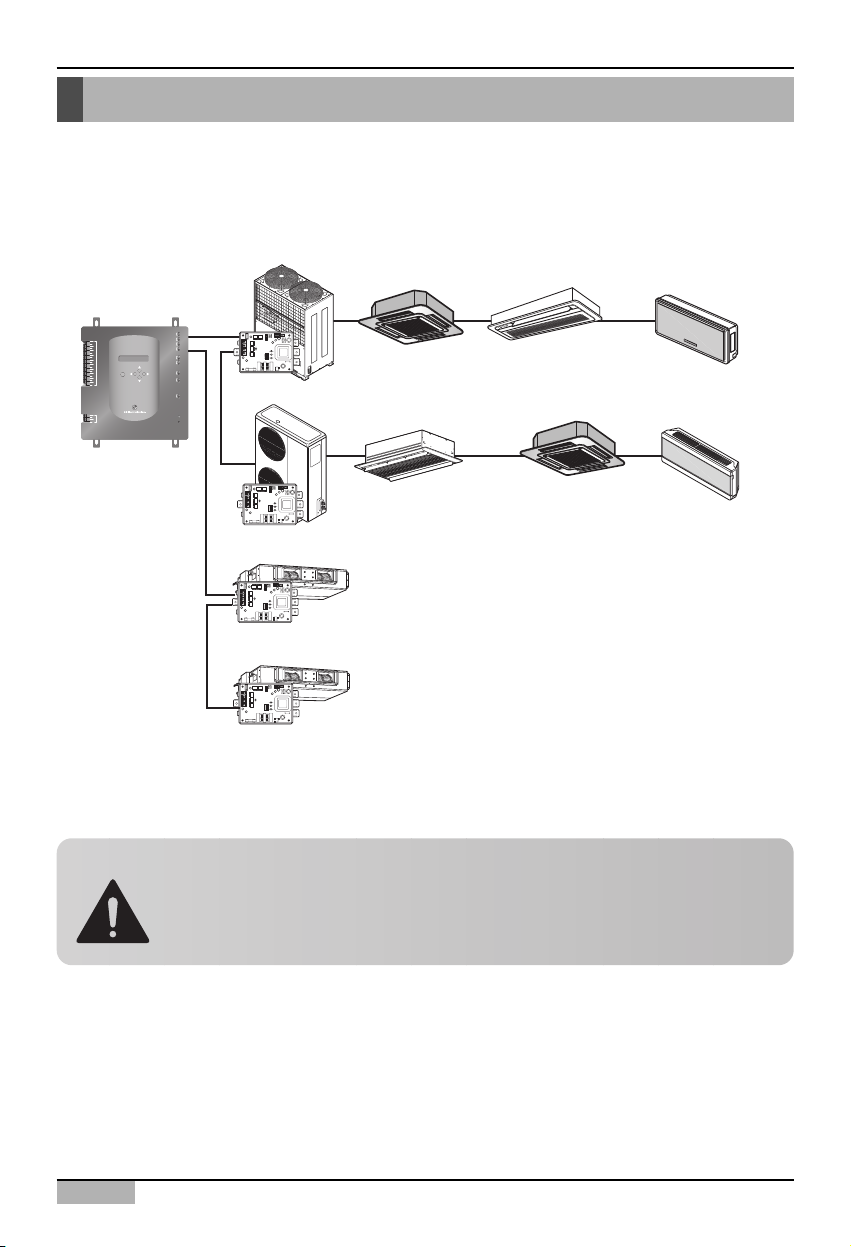

Setting the indoor unit address

By considering the entire installation configuration connecting to one ACP, set the address to each

indoor unit not to be overlapped. 00~FF in hexadecimal can be set to the indoor unit address.

The next section describes how to set the address to each indoor unit by using the wired or wireless

remote controller according to the given number.

The following example sets the address to the indoor unit.

When the ACP is interconnected with the AC Manager, the ventilator can be together installed and

controlled. The above figure shows the example that sets 30 and 31 to the ventilators as address and

connects to the ACP.

Caution: Connecting the ventilator to the RS485

The ventilator and the air conditioner can not be connected together to the same

RS485 communication cable. When connecting the ventilator to the RS485

communication cable, the cable other than the RS485 communication cable

connecting the air conditioner should be used.

Multi V

00 01 02

TX

LG-NET 1

RX

TX

LG-NET 2

1

DI

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

MENU/

17

SELECT

18

19

20

1

DO

2

3

4

RX

TX

LG-NET 3

RX

TX

LG-NET 4

RX

TX

FDD

RX

TX

Ext.

