Page 1

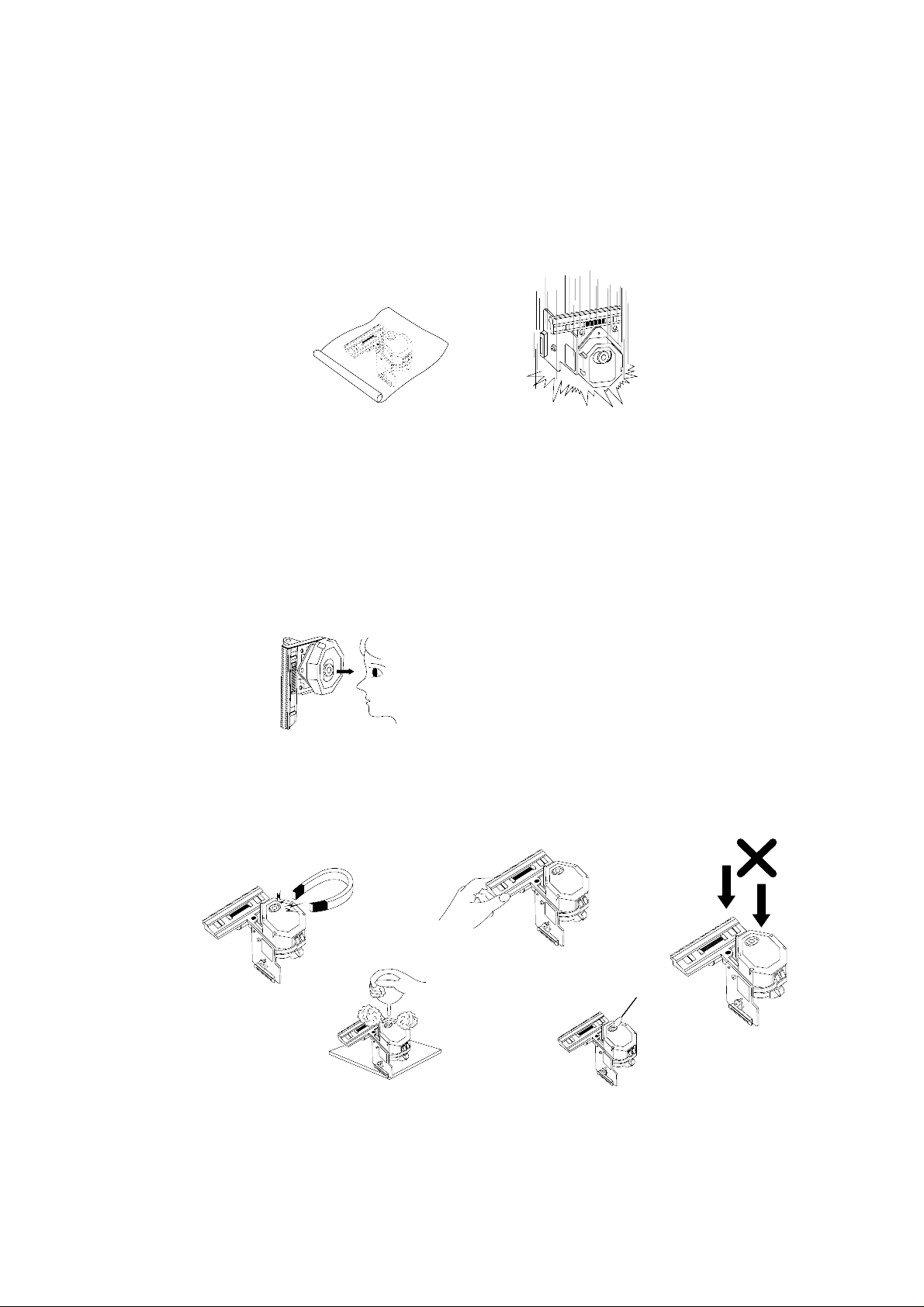

NOTES REGARDING HANDLING OF THE PICK-UP

1. Notes for transport and storage

1) The pick-up should always be left in its conductive bag until immediately prior to use.

2) The pick-up should never be subjected to external pressure or impact.

2. Repair notes

1) The pick-up incorporates a strong magnet, and so should never be brought close to magnetic materials.

2) The pick-up should always be handled correctly and carefully, taking care to avoid external pressure and

impact. If it is subjected to strong pressure or impact, the result may be an operational malfunction and/or

damage to the printed-circuit board.

3) Each and every pick-up is already individually adjusted to a high degree of precision, and for that reason

the adjustment point and installation screws should absolutely never be touched.

4) Laser beams may damage the eyes!

Absolutely never permit laser beams to enter the eyes!

Also NEVER switch ON the power to the laser output part (lens, etc.) of the pick-up if it is damaged.

5) Cleaning the lens surface

If there is dust on the lens surface, the dust should be cleaned away by using an air bush (such as used

for camera lens). The lens is held by a delicate spring. When cleaning the lens surface, therefore, a

cotton swab should be used, taking care not to distort this.

6) Never attempt to disassemble the pick-up.

Spring by excess pressure. If the lens is extremely dirty, apply isopropyl alcohol to the cotton swab. (Do

not use any other liquid cleaners, because they will damage the lens.) Take care not to use too much of

this alcohol on the swab, and do not allow the alcohol to get inside the pick-up.

SERVICING PRECAUTIONS

- 3 -

Storage in conductive bag

Drop impact

NEVER look directly at the laser beam, and don

′t let

contact fingers or other exposed skin.

Magnet

How to hold the pick-up

Pressure

Pressure

Cotton swab

Conductive Sheet

Page 2

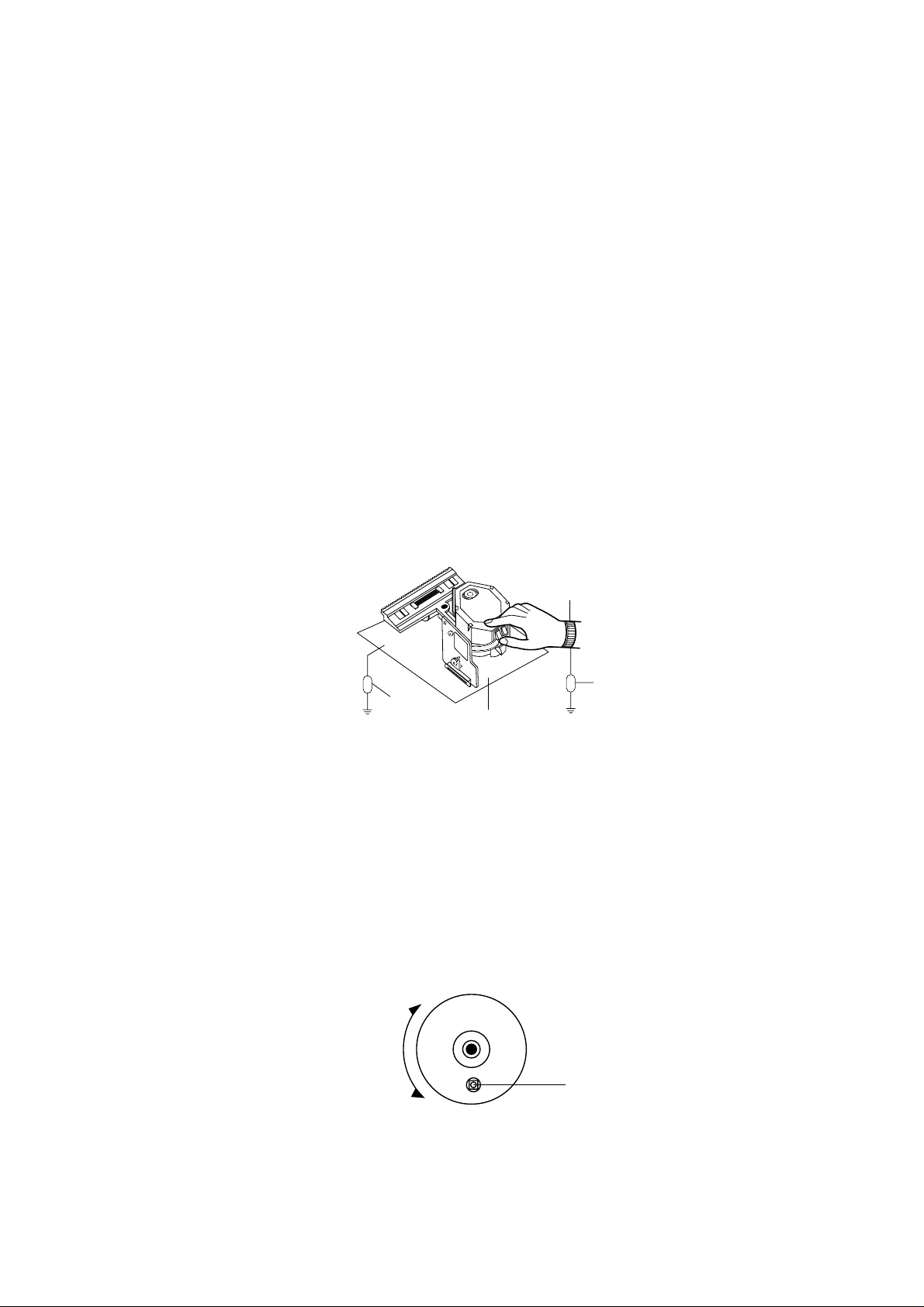

1. Preparations

1) Compact disc players incorporate a great many ICs as well as the pick-up (laser diode). These

components are sensitive to, and easily affected by, static electricity. If such static electricity is high

voltage, components can be damaged, and for that reason components should be handled with care.

