Page 1

Service Manual

Internal Use Only

Service Manual

KP220

Model : KP220

Date: March, 2008 / Issue 1.0

Page 2

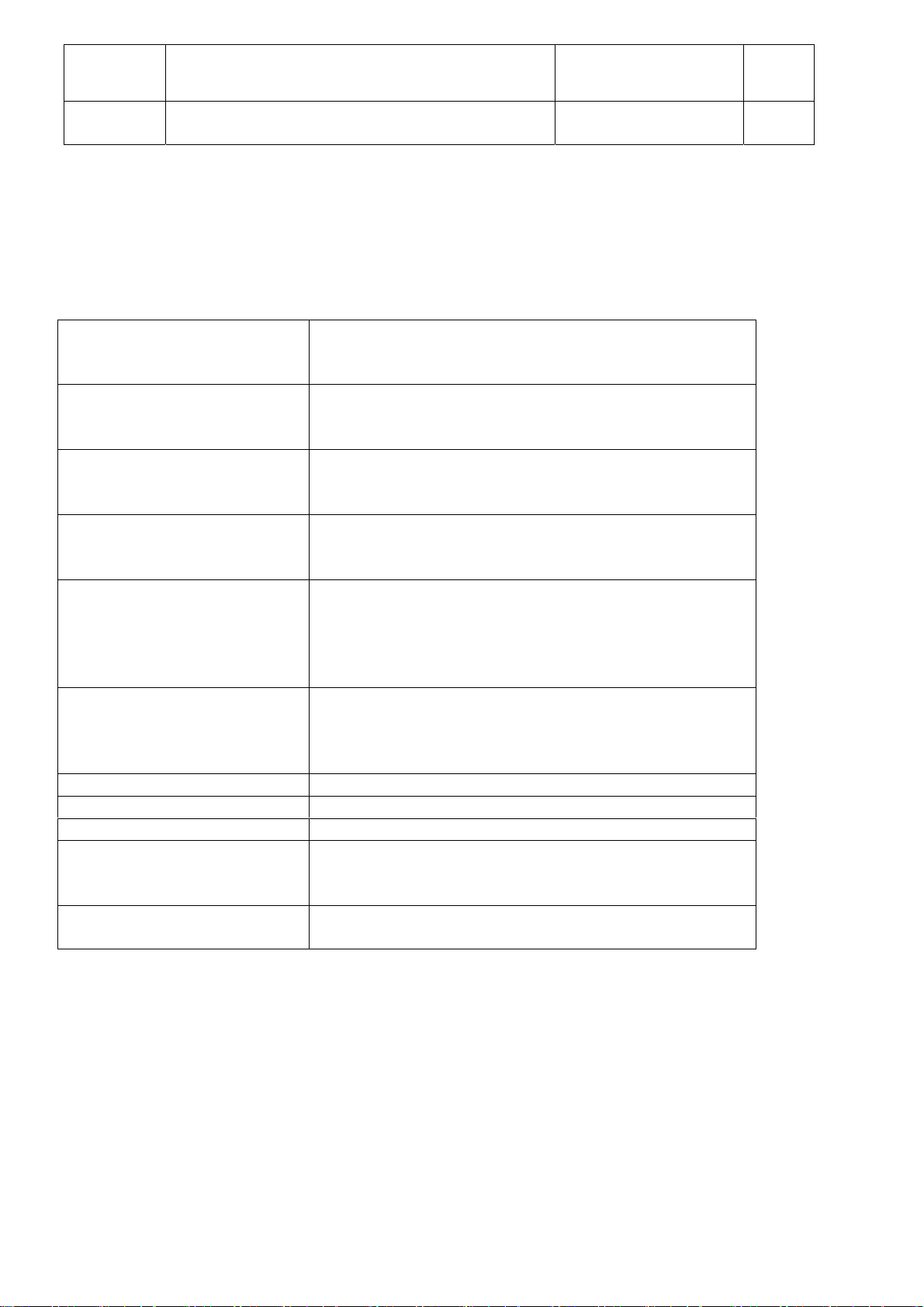

AMENDMENT RECORD

AMENDMENT RECORD SHEET

Issue Number Date

Draft 1.00 29.11.2007

Draft 1.2 14.02.2008

Draft 1.3 18.02.2008

For details of previous history refer to archival documents.

New Issue Number – Date Changes This Issue, Page and Description Remarks

Draft 1.00 29.11.2007 All for Publication

First draft

Issue

Draft 1.2 14.02.2008 All for Publication

Draft 1.3 18.02.2008

All for Publication

Second

draft Issue

Third draft

Issue

KP220 SERVICE MANUAL V1.2

Page 3

Next Section >>

Main Menu

SECTION 1

1

Introduction

KP220 SERVICE MANUAL V1.2

Page 4

1. Introduction

The variation of “KP220” is shown below.

This Service Manual is indicated for 7338.

Variation Note.

Product Code Trade Name

7338

XXXXXXXX KP220

KP220 SERVICE MANUAL V1.2

Page 5

This is the Electronic Service Manual for KP220 Triple Band GSM Digital

Cellular Telephone from LG. It contains specific information on repair and test

procedures.

For details of user functions, general operation and installation, please refer to the

User Guide.

The Service Manual is set out in the following sections.

1. Precautions for Repair Work : provides general guidelines for

undertaking safe and efficient repair work.

2. Unit Specification: provides the technical specifications for

KG195 Triple Band GSM Digital Cellular Telephone.

3. Introduction of Service Level :

a)

Service Level 1:describes definition of Service Level 1, equipment and

tools required for this level.

b)

Service Level 2 :describes definition, equipment and tools required for

Service Level 2.

4. Circuit Description: provides functional details of the circuits, block

diagrams and component purpose descriptions.

5.

Servicing : defines the jigs, fixtures and test configurations required for

servicing the product; and describes the processes of assembly and

disassembly.

6.

Troubleshooting : provides an aid to fault finding the product. Includes,

using the signal levels and plots at various parts of the circuit.

7. Device Information : provides functional information and pin-outs of

most of the semiconductor devices within the HHP.

8. Glossary :

terms used in this GSM and this manual.

KP220 SERVICE MANUAL V1.2

Page 6

Next Section >>

Main Menu

SECTION 2

2

Precautions

for Repair Work

KP220 SERVICE MANUAL V1.2

Page 7

PRECAUTION

Important

Please read the following cautions, notes and

warnings before progressing through this manual or

undertaking any repair action.

Remember: SAFETY FIRST!

CAUTION:

AC Power Cord:

Care must be taken not to damage the AC power cord as fire or electric shock may

result.

Battery Pack:

Only use the specified batteries and chargers with this equipment.

Do not short the battery terminals together.

Keep the battery pack away from fire and sources of ignition.

Remember to recharge the battery pack after each use.

Before Powering up the Equipment:

• Only switch on the telephone’s power once the test or installation set-up is

complete.

• Switching on at the wrong time may result in electric shock or damage to system

components.

• Always ensure that the power is switched off before making connections /

disconnection’s.

• It is important to check that the correct DC voltage is applied to the equipment to

prevent electrical damage.

Component Polarity:

Always check the polarity of connections and components before soldering.

Particular attention must be paid to IC.s, diodes, transistors, capacitors and any

other semiconductor device that is polarity dependent.

KP220 SERVICE MANUAL V1.2

Page 8

Electrostatic Damage (ESD):

Semiconductor devices are easily damaged by electrostatic discharge. Many of the

procedures detailed in this manual involve disassembly of the equipment and

therefore handling of the printed circuit boards.

To protect these devices from ESD a wrist strap connected to ground must be worn.

In addition to this the work surface must be covered with an anti-electrostatic mat,

which should also be grounded.

If printed circuit boards are to be stored without being re-assembled into their

equipment, then they must be kept in an anti-electrostatic bag.

Grounding:

Each piece of test equipment should be electrically grounded. A third (grounding)

pin is provided as a safety feature. Ensure that the electrical outlet also contains

this feature.

Cosmetic Protection during Repair Work:

Always ensure that the working surface is kept clean and free from abrasive

materials.

The LCD is very susceptible to scratches and damage. It should be covered with

clear adhesive vinyl while the equipment is disassembled.

Storage of Faulty Components:

Any components that are replaced due to failure should be kept safely in an antielectrostatic container. NEC’s Quality or Research & Development Departments

may require them to make quality and reliability investigations.

No Fault Found Equipment:

In some cases the reported symptom may not be apparent. You may subject the

equipment to a controlled amount of stress, vibration and temperature variation to

see if the fault occurs.

Care should be taken not to apply excessive stress or vibration or extreme

temperature variations as further faults may develop.

KP220 SERVICE MANUAL V1.2

Page 9

Soldering and Disordering :

The solder used is only Pb-free.

Fast, accurate and high quality soldering is required to minimize the risk of heat

damage to the electronic components.

It is necessary to adjust the temperature of soldering tip to 330 degrees or less.

The soldering tip should not be in contact with components or PCB tracks for longer

than 4 seconds (average). This time depends on temperature conditions of parts.

Heat the pad on the PCB and the lead, quickly apply solder, remove heat and cool.

After soldering is complete, ensure that all solder joints are of good quality - no dry

joints, solder bridges, cracks or excess solder.

The majority of chip components are machine mounted using solder paste.

Removal of the solder is not sufficient for chip component removal. Each solder

point must be heated simultaneously and quickly (to prevent component and PCB

damage). When the solder has melted, remove the component with tweezers.

Short Circuits:

Care must be taken to avoid short circuits. Soldering, solder dust, screws, metal

clippings, metal wrist watches etc. can cause short circuits on PCBs which may

result in component damage.

Test Equipment Calibration:

Your test equipment should be calibrated before use. Frequent calibration is

essential to ensure high quality and reliable repairs.

Cleaning:

Before cleaning ensure that the telephone is switched off and disconnected from the

power source. Cleaning should be done using a soft dry cloth. If the equipment is

heavily soiled a soft cloth soaked in a mild synthetic detergent diluted in water may

be used.

Never use benzene or any other chemicals to clean the equipment.

RF Shielding:

It is advisable to carry out detailed measurements and repair (in particular RX) in a

shielded area to minimize RF interference.

AC Adapter and Battery Charger:

The AC adapter and battery chargers are for indoor use only. Ensure that the

devices are not exposed to rain or moisture

KP220 SERVICE MANUAL V1.2

Page 10

Electrical Safety:

Electrical equipment is hazardous if misused. Any repairs must be carried out with

care and only by authorized personnel.

Ensure all power sources are switched off and power cords removed before

undertaking any repairs.

Hazardous Waste:

The battery pack, if incorrectly disposed of, is an environmental hazard. It must be

disposed of in accordance with the regulations of the country concerned.

Never dispose of the battery pack in fire or water.

Confidentiality:

The circuitry within this equipment contains several components that are regarded

as company confidential. Only use NEC specified parts as replacements.

RF Injury:

To avoid RF injury, direct exposure to radio frequency energy should be avoided. In

particular, exposed parts of your body (especially the eyes and face) should not

come into contact with the antenna while the equipment is transmitting.

Storage Conditions:

It is recommended that the following storage conditions should be avoided to

prevent damage to the equipment: Dusty.

Humid.

Near to magnetic equipment

In direct sunlight

Ventilation:

Repair areas should be well ventilated and fume extraction systems should be

installed where necessary. Potential hazardous substances are solder fumes, flux,

alcohol etc.

PCB Handling:

It is recommend that cotton gloves are worn during repair work. This is to protect

your hands from chemical contamination and to protect the PCBs from fingerprints

and humidity

.

KP220 SERVICE MANUAL V1.2

Page 11

SIM Card:

• Do not bend.

• Clean by using a soft dry cloth.

AUDIO Parts:

• Be careful for alien substance/oils and fats, etc. not to adhere to the terminal contact part of

MIC, the receiver, the speaker.

• Be careful to handle AUDIO parts with electrostatics measures at the worker/in the working

place.

• Be careful not to spend a stress on the MIC side part to the utmost.

• Be careful not to pressurize the coil joint (protection Bond part) of the receiver and speaker

because they are easy of broken.

• Be careful for alien substance to approach to sound hole part of the speaker.

• Be careful sufficiently so as not to blow air with the process into the receiver, speaker/MIC

sound hole. It causes sounds being small by the diaphragm transformation or vibration.

