Page 1

PDP MODULE

English

SERVICE MANUAL

MODEL : PDP42V7####

CAUTION

1. BEFORE SERVICING THE PDP MODULE,

READ THE SAFETY PRECAUTIONS IN THIS MANUAL.

2. WHEN REPLACEMENT PARTS ARE REQUIRED, BE SURE TO USE

REPLACEMENT PARTS SPECIFIED BY THE MANUFACTURER.

Page 2

- 2 -

[PDP42V7#### Module]

CONTENTS

Ⅰ. Safety Precautions/Technical Feature

Ⅱ. Formation and Specification of Module

Ⅲ. Adjustment

Ⅳ. Trouble Shooting

1. Checking for No Picture

2. Hitch Diagnosis Following Display Condition

2-1. All or 1/2 of the screen doesn’t be shown

2-2. Screen doesn’t be shown as Data TCP

2-3. It is generated unusual pattern of Data TCP IC unit

2-4. Regular Stripe is generated about the quantity of one Data TCP IC or more

2-5. Screen doesn’t be shown at all as Scan FPC

2-6. Regular stripe is generated at regular internal on the whole screen

2-7. Data copy is generated to stripe direction

2-8. One or more stripe is generated on the screen

2-9. One or more horizontal line is generated on screen

2-10. Lightness of screen is wholly darken though there is input-signal-pattern

2-11. Different color is shown partially during full-white-screen or electric discharge is generated

during full-black-screen

2-12. Some lightness of some color doesn’t not generated well

3. Checking for component damage

3-1. Y IPM(IC15) or Z IPM(IC2) damage

3-2. Pass Top FET(Y B/D: HS2) damage

3-3. FET Ass’y(Y B/D: HS1) damage

3-4. SCAN IC(Y DRV B/D: IC1~8) damage

3-5. TCP damage

3-6. Crystal(CTRL B/D: X1) damage

4. Shift breakdown component compatibility consideration

4-1. Scan IC follows in application, compatibility of Y DRV Top, Bottom B/D

Ⅴ. Block Diagram

Ⅵ. Safety Components List

Ⅶ. Records of Revision for Boards, Components and ROM DATA

* Annexing : Schematic Diagram

Page 3

English

- 3 -

1. Safety Precautions

When servicing of PDP Module, it should be not enforced into

another way aside next rule, or a unaccustomed person

should not repairing.

When using/handling this PDP Module, pay attention to the

below warning and cautions.

Warning

Indicates a hazard that may lead to death or injury if the

warning is ignored and the product is handled incorrectly.

Caution

Indicates a hazard that can lead to injury or damage to

property if the caution is ignored and the product is handled

incorrectly.

1) WARNING

(1) Do not touch Signal and Power Connnector while this

product operates.

Do not touch EMI ground part and Heat Sink of Film Filter.

(2) Do not supply a voltage higher than that specified to this

product. This may damage the product and may cause a

fire.

(3) Do not use this product in locations where the humidity is

extremely high, where it may be splashed with water, or

where flammable materials surround it.

Do not install or use the product in a location that does no

satisfy the specified environmental conditions. This may

damage the product and may cause a fire.

(4) If a foreign substance (such as water, metal, or liquid) gets

inside the product, immediately turn off the power.

Continuing to use the product, it is may cause fire or

electric shock.

(5) If the product emits smoke, and abnormal smell, or makes

an abnormal sound, immediately turn off the power.

Continuing to use the product, it may cause fire or electric

shock.

(6) Do not disconnect or connect the connector while power to

the product is on. It takes some time for the voltage to drop

to a sufficiently low level after the power has been turned

off.

Confirm that the voltage has dropped to a safe level before

disconnecting or connecting the connector.

(7) Do not pull out or insert the power cable from/to an outlet

with wet hands. It may cause electric shock.

(8) Do not damage or modify the power cable. It may cause

fire or electric shock.

(9) If the power cable is damaged, or if the connector is loose,

do not use the product: otherwise, this can lead to fire or

electric shock.

(10) If the power connector or the connector of the power

cable becomes dirty or dusty, wipe it with a dry cloth.

Otherwise, this can lead to fire.

(11) PDP Module uses a high voltage (Max.450V dc). Keep

the cautions concerning electric shock and do not touch

the Device circuitry when handling the PDP Unit. And

because the capacitor of the Device circuitry may remain

charged at the moment of Power OFF, standing by for 1

minute is required in order to touch the Device circuitry.

2) CAUTIONS

(1) Do not place this product in a location that is subject to

heavy vibration, or on an unstable surface such as an

inclined surface. The product may fall off or fall over,

causing injuries.

(2) Before disconnecting cable from the product, be sure to

turn off the power. Be sure to hold the connector when

disconnecting cables. Pulling a cable with excessive force

may cause the core of the cable to be exposed or break

the cable, and this can lead to fire or electric shock.

(3) This product should be moved by two or more persons. If

one person attempts to carry this product alone, he/she

may be injured.

(4) This product contains glass. The glass may break, causing

injuries, if shock, vibration, heat, or distortion is applied to

the product.

(5) The temperature of the glass of the display may rise to

80°C or more depending on the conditions of use.

If you touch the glass inadvertently, you may be burned.

(6) If glass surface of the display breaks or is scratched, do

not touch the broken pieces or the scratches with bare

hands. You may be injured.

(7) PDP Module requires to be handled with care not to be

touched with metal or hard materials, and must not be

stressed by heat or mechanical impact.

(8) There are some exposed components on the rear panel of

this product. Touching these components may cause an

electric shock.

(9) When moving the product, be sure to turn off the power

and disconnect all the cables. While moving the product,

watch your step. The product may be dropped or all,

leading to injuries of electric shock.

Ⅰ. Safety Precautions/Technical Feature

Page 4

(10) In order to protect static electricity due to C-MOS circuitry of

the Drive part, wear a wrist band to protect static electricity

when handling.

(11) If cleaning the Panel, wipe it with a soft cloth moistened with

water or a neutral detergent and squeezed, being careful not

to touch the connector part of the Panel. And don’t use

chemical materials like thinner or benzene.

(12) If this product is used as a display board to display a static

image, “image sticking” occurs. This means that the luminance

of areas of the display that remain lit for a long time drops

compared with luminance of areas that are lit for a shorter

time, causing uneven luminance across the display.