2) The pick-up is composed of many optical components and other high-precision components. Care must

be taken, therefore, to avoid repair or storage where the temperature of humidity is high, where strong

magnetism is present, or where there is excessive dust.

2. Notes for repair

1) Before replacing a component part, first disconnect the power supply lead wire from the unit

2) All equipment, measuring instruments and tools must be grounded.

3) The workbench should be covered with a conductive sheet and grounded.

When removing the laser pick-up from its conductive bag, do not place the pick-up on the bag. (This is

because there is the possibility of damage by static electricity.)

4) To prevent AC leakage, the metal part of the soldering iron should be grounded.

5) Workers should be grounded by an armband (1MΩ)

6) Care should be taken not to permit the laser pick-up to come in contact with clothing, in order to prevent

static electricity changes in the clothing to escape from the armband.

7) The laser beam from the pick-up should NEVER be directly facing the eyes or bare skin.

CLEARING MALFUNCTION

You can reset your unit to initial status if malfunction occur(button malfunction, display, etc.).

Using a pointed object(such as driver), simply press the RESET button on the inside of the volume knob for

more than 3 seconds.

If you reset your unit, you must reenter all its settings(stations, clock, timer)

NOTE: 1. To operate the RESET jump wire, pull the volume rotary knob and release it.

2. If you wish to operate the RESET jump wire, it is necessary to unplug the power cord.

NOTES REGARDING COMPACT DISC PLAYER REPAIRS

- 4 -

Armband

Conductive

Sheet

Resistor

(1 Mohm)

Resistor

(1 Mohm)

VOLUME

VOLUME KNOB

DOWN

RESET button

Page 3

Electrostatically Sensitive Devices (ESD)

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such components

commonly are called Electrostatically Sensitive Devices (ESD). Examples of typical ESD devices are integrated

circuits and some field-effect transistors and semiconductor chip components. The following techniques should

be used to help reduce the incidence of component damage caused by static electricity.

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off

any electrostatic charge on your body by touching a known earth ground. Alternatively, obtain and wear a

commercially available discharging wrist strap device, which should be removed for potential shock reasons

prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ESD devices, place the assembly on a conductive

surface such as aluminum foil, to prevent electrostatic charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ESD devices.

4. Use only an anti-static solder removal device. Some solder removal devices not classified as "anti-static" can

generate electrical charges sufficient to damage ESD devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ESD

devices.

6. Do not remove a replacement ESD device from its protective package until immediately before you are ready

to install it. (Most replacement ESD devices are packaged with leads electrically shorted together by

conductive foam, aluminum foil or comparable conductive materials).

7. Immediately before removing the protective material from the leads of a replacement ESD device, touch the

protective material to the chassis or circuit assembly into which the device will by installed.

CAUTION : BE SURE NO POWER IS APPLIED TO THE CHASSIS OR CIRCUIT, AND OBSERVE ALL OTHER

SAFETY PRECAUTIONS.

8. Minimize bodily motions when handing unpackaged replacement ESD devices. (Otherwise harmless motion

such as the brushing together of your clothes fabric or the lifting of your foot from a carpeted floor can

generate static electricity sufficient to damage an ESD device).

ESD PRECAUTIONS

- 5 -

Page 4

SPECIFICATIONS

1. AMP SECTION

① Power Output (6 Ω, 2 channel, T.H.D. 10%)

....................................................................

100W+100W

② T.H.D

...........................................................................................................................................

0.15%

③ Frequency Response (-3dB down)

...................................................................................

30Hz~20kHz

④ Signal-to-noise Ratio

....................................................................................................................

81dB

⑤ Input Sensitivity AUX

...........................................................................................................

300±50mV

⑥ Channel Difference 1kHz

................................................................................................................ 2dB

2. TUNER SECTION

1) FM/OIRT

① Frequency Range.................................................................................................... 87.5MHz~108MHz

................................................................................................or 65.0MHz~74.0MHz & 87.5MHz~108MHz

② Intermediate Frequency.......................................................................................................... 10.7MHz

③ Sensitivity (69MHz/70MHz/71MHz/90.1MHz/98.1MHz/106.1MHz).............................................. 14dB

④ Signal-to-noise Ratio 98.1MHz(Mono/Stereo)..................................................................... 63dB/58dB

⑤ Image Rejection 106.1MHz .......................................................................................................... 38dB

⑥ IF Rejection 90MHz...................................................................................................................... 85dB

⑦ Distortion 98MHz(Mono/Stereo).......................................................................................... 0.7%/1.2%

⑧ Frequency Response (-3dB)............................................................................................ 60Hz~14kHz

⑨ Stereo Separation (100Hz/1kHz/10kHz).................................................................... 28dB/28dB/23dB

2) AM(MW)

① Frequency Range.................................... 522kHz~1,611kHz,530kHz~1,720kHz or 530kHz~1,610kHz

② Intermediate Frequency............................................................................................................ 450kHz

③ Usable Sensitivity ......................................................................................................................... 56dB

④ Image Rejection 1404kHz............................................................................................................. 25dB

⑤ IF Rejection 603kHz ..................................................................................................................... 45dB

⑥ Selectivity 1008kHz ...................................................................................................................... 38dB

⑦ Signal-to-noise Ratio 1008kHz..................................................................................................... 37dB

⑧ Distortion 1008kHz........................................................................................................................ 1.6%

⑨ Frequency Response (-6dB)........................................................................................ 100Hz~2000Hz

3) SW(OPTIONAL)

① Frequency Range......................................................................................................... 5.8MHz~18MHz

② Intermediate Frequency............................................................................................................ 450kHz

③ Usable Sensitivity ......................................................................................................................... 40dB

④ Signal-to-Noise Ratio.................................................................................................................... 37dB

⑤ Distortion ......................................................................................................................................... 2%

4) LW(OPTIONAL)

① Frequency Range........................................................................................................ 153kHz~281kHz

② Intermediate Frequency............................................................................................................ 450kHz

③ Usable Sensitivity ......................................................................................................................... 62dB

④ Signal-To-Noise Ratio (200kHz)................................................................................................... 30dB

⑤ Distortion (200kHz) ......................................................................................................................... 3%

- 6 -

Page 5

3. TAPE DECK SECTION

① Tape Speed (MTT-111) / Normal Speed............................................................................... 3kHz±1.5%

② Wow Flutter (MTT-111) .................................................................................................................. 0.25%

③ Fast Forward and Rewind Time (C-60)......................................................................................... 130sec

④ Frequency Response (6dB range) ....................................................................................... 125Hz~8kHz

⑤ Signal-to-noise Ratio (Playback/Record) ................................................................................ 48dB/43dB

⑥ Distortion (Playback/Record).................................................................................................... 2% / 3.5%

⑦ Crosstalk (Playback: 1kHz)..................................................................................................... 55dB/53dB

⑧ Channel Separation (Playback: 1kHz) .................................................................................... 50dB/43dB

⑨ Erase Ratio....................................................................................................................................... 55dB

4. COMPACT DISC PLAYER SECTION

① Frequency Response (40Hz-18kHz)...................................................................................... +0.5/-3.5dB

② Signal-to-noise Ratio (1kHz)............................................................................................................. 73dB

③ Dynamic Range (1kHz)..................................................................................................................... 70dB

④ T.H.D. (1kHz).................................................................................................................................... 0.4%

⑤ Separation (100Hz/1kHz/10kHz) ................................................................................... 42dB/48dB/40dB

⑥ Access Time Short / Long......................................................................................................... 2sec/5sec

5. GENERAL

① Power requirement.................................................................................... Refer to the back panel of unit

② Power consumption......................................................................................................................... 410W

③ Dimension (W x H x D)........................................................................................... 360 x 362 x 374 (mm)

④ Weight (net).................................................................................................................................... 10.0kg

NOTE : Specification are subject to change without notice in the course of product improvement.