KP220 SERVICE MANUAL V1.2

10

Page 12

<< Previous Section

Next Section >>

Main Menu

SECTION 3

3

Unit Specifications

KP220 SERVICE MANUAL V1.2

11

Page 13

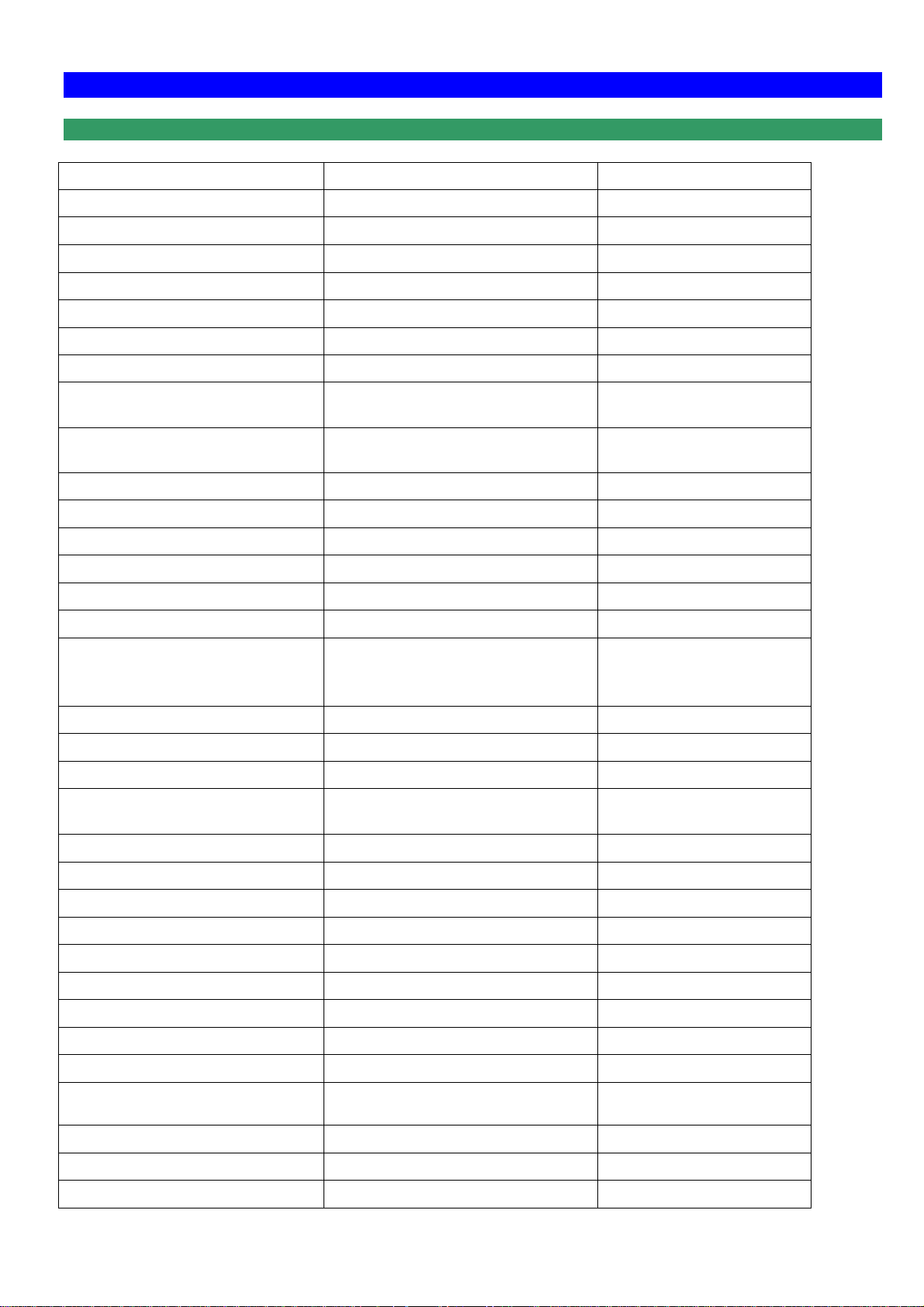

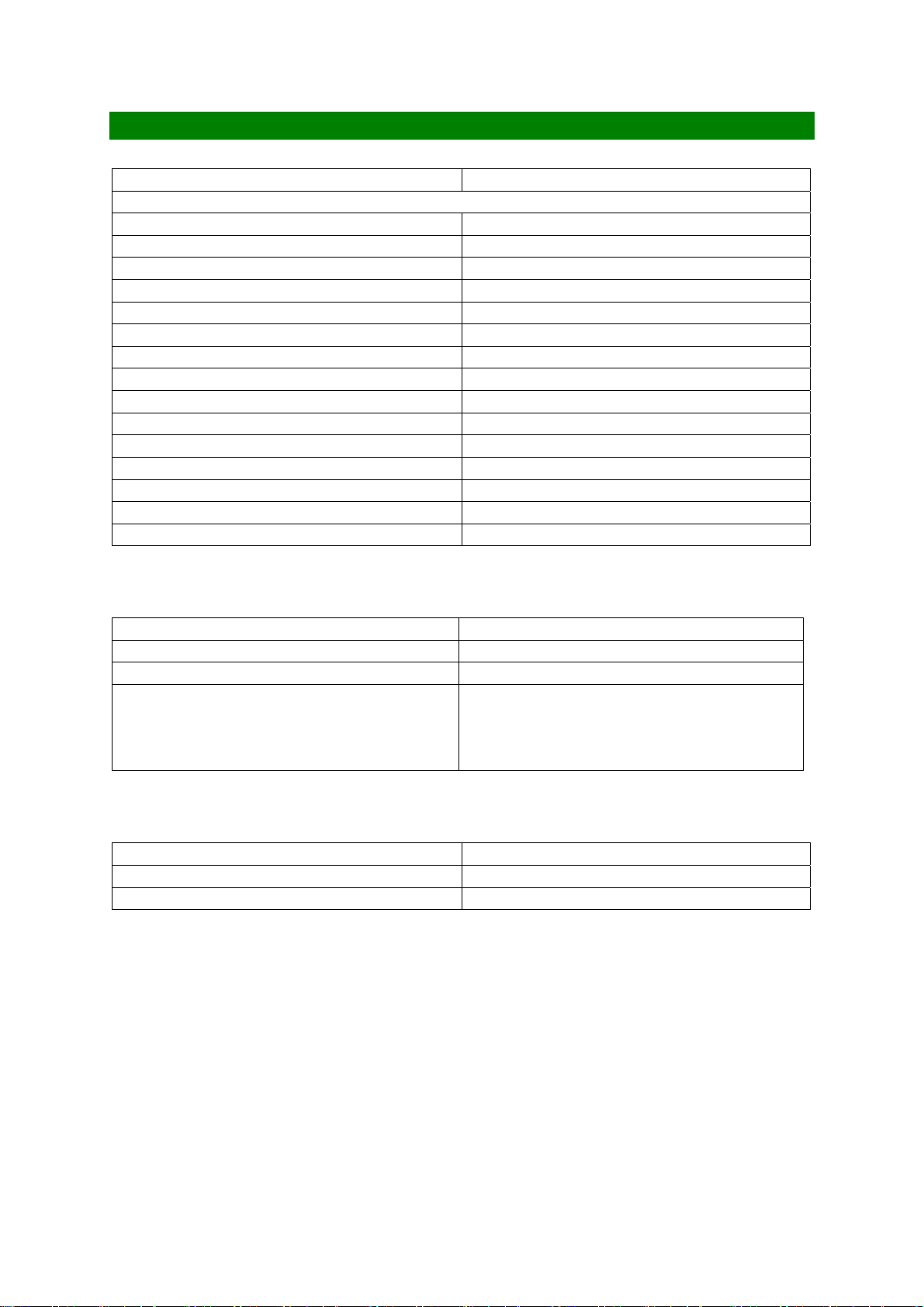

3. UNIT SPECIFICATION

PRODUCT FEATURES AND SPECIFICATION

Solution MT6226M

Media Tek

Type Bar type

Antenna Type Internal (tri-Band)

Main Display 1.77”, 128x160

GPRS Class 10

MMS Yes, 1.1

Camera 1.3M (OV9660)

Battery 900mAh Li-ion inner pack

Audio player

FM Receiver

MPEG4/H.263 Yes (support 3GP)

H.264 No(no support)

AAC Yes

AAC+ No

FM as alarm Yes

Scheduled FM recording Yes

MP4 for incoming call/ power

on off animation and screen

saver

Loud Speaker Yes

Yes (support MP3 and AAC

playback)

Yes , US/Europe

band(87.5~108MHz)

Yes

LG Chemical

Audio player--real resuming Yes, for MP3 only

Video recording Yes

Memory Size

Internal NAND 512Mb NAND

Memory Card Micro SD

Bluetooth Yes, version 1.2

USB Yes, slave 1.1

IrMC No

WAP Yes, 2.0

Java Yes

PoC No

EMAIL

Status LED Yes

DRM No

Dictionary No

MPEG4 caller ID

128Mb NOR Flash + 64Mb

PSRAM + 512Mb NAND

No

Yes

Up to 4GB

Network Link,

Charging

KP220 SERVICE MANUAL V1.2

12

Page 14

Finger handwriting No

Touch Panel No

Caption

OTA

語言學習機(AB repeat)