The degree to which this occurs is in proportion to the

luminance at which the display is used. To prevent this

phenomenon, therefore, avoid static images as much as

possible and design your system so that it is used at a low

luminance, by reducing signal level difference between bright

area and less bright area through signal processing.

(13) Because PDP Module emits heat from the Glass Panel part

and the Drive circuitry, the environmental temperature must

not be over 40°C.

The temperature of the Glass Panel part is especially high

owing to heat from internal Drive circuitry. And because the

PDP Module is driven by high voltage, it must avoid

conductive materials.

(14) If inserting components or circuit board in order to repair, be

sure to fix a lead line to the connector before soldering.

(15) If inserting high-power resistor(metal-oxide film resistor or

metal film resistor) in order to repair, insert it as 10mm away

as from a board.

(16) During repairs, high voltage or high temperature components

must be put away from a lead line.

(17) This is a Cold Chassis but you had better use a cold

transformer for safety during repairs. If repairing electricity

source part, you must use the cold transformer.

(18) Do not place an object on the glass surface of the display.

The glass may break or be scratched.

(19) This product may be damaged if it is subject to excessive

stresses (such as excessive voltage, current, or temperature).

The absolute maximum ratings specify the limits of these

stresses.

(20) The recommended operating conditions are conditions in

which the normal operation of this product is guaranteed. All

the rated values of the electrical specifications are guaranteed

within these conditions.

Always use the product within the range of the recommended

operating conditions. Otherwise, the reliability of the product

may be degraded.

(21) This product has a glass display surface. Design your

system so that excessive shock and load are not applied to

the glass. Exercise care that the vent at the corner of the glass

panel is not damaged.

If the glass panel or vent is damaged, the product is

inoperable.

(22) Do not cover or wrap the product with a cloth or other

covering while power is supplied to the product.

(23) Before turning on power to the product, check the wiring of

the product and confirm that the supply voltage is within the

rated voltage range. If the wiring is wrong or if a voltage

outside the rated range is applied, the product may

malfunction or be damaged.

(24) Do not store this product in a location where temperature

and humidity are high. This may cause the product to

malfunction. Because this product uses a discharge

phenomenon, it may take time to light (operation may be

delayed) when the product is used after it has been stored for

a long time. In this case, it is recommended to light all cells for

about 2 hours (aging).

(25) This product is made from various materials such as glass,

metal, and plastic. When discarding it, be sure to contact a

professional waste disposal operator.

(26) If faults occur due to arbitrary modification or disassembly,

LG Electronics is not responsible for function, quality or other

items.

(27) Use of the product with a combination of parameters,

conditions, or logic not specified in the specifications of this

product is not guaranteed. If intending to use the product in

such a way, be sure to consult LGE in advance.

(28) Within the warranty period, general faults that occur due to

defects in components such as ICs will be rectified by LGE

without charge. However, IMAGE STICKING due to

misapplying the above (12) provision is not included in the

warranty. Repairs due to the other faults may be charged for

depending on responsibility for the faults.

(29) In assembling Module into SET, in case Film Filter and as a

protective film is bared, static electricity of exfoliated protective

film which is bared from beginning X-Board down ward getting

TCP to no getting TCP should not influence on TCP.

Also Filter after protective film is bared or in the storage can

be charged with electricity, so the EMI ground part of Film

Filter should be used after Grounding.

- 4 -

Page 5

English

2. Technical Feature

PDP Module is a display device to be divided into a Panel part and a Drive part. The Panel part consists of

Electrodes, Phosphor, various dielectrics and gas, and the Drive part includes electronic circuitry and PCB.

PDP42V7#### model produced in the LG electronic is 42inches color Plasma display module of WVGA(852(H)x480(V)), and it is a

display device giving concrete to bright image by using AC Plasma technology of LG electronic.

1) General Specification

(1) Model Name : PDP42V7####

(2) Number of Pixel : 852(H) x 480(V) (1pixel=3 RGB cells)

(3) Pixel Pitch : 1080μm(H) x 1080μm(V)

(4) Cell Pitch : 320μm(H) x 1080μm(V) (Base: Green Cell)

(5) Display area : 920.1(H) x 518.4(V)±0.5mm

(6) Outline dimension : 1005(H) x 597(V)x 60.6(D)±1mm

(7) Color arrangement : RGB Closed type

(8) Number of COLRO : (R)1024 x (G)1024 x (B)1024

(9) Weight : 14.7Kg±0.5Kg

: 100Kg±5Kg(5EA/1BOX)

(10) Aspect Ratio : 16:9

(11) Peak Brightness : Typical 1500dc/㎡(1/10 White Window)

: Avergae 100:1(Light room 100 Lx at center)

(12) Contrast Ratio : Typical 10000:1(Dark room 1/10 White Window)

(White Window Pattern at Center)

(13) POWER CONSUMPTION : Typical 200 W(Full White)

* Note 1)

(14) Lifetime : Over 60,000 Hrs (Initial brightness 1/2)