RX

ACT

Ethernet 1

LNK

ACT

Ethernet 2

LNK

TX

Console

RX

Run

Power

PI485

ON

L1 2 3 4

KSDO4H

Multi

10

11 12

ACP

ON

L1 2 3 4

KSDO4H

Ventilator

30

ON

L1 2 3 4

KSDO4H

PI485

Ventilator

31

ON

L1 2 3 4

KSDO4H

PI485

Installation/Owner's Manual

2-9

2. Installing ACP

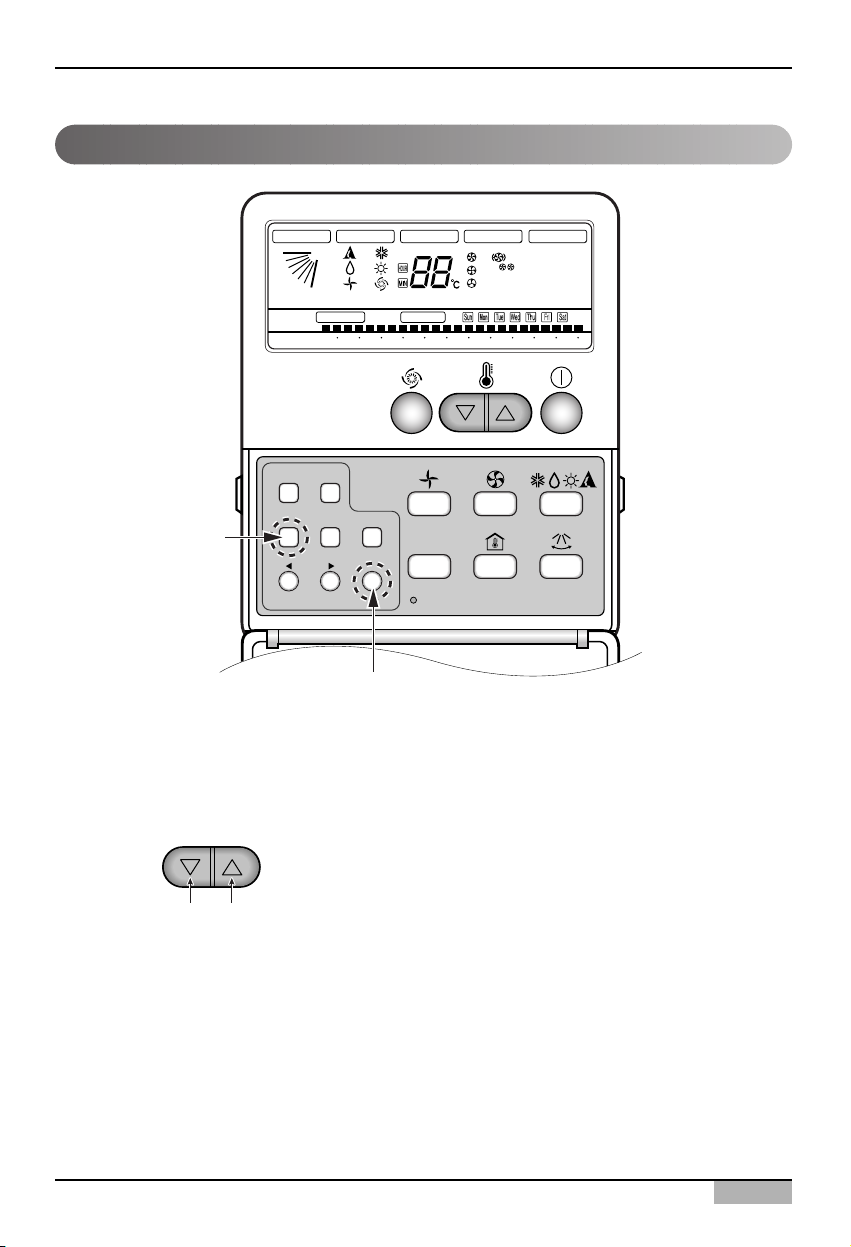

Setting address with wired remote controller

Timer Cancel

Program Week

Hour Min

Holiday

Set/Clr

RESET

ZONE

1234

Operation unit

Humidify

JET

AUTO

AUTO SWING OPERATION

FAN SPEED

Program set

SUB FUNCTION

SET TEMP

Room Temp

HI

MED

LO

Heater

Defrost

Filter

Preheat

Out door

Time

Timer

On

Set no. Time

Off

01 03 05 07 09 11 13 15 17 19 21 23

Plasma

Program

Set/Ctl

1. Press Week Program & Set/Clr keys at the same time.

2. Set the indoor unit address using the temperature controller.

Allowed Range : 00-FF

3. Complete the address setting to press the week Program & Set/Clr keys at the same time for 3

seconds.

❈ Some remote controllers may not be suported by above functions, a coording to the production date

of wired/wireless remote conrollers. As it has no concem with customers' use, use the remote

controller available for the address setting during installation.