- 7 -

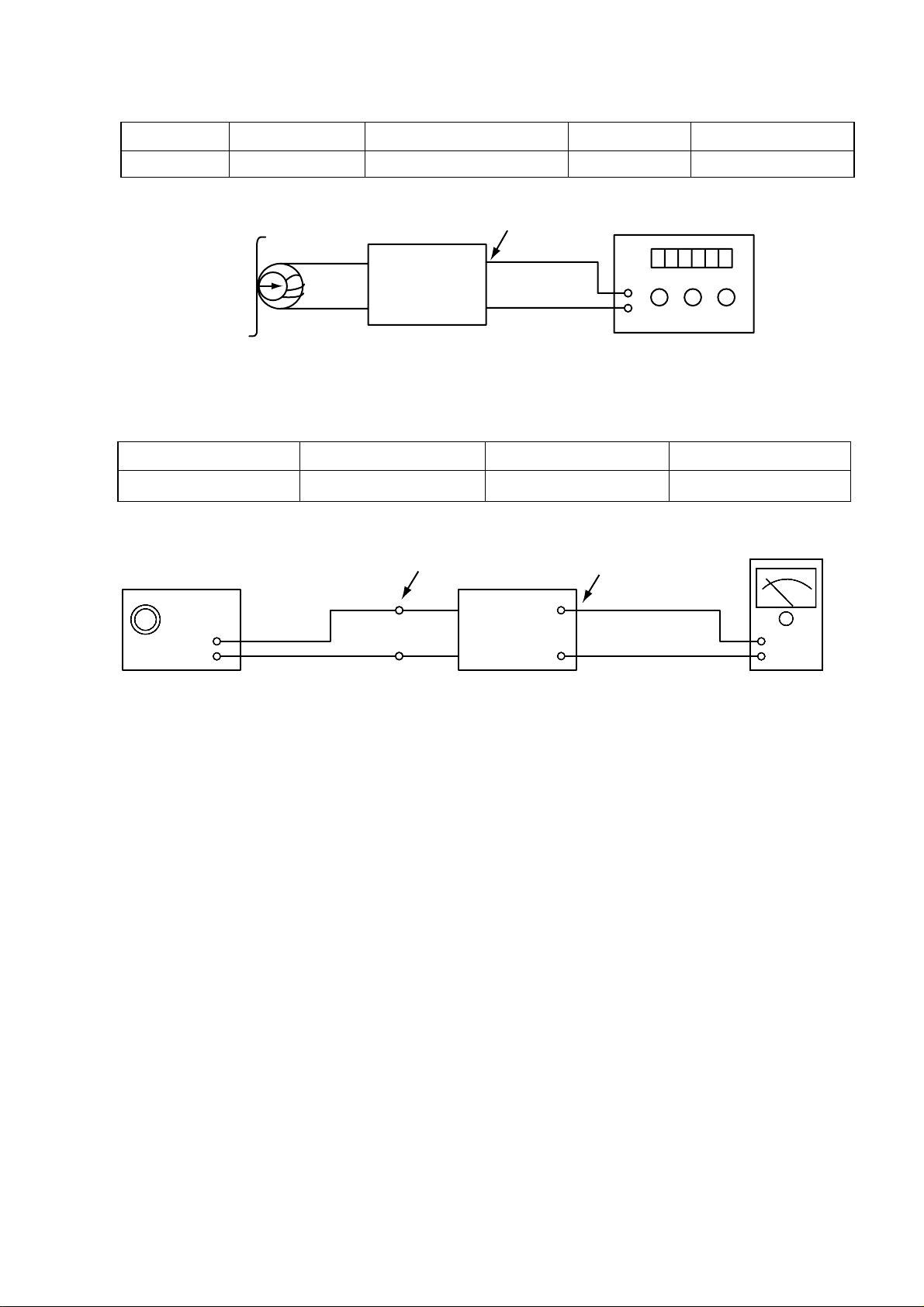

Page 6

- 17 -

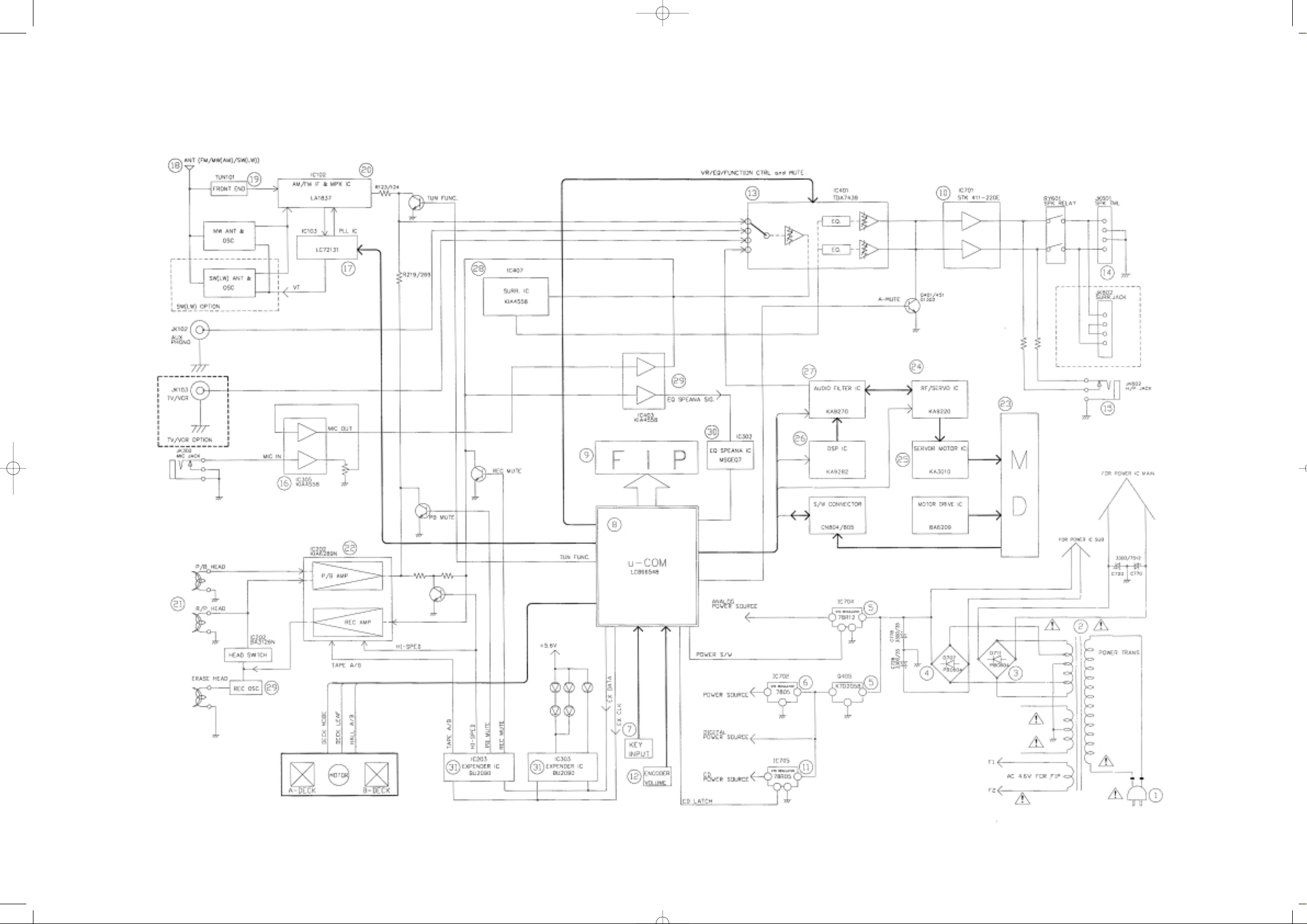

BLOCK DIAGRAM

FFH-8900A/S.JA5SSSR_A3 1996.2.7 11:7 AM 페이지17

Page 7

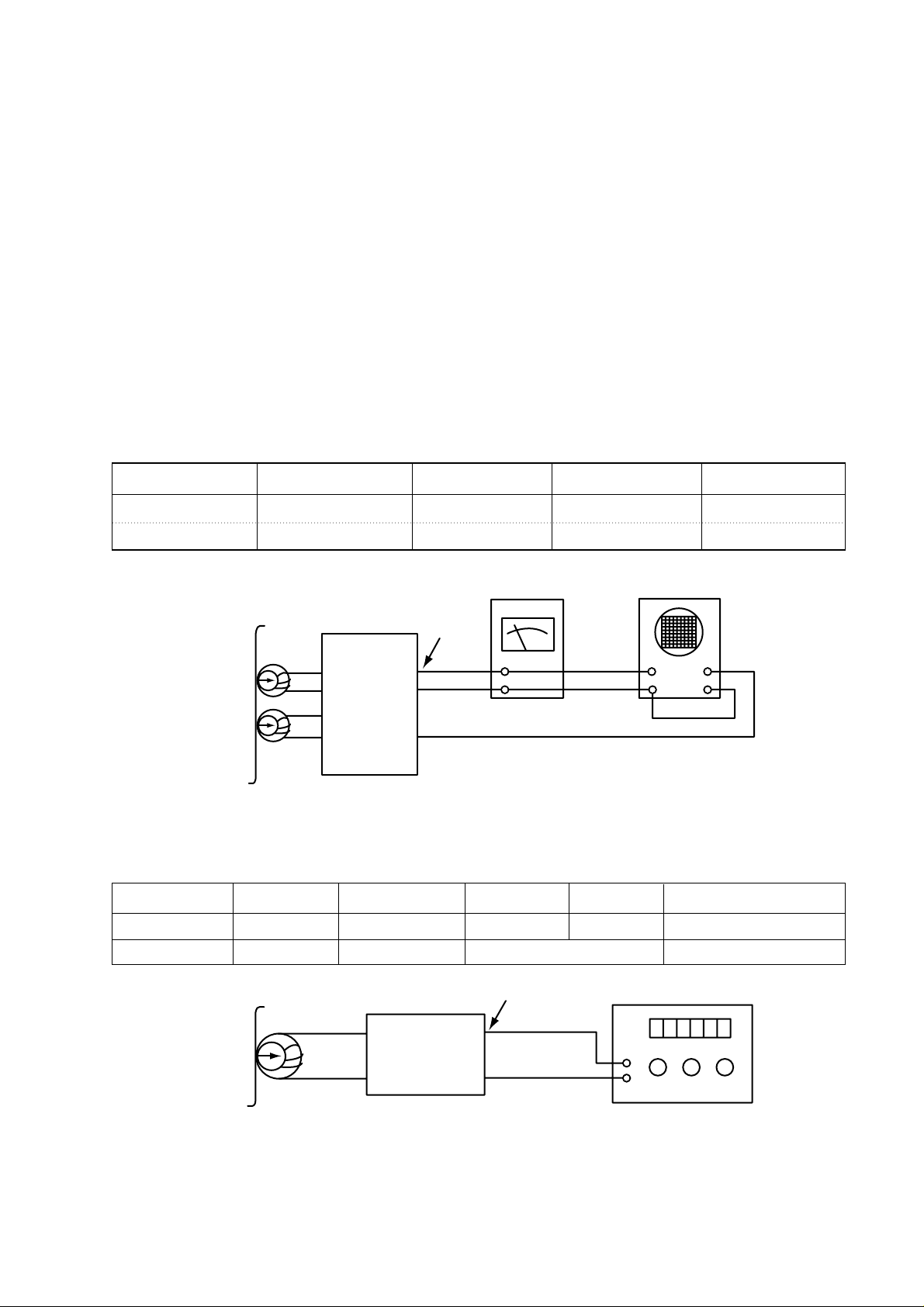

- 8 -

CH1 CH2

Speaker Out

Playback Mode

Head

Test Tape

MTT-114

L ch

R ch

GND

Dual-trace

synchroscope

Electronic

Voltmeter

L out

R out

Unit

This set has been aligned at the factory and normally will not require further adjustment. As a result, it is not

recommended that any attempt is made to modificate any circuit. If any parts are replaced or if anyone tampers

with the adjustment, realignment may be necessary.