Music Equalizer

Image Editing

In flight mode

No

Yes

No

Yes

No

Yes

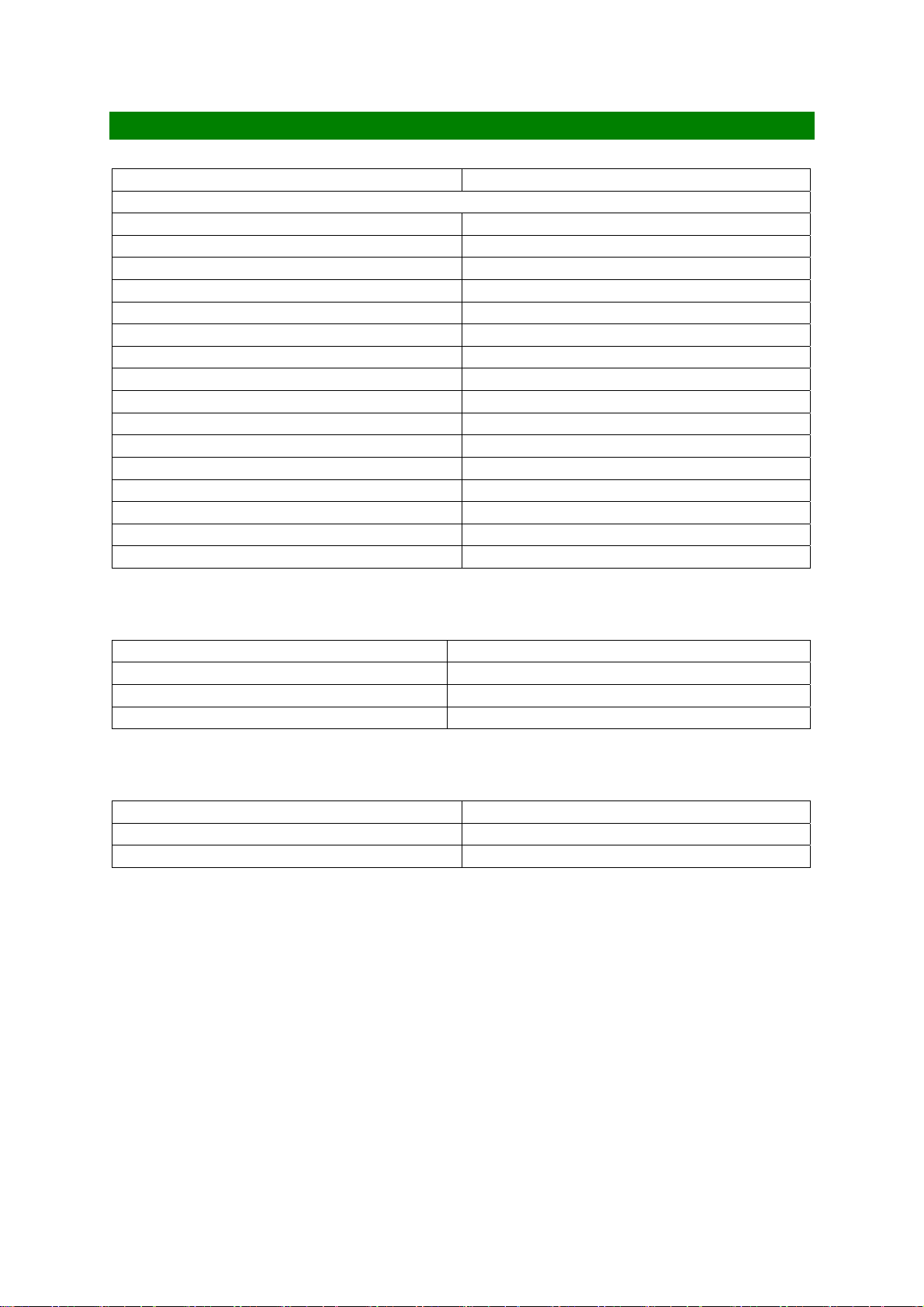

ERAL REQUIREMENT

General Requirement

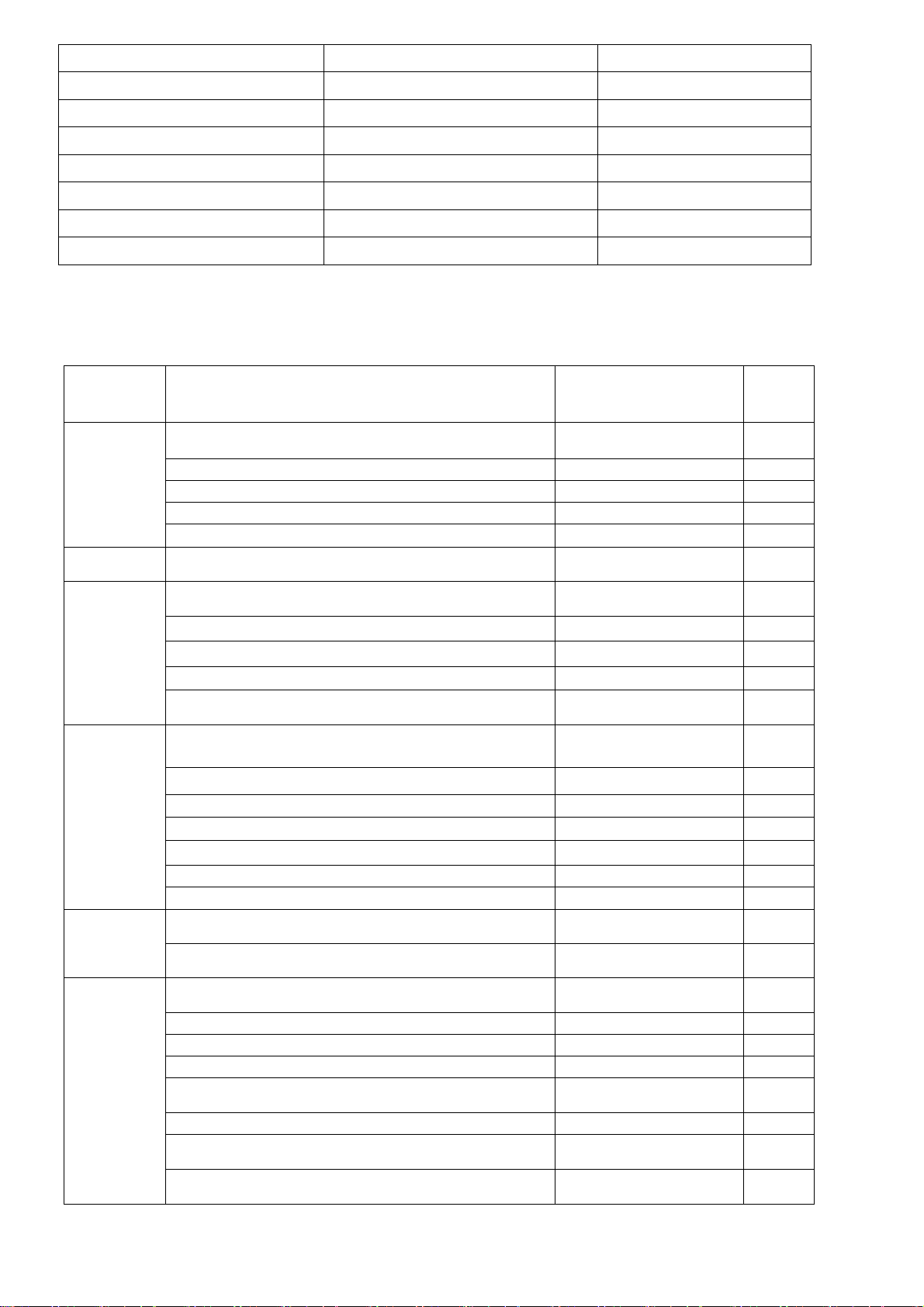

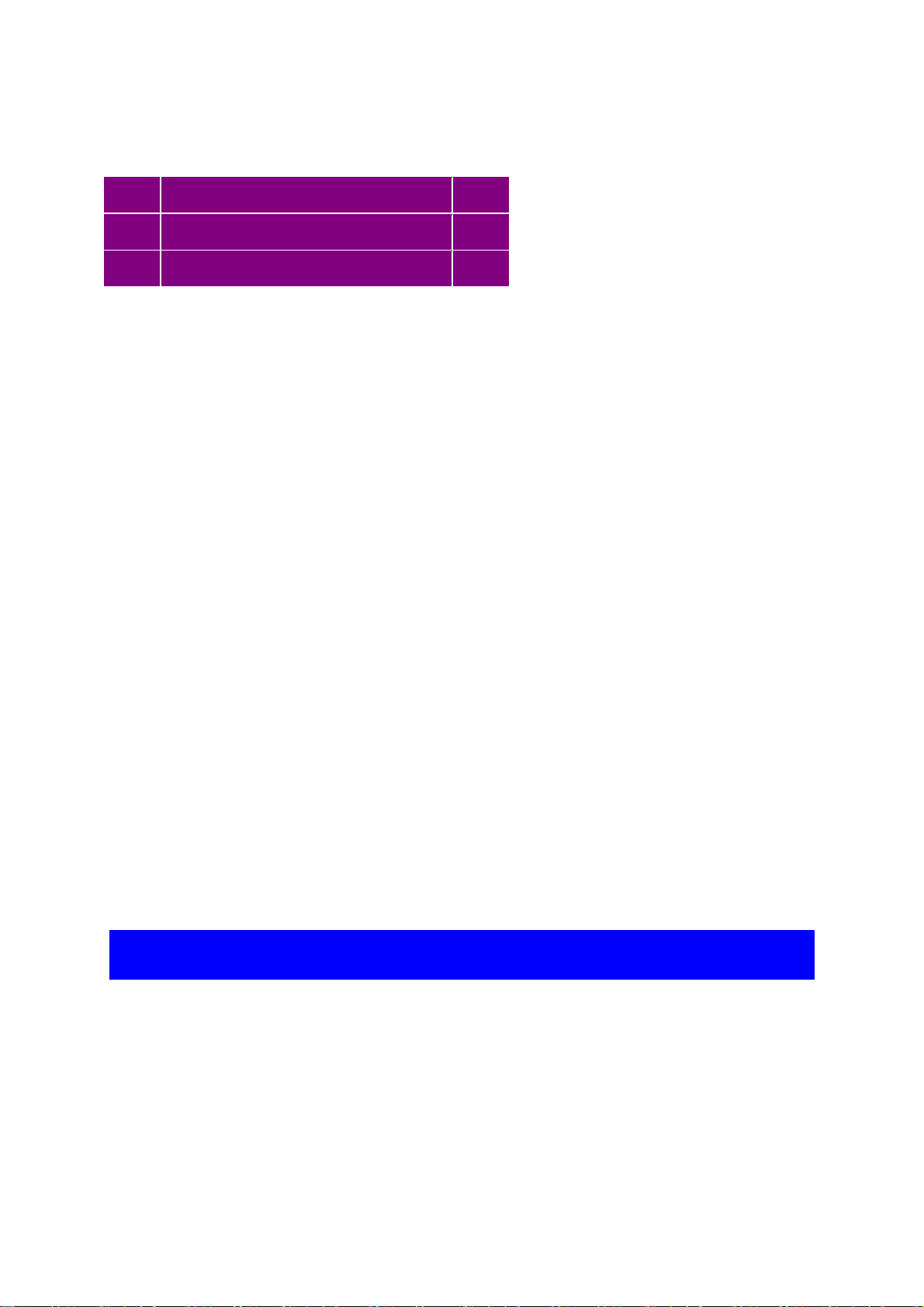

Category Requirement Description Parameter Support

Shall support multiple radio bands/power

Frequency

- 850 MHz/class 4 (2W) N

- 900 MHz/class 4 (2W) Y

- 1800 MHz/class 1 (1W) Y

- 1900 MHz/class 1 (1W) Y

Antenna Shall support [Internal/External] antenna Internal Y

Shall support GPRS bearer

R98 Y

GPRS

Data

Service

Java

oice codec

Audio

decoder

- release [R#]

- multi-slot class [class #] 10 Y

- Service class [Class #] Class B Y

- Coding scheme [CSn] CS1,CS2, CS3, CS4 Y

Shall support following data transaction mode

and services.

- Fax N

- Data N

- WAP [rel #] 2.0 Y

- SMS Y

- EMS [rel #] Code 5.0 Y

- MMS [rel #] 1.1 Y

Support JAVA MIDP [ver #] 2.0 Y

Support JAVA CLDC [ver #] 1.0 Y

Shall support multiple voice codec Y

- FR Y

- EFR Y

- HR Y

- AMR NB (air link) Y

Shall support multiple audio decoders

- MP3 Y

- WMA N

KP220 SERVICE MANUAL V1.2

13

Page 15

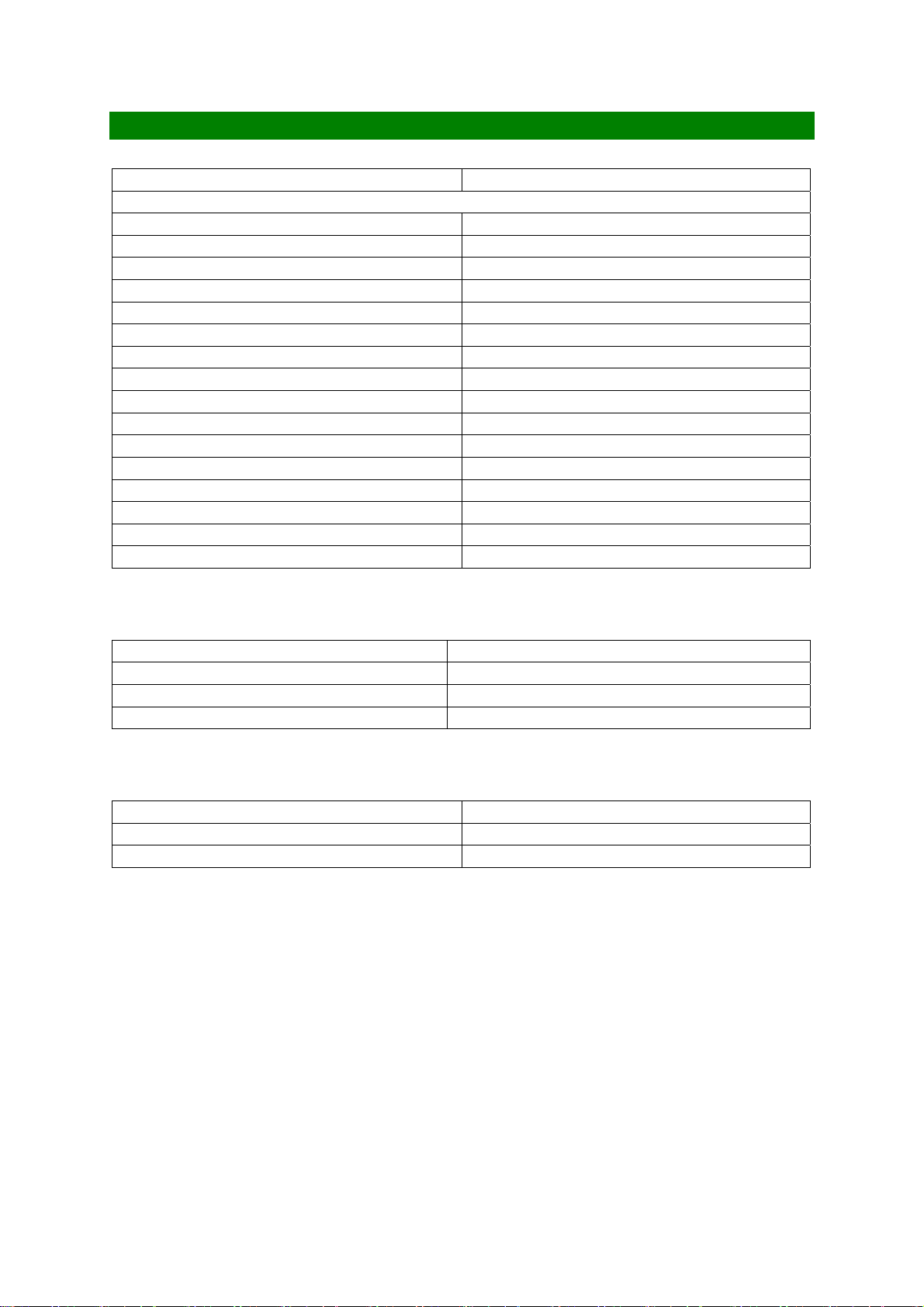

Category Requirement Description Parameter Support

- AAC Y

- AAC+ N

Physical

Display

Camera

FM radio

Battery

The physical dimension is [Length x Width x

Thickness mm]

TBD Y

The overall volume is [# cc] TBD Y

The weight is [# g] TBD Y

Shall support main display with following

characteristics:

Y

- Size 1.77” Y

- Type TFT, Transmissive Y

- Color depth 262K Y

- Pixel resolution [width x height] 128x160 Y

- Active area [W x H mm]

28.032(W) x 35.04(H)

Y

mm

Shall support high resolution camera with

following characteristics:

- Active pixel array up to resolution [ X x Y

pixels]

Y

1280x1024 Y

- Sensor type [CMOS or CCD] CMOS Y

Shall support FM radio bands

- US/Europe band 87.5~108MHz Y

- Japan band

Shall support Li-Ion battery with minimum

capacity of [mAh].

Shall support following device to connect

external devices.

76~90MHz

900mAh Y

N

Connectivity

Storage

Indication

- USB [ver, host or slave or OTG] 1.1 slave Y

- Bluetooth [ver, power class] 1.2, class 2 Y

GAP

SDAP

DUN

SPP

- Bluetooth profiles

HSP

Y

HFP

OPP

FTP

A2DP, AVRCP

Shall support mass data storage for different

multimedia content.

Y

- Build-in NAND [MB]. Used as mobile disk.

(Notes : Designed footprint shall be possible to

Y

support multiple memory capacity)

- Micro SD Y

Shall support LED for status indication.

1 Blue LED

Y

KP220 SERVICE MANUAL V1.2

14

Page 16

Category Requirement Description Parameter Support

(*Table 1.) Shall support LED for charger (TA or USB) plug-in

status indication.

1 Orange LED

Y

* Battery life is Network dependent; variations may occur.

The KG195 HHP works closely with the network and the standby and talk times achieved depend

upon this. In particular the location of the HHP within the network, the type of SIM, reception of

area messages, the use of AMR, Full Rate speech, Half Rate speech or Enhanced Full Rate

speech and other factors will affect both standby and talk times.

Transmitting Frequency

Range:

Receiving Frequency

Range:

TX - RX Duplex Spacing: EGSM : 45MHz

Channel Spacing: EGSM : 200KHz

Number of Channels

(ARFCN):

Power Class:

Tx Peak Current:

GPRS Class:

GPRS Coding Scheme:

Data Rates (Packet):

Data Rates (Circuit

Switch):

EGSM : 880 - 915MHz

DCS1800 : 1710 - 1785MHz

PCS1900 : 1850 - 1910MHz

EGSM : 925 - 960MHz

DCS1800 : 1805 - 1880MHz

PCS1900 : 1930 - 1990MHz

DCS1800 : 95MHz

PCS1900 : 80MHz

DCS1800 : 200KHz

PCS1900 : 200KHz

GSM : 124 (Numbered 1 to 124) std.

EGSM : 50 (Numbered 975 to 1023 & 0)

DCS1800 : 374 (Numbered 512 to 885)

PCS1900 : 299 (Numbered 512 to 810)

EGSM : Class 4 MTS (33 +/- 2dBm)

DCS1800 : Class 1 MTS (30 +/- 2dBm)

PCS1900 : Class 1 MTS (30 +/- 2dBm)

2500mA

Class 10; Operation class B

CS1/CS2/CS3/CS4

EGSM/DCS1800/PCS1900 :

Uplink : Up to 21.4Kbps (1 slot)

Downlink : Up to 85.6Kbps (4 slots)

EGSM/DCS1800/PCS1900 : Up to 9600Kbps

KP220 SERVICE MANUAL V1.2

15

Page 17

TRANSMITTER (EGSM)

RF Power Output

Power Levels 15 decrements in 2dB steps

Power Control Level 5 33dBm +/-2dB

Power Control Level 6 31dBm +/-3dB

Power Control Level 7 29dBm +/-3dB

Power Control Level 8 27dBm +/-3dB

Power Control Level 9 25dBm +/-3dB

Power Control Level 10 23dBm +/-3dB

Power Control Level 11 21dBm +/-3dB

Power Control Level 12 19dBm +/-3dB

Power Control Level 13 17dBm +/-3dB

Power Control Level 14 15dBm +/-3dB

Power Control Level 15 13dBm +/-3dB

Power Control Level 16 11dBm +/-5dB

Power Control Level 17 9dBm +/-5dB

Power Control Level 18 7dBm +/-5dB

Power Control Level 19 5dBm +/-5dB

TX Frequency Output

Low Channel (Ch 975) 880.2 MHz

Mid Channel (Ch 62) 902.4 MHz

High Channel (Ch 124) 914.8 MHz

TX Frequency Calculation (Ftx)MHz

(0 - 124)

(975 - 1023)

890 + (ARFCN x 0.2)MHz

890 + 0.2x(ARFCN - 1024)MHz

Phase and Frequency Error

Peak Phase Error < 20 degrees

RMS Phase Error < 5 degrees

Frequency Stability < +/- 90Hz

KP220 SERVICE MANUAL V1.2

16

Page 18

TRANSMITTER (DCS1800)

