LG Dishwasher SVC Schematic

Dishwasher

Page

1

Service Handbook LDF6920 + V1 090603

Service Handbook LDF6920 + V5 100525

1. Test mode ( Check electric parts operation )

1. Test mode method …………………………………. 2

2. Electric parts function test …………………………. 3

2. Error mode ( Connecting to Test mode )

1. IE …………………………………………………… 5

2. OE …………………………………………………… 7

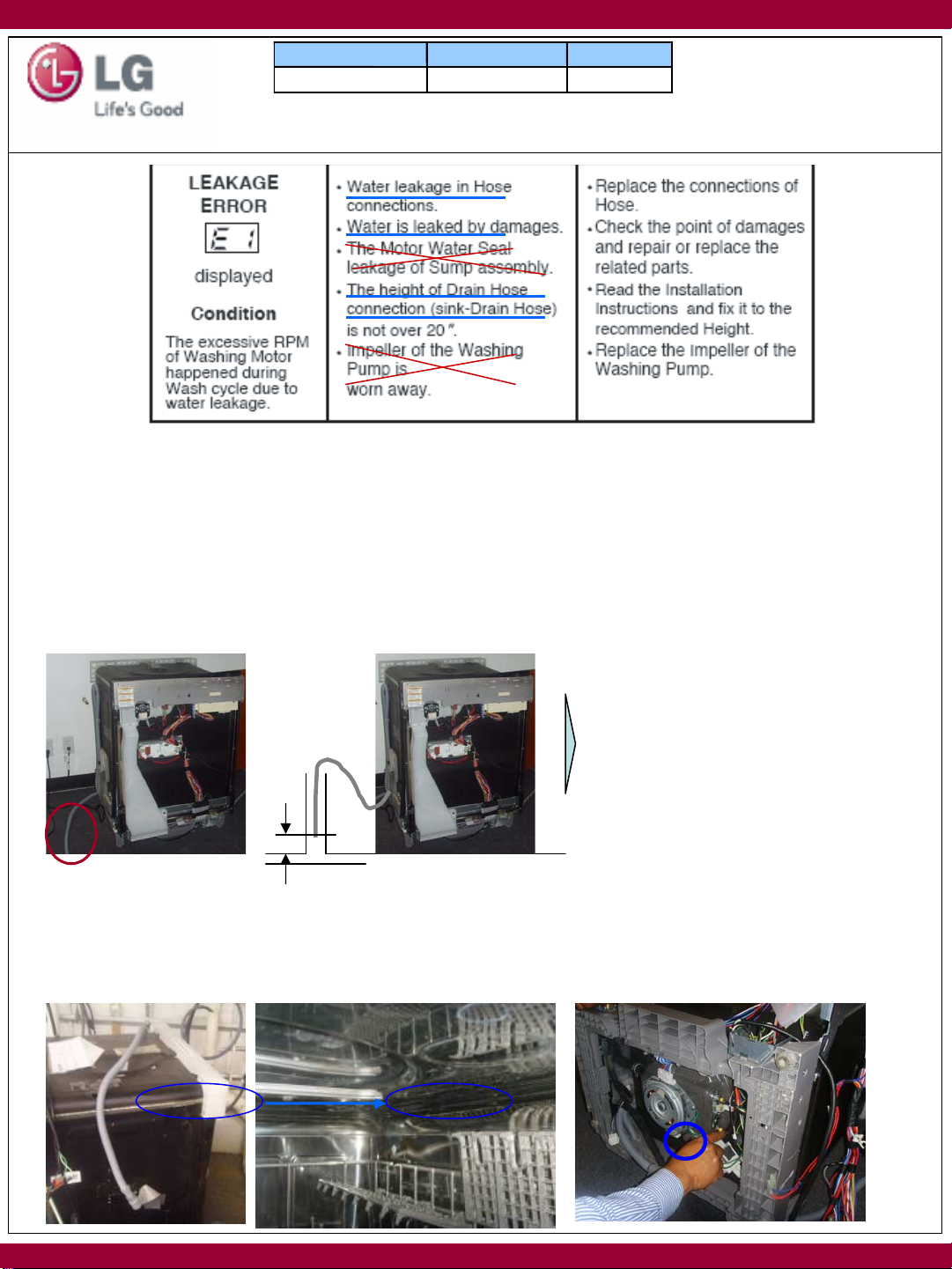

3. E1 ……………………………………………………10