IMPORTANT

1. Check Power-source voltage.

2. Set the function switch to band being aligned.

3. Turn volume control to minimum unless otherwise noted.

4. Connect low side of signal source and output indicator to chassis ground unless otherwise specified.

5. Keep the signal input as low as possible to avoid AGC and AC action.

ADJUSTMENTS

Deck Mode Test Tape Test Point Adjustment Adjust for

A Deck Playback MTT-114 Speaker Out DECK Screw Maximum

B Deck Playback MTT-114 Speaker Out Azimuth Screw Maximum

2. MOTOR SPEED ADJUSTMENT

Figure 1. Azimuth Adjustment Connection Diagram

Figure 2. Motor Speed Adjustment Connection Diagram

Head

Playback Mode

Unit

Speaker Out

GND

L out

R out

Record/Playback

head

Test Tape

MTT-111

Frequency Counter

Deck Mode Test Tape Test Point Adjustment Adjust for Remark

Normal Speed MTT-111 Speaker Out VR201 3kHz ± 1%

Hi-Speed MTT-111 Speaker Out more than 5.4kHz High-Speed Dubbing Mode

TAPE DECK ADJUSTMENT

1. AZIMUTH ADJUSTMENT

Page 8

- 9 -

3. RECORD BIAS ADJUSTMENT

Head

Unit

PN202

GND

Record/Playback

head

Test Tape

MTT-5511

Record/Playback

and Pause Mode

Frequency Counter

Deck Mode Test Tape Test Point Adjustment Adjust for

Rec/Pause MTT-5511 ERASE HEAD Wire(PN202) L203 90kHz±5kHz

Figure 3. Record Bias Adjustment Connection Diagram

Figure 4. Tuner(S curve) Adjustment Connection Diagram

4. TUNER ADJUSTMENT

Unit

Signal Generator

GND

Electronic

OSCILLOSCOPE

FM Antenna

Terminal

Speake

Item Test Point Adjustment Adjust for

DC Voltage Checker Pin TP1, TP2 L106 0V±50mV

Page 9

- 38 -

EXPLODED VIEW/PARTS LIST

••

CABINET

FFH-8900A/S.JA5SSSR_A3 1996.2.7 11:8 AM 페이지38

Page 10

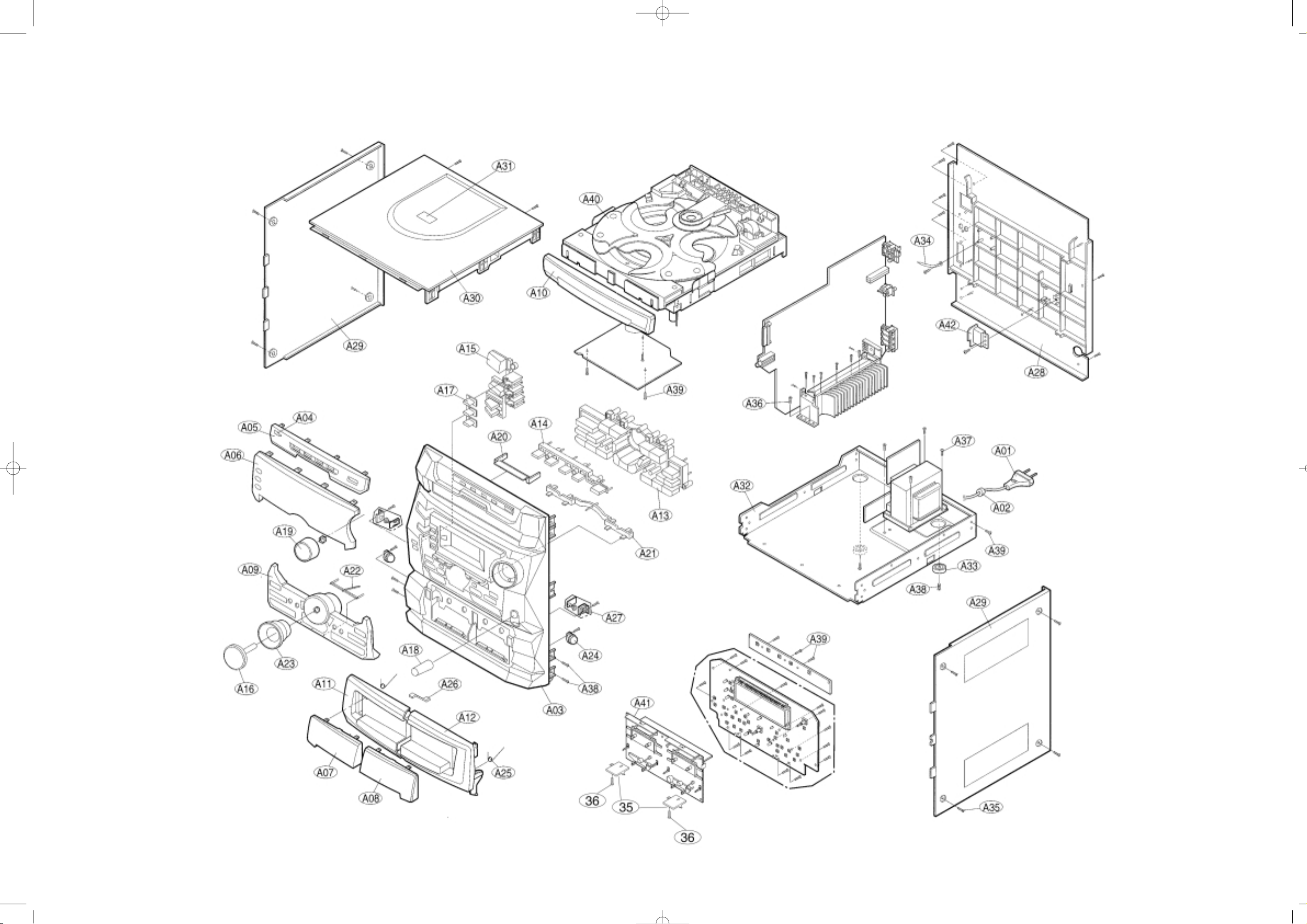

- 40 -

400

011

503

401

401

009

010

501

502

507

508

013

406

409

410

036

032

038

034

035

039

029

040

031

028

027

026

014

015

403

504

024

025

023

405

A01

402

022

016

017

018

019

020

021

505

007

008

003

004

005

001

002

404

400

400

506

037

006

••

TAPE DECK MECHANISM: AUTO REVERSE DECK

LOCA.NO. PART NO. SPECOFOCATION

A01 6768R-UP01A 50-093-4249 PCB AS

001 6768R-BP01B 02-084-4202 BELT/FELT

002 6768R-BP01A 02-084-4204 BELT/FELT

003 6768R-AP01D 50-239-4027 CWL44

004 6768R-AP01E 50-239-4026 ARM

005 6768R-SP01E 01-082-4645 SPRING

006 6768R-QP01A 50-093-4316 MOTOR

007 6768R-GP01A 50-093-4603 GEAR

008 6768R-SP01F 01-082-4598 SPRING

009 6768R-MP01C 50-219-4014 MOLD

010 6768R-SP01C 01-082-4652 SPRING

011 6768R-SP01A 01-081-4601 SPRING

013 6768R-SP01B 01-082-4651 SPRING

014 6768R-SP01G 0-082-4597 SPRING

015 6768R-AP01A 50-268-3016 ARM

