Page 1

PCS200R Pro:Centric

®

Server

Installation & Setup Guide

Warranty

© Copyright 2015 LG Electronics U.S.A., Inc.

P/N: 206-4227 (Rev F)

Page 2

For Customer Support/Service, please call: 1-888-865-3026

The latest product information and documentation is available online at: www.LGsolutions.com

WARNING

RISK OF ELECTRIC SHOCK

DO NOT OPEN

WARNING:

TO REDUCE THE RISK OF ELECTRIC SHOCK DO NOT REMOVE COVER (OR BACK). NO USERSERVICEABLE PARTS INSIDE. REFER TO QUALIFIED SERVICE PERSONNEL.

The lightning flash with arrowhead symbol, within an equilateral triangle, is intended to alert

the user to the presence of uninsulated “dangerous voltage” within the product’s enclosure that

may be of sufficient magnitude to constitute a risk of electric shock to persons.

The exclamation point within an equilateral triangle is intended to alert the user to the presence

of important operating and maintenance (servicing) instructions in the literature accompanying the

appliance.

WARNING:

TO PREVENT FIRE OR SHOCK HAZARDS, DO NOT EXPOSE THIS PRODUCT TO RAIN OR

MOISTURE.

Apparatus shall not be exposed to dripping or splashing and no objects filled with liquids, such as vases,

shall be placed on the apparatus.

L’appareil ne doit pas être exposé à des égouttements d’eau ou des éclaboussures et de plus qu’aucun

objet rempli de liquide tel que des vases ne doit être placé sur l’appareil.

WARNING:

This product contains chemicals known to the State of California to cause cancer and birth defects or other

reproductive harm. Wash hands after handling.

FCC NOTICE (For USA and Canada):

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant

to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment. This equipment generates, uses

and can radiate radio frequency energy and, if not installed and used in accordance with the instructions

manual, may cause harmful interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference in which case the user will be required to correct the

interference at his own expense.

This device complies with part 15 of the FCC Rules. Operation is subject to the following two conditions:

(1) this device may not cause harmful interference and (2) this device must accept any interference received,

including interference that may cause undesired operation of the device. Any changes or modifications in

construction of this device which are not expressly approved by the party responsible for compliance could

void the user’s authority to operate the equipment.

CAUTION:

Do not attempt to modify this product in any way without written authorization from LG Electronics U.S.A.,

Inc. Unauthorized modification could void the user’s authority to operate this product.

COMPLIANCE:

The responsible party for this product’s compliance is: LG Electronics U.S.A., Inc.

2000 Millbrook Drive, Lincolnshire, IL 60069, USA • Phone: 1-847-941-8000

Marketed and Distributed in the United States by LG Electronics U.S.A., Inc.

2

2000 Millbrook Drive, Lincolnshire, IL 60069

© Copyright 2015 LG Electronics U.S.A., Inc.

206-4227

Page 3

IMPORTANT SAFETY INSTRUCTIONS

1. Read these instructions.

2. Keep these instructions.

3. Heed all warnings.

4. Follow all instructions.

5. Do not use this apparatus near water.

6. Clean only with dry cloth.

7. Do not block any ventilation openings.

Install in accordance with the manufacturer's instructions.

8. Do not install near any heat sources, such

as radiators, heat registers, stoves, or

other apparatus (including amplifiers) that

produce heat.

9. Do not defeat the safety purpose of the

polarized or grounding-type plug. A polarized plug has two blades with one wider

than the other. A grounding-type plug has

two blades and a third grounding prong.

The wide blade or the third prong are

provided for your safety. If the provided

plug does not fit into your outlet, consult

an electrician for replacement of the

obsolete outlet.

10. Protect the power cord from being walked

on or pinched, particularly at plugs,

convenience receptacles, and the point

where it exits from the apparatus.

11. Only use attachments/accessories

specified by the manufacturer.

12. Use only with the cart, stand, tripod,

bracket, or table specified by the

manufacturer or sold with the apparatus.

When a cart is used, use caution when

moving the cart/apparatus combination

in order to avoid injury from tip-over.

13.

Refer all servicing to qualied service

personnel. Servicing is required when the

apparatus has been damaged in any way,

such as power-supply cord or plug is

damaged, liquid has been spilled or

objects have fallen into the apparatus, the

apparatus has been exposed to rain or

moisture, does not operate normally, or

has been dropped.

14. Power Sources

This product should be operated only from the

type of power source indicated on the marking

label. If you are not sure of the type of power

supply to your INSTALLATION, consult your

product dealer or local power company.

15. Overloading

Do not overload wall power outlets and

extension cords as this can result in a risk of

fire or electric shock.

16. Disconnect Device

The AC mains plug is used as the disconnect

device. The disconnect device must remain

readily operable.

17. Object and Liquid Entry

Never push objects of any kind into this

product through openings as they may touch

dangerous voltage points or short-out parts

that could result in a fire or electric shock.

Never spill liquid of any kind on the product.

Do not use liquid cleaners or aerosol cleaners.

18. Outdoor Use

Warning: To prevent fire or shock

hazards, do not expose this product

to rain or moisture.

19. Wet Location

Do not use this product near water or mois-

ture or in an area, such as a basement, that

might become flooded. The apparatus shall

not be exposed to dripping or splashing and

no objects filled with liquids, such as vases,

shall be placed on the apparatus.

20. Test Equipment

In some cases, LG has supplied or recommended the use of test equipment and

devices for the setup and testing of the equipment. The operation and maintenance of test

equipment is described in their associated

instruction manuals. Please refer to these

manuals for explicit instructions regarding the

safe use and handling of the equipment.

(Continued on next page)

206-4227

3

Page 4

IMPORTANT SAFETY INSTRUCTIONS

(Continued from previous page)

21. Damage Requiring Service

Unplug this product from the wall power

outlet and refer servicing to qualied service

personnel under the following conditions:

a. If the power-supply cord or plug is damaged.

b. If liquid has been spilled, or objects have

fallen into the product.

c. If the product has been exposed to rain or

water.

d. If the product does not operate normally

by following the operating instructions.

Adjust only those controls that are covered

by the operating instructions, as an

improper adjustment of other controls may

result in damage and will often require

extensive work by a qualied technician to

restore the product to its normal operation.

e. If the product has been dropped or the

cabinet has been damaged.

f. If the product exhibits a distinct change in

performance.

Caution: Refer all servicing to qualied

service personnel.

22. Servicing

23. Replacement Parts

When replacement parts are required, be sure

24. Safety Check

25. Handling Notice

Caution: These servicing

instructions are for use by qualied

service personnel only. To reduce

the risk of electrical shock, do not perform

any servicing other than that described in

the operating instructions unless you are

qualied to do so.

the service technician uses replacement parts

specied by the manufacturer or that have the

same characteristics as the original parts.

Unauthorized substitutions may result in re,

electric shock, or other hazards.

Upon completion of any service or repairs to

this product, ask the service technician to

perform safety checks to determine that the

product is in proper operating condition.

Caution: Only qualified service

personnel should handle and install

this unit. A series of screws with

lock washers are used to secure the top

and bottom covers of the unit. Use

caution when handling the unit as the

lock washers may have rough edges. Do

NOT run your fingers over the top and

bottom covers of the unit.

4

206-4227

Page 5

IMPORTANT SAFETY INSTRUCTIONS

PCS200R Rack Installation

(also see pages 11 to 12)

• Wear a properly grounded, antistatic wrist strap

to avoid causing electrostatic (ESD) damage to

the PCS200R.

• Carefully slide the PCS200R into a standard

19-inch equipment rack.

• When mounting in the rack, make sure to use

the appropriate hardware. ALL FOUR MOUNTING SCREWS MUST BE USED.

• This equipment is not designed to support

other devices. Do NOT stack other equipment

on the top of the PCS200R.

• Rear cabling must be dressed and supported

so that the weight of the cabling is not a strain

on the PCS200R connectors.

• MOUNTING OF THE EQUIPMENT IN THE

RACK SHOULD BE SUCH THAT A HAZARDOUS CONDITION IS NOT ACHIEVED DUE TO

UNEVEN MECHANICAL LOADING.

Rack-mount Considerations

A. Elevated Operating Ambient

If installed in a closed or multi-unit rack

assembly, the operating ambient temperature

of the rack environment may be greater than

room ambient. Therefore, consideration should

be given to installing the equipment in an

environment compatible with the maximum

ambient temperature (Tma) specified by the

manufacturer (see Specifications information

in this document).

B. Reduced Air Flow

Installation of the equipment in a rack should

be such that the amount of air flow required

for safe operation of the equipment is not

compromised. To ventilate the system normally and avoid overheating, leave at least

1 inch (2.5 cm) on each side (including top

and bottom) of the PCS200R. Do NOT stack

other equipment on the top of the PCS200R.

Also, ensure that the unit’s AC power adapter

is never stacked or bundled with other AC

power adapters. Each adapter should have

adequate ventilation and should be isolated

from other heat sources.

C. Circuit Overloading

Consideration should be given to the

connection of the equipment to the supply

circuit and the effect that overloading of the

circuits might have on overcurrent protection

and supply wiring.

D. Reliable Earthing

Maintain reliable earthing of rack-mounted

equipment. Particular attention should be

given to supply connections other than direct

connections to the branch circuit (e.g., use of

power strips).

E. Mains Outlet Earthing

The apparatus with Class I construction must

be connected to a mains socket outlet with a

protective earthing connection.

206-4227

5

Page 6

Table of Contents

Safety Warnings ....................... 2

Important Safety Instructions. . . . . . . . . . . . 3 – 5

Table of Contents ...................... 6

PCS200R Product Description ............ 7

Setup Information ................... 8 – 9

Rear and Front Panel Overviews ......... 10

Rack Installation ...................11 – 12

Typical Rack Installation ...............11

Rack-mount Considerations ............ 12

System Setup .....................13 – 19

Typical Setup Flow Chart for PCS200R

with ASI Output .......................13

Typical Setup Flow Chart for PCS200R

with RF Output ........................14

Typical Setup Flow Chart for PCS200R

with IP Output ........................15

VPN Network Connections Overview .... 15

Typical System Installation ............. 16

Network and Communication Setup ....... 20

PCS200R Configuration Options. . . . . . . 21 – 30

Log In to the PCS200R and Access

the Main Menu ...................... 21

View System Information .............. 22

Configure Network Settings ............ 22

Set the Time Zone ................... 25

Set the Date and Time ................ 27

Change the Login Password ........... 28

Monitor the System .................. 29

Format the Solid State Drive File System . 30

Update the PCS200R Operating System

via Ethernet ........................ 30

Update the PCS200R Operating System

via Serial Link ....................... 31

Update the VPN Setup ................ 31

Shut Down the System ............... 32

Reset the System .................... 32

Exit the Current Session .............. 32

Reference: Using an SSD Storage

Device with the PCS200R ............33 – 34

Troubleshooting ................... 35 – 36

PCS200R Setup ..................... 35

PCS200R Communication ............. 36

Specifications ........................ 37

Document Revision History / Notes ....... 38

Open Source Software Notice ............ 39

Warranty .....................Back Cover

Notes

• Design and specications subject to change without prior notice.

• This document provides examples of typical command line interface displays. Your displays may vary from those

shown in this document.