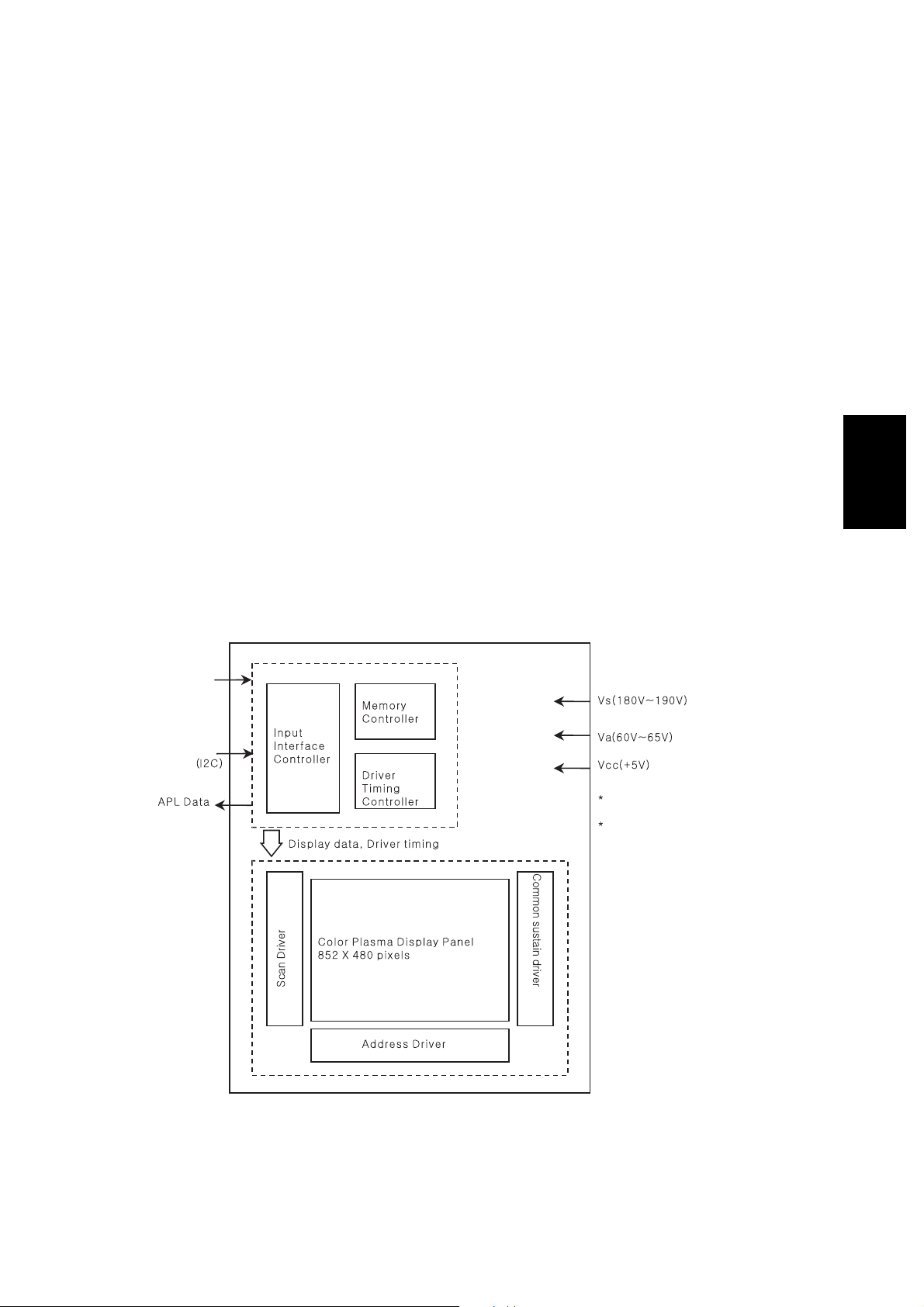

2) Block Diagram

- 5 -

LVDS Input

Controller Signal

Full White standard

Mentioned voltage follows

a standard of each Board input voltage

* Note 1) It can be changed maximum 300W according to input image.

Page 6

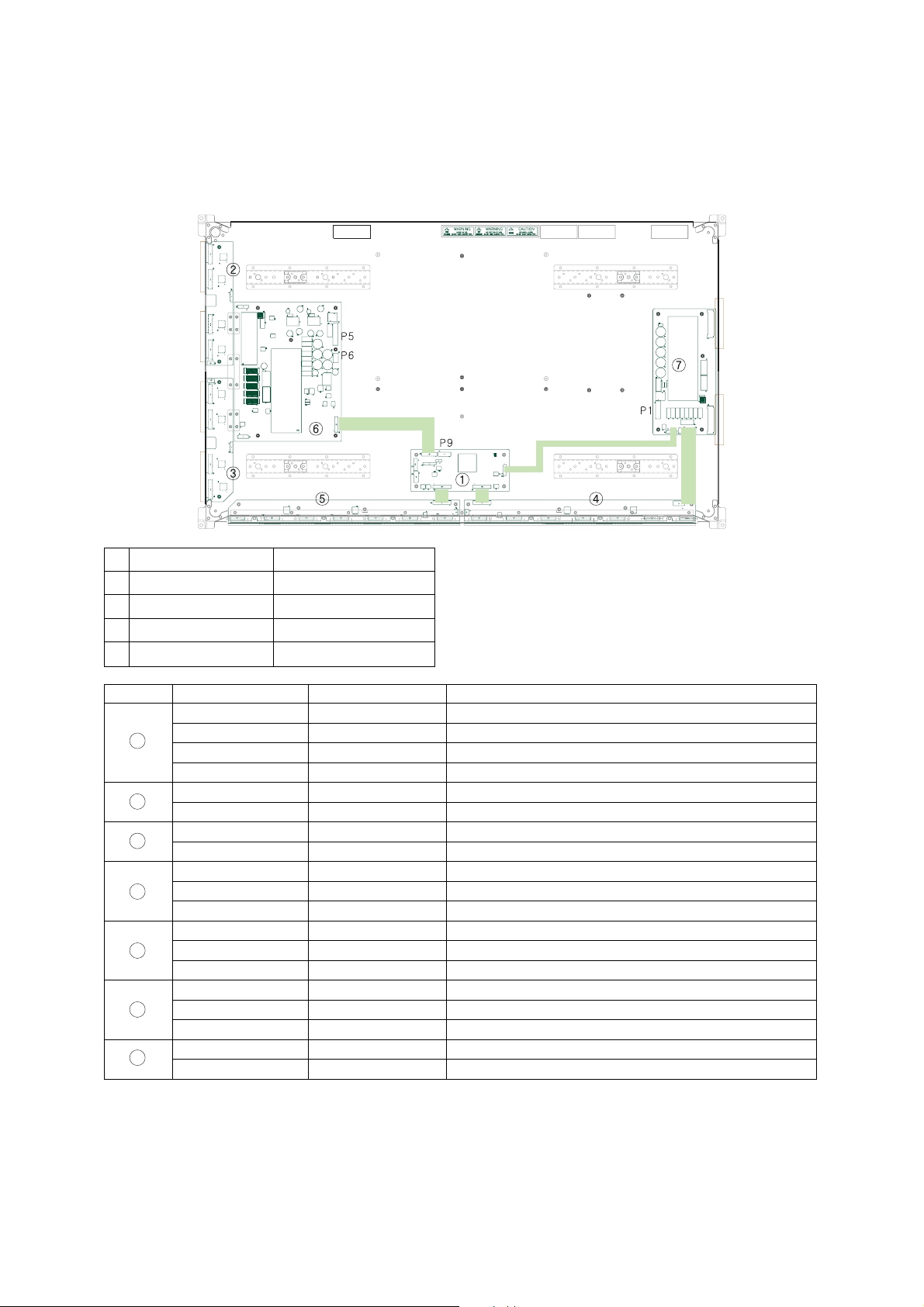

Ⅱ. Formation and Specification of Module

- 6 -

No

1

2

3

4

Connector

P1[Z SUS B/D]