Group No. Indoor Unit No.

EX)

3A

ACP

2-10

2. Installing ACP

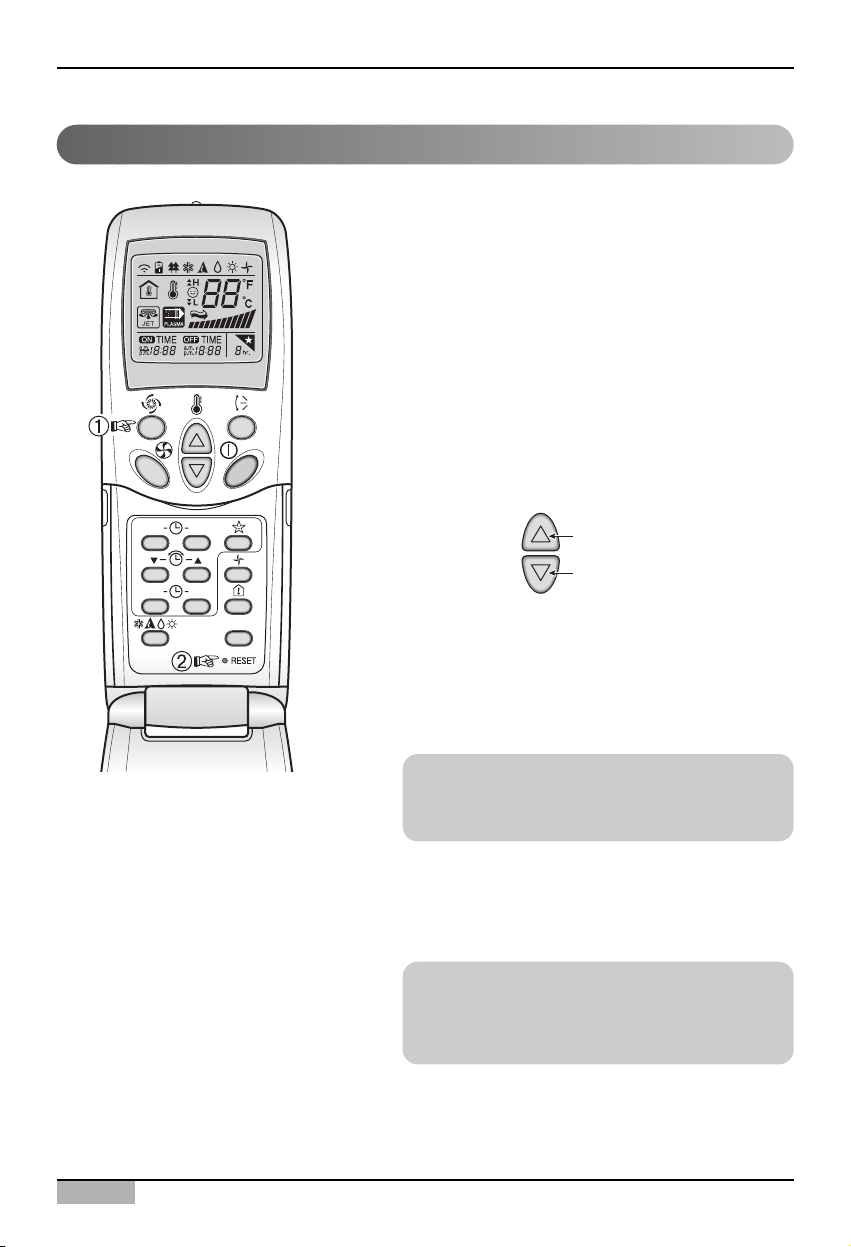

You can set the address of the indoor unit through the

wireless remote controller that controls the indoor

unit. To set the address of the indoor unit with the

wireless remote controller, proceed as follows.

1. With the [Power Cool] button pressed, press the

[RESET] button. The [Power Cool] button must be

pressed for more than 3 seconds.

2. Use the [Temperature Adjustment] button to set the

address of the indoor unit.

3. After setting the address, press the [Operate/Stop]

button once toward the indoor unit.

4. When the set address is displayed on the indoor

unit, the address setting is complete.

5. When you reset the remote controller, it switches

from the address setting mode to general operation

mode.

Setting address with wireless remote controller

Reference: Address display time and method

The address display time and method may differ

by the type of the indoor unit.

Reference: Type of remote controller

When using a different type of remote controller

from the one described above, refer to the user

manual of the applicable remote controller.

Group No.

Indoor unit No.