016 6768R-GP01C 50-093-4069 GEAR

017 6789R-AP01C 50-239-4072 ARM

018 6768R-GP01D 50-222-4007 GEAR

019 6768R-SP01H 01-081-4657 SPRING

020 6768R-BP01C 02-083-4188 BELT/FELT

021 6768R-LP01A 50-223-4254 PULLEY

022 6768R-VP01A 50-093-4125 SOLENOID

023 6768R-GP01B 50-221-3009 GEAR

024 6768R-AP01B 50-139-4292 ARM

025 6768R-JP01B 50-093-3361 PULLEY

026 6768R-SP01D 01-080-4609 SPRING

027 6768R-DP01A 50-259-3342 LEVER

028 6768R-RP01A 22-027-41054 ROLLER

029 6768R-MP01A 50-219-4033 MOLD

031 6768R-SP01L 01-080-4649 SPRING

032 6768R-EP01A 50-093-4070 HEAD AY

033 6768R-JP01A 50-093-3360 PULLEY

034 6768R-SP01K 01-082-4650 SPRING

035 6768R-PP01A 50-119-4046 PRESS

036 6768R-PP01B 50-160-4108 PRESS

037 6768R-JP01C 50-093-3315 PULLEY

038 6768R-MP01D 50-219-4034 MOLD

040 6768R-SP01M 01-080-4607 SPRING

400 6768R-CP01A GRE10A2003 SCREW

401 6768R-CP01B GRE20A2005 SCREW

402 6768R-CP01C GSE10A1704 SCREW

403 6768R-CP01D GSL10A2004 SCREW

404 6768R-CP01E GSP10A2603 SCREW

405 6768R-CP01F GSP11A2012 SCREW

406 6768R-CP01G GSE20A2004 SCREW

409 6768R-CP01L GSD10A2018 SCREW

410 6768R-CP01M 03-300-4056 SCREW

501 6768R-WP01A GWM19S035035 WASHER

502 6768R-WP01B GWM17S0500035S WASHER

503 6768R-WP01C GWM40X075010 WASHER

504 6768R-WP01D GWP21X045020 WASHER

505 6768R-WP01E GWM12X030040S WASHER

506 6768R-WP01H GWM23X040020 WASHER

507 6768R-WP01F GWM21X040040 WASHER

508 6768R-WP01G GWM19X055035S WASHER

FFH-8900A/S.JA5SSSR_A3 1996.2.7 11:8 AM 페이지40

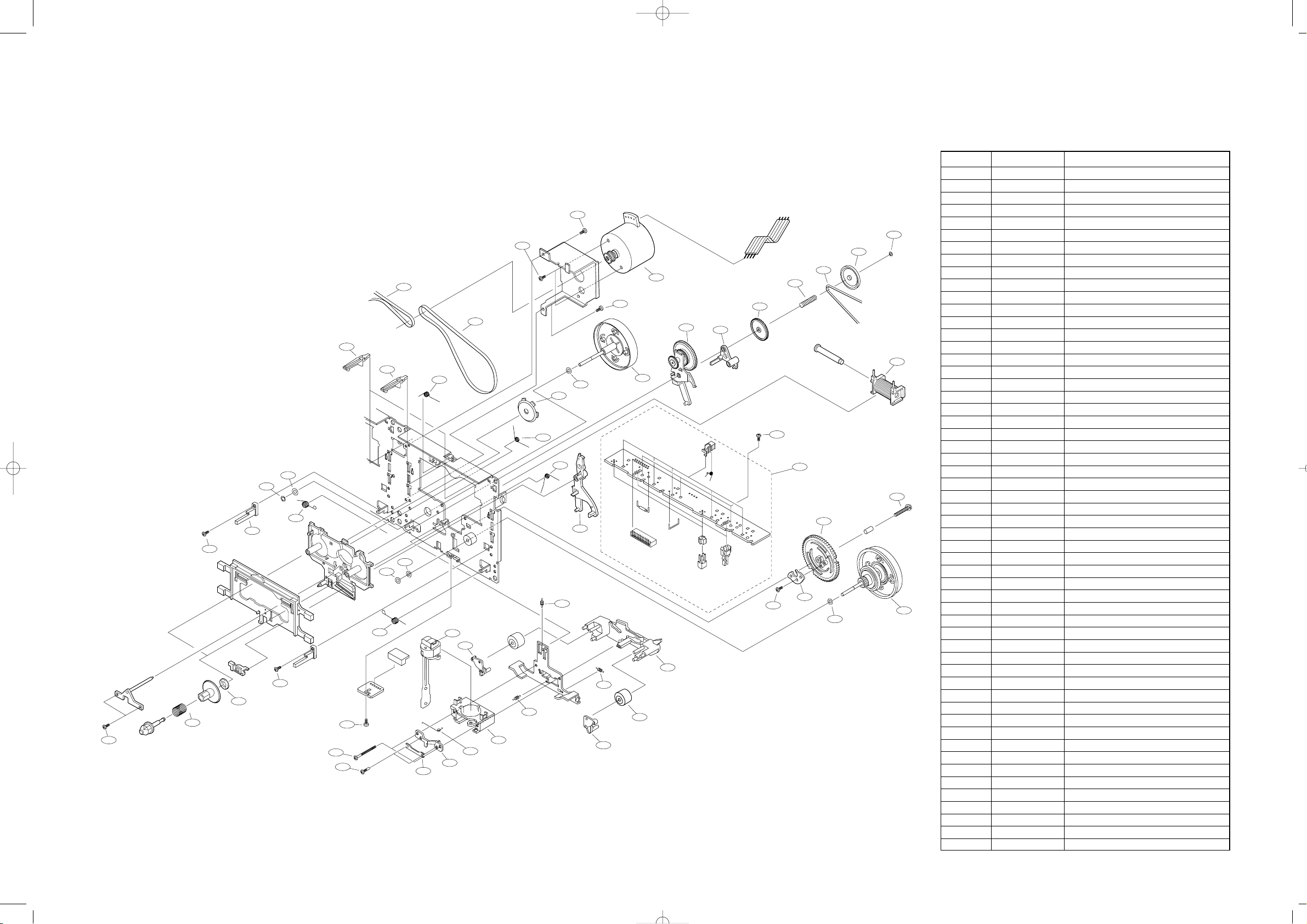

Page 11

- 41 -

••

CD MECHANISM

416

101

102

105

134

135

134

A35

421

A30

421

118

417

417

103

109

A26

119

104

108

107

106

418

416

419

115

112

116

420

117

127

126

114

113

125

120

121

124

416

123

122

417

A30 3040SB0004A BASE PU ASSY(CDM-H1303)

A35 4405SCB001A MECHANISM ASSY KSM-213CCM SONY HI-FI FRONT LO

101 3390SB0002A TRAY DISC(CDM-H1303)

102 4470SB0011A GEAR TRAY B(CDM-H1303)

103 4470SB0010A GEAR TRAY A(CDM-H1303)

104 4400SB0001B BELT TRAY(CDM-H1303)

105 4680SBP002A MOTOR(MECH) ASSY TRAY

106 6871SF21RAD PWB(PCB)ASSY 3CH M/D SENSOR PWB ASSY

107 4794SB0003A GUIDE WCRM(CDM-1303)

108 4371SB0002A SHAFT ASSY TRAY(CDM-H1303)

109 3390SB0001A TRAY LOADING(CDM-H1303)

112 4400SB0001A BELT MAIN(CDM-H1303)

113 4470SB0003A GEAR PULLEY(CDM-H1303)

114 4470SB0004A GERA LOADING(CDM-H1303)

115 6871SB21RAD PWB(PCB)ASSY 3CH M/D U/D/O/C PWB ASSY

116 4470SB0006A GEAR PU DOWN(CDM-H1303)

117 4470SB0008A GEAR PU UP-B(CDM-H1303)

118 4471SB0001A GEAR ASSY GEAR CAM ASSY

119 4860SB0002A CLAMP CLAMP ASSY

120 4974SB0001A GUIDE CAM(CDM-H1303)

121 4970SBN002A SPRING CAM(CDM-H1303)