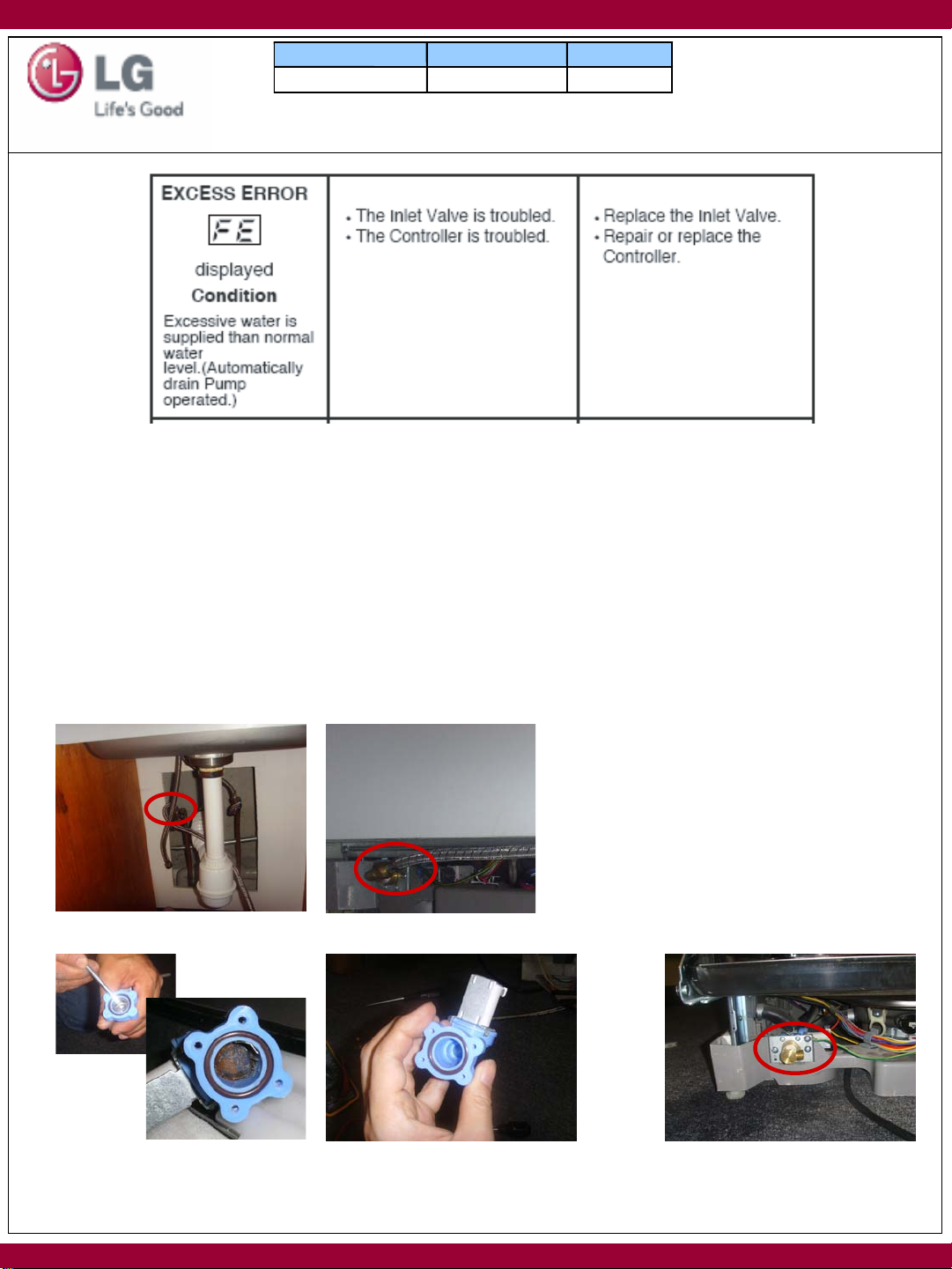

4. FE ……………………………………………………11

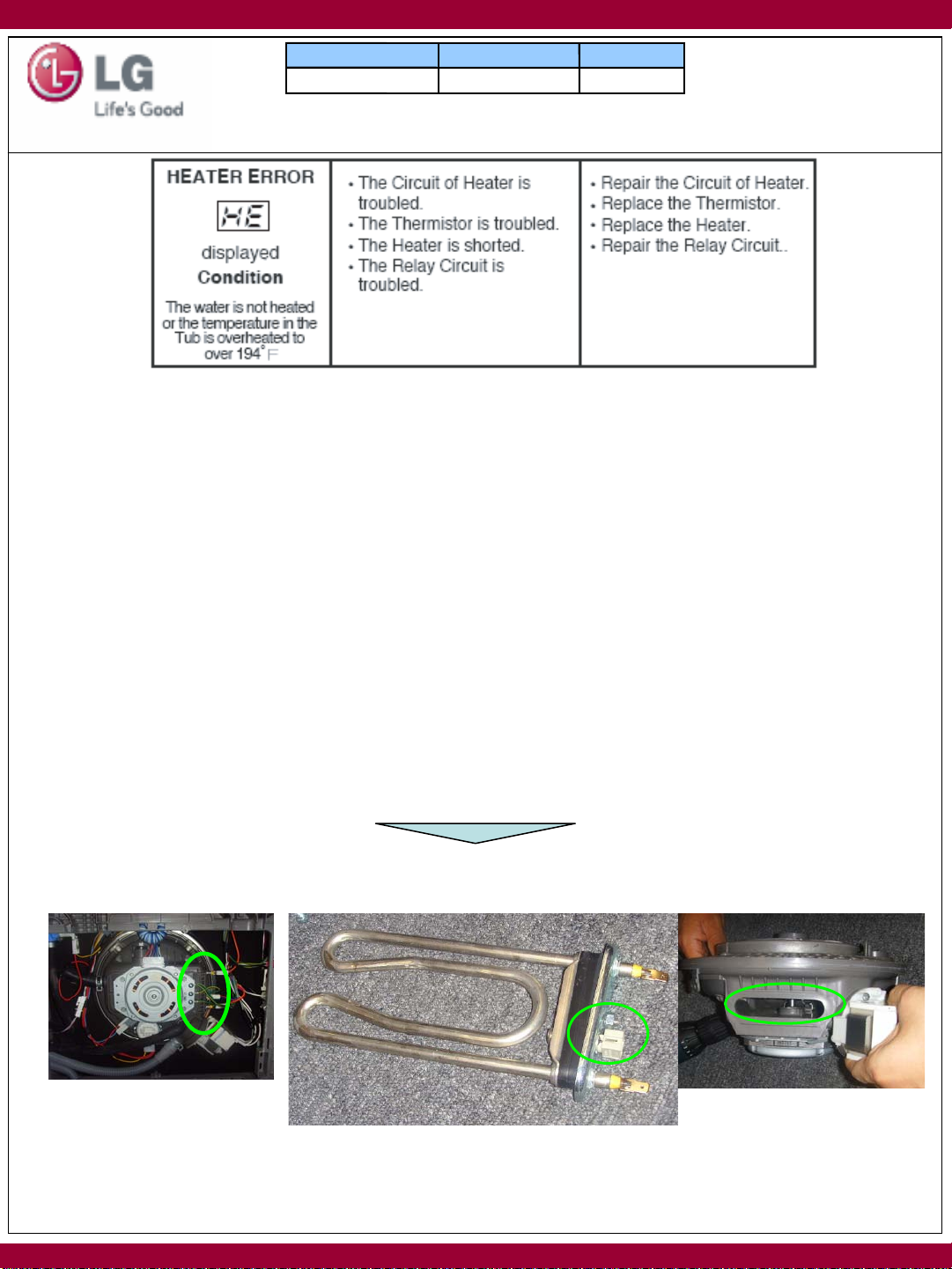

5. HE ……………………………………………………12

2

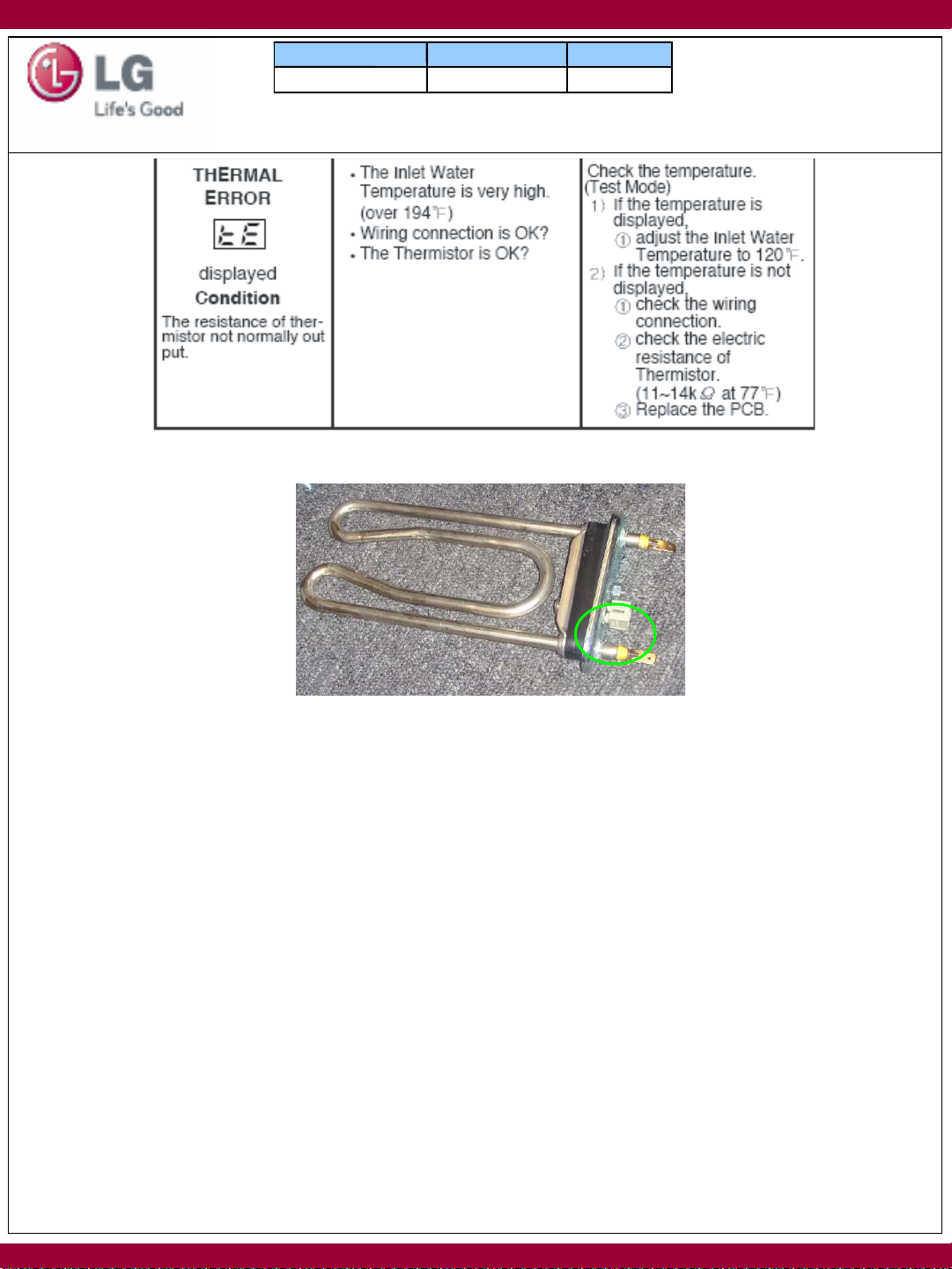

6. tE …………………………………………………… 13

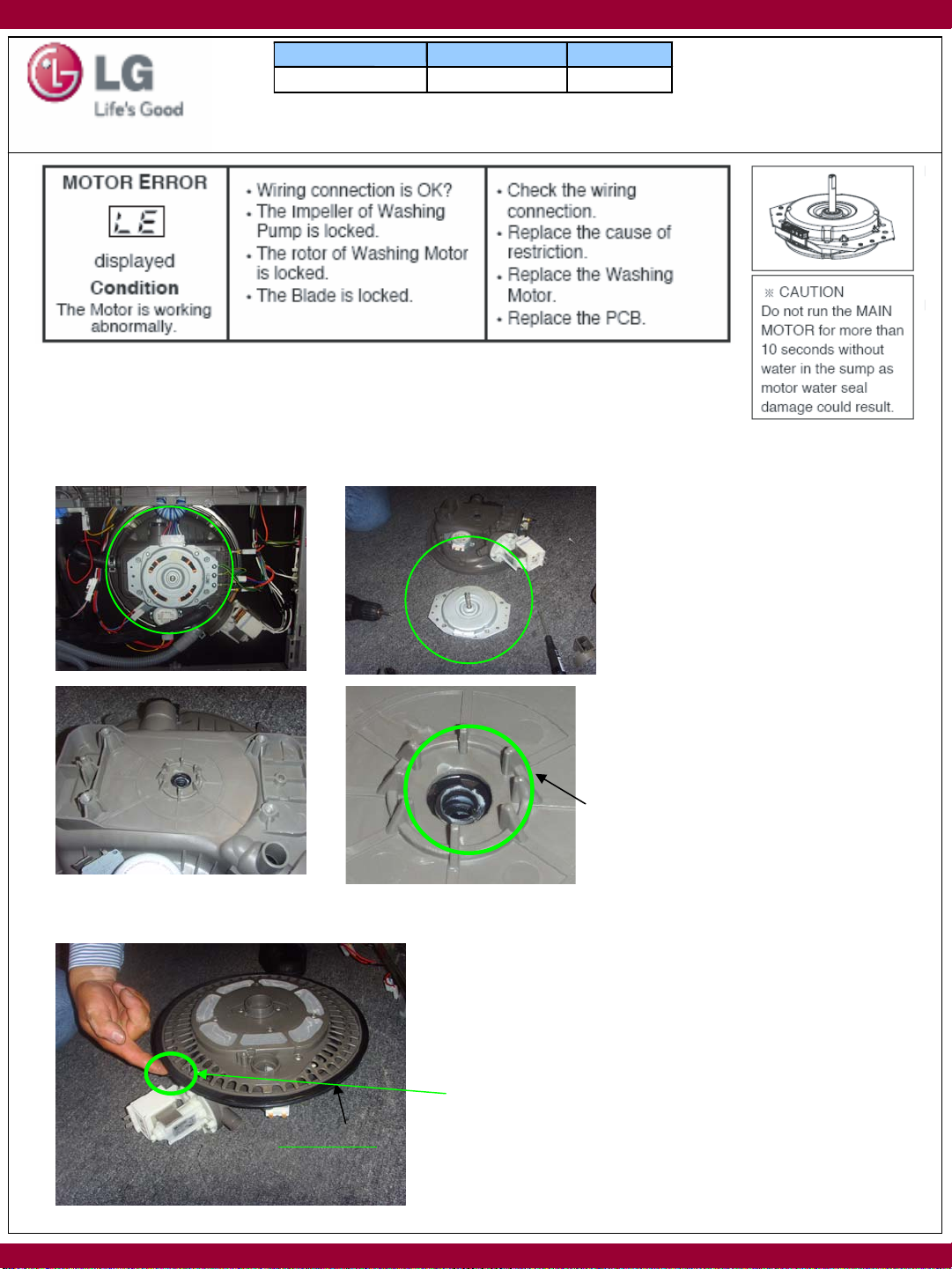

7. LE …………………………………………………….. 14

8 PF ( Not error message ) …………………………….15

Service Handbook

Model : 24” Built In Dishwasher

Customer Model Factory Model Suffix