Temperature

adjustment

ON OFF

SET

CANCEL

PLASMA

Installation/Owner's Manual

2-11

2. Installing ACP

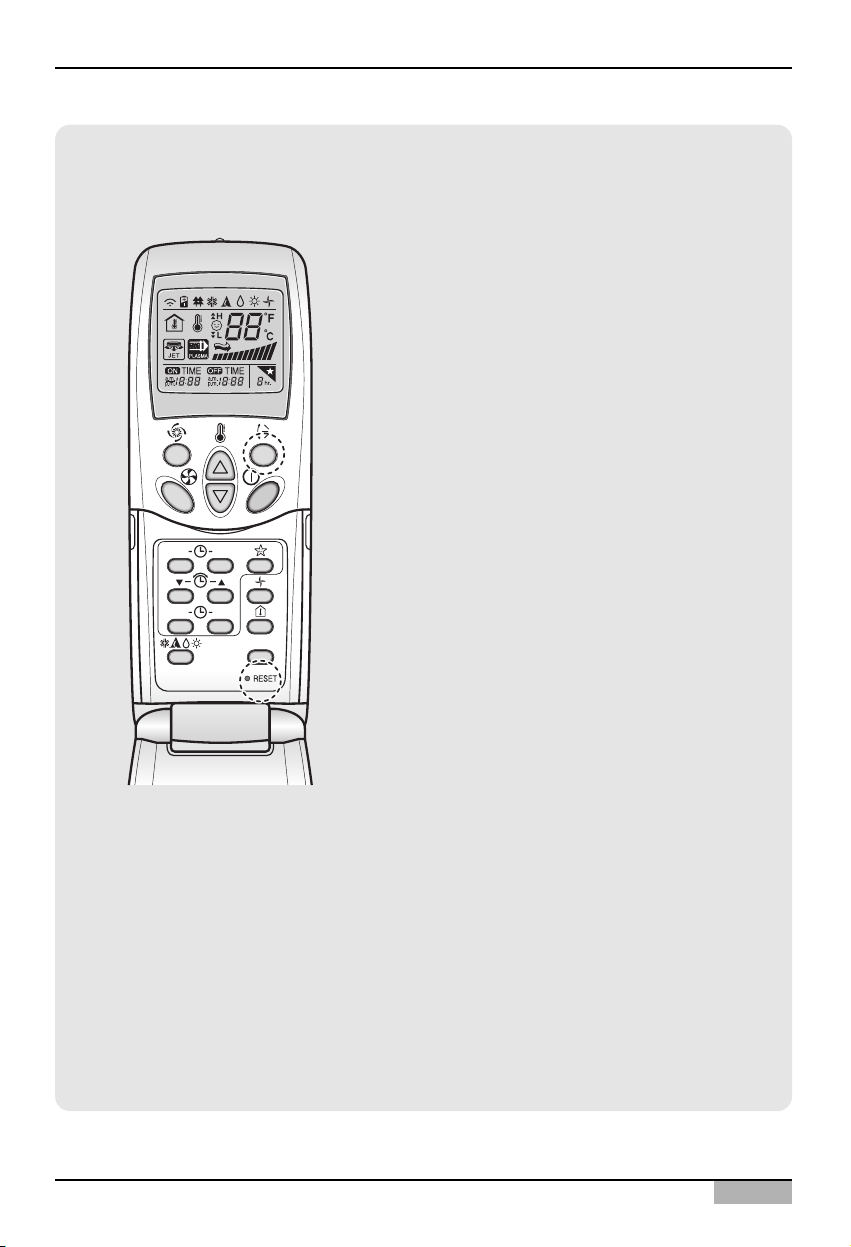

ON OFF

SET

CANCEL

PLASMA

Information: Checking the set address

You can check the set address by using the

wireless remote controller. To check the set

address, proceed as follows.

1. With the [Wind Up/Down] button pressed,

press the [RESET] button. The [Wind

Up/Down] button must be pressed for more

than 3 seconds.

2. Press the [Operate/Stop] button once toward

the indoor unit. The set address will be shown

on the display part of the indoor unit. The

address display time and method can differ by

the type of indoor unit.

3. Reset the remote controller again to use it in

general operation mode.

ACP

2-12

2. Installing ACP

Setting the PI485 and Connecting the cable

After setting the address of the indoor unit, install the PI485 and set the DIP switch. And then, connect

the RS485 cable for communicating with the ACP.

After installing the PI485 suitable to the product, the DIP switch should be set. The DIP switch of the

PI485 can be checked at the following place.

