Page 1

Preparation for VCO Adjustment

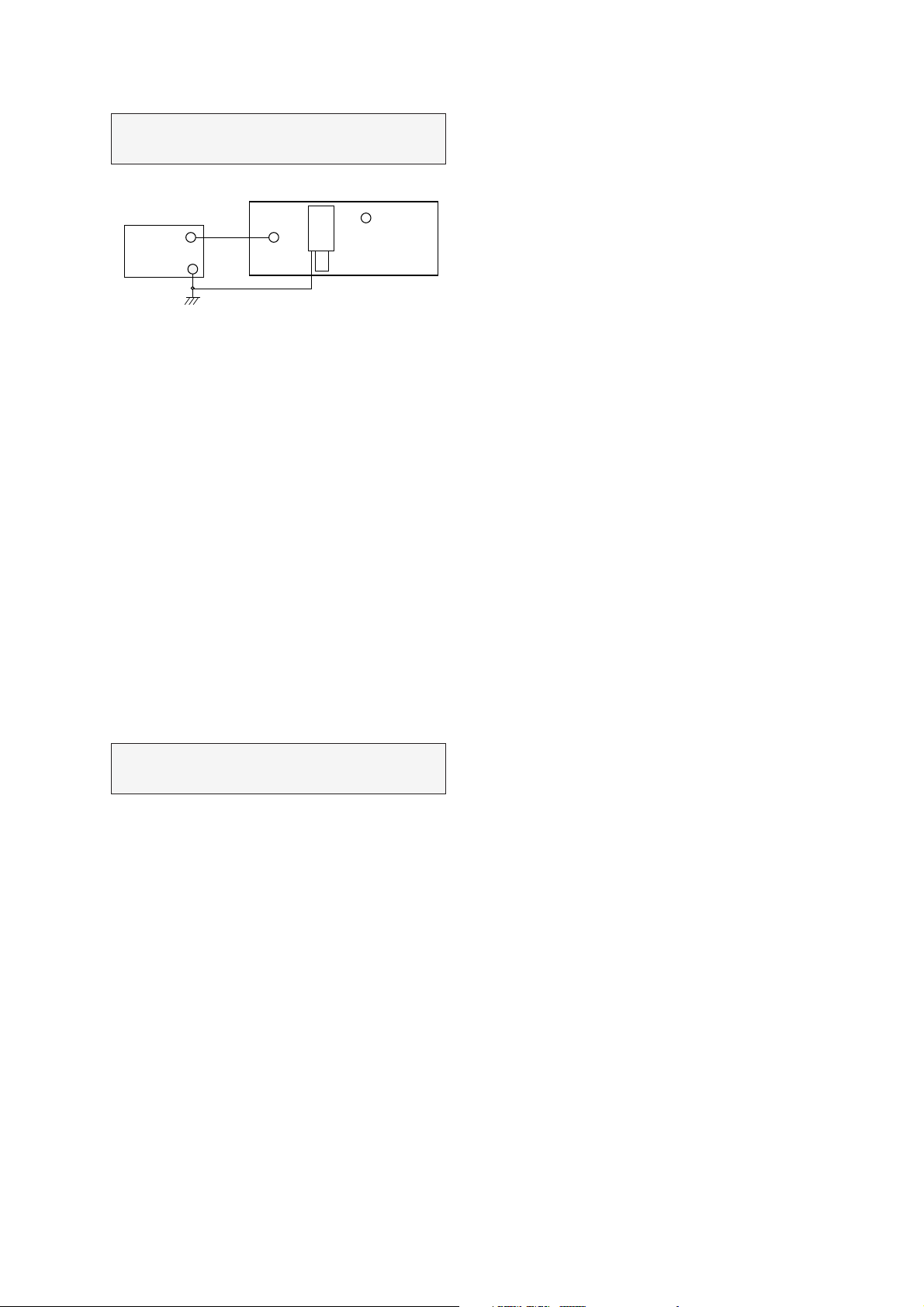

1. Connect the measuring equipment to the TV as shown in Fig. 1.

2. Set RF output level of sweep S.G.(Signal Generator) to 80dBuV.

3. Set Alignment Scope, Volts/Div to 100mV, AC/DC switch to

AC, Line/Ext switch to Ext.