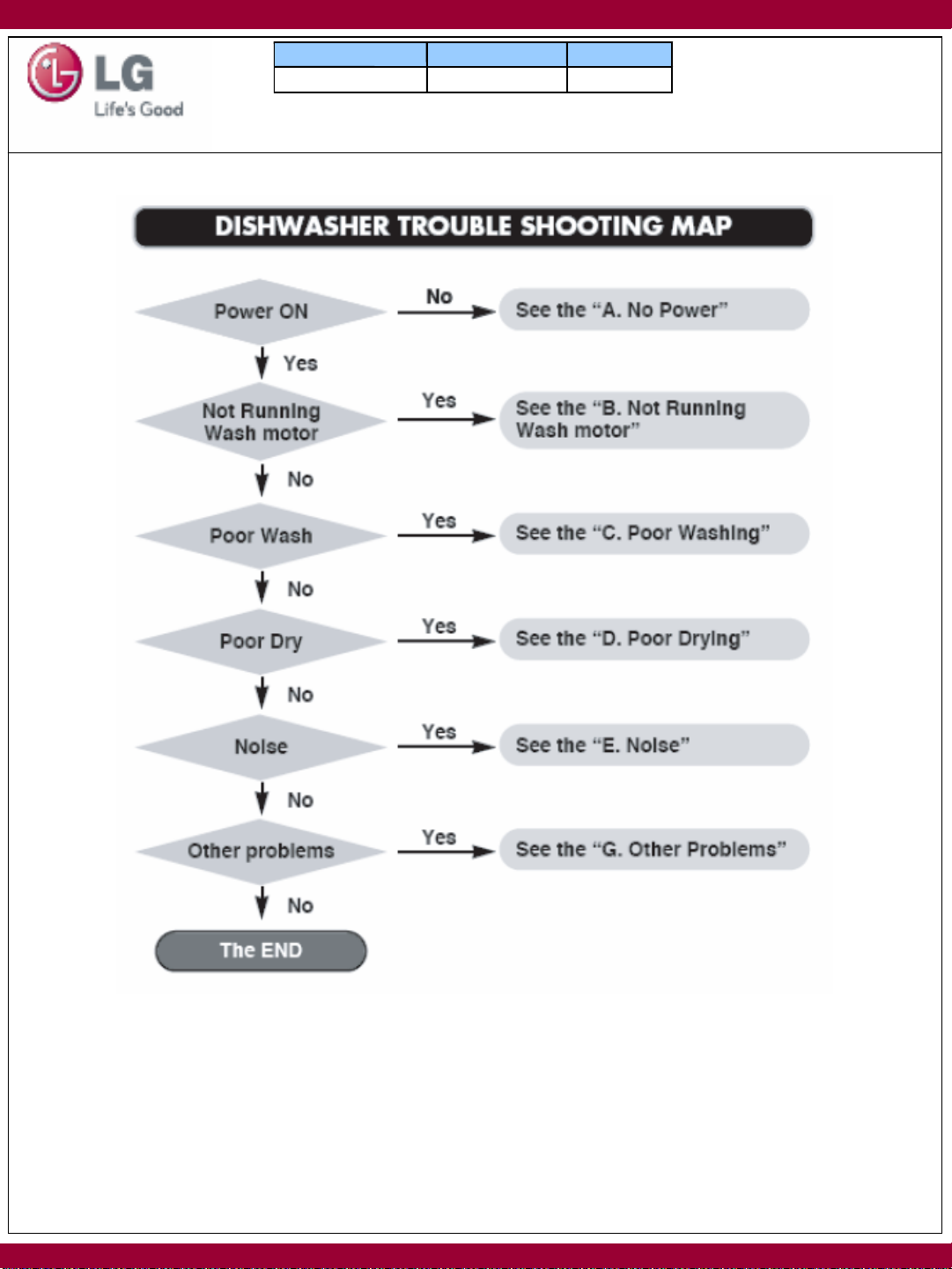

3. Trouble shooting guide ……………………………….16

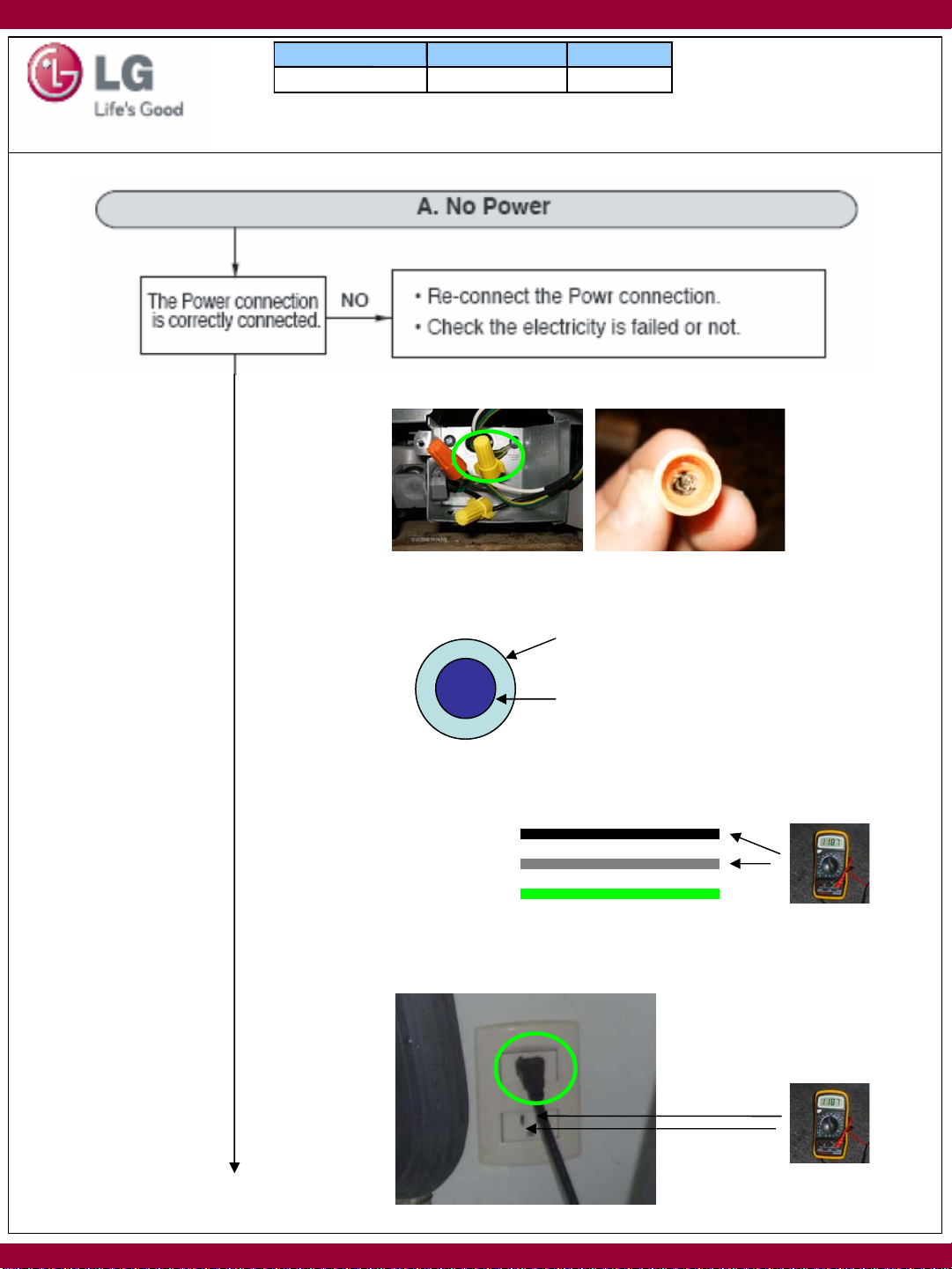

1. No power ………………………………………………17

2. Not running ( washing motor ) ………………………19

3. Poor wash ……………………………………………. 21

. White spot, white powder, cloudy glasses

. Soil spot, really not washing/clean

4. Poor dry ………………………………………………25

5. Noise …………………………………………………..28

6. Leakage ……………………………………………….30