P5[Y SUS B/D]

P6[Y SUS B/D]

P9[CTRL B/D]

Input Voltage & Signal

5V, Va, Vs

Vs

5V

Control Signal

No

1

2

3

4

5

6

7

6871QCH053A

6871QCH073A

6871QCH053B

6871QCH053C

6871QDH084A

6871QDH105A

6871QDH085A

6871QDH106A

6871QRH055A

6871QRH055B

6871QRH066A

6871QLH047A

6871QLH047B

6871QLH056A

6871QYH036A

6871QYH036B

6871QYH050A

6871QZH041A

6871QZH052A

PWB(PCB) ASS’Y

PWB(PCB) ASS’Y

PWB(PCB) ASS’Y

PWB(PCB) ASS’Y

PWB(PCB) ASS’Y

PWB(PCB) ASS’Y

PWB(PCB) ASS’Y

PWB(PCB) ASS’Y

PWB(PCB) ASS’Y

PWB(PCB) ASS’Y

PWB(PCB) ASS’Y

PWB(PCB) ASS’Y

PWB(PCB) ASS’Y

PWB(PCB) ASS’Y

PWB(PCB) ASS’Y

PWB(PCB) ASS’Y

PWB(PCB) ASS’Y

PWB(PCB) ASS’Y

PWB(PCB) ASS’Y

LVDS CTRL B/D ASS’Y

HITACHI COPPER LVDS CTRL B/D ASS’Y

LVDS OUTER SIDE CTRL B/D ASS’Y

PB-FREE FFC & CON LVDS OUTER SIDE CTRL B/D ASS’Y

YDRV TOP B/D ASS’Y

HITACHI COPPER YDRV TOP B/D ASS’Y

YDRV BTM B/D ASS’Y

HITACHI COPPER YDRV BTM B/D ASS’Y

XR B/D ASS’Y

PB-FREE FFC & CON XR B/D ASS’Y

HITACHI COPPER XR B/D ASS’Y

XL B/D ASS’Y

PB-FREE FFC & CON XL B/D ASS’Y

HITACHI COPPER XL B/D ASS’Y

YSUS B/D ASS’Y

PB-FREE FFC & CON YSUS B/D ASS’Y

HITACHI COPPER YSUS B/D ASS’Y

ZSUS B/D ASS’Y

HITACHI COPPER ZSUS B/D ASS’Y

Part No. Description

※ The composition and specification of Initial production module

Revision information refers to ‘Ⅶ Revision for Boards, Components and ROM DATA’

Page 7

Ⅲ. Adjustment

1. Application Object

This standard is applied to the PDP42V7#### PDP Module

which is manufactured by the manufacturing team of PDP

promotion department or elsewhere.

2. Notes

(1) Without any special specification, the Module should be at

the condition of preliminaries more than 10minutes before

adjusting.

- Service signal : 100% Full White signal

- Service DC voltage : Vcc: 5V, Va: 65V, Vs: 187V

- DC/DC Pack voltage : Vsc=115V

- Preliminaries environment : Temp (25!5°C), Relative

humidity (65!10%)

(2) Module should get the Aging for the equilibrium after finish

the assembling. Aging condition is shown below.

- Service signal: 100% Full White, Red, Green, Blue pattern

signal(Service time of each pattern : within 5minutes/cycle)

- Service DC voltage : Match the voltage with the set up

voltage in the first adjustment.

- Aging time : More than 30 minutes

- Aging environment : Temp (25!2°C), Relative humidityLess than 65%

(3) Module adjustment should be followed by below sequence.

- Setting up the Vsc/-Vy voltage(Vsc=115V, -Vy=-85V)

-

Adjusting the voltage wave form(Refer to adjustment)

-

25!5°C, 65!10%

(4) Without any special specification, you should adjust the

Module in the environment of Temp (25!5°C) and Relative

humidity (65!10%)

Caution) If you let the still image more than 10 minutes(especially

The Digital pattern or Cross Hatch Pattern which has

clear gradation), after image can be presented in the

black level part of screen.