38.9MHz

Signal

generator

GND

12Vdc

Power

Supply

GND(C26(-))

Ceramic

CAP.

10000pF

Ceramic

CAP.

10000pF

Fig.1: Connection Diagram of Equipment for BG VCO Adjustment

3

MAIN BOARD

Z101

4 5

G3962

C25(+)

C25(-)

IC101

TDA4474

J77

R124

L107

C123(+)

24

J169 5V

R139

Multimeter &

oscilloscope

2.5Vdc

SW1

AM/FM SW

GND

SW2

L/L'SW

* VCO (Voltage Controlled Oscillation) Adjustment

a) For B/G system

Test Poin t : Pin 24 of IC101 (+ lead of C123)

Adjust : L107

1) Turn on DC power supplies.

2) Adjust VCO adjust

coil(L107)so that DMM reads 2.5Vdc+_0.1V.

Page 2

Ceramic

CAP.

33.9MHz

Signal

generator

GND

12Vdc

Power

Supply

GND(C26(-))

10000pF

Ceramic

CAP.

10000pF

Fig. 2 : Connecting Diagram of Equipments for secam-L' system.

b) For Secam-L' system

3

MAIN BOARD

Z102

4 5

G3953

C25(+)

C25(-)

IC101

TDA4474

J77

R124

VR102

C123(+)

24

J139 GND

R169

Multimeter &

oscilloscope

2.5Vdc

GND(C122(-))

SW1

AM/FM SW

5V

SW2

L/L'SW

Test Poin t : J5 (one lead of R533)

Adjus t : VR102

1) Turn on DC power supplies.

2) Apply 5Vdc to the + lead of C25.

3) Adjust VCO adjust

volume(VR102) so that the DMM reads 2.5Vdc+_0.1V.

* Screen voltage adjustment

1) Tune the TV set to receive digital pattern.

2) Press PSM button on the Remote Controller to get the STANDARD picture.

3) Turn the screen VR of FBT until the black level of picutre signal is 150Vdc at the digital pattern.

CPT BOARD

GND

Rk

BLACK Level

150Vdc 1.5V

OSCILLSCOPE

Fig. 3 Fig. 4

Page 3

* RF AGC (Auto Gain Control) Adjustment

TUNER

Test Poin t : J173 or Observing Display

Adjus t : VR101

MAIN BOARD

AGC TP.

6Vdc

Digital

Multimeter

The RF AGC contro l(VR101)was aligned at the time of manufacture for optimum performance over a wide range

conditions. Readjust of VR101 should not be necessary unless unusual local conditions exist, such as ;

1) Channel interference in a CATV system

2) Picture bending and/or color beats, which are unusually due to excessive RF signal input when the receiver is too close

to a transmitting tower or when the receiver is connected to an antenna distribution system where the RF signal has

been amplified.

In this case, the input signal should be attenuated (with pad or filter) to a satisfactory level.

3) Picture noise caused by “broadcast noise” or weak signal.

If the broadcast is “clean” and the RF signal is at least 1mV (60dBu), the picture will be noise free in any area.

J173

Fig. 5

VR101

(AGC ADJ.)

Adjusting th e

Adjusting to the other end of rotation will usually cause a degradation of over load capabilities resulting in color beats or

adjacent channel reference.

For best results,

(RF level: 60dBuV).

VR101 (RF AGC)control to one end of rotation will usually cause a relatively poor signal to noise ratio;

adjust VR101 control while performing on all other local channels, or the voltage at J173 will be 6.0+_0.1Vdc.

* Focus Adjustment

NOTE : This adjustment should be performed after warming up for 10 minutes.

Test Poin t : Observing Display

Adjus t : Focus control of FBT

1) Set color & brightness to minimum, contrast to 50% respectively.