6

206-4227

Page 7

PCS200R Product Description

The LG PCS200R Pro:Centric ® server is a stand-alone, remotely-controlled processor and

controller for the Pro:Centric system. The server can be used to capture data from an Internet

source, assemble the data as display pages, and output the pages in DTV format over ASI, RF,

or IP.

Features

• Three output options: ASI, RF, or IP

− ASI output: The PCS200R generates one channel for GEM data only or multiplexed

GEM/site data.

− RF output: Both QAM-B (6 MHz) and DVB-C (7 MHz or 8 MHz) modulations are supported.

The PCS200R generates one 256-QAM or 64-QAM RF channel for GEM/site data.

− IP output: The PCS200R generates two multicast streams for GEM/site data.

• Customer may work with content provider to create Pro:Idiom ® encrypted content on a

SATA solid state drive (SSD) for RF or IP video playout channels

− RF output: In addition to the GEM/site data channel, the PCS200R generates up to seven

contiguous 256-QAM or 64-QAM RF channels for video playout. Each of these channels

supports either two or three program streams multiplexed on each channel. This capability

provides output of up to 21 programs of video content.

− IP output: In addition to two multicast streams for GEM/site data, the PCS200R generates

21 multicast data streams for video playout. Each data stream supports one program. This

capability provides output of up to 21 programs of video content.

• Provides remote management capability over Ethernet

• Small, lightweight chassis

• 19-inch rack-mountable

• 1U height prole to minimize rack space usage

An Internet browser-based Admin Client graphical user interface (GUI), provided for system

integrator (SI) partners and lodging/institution administrators, facilitates support and

maintenance of the Pro:Centric system. The Admin Client enables users to remotely manage

system backups, output conguration, software updates, portal/information section content,

TV conguration settings, etc.

206-4227

7

Page 8

Setup Information

Check the following items before you begin the PCS200R installation and setup procedures.

Note: Once the PCS200R hardware is installed and the initial setup completed, output parameters

are congured in the Pro:Centric server Admin Client. Along with this document, it is recommended

that you have a copy of the Pro:Centric Server Admin Client User Guide readily available.

PCS200R

__ Unpack the PCS200R Pro:Centric server unit and all accessories.

PCS200R Accessories: • AC Power Cord and Adapter

• Four M3 x 5 mm screws for (optional) SATA SSD assembly

• Four lock washers for (optional) SATA SSD assembly

__ Select the location for mounting the PCS200R. Ensure adequate ventilation is available

__ Obtain the necessary attachment hardware to mount the PCS200R chassis in its targeted

location.

__ Plan and install the necessary cabling and network (Ethernet) and AC power access for

the PCS200R. You also will need the following to connect a PC directly to the PCS200R for

system setup purposes: FTDI TTL-USB cable (P/N TTL-232R-5V-AJ).

SATA Solid State Drive (Optional)

__ To provide additional media/video playout channels, a customer-supplied SATA solid state

drive may be installed in the SSD slot on the PCS200R rear panel. The solid state drive used

must be UL listed, FCC compliant, and/or other applicable agency-recognized/listed. (Maximum

current draw = +5V DC @ 2.0 Amps)

Video Channel Assignments for RF Output (QAM-B) with Solid State Drive

Each input program is limited to one-half or one-third of the output channel bitrates (Mbps), which

in turn are dependent on the modulation format. 256-QAM modulation supports up to 38.8 Mbps,

and 64-QAM modulation supports up to 26.97 Mbps.

__ Create a channel assignment plan for the installation site, or modify an existing plan to

incorporate the RF output of the PCS200R. Ensure that up to eight contiguous CATV broadcast channels are allocated for the PCS200R RF output. The PCS200R uses a 256-QAM or

64-QAM modulation format, thereby occupying approximately 48 MHz of frequency spectrum.

The RF start channel is user-assigned during system setup (in the Admin Client), and the

remaining channels (up to seven) are then automatically assigned per EIA-542 STD CATV

frequency allocation standards. For example, if the RF start channel assignment is channel 2,

the seven remaining channels will be 3, 4, 5, 6, 95, 96, and 97. Refer to EIA-542 STD CATV

frequency allocation tables for further information as required.

The highest available RF channel number for the PCS200R is 135. Thus, to allocate all eight

channels available for PCS200R RF output, the RF start channel must be set no higher than 128.

__ Find a location on the frequency spectrum that is free of existing noise.

.

8

206-4227

Page 9

Setup Information (Cont.)

Video Channel Assignments for RF Output (DVB-C) with Solid State Drive

Each input program is limited to one-half or one-third of the output channel bitrates (Mbps), which

in turn are dependent on the modulation format. 256-QAM modulation supports up to 45.05 Mbps

(7 MHz bandwidth) or 50.87 Mbps (8 MHz bandwidth), and 64-QAM modulation supports up to

33.79 Mbps (7 MHz bandwidth) or 38.15 Mbps (8 MHz bandwidth).

__ Create a channel assignment plan for the installation site, or modify an existing plan to

incorporate the RF output of the PCS200R. Ensure that up to eight contiguous CATV channel

frequencies are allocated for the PCS200R RF output. The PCS200R uses a 256-QAM or

64-QAM modulation format, thereby occupying approximately 56 MHz or 64 MHz (depending

on channel bandwidth) of frequency spectrum.

The RF start channel frequency is user-assigned, in KHz, during system setup (in the Admin

Client), and the remaining channel frequencies (up to seven) are then automatically assigned in

accordance with the specied bandwidth. For example, if the RF start channel frequency assignment is 57000 KHz with a 7 MHz bandwidth, the seven remaining channel frequencies will be

64000 KHz, 71000 KHz, 78000 KHz, 85000 KHz, 92000 KHz, 99000 KHz, and 106000 KHz.

The highest available RF channel frequency for the PCS200R is 861000 KHz.

__ Find a location on the frequency spectrum that is free of existing noise.

Video Channel Assignments for IP Output with Solid State Drive

Each IP stream is limited to 19.4 Mbps.

__ The PCS200R outputs IPv4 multicast streams. Ensure the institution’s IP network and room

receivers support IPv4 multicast and that the network is capable of selectively routing multicast

traffic. Refer to vendor equipment documentation for further information.

__ Create a channel assignment plan for the installation site, or modify an existing plan to

incorporate the IP output of the PCS200R. Ensure that up to 23 unused and unreserved IPv4

multicast addresses, within the designated range 224.0.0.0 to 239.255.255.255, are allocated

for the PCS200R IP output.

The IP start channel is user-assigned during system setup (in the Admin Client), and the

remaining channel assignments are then automatically incremented. For example, if the IP start

channel assignment is 227.0.0.40, the remaining channels will be 227.0.0.41, 227.0.0.42, etc.

__ Reserve one User Datagram Protocol (UDP) port for the multicast data streams. You can use

the system default (1234) or another unassigned port number, for example, 50000, 50001, etc.

The port must avoid conict with other protocols in use.

Note: Refer to the IANA IPv4 Multicast Address Space Registry and/or the IANA Service Name

and Transport Protocol Port Number Registry for further IP address/port information as required.

ASI Output (Optional)

ASI output supports up to 19.4 Mbps each for GEM and site data (total of 38.8 Mbps).

__ If the system is using ASI output, install the modulator and upconverter that will receive

the ASI output signal from the PCS200R. Refer to the manufacturer’s documentation.