-Vy: -85V

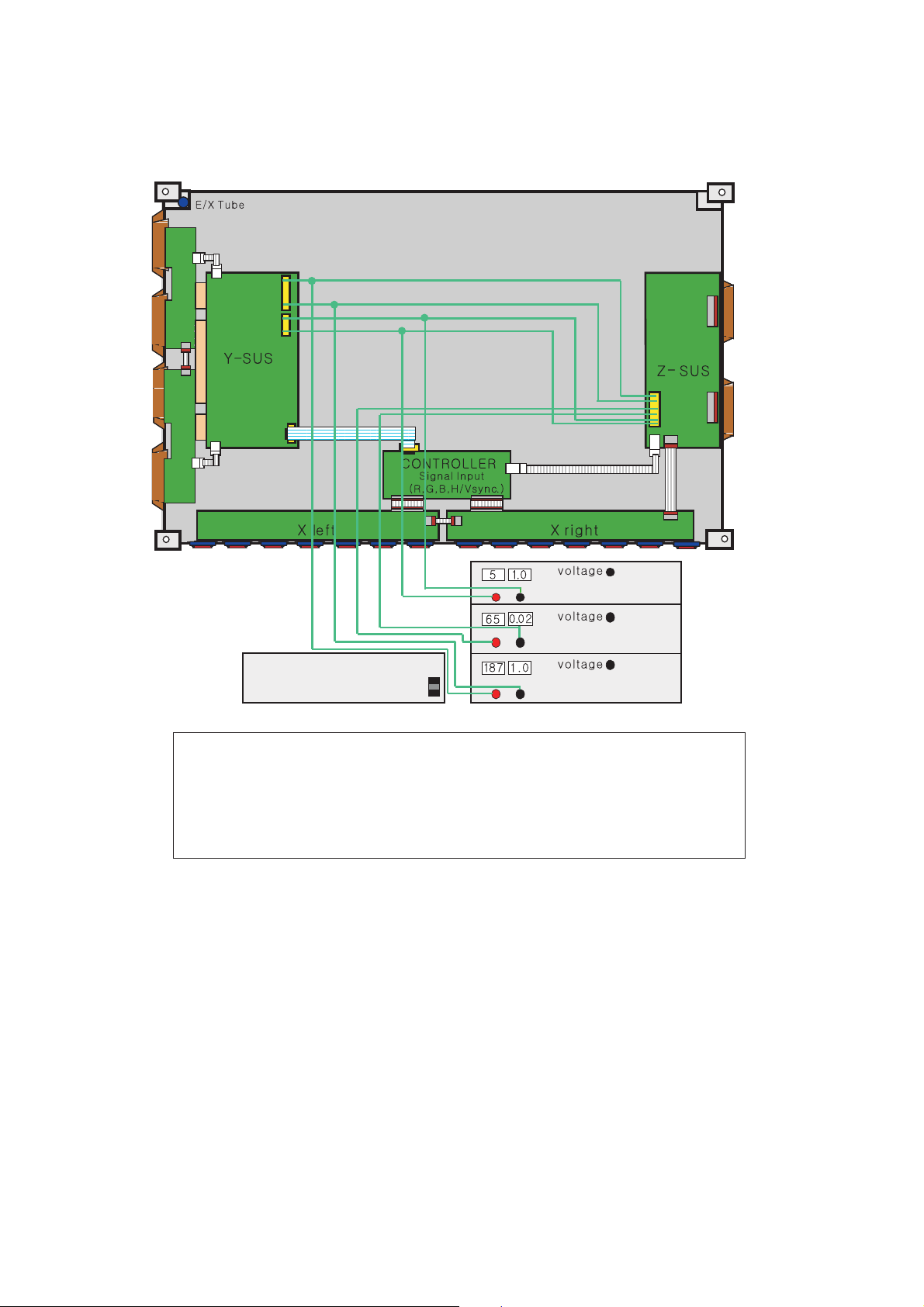

3-2. Connection diagram of measuring

instrument and setting up the initial

voltage

(1) For connection diagram of measuring instrument,

refer to Fig. 1.(Connection diagram of measuring

instrument that adjusting the voltage wave form)

(2) Setting up the initial voltage(Voltage Label)

Vcc: 5V, Va: 65V, Vs: 187V

But, Initially setting up voltage can be changed by the set

up range according to the Module’s characteristic.

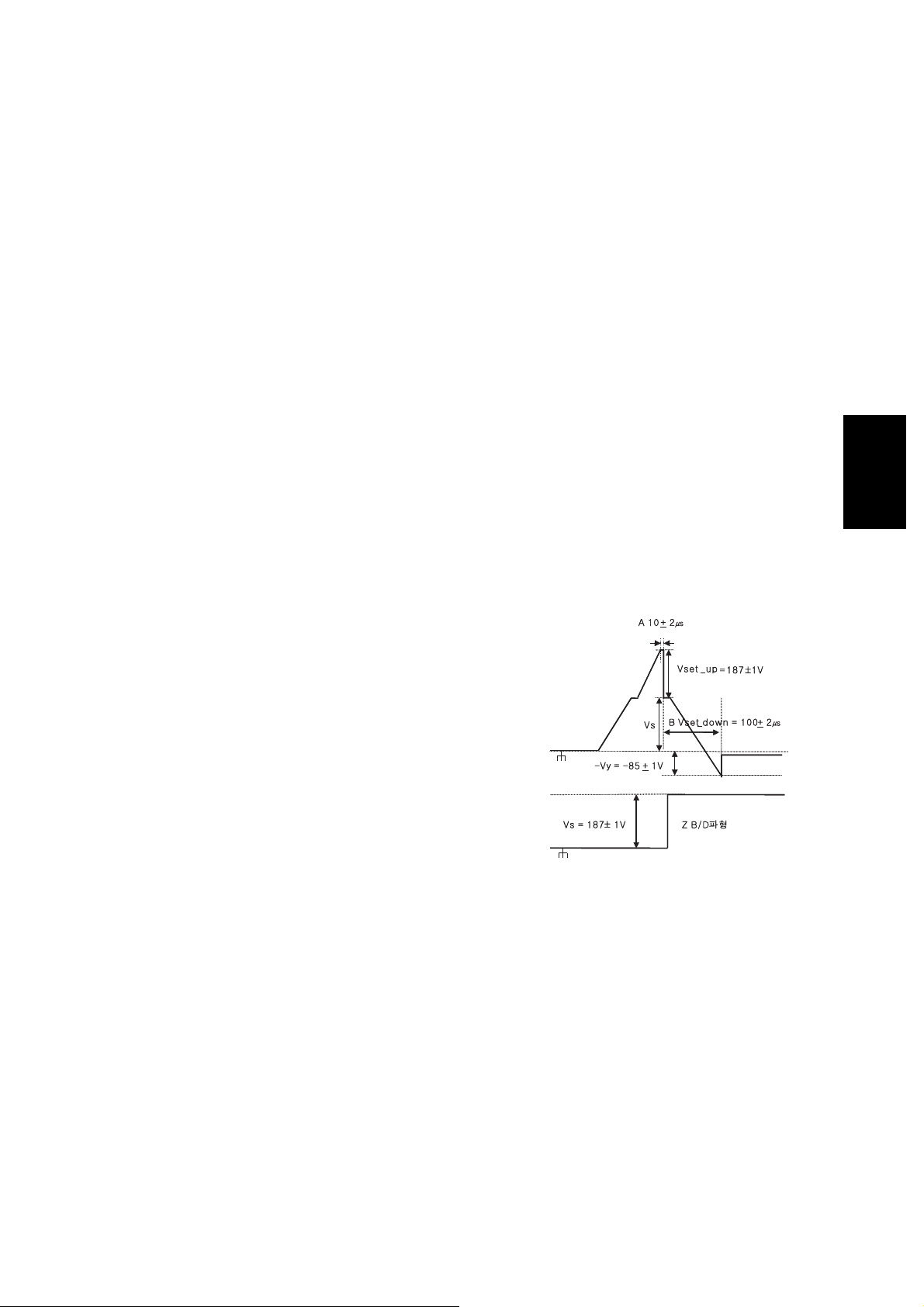

3-3. How to Adjust

(1) Adjusting Vset-up Voltage Wave form

① Connect the measuring instrument to be (Fig. 1).

② Turn on the measuring instrument with Caution of (Fig. 1).

③ Connect the oscilloscope probe to B39(Bead) of Y B/D

bottom and GND.

④ Turn the VR1 of Y B/D and make the “A“ waveform Fig.

2 to be 10!2µs.

(2) Adjusting Vset-down Voltage Wave form

① Turn the VR2 of YSUS B/D and make the “B“ waveform

Fig. 2 to be 100!2µs.