RF Power Output

Power Levels 16 decrements in 2dB steps

Power Control Level 0 30dBm +/-2dB

Power Control Level 1 28dBm +/-3dB

Power Control Level 2 26dBm +/-3dB

Power Control Level 3 24dBm +/-3dB

Power Control Level 4 22dBm +/-3dB

Power Control Level 5 20dBm +/-3dB

Power Control Level 6 18dBm +/-3dB

Power Control Level 7 16dBm +/-3dB

Power Control Level 8 14dBm +/-3dB

Power Control Level 9 12dBm +/-4dB

Power Control Level 10 10dBm +/-4dB

Power Control Level 11 8dBm +/-4dB

Power Control Level 12 6dBm +/-4dB

Power Control Level 13 4dBm +/-4dB

Power Control Level 14 2dBm +/-5dB

Power Control Level 15 0dBm +/-5dB

TX Frequency Output

Low Channel (Ch 512) 1710.2 MHz

Mid Channel (Ch 699) 1747.6 MHz

High Channel (Ch 885) 1784.8 MHz

TX Frequency Calculation (Ftx)MHz 1710.2 + 0.2 x (ARFCN - 512) = Ftx MHz

Phase and Frequency Error

Peak Phase Error < 20 degrees

RMS Phase Error < 5 degrees

Frequency Stability < +/- 180Hz

KP220 SERVICE MANUAL V1.2

17

Page 19

TRANSMITTER (PCS1900)

RF Power Output

Power Levels 16 decrements in 2dB steps

Power Control Level 0 30dBm +/-2dB

Power Control Level 1 28dBm +/-3dB

Power Control Level 2 26dBm +/-3dB

Power Control Level 3 24dBm +/-3dB

Power Control Level 4 22dBm +/-3dB

Power Control Level 5 20dBm +/-3dB

Power Control Level 6 18dBm +/-3dB

Power Control Level 7 16dBm +/-3dB

Power Control Level 8 14dBm +/-3dB

Power Control Level 9 12dBm +/-4dB

Power Control Level 10 10dBm +/-4dB

Power Control Level 11 8dBm +/-4dB

Power Control Level 12 6dBm +/-4dB

Power Control Level 13 4dBm +/-4dB

Power Control Level 14 2dBm +/-5dB

Power Control Level 15 0dBm +/-5dB

TX Frequency Output

Low Channel (Ch 512) 1850.2MHz

Mid Channel (Ch 657) 1879.2MHz

High Channel (Ch 810) 1909.8MHz

TX Frequency Calculation (Ftx)MHz 1850.2 + 0.2 x (ARFCN - 512) = Ftx MHz

Phase and Frequency Error

Peak Phase Error < 20 degrees

RMS Phase Error < 5 degrees

Frequency Stability < +/- 185Hz

KP220 SERVICE MANUAL V1.2

18

Page 20

RECEIVER (EGSM)

RX Frequency Input

Low Channel (Ch 975) 925.2 MHz

Mid Channel (Ch 62) 947.4 MHz

High Channel (Ch 124) 959.8 MHz

RX Frequency Calculation (Frx)MHz

(0 - 124)

(975 - 1023)

BER (Bit Error Ratio) Type II BER <2.4% at -102dBm

F

+ 45 Mhz = F

tx

Ftx + 45 Mhz = F

Type II BER <0.1% at -15dBm

MHz

rx

MHz

rx

RECEIVER (DCS1800)

RX Frequency Input

Low Channel (Ch 512) 1805.2 MHz

Mid Channel (Ch 699) 1842.6 MHz

High Channel (Ch 885) 1879.8 MHz

RX Frequency Calculation (Frx) Ftx + 95 Mhz = F

BER (Bit Error Ratio) Type II BER <2.4% at -102dBm

Type II BER <0.1% at -23dBm

MHz

rx

RECEIVER (PCS1900)

RX Frequency Input

Low Channel (Ch 512) 1930.2MHz

Mid Channel (Ch 657) 1959.2MHz

High Channel (Ch 810) 1989.8 MHz

RX Frequency Calculation (Frx) Ftx + 80 Mhz = F

BER (Bit Error Ratio) Type II BER <2.4% at -102dBm

Type II BER <0.1% at -23dBm

MHz

rx

KP220 SERVICE MANUAL V1.2

19

Page 21

<< Previous Section

Next Section >>

Main Menu

4

Introduction of

Service Level

4-1. SERVICE LEVEL 1

4-2. SERVICE LEVEL 2

Section 4

22

KP220 SERVICE MANUAL V1.2

Page 22

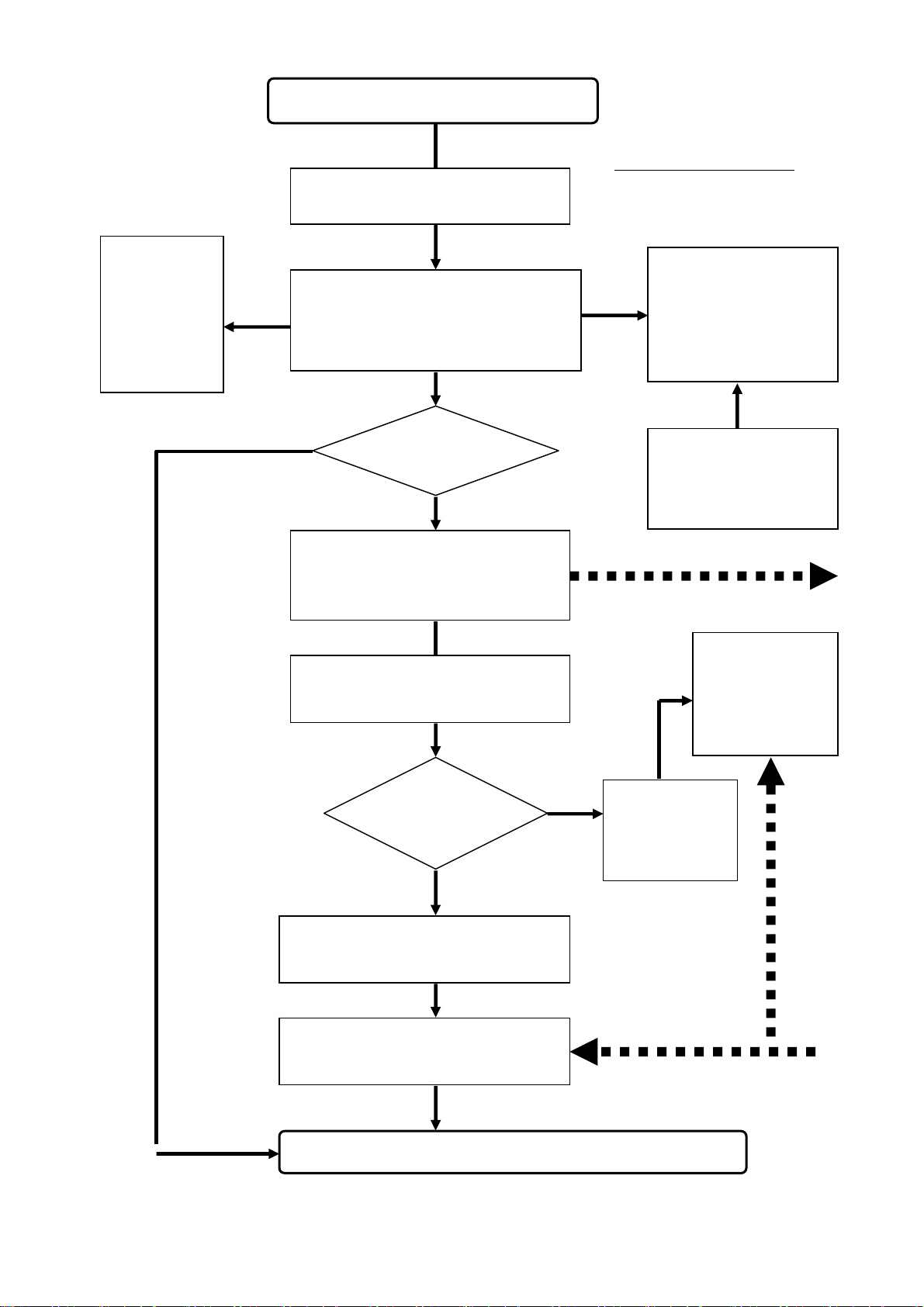

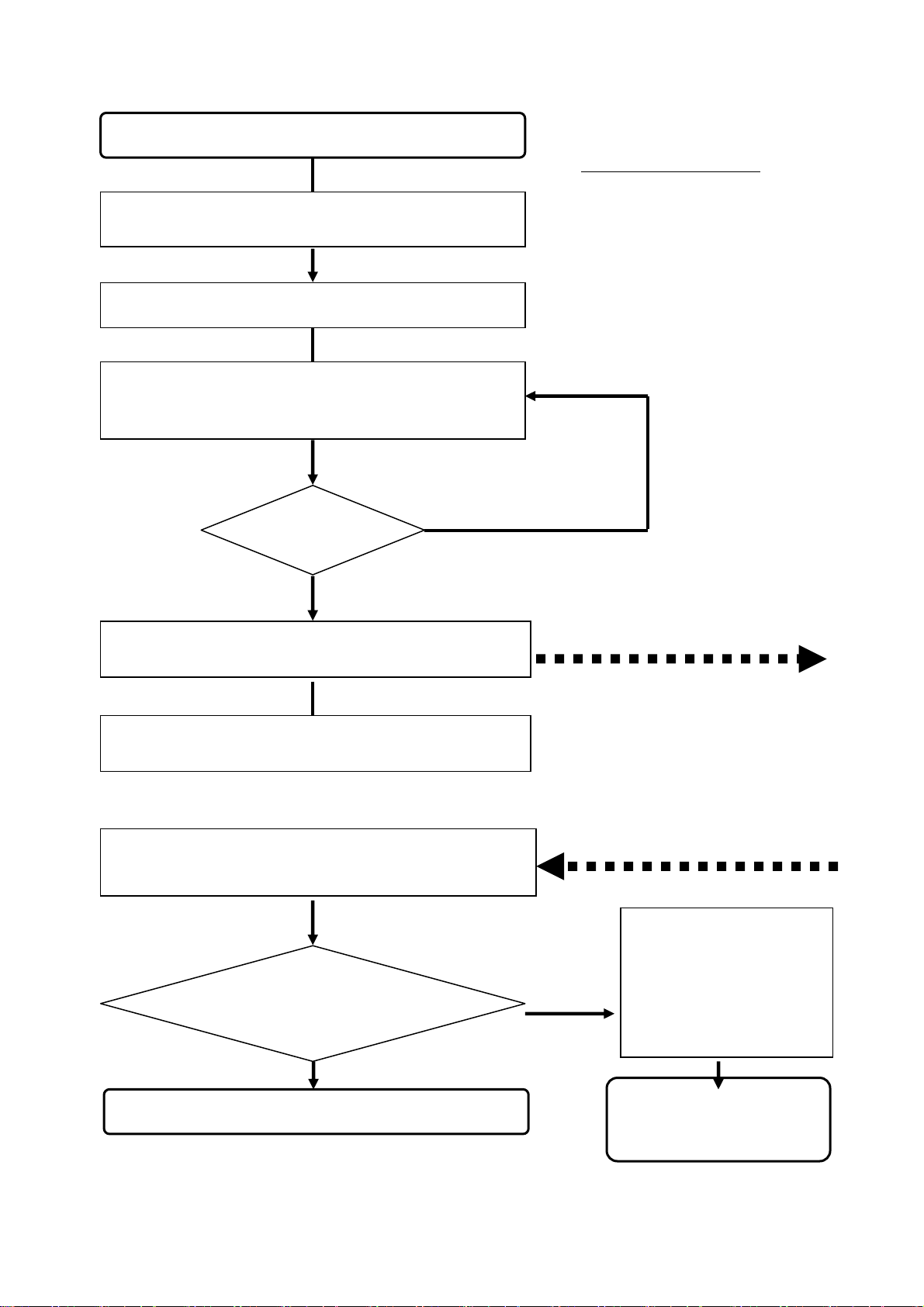

4-1. SERVICE LEVEL 1

INTRODUCTION OF SERVICE LEVEL 1

The dealers at service level 1 will have to do the following:

1. Attend to the subscriber’s complaint. Receive the equipment for servicing from

the customer and checking that the warranty period is valid or not.

2. Check the external appearance of the main equipment, peripheral units, and

accessories.

3. Check the normal operation and performance of the main equipment, peripheral

unit, and accessories.

4. If necessary, replace detachable parts, peripheral units, and accessories that

cannot be repaired. Keep a stock of good replacement phone and accessories.

5. If necessary, explain the correct method of operation to the customer.

6. Verify any faulty reported by the end-user at 2. and 3. Above.

7. Specify the symptom and fill out the fault report.

8. Send the fault report and faulty equipment to service level 2. Ask the subscriber

to wait for the equipment to be repaired.

9. In certain cases, replace the entire main equipment.

10. Receive back the repaired equipment and carry out a final check.

11. Return the repaired and correctly functioning equipment to the end-user.

23

KP220 SERVICE MANUAL V1.2

Page 23

If necessary,

explain the

correct

method of

operation to

the

customer.

Receive the equipment for

Is warranty period valid?

If not, charge the repair fee.

Physically inspect the equipment.

Check normal operation. Try to

verify the fault.

Fill out a fault report.

Fault

Yes

Send the fault report, faulty

main unit and / or repairable

accessories to Level 2.

cleared?

No

Tell the customer to wait

the estimated maximum

Is the case

urgent?

No

Wait to receive repaired

equipment from level 2.

Physical inspects the

equipment. Check normal

Return the equipment to the customer.

Yes

Flow of Service Level 1

If necessary, replace

any detachable

peripheral parts or

accessories. Discard

consumable

accessories.

Adequate stock of

good replacement

peripheral parts &

accessories

Go to Level 2

Adequate

stock of

good

replacement

Replace the

entire main

unit and

Return From Level

24

KP220 SERVICE MANUAL V1.2

Page 24

TEST EQUIPMENT AND TOOLS FOR SERVICE LEVEL 1

No GSM tester and soldering are required for Service Level 1. The following

equipment and tools are recommended for this level.

1. Fully charged battery :

Use as a power source or a temporary replacement of original battery for

faulty equipment.

2. Workable SIM card :

Used for testing the performance and functions of faulty equipment.

3. Rubber :

Used for cleaning electronic contacts, such as battery terminals, etc.

4. AC Adapter :

Used for testing the charging function of faulty equipment and / or battery.