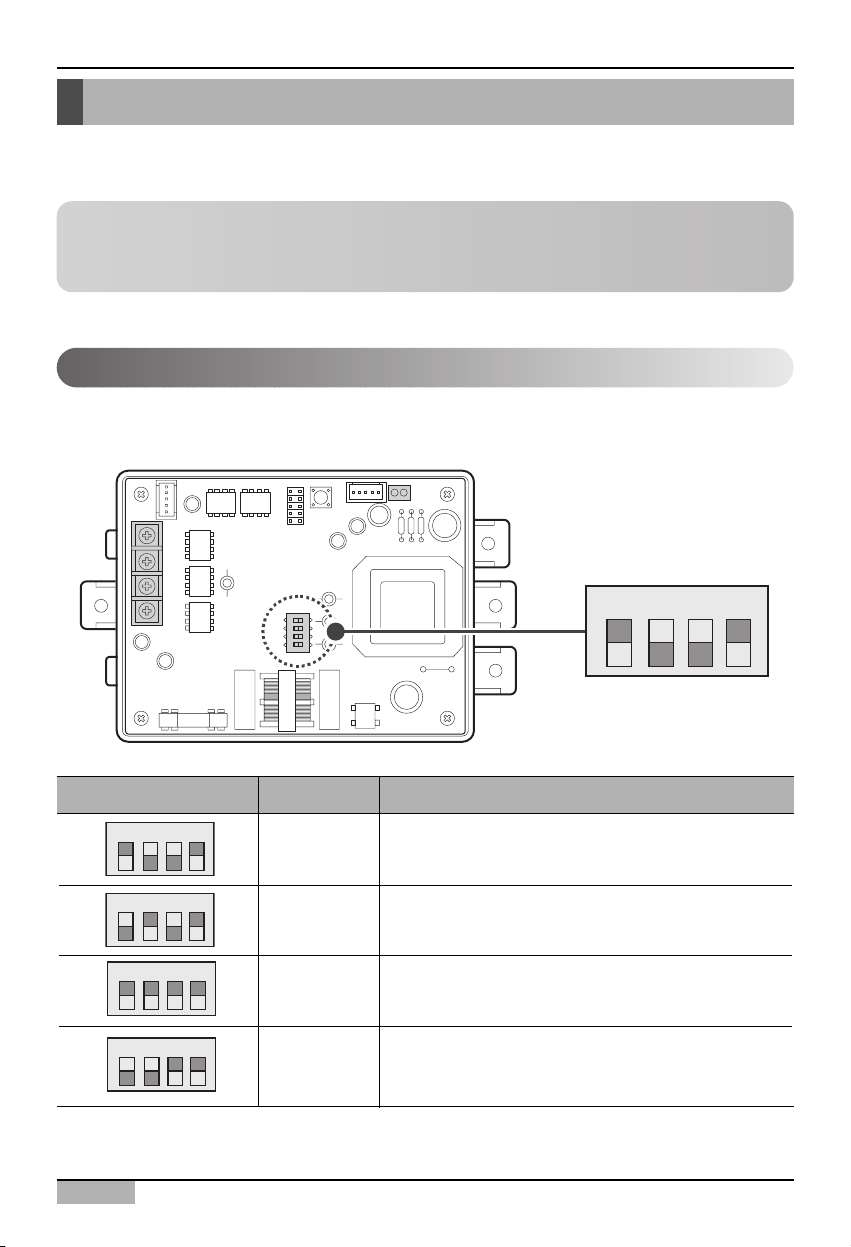

Setting the PI485 DIP switch

Dip switch Setting Product type

1, 4 ON - Multi V product(CRUN, LRA product excluded)

2, 3 OFF - MPS product with the common PCB applied

- MPS inverter product

2, 4 ON

- MPS product with the common PCB not applied

1, 3 OFF

1, 2, 3, 4 ON - Multi V CRUN, LRA product

3, 4 ON

- Single indoor unit (connected to the PI485 for the

indoor unit)

- Ventilator (connected to the PI485 for ventilating)

O N K S D O 4 H

O N K S D O 4 H

O N K S D O 4 H

O N K S D O 4 H

Note: Installing the PI485

Installing the PI485 deponds on the outdoor unit. So, install the PI485 by referring to the PI485

manual or the installation technique information.

ON

L1 2 3 4

KSDO4H

O N K S D O 4 H

Installation/Owner's Manual

2-13

2. Installing ACP

Tip: Checking the PI485 DIP switch setting

It can be checked whether the indoor unit address and the DIP switch of the PI485 are correctly set

as follows:

• The LED01G blinks as many as the number of the connected indoor units.

• The LED02G and the LED03G continue to blink alternately. (When the LRA/CRUN is

connected, the LED02G may blink more than the LED03G.)

If the LED is abnormally different from the above description, check again the indoor unit address

setting and the DIP switch setting.

O N K S D O 4 H

Note: PCB part number

The MPS product with the common PCB applied has the following PCB part number:

• PCB P/NO. : 6871A20910A ~ Z

• PCB P/NO. : 6871A20917A ~ Z

• PCB P/NO. : 6871A20918A ~ Z

Caution: Setting the PI485 DIP switch

If the air conditioner selection switch is incorrectly set, the air conditioner may

incorrectly operate.