English

3. Adjustment after Assembling

3-1. Using Tools

(1) Digital oscilloscope : More than 200MHz

(2) DVM(Digital Multimeter) : Fluke 87 or similar one

(3) Signal generator : VG-825 or similar one

(4) DC power supply or PSU

- DC power supply for Vs (1) : Should be changeable

between 0V to 200V/ more than 10A

- DC power supply for Va (1) : Should be changeable

between 0V to 100V/ more than 5A

- DC power supply for 5V (1) :Should be changeable

between 0V to 10V/ more than 10A

- DC-DC Converter Jig (1) : The Jig which has equivalent

voltage output of PDP42V7#### Module after taking the

Vs, Va, 5V voltage

- Voltage stability of power supply : Within !1% for Vs/Va,

within !3% for 5V

(Fig. 2) Y, Z set-up Waveform

(3) Checking the DC/DC pack voltage

① Convert the signal of signal generator to the 100% Full

White signal.

② Connect the GND terminal of DVM to the right leg of R53

on the Y B/D and set the Plus terminal to the left leg of

R53 to check the Vsc voltage(115!1V) and when there is

abnormality in voltage turn the variable resistor(VR3) of

DC/DC Pack(Vsc) PS1 on Y B/D to adjust.

③ Connect the GND terminal of DVM to the right leg of

R78 on the Y B/D and set the Plus terminal to the left

leg of R78 to check the -Vy voltage(-85!1V) and when

there is abnormality in voltage turn the variable

resistor(VR4) of DC/DC Pack(-Vy) PS1 on Y B/D to

adjust.

- 7 -

Page 8

- 8 -

<Caution>

(1) The power of the signal generator should be turned on before turning on the power of DC power supply.

(2) The voltage of DC power supply , in standard of Module input voltage, should be preset as below.

Vcc: 5V, Va: 65V, Vs: 187V

(3) The power of power supply must turned on by this sequence. Reverse direction When turning off.

* Module on : 5V

(Va(

Vs, Module off: Vs(Va(5V

(4) Signal generator should be selected with 852)480(WVGA) mode.

(Fig. 1) Connection diagram of measuring instrument

DC Power Supply for 5V

DC Power Supply for Va

DC Power Supply for Vs

Power

Signal Generator(VG-825)

※ Also the PSU(Power Supply Unit) use is possible

Page 9

1. Checking for no Picture

A screen doesn’t display at all and condition of black pattern or power off.

(1) Check whether the CTRL B/D LED(D1, D2, D3, D4, D5) is turned on or not.

(2) Check the power and signal cable of CTRL B/D.

(3) X B/D, Y B/D, Z B/D is well plugged in.

(4) Check the connection of X B/D, Y B/D and Z B/D to CTRL B/D.

(5) Measure the output wave of X, Y, Z B/D with oscilloscope(more than 200MHz)

and find the trouble of B/D by comparing the output wave with below figure.

- Measure Point fo Y B/D : Bead B39

- Measure Point fo Z B/D : Bead B28

- Measure Point fo X B/D : P3

(6) Check the SCAN(Y side) IC

(7) Check the DATA(X side) TCP IC

(8) Replace the CTRL B/D.

(9) Check the Fuse of Y, Z B/D is open and replace when open.

(10) Check the input voltage. (Vcc=5V/Va=65V/Vs=187V)

English

- 9 -

Ⅳ. Trouble Shooting

Y B/D Output wave (1frame)

Z B/D Output wave (1frame)

Page 10

- 10 -

Y B/D Output wave(1SF)

Z B/D Output wave(1SF)

X B/D Output wave(1frame): Va measurement

Page 11

English

2. Hitch Diagnosis Following

Display Condition

2-1. All or 1/2 of the screen doesn’t be shown

(1) In case of all of the screen doesn’t be shown, Confirm the

8pin connection of X B/D to Z B/D is well plugged in which

is correspond

(2) In case of 1/2 of the screen doesn’t be shown

①

XR B/D

- Confirm the 60pin connection of CTRL B/D to XR B/D

is well plugged in which is correspond

②

XL B/D

- Confirm the 5pin connection of XR B/D to XL B/D is

well plugged in which is correspond

- Confirm the 60pin connection of CTRL B/D to XL B/D

is well plugged in which is correspond

(3) Replace relevant X B/D.

[[

Relationship between screen and X B/D

Screen X B/D

Left of the Screen 1/2 <--> Right X B/D

Right of the Screen 1/2 <--> Left X B/D

[[

Screen Display Form

[[

1/4 of the screen doesn’t be shown

Equality with 2-1

2-2. The screen doesn’t be shown as Data

TCP

(Include not be shown part of DataTCP quantity or a part)

(1) The problem between Data TCP and X B/D is more

possible that the screen is not be shown as data TCP.

(2) Confirm the connector of Data TCP is well connected to X

B/D. Correspond to the part that screen is not showing

(3) Confirm whether the Data TCP is failed.

(Inclusion examination with the naked eye(IC Burnt and

others)

①

IC is Fail: Replace the Module

②

In case of shorting the X B/D by foreign or PCB pattern

is open: When TCP IC is not Fail, replace the X B/D.

[[

Example of the screen display form

(Anything of the 14 Data TCP can be shown beside below

pictures)

- 11 -

Left of the Screen(1/2) Right of the Screen(1/2)

Display

Not display

: All

: Partial

: not at all

[[

How to examine Data TCP IC

● Change ‘①(Va Power)‘ into CATHOD, ‘②(GND)‘ into

ANODE and then examine the Diode to the forward

or reverse direction.

● Burnt of ‘③(IC)’ and others examine with the naked

eye.

Page 12

2-3. It Generates Unusual Pattern of Data

TCP IC unit

(1) In case of generating unusual pattern of Data TCP IC unit

as below picture, there is problem in the Signal(CLK, data,

STB) or connector that is input into Data TCP IC

(2) In case of <case 1>

- Confirm the connection of Data TCP connector and IC

Fail.

- Replace the relevant X B/D.

(3) In case of <case 2>, <case 3>

- Confirm the connection of Data TCP connector and

connector that is connected from CTRL to X B/D.

- Check the foreign on the CTRL B/D and X B/D.

- Replace the relevant X B/D or CTRL B/D.

(4) In case of <case 4>, <case 5>

- Confirm the connector that is connected from CTRL to X B/D

- Replace relevant X B/D or CTRL B/D

- Confirm the connection of Z B/D and XR B/D(8pin), XR

B/D and XL B/D(5pin) power connector.