206-4227

9

Page 10

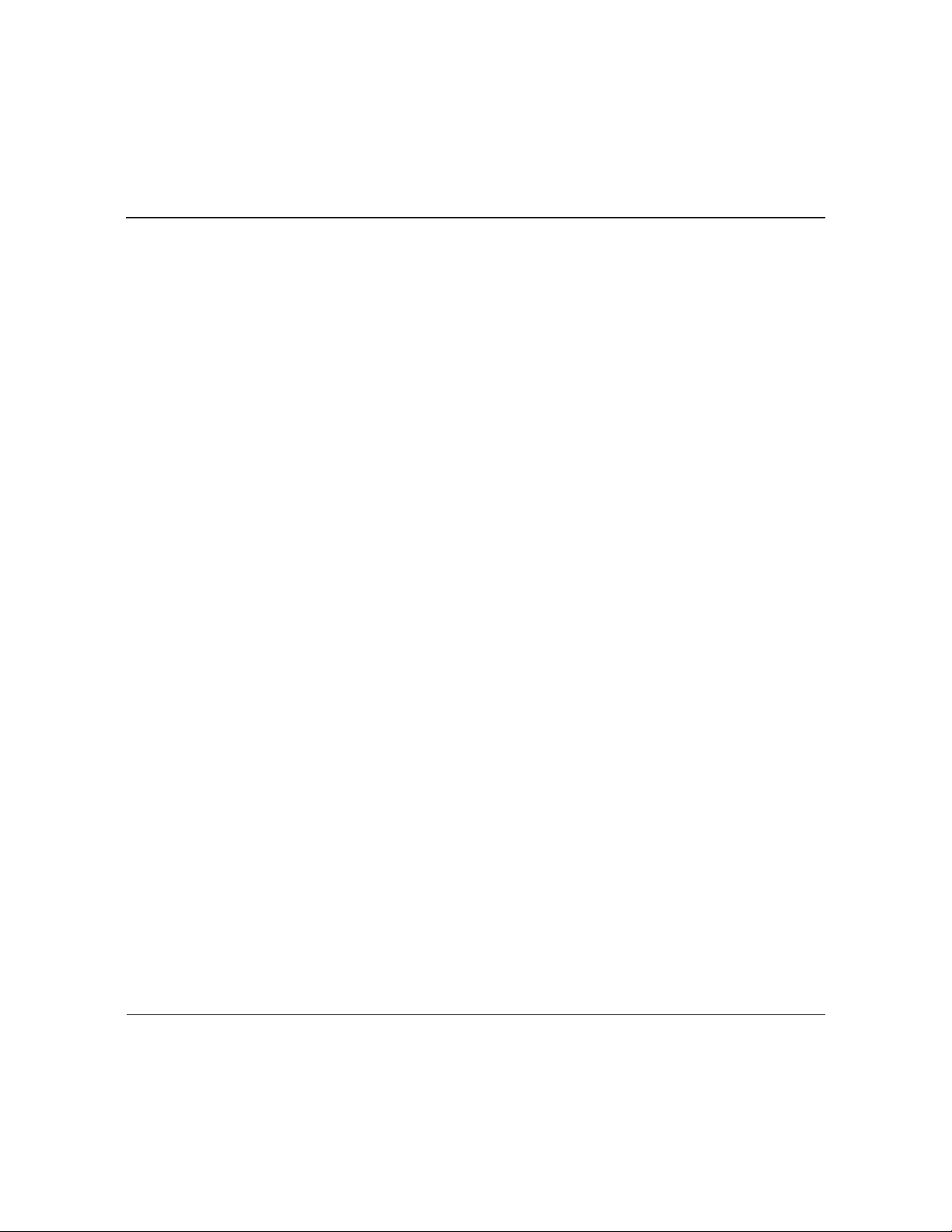

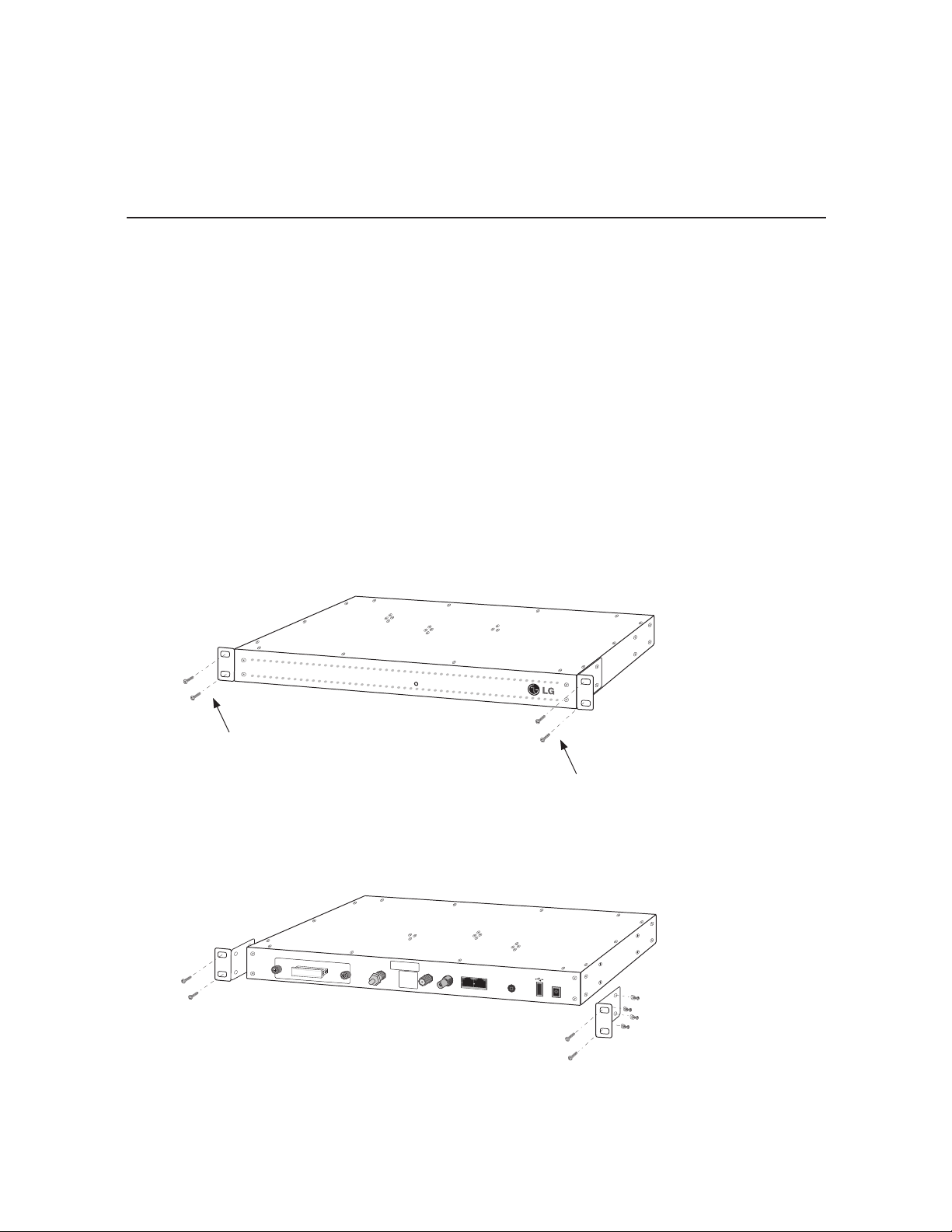

Rear and Front Panel Overviews

PCS200R Rear View

SSD (OPTIONAL)

MAXIMUM CURRENT +5V DC @ 2.0A

SSD Slot

(for SATA solid state

drive functionality)

RF OUT

(0 dBmV)

Disconnect Device

The AC mains plug is used as the disconnect device. The disconnect device

must remain readily operable.

MODEL: PCS200R DATE: xx/xx/xx

I IIIII IIIIIIII IIIIIIIIIIIIIIIIIIII IIIIIIIIIIIIIIIIIIIIII

RF-OUT

*201-1252008*

0 dBmV

FIRMWARE VER:

Rx.x

MAC ADDRESS:

<Eth0>

xx:xx:xx:xx:xx:xx

<Eth1>

xx:xx:xx:xx:xx:xx

RF OUT

ASI OUT

FEATURE

& CONTROL

(Ethernet) Ports

RF-OUT

ASI-OUT

Feature Port Control Port

Service Port

USB Port

(service use

Service Port

only)

SERVICE USE ONLY

POWER

12V

AC Power

Cord & Adapter

RF OUT (0 dBmV) Connector

Reserved for service technician use only. When not in use, this connector must

remain terminated with attached terminator accessory.

USB Port

Reserved for service technician use only.

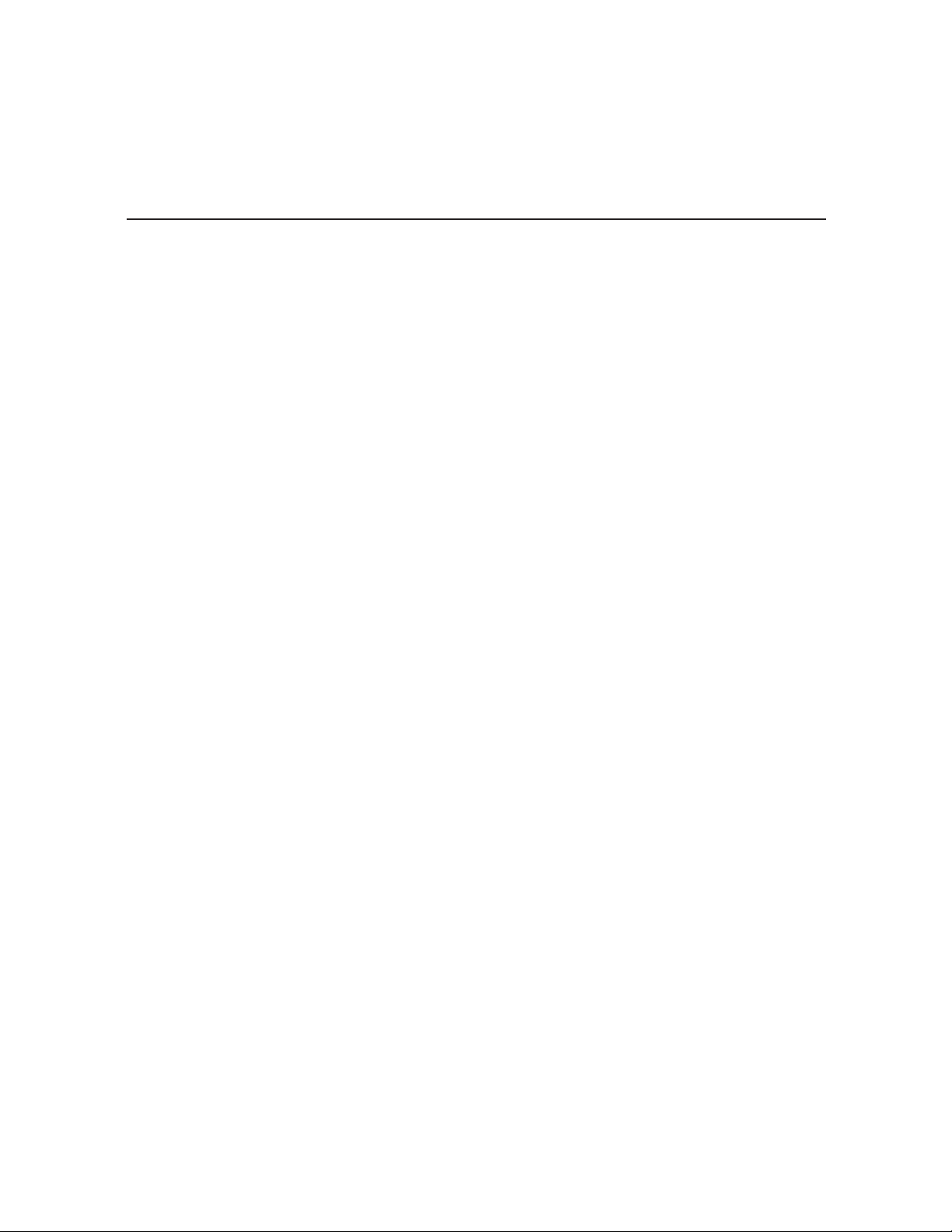

PCS200R Front View

PWR

POWER LED

Ventilation

Air flow must not be obstructed. To ventilate the system normally and avoid

overheating, leave at least 1 inch (2.5 cm) on each side (including top and bottom)

of the PCS200R. Do NOT stack other equipment on the top of the PCS200R.

Screws with Lock Washers

Only qualified service personnel should handle and install the PCS200R. A series

of screws with lock washers are used to secure the top and bottom covers of the

PCS200R. Use caution when handling the unit as the lock washers may have

rough edges. Do NOT run your fingers over the top and bottom covers of the unit.