2) Input the PAL BG Digital Pattern signal.

3) Adjust the Focus control for best overall focus.

Page 4

PURITY & CONVERGENCE ADJUSTMENT

Caution:

Convergence and Purity have been factory aligned. Do not

attempt to tamper with these alignments.

However, the effects of adjacent receiver components, or

replacement of picture tube or deflection yoke may require the

need to readjust purity any convergence.

DEFLECTION YOKE

PURITY &CONVERGENCE

MAGNET ASSEMBLY

6-POLE

,,,

RUBBER

WEDGES

,,

,,

,,,

PURITY MAGNET

4-POLE

GLASS CLOTH TAPE

X-AXIS YOKE

POSITIONING

(L/R PURITY)

5.Reconnect the internal degaussing coil.

6. Position the beam bender locking rings at the 9 o'clock

position and the other three pairs of tabs (2,4 and 6 pole

magnets) at the 12 o'clock position.

6-POLE

6-POLE

MAGNETS

4-POLE

MAGNET

MAGNES

CONVERGENCE MAGNET ASSEMBLY

CONVERGENCE MAGNET ASSEMBLY

PURITY MAGNET(2-POLE)

* Purity Adjustment

This procedure DOES NOT apply to bonded yoke and picture

tube assemblies.

The instrument should be at room temperature (60 degrees F or

above) for six (6) hours and be operating at low beam current

(dark background) for approximately 20 to 30 minutes before

performing purity adjustments.

CAUTION:Do not remove any trim magnets that may be

attached to the bell of the picture tube.

1. Remove the AC power and disconnect the internal

degaussing coil.

2. Remove the yoke from the neck of the picture tube.

3. If the yoke has the tape version beam bender, remove it and

replace it with a adjustable type beam bender (follow the

instructions provided with the new beam bender)

4. Replace the yoke on the picture tube neck, temporarily

remove the three (3) rubber wedges from the bell of the

picture tube and then slide the yoke completely forward.

7. Perform the following steps, in the order given, to prepare the

receiver for the purity adjustment procedure.

a. Face the receiver in the "magnetic north" direction.

b. Externally degauss the receiver screen with the television

power turned off.

c. Turn the television on for approximately 10 seconds to

perform internal degaussing and then turn the TV off.

d. Unplug the internal degaussing coil. This allows the

thermistor to cool down while you are performing the purity

adjustment. DO NOT MOVE THE RECEIVER FROM ITS

"MAGNETIC NORTH" POSITION.

e. Turn the receiver on and obtain a red raster by increasing

the red bias control (CW) and decreasing the bias controls

for the remaining two colors (CCW).

f. Attach two round magnets on the picture tube screen at 3

o'clock and 9 o'clock positions, approximately one (1) inch

from the edge of the mask (use double-sided tape).

3-2

Page 5

1.ADJUST YOKE Z-AXIS FIRST

TO GET EQUAL BLUE

COLOR CIRCLES

MAGNETS

RED RED

2 .ADJUST BEAM BENDER 2 POLE

MAGNET TO GET FOUR EQUAL

COLOR CIRCLES

8. Referring to above, perform the following two steps:

a. Adjust the yoke Z-axis to obtain equal blue circles.

b. Adjust the appropriate beam bender tabs to obtain correct

purity (four equal circles).

9. After correct purity is set, tighten the yoke clamp screw and

remove the two screen magnets.

10.Remove the AC power and rotate the receiver 180 degrees

(facing "magnetic south").

11. Reconnect the internal degaussing coil.

12. Turn the receiver on for 10 seconds (make sure the receiver

came on) to perform internal degaussing, and then turn the

receiver off.

13. Unplug the internal degaussing coil.

14. Turn on the receiver and check the purity by holding one (1)

round magnet at the 3 o'clock and a second round magnet at

9 o'clock position. If purity is not satisfactory, repeat steps 8

through 14.