122 3040SB0002A BASE MAIN(CDM-H1303)

123 6871SD21RAD PWB(PCB)ASSY 3CH M/D CAM PWB ASSY

124 6871SC21RAD PWB(PCB)ASSY 3CH M/D OPEN PWB ASSY

125 4680SBP001A MOTOR(MECH) PULLEY ASSY(CDM-H1303)

126 4470SB0007A GEAR PU UP-A(CDM-H1303)

127 4470SB0005A GEAR MAIN(CDM-H1303)

134 4900SB0001A DAMPER DAMPER RUBBER

135 3040SB0003A BASE PU(CDM-H1303)

416 88H-0004 CD MECHA PARTS 3X12X12FNM

417 88H-0002 CD MECHA PARTS 3X9X12FZMY

418 353-025BAAA SCREW D3.0 L8.0 MSWR3/(BK)

419 88H-0003 CD MECHA PARTS 3X12X10FZMY

420 353S353F SCREW D2.6 L4.0 MSWR3/(BK)

421 6756SBX001A

CD MECHANISM PARTS SCREW 2.6X10X10XFZMY CDM-H813

REF.NO. PART NO. DESCRIPTION SPECOFOCATION

FFH-8900A/S.JA5SSSR_A3 1996.2.7 11:8 AM 페이지41

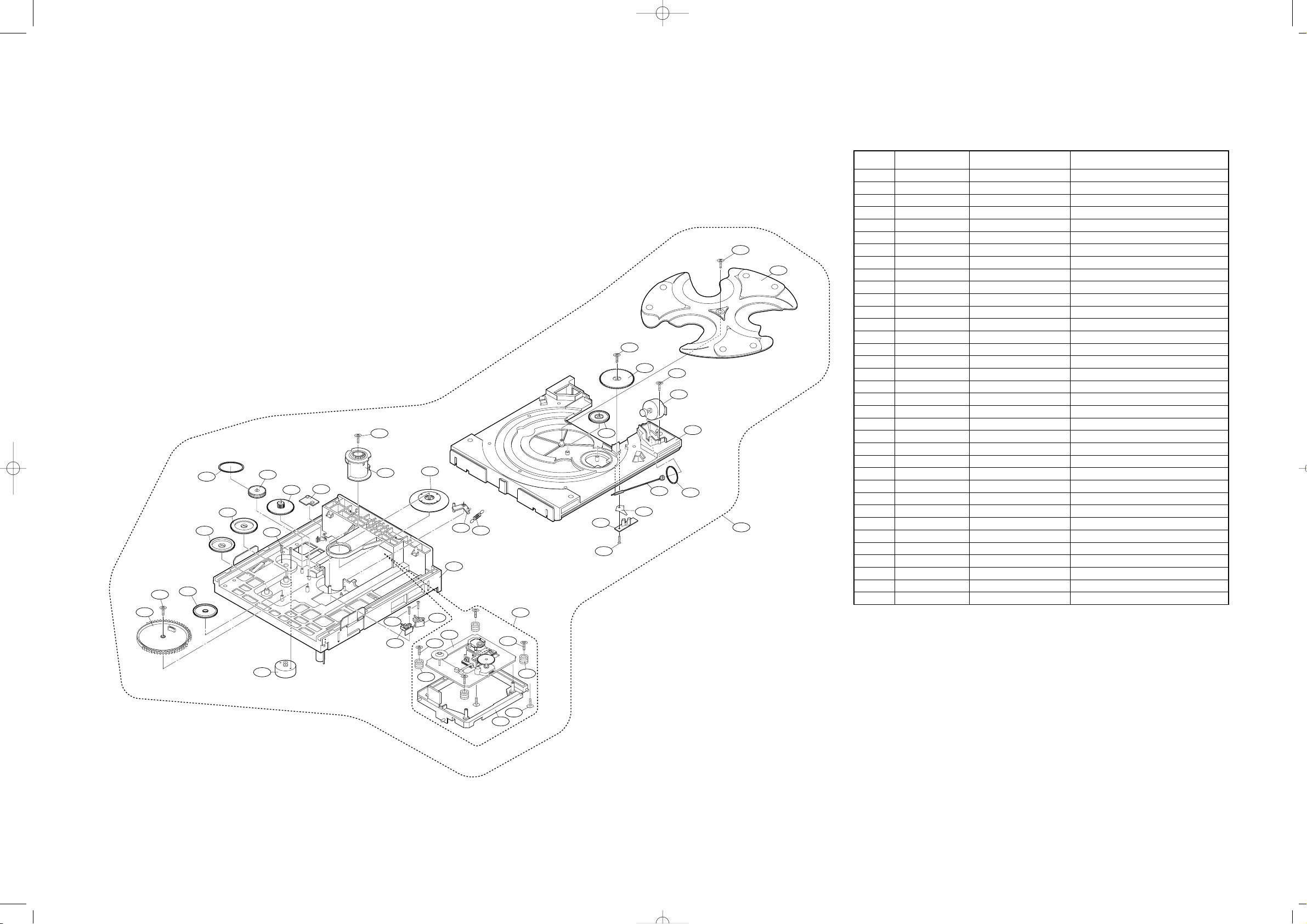

Page 12

- 19 -

••

FRONT CIRCUIT

FFH-8900A/S.JA5SSSR_A3 1996.2.7 11:7 AM 페이지19

Page 13

- 24 -

••

FRONT P.C. BOARD

FFH-8900A/S.JA5SSSR_A3 1996.2.7 11:8 AM 페이지24

Page 14

SCHEMATIC DIAGRAMS

••

POWER CIRCUIT

- 18 -

FFH-8900A/S.JA5SSSR_A3 1996.2.7 11:7 AM 페이지18

Page 15

- 10 -

TROUBLESHOOTING

Turn power on.

Is power on?

Does initial read work?

Does it play?

Does it output audio?

Check power supply circuit.

(Check PN 701)

Check laser circuit.

Check focus circuit.

Check disc.

Check tracking servo circuit.

Check audio circuit.

OK

YES

YES

YES

YES

NO

NO

NO

NO

Page 16

- 11 -

Fails to initial read

1.3V

A

B

YES

YES

YES

YES

YES

YES

YES

YES

NO

NO

NO NO NONO

NO

NO

NO

NO

Does laser light?

Disc motor turns.

Does RF

waveform

appear?

TP 801(RF)

Does tracking

servo work?

Lower envelope

of TP801(RF)

waveform is flat.

Does signal

appear at

TP801(TEO)?

Does signal appear at IC 803

Pin and Pin ?

Does GFS (IC802 pin )

show as below?

Is rotation normal?

Is there no dropout of RF

signal?

Does TE2 signal

appear at pin

of IC801?

Defective IC

801, pick up

and/or open

wire.

Detective pattern.

Defective IC 801

and/or IC 803

Defective pick-up

and/or connector.

Defective IC 801.

Scratch in disc

initial read area.

Defective pick-up

adjustment focus offset.

53

26

27

Page 17

- 12 -

A

NO

NO

NO

NO

NO

NO

Laser does not light.

Is “3.5V” applied to pin of IC 801?

Is power supplied to laser Q801?

(Q 801 collector: about 1.8V)

Does laser current flow?

1.0V across R801

Is data transferred from

MICOM IC ?

Does voltage appear at IC

803 pin ⑪, ⑫?

Defective MICOM.

Defective MICOM.

Defective connector.

Defective IC 801, 803

Defective slide motor and/or

connector.

Defective LMT SW and/or

connector.

Defective Q 801 and/or laser.

Defective laser and/or

connector.

Did pickup return to

innermost circular?

Does it stop at inner pick

circular after shift?

Is defect output from LM

SW applied to pin ② of

PN803?

R801»1.0V

R801«1.0V

YES

YES

YES

YES

OPEN

CLOSE

YES

YES

YES

YES

YES

YES

70

Page 18

- 13 -

B

C

Does lens move up/down?

Does IC 801 out focus

search signal?

IC 801 pin (FEO)

Is focus search signal

applied to pin , of

CN801?

Laser lights.

Confirm

initial

read with

disc

Defective IC801

Defective IC803

Defective IC 801.

Open activator and/or

connector.

Open connector and/or

defective IC 801.

Incorrect turntable height.

Degraded laser diode.

Does TP 801 RF signal appear even in

low level?

Is laser output adjustment correct?

Does FOK(focus ok) signal appear?

YES

YES

YES

YES

YES

YES

TP801

(RF)

IC801 pin

(FOK)

NO

NO

NO

NO

NO

NO

48

13

16

40

Page 19

- 14 -

FER

ISTAT(SENSE)

C

Start mode

Does FE1 signal appear? IC 801 pin

Does FZC signal (focus zero cross signal)

appear at pin of IC 801, ISTAT (SENSE)

terminal?

Does SMON signal appear

at pin of IC 802?

Does SMPO signal appear

at pin of IC 802?

Is drive voltage applied to disk motor?

Defective IC 801.

Open pick diode

Defective IC 801.

Defective Pattern between IC 801 and

IC 802.