[[

Screen Display Form

2-4. Regular Stripe is Generated about the

Quantity of one Data TCP IC or more

(1) In case of generating regular stripe about the quantity of one

Data TCP IC or more, check the connection of connector or

foreign.

(2) Confirm the connection connector/foreign of XB/D or CTRL

B/D to X B/D correspond to unusual screen.

(3) Replace relevant XB/D or CTRL B/D.

[[

Screen Display Form

- 12 -

<Case 1>

Unusual screen comes

out about one TCP IC

quantity or more

Unusual screen comes

out about 1/2 of screen

or equal distances of

all screen

Unusual screen comes

out about 4/14 quantity

of screen or 3/14

Unusual screen comes

out about 1/2 quantity

of screen

Unusual screen comes

out about all screen

<Case 2>

<Case 3>

<Case 4>

<Case 5>

It comes out partial field about

the quantity of one IC or more

or It may come out together

at other field of screen.

Page 13

English

- 13 -

2-5. The screen display has a problem for

Scan FPC.

(1) It’s may be a problem between Scan FPC and Y DRV B/D.

(2) Check the connection of Y DRV B/D and Scan FPC.

(3) If the Scan IC is failed, replace the Y DRV B/D.

[[

Screen Display Form

[[

Check a method of SCAN IC

Change the Vpp Pin into ANODE and GND Pin into CATHOD

and then test the Diode with forward or reverse direction.

2-6. The screen has a vertical line with

regular gap.

(A vertical stripe flash at especial color)

(1) This is a problem about CTRL B/D.

(2) Replace the CTRL B/D.

[[

Screen Display Form

2-7. A data copy is happened into vertical

direction

(1) In this case, it’s due to incorrect marking of scan wave.

(2) Replace the Y DRV B/D or Y B/D.

[[

Screen Display Form

one eighth

of screen

The screen display is very good

The screen display is poor

The screen has a vertical line

with regular gap

<Case 1 : Entire Copy><Display Pattern>

<Case 2 : Top Copy>

<Case 3 : Bottom Copy> <Case 4 : Entire Copy>

Page 14

- 14 -

2-8. The screen has one or several vertical

line

(1) In this case, It isn’t a problem about CTRL B/D or X B/D.

(2) It may cause followings.

- It’s out of order a panel

- Open or short of DATA TCP FPC attached panel

- It’s out of order a DATA TCP attached panel

(3) Replace Module.

[[

Screen Display Form

2- 9. The screen has one or several

horizontal line

(1) In this case, it isn’t a problem about CTRL B/D or Y B/D.

(2) It may cause followings.

- It’s out of order a panel

- Open or short of SCAN FPC attached panel

- It’s out of order a SCAN IC attached panel

(3) Replace Y DRV B/D

[[

Screen Display Form

2-10. The screen displays input signal

pattern but the brightness is dark

(1) In this case, Z B/D operation isn’t complete.

(2) Check the power cord of Z B/D.

(3) Check the connector of Z B/D and CTRL B/D.

(4) Replace the CTRL B/D or Z B/D.

2-11. The screen displays other color

partially on full white screen or happens

discharge partially on full black screen.

(1) Check the declination of Y B/D set up, set down wave.

(2) Measure each output wave with oscilloscope(more than

200MHz) and compare the data with below figure data.

Adjust the Y B/D Set_up(A) and Set_down(B) declination

by changing VR1 and VR2 as same writing on the

adjustment label.

- Measuring Point of Y B/D : B39

2-12. It doesn’t display a specified

brightness at specified color

(1) Check the connector of CTRL B/D input signal.

(2) Replace the CTRL B/D.

It may show several vertical

lines in a quarter or other

division part of screen

including left case.

It may show several horizontal

lines including left case.

Y Output Voltage Wave form

Page 15

English

- 15 -

3. Checking for Component Damage

3-1. Y IPM(IC 15) or Z IPM(IC 2) Damage

(1) When the internal Sustain_IGBT or ER_FET of Y IPM(IC

15) or Z IPM(IC 2) is damaged, VS FUSE is open and

screen doesn’t be shown.

O Test Point: B32~GND(Y B/D), B28~GND(Z B/D)

O Wave format: B32(Y B/D) or B28(Z B/D) has no output

wave.

O Measurance position: Sustain section enlarge the after

measuring B32 wave of Y B/D and B28 wave of Z B/D.

(Full White Pattern)

3-2. Pass Top FET(Y B/D: HS2) Damage

(1) When Pass Top FET is damaged, electric discharge of

entire screen is generated.

O Test Point: Enlarge the after measuring GND~B32(Y B/D)

O Wave format: When the Set_dn does not descend until

-Vy.

3-3. FET Ass’y(Y B/D: HS1) Damage

(1) When Set_Up FET is damaged, screen doesn’t be shown

O Test Point: Enlarge the after measuring GND~B32(Y B/D)

O Wave format: Set_up waveform does not come out.

(2) When Set_Down FET is damaged, electric discharge of

entire screen is generated.

O Test Point: Enlarge the after measuring GND~B32(Y B/D)

O Wave format: Set_down waveform does not come out.

O Measurance position: Reset section enlargement wave of

B32(Y B/D) (Full White Pattern)

Set_up waveform

does not come out

<When the Set_Up FET is damaged>

Set_down waveform

does not come out

<When the Set_Down FET is damaged>

<IPM Normal Output Wave>

It does not descend until -Vy

<When the Pass Top FET is damaged>

<Reset section normal output wave>

Page 16

- 16 -

3-4. SCAN IC(Y DRV B/D: IC1~8) Damage

(1) In case of SCAN IC poor, one horizontal line may open at

screen.

O Test Point: ICT measurance of GND~Y DRV B/D output

O Wave format: As shown below figure.

(2) Screen may not shown when SCAN IC is damaged by

SCAN IC poor, external electricity or spark.

O Test Point: ICT measurance of GND~Y DRV B/D output

O Wave format: Output wave format isn’t output (You can

see the damage for Y DRV B/D Top or Bottom’s SCAN

IC)

(3) Screen shaked horizontally when Y DRV B/D Top and

Bottom cable is poor

O Test Point: ICT measurance of GND~Y DRV B/D output

O Wave format: As shown below figure.

(4) In case of shorting the SCAN IC output by a dust, foreign

substance, it may overlap two horizontal lines on screen.

O Test Point: ICT measurance of GND~Y DRV B/D output

O Wave format: As shown below figure.