15. Turn off the receiver and reconnect the internal degaussing

coil.

* Convergence Adjustment

Caution:This procedure DOES NOT apply to bonded yoke and

picture tube assemblies.

Do not use screen magnets during this adjustment

procedure. Use of screen magnets will cause an

incorrect display.

1. Remove AC power and disconnect the internal degaussing

coil.

2. Apply AC Power and set the brightness to the Picture Reset

condition. Set the Color control to minimum.

3. Apply 8V to the pin.

6. Reconnect the internal degaussing coil and apply AC power.

7. Turn the receiver on for 10 seconds to perform internal

degaussing and then turn the receiver off again.

8. Unplug the internal degaussing-coil.

9. Turn on the receiver, connect a signal generator to the VHF

antenna terminal and apply a crosshatch signal.

Caution:During the convergence adjustment procedure, be

very careful not to disturb the purity adjustment tabs

are accidentally move, purity should be confirmed

before proceeding with the convergence adjustments.

Note:

Make sure the focus is set correctly on this instrument

before proceeding with the following adjustment.

10. Converge the red and blue vertical lines to the green vertical

line at the center of the screen by performing the following

steps (below TABLE).

a. Carefully rotate both tabs of the 4-pole ring magnet

simultaneously in opposite directions from the 12 o'clock

position to converge the red and blue vertical lines.

b. Carefully rotate both tabs of the 6-pole ring magnet

simultaneously in opposite directions form the 12 o'clock

position to converge the red and blue (now purple)

vertical lines with the green vertical line.

11. Converge the red and blue horizontal with the green line at

the center of the screen by performing the following steps.

(below TABLE)

a. Carefully rotate both tabs of the 4-pole ring magnet

simultaneously in the same direction (keep the spacing

between the two tabs the same) to converge the red and

blue horizontal lines.

b. Carefully rotate both tabs of the 6-pole ring magnet

simultaneously in same direction (keep the spacing

between the two tabs the same) to converge the red and

blue (now purple) horizontal lines with the green

horizontal line.

c. Secure the tabs previsouly adjusted by locking them in

place with the locking tabs on the beam bender.

4. Adjust the Red, Green and Blue Bias controls to get a dim

white line.

5. Remove the AC power and 8V from the pin.

3-3

Page 6

3-4

RING

PAIRS

4

POLE

ROTATION DIRECTION

OF BOTH TABS

OPPOSITE

SAME

OPPOSITE

SAME

MOVEMENT OF RED

AND BLUE BEAMS

B B

RR

OR

OR

B R B R

OR

B

R

B

R

B R

OR

B

R

6

POLE

12. While watching the 6 o'clock positions on the screen, rock the

front of the yoke in a vertical (up/down) direction to converge

the red and blue vertical lines. (Fig upper left)

13. Temporarily place a rubber wedge at the 12 o'clock position

to hold the vertical position or the yoke.

14.

Check the 3 o'clock and 9 o'clock areas to confirm that the red

and blue horizontal lines are converged.

If the lines are not converged, slightly offset the vertical tilt of the

yoke (move the rubber wedge if necessary) to equally balance the

convergence error of the horizontal lines at 3 o'clock and 9 o'clock

and the vertical lines at 6 o'clock and 12 o'clock.

15. Place a 1.5 inch piece of glass tape over the rubber foot at

the rear of the 12 o'clock wedge.

16. While watching the 6 o'clock and 12 o'clock areas of the

screen, rock the front of the yoke in the horizontal (left to

right) motion to converge the red and blue horizontal lines.

(Fig. upper right)

17. Temporarily place a rubber wedge at the 5 o'clock and 7

o'clock positions to hold the horizontal position of the yoke.

18. Check the 3 o'clock and 9 o'clock areas to confirm that the

red and blue vertical lines are converged. If the lines are not

converged, slightly offset the horizontal tilt of the yoke (move

the temporary rubber wedges if necessary) to equally

balance the convergence error of the horizontal lines at 6

o'clock and 12 o'clock and the vertical lines at 3 o'clock and 9

o'clock.