5. Simple Hands free Kit :

Used for testing the Hands free relevant functions of faulty equipment.

6. USB Cable :

Used for testing the connection between HHP and PC.

25

KP220 SERVICE MANUAL V1.2

Page 25

4-2. SERVICE LEVEL 2

INTRODUCTION TO SERVICE LEVEL 2

The tasks at Service Level 2 will have to :

1. Receive the fault report and faulty equipment from Service Level 1.

2. Verify the faults reported at Level 1 and check the doubtful modular sub-units or

part.

3. Identify the faulty modular sub-unit or part.

4. Disassemble the equipment. Temporarily replace the faulty modular sub-unit or

part with a good one to see if this clears the trouble. Specify the faulty modular

sub-unit or part in the faulty report.

5. Send the fault report and faulty modular sub-unit together to Service Level 3. In

certain cases, replace the faulty modular sub-unit in the equipment with the good

one for quick repair.

6. Receive back the repair report, the repaired modular sub-unit from Service Level 3 and

re-install it in the equipment. Or keep this repaired modular sub-unit for next

replacement, if the faulty modular sub-unit had been replaced with a good one in step 5.

7. Perform the final test with a workable SIM card. Fill out the repair report.

8. Return the equipment to Service Level 1 with the repair report.

26

KP220 SERVICE MANUAL V1.2

Page 26

y

Receive the fault report, faulty equipment.

Verify the faults reported at Service Level 1

Disassemble the equipment.

Temporarily replace the faulty modular sub-unit or

trouble.

Fill out the fault report. Send the fault report

and fault

In certain cases, replace the faulty modular subunit in the equipment with the good one.

Receive back the repair report, the repaired

modular sub-unit from Service Level 3.

Keep as buffer stock for next replacement.

modular sub-unit together to

Had the faulty

equipment been

Fault

cleared?

Yes

lears the part with a good one to see if this c

Yes

-

No

Flow of Service Level 2

Go to Level 3

Return from Level 3

Re-install the

repaired modular

sub-unit in the

No

equipment. Perform

final test and fill out

Return the equipment to

Service Level 1 with the

repair report.

27

Page 27

<< Previous Section

Next Section >>

Main Menu

5

Section 5

Circuit

Description

5-1. LOGIC BLOCK DIAGRAM

5-2. LOGIC

Page 28

Page 29

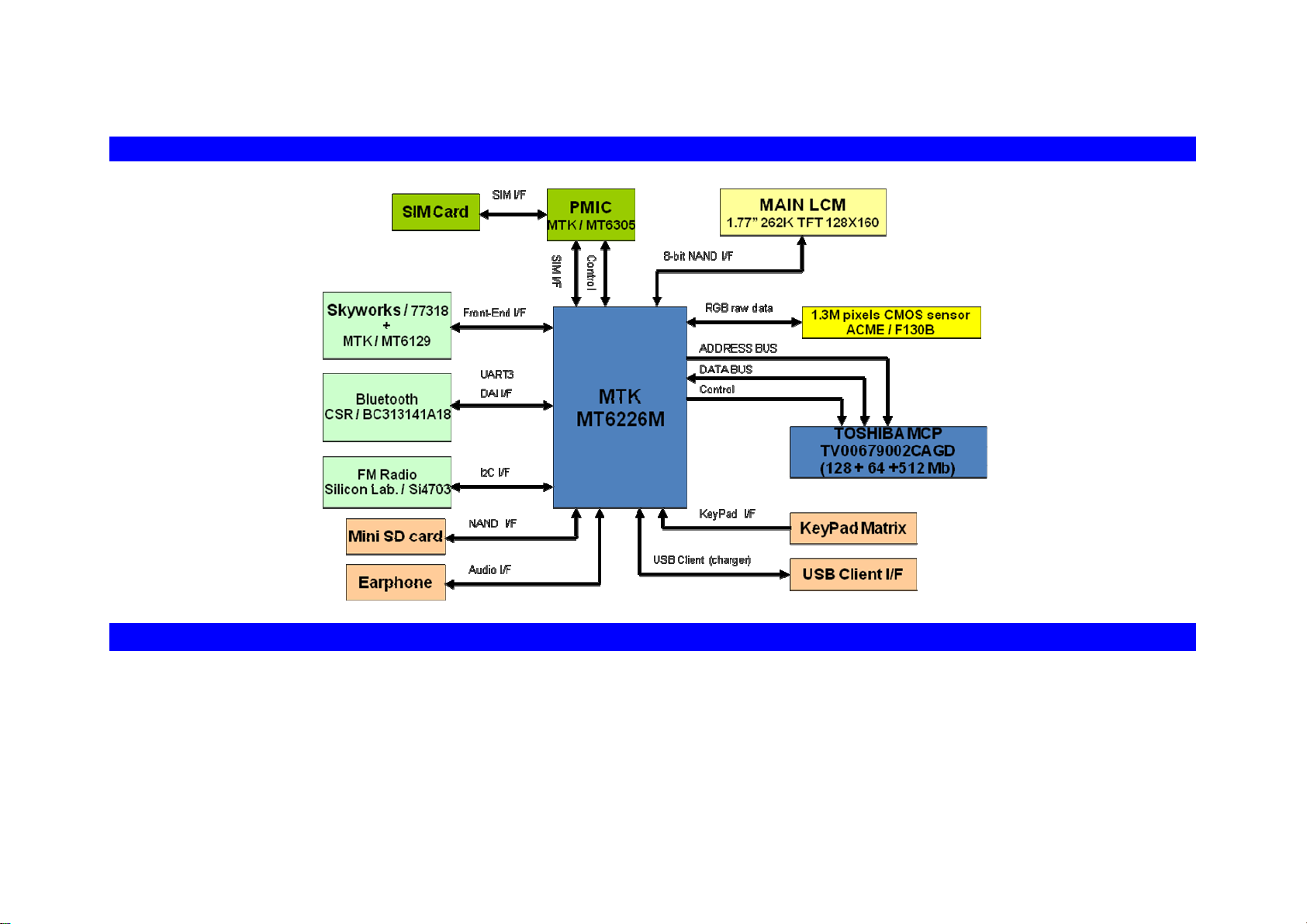

5-1. LOGIC BLOCK DIAGRAM

Page 30

5-2. LOGIC

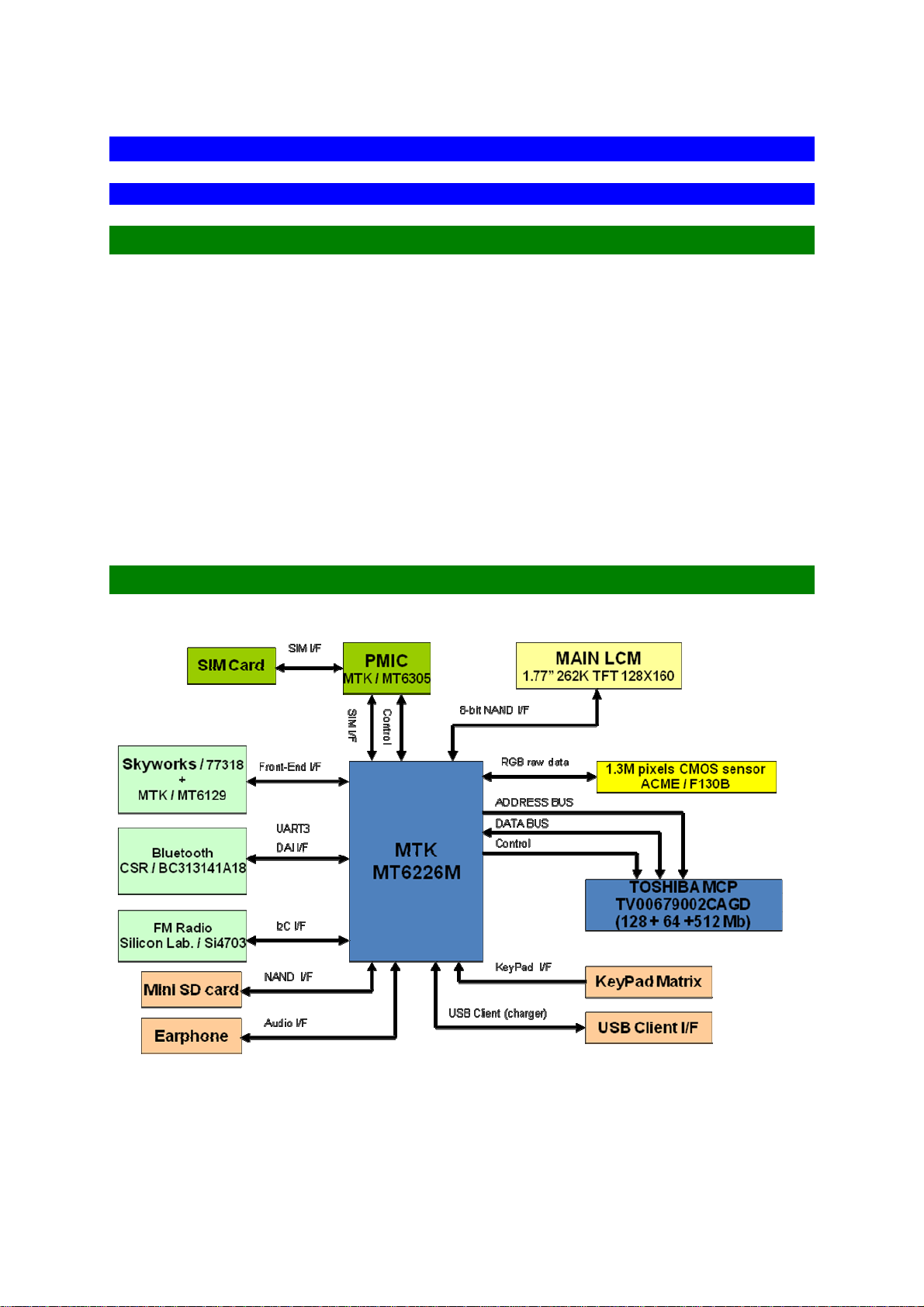

LOGIC AND BASE BAND PORTION

5-2-1. INTRODUCTION

The logic part of 7332 phone is based on Leonardo that is MTK Systems platform.

The circuit comprises the following main functional blocks:

• Memory Subsystem

• Baseband CPU(MTK6226M):

RISC ARM7EJ-STM

• MT6305: PMIC handles all baseband power

• FM Radio IC(SI4703)

• Main LCM (262K TFT)

• Camera (1.3M pixels CMOS sensor)

• Bluetooth(BC313141A18)

• TOSHIBA MCP(128+32+512MB)

• User I/O (KEY,MINI SD CARD,USB Client, SIM card )

Baseband Controller, 52MHz 32bit

5-2-2. SYSTEM BLOCK DIAGRAM

KP220 SERVICE MANUAL V1.2

Page 31

5-2-3. MEMORY SUBSYSTEM

KP220 handset memory;

Memory: (NOR128MB+PSRAM32MB+NAND512MB)

Its detail is as follows.

The consists of 128M-bit NOR Type Flash memory, 32M-bit PSRAM,

NAND512MB in a 107-ball FBGA .

5-2-3.1. Memory

Type and capacity of memories, used for 311-0000-00015 are as follows:

Description Manufacturer Type of memory Capacity

311-0000-00015

TOSHIBA

Flash Memory (NOR)

Flash Memory (NAND) 512Mb

PSRAM

311-0000-00015 is the Stacked Memory comprising of the above four memories.

128Mb

32Mb

5-2-3.2. Memory Interface Description

MT6226 incorporates a powerful and flexible memory controller, External Memory Interface, to

connect with a variety of memory components. This controller provides one generic access scheme

for FLASH Memory, SRAM and PSRAM. Up to 8 memory banks can be supported

simultaneously, BANK0 - BANK7, with a maximum size of 64MB each. Since most of the

FLASH Memory, SRAM and PSRAM have similar AC requirements, a generic configuration

scheme to interface them is desired. This way, the software program can treat different

components by simply specifying certain predefined parameters. All these parameters are based on

cycle time of system clock.

The interface definition based on such scheme is listed in following table. Note that, this interface

always operates data in Little Endean format for all types of accesses

KP220 SERVICE MANUAL V1.2

Page 32

5-2-4. MTK6226 BASE BAND CHIP

Details the block diagram of MT6226. Based on a dual-processor architecture, MT6226 integrates

both an

ARM7EJ-S core and a digital signal processor core. ARM7EJ-S is the main processor that is

responsible for running

high-level GSM/GPRS protocol software as well as multi-media applications. The digital

signal processor handles the low-level MODEM as well as advanced audio functions.

Except for some mixed-signal circuitries, the other building blocks in MT6226 are

connected to either the microcontroller or the digital signal processor.

Specifically, MT6226 consists of the following subsystems:

1.

Microcontroller Unit (MCU) Subsystem - includes an ARM7EJ-S RISC processor and its

accompanying memory management and interrupt handling logics.

2.

Digital Signal Processor (DSP) Subsystem - includes a DSP and its accompanying memory,

memory controller, and interrupt controller.

3.

MCU/DSP Interface - where the MCU and the DSP exchange hardware and software

information.

4.

Microcontroller Peripherals - includes all user interface modules and RF control interface

modules.

5.

Microcontroller Coprocessors - runs computing-intensive processes in place of Microcontroller.

6.

DSP Peripherals - hardware accelerators for GSM/GPRS channel codec.

7.

Multi-media Subsystem - integrates several advanced accelerators to support multi-media

applications.

8.

Vo i ce Front End - the data path for converting analog speech from and to digital speech.

9.

Audio Front End - the data path for converting stereo audio from stereo audio source

10.

Baseband Front End - the data path for converting digital signal from and to analog signal of

RF modules.

11.

Timing Generator - generates the control signals related to the TDMA frame timing.

12.

Power, Reset and Clock subsystem - manages the power, reset, and clock distribution

inside MT6226. Details of the individual subsystems and blocks are described in

following Chapters.

KP220 SERVICE MANUAL V1.2

Page 33

MTK 6226 Interface

KP220 SERVICE MANUAL V1.2

Page 34

5-2-5.PMU IC MT 6305

The MT6305 is a power management system chip optimized for GSM handsets, especially those based on the

MediaTek MT620x system solution. It contains seven Low Drop Out Regulators (LDO), one to power each of the

critical GSM sub-blocks. Sophisticated controls are available for power-up during battery charging, keypad

interface, and RTC alarm. The MT6305 is optimized for maximum battery life, featuring a ground current of only

107μA and 187μA when the phone is in standby and operation respectively.