10

206-4227

Page 11

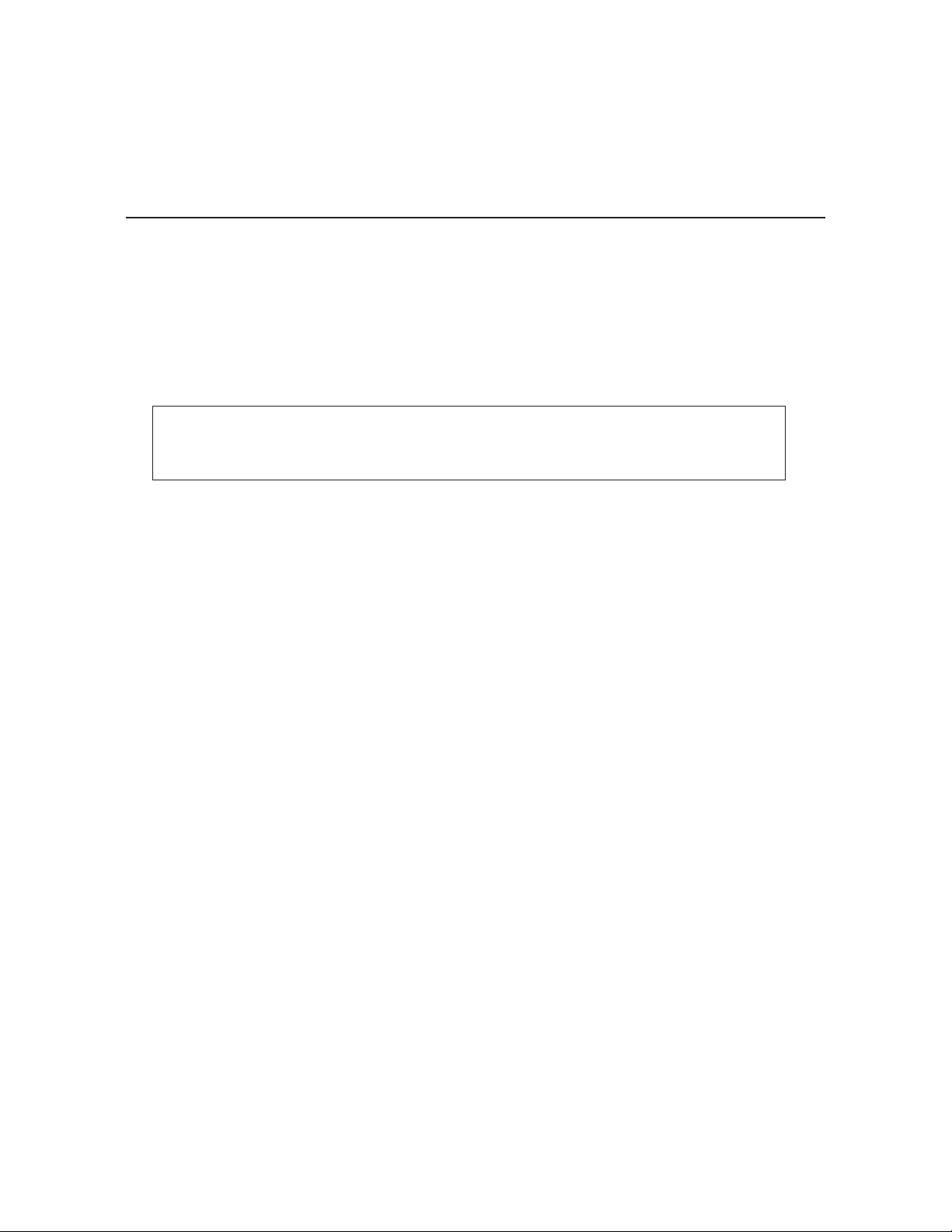

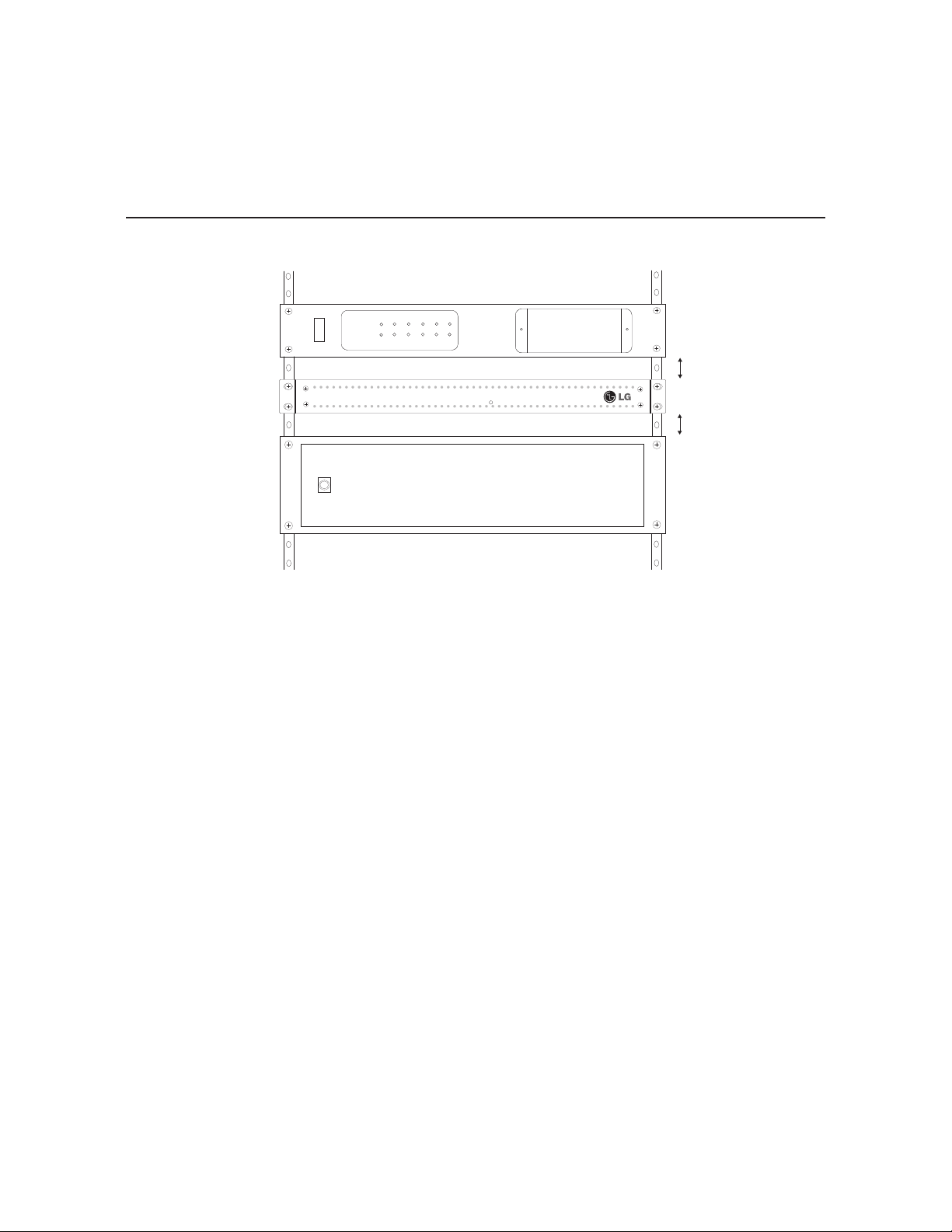

Rack Installation

PWR

Typical Rack Installation

1. To avoid causing electrostatic (ESD) damage to the PCS200R during installation, attach an

antistatic wrist strap to a properly grounded rack/object and put it on.

2. (Optional) As shipped, the PCS200R mounting brackets are attached ush with the front of

the unit (see diagram a). If desired, the mounting brackets may be detached from the unit

and reattached, for example, so that they are ush with the rear of the unit (see diagram b).

If you wish to change the location/orientation of the mounting brackets, carefully remove

each of the four (M4 x 10 mm) screws and attendant washers (one at and one lock washer

per screw) holding each bracket in place. Then, use the same screws and washers to

reattach the mounting brackets in the desired location.

3. Carefully slide the chassis into a standard 19-inch equipment rack.

4. Use all four mounting screws to secure the chassis to the rack.

(a)

206-4227

(b)

To rack

PWR

To rack

SSD (OPTIONAL)

MAXIMUM CURRENT +5V DC @ 2.0A

MODEL: PCS200R DATE: xx/xx/xx

I IIIII IIIIIIII IIIIIIIIIIIIIIIIIIII IIIIIIIIIIIIIIIIIIIIII

RF-OUT

*201-1252008*

0 dBmV

RF-OUT

ASI-OUT

FIRMWARE VER:

Rx.x

MAC ADDRESS:

<Eth0>

xx:xx:xx:xx:xx:xx

<Eth1>

xx:xx:xx:xx:xx:xx

Feature Port Control Port

Service Port

SERVICE USE ONLY

POWER

12V

Use at washer and

lock washer with each

M4 x 10 mm mounting

bracket screw.

11

Page 12

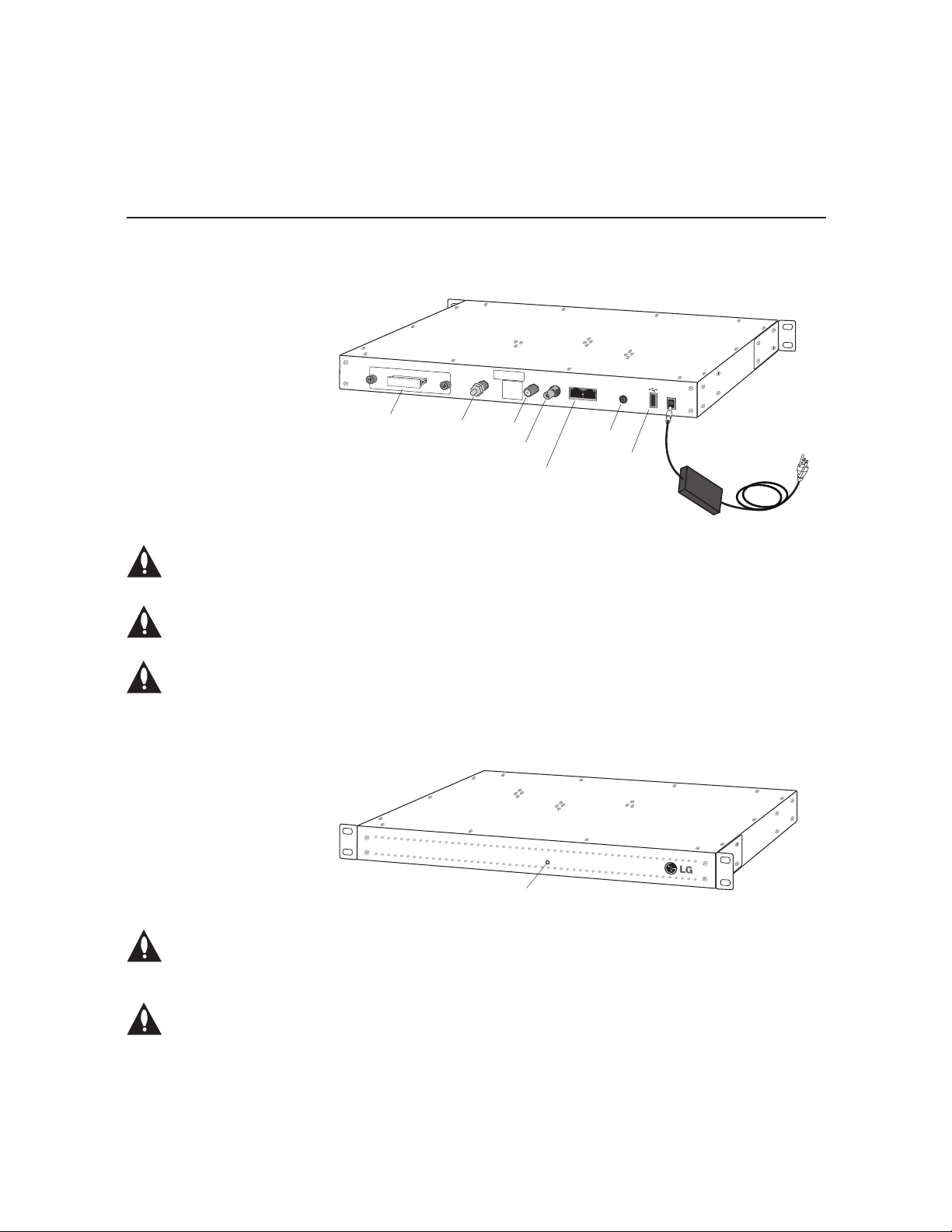

Rack Installation (Cont.)

Front View

of Rack Cabinet

1 inch minimum

PWR

1 inch minimum

Rack-mount Considerations

A. Elevated Operating Ambient

If installed in a closed or multi-unit rack assembly, the operating ambient temperature of the rack

environment may be greater than room ambient. Therefore, consideration should be given to

installing the equipment in an environment compatible with the maximum ambient temperature

(Tma) specified by the manufacturer (see Specifications information in this document).

B. Reduced Air Flow

Installation of the equipment in a rack should be such that the amount of air flow required for

safe operation of the equipment is not compromised. To ventilate the system normally and

avoid overheating, leave at least 1 inch (2.5 cm) on each side (including top and bottom) of the

PCS200R. Do NOT stack other equipment on the top of the PCS200R unit. Also, ensure that

the unit’s AC power adapter is never stacked or bundled with other AC power adapters. Each

adapter should have adequate ventilation and should be isolated from other heat sources.