For more information about installing the PI485, see the PI485(M) manual.

LED03G

ON

L1 2 3 4

KSDO4H

LED02G

LED01G

ACP

2-14

2. Installing ACP

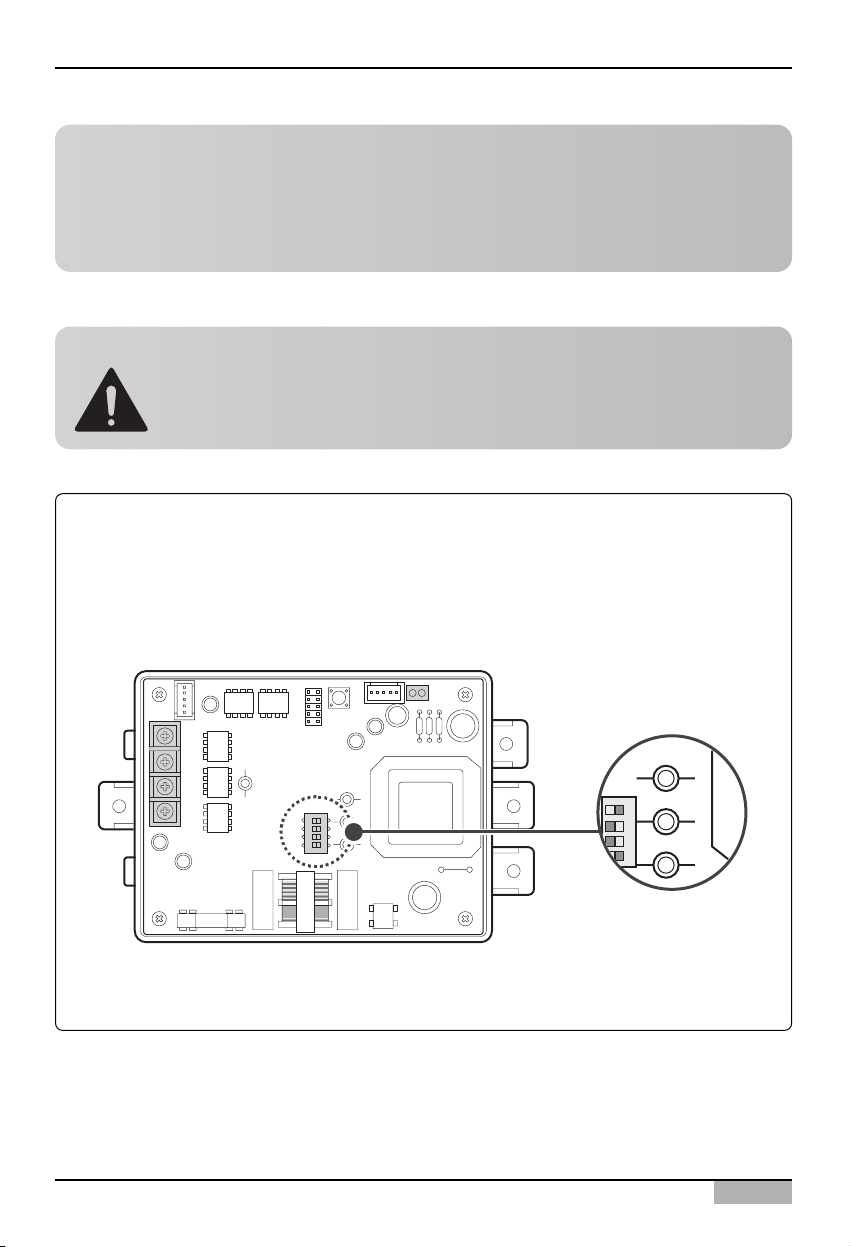

Connecting the 2PIN connector

If you want to use the individual lock function for setting mode, wind flow, and temperature lock by the

central control, the 2PIN connector should be connected to the CN_DRY terminal of the PI485

according to the product type.

ON

L1 2 3 4

KSDO4H

Installation/Owner's Manual

2-15

2. Installing ACP

The following figure shows the example of the central control for connecting the 2PIN connector to the

CN_DRY terminal.

1) 'Heating operation, 20°C , Strong wind, Temperature lock' function is ordered by the central control

such as ACP or AC Manager, which is transferred to the remote controller.

2) If the user changes the temperature to 25°C by the remote controller, the related command is

transferred to the outdoor unit and the remote controller displays the 25°C setting.

3) The outdoor unit receives the related command and transferrs it to the PI485.

4)

The PI485 cancels this command and transferrs the previous central control command again. And, the

remote controller displays again the 20°C temperature transferred by the central control command.