KP220 SERVICE MANUAL V1.2

Page 35

PMU data

IC sheet

PIN

1

2

3,29

4

5

6

7

8

9

10

11

12

13

14

15

16

17,21,46

18

19

20

22

23

24

25

26

27

28

30

31

32

33

34

35

36

37,40

38

39

41

42

43

44

45

47

48

NAME

CHRIN

Charger Input Voltage

GATEDRV

ISENSE

CHRCNTL

CHRDET

B ATSNS Battery Input Voltage Sense

SIMIO

SIMRST

SIMCLK

S IMVCC SIM Enable

SIMSEL

DGND

RSTCAP

/RESET

VTCXO

AVBAT

AGND

SRCLKEN

PWRKEY

PWRBB

VIBRATOREN Vibrator Driver Enable, Internal Pull Low to DGND

ALERTEREN Alerter Driver Enable, Internal Pull Low to DGND

LEDEN

PGND

VIBRATOR

ALERTER

BATUSE

BATDET

VASEL

VMSEL

VCORE

NC

VSIM

SIO

SRST

SCLK

VM

VBAT

VIO

VRTC

VA

VREF

LED

VBAT

Gate Drive Output

Charger Current Sense Input

Microprocessor Control Input Signal for Gate Drive, Internal Pull Low to DGND

Charger Detect Output

SIM Supply

Non-Level-Shifted Bidirectional Data I/O

Non-Level-Shifted SIM Reset Input, Internal Pull High to VIO

Non-Level-Shifted SIM Clock Input

High for Vsim=3.0V, Low for Vsim=1.8V

Level-Shifted SIM Bidirectional Data Input/Output

Level-Shifted SIM Reset Output

Level-Shifted SIM Clock Output

Digital Ground

Memory Supply

Battery Input Voltage

Digital IO Supply

Real Time Clock Supply

Reset Delay Time Capacitance

System Reset, Low Active

TCXO Supply

Battery Input Voltage for Analog Block Circuits

Analog Supply

Analog Ground

Reference Voltage Output

VTCXO and VA Enable

Power on/off Key, Internal Pull High to VBAT

Power on/off Signal from Microprocessor

LED Driver Enable, Internal Pull Low to DGND

Power Ground

Vibrator Driver Input

Alerter Driver Input

LED Driver Input

Battery Type Selection, High for NiMH, Low for Li-ion, Internal Pull Low to DGND

Battery Detect Input, Low for Battery Connected, Internal Pull High for Battery Disconnected

High for VA enabled with VTCXO, Low for VA enabled with VD, Internal Pull Low to DGND

High for Vm=2.8 V, Low for Vm=1.8V, Internal Pull High to VIO

Battery Input Voltage

Digital Core Supply

FUNCTIO

N

KP220 SERVICE MANUAL V1.2

Page 36

5-2-5.1. Voice Band Interface

The audio front-end essentially consists of voice and audio data paths. Figure 1 shows the block

diagram of the audio front-end. The entire voice band data paths comply with the GSM 03.50

specification. In addition, Mono hands-free audio or external FM radio playback path are provided.

The audio stereo audio path facilitates audio quality playback, external FM radio, and voice

playback through headset.

Figure 2 shows the digital circuits block diagram of the audio front-end. The APB register block is

an APB peripheral that stores settings from the MCU. The DSP audio port block interfaces with the

DSP for control and data communications.

The digital filter block performs filter operations for voice band and audio band signal processing.

The Digital Audio Interface (DAI) block communicates with the System Simulator for FTA or

external Bluetooth modules.

Figure 1 Block diagram of audio front-end

KP220 SERVICE MANUAL V1.2

Page 37

2. Figure 2 Block Diagram of Digital Circuits of the Audio Front-End

Figure 2

5-2-5.2 Monitor ADC

The following is 7332 ADC in use.

External ADC name Purpose in 7332

ADC0_1- Detect Battery Voltage and Current

ADC0_1+ Detect Battery Voltage and Current

ADC2_TBAT Detect Battery tempter

ADC3_VCHG Detect Charging voltage

ADC5_USB Detect USB device

ADC6_ASS_ID Detect hand free

KP220 SERVICE MANUAL V1.2

Page 38

Circuit Diagram

5-2-6. KEY SWITCHES

KP220 SERVICE MANUAL V1.2

Page 39

KP220 SERVICE MANUAL V1.2

Page 40

Circuit Diagram

5-2-7. VIBRATOR

5-2-8. KEY BACKLIGHT LED

There are eight LEDs used for key backlighting. The LED driver of 6305 controls

these LEDs.

Circuit Diagram

KP220 SERVICE MANUAL V1.2

Page 41

5-2-9 BATTERY CHARGING

Battery management, which controls charge and discharge of the battery is

the most important function for safety. 7338 SW performs charging algorithm. To

regulator the power PMOS for set the charging current.

KP220 CHARGING CIRCUIT AND ALGORITHM

charging Circuit and Algorithm

7338 Charging circuit:

The schematic below shows the external charging components used in the Arima

7338 project. All ports are directly connected to the corresponding pins of PMU IC

(6305). VCHG is the V charger supply rail coming directly from the wall-plug constant

voltage charger via the system connector, and VBAT is the Battery Voltage rail,

connected directly to the battery pack terminal connector. The system uses a solid

ground plane, and both the Battery Pack terminal and the wall-plug charger return

paths are connected directly to ground.

KP220 SERVICE MANUAL V1.2

Page 42

Charger Sub-system

The MT6305 battery charger can be used

with Li-ion and NiMH batteries. BATUSE

pin can set MT6305 to fit the battery type.

When BATUSE is set low, Li-ion battery is

used. When BATUSE is set high, then

NiMH battery is used. MT6305 charges

the battery in three phases: pre-charging,

constant current mode charging, and

constant voltage mode charging. Figure 2

shows the flow chart of charger behavior.

The circuitry of MT6305 combines with a

PMOS transistor, diode and current-sense

resistor externally to form a simple and

low cost linear charger shown in Figure 3.

MT6305 is available pulsed top-off

charging algorithm by the CHRCNTL pin

control from baseband chipset.

Charge Detection

The MT6305 charger block has a

detection circuit that determinates if an

adapter has been applied to the CHRIN

pin. If the adapter voltage exceeds the

battery voltage by 3.75%, the CHRDET

output will go high. If the adapter is then

removed and the voltage at the CHRIN

pin drops to only 2.5% above the VBAT

pin, CHRDET goes low.

Pre-Charging mode

When the battery voltage is below the

UVLO threshold, the charge current is in

the pre-charging mode. There are two

steps in this mode. While the battery

voltage is deeply discharged below 2V, a

10mA trickle current of MT6305 charges

the battery internally. When the battery

voltage exceeds 2V, the pre-charge

current is enabled, which allows 10mV

(typically) across the external current

sense resistor. This pre-charge current

can be calculated:

KP220 SERVICE MANUAL V1.2

Page 43

Constant Current Charging Mode

Once the battery voltage has exceeded the UVLO threshold the charger will switch to the constant

current charging mode. The MT6305 allows 160mV (typically) across the external current sense resistor.

This constant current can be calculated.

If the voltage of Li-ion battery is below 4.2V (5.1V for NiMH battery), the battery will be in the

constant current charging mode.

Constant Voltage Charging Mode

This mode is only applied to Li-ion battery charging. If the battery has reached the final charge

voltage, a constant voltage is applied to the battery and keeps it at 4.2V. The charge termination is

determined by the baseband chip internally, which will pull the CHRCNTL low to stop the charger. Once

the battery voltage exceeds 4.3V of Li-ion battery (5.1V of NiMH battery), a hardware over voltage

protection (OV) should be activated and turn off the charger block of MT6305.

Pulsed Charging Algorithm

MT6305 is available to pulsed top-off charging algorithm by the CHRCNTL pin. The control signal is

from baseband chipset to limit the charging duty cycle. This charging algorithm combines the efficiency

of switch-mode chargers with the simplicity and low cost of linear chargers.

Battery Voltage Monitor

As the Table 2 shown, the relations of battery voltage and charger control signals are listed. When

Vbat < 3.2V, an UVLO signal is active low. When Vbat >= 4.3, an OV signal is active and terminates

charging. The disconnection of battery could be detected by BATDET pin. BATDET is pulled high

internally when battery disconnected and terminates charging immediately.

KP220 SERVICE MANUAL V1.2

50

Page 44

5-2-10. REAL-TIME CLOCK (RTC)

RTC is the feature to count “second”.

MTK6226M’s clock generation on 32.768kHz is made by OSC(X401 in 7338),

connecting to OSC32K_IN/ OSC32K_OUT and supply the clock to 6305.

KP220 SERVICE MANUAL V1.2

Page 45

TThe real-time clock (RTC) is driven by a 32.768 kHz clock from a crystal oscillator.

he input clock is di cond period. In

ddition, it can gene wing are basic

function of RTC:

- ime information (seconds/minutes/hours) coded in T

-Calendar information (Day/Month/

ear 2099.

y

larm function with interrupts generation bases on a periodical

-A

econd/minute/hour/day) or a precise time event in the century (second accuracy).

(s

0s time range correction

-3

2khz oscillator frequency gauging.

-3

he RTC module of 7338 is supplied by 3V Backup Battery made by Sanyo.

T

he target of running time of the backup battery (fully charged) is longer than two

T

ours after the main battery is removed.

h

vided by 32.768 to generate a clock with a 1 se

rate interrupts at a programmed time. The folloa

BCD

Year/Day of the week) directly in BCD code up to

51

KP220 SERVICE MANUAL V1.2

Page 46

5-2-11. EXTERNAL INTERFACE

The pin arrangement of system I/O is shown below.

52

KP220 SERVICE MANUAL V1.2

Page 47

5-2-12. SIM INTERFACE

he SIM int

T

module smart card. With the appropriate software and level conversion by MT6305,

the interface is compliant with GSM 11.11 a

SIMVCC

This output connects to contact C306 (VCC) of the SIM conne

supply power to the SIM card and is supplied directly from MT6305.

It is controlled by MTK6226M , and enable the power and 3V operation

respectively. Note that while SIMPWR is low, the software sets SIMRST, SIMCLK

and SIMDATA signals low.

SIMRST

This output connects to contact V502 (RST) of the SIM connector. It is set directly

by the CPU writing to the SIM control register.

SIMCLK

This output connects to contact V501 (CLK) of the SIM connector. The clock may

be set high or low, or a choice of 13/4 MHz or 13/12 MHz clock frequencies may

be selected, by writing to the SIM control register. In order to save power, the

clock should be stopped when not required, if the SIM allows it.

SIMDATA

This is a bi-directional, open drain signal, connected to contact V504 (I/O) of the

SIM connector. Control of the data signal is done in the SIM interface section of

MTK6226M, although the output can be disabled by writing to the SIM control

register. Being open-drain with an external pull-up, the output floats high when

not being driven low by either Trident-HP or the SIM card.

All the above control signals maintain their state when MTK6226M is powered down.

This allows the SIM to remain powered during soft-OFF. SIMPWR should be

switched OFF when handset ‘hard-OFF’ mode is selected.

erface module within MTK6226M allows access to the subscriber identity

nd GSM 11.12.

The electrical interface consists of five signals:

ctor. It is used to

53

KP220 SERVICE MANUAL V1.2

Page 48

5-2-13. SIGNAL CONTROL PATH FOR BACKLIGHT LED,

CAMERA FLASH LED AND INDICATOR LED

5-2-13.1 Backlight LED Control

The LCD backlight is controlled by the PWL signal from the MTK6226M. The

backlight is turned on when PWM1_LCM_EN is high. The LCD backlight a 5V power

supply. The RT9396 DC/DC converter (U801) generates the signal for

LED1,LED2 ,LED3 Detailed circuit diagram is as shown below.

KP220 SERVICE MANUAL V1.2

Page 49

5-2-13.2 Camera Control

Overview of voltage supply for Camera

RT9182 provides power supply for Camera shown below.

KP220 SERVICE MANUAL V1.2

Page 50

5-2-14. DISPLAY SYSTEM

2-14.1 TFT LCD Module

5-

The IM177BBNBA model is a Color TFT LCD supplied by LG .

This Module has a 1.77 inch diagonally measured active display area with

128(RGB)X160 resolution

Each pixel is divided into Red, Green and Blue sub-pixels and dots which are

arranged in vertical stripes.

LCD color is determined with 262K Colors signal for each pixel.

The IM177BBNBA has been designed to apply the interface method that

enables low power, high speed, and high contrast.

The IM177BBNBA is intended to support applications where thin

thickness, wide viewing angle and low power are critical factors and

graphic displays are important.

Item Main Display Remark

Display Mode

Normally White, Tran missive LCD

Driving Method TFT Active Matrix

Input Signals 8bit CPU I/F Parallel

Outside Dimensions 33.9mm(W) x 46.4mm(H) x 2.1mm(D) (Typ.)

Active Area 28.032mm(W) X 35.04mm(H)

Number of Pixels

Pixel Pitch 0.219mm(H) X 0.219mm(W) Note 1)

Pixel Arrangement

128×RGB×160 Pixels

RGB Vertical stripes

Note 1)

Note 1)

56

KP220 SERVICE MANUAL V1.2

Page 51

5-2-14.2 LCD interface

KP220 SERVICE MANUAL V1.2

57

Page 52

5-2-15.1 Camera Module

5-2-15. CAMERA

5-2-15.2 Specifications

KP220 SERVICE MANUAL V1.2

Page 53

5-2-16. AUDIO SUBSYSTEM

5-2-16.1 Outline

The audio system is composed of MTK6226M, PMU IC (MT6305). The attached

device is MIC, Receiver, Speaker.

5-2-16.2. Audio Control

Speaker interface

Use U702 to amplify voice and voice signal from MP3_OUTL

Receiver and Microphone

The receiver is a 32Ω dynamic type and is driven directly from MT6305.

The Microphone is also directly connected to MT6305 MICIP0 and MICIN0.