4. Exploded view & location number ………………….. 35

Appendix. SVC Bulletin

1) Installation ( Base ) ……………………………………...39

2) Drain hose with siphon protector ……………………..46

3) Hinge rope & spring about door drop …………………49

4) Vent modified for protecting moisture condensing …..51

5) HE error……………………………………………………52

6) Air Sucking noise cause by program …………………56

4

7) Install improvement for worm gear leg………………….59

8) Poor Washing cause by the defectivc filter asm …….63

5

Service Handbook LDF6920 + V1 090603

3

Written by Jhe Hyouk Lee

LG Dishwasher June 4, 2009

Customer Model Factory Model Suffix

LDF6920XX D1608

Page

2

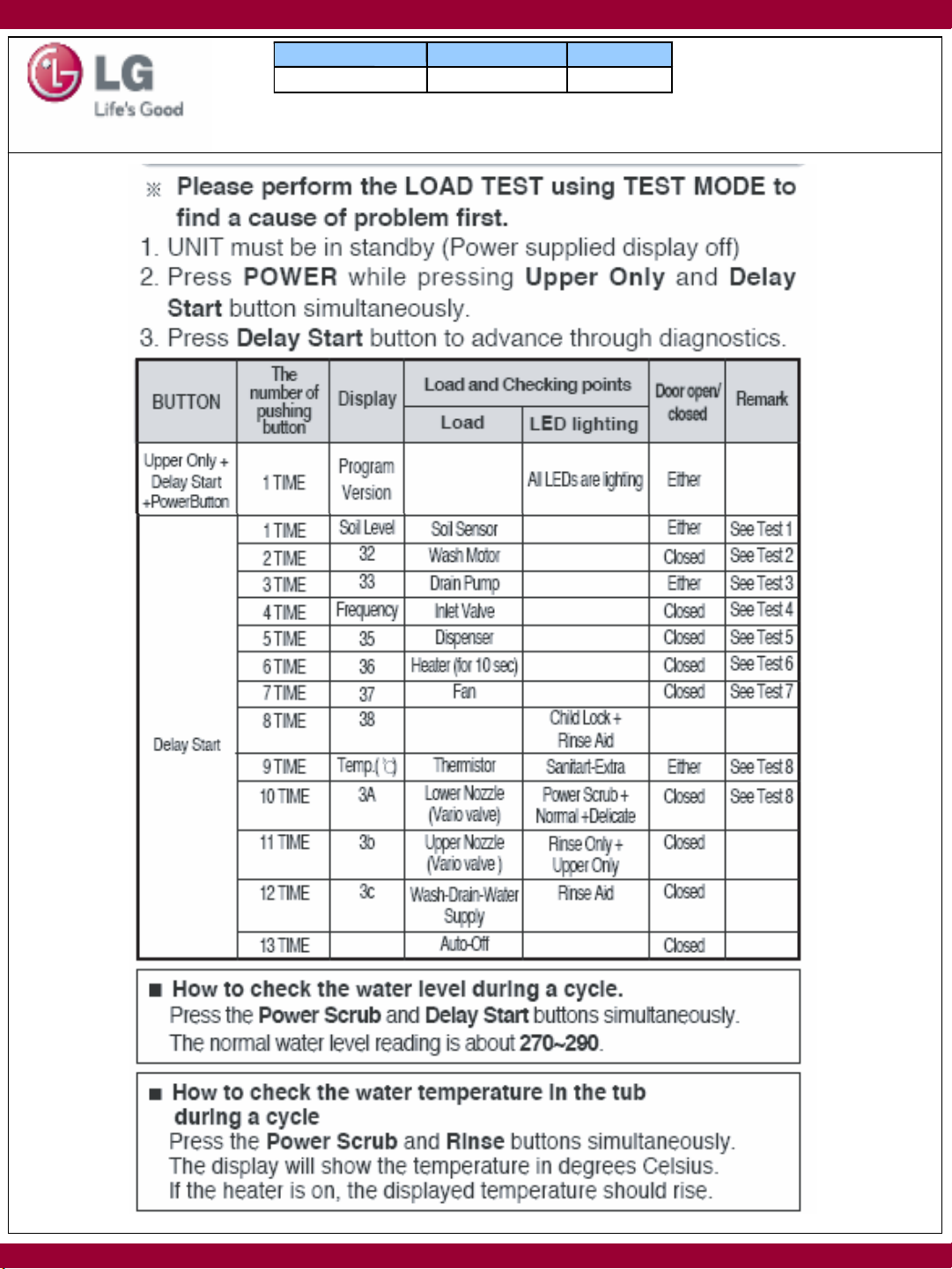

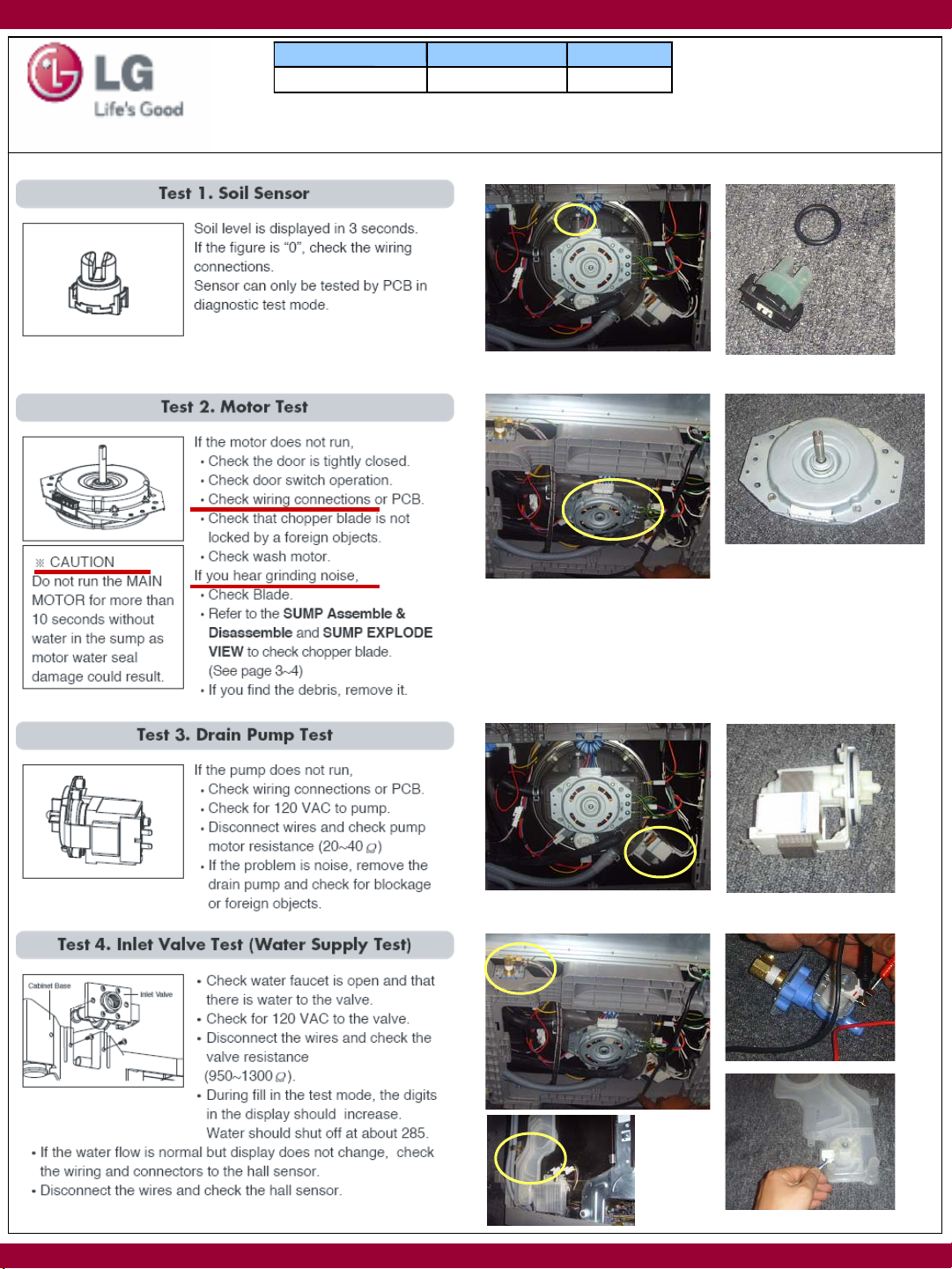

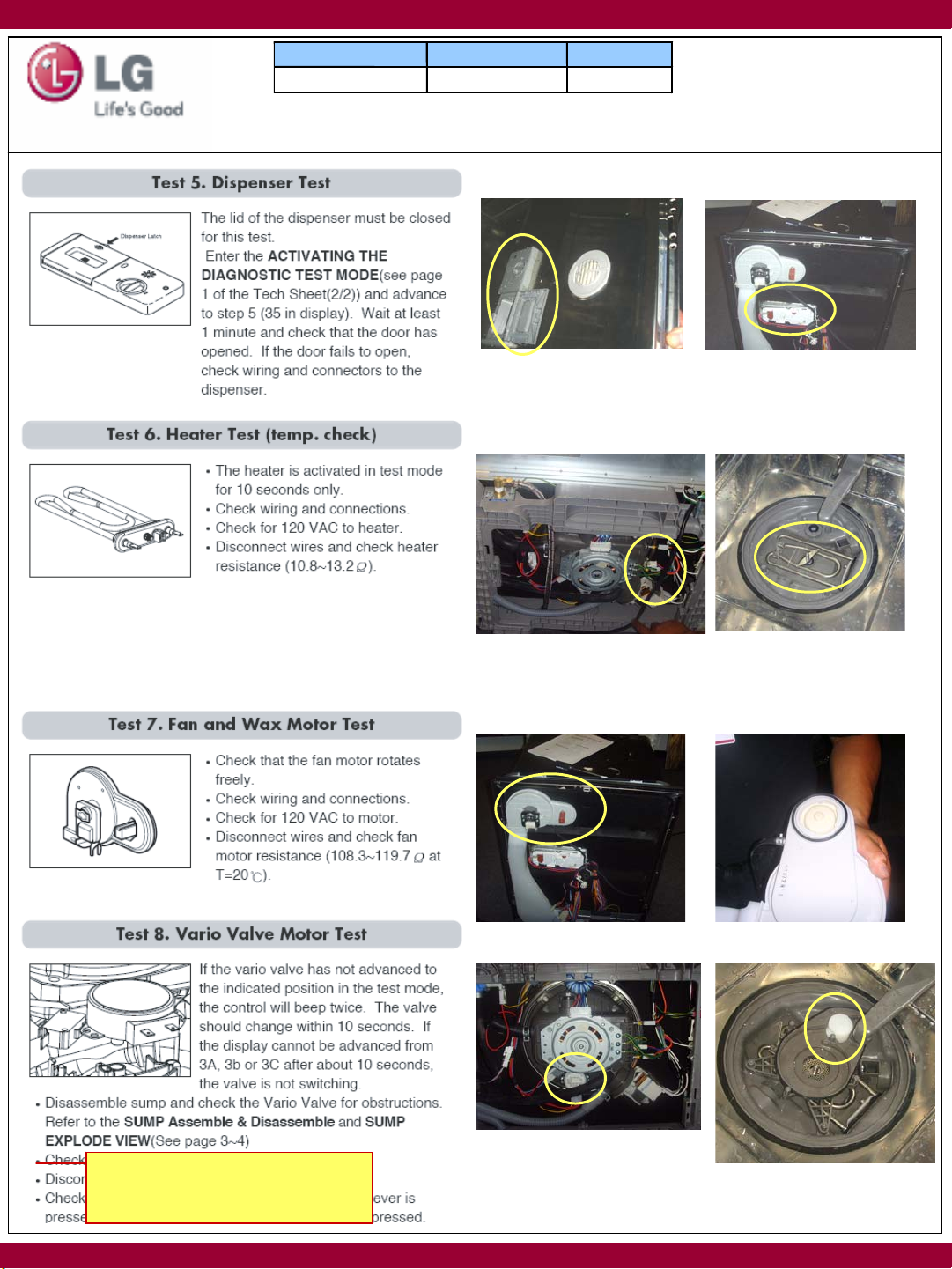

1. Test Mode

Air guide

Customer Model Factory Model Suffix

LDF6920XX D1608

Page

3

If we disconnect the wire plug,

Only Auto1(Strong) program is running

1. Test Mode

Washing motor problem

Customer Model Factory Model Suffix

LDF6920XX D1608

Page

4

• For 10 seconds check the power

or current by using probe

( 8A ~ 10A)

- remove junction cover

- contact the probes to Black, White

harness wire.

1. Test Mode

Open the door Remove the door

Bottom area In the sump

( Soft noise & vibration )