On the other hand, let's see an example of connecting the 2PIN connector to CN_DRY terminal.

When a command is given for function of "Heat operation, 20°C setting, high fan level, temperature

lock" through the central control, the applicable command is transmitted through the remote

controller. "HL (Hard Lock)" message showing the central control status is displayed on the remote

controller. If the user sets the temperature to 25°C, the command is blocked at the remote controller.

Multi V

TX

LG-NET 1

RX

TX

LG-NET 2

RX

1

DI

TX

LG-NET 3

2

RX

3

TX

4

LG-NET 4

RX

5

6

7

TX

8

FDD

RX

9

TX

10

Ext.

RX

11

12

13

14

ACT

Ethernet 1

15

LNK

16

MENU/

17

ACT

Ethernet 2

18

SELECT

LNK

19

20

TX

Console

RX

1

Run

DO

2

3

Power

4

ACP

1) Set ‘Heating, 20°C, Strong wind, Temperature lock’

2) Change temperature to 25°C

3) Heating, 25°C, Strong wind

5) Heating, 20°C, Strong wind

6) Return to Heating, 20°C, Strong wind

ON

L1 2 3 4

KSDO4H

4) Heating, 20°C, Strong wind

Multi V

TX

LG-NET 1

RX

TX

LG-NET 2

RX

1

DI

TX

LG-NET 3

2

RX

3

TX

4

LG-NET 4

RX

5

6

7

TX

8

FDD

RX

9

TX

10

Ext.

RX

11

12

13

14

ACT

Ethernet 1

15

LNK

16

MENU/

17

ACT

Ethernet 2

18

SELECT

ON

L1 2 3 4

KSDO4H

LNK

19

20

TX

Console

RX

1

Run

DO

2

3

Power

4

Set ‘Heating, 20°C, Strong wind, Temperature lock’

The remote controller displays ‘HL’ message

It is not possible for the user to operate.