C. Circuit Overloading

Consideration should be given to the connection of the equipment to the supply circuit and the

effect that overloading of the circuits might have on overcurrent protection and supply wiring.

D. Reliable Earthing

Maintain reliable earthing of rack-mounted equipment. Particular attention should be given to

supply connections other than direct connections to the branch circuit (e.g., use of power strips).

E. Mains Outlet Earthing

The apparatus with Class I construction must be connected to a mains socket outlet with a

protective earthing connection.

12

206-4227

Page 13

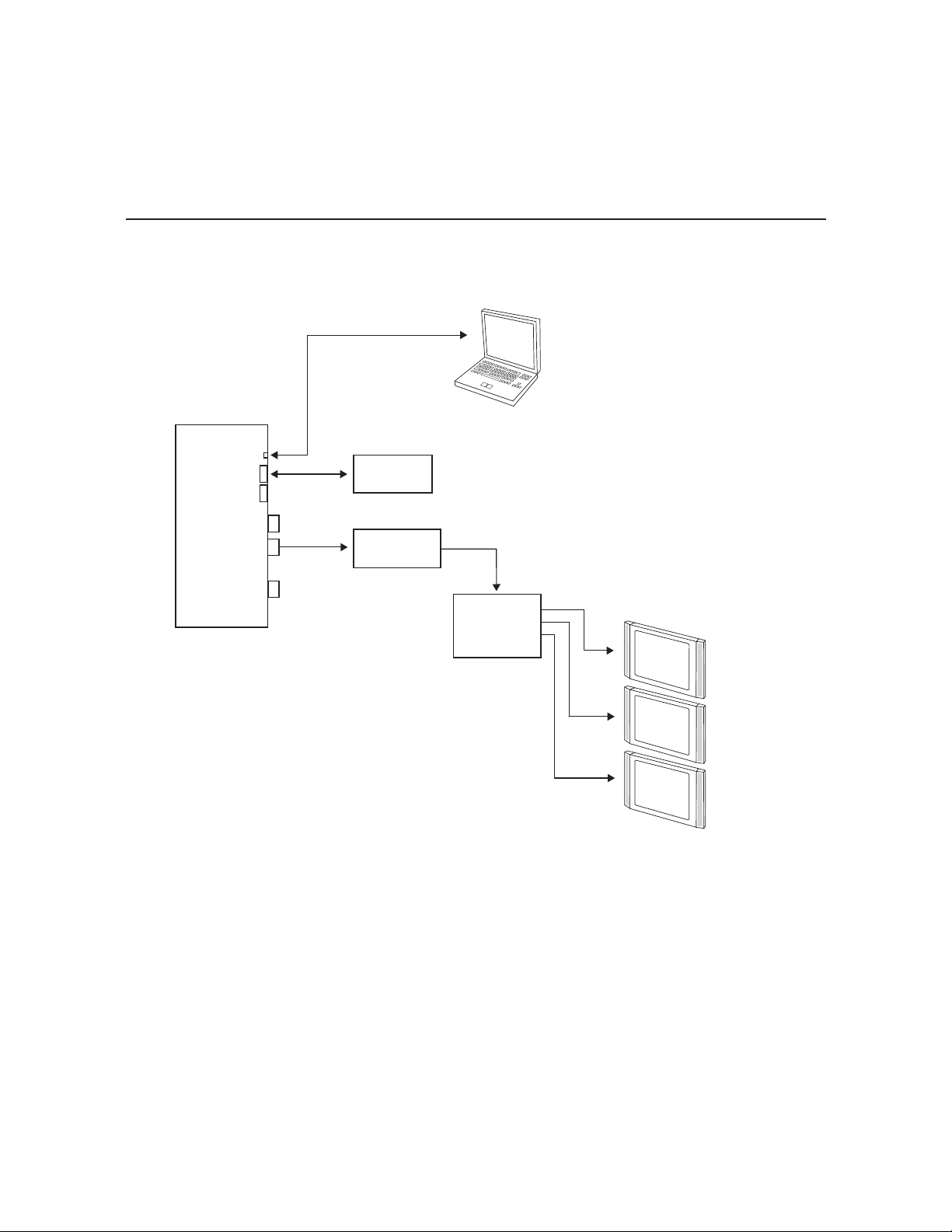

System Setup

Refer to the following diagrams, and complete the system installation as described on pages

16 to 19.

Caution: Do NOT make system connections until instructed to do so during the

system installation procedure. In some instances, configuration steps must be

performed before physical connections are made.

Typical Setup Flow Chart for PCS200R with ASI Output

Laptop

PC

Service Port

Connection

PCS200R

Control Port

Feature Port

ASI Out

RF Out

RF Out

(0 dBmV)

ASI

Coaxial

Cable

Network

ASI In

QAM

Modulator

IF Out

RF

Coaxial

Cable

IF In

DTV

Upconverter

RF Out

Combiner

RF

Distribution

System

RF

Cable

Room

Receiver

Room

Receiver

Room

Receiver

206-4227

13

Page 14

System Setup (Cont.)

Typical Setup Flow Chart for PCS200R with RF Output

Laptop

PC

Service Port

Connection

PCS200R

Control Port

Feature Port

ASI Out

RF Out

RF Out

(0 dBmV)

RF

Cable

Network

Combiner

RF

Distribution

System

Room

Receiver

Room

Receiver

Room

Receiver

14

206-4227

Page 15

System Setup (Cont.)

Typical Setup Flow Chart for PCS200R with IP Output

Laptop

PC

Service Port

Connection

PCS200R

Control Port

Feature Port

ASI Out

RF Out

RF Out

(0 dBmV)

1000BaseT (default)

Full Duplex

Network

CAT5E

Cable

VPN Network Connections Overview

Pro:Centric

VPN Server

Internet/

VPN

Laptop

PC

IP

Distribution

Network

VPN Client

PCS200R

Room

Receiver

Room

Receiver

Room

Receiver

206-4227

VPN Client

15

Page 16

System Setup (Cont.)

Typical System Installation

(see also Typical Setup Flow Charts and VPN Network Connections Overview diagrams)

1. (Optional) To provide capacity for additional media/video playout channels, install a SATA

solid state drive (customer-supplied) in the SSD slot on the PCS200R rear panel. See

Reference section, “Using an SSD Storage Device with the PCS200R,” for further information.

2. If your system is using ASI output, make the following connections; otherwise, go to step 3.

• Connect a 75 ohm BNC-to-BNC coaxial cable between ASI OUT on the PCS200R and

ASI IN on the modulator.

• Connect an RF coaxial cable between IF OUT on the modulator and IF IN on the

upconverter.

Note: The BNC cable must be less than 30 feet (9.2 meters) in length.

3. To enable remote management, connect one end of a CAT5 RJ-45 Ethernet cable to the

Control Port on the PCS200R rear panel, and connect the other end of the cable to the

institution’s network.

4. Connect the PCS200R power supply to the POWER connector on the PCS200R rear panel.

Then, plug the AC power cord into a powered AC line receptacle. When power is applied,

the PWR (Power) LED on the PCS200R front panel will initially flash red and then turn green

(blinking during boot-up).

The boot-up process for the PCS200R may take up to two minutes. When boot-up is

complete, the PWR LED on the PCS200R front panel will light continuously green.

5. Once the PWR LED is lit continuously (no longer blinking), use the FTDI TTL-232R-5V-AJ

cable to connect a PC to the Service Port on the PCS200R rear panel.

6. Using HyperTerminal or an equivalent terminal emulation program on the PC, congure the

serial port as follows: Bits per second/baud = 115200; Data bits = 8; Parity = None; Stop

bits = 1; Flow Control = None

Note: To avoid conguration errors, make sure the keyboard settings on the terminal

emulator assign the backspace character to Ctrl + H (ASCII 8).

Once the connection is established, you should see a login prompt. (If the login prompt is

not automatically displayed, press Enter to refresh the screen.)

7. At the

8. At the

login as:

prompt, type Password4Partners (case-sensitive) and press Enter.

Command >

PCS200R command prompt to view current menu, if desired.)

Note: After the system setup is complete, it is highly recommended that you

change the admin user password from its default value. See “Change the Login

Password” on page 28 for further information.

prompt, type admin and press Enter. Then, at the

prompt, type info and press Enter. (You can press Enter at any

password:

16

(Continued on next page)

206-4227

Page 17

System Setup (Cont.)

(Continued from previous page)

The initial System Information display identies PCS200R default conguration settings,

including the Control Port IP address and the output conguration, for example:

PCS200R Pro:Centric Server v7.4

Copyright (c) 2010 - 2015 Zenith Electronics LLC

SN:

Hardware ID:

OS version:

OS release:

Ctrl MAC:

Ctrl IP:

Feat MAC:

Feat IP:

VPN IP:

RF config:

RF channel:

Channels:

Local time:

201-12301011

2

Linux 3.4.0-zenith-pcs200+

#121 SMP Mon Dec 8 10:38:49 CST 2014

00:0C:63:40:36:14

10.1.2.3

00:0C:63:40:36:15

n/a

n/a

Mode 3, 256-QAM-B, RF: 6 MHz, 5.36 MSps, ASI: 38.81 Mbps

75

1

Mon Jan 19 14:42:02 EST 2015

9. Check the Ctrl IP (Control Port IP address) eld in the System Information display. By

default, the PCS200R uses DHCP; thus, the DHCP server, if congured, assigns an IP

address to the Control Port once the PCS200R successfully connects to the network.

• If the Crtl IP eld shows an IP address, the PCS200R is up and running on the network.

If you wish to congure a static IP address for the Control Port and/or if you need to

congure a static IP address for the Feature Port (for IP output purposes), continue with

step 10. Otherwise, you can go to step 11 at this time.

• If the network is congured for DHCP but the Ctrl IP eld is blank, refer to “Network Setup”

troubleshooting information on page 35.

• If the network is not congured for DHCP, you will need to congure a static IP address

for the PCS200R Control Port as described in step 10.

10. This step describes how to set a static IP address for the Control Port and/or Feature Port.

Caution: Setting a static IP address for the Control Port (for remote management

purposes) is optional. However, if you will be using IP output from the PCS200R,

you MUST configure the Feature Port as described in step (c) below.

a) At the

Command >

current network configuration, followed by the Network Configuration Menu.

prompt, type setip and press Enter. The system will display the

(Continued on next page)

206-4227

17

Page 18

System Setup (Cont.)

(Continued from previous page)

Use the Network Configuration Menu commands indicated below and follow the system

prompts to configure the port(s). See “Configure Network Settings” on pages 22 to 25

for further information.

b) Use the “eth0” and “dns” commands to congure the Control Port, as necessary.

c) Use the “eth1” command to congure the Feature Port, if required, for PCS200R IP

output.

Note that the Feature Port MUST be congured with a static IP address that is on a

different subnet than the Control Port IP address. Also, make sure the Feature Port

speed (default: 1000 Mbps) is appropriate for your system. If necessary, at the prompt

for the port speed, change the value to 100 Mbps.

d) When you are nished with network conguration, type exit at the Network Conguration

Menu

>

prompt. The system will display an overview of the new network conguration

and then prompt for conrmation to save the changes:

Do you want to save the new configuration? [y/n]:

Type y or n and press Enter, as appropriate.