NEC Confidential & Proprietary

Page 54

Hands Free Interface

NEC Confidential & Proprietary

Page 55

5-2-17 FM interface

MT6226 integrates a mixed-signal Baseband front-end in order to provide a wellorganized radio interface with flexibility for efficient customization. It contains gain

and offset calibration mechanisms, and filters with programmable coefficients for

comprehensive compatibility control on RF modules. This approach also allows the

usage of a high resolution D/A Converter for controlling VCXO or crystal, thus

reducing the need for expensive TCVCXO. MT6226 achieves great MODEM

in

performance by utilizing 14-bit high resolution A/D

Furthermore,

driving

strength of some BPI outputs is designed to be configurable.

to

reduce the need for extra external current-driving component, the

Converter

the RF downlink path.

NEC Confidential & Proprietary

Page 56

5-2-18 Bluetooth interface

BuleCore3-ROM CSP is signal chip radio and baseband chip for Bluetooth wireless

technology 2.4G Hz system .it is implemented in 0.18um CMOS technology.

The 4Mbit ROM is metal programmable ,which enables an eight week turn-around

from approval of firm are to production samples.

NEC Confidential & Proprietary

Page 57

5-2-19 RF Sub-systems

MT6129 is a highly integrated RF transceiver IC for multi-band Global Systems for

obile communication (GSM) and General Packet Radio Service (GPRS) cellular M

system applications. The MT6129 includes four LNAs, two RF quadrature mixers, an

integrated channel filter, programmable gain am

the

receiver, a precision IQ modulator with offset PLL for the transmitter, two internal

TX VCOs, a VCXO, on-chip regulators, and a fully programmable sigma-delta

fractional-N synthesizer with an on-chip RF VCO. The MT6129 also includes contr

circuits to enable different operating modes. The device is housed in a 56-pin Q

SMD package with a down set paddle for additional grounding.

plifiers (PGA), an IQ demodulator for

ol

FN

NEC Confidential & Proprietary

Page 58

5-2-19.1 Receiver

The receiver section of MT6129 includes Quad-band low noise amplifiers (LNAs),

RF

quadrature mixers, an on-chip channel filter, Programmable Gain Amplifiers

(PGAs), quadrature second mixers, and a final low-pass filter. The very low-IF

MT6129 uses image-rejection mixers and filters to eliminate int

accurate RF quadrature signal generation and mixer matching techniques, the image

rejection of the MT6129 can reach 35 dB for all bands. The fully integrated channel

filters rejects interference, blocking signals, and images without any external

components. Compared to a

arc

hitecture improves the blocking rejection, AM suppression, as well as the

adjacent channel interference performance. Moreover, the very low-IF architectu

eliminates the need for complicated DC offset calibration that is necessary in a DCR

architecture. In addition, the common-mode balance requirement of the SAW filter

put is relaxed. The MT6129 provides the analog IQ baseband outpin

xtra frequency conversion components.

e

The MT6129 includes four differential LNAs for GSM 850 (869 MHz – 893 MHz

E-GSM 900 (925 MHz-960 MHz), DCS 1800 (1805 MHz-1880 MHz) and PCS 1900

(1930 MHz –1990 MHz). The differential inputs are matched to 200 _ SAW filters

using LC networks. The gain of the LNAs can be controlled either high or low for an

additional 35 dB dynamic range control. Following the LNAs are the image-rejection

quadrature RF mixers that down-convert the RF signal to the IF frequency. No

external components are needed at the output of the RF mixers.

The IF signal is then filtered and amplified through an image-rejection filter and a

PGA. The multi-stage PGA is implemented between filtering stages to control the

gain of the receiver. With 2 dB gain steps, a 78 dB dynamic range of the PGA

ensures a proper signal level for demodulation. The quadrature 2nd mixers are

provided on-chip to down convert IF signal to baseband in an analog differential IQ

format.

direct conversion receiver (DCR), MT6129’s very low-IF

erference. With

re

ut without any

),

5-2-19.2 Transmitter

The MT6129 transmitter section consists of two on-chip TX VCOs, buffer

amplifiers, a down-converting mixer, a quadrature modulator, an analog phase

detector (PD) and a digital phase frequency detector (PFD), each with a charge

pump output and on chip loop filter. The dividers and loop filters are used to achieve

the desired IF frequency from the down-conversion mixer and quadrature modulator.

For a given transmission channel, the transmitter will select one of the two different

TX reference dividing numbers. These built-in components, along with an internal

voltage controlled oscillator (TX VCO) and a loop filter, implement a translation loop

modulator. The TX VCO output is fed to the power amplifier (PA). A control loop,

implemented externally, is used to control the PA’s output power level.

NEC Confidential & Proprietary

Page 59

5-2-Tw1

he TX ypically 9 dB th +/- 2.5dB variation in E-GSM900/

T VCO output power is t

SM8 utput power

CS19 me temperature conditions. Inside the chip, the VCO

P

ifferen re fed into the output buffer, the OPLL input feedback

d

uffer, and the calibration circuit. The off chip signal is transformed into a single

b

nded output which needs impedance matching to 50_to drive the power amplifier.

e

ike RF VCO, the oscillation bandwidth is partitioned into 128 (or 64) sub-bands for

L

CS/ PCS (for E-GSM900/ GSM850) TX VCO to cover the process and temperature

D

ariation. Calibration process begins after a period of programmable time when the

v

n chip TX VCO regulator is turned on. Total calibration time needs about 60us

o

aximally and the frequency error after calibration is within +/-5 MHz. For Vtune =

m

.2 V, the variation of kvco is about 14% and 40% for GSM and DCS/PCS TX VCO,

1

espectively, across the desired fre

r quency range.

9.3 TX VCO

o power VCOs are integrated w P

50 bands and +8 dB

00 bands over extre

tial output signals a

m o

ith O LL to form a complete transmitter circuit.

s

m wi

with +/- 2dB variation in DCS1800/ G

5-2-19.4 Frequency Synthesizer

The MT6129 includes a integrated RF VCO to

generate RX and TX local oscillator frequencies. The PLL locks the RF VCO to a

precision reference frequen the inherent spur

aused by fractional-N syn modulator with

ithering function is used to generate the presale divider number N. The presale is

d

ased on a multi-modulus architecture with programmable divider numbers ranging

b

om 64 to 127. A conventional digital-type PFD with a charge pump is used for

fr

hase comparison in the PLL. By changing the output current of the charge pump,

p

e phase detector gain can be programmed from75/_ _A/rad to 600/_ _A/rad.

th

To reduce the acquisition time or to enable

services such as GP

system are implemente

loop. After the calibr

cilitate fast locking. Once the acquisition is done, the PLL reverts back to the

fa

ormal operation mode.

n

RS, a digital loop (calibration loop) along with a fast-acquisition

et tthe RF VCO is pre-s

ation, a fast-acquisition system is utilized for a period of time to

frequency synthesizer with a fully

cy at 26 MHz. In order to reduce

thesizers, a 3rd-order sigma-deltac

fast settling time for multi-slot data

d in the synthesizer. Once the synthesizer is programmed,

o the vicinity of the desired frequency by a digital calibration

NEC Confidential & Proprietary

Page 60

5-21-19.5 Volta

Voltage Control Crystal Oscillator (VCXO) consists of an amplifier, a buffer, and a

programmable

reference freq

eries resonance with a standard 26 MHz crystal. The crystal is connected from the

s

put pin XTAL of amplifier to ground through a series load capacitance. The buffer

in

rovides a typical 600mVpp voltage swing at either 13 MHz or 26 MHz. It is designed

p

to drive a tuned load to improve harmonic contents and reduce the oscillator current

consumption. The capacitor array, from 0.0625 pF to 4 pF in steps of 0.0625 pF, is

used to shunt the series load capacitor for coarse tuning and remove any fixed

offsets due to crystal manufacturing variations. An internal varactor that provides fine

tuning combines with the capacitor array. As an alternative, the reference frequency

can be provided by an external 26 MHz VCTCXO module.

When pin VCXOCXR is tied to the VCCVCXO supply, the XTAL pin will accept

an external signal. Furthermore, the VCXO control pin can be tied to VCCVCXO to

prevent the current leakage during the sleep mode operation.

capacitor array. The VCXO provides the MT6129 with a selectable

uency of either 13 MHz or 26 MHz. The amplifier is designed to be in

ge Control Crystal Oscillator

5-2-19.6 Regulator

The MT612X internal regulators provide low noise, stable, temperature and

independent supply voltages to critical blocks in the transceiver. An internal Pchannel MOSFET pass transistor is used to achieve a low dropout (LDO) voltage of

less than 150 mV in all regulators.

69

NEC Confidential & Proprietary

Page 61

<< Previous Section

Next Section >>

Main Menu

SECTION 6

6

6-1. Structure

6-2. Accessories

6-3. Soldering

Servicing

70

NEC Confidential & Proprietary

Page 62

6-1. STRUCTURE

1. KP220

Front View Back View

72

NEC Confidential & Proprietary

Page 63

MAIN BOARD ASSEMBLY

he lower board consists of the following cir

T cuits:-

1.Tri band GPRS GSM Transceiver and logi

nection socket 2.SIM con

3.System

4.battery term

6.Embedded tri

7.Vibrator conn

9.Camera con

10.Receiver connection terminal

11.Speaker connection terminal

12.SD Card connection terminal

13.LED, camera control and LCD driver circuit

I/O connector with charge capability

inals

jack

ree5.Hands f

band antenna connection terminal

ection terminal

connection terminal

8.Microphone

nection terminal

c Unit

NEC Confidential & Proprietary

Page 64

FRONT COVER

The Front cover contains following m

.Receiver

1

2.Keypad

ain parts :-

2. keypad

1.Receiver

NEC Confidential & Proprietary

Page 65

REAR COVER

The Rear cover contains following main parts :-

1. Speaker

2. Vibrator

3. Microphone

4. Antenna

5. Charger cover

6. SD card cover

7. Volume key

8. Camera key

Charger cover

vibrator

microphone

Antenna

SD Card cover

speaker

Volume key

Camera key

75

KP220 SERVICE MANUAL V1.2

Page 66

6-2. ACCESSORIES

BATTERY

AC ADAPTER

KP220 SERVICE MANUAL V1.2

Page 67

HANDSFREE & USB CABLE

Cable

KP220 SERVICE MANUAL V1.2

Page 68

6 -3.SOLDERING

SOLDERING PARTS LOCATION

SOLDERING REPAIRED PARTS AT SERVICE LEVEL 2 ARE SHOWN AS BELOW.

Bluetooth

BC313141A18

RTC

32.768KHz

antenna switch

ESHS-C085TK

PA

SKY77318

PMIC

MT6305

Cr

ystal

26 MHZ

MCP Memory

TV00579002EAGD

LDO

LP3995

Baseband Controller

Status

LED

Key Board

Connector

FM Receiver

Si4703

Receiver

Contact

MT6226

LCM

Hot Bar

KP220 SERVICE MANUAL V1.2

Page 69

A

A

Micro SD

Slot

Microphone

Contact

Vibrator

Contact

Battery

Contact

LDO

RT918 2

SIM Card

Connector

ntenna

Pogo Pin

RF Switch Connector

MM8430

KP220 SERVICE MANUAL V1.2

Camera Modu

Socket

le

udio Amplifier

LM4671

Speaker

Contact

Mini USB

Connector

Page 70

DC

-DC

MO

P Ch

SFE

Si58

annel

T+Sch

53DC

ottky

TV

PES

TVS

ESD

S ARR

D5V0L

CONVER

ARRAY

5V0L5UY P

LDO

298LP 5

AY

5UY

RT9

363

T

TCXO

26MHz

GS

M/G

PRS

Tra

nscei

ver

S

AW

Fil

5EB

ter

-9

42M50FA

R-F

Backup Batt

XH414H IV01E

KP220 SERVICE MANUAL V1.2

ery

S

FAR-AWF6E

SAW Filter

Filt

B-1erG 8425

B-1FAR- GF6E 9600

95

Page 71

<< Previous Section

Next Section >>

Main Menu

7

Repairing

7-1. Testing

7-2. Troubleshooting

Section 7

97

KP220 SERVICE MANUAL V1.2

Page 72

7-1. TESTING

OVERVIEW

1. Product overview and frequency assignment

TX E-GSM 880MHz to 915MHz (deltaF=2

RX E-GSM 925MHz to 960MHz (deltaF=200KHz)

Radio Frequency Band

ARFCN

RF Loc

T requency X IF F

Access form 8 channel multiple TDMA

Multiple 8 channel / carrier ( E-GSM/DCS1800/PCS1900)

Modulation 270.8333Kbit/s GMSK

Peak output power

Nominal supply

voltage

TX peak current 2500mA max.

GPRS Class Class10 (max 1UL/4DL) Operation class B

GPRS Coding scheme CS1/CS2/CS3/CS4

al Synthesizer

TX DCS1800 1710MHz to 1785MHz

RX DCS1800 1805MHz to 1880MHz

TX PCS1900 1850MHz to 1910MHz

RX PCS1900 1930MHz to 1990MHz

E-GSM Ful(n) = 890 + 0.2 x n at ( 0 <= n <= 124 )

Ful(n) = 880 + 0.2 x (n-1024) at ( 975 <= n <= 1023)

Fdl(n) = Ful(n) + 45

DCS1800 Ful(n) = 1710.2 + 0.2 x (n-512) at ( 512 <= n <= 885 )

Fdl(n) = Ful(n) + 95

PCS

1900 Ful(n) = 1850.2 + 0.2 x (n-512) at ( 512 <= n <= 810 )

Fdl(n) = Ful(n) + 80

E-GSM 1279~1314 MHz

DCS1800 1327~1402 MHz

PCS1900 1423~1483 MHz

E-GSM 798 MHz (Typ) (880-895 MHz, 900-915 MHz)

790 MHz (Typ) (895-900 MHz)

DCS1800 766 MHz (Typ)

PCS1900 854 MHz (Typ)

E-GSM 2W(33dBm) Class4 MTS

DCS1800 1W(30dBm) Class1 MTS

PCS1900 1W(30dBm) Class1 MTS

+3.8V

00KHz)

2. Channel selection conditions

Verify that there is no interference from other radio devices or neighboring

easurement systems in the frequencies to be used for the test. If there is

m

terference, select the test channels within the range of the following channels.

in

specially in case of bit error tests, make sure that there is no influence from outside

E

efore the test. If necessary, use a shielded box or take other channel measures.

b

E-GSM DCS1800 PCS1900

Lch

Mch

Hch

975ch to 980ch 513ch to 523ch 512ch to 522ch

60ch to 65ch 690ch to 710ch 657ch to 667ch

120ch to 124ch 874ch to 884ch 800ch to 810ch

KP220 SERVICE MANUAL V1.2

98

Page 73

3. Product Specification

Based on GSM 11.10-1 / 3G TS 51.110

4. Measurement adapter

Dumm

Test S

RF connect

PC-Link cable

y battery

Dummy battery should be used shown as follows:

IM card

In confidence test, general Phase2 (or Phase2+) test SIM should be used.

or and RF cable

RF

connector and RF cable should be used for RF test

PC-link cable (Serial Link Cable) should be used.