ACP

2-16

2. Installing ACP

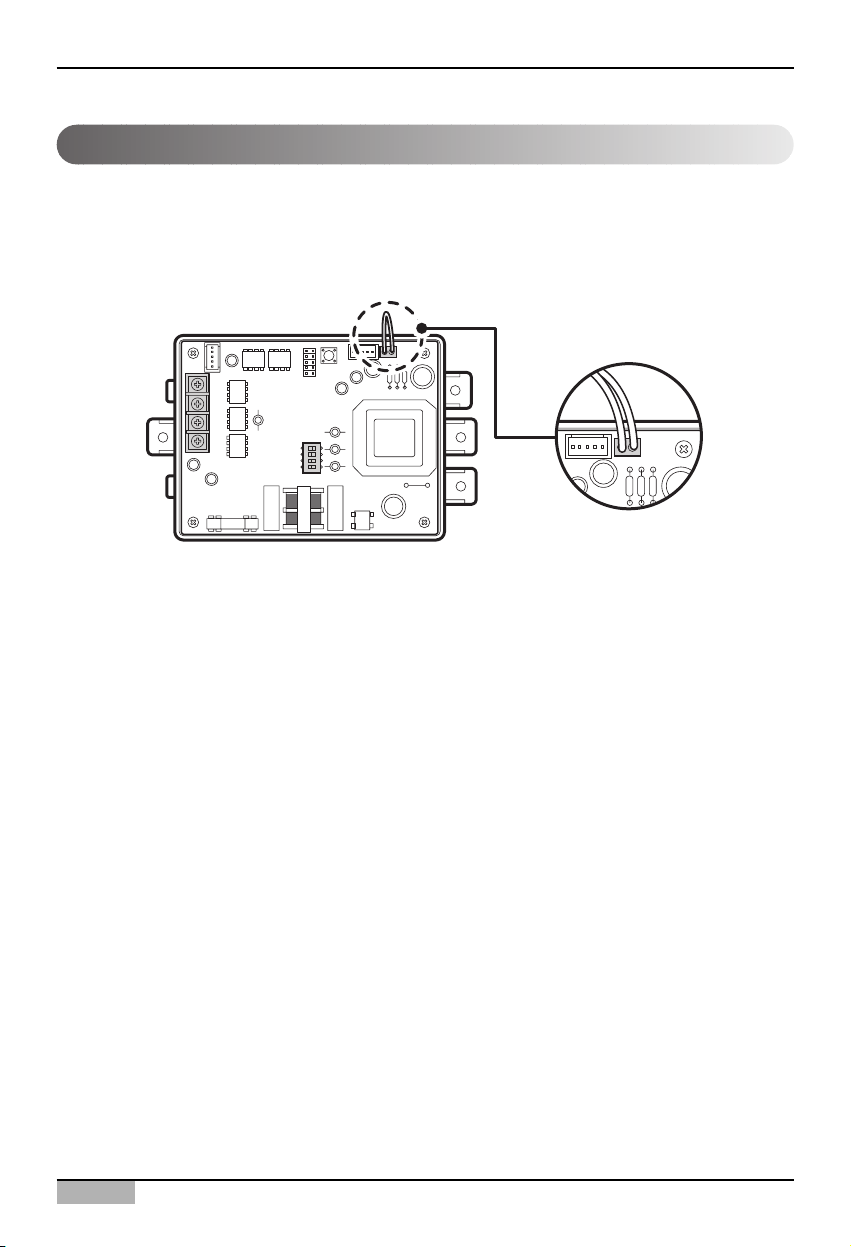

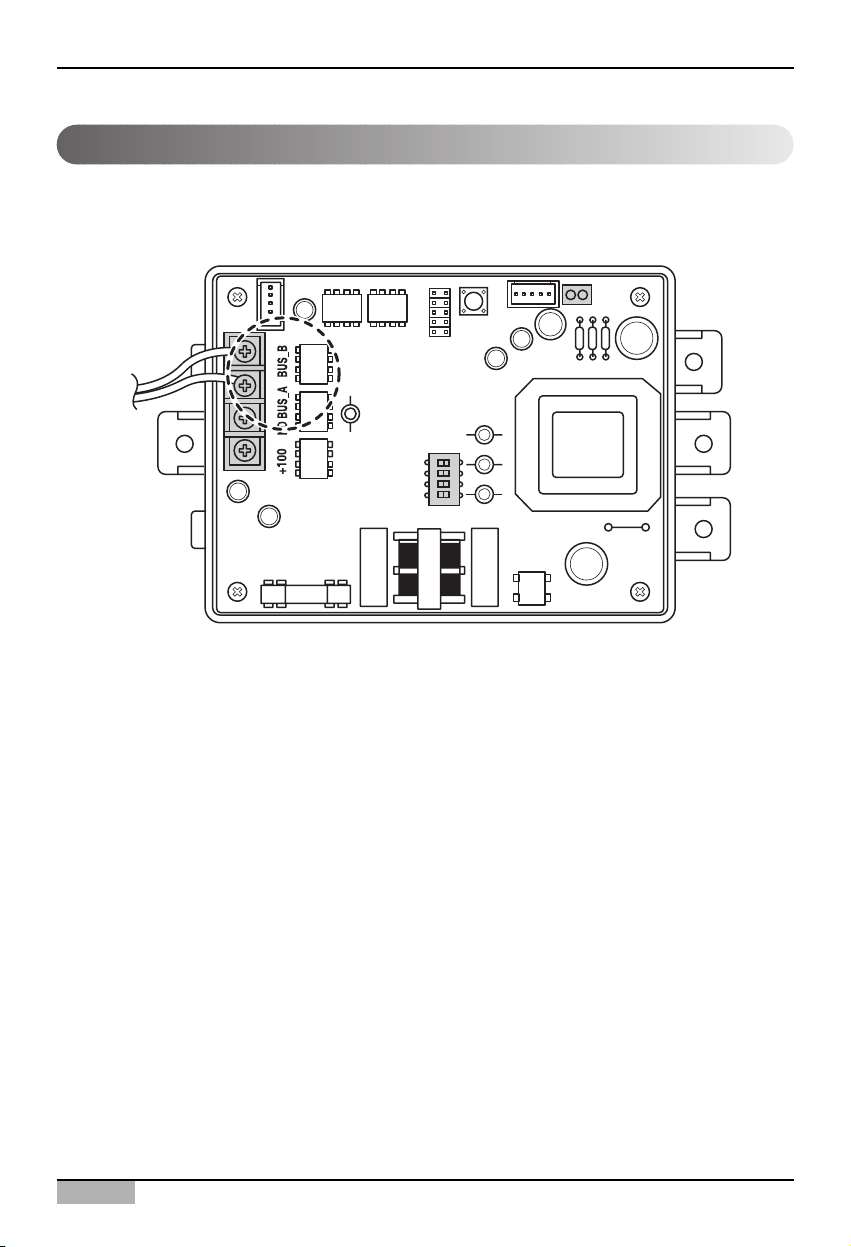

Connceting RS485 cable to PI485

In order to connect the PI485 and the ACP, two RS485 cables should be connected to the BUS_A and

the BUS_B of the PI485. Connect the RS485 cables by referring to the following figure.

When connecting more than one PI485 to one ACP, connect the BUS_A/BUS_B of the PI485 to the

BUS_A/BUS_B of the other PI485 respectively.

ON

L1 2 3 4

KSDO4H

Loading...

Loading...