Note: Review the New Network Configuration overview carefully before you confirm the

configuration settings. Ensure each of the addresses was entered correctly.

Note: If you changed the conguration of the port(s), you will be prompted to reset the

system. You may wait to reset the system until you are directed to do so in step 13.

11. (Optional) Set the date and time on the PCS200R.

By default, the PCS200R is synchronized with an NTP server and congured for the US

Eastern time zone. If the PCS200R is connected to the Internet, the NTP client will

periodically update the time setting on the PCS200R. You can set the time zone as

required. If the PCS200R is not connected to the Internet, you also have the option to

disable NTP synchronization and specify date and time data manually.

Use the PCS200R “tz” and/or “time” commands (available from the

as necessary, to set the date and time on the PCS200R.

• Use the “tz” command and follow the system prompts to change the time zone.

• Use the “time” command and follow the system prompts to change the NTP

conguration or manually congure the date and time parameters on the PCS200R.

See “Set the Time Zone” and “Set the Date and Time” on pages 25 to 28 for further

information.

Note: If you changed the time zone and/or the NTP conguration, you will be prompted to

reset the system. You may wait to reset the system until you are directed to do so in step 13.

Command >

prompt),

18

(Continued on next page)

206-4227

Page 19

System Setup (Cont.)

(Continued from previous page)

12. If a SATA solid state drive is installed (see step 1), the drive’s le system must be properly

formatted. If the drive was previously formatted for use with another PCS200R, you do not

need to reformat the drive. Otherwise, at the

Enter. Then, follow the system prompts to initiate the formatting.

Caution: This operation deletes any les that are currently present on the

drive. See “Format the Solid State Drive File System” on page 30 for further

information.

13. If you made any conguration changes in steps 10 and 11 that require a system reset, at

the

Command >

The reset process may take up to two minutes, after which the PCS200R resumes normal

operation.

14. Make the appropriate connection to the RF distribution system or IP distribution network

depending on the PCS200R output option to be used:

• ASI output: Connect the RF output on the upconverter to the RF distribution center

combiner, and balance the RF signal so that the Pro:Centric signal level at the TV(s) is

between 0 to +7 dBmV.

• RF output: Connect RF OUT on the PCS200R to the RF distribution center combiner,

and balance the RF signal so that the Pro:Centric signal level at the TV(s) is between 0

to +7 dBmV.

• IP output: Connect a CAT5E or better Ethernet cable between the Feature Port on the

PCS200R rear panel and the institution’s IP distribution network.

Caution (ASI/RF Output only): For proper system performance, the Pro:Centric

signal level at the TV input (ANTENNA IN) must be between 0 to +7 dBmV. Note

that additional equipment may be required to adjust the signal level.

Caution: When not in use, the RF OUT (0 dBmV) connector must remain

terminated with attached terminator accessory.

15. Congure the ASI/RF or IP output parameters and/or the Video Playout settings in the

Pro:Centric server Admin Client. Refer to the Pro:Centric Server Admin Client User

Guide for further information.

Note: By default, the server output is enabled for 256-QAM-B modulation (RF output), with

the data channel set to 75.

16. Check one or more room receivers to make sure all content is properly mapped and

available.

prompt, type reset and press Enter.

Command >

prompt, type format and press

206-4227

19

Page 20

Network and Communication Setup

This section describes PCS200R communication options for configuration purposes.

Note: Before you proceed with any additional configuration, the system should

be installed and operating as described in the system installation procedure on

pages 16 to 19.

Also note that configuration updates periodically require that you reset the PCS200R. Make

sure to reset the unit when directed to do so.

There are two options for communicating with the PCS200R:

• When the PCS200R is connected to an IP network, you can use an SSH client to communicate

with the PCS200R via a command line interface.

• To establish a direct connection to the PCS200R, connect a PC to the serial port on the

PCS200R rear panel using the FTDI TTL-USB cable (P/N TTL-232R-5V-AJ). Plug the USB

end of the cable into an open USB port on your PC. If necessary, install the device driver.

Plug the other end of the cable into the Service Port jack on the PCS200R rear panel.

Using HyperTerminal or an equivalent terminal emulation program on the PC, configure the

serial port as follows:

− Bits per second/baud = 115200

− Data bits = 8

− Parity = None

− Stop bits = 1

− Flow Control = None

Note: To avoid conguration errors, make sure the keyboard settings on the terminal

emulator assign the backspace character to Ctrl + H (ASCII 8).

You will need to know the “admin” user password in order to log in to the command line

interface. The default admin user password is “Password4Partners” (case-sensitive). If

necessary, for example, if the password has been changed from its default value, consult the

system administrator to obtain the current admin user password.

Note: The default network setting for the PCS200R is DHCP, in which case the server assigns

an IP address to the PCS200R. If necessary, consult the network administrator to obtain the IP

address that has been assigned to the PCS200R.

Note: If you want to connect the PC directly to the PCS200R Control Port using an Ethernet

CAT5E cable, in order to establish communication you must rst connect the PC to the

PCS200R Service Port and set the PCS200R’s IP address (see “Congure Network Settings”

on pages 22 to 25). The PCS200R’s IP address must be on the same subnet as the PC’s IP

address.

20

206-4227

Page 21

PCS200R Conguration Options

Log In to the PCS200R and Access the Main Menu

Note: The PCS200R must be connected to an IP network for SSH client access. For direct

access to the PCS200R Service Port, use the FTDI TTL-USB cable (P/N TTL-232R-5V-AJ).

See also “Network and Communication Setup” on page 20 for further information.

If necessary, consult the system administrator to obtain the current “admin” user password

before proceeding. The default admin user password is “Password4Partners” (case-sensitive).

1. Establish communication with the PCS200R using an SSH client or via a direct connection

to the PCS200R Service Port.

Once communication is established, you should see a login prompt. (If the login prompt is

not automatically displayed, press Enter to refresh the screen.)

2. At the

3. At the

4. At the

login as:

Password:

Command >

• Press Enter to display the PCS200R Main Menu (see example below).

• Type the desired command and press Enter.

prompt, type admin and press Enter.

prompt, type the admin password and press Enter.

prompt, either:

The following sections describe each of the configuration commands.

Note: You can always press Enter at the

Menu.

Example: PCS200R Main Menu

Command >

prompt to display the PCS200R Main

---------

Main Menu

---------

info System information

setip TCP/IP Setup Menu

tz Timezone setup

time Time setup

pwd Change password

monitor System monitor

format Format drive to ext3 file system

update Update

updser Update via serial link

vpn VPN setup

shut Shutdown the system

reset System Reset

exit End the session

Command >

206-4227

21

Page 22

PCS200R Conguration Options (Cont.)

View System Information

1. Log in to the PCS200R as described on the previous page.

2. At the

The System Information display identies important information about the PCS200R, including

the unit serial number, hardware ID (rmware version), software versions, MAC addresses, and

IP addresses, for example:

PCS200R Pro:Centric Server v7.4

Copyright (c) 2010 - 2015 Zenith Electronics LLC

SN: 201-12301011

Hardware ID: 2

OS version: Linux 3.4.0-zenith-pcs200+

OS release: #121 SMP Mon Dec 8 10:38:49 CST 2014

Ctrl MAC: 00:0C:63:40:36:14

Ctrl IP: 10.1.2.3

Feat MAC: 00:0C:63:40:36:15

Feat IP: n/a

VPN IP: n/a

RF config: Mode 3, 256-QAM-B, RF: 6 MHz, 5.36 MSps, ASI: 38.81 Mbps

RF channel: 75

Channels: 1

Local time: Mon Jan 19 14:42:02 EST 2015

Command >

prompt, type info and press Enter.

Note: If RF output is configured for DVB-C modulation, the display will identify the RF

frequency (in KHz) in place of the RF channel.

It is recommended that you record this information for future reference. If you nd it

necessary to call customer service or engineering support, please have this information

available.

Congure Network Settings

This option enables you to configure the network settings of the PCS200R Ethernet ports.

The Control Port is used for remote communication purposes, while the Feature Port is

designated for PCS200R IP output.

1. Log in to the PCS200R as described on the previous page.

2. At the

22

Command >

The system displays an overview of the current network conguration followed by the

Network Conguration Menu, for example:

prompt, type setip and press Enter.

(Continued on next page)

206-4227

Page 23

PCS200R Conguration Options (Cont.)

(Continued from previous page)

Current Network Configuration

Interface eth0

Host name: pcs200r

Using DHCP: YES

Interface eth1

Host name: pcs200r

Using DHCP: NO

Host IP address:

Network mask:

Gateway IP address:

Speed: 1000Mbps

DNS servers

Primary DNS: xxx.xxx.xxx.xxx

Secondary DNS: xxx.xxx.xxx.xxx

-------------------------Network Configuration Menu

------------------------- eth0 Configure Control Port IP

eth1 Configure Feature Port IP

dns Configure DNS

exit Exit network configuration

Choose item to modify >

3. Either:

• Continue with step 4 for information on modifying the IP conguration of either the Control

Port or the Feature Port.

• Go to step 10 for information on modifying the DNS conguration.

• To exit the Network Conguration Menu without modifying any settings, type exit at the

Network Conguration Menu

4. Type eth0 or eth1, as applicable, and press Enter to modify the conguration of the

Control Port or the Feature Port, respectively.

5. At the

6. (Control Port conguration only) At the

Host name [pcs200r]:

square brackets, or type a new host name and then press Enter.

DHCP, or type n to specify the network IP addresses. Then, press Enter.

>

prompt.

prompt, either press Enter to accept the default value in

Using DHCP (Y/N) [Y]:

prompt, type y to use

206-4227

(Continued on next page)

23

Page 24

PCS200R Conguration Options (Cont.)

(Continued from previous page)

7. If the port is NOT using DHCP, type the information requested at each of the following

prompts. Type each address in the format xxx.xxx.xxx.xxx, and press Enter after each entry.

Note: If the Feature Port is to be used for IP streaming, you MUST congure

the port with a static IP address that is on a different subnet than the Control

Port IP address.

This host IP address []:

Network mask []:

Gateway IP address []:

Note: If you are currently conguring the Feature Port, you will not be prompted for a

gateway IP address, though you will be prompted for the port speed (see step 8).

8. (Feature Port conguration only) At the

either press Enter to accept the default value in square brackets, or type “100” or “1000,”

as applicable, and press Enter to set the appropriate port speed (in Mbps).

9. Once you enter the gateway address (eth0) or the port speed (eth1), the system will

redisplay the Network Configuration Menu.

• To modify the conguration of the second Ethernet port, repeat steps 4 to 8.

• To modify the DNS conguration, continue with step 10.

• If no additional network conguration is required, go to step 11.

10. To change the DNS conguration, type dns and press Enter.

At each of the following prompts, type the information requested. Type each address in

the format xxx.xxx.xxx.xxx, and press Enter after each entry.

Configuring DNS

Primary DNS IP address []:

Secondary DNS IP address []:

(Control Port conguration only)

Enter Speed 100 or 1000 [1000]:

prompt,

Once you enter the secondary DNS IP address, the system will redisplay the Network

Configuration Menu. You can select another option to modify (see previous steps) or you

can exit as described below.