99

KP220 SERVICE MANUAL V1.2

Page 74

. Test purpose

1

a) To verify Ap

b) To verify re

c) To v

d) To verif

erify Function Test in the table shown as below

FUNCTION TEST

pearance by visual check

cognition of SIM card

y power down phone

2. Te

3 st Procedure

a. Power on Phone

*#878#

Select item 1 “Servi

st System

1. nit (PSU)+Dummy Battery or Battery

Power Supply U

2. SM Phase 2+ Test SIM Standard 1(3.1))

Test SIM Card (Spec: G

3. (SHF, Stereo)

Sample Hands free Kit

. Te

3.1 Appearance Test

Verify appearance by visual check

3.2 SIM Test

Verify recognition of SIM card

If “Insert SIM” indicated on Display, it is NG.

3.3 Enter Service Mode

3.1.1 No SIM Card installed

b. Press 878 to enter service mode.

3.1.2 SIM Card installed

a. Power on Phone

b. Press to enter service mode.

3.1.3 Software Version Check

ce Info” in Service mode to check software version.

100

KP220 SERVICE MANUAL V1.2

Page 75

3.4 MMI Tests

1. Auto test

2. BT Mode

3. Echo Loop

4. Version

. Resource B

5 IN

6. Keypad

7. Vibrator

8. Loud SPK

9. Ring Tone

10. LED

11. LCD

12. Receiver

13. ADC

14. Ch

15. Hea

16. R

17. MT

18

19. Memory Card

20. Nand Flash

arger

dset

TC

BF

. UART

21. Camera

22. Total call time

23.

FM Radio

101

KP220 SERVICE MANUAL V1.2

Page 76

. Te

1 st purpose

This test is for check RF characteristics.

. Test system

2

1. PC

2. Printer

3. PSU

4. GSM Test Set

5. USB Cable

6. UART Cable

7. Calibration Adapter

8. RF Cable

Measurement setup is shown

Test Instruments

1. PC

2. PRINTER

CONFIDENCE TEST

as follows:

5. USB Cable

6. UART Cable

4. GSM Test Set

E5515B

(HP8960)

Calibration adapter

Lower

Board

8. RF Cable

3. PSU

HPE3631A

102

KP220 SERVICE MANUAL V1.2

Page 77

3. Test Specification

Measurement item and specification is defined as follows:

Test Item

TX Maximum Power

T

X Power

R

MS Phase error

PEAK Phase error

Frequency Error

P

ower Vs Time

R

X Class2 RBER

R

X Level

R

X Quality

31dBm +

29dBm + B @ PL7

27dBm + @ PL8

25dBm +

23dBm +/ L10

21dBm +/

19dBm +

17dBm +

15dBm /- 3dB @ PL14

13dBm +/- 3dB @ P

11dBm +/

9dBm +/ B @ PL17

7dBm +/ B @ PL18

5dBm +/

pass/ ail specification is shown as table 4.1

Specification

E-GSM DCS1800 PCS1900

33dBm +/-2dB 30dBm +/-2dB

/- 3dB @ PL6

/- 3d

/- 3dB

/- 3dB @ PL9

- 3dB @ P

- 3dB @ PL11

/- 3dB @ PL12

/- 3dB @ PL13

+

L15

- 5dB @ PL16

- 5d

- 5d

- 5dB @ PL19

< < 180Hz < 185Hz 90Hz

fail indication. Det

<2.4% @ -10

<5deg

<20deg

3.5dBm (avg 10000bit)

7 +/-4 @

<3 @ -1

28dBm +/- 3dB @ PL1

26dBm +/- 3dB @ PL2

24dBm +/- 3dB @ PL3

22dBm +/- 3dB @ PL4

20dBm +/- 3dB @ PL5

18dBm +/- 3dB @ PL6

16dBm +/- 3dB @ PL7

14dBm +/- 3dB @ PL8

12dBm +/- 4dB @ PL9

10dBm +/- 4dB @ PL10

8dBm +/- 4d

6dBm +/- 4d

4dBm +/- 4dB @ PL13

2dBm +/- 5dB @ PL14

0dBm +/- 5dB @ PL15

-103.5dBm

03.5dBm

B @ PL11

B @ PL12

103

KP220 SERVICE MANUAL V1.2

Page 78

(*)

(**)

wer Vs Time mask specification Po

dB

+ 4

+ 1

- 1

- 6

(**)

- 30

(***)

(147 bits)

(*)

8

탎

10

탎

10

Time mask for ormal d tion bursts(NB,FB,dB and SB) at GM

탎

n ura SK modulation

7

056/13 (542.8)

10 탎8

탎

탎

10

탎

t

For GSM 900 MS the

For DCS1800 and PCS1900 the

MS : -48 dBc or -48 dBm, whichever is

: -59 dBc or -54 dBm, whichever is

greater, except for th

preceding the active slot, for w

the allowed level is -59

e time slot

hever isor -36 dBm whic

hich

dBc

the greater

higher.

For GSM 900 MS

-4 dBc for powe:

-2 dBc for power level 1

r control level 16;

7;

level co-1 dBc for power

ntrols levels

18 and 19.

For DCS1800 and PCS1900

-4dBc for power contro MS :

-2dBc for power level

-1dBc for power control levels 13,1

l level 11,

12,

4

and 15

For GSM S : -30 dBc or -17 dBm, whichever is the

900 M (***)

higher.

For DCS1800 an 00

d PCS19 MS : -30dBc or -20dBm, whichever is the

higher.

104

KP220 SERVICE MANUAL V1.2

Page 79

4. Test Pr

Test items should be s

of GSM test set, th est shou over to

oce

dure

equential in the table shown as below. Due to

e t ld be started under E-GSM mode and hand

limitation

DCS1800. In PCS1900 mode, the test should be started under PCS1900 mode.

fault se M ws:

De tting of GS test set and PSU is shown as follo

(Internal L (Please measure cable loss on first se

CALL STATUS IDLE

CELL STATUS ACTIVE CELL

OPERATING MODE E-GSM

Expected input level TX Level 5 : 33dBm

Control Base station Broadcast Broadcast ON

Control Base station Channel 20

Control Base station Amplitude -85dBm

Mobile Phone Channel 62 ( could be changed ARFCN Mch )

Mobile Phone TX Level 5

Mobile Phone Timeslot 4

PSU output voltage +3.8V +/- 0.05V

PSU maximum current limit 2500mA

oss) t-up and calibrate

it.)

CALL STATUS IDLE

CELL STATUS ACTIVE CELL

OPERATING MODE PCS1900

Expected input level TX Level 0 : 30dBm

Control Base statio stn Broadca Broadcast ON

Control Base station Channel 512

Control Base station Amplitude -85dBm

Mobile Phone Channel 661 ( could be changed ARFCN Mch )

Mobile Phone TX Level 0

Mobile Phone Timeslot 4

PSU output voltage +3.8V +/- 0.05V

PSU maximum current limit 2800mA

105

KP220 SERVICE MANUAL V1.2

Page 80

Test item MODE Procedure

Start up

E-GSM 1. Set SIM card and dummy battery to HHP

2. Power on HHP

3. Wait to indicate “GSM Test Net 001”

Call setup

X Power

T

RMS Phase error

PEAK Phase error

Frequency Error

Power Vs Time

RX Class2 RBER

RX Level

RX Quality

Hand over

Close down

*1 Refer to 1.Overview Channel selection condition

E-GSM 1. Input the PTE comma “StartCall” nd

2. “Receivecall”. Input the PTE command

3. Wait to indicate “Active” to establish call

E-GSM

DCS

1800 Set PL to 5(E-GSM)

E-GSM

DCS1800

E-GSM

DCS1800

E-GSM

DCS1800

E-GSM

DCS1800

E-GSM

DCS1800

E-GSM

DCS1800

E-GSM 1. Same sett RX RBER ing and procedure as

E-GSM to

DCS1800

( Test is repeated under DCS1800 band )

DCS1800 1. Push “END Call” of GSM tester

1. ARFCN is assign to Mch ( and Lch/Hch )

2. or 0(DCS1800)

3. Wait to establish hand over

4. power Measure output

1. Hch ) ARFCN is assigned to Mch ( or Lch/

2. Set PL to 5(E-GSM) or 0(DCS1800)

3. Wait to establish hand over

4. Change mode of GSM tester to “Phase/FREQ”

5. Set analyze burst number to 50

6. Read “RMS maximum” window

1. ARFCN is assigned to Mch ( or Lch/Hch )

2. Set PL to 5(E-GSM) or 0(DCS1800)

3. Wait to establish hand over

4. Change mode of GSM tester to “Phase/FREQ”

5. Set analyze burst number to 50

6. Read “PEAK maximum” window

1. ARFCN is assigned to Mch ( or Lch/Hch )

2. Set PL to 5(E-GSM) or 0(DCS1800)

3. Wait to establish hand over

4. Change mode of GSM tester to “Phase/FREQ”

5. Set analyze burst number to 50

6. Read “Frequency error maximum” window

1. ARFCN is assigned to Mch

2. Set PL to 5(E-GSM) or 0(DCS1800)

3. Wait to establish hand over

4. Change mode of GSM tester to “Power Ramp”

5. To check pass/fail indication under three mode “TOP 2dB”

“Rise edge” and “Fall edge”

1. ARFCN is assigned to Mch*1

2. Set PL to 5(E-GSM) or 0(DCS1800)

3. Wait to establish hand over

4. Change mode of GSM tester to “Bit error”

5. To define sampling value to 10000

6. To define measure “Res Type 2”

7. To adjust base station output level to -103.5dBm

8. Wait to indicate BE Ratio and read it.

1. Same setting and procedure as RX RBER

2. Wait to ind v” and read it. icate “Mobile reported Rxle

2. Wait to ind l” and reicate “Mobile reported RX Qua ad it. DCS1800

1. Change mode of GSM tester to “DUAL BAND”

2. To define DCS1800 parameter. ARFCN to Mch, Base station

output level to –85dBm, Mobile power level to PL0.

3. Push “Execute” and check establish hand over.

2. Wait to indicate “Call End” and change to idle screen.

3. Push “Power” to check shut down.

106

KP220 SERVICE MANUAL V1.2

Page 81

Test item MODE Procedure

Band Change E-GSM /

DCS1800

->

PCS1900

Call setup

TX Power

RMS Phase error

PEAK Phase error

requency Error

F

Power Vs Time

RX Class2 RBER

RX Level

RX Quality

Close down

*1 Refer to 1.Overview Channel selection condition

PCS1900 1. Input the PTE command “Start Call”

PCS1900 1. ARFCN is assign to Mch ( or Lch/Hch )

PCS1900 1. ARFCN is assigned to Mch ( or Lch/Hch )

PCS1900 1. ARFCN is assigned to Mch ( or Lch/Hch )

PCS1900 1. ARFCN is assigned to Mch ( or Lch/Hch )

PCS1900 1. ARFCN is assigned to Mch

PCS1900 1. ARFCN is assigned to Mch*1

PCS1900 1. Same setting and procedure as RX RBER

PCS1900 1. Same setting and procedure as RX RBER

PCS1900 1. Push “END Call” of GSM tester

1. Change mode of GSM tester to “PCS1900”.

2. Set HHP to PCS1900 mode using PTE Command

Use PTE command 00140 => SetBandSelect,1

2. input the PTE command “Receive call”

3. Wait to indicate “Active” to establish call

2. Set PL to 0(PCS1900)

3. Wait to establish hand over

4. Measure output power

2. Set PL to 0(PCS1900)

3. Wait to establish hand over

4. Change mode of GSM tester to “Phase/FREQ”

5. Set analyze burst number to 50

6. Read “RMS maximum” window

2. Set PL to 0(PCS1900)

3. Wait to establish hand over

4. Change mode of GSM tester to “Phase/FREQ”

5. Set analyze burst number to 50

6. Read “PEAK maximum” window

2. Set PL to 0(PCS1900)

3. Wait to establish hand over

4. Change mode of GSM tester to “Phase/FREQ”

5. Set analyze burst number to 50

6. Read “Frequency error maximum” window

2. Set PL to 0(PCS1900)

3. Wait to establish hand over

4. Change mode of GSM tester to “Power Ramp”

5. To check pass/fail indication under three mode “TOP 2dB”

“Rise edge” and “Fall edge”

2. Set PL to 0(PCS1900)

3. Wait to establish hand over

4. Change mode of GSM tester to “Bit error”

5. To define sampling value to 10000

6. To define measure “Res Type 2”

7. To adjust base station output level to -103.5dBm

8. Wait to indicate BE Ratio and read it.

2. Wait to indicate “Mobile reported Rx lev” and read it.

2. Wait to indicate “Mobile reported RX Qual” and read it.

2. Wait to indicate “Call End” and change to idle screen.

3. Push “Power” to check shut down.

107

KP220 SERVICE MANUAL V1.2

Page 82

3. Test Specification

Measurement item and specification is shown as below :

Test item MODE Specification

TX Maximum

Power

Test item MODE Specification

Current Value

USB I/F Check

E-GSM +24dBm ~ +43dBm

Max 100mA

Detection of HHP COM port

4. Test Procedure

Test items should be sequential in the table shown as below :

Test item MODE Procedure

Start up

TX Power

Current Check

USB I/F Check

E-GSM 1. Set dummy battery to HHP

2. Link cable is connected (auto power ON)

3. Put Into test mode

E-GSM 1. ARFCN is assign to Mch

2. Set PL to 5(E-GSM)

3. Measure output power

1. Input following PTE command.

Use PTE Command, <Magic Number>

Cont Tx off

Backlight off

Key Backlight off

Select Backlight off

2. Check current value

1. Check detection of HHP COM port

*1

5. Back Up Battery Check

Back Up Battery Check must performed after FT process

Back Up Battery Check process is shown as follows :

.RTC time is automatically set up at FT process(2004/01/01 00:00)

1

.Check the RTC time next process

2

ITEM DETAIL PTE command Specification

Check RTC time

Note : Stingray’s Back Up Battery will become empty in 2.5 days.

Back Up Battery test must be performed within two days after soldering