Defective IC 801, 803 and/or

peripheral circuit.

Defective disk motor and/or insulation.

(Focus servo turns

ON by FZC signal

of FOK mod.)

NO

NO

NO

NO

YES

YES

YES

YES

YES

73

75

31

59

Page 20

- 15 -

(CH1)

(CH2)

WAVEFORMS OF MAJOR CHECK POINT

1. HF signal (RF signal ) waveform

(Test Point TP801) during normal play

2. EFM signal (pin IC 801)waveform

during Normal Play

3. Focus coil drive waveform(Pin NO

① , ② of IC 803)

·When focus search failed or there is no disc on the tray

·Focus coil drive waveform(pin NO ①, ② of IC803) and

FOK (pin NO of IC 801) when focus search is

accomplished

4. Tracking coil drive waveform (pin NO , of IC 803)

and TEO during track traverse

(1) When time division is 20nS/div

(2) When time division 0.5nS/div.

(During forward track traverse)

(3) When time division is 0.5nS/div.

(During backward Track Traverse)

5. Feed motor drive waveform(pin NO

⑪, ⑫ of IC 803)

During normal play

CH1 : FOCUS COIL DRIVE

SIGNAL 2V/Div.

CH2 : FOAK

CH1 : TEO(TP801)

1V/Div.

CH2 : TRACKING COIL DRIVE

SIGNAL 2V/Div.

CH1 : TEO(TP801)

1V/Div.

CH2 : TRACKING COIL DRIVE

SIGNAL 2V/Div.

CH1 : TEO(TP801)

1V/Div.

CH2 : TRACK COIL DRIVE

SIGNAL 2V/Div.

40

26

33

27

0.5V/Div.

500nS/Div.

2V/Div.

500nS/Div.

0.5V/Div.

500nS/Div.

OV

OV

OV

(CH1)

(CH2)

(CH1)

(CH2)

(CH2)

OV

OV

OV

OV

OV

OV

OV

OV

OV

Page 21

- 20 -

••

TUNER & DECK CIRCUIT

FFH-8900A/S.JA5SSSR_A3 1996.2.7 11:7 AM 페이지20

Page 22

- 25 -

••

CD MAIN P.C. BOARD

Page 23

- 21 -

••

CD CIRCUIT

FFH-8900A/S.JA5SSSR_A3 1996.2.7 11:7 AM 페이지21

Page 24

- 26 -

●●

BU2090/BU2090F/BU2090FS/BU2092/BU2092F

●●

KIA78XXPI

INTERNAL BLOCK DIAGRAM OF ICs

Page 25

- 27 -

●●

KIA6289N

●●

TDA7439

Page 26

- 28 -

●●

KIA4558P, KIA4558F

●●

KA8301

●●

BA3126N

DRIVER

PRE

LOGIC

23456789101

GND

Vout1

Vz1VrFin

Rin

Vcc1

Vcc2

Vz2

Vout2

Page 27

- 29 -

●●

KA3010

PIN DESCRIPTION

28 27

26 25 24 23 22

T S D

REGULATOR

MUTE

LEVEL

SHIFT

LEVEL

SHIFT

100K

50K

50K

10K

10K

10K 10K

10K

BUY

BUY

BUY

LEVEL

SHIFT

LEVEL

SHIFT

1234567

8 9 10 11 12 13 14

21 20 19 18 17 16 15

Pin No. Symbol I/O Description

1 DO1.1 O DRIVE OUTPUT

2 DO1.2 O DRIVE OUTPUT

3 DI1.1 I DRIVE INPUT

4 DI1.2 I DRIVE INPUT

5 REG REGULATOR

6 REO O REGULATOR OUTPUT

7 MUTE MUTE

8 GND1 GROUND

9 DI2.1 I DRIVE INPUT

10 DI2.2 I DRIVE INPUT

11 DO2.1 O DRIVE OUTPUT

12 DO2.2 O DRIVE OUTPUT

13 GND2 GROUND

14 OPOUT O OPAMP OUTPUT

15 OPIN (-) I OPAMP OUTPUT (-)

16 OPIN (+) I OPAMP INPUT (+)

17 DO3.1 O DRIVE OUTPUT

18 DO3.2 O DRIVE OUTPUT

19 DI3.1 I DRIVE INPUT

20 DI3.2 I DRIVE INPUT

21 VCC1 SUPPLY VOLTAGE

22 VCC2 SUPPLY VOLTAGE

23 VREF 2.5V BIAS VOLTAGE

24 DI4.1 I DRIVE INPUT

25 DI4.2 I DRIVE INPUT

26 DO4.1 O DRIVE OUTPUT

27 DO4.2 O DRIVE OUTPUT

28 GND3 GROUND

Page 28

- 30 -

KB9223

MICOM TO SERVO CONTROL

AUTO SEQUENCER

FOK DETECTION

CIRCUIT

MIRROR DETECTION

CIRCUIT

Spindle Servo LPF

(Double Speed)

Sled Servo Amplifier

& Sled Kick GEN.

Tracking Phase

Compensation Block

& Jump Pulse GEN.

Focus Phase

Compensation

& Offset cancel circuit

Micom Data

Interface Logic

RF Amp

73

74

65

66

63

67

68

79

69

70

71

78

76

75

32

33

77

2

4

RF-

RFO

PD1

PD2

F

E

EI

PD

LD

VR

ARF

IRF

ASY

EFM

RFI

DCB

DCC1

GC1O

MLT

TZC

FE2

FLB

FGD

FS3

TE1

FE1

GC1I

CH1O

CH1I

MUTEI

RRC

CH2O

CH2I

GC2I

GC2O

5

15 16 13 14 19 17 12 11 9 10

40

1

39

6

25

24

23

45

46

42

44

43

61

62

55

53

50

49

57

48

47

60

FOK

MCP

MIRROR

FSET

SMEF

SMON

FS1 to

FS4

TM1 to

TM6

BAL1 to

BAL5

PS1 to

PS4

GA1 to

GA5

SMPD

SPDL-

SPDLO

SL+

SL-

SLO

TGU

TG2

LPFT

TE2

TEO

TE-

TDFCT

FEO

FE-

FDFCT

327282658525135363738312930225459

APC Amp

Center Voltage Amp.

Focus Error Amp

FE-BIAS Adjustment

Tracking Error Amp

E/F Balance & Gain

Control

RF Level AGC

&

Equalizer

EFM

Comparator

Defect Detection

CircuitT

ADJUSTMENT-FREE CONTROL

Built-in Post Filter Amp(L&R)