O Measurance position: SCAN section enlarge the after

measuring output ICT of Y DRV B/D.

(Full White Pattern)

<When SCAN IC is poor>

<When Y DRV B/D Top and Bottom cable is poor>

<When SCAN IC output is short>

<SCAN IC Normal Output Wave >

Section

Page 17

English

- 17 -

3-5. TCP Damage

(1) In case of shorting or opening the IC output of TCP, it may

show one or several vertical lines.

O Test Point: Enlarge the after measuring output TP of

GND~TCP

O Wave format: As shown output below figure.

In case of normal wave output, when STB signal is

generated, maintain High output. And when STB signal

is generated again must be fall Low.

But when IC of TCP is poor, STB signal is not generated

Output falls with Low.

(2) In case of being damage IC of TCP or power resistance, the

screen doesn’t be shown or happens discharge partially.

O Test Point: Enlarge the after measuring output TP of

GND~TCP

O Wave format: Output wave doesn’t come out

O Measurance position: Enlarge the after measuring output

TP of TCP (Full White Pattern)

3-6. Crystal(CTRL B/D: X1) Damage

(1) When Crystal is damage, the screen doesn’t be shown.

O Test Point: Measuring 3pin of GND~Crystal(CTRL B/D:

X1)

O Wave format: Output wave doesn’t come out

(2) In case of unusual launch of the Crystal, it may blink the

screen.

O Wave format: As shown below figure

O Measurance position: Measuring output 3pin of

Crystal(X1: 100MHz) on CTRL B/D (Full White Pattern)

<When IC output of COF is poor>

<TCP Normal Output Wave >

<When Crystal is poor>

<Crystal Normal Output Wave >

Page 18

- 18 -

4. Shift breakdown component

compatibility consideration

4-1. Scan IC follows in application,

compatibility of Y DRV Top, Bottom B/D

(1) When B/D applicated FD3284F is breakdown, you must

mutually only replace Top B/D and Bottom B/D applicated

FD3284F.

(2) When IC of B/D applicated FD3284F IC is breakdown, you

must only replace FD3284F IC.

Different IC application being not right

[ When replacing the IC, notice

To prevent dust, fix the same IC after removing the silicon

and then it again stick the IC.

B/D applicated FD3284F

TOP: 6871QDH084A

BTM: 6871QDH085A

When B/D is breakdown

When IC is breakdown

Only use B/D applicated FD3284F

TOP: 6871QDH084A

BTM: 6871QDH085A

B/D applicated FD3284F

TOP: 6871QDH084A

BTM: 6871QDH085A

Silicon Part No.: 7254Q00002A(Tube Type)

7254Q00002B(Can Type)

Only use FD3284F IC

IC: 0ILNRFE001A

Page 19

English

- 19 -

Ⅴ. Block Diagram

DC Power Supply for 5V

DC Power Supply for Va

DC Power Supply for Vs

Page 20

- 20 -

Ⅵ.

Safety Components List

(1) The safety components list of PDP42V7#### Model is as below.

(2) A component of mark is important to keep product’s security. Therefore in exchanging a component, appointed component is

necessary used.

(3) is an abbreviated word which is instead of <Safety>mark.

S

S

Page 21

English

- 21 -

Page 22

Ⅶ. Records of Revision for Boards, components and ROM DATA

1. Boards

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

Date

2005.03.04

2005.03.04

2005.03.04

2005.03.04

2005.03.04

2005.03.04

2005.03.04

2005.03.04

2005.03.04

2005.03.04

2005.03.04

2005.03.04

2005.03.04

2005.03.04

2005.03.04

Board

LVDS CTRL B/D ASS’Y

HITACHI COPPER LVDS CTRL B/D ASS’Y

LVDS OUTER SIDE CTRL B/D ASS’Y

PB-FREE FFC & CON LVDS OUTER SIDE

CTRL B/D ASS’Y

YDRV TOP B/D ASS’Y

HITACHI COPPER YDRV TOP B/D ASS’Y

YDRV BTM B/D ASS’Y

HITACHI COPPER YDRV BTM B/D ASS’Y

XR B/D ASS’Y

PB-FREE FFC & CON XR B/D ASS’Y

HITACHI COPPER XR B/D ASS’Y

XL B/D ASS’Y

PB-FREE FFC & CON XL B/D ASS’Y

HITACHI COPPER XL B/D ASS’Y

YSUS B/D ASS’Y

Part Number

6871QCH053A

6871QCH073A

6871QCH053B

6871QCH053C

6871QDH084A

6871QDH105A

6871QDH085A

6871QDH106A

6871QRH055A

6871QRH055B

6871QRH066A

6871QLH047A

6871QLH047B

6871QLH056A

6871QYH036A

Note

Initial Product

Initial Product

Initial Product

Initial Product

Initial Product

Initial Product

Initial Product

Initial Product

Initial Product

Initial Product

Initial Product

Initial Product

Initial Product

Initial Product

Initial Product

16

17

18

19

2005.03.04

2005.03.04

2005.03.04

2005.03.04

PB-FREE FFC & CON YSUS B/D ASS’Y

HITACHI COPPER YSUS B/D ASS’Y

ZSUS B/D ASS’Y

HITACHI COPPER ZSUS B/D ASS’Y

- 22 -

6871QYH036B

6871QYH050A

6871QZH041A

6871QZH052A

Initial Product

Initial Product

Initial Product

Initial Product

Page 23

English

- 23 -

2. COMPONENTS

No.

1

2

3

4

5

Date

2005.03.04

2005.03.04

2005.03.04

2005.03.04

2005.03.04

Part Number

4921QP1031A

4921QP1031A

0ILNRFE001A

0ILNRD1002A

4921QF2007A

Remark

Initial Product

Initial Product

Initial Product

Initial Product

COMPONENT

Y IPM(YSUS B/D: IC15)

Z IPM(ZSUS B/D: IC2)

SCAN IC(YDRV B/D: IC1~8)

TCP

FET(Y B/D: HS1)

Initial Product

(Set_up/Set_dn FET Ass’y)

Page 24

- 24 -

3. ROM DATA

No.

1

2

Date

2005.03.04

2005.03.04

Contents

Inner Type LVDS Initial ROM Data

External Type LVDS Initial ROM Data

ROM Data Version

42V73DN03

42V73LV03

Page 25

March, 2005

Printed in Korea3828VD0143R

Loading...

Loading...