19. Using a round magnet confirm purity at the center, right and

left sides and corners. See Purity Adjustment Procedure.

20. Reconfirm convergence and apply a 1.5 inch piece of glass

tape over the rubber foot at the rear of the 5 o'clock and the 7

o'clock wedges.

RED

BLUE

RED BLUE

BLUE

RED

GREEN

GREEN

BLUE RED

GREEN

GREEN

ADJUSTMENT

VIEWING

AREA

UP/DOWN ROCKING OF THE YOKE

CAUSES OPPOSITE ROTATION OF RED

AND BLUE RASTERS

ADJUSTMENT

VIEWING

AREA

RED

RED

GREEN

TV

SCREEN

LEET/RIGHT ROCKING OF THE YOKE

CAUSES OPPOSITE SIZE CHANGE OF

THE RED AND BLUE RASTERS

UP/DOWN ROCKING OF THE YOKE

CAUSES OPPOSITE ROTATION OF RED

AND BLUE RASTERS

LEFT/RIGHT ROCKING OF THE YOKE

CAUSES OPPOSITE SIZE CHANGE OF THE

RED AND BLUE RASTERS

Page 7

TUNER

TUKE9CO7DF

VIF

TDA4474A

AUDIO SW.

LA7222

1H DELAY

TDA4665

MEGA TEXT

SDA5273/SDA5275

u-PROCESSOR

SDA30C163-2

EEPROM

24C16

EEPROM 128K

27C010A

1M DRAM

GM71C4256B

VIDEO SW.

TEA6415

50Hz C DECODER

TDA9141

DIGITAL

BOARD

(DOUBLE

SCAN)

POWER &

DEFLECTION

COLOR SW.

GD4052B

H/P AMP

TDA2882

SOUND PROCESSOR

MSP3410P

LPF

GL4558

L/S AMP

LA4282

IIC1

IIC1

AGC

CVBS

IF2

SW

2

2

2

Headphone

SPEAKER1(L)

SPEAKER2(R)