.Check the resistance of vario motor

.Check the loose fitting of micro s/w “

.Heavy soil remain around the valve

Remove the door Opposite side

In the sump

Customer Model Factory Model Suffix

LDF6920XX D1608

Page

5

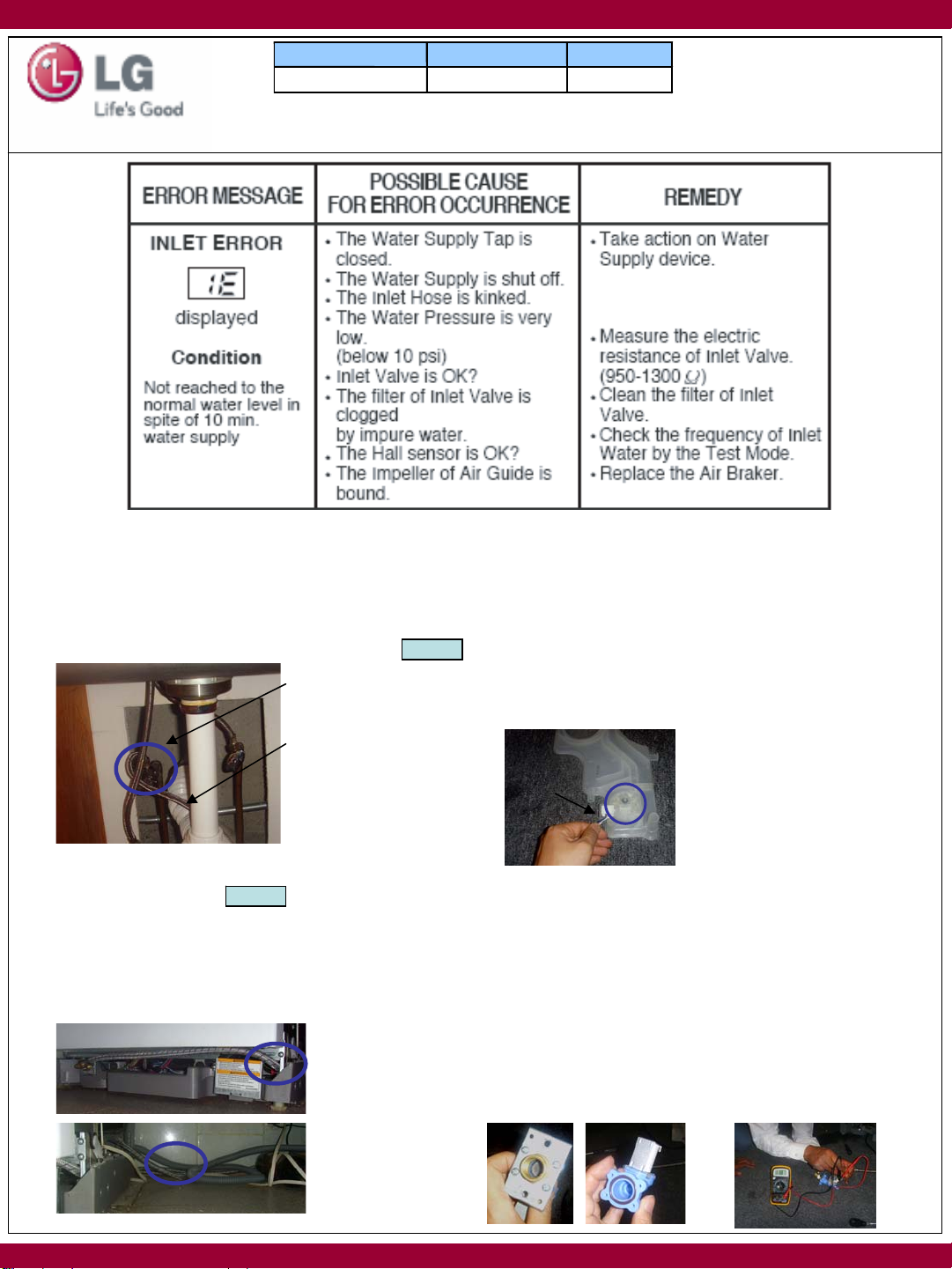

2. Error Mode

Micros switch loose connection ( next page )

Check the water supply system ( Parts , sensor , environment ) by TEST MODE – 4 ( Page 1), Test 4 (Page2)

Î If there is water flow in & can see the frequency raise : No problem

Î No water flow in or no frequency raise : Problem in water supply system or environment

1) Water supply tap is closed or no water supply

.Check the water tap

is closed

Î Open

.Check that water supply

is ok in this water tap

( Remove water hose,

open the water tap a

Hose

2) Water supply shut off

9

.Check the status of other water tap

( Water supply is ok or not )

3) Water supply hose kinked Î Make not kinked

CIC

little bit and check the

water supply ) If not

Î Change water supply

source

CIC

4) If water supply is ok ( open the door, we can check )

but no frequency raise.

- Water supply pressure is very low ( below 0.3 bar )

Air guide

Flow meter

(sensor)

- Air guide problem

. Impeller is stuck so not rotate Î Change Air guide

( Disassemble the air guide & blow, can check rotation )

. Flow meter ( sensor ) can not check the impeller rotation

Î Change Air guide or Flow meter

5) Inlet valve problem ( No water supply, No frequency )

-Loose connection of electric harness wire Î Reconnecting

-Inlet valve filter clogged

Î Remove filter and

clean the filter & valve

assemble the filter

Impeller

The water pressure is too low

to rotate a impeller for checking

Water flow

Î Open the water tap fully

Î Change the water supply

source which is high water

pressure

-Bad inlet valve

ÎCheck the resistance

( short or cut = 0 or infinite )