11. When you are nished with network conguration, type exit at the Network Conguration

Menu

>

prompt.

The system will display an overview of the new network conguration and then prompt for

conrmation to save the changes, for example:

New Network Configuration

Interface eth0

Host name: pcs200r

Using DHCP: YES

(Continued on next page)

24

206-4227

Page 25

PCS200R Conguration Options (Cont.)

(Continued from previous page)

Interface eth1

Host name: pcs200r

Using DHCP: NO

Host IP address: xxx.xxx.xxx.xxx

Network mask: xxx.xxx.xxx.xxx

Gateway IP address:

Speed: 1000Mbps

DNS servers

Primary DNS: xxx.xxx.xxx.xxx

Secondary DNS: xxx.xxx.xxx.xxx

Do you want to save the new configuration? [y/n]:

12. Type y or n and press Enter, as appropriate.

If you opt NOT to save the new configuration, the system will return immediately to the

Main Menu

updates and prompt you to reset the system:

New configuration has been saved. Please restart the system.

Command >

prompt. Otherwise, the system will confirm the configuration

13. If you are ready to reset the system immediately, at the

and press Enter (see “Reset the System” on page 32 for further information).

Note: If you intend to modify additional conguration settings during the current session,

you may wait until all changes are complete before you reset the system.

Command >

prompt, type reset

Set the Time Zone

Note: See “Set the Date and Time” on page 27 for information on setting the date and time

for the PCS200R.

1. Log in to the PCS200R as described on page 21.

2. At the

The system displays the current time zone information for the PCS200R and prompts you

3. Either:

Command >

to specify whether or not you wish to change the time zone.

prompt, type tz and press Enter.

Current time zone is: America/New York

Change the time zone? [y/n]:

• Type n and press Enter to return to the Main Menu

the current time zone.

• Type y and press Enter to change the time zone. Then, continue with step 4.

Command >

prompt without changing

(Continued on next page)

206-4227

25

Page 26

PCS200R Conguration Options (Cont.)

(Continued from previous page)

4. The system will display the following prompt for a location, followed by a list of options:

Please identify a location so that time zone rules can be set correctly.

Please select a continent or ocean.

At the

5. The system will display the following prompt for a country, followed by a list of options:

6. The system will display the following prompt for a region, followed by a list of options:

At the

#?

prompt, type the number that corresponds to the appropriate option for your

location, and then press Enter.

Please select a country.

At the

#?

prompt, type the number that corresponds to the appropriate option for your

country, and then press Enter.

Please select one of the following time zone regions.

#?

prompt, type the number that corresponds to the appropriate option for your

region, and then press Enter.

After you specify the time zone region, the system displays an overview of your location

selections and prompts for conrmation, for example:

The following information has been given:

United States

Central Time

Therefore TZ=’America/Chicago’ will be used.

Local time is now: Mon Jan 19 16:23:10 CDT 2015.

Universal Time is now: Mon Jan 19 22:23:10 UTC 2015.

Is the above information OK?

1) Yes

2) No

#?

7. Either:

• Type 1 and press Enter if the information in the display is correct. The system will conrm

the setting and then prompt you to reset the PCS200R:

Time zone has been set. Please reset the board.

Continue with step 8.

• Type 2 and press Enter to return to the initial location prompt and reset the time zone

(repeat this procedure from step 4).

8. If you are ready to reset the system immediately, at the

and press Enter (see “Reset the System” on page 32 for further information).

Note: If you intend to modify additional conguration settings during the current session,

you may wait until all changes are complete before you reset the system.

26

Command >

prompt, type reset

206-4227

Page 27

PCS200R Conguration Options (Cont.)

Set the Date and Time

By default, the PCS200R is synchronized with an NTP server and congured for the US

Eastern time zone. If the PCS200R is connected to the Internet, the NTP client will periodically

update the time setting on the PCS200R. If the PCS200R is not connected to the Internet, you

also have the option to disable NTP synchronization and specify date and time data manually.

Refer to “Set the Time Zone” above for information on setting the time zone.

1. Log in to the PCS200R as described on page 21.

2. At the

3. At the

4. The remaining steps depend on whether or not you opted in the previous step to synchronize

Command >

Synchronize time automatically via NTP (Y/N) ? [Y]:

• Type y and press Enter if you intend to use an NTP server for time synchronization.

• Type n and press Enter to set the time manually.

time via an NTP client. Refer to the appropriate subsection below.

prompt, type time and press Enter.

prompt, either:

Synchronize Time via NTP Client

a) At the

b) At the

Enter a new NTP server IP: [time.nist.gov]:

Enter to accept the default value in square brackets, or type the appropriate NTP server

name or IP address and press Enter.

Enter a new NTP update interval, in hours [12]>

press Enter to accept the default value in square brackets, or type the appropriate NTP

update interval (in hours) and press Enter.

The system will display conrmation and then prompt you to reset the PCS200R, for

example:

prompt, either press

prompt, either

Time will be synchronized every 12 hours via NTP from server: xxx

Please reset the board

(where xxx is the NTP server name or IP address you provided above)

c) If you are ready to reset the system immediately, at the

reset and press Enter (see “Reset the System” on page 32 for further information).

Note: If you intend to modify additional conguration settings during the current session,

you may wait until all changes are complete before you reset the system.

Manual Specication of Date and Time

The system will display the current time (for example:

18:49:56)

a) At each of the following prompts, type the year, month, and day, respectively. Note that

all three of these elds require numerical values. Press Enter after each entry.

and then initiate a series of prompts to enable you to set the time.

Command >

prompt, type

Current time: 2015-01-19

(Continued on next page)

206-4227

27

Page 28

PCS200R Conguration Options (Cont.)

(Continued from previous page)

If applicable, you can also press Enter at each prompt to accept the default value in

square brackets.

Enter new year [2015]>

Enter new month [01]>

Enter new day [19]>

b) At each of the following prompts, type the hour and minute, respectively. Note that the

hour should be entered in 24-hour format. Press Enter after each entry.

If applicable, you can also press Enter at each prompt to accept the default value in

square brackets.

Enter new hour (0-23) [18]>

Enter new minute [49]>

c) The system will display the new time and then prompt for conrmation, for example:

New time: 2015-01-19 18:53:00

Apply? [y/n]

Either, type y and press Enter to apply the new conguration to the system, or type n and

press Enter to return to the

If you apply the new conguration, the system will display conrmation, for example:

New time is set

Command >

prompt without changing the time conguration.

Change the Login Password

For security purposes, it is recommended that the admin user login password be unique to

the system. Note that the login password is case-sensitive.

1. Log in to the PCS200R as described on page 21.

2. At the

3. Type the current password and press Enter. The system will then prompt you to type and

4. Type and then retype the new password at the prompts. Press Enter after each entry.

Once you complete the Password elds successfully, the system displays conrmation:

Password for admin changed by admin.

28

Command >

The system prompts for the current admin user password:

prompt, type pwd and press Enter.

Changing password for admin

Old password:

retype the new password:

New password:

Retype password:

206-4227

Page 29

PCS200R Conguration Options (Cont.)

Monitor the System

This option enables you to view dynamic system streaming data.

1. Log in to the PCS200R as described on page 21.

2. At the

3. The system data will refresh every second. When you are nished monitoring streaming

Example: System Monitor Display

SYSTEM MONITOR

Date: 2015-01-19 16:44:27

SN: 401-12080008

Version: 1.1

Output: RF_QAM256_6M

Pg/RF: 2

Command >

prompt, type monitor and press Enter to display the current system

data, for example:

data, press Enter to stop the system monitor and return to the

Command >

prompt.

Bitrates (Mbps):

------+--------------------+---------+-------+------+--------- Slot | Content | Secs | Mbit | Pct | RF Out

------+--------------------+---------+-------+------+--------- 1 | GEM Data |

2 | Video1.ts |

4 | Video2.ts |

5 | Video3.trp |

7 | Video4.ts |

8 | Video5.trp |

10 | Video6.ts |

11 | |

13 | Video7.ts |

14 | |

16 | |

17 | |

19 | |

20 | |

22 | |

23 | |

685 | 8.9 | - | 75-1

100 | 5.3 | 86 | 75-47 :)

6 | 5.1 | 1 | 76-1 :)

205 | 4.6 | 78 | 76-2 :)

40 | 4.2 | 12 | 77-1 :)

172 | 2.7 | 66 | 77-2 :)

12 | 3.5 | 3 | 78-1 :)

- | 0.0 | - | 78-2

171 | 4.7 | 94 | 79-1 :)

- | 0.0 | - | 79-2

- | 0.0 | - | 80-1

- | 0.0 | - | 80-2

- | 0.0 | - | 81-1

- | 0.0 | - | 81-2

- | 0.0 | - | 82-1

- | 0.0 | - | 82-2

------+--------------------+---------+-------+------+---------Press <Enter> key to exit the monitor

Note: This example shows data for a system that is congured for QAM-B RF output (the rst

channel is reserved for GEM/site data). If a solid state drive is installed in the server’s SSD

slot, the system monitor display shows streaming data for each of the active video programs.

206-4227

29

Page 30

PCS200R Conguration Options (Cont.)

Format the Solid State Drive File System

This command formats the le system of the solid state drive installed in the PCS200R SSD

slot and is essential for video playout operation (see Reference section, “Using an SSD Storage

Device with the PCS200R,” for further information).

Note: If the drive was previously formatted for use with a different PCS200R server, you do

not need to reformat the le system.

Caution: Any les that are currently loaded on the solid state drive will be deleted

during formatting; it is not possible to recover les once the formatting is initiated.

1. Log in to the PCS200R as described on page 21.

2. At the

3. Either type y and press Enter to continue, or type n and press Enter to return to the Main

If you elect to continue, the system will then prompt you to re-enter the admin user

4. Type the admin password and press Enter.

Formatting progress is displayed on the screen. When formatting is complete, the system

redisplays the

Command >

The system will prompt for conrmation:

prompt, type format and press Enter.

Are you sure you want to continue? [y/n]:

Menu without formatting the drive.

password before initiating the formatting process.

Please re-enter the admin password to format the drive.

Password:

Command >

prompt.

Update the PCS200R Operating System via Ethernet

Caution: Do NOT initiate simultaneous menu sessions while a software update

is in progress. Doing so may interfere with the active process and may corrupt

the system configuration and/or cause the PCS200R to cease normal operation.

This option enables you to update the PCS200R operating system via the Ethernet. The

appropriate update file must be provided by LG; the system will not download an improper file.

Note: See “Update the PCS200R Operating System via Serial Link” on the following page for

information on updating software via a serial link.

1. Log in to the PCS200R as described on page 21.

2. At the

3. At the

30

Command >

prompt, type update and press Enter.

Enter update filename:

press Enter.

prompt, type in the software update lename and

(Continued on next page)

206-4227

Page 31

PCS200R Conguration Options (Cont.)

(Continued from previous page)

The system will initiate the download and conrm progress, for example:

Downloading file: pcs200r_app_xxxx.upd

4. When the update is successfully completed, reset the system (see “Reset the System” on

the following page for further information).

Update the PCS200R Operating System via Serial Link

Caution: Do NOT initiate simultaneous menu sessions while a software update is

in progress. Doing so may interfere with the active process and may corrupt the

system configuration and/or cause the PCS200R to cease normal operation.