2

2

2

2

2

2

2

2

2

2

4

RGB/FB

CVBS

RESET

IIC0

IIC1 Addr & Data

Addr & Data

Co

L

R

Y

C

L

R

V

Lo/Ro2

Li/Ri2

Vo2

Vi2/Yi

Ci

Lo/Ro1

Li/Ri1

Vi1

Vo1

RGB/FB

4 RGB/FB

IIC1

IIC1

H/V

YUV50

YUV100

RGB

CPT

A66EAK552X54

RGB

IIC0 IIC1

AUDIO OUT SCART I

SCART II HALF & Y,C

FULL With

RGB

SVHS FRONT AV

100Hz VIDEO PROCESSOR

TDA 4780

VIDEO AMP & SVM

TDA6111Q X3

Page 8

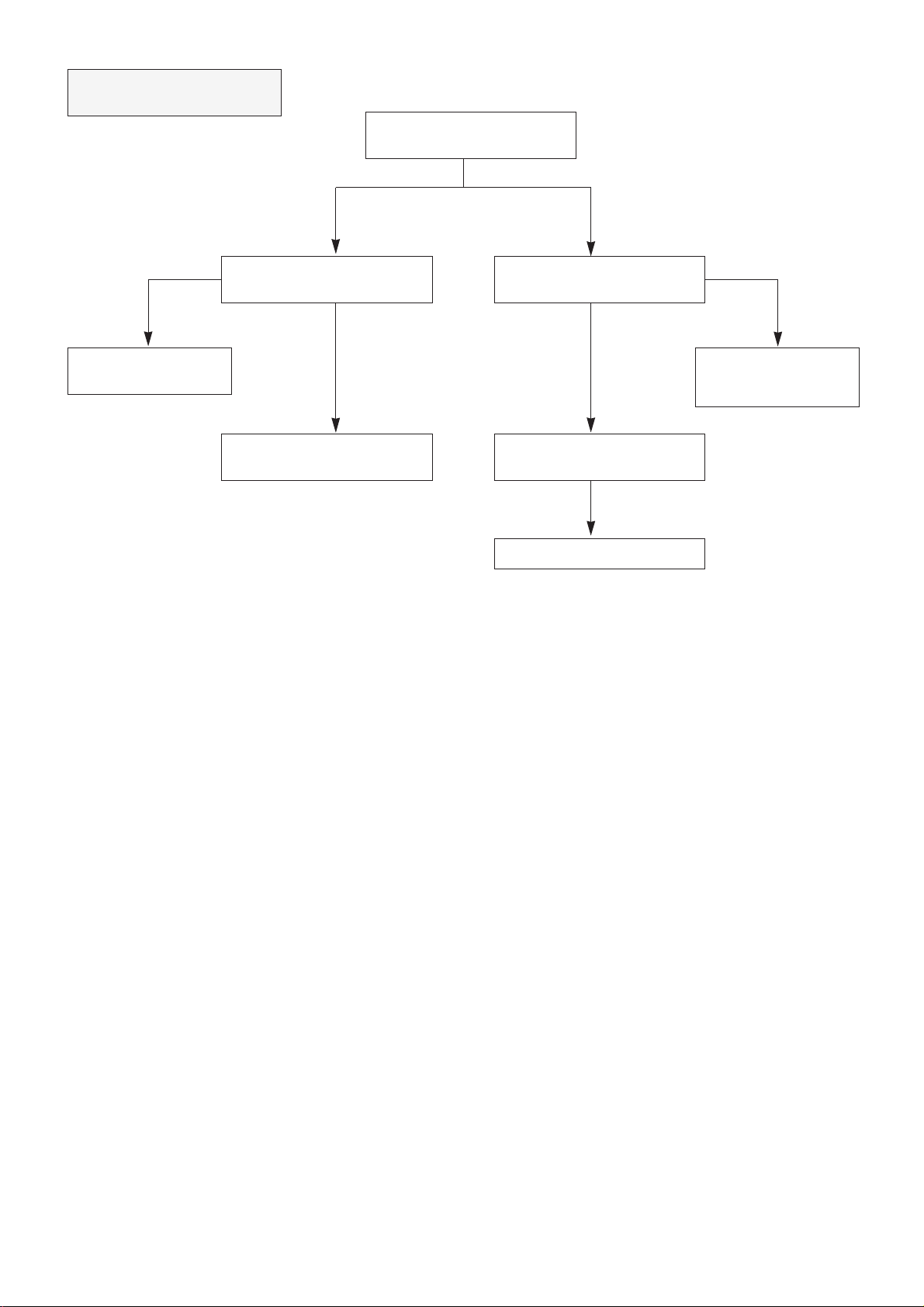

NO TELETEXT

NO RASTER

(SOUND OK)

Check the voltage

of ZD701 (5V)

Abnormal Normal

NG

NG

NG NG

Check the 5V line

to be correct.

Check if the video signal is

at pin 10 of IC702.

Check the

CVBS line.

Check/Replace

IC702, 703, X701.

Check I2C BUS lines.

(SDA, SCL)

Check pin 51, 52, 53 and 54

of IC702.

Check the voltage of

CPT Heater

Check the voltage of

HV and SCREEN of CPT.

Check/Replace

CPT Board.

Check the Heater pulse

at pin 9 of T701.

Check/Replace

T701.

Check/Replace

T701.

Check/Replace

Connector, FR459 and FR901.

Check/Replace IC503.

Page 9

NO PICTURE/NO COLOR

Is the CVBS signal at pin 14

of IC101 normal?

Check/Replace

IC101.

Is the CVBS signal at pin 26

of IC501 normal?

Check/Replace

Q201.

Is the R-Y, B-Y signal at pin 3, 4

of IC501 normal?

Check/Replace

IC501, 502.

Is the Y, U, V(in, 50Hz) signal at

pin 12, 13 and 14 of IC501 normal?