LDON

PIN DESCRIPTION

Pin No. System Description

1 MCP Capacitor connection pin for mirror hold

2 DCB Capacitor connection pin for defect Bottom hold

3 FRSH. Capacitor connection pin for time constant to generate focus search waveform

4 DCC2 The input pin through capacitor of defect bottom hold output

5 DCC1 The output pin of defect bottom hold

6 FSET The peak frequency setting pin for focus, tracking servo and cut off frequency of CLV LPF

7 VDDA Analog VCC for servo part

8 VCCP VCC for post filter

9 GC2I Amplifier negative input pin for gain and low pass filtering of DAC output CH2

10 GC2O Amplifier output pin for gain and low pass filtering of DAC output CH2

11 CH2I The input pin for post filter channel2

12 CH2O The output pin for post filter channel2

13 CH1O The output pin for post filter channl1

14 CH1I The input pin for post filter channel1

15 GC1O Amplifier output pin for gain and low pass filtering of DAC output CH1

Page 29

- 31 -

Pin No. System Description

16 GC1I Amplifier negative input pin for gain and low pass filtering of DAC output CH1

17 RRC The pin for noise reduction of post filter bias

18 VSSP VSS for post filter

19 MUTEI The input pin for post filter muting control

20 ISET The input pin for current setting of focus search, track jump and sled kick voltage

21 VREG The output pin of regulator

22 WDCK The clock input pin for auto sequence

23 SMDP The input pin of CLV control output pin SMDP of DSP

24 SMON The input pin for spindle servo ON through SMON of DSP

25 SMEF The input pin of provide for an external LPF time constant

26 FLB Capacitor connection pin to perform rising low bandwidth of focus loop

27 FS3 The pin for high frequency gain change of focus loop with internal FS3 switch

28 FGD Reducing high freqency gain with capacitor between FS3 pin

29 LOCK Sled runaway prevention pin

30 TRCNT Track count output pin

31 ISTAT Internal status output pin

32 ASY The input pin for asymmetry control

33 EFM EFM comparator output pin

34 VSSA Analog VSS for servo part

35 MCK Micom clock input pin

36 MDATA Micom data input pin

37 MLT Micom data latch input pin

38 RESET Reset input pin

39 MIRROR The mirror output for test

40 FOK The output pin of focus OK comparator

41 SSTOP The pin for detection whether pick_up position is innermost or not

42 SL+ The noninverting input pin of sled servo amplifier

43 SLO The output pin of sled servo amplifier

44 SL- The inverting input pin of sled servo amplifier

45 SPDL- The noninverting input pin of spindle servo amplifier

46 SPDLO The output pin of spindle servo amplifier

47 FE- The inverting input pin of focus servo amplifier

48 FEO The output pin of focus servo amplifier

49 TE- The inverting input pin of tracking servo amplifier

50 TEO The output pin of tracking servo amplifier

51 ATSC The input pin for Anti-shock detection

52 TZC The comaparator input pin for tracking zero crossing detection

53 TE2 Tracking servo input pin

54 TE1 Tracking error amplifier output pin

55 LPFT The input pin of tracking error low pass filtering signal

56 DVDD The power supply pin for logic circuit

57 TDFCT The capacitor connection pin for tracking defect compensation

58 FE2 Focus servo input pin

59 FE1 Focus error amplifier output pin

60 FDFCT The capacitor connection pin for focus defect compensation

61 TGU The capacitor connection pin for high frequency tracking gain switch

62 TG2 The pin for high frequency gain change of tracking servo loop with internal TG2 switch

63 FEBIAS Focus error bias voltage control pin

64 DVEE The DVEE pin for logic circuit

65 PD1 The negative input pin of RF I/V amplifier1 (A+C signal)

66 PD2 The negative input pin of RF I/V amplifier2 (B+D signal)

67 F The negative input pin of F I/V amplifier (F signal)

68 E The negative input pin of E I/V amplifier (E signal)

69 PD The input pin for APC

70 LD The output pin for APC

71 VR The output pin of (AVEE+AVCC)/2 voltage

72 VCC VCC for RF part

73 RF- RF summing amplifier inverting input pin

74 RFO RF summing amplifier output pin

75 IRF The input pin for AGC

76 ARF The output pin for AGC

77 RFI The input pin for EFM comparating

78 CAGC The capacitor connection pin for AGC

79 EI Feedback input pin of E I/V amplifier for EF Balance control

80 GND GND for RF part

Page 30

- 32 -

KS9286

SUBCODE

SYNC

DETECTOR

SUBCODE

OUTPUT

EFM

DEMODULATOR

8BIT DATA BUS

ADDRESS

GENERATOR

EFM

PHASE

DETECTOR

DIGITAL

PLL

DIGITAL

CLV

SERVO

CPU

INTERFACE

MODE

SELECTOR

DIGITAL

OUTPUT

D/A

CONVERTER

DIGITAL

FILTER

& DE-EMPH

INTERPOLATOR

ECC

16K

SRAM

TRACK

COUNTER

23BIT

SHIFT

REGISTER

FRAME SYNC

DETECTOR

PROTECTOR

INSERTOR

X-TAL

TIMING

GENERATOR

SUBCODE-Q

REGISTER

SQDT

30

29

11

66

5

3

4

2

72

73

75

76

70

9

8

37

38

36

616263

65

7

19

20

33

32

26

69

68

12

14

77

67

60

24

17

22

SDAT

SBCK

S0S1

LRCHO

ADATAO

BCKO

BCKI

ADATAI

LRCHI

EMPH

VREFL1

VREFH1

EFMI

CNTVOL

DPFIN

DPFOUT

DPDO

SMEF

SMON

SMDP

SMSD

LOCK

XOUT

LCHOUT

RCHOUT

DATX

TEST1

TEST0

XTALSEL

CDROM

XIN

MDAT

MCK

MLT

TRCNT

/ISTAT

SQCK

PIN DESCRIPTION

Pin No. Symbol IO Description

1 AVDD1 - Analog VCC1

2 DPDO O Charge pump output for Digital PLL

3 DPFIN I Filter input for Digital PLL

4 DPFOUT O Filter output for Digital PLL

5 CNTVOL I VCO control voltage for Digital PLL

6 AVSS1 - Analog Ground1

7 DATX O Digital Audio output data

8 XIN I X’tal oscillator input

9 XOUT O X’tal oscillator output

10 WDCHO O Word clock output of 48bit/Slot (88.2KHz)

11 LRCHO O Channel clock output of 48 bit/Slot (44.1KHz), 88.2KHz when ESP ON

12 ADATAO O Serial audio data output of 48 bit/Slot (MSB first), double speed output when ESP ON

13 DVSS1 - Digital Ground1

14 BCKO O Audio data bit clock output of 48 bit/Slot (2.1168MHz), 4.2336MHz when ESP ON

15 C2PO O C2 Pointer for output audio data

16 VREFL2 I Input terminal2 of reference voltage “L”(Floating)

Page 31

- 33 -

Pin No. Symbol IO Description

17 VREFL1 I Input terminal1 of reference voltage “L”(GND connection)

18 AVDD2 - Analog VCC2

19 RCHOUT O Right-Channel audio output through D/A converter

20 LCHOUT O Left-Channel audio output through D/A converter

21 AVSS2 - Analog ground2

22 VREFH1 I Input terminal1 of reference voltage “H”(VDD connection)

23 VREFH2 I Input terminal2 of reference voltage “H”(Floating)

24 EMPH O Emphasis/Non-Emphasis output, H: Emphasis ON, L: Emphasis OFF

25 LKFS O The Lock Status output of frame sync

26 S0S1 O Output of subcode sync signal (S0+S1)

27 RESET I System reset at “L”

28 /ESP I ESP function ON/OFF control (“L”: ESP function ON, “H”: ESP function OFF)

29 SQCK I Clock for output Subcode-Q data

30 SQDT O Serial output of Subcode-Q data

31 SQOK O The CRC (Cycle Redundancy Check) check result signal output of Subcode-Q

32 SBCK I Clock for output subcode data

33 SDAT O Subcode serial data output

34 DVDD1 - Digital VDD1

35 MUTE I Mute control input (“H”: Mute ON)

36 MLT I Latch Signal Input from Micom (Scmit Trigger)

37 MDAT I Signal data input from Micom (Scmit Trigger)

38 MCK I Signal clock Input from Micom (Scmit Trigger)

39 DB8 I/O SRAM data I/O port 8 (MSB)

40 DB7 I/O SRAM data I/O port 7

41 DB6 I/O SRAM data I/O port 6

42 DB5 I/O SRAM data I/O port 5

43 DB4 I/O SRAM data I/O port 4

44 DB3 I/O SRAM data I/O port 3

45 DB2 I/O SRAM data I/O port 2

46 DB1 I/O SRAM data I/O port 1 (LSB)

47 C1F1 I/O Monitoring output for C1 error correction (RA1)

48 C1F2 I/O Monitoring output for C1 error correction (RA2)

49 C2F1 I/O Monitoring output for C2 error correction (RA3)

50 C2F2 I/O Monitoring output for C2 error correction (RA4)

51 C2FL I/O C2 decoder flag (RA5, “H”: When one processing C2 code is impossible correction status.)

52 /PBCK I/O Output of VCO/2 (4.3218MHz) (RA6)

53 DVSS2 I/O Digital ground 2

54 FSDW I/O Window or unprotected frame sync (RA7)

55 ULKFS I/O Frame sync protection state (RA8)

56 /JIT I/O Display of either RAM overflow onncerflow for ±4 frame jitter margin (RA9)

57 C4M I/O Only monitoring signal (4.2336M .. RA10)

58 C16M I/O 16.9344MHz signal output (RA11)

59 /WE I/O Terminal for test

60 /CS I/O Terminal for test

61 XTALSEL I Mode Selection1 (H: 33.8688MHz, L: 16.9344MHz)

62 TEST0 I TEST input terminal (GND connection)

63 CDROM I Mode Selection2 (H: CD-ROM, L: CDP)

64 SRAM I TEST input terminal (GND connection)

65 TEST1 I TEST input terminal (GND connection)

66 EFMI I EFM signal input

67 ADATAI I Serial audio data input of 48 bit/Slot (MSB first)

68 /ISTAT O The internal status output

69 TRCNT I Tracking counter input signal

70 LOCK O Output signal of LKFS condition sampled PBFR/16 (if LKFS is “H”, LOCK is “H”, if LKFS is sampled

“L”at least 8 times by PBFR/16, LOCK is “L”.)

71 PBFR O Write frame clock (Lock: 7.35KHz)

72 SMEF O LPF time constant control of the spindle servo error signal

73 SMON O ON/OFF control signal for spindle servo

74 DVDD2 - Digital VDD2

75 SMDP O Spindle Motor drive (Rough control in the SPEED mode, Phase control in the PHASE mode)

76 SMSD O Spindle Motor drive (Velocity control in the PHASE mode)

77 BCKI I Audio data bit clock input of 48 bit/Slot (2.1168MHz)

78 TESTV I TEST input terminal (GND connection)

79 DSPEED I TEST input terminal (VDD connection)

80 LRCHI I Channel clock input of 48 bit/Slot (44.1KHz)

Page 32

- 34 -

••

LC72131

••

LA1837

••

LC72131M

Page 33

- 35 -

••

MSGEQ7

PIN CONFIGURATION

PIN DESCRIPTION

Page 34

- 22 -

WIRING DIAGRAM

FFH-8900A/S.JA5SSSR_A3 1996.2.7 11:7 AM 페이지22

Loading...

Loading...