This option enables you to update the PCS200R operating system via a serial link to the

PCS200R. The appropriate update file must be provided by LG; the system will not transfer an

improper file.

Note: See “Update the PCS200R Operating System via Ethernet” on the previous page for

information on updating software via the Ethernet.

1. Log in to the PCS200R as described on page 21.

2. At the

3. At the

The system will display progress messages as well as the result of the update process

4. When the update is successfully completed, reset the system (see “Reset the System” on

Command >

Send file using XMODEM

Xmodem protocol. For example, in HyperTerminal, select Transfer and then Send File....

In the Send File window, enter or select the appropriate filename in the Filename field,

and select Xmodem in the Protocol field.

(which may take several minutes).

the following page for further information).

prompt, type updser and press Enter.

prompt, transfer the new application/OS le using

Update the VPN Setup

This option enables you to update the VPN client via a serial link to the PCS200R. The

appropriate update file must be provided by LG; the system will not transfer an improper file.

1. Log in to the PCS200R as described on page 21.

2. At the

3. At the

206-4227

Command >

Send VPN client file using Xmodem ...

client le using Xmodem protocol. For example, in HyperTerminal, select Transfer and

then Send File.... In the Send File window, enter or select the appropriate filename in the

Filename field, and select Xmodem in the Protocol field.

prompt, type vpn and press Enter.

prompt, transfer the new VPN

(Continued on next page)

31

Page 32

PCS200R Conguration Options (Cont.)

(Continued from previous page)

The system will display progress messages as well as the result of the update process

(which may take several minutes).

4. When the update is successfully completed, reset the system (see “Reset the System”

below for further information).

Shut Down the System

This command allows you to shut down the system in an orderly manner. Use this command

to shut down the PCS200R, for example, if you intend to physically move the unit from one

location to another. It is also recommended that you run this command from the PCS200R

Service Port in order to track detailed shutdown log messages.

Note: Once you use this command, you must remove power from (i.e., unplug) the unit and

then plug the AC power cord back into a powered AC line receptacle when you are ready to

restart the server. It is not possible to restart the server remotely.

1. Log in to the PCS200R as described on page 21.

2. At the

Command >

The system will prompt for conrmation:

prompt, type shut and press Enter.

Are you sure you want to shut down the system? [y/n]:

3. Either:

• Type y and press Enter to shut down the system immediately. The shutdown typically

takes about a minute. When the PCS200R is in its shutdown state, the front panel LED

will blink steadily green.

• Type n and press Enter to return to the Main Menu without shutting down the system.

Reset the System

1. If not already logged in, log in to the PCS200R as described on page 21.

2. At the

Command >

The system will prompt for conrmation:

prompt, type reset and press Enter.

Are you sure you want to reset the system? [y/n]:

3. Either:

• Type y and press Enter to initiate an immediate reset of the PCS200R. The reset process

may take up to two minutes, after which the system resumes normal operation.

• Type n and press Enter to return to the Main Menu without resetting the system.

Exit the Current Session

At the

Command >

32

prompt, type exit and press Enter to end the current session.

206-4227

Page 33

Reference: Using an SSD Storage Device with the

PCS200R

To provide capacity for additional media/video playout channels, a (customer-supplied) SATA

solid state drive may be installed in the SSD slot on the PCS200R rear panel. This section

describes how to install the drive and also provides information on the required formatting.

Install the Solid State Drive

You will need to have available the four M3 x 5 mm screws and attendant washers (one lock

washer per screw) shipped with the PCS200R. These will be used to attach the solid state

drive to the PCS200R SSD drive tray assembly.

Caution: The Pro:Centric server is NOT designed to be hot-swappable!!!

Power to the PCS200R must be removed before the solid state drive is inserted

or removed.

Caution: The solid state drive used must be UL listed, FCC compliant, and/or

other applicable agency-recognized/listed. (Maximum current draw = +5V DC @

2.0 Amps)

Caution: The solid state drive must be inserted and removed by qualied service

personnel only.

1. Log in to the PCS200R command line interface and use the “shut” command to shut down

the system in an orderly manner. See “Shut Down the System” on page 32 for further

information.

2. Put on a properly grounded, antistatic wrist strap to avoid causing electrostatic (ESD)

damage both to the solid state drive and the PCS200R.

3. Unpack the solid state drive unit.

4. Remove the PCS200R AC power cord from the AC line receptacle from which it is receiving

power.

5. Disengage the SSD slot cover from the PCS200R rear panel by turning the thumbscrew

on each side of the cover counterclockwise (use a Phillips screwdriver if necessary). Then,

slowly, slide out the SSD drive tray assembly.

Caution: As shipped, the cabling/SATA connector for the solid state drive is

connected by zip tie to the rear end of the SSD drive tray assembly. Use

scissors or a similar tool to remove the zip tie, taking care not to damage the

cables.

6. Place the solid state drive onto the drive tray, and use the four M3 x 5 mm screws and

washers to attach it to the drive tray assembly. You may attach the drive either from the

bottom or from the sides (see diagram a on following page).

7. Plug the PCS200R SATA connector/cabling into the solid state drive (see diagram b on

following page).

(Continued on next page)

206-4227

33

Page 34

Reference: Using an SSD Storage Device with the

Cabling/SATA

connector initially

will be tied here.

Attach the four M3 x 5 mm

screws and washers either

at the sides or the bottom

of the drive tray assembly.

PCS200R (Cont.)

(Continued from previous page)

8. Slide the drive tray assembly back into the PCS200R. Then, engage and tighten the

thumbscrew on each side of the slot cover securely.

Note: It is recommended that you use a Phillips screwdriver to secure the

thumbscrews on the SSD slot cover.

9. Plug the PCS200R AC power cord back into its powered AC line receptacle to restore

power. After it is powered back on, the PCS200R resumes normal operation.

(a)

Cabling/SATA

connector initially

will be tied here.

Attach the four M3 x 5 mm

screws and washers either

at the sides or the bottom

of the drive tray assembly.

(b)

Format the Solid State Drive

Caution: In order to use the solid state drive for video playout, you MUST format

the le system. Note that during formatting, any les that are currently loaded on

the solid state drive will be deleted.

Log in to the PCS200R command line interface and use the “format” command to format

the drive’s le system. See “Format the Solid State Drive File System” on page 30 for further

information. All additional video playout conguration is performed in the Pro:Centric server

Admin Client (refer to the Pro:Centric Server Admin Client User Guide).

Note: If the drive was previously formatted for use with another PCS200R server, you do not

need to reformat the le system.

34

206-4227

Page 35

Troubleshooting

PCS200R Setup

The following sections provide basic troubleshooting information for the PCS200R.

Equipment Setup Review

• Make sure all connectors and connections are tight and secure on all entertainment system

components.

• Check the PCS200R LED. Under standard operating conditions, i.e., when the PCS200R

is booted and operating normally, the PWR (Power) LED on the PCS200R front panel is

continuously lit green. If there is a hardware fault, the PWR LED will turn and stay red.

Note: When power is rst applied to the PCS200R, the PWR LED initially flashes red and

then turns green (blinking during boot-up).

Network Setup

If the network is configured for DHCP but the PCS200R has not been assigned an IP

address, i.e., the Ctrl IP field in the PCS200R System Information display is blank:

1. Check the Control Port connector on the rear panel of the PCS200R. Make sure the

cable connection is tight and secure.

2. Observe the green LED on the Control Port. Once the PCS200R is connected to the

network, the LED will be lit continuously.

3. Contact the network administrator to verify the network status and check that the DHCP

server is working properly.

206-4227

35

Page 36

Troubleshooting (Cont.)

PCS200R Communication

If you are unable to establish remote communication with the PCS200R, refer to the

following flow chart.

Cannot Communicate

with PCS200R

To verify the PCS200R IP address:

Check that the proper IP

address for the PCS200R

is being targeted. If

necessary, adjust and then

reattempt communication.

• If DHCP is enabled, check the router for DHCP IP address

assignments to determine whether the proper IP address is being

used to communicate with the PCS200R.

• If DHCP is not enabled, connect a PC to the PCS200R Service

Port, display the System Information, and ensure the IP address

shown in the Ctrl IP field is the IP address being used to

communicate with the PCS200R. If necessary, update the Control

Port configuration as described in this document.

Problem

solved?

No

Ensure your PC’s IP address

is on the same subnet as the

PCS200R’s IP address. If

necessary, adjust and then

reattempt communication.

Problem

solved?

No

Contact LG.

Yes

Yes

End

Note: For example, if the PCS200R is

configured with IP address: 192.168.1.x

and Network mask: 255.255.255.0, the

PC’s IP address cannot be: 192.168.2.x.

End

36

206-4227

Page 37

Dimensions

Height: 1.692 inches (42.977 mm)

Width: 19.0 inches (482.6 mm) (for EIA standard 19-inch rack mount)

Depth: 8.5 inches (215.9 mm)

Weight: 5.65 pounds (2.56 kgrms) rack-only weight

Specications

Environmental Operating Conditions

Temperature (Tma): 0° to 40° Celsius

32° to 104° Fahrenheit

Humidity: 95% non-condensing

Electrical

RF Out Connectors (2) *: 75 Ohm, Type ‘F’

Frequency: VHF/UHF 54-865 MHz

RF Output Span : Up to 8 Contiguous Channels (typically 48–64 MHz)

RF Output Frequency Range : 54 MHz to 865 MHz

Active Output Level at RF Out jacks : -1 dBm (+47.75 dBmV) Typical

Test Output Level: -47.75 dBm (+1 dBmV) Typical

Frequency Accuracy: ±5 ppm

Impedance at ASI Out jack: 75 Ohms

Level at ASI Out jack: 800 mv

DC Input: +12V DC @ 3.25 Amps

Ethernet Connector (Control Port): 10/100/1000BaseT, RJ-45

Ethernet Connector (Feature Port): 100/1000BaseT Full Duplex, RJ-45

USB Port *: USB 2.0

Solid State Drive: UL listed, FCC compliant, and/or other applicable agency-recognized/listed

(Maximum current draw = +5V DC @ 2.0 Amps)

Modulation Specications

Standard: ITU-T J.83 Annex B (QAM-B)

Constellations: 64-QAM, 256-QAM

Symbol Rate: 64-QAM 5.056941 MBaud

256-QAM 5.360537 MBaud

Interleaving: Fixed I = 128, J = 1

Standard: EN 300 429 V1.2.1 (DVB-C)

Constellations: 64-QAM, 256-QAM

Symbol Rate: 64-QAM 6.9 MBaud

64-QAM 6.111 MBaud

256-QAM 6.9 MBaud

256-QAM 6.111 MBaud

Environmental Storage Conditions

Temperature: -20° to 70° Celsius

-4° to 158° Fahrenheit

Humidity: 95% non-condensing

* RF OUT (0 dBmV) connector and USB port reserved for service technician use only.

Note: Design and specications subject to change without prior notice.

206-4227

37

Page 38

Document Revision History / Notes

Document Revision History

Date Description

June 2014 Revision A: New document

July 2014 Revision B: FCC notice update

October 2014 Revision C: New system shutdown command

December 2014 Revision D: Safety warning update

February 2015 Revision E: SSD and system monitor updates