Check/Replace

IC101.

Is the Y, U, V(out, 100Hz) signal at

pin 3, 4 and 6 of P101 normal?

GO to

DIGITAL BLOCK.

Is the R, G, B signal at

pin 1, 3 and 5 of IC501 normal?

Check/Replace

IC503.

Check/Replace

IC503.

NG

NG

NG

NG

NG

NG

Page 10

NO SOUND

(PICTURE OK)

(NO AM Sound)

Check the Audio signal

at pin27 of IC101.

Check/Replace

IC101

Check the Audio signal

at pin55 of IC601.

(NO FM/NICAM Sound)

Check if the SIF signal at pin26 of

IC101 normal.

Check/Replace

IC101.

Are the Audio signal at pin28 and

29 IC601 normal?

Are the Audio signal at pin 2 and

5 of IC605 normal?

Are the Audio signal at pin 7 and

11 of IC605 normal?

Check/Replace

Connectors and Speakers.

Check/Replace

X601, IC601 and IC606.

Check LO, RO lines.

Check/Replace

IC605, Sound +B Line.

Check AM line

NG

NG

NG

NG

NG

NG

Page 11

NO PICTURE/NO SOUND

(RASTER OK)

Is the Auto programme

operation normal?

Is the CVBS signal at pin14

of IC101 normal?

yes

yes

OK

OK

no

no

no

Go to NO PICTURE Block.

NO SOUND Block

Check the voltages

5V, 12V and 33V of Tuner.

Check/Replace

ZD101, 102,

5V, 12V and 33V Lines.

Check/Replace

IC101.

Check I2C bus lines.

(SDA, SCL)

Check/Replace TUNER.

Page 12

NO RASTER

NO SOUND

Check +B voltage at J306.

Is there the square waveform at

pin4 of P101 (H-out)

140V

yes

yes

yes

OK

230~380V

Lower than 6V

no

NG

0V

no

Is the waveform at the collector of

Q402 normal?

Check/Replace

T701 and CONNECTORS.

Is the voltage at pin 24

of IC01 5V?

Check/Replace IC803,

D826, 827, 828, 829, T805,

T801, 804 and Fuse (FC02).

Check the part of

Digital PCB ASSY

Check the voltage of C834.

Check the voltage at pin9

of IC801.

Check/Replace

D802, D803, Q801 and

IC801.

Check/Replace

D801.

no

Check/Replace

Q401, T401and Q402.

Check/Replace

IC802, IC804, D810 and R832.

Page 13

Digital assy Trouble shooting

Check with Color Bar signal input.

Check the circuit from PQ101

to CQ54,57

Replace an IC causing Power

drop.

Check ICQ501.

Replace ICQ05

Replace ICQ04

Replace ICQ09

Replace ICQ08

Replace ICQ07

Replace ICQ02

Check Deflection Part

Replace ICQ01

Replace IC501

Replace ICQ06

Check IC503

No Picture or

screen flows

Check Y,U,V signal

input of PQ101.

Check Y,U,V

signals at CQ54(+),CQ57(+)

and CQ58(+).

Check the Vcc

of each IC.

Check Pin 34~40 and

Pin 48~51 of ICQ05.

Check Pin10 of ICQ06

Check Pin15 and

16 of ICQ06 for 27MHz and

13.5MHz waveform.

Check the Video

Sync at CQ54(+).

Check if Pin13 and 20

of ICQ01 have 32

¥s?

Check Pin61~68 and

Pin2~5 of ICQ04

Check Pin13~16, Pin18~21,

Pin22~25 of ICQ02.

Check the outputs

of Pin 2,4,5 of PQ102.

no

no

no

no

no good

no good

Pin13~16 no signal

Pin18~21

no signal

Pin22~25

no signal

no signal

Yes

No Picture

Screen flows

good

no good

no good

no good

good

Yes

good

Yes

good

good

Yes

Yes

Yes

Page 14

Page 15

Loading...

Loading...