& replacement

Customer Model Factory Model Suffix

LDF6920XX D1608

Page

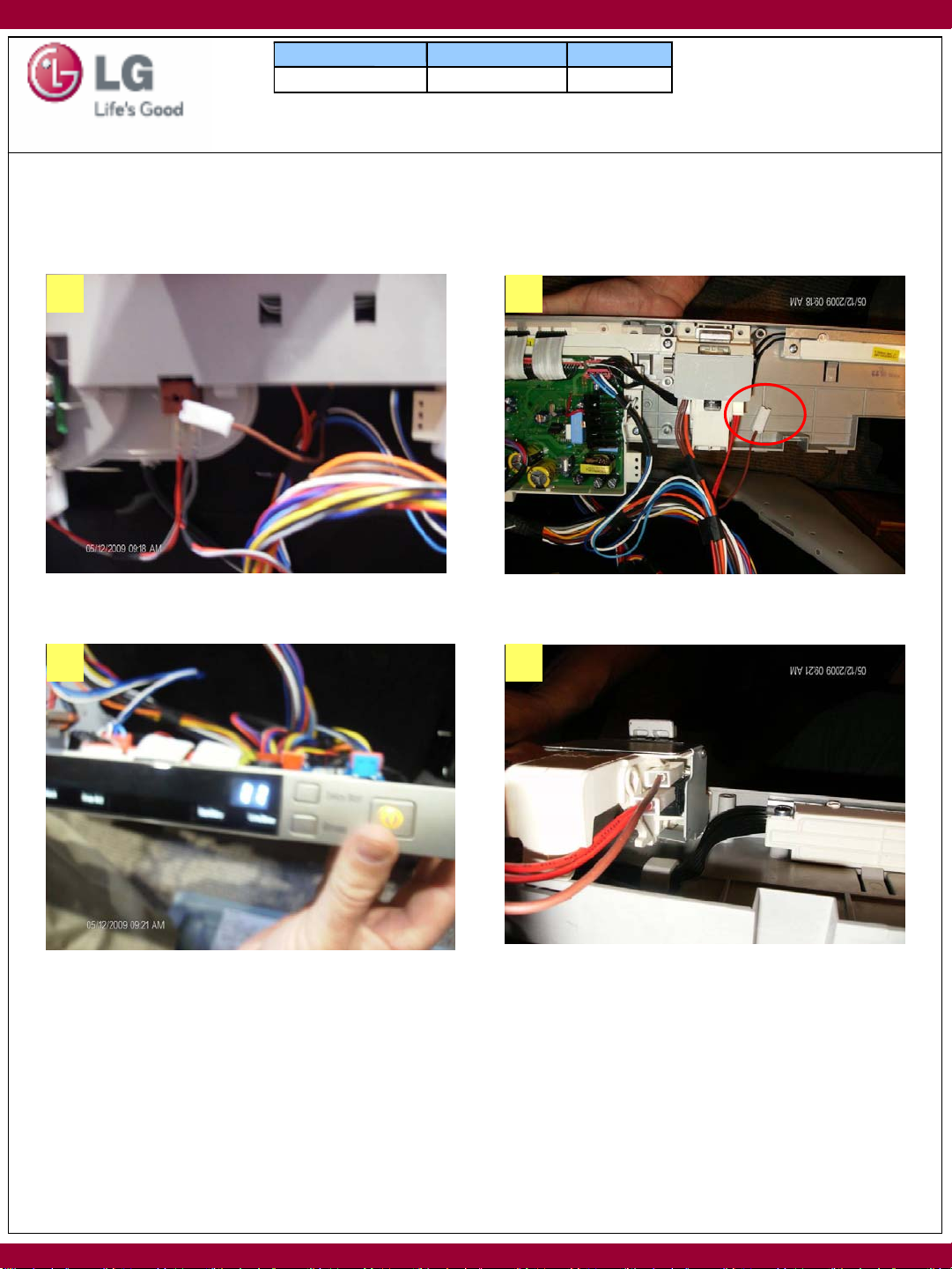

What was seen when the panel was removed This is a better view of the disconnected wire

6

6) Micros switch loose connection

1 2

2. Error Mode

The connector was reinserted back into placeThe unit is now responding to SC test normally

34

Customer Model Factory Model Suffix

LDF6810XX D1608

Page

7

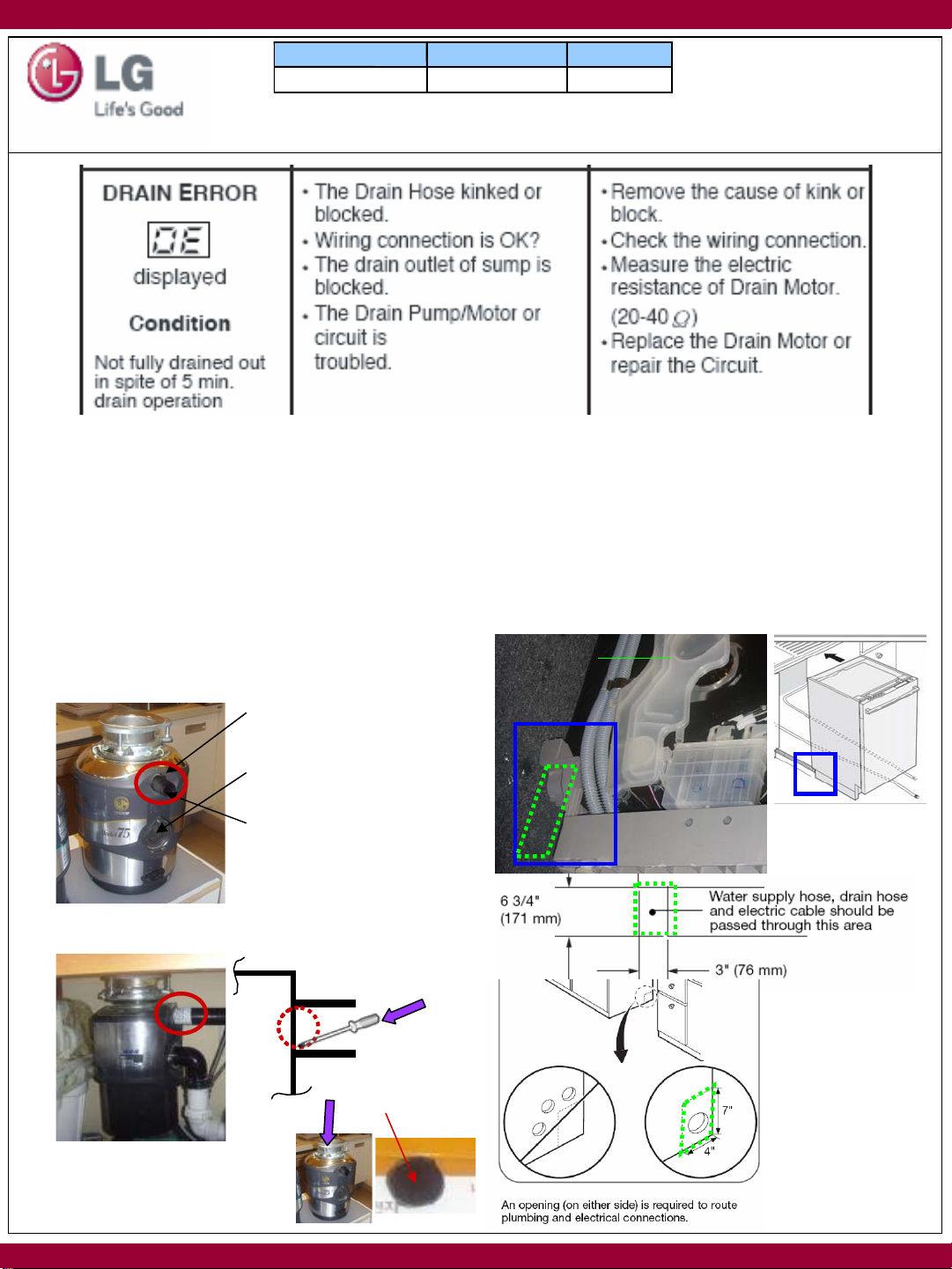

2. Error Mode

Garbage disposal plug block the

drain flow ( Installation )

too long extension hose ( 6ft )

Float hinge stuck ( Wrong sensing )

can happen in Serial no : 501 ~ 706

Drain pressure drop from the gap in

drain cover ,can happen serial no :

612~711

Make a hole at connection area

of disposal ~ drain hose

Shorten extension hose less

than 6ft

Replace the float assembly or

cut 1mm at float guide

Change sump assembly

Product (S/NO: 901~ )

Check the water drain system ( Parts , sensor , environment ) by TEST MODE – 3 ( Page 1), Test 3 (Page2)

Î If there is water drain & can hear the drain pump operation : No problem

Î Water remain in the tub or can’t hear the drain pump operation : Problem

1) Water remain in the Tub after installation [Installation]

9

.Can hear the drain pump operation, but not drain

Î Check the garbage disposal ~ drain hose connecting

by finger or drive ( + or - )

Connecting pipe to dishwasher

Drain hose

Connecting pipe to house main

Drain pipe

2) Drain hose kinked by bad installation [ Installation ]

Side View

Sell the disposal dishwasher

Drain hose connecting pipe

Blocking for protecting

Leakage ( for Non dishwasher

Customer )

ÎIf the connecting area was block, make a hole for drain

by using – drive & small hammer – circle direction

Block

Pick up block parts

ÎDisconnect garbage disposal

power and Remove broken

block area in the disposal

& power reconnect the disposal

NG

OK

If the passing hole

Is out of the 7”x4”,

Drain and water

Supply hose will

Be kinked

Î Make a new hole

Customer Model Factory Model Suffix

LDF6920XX D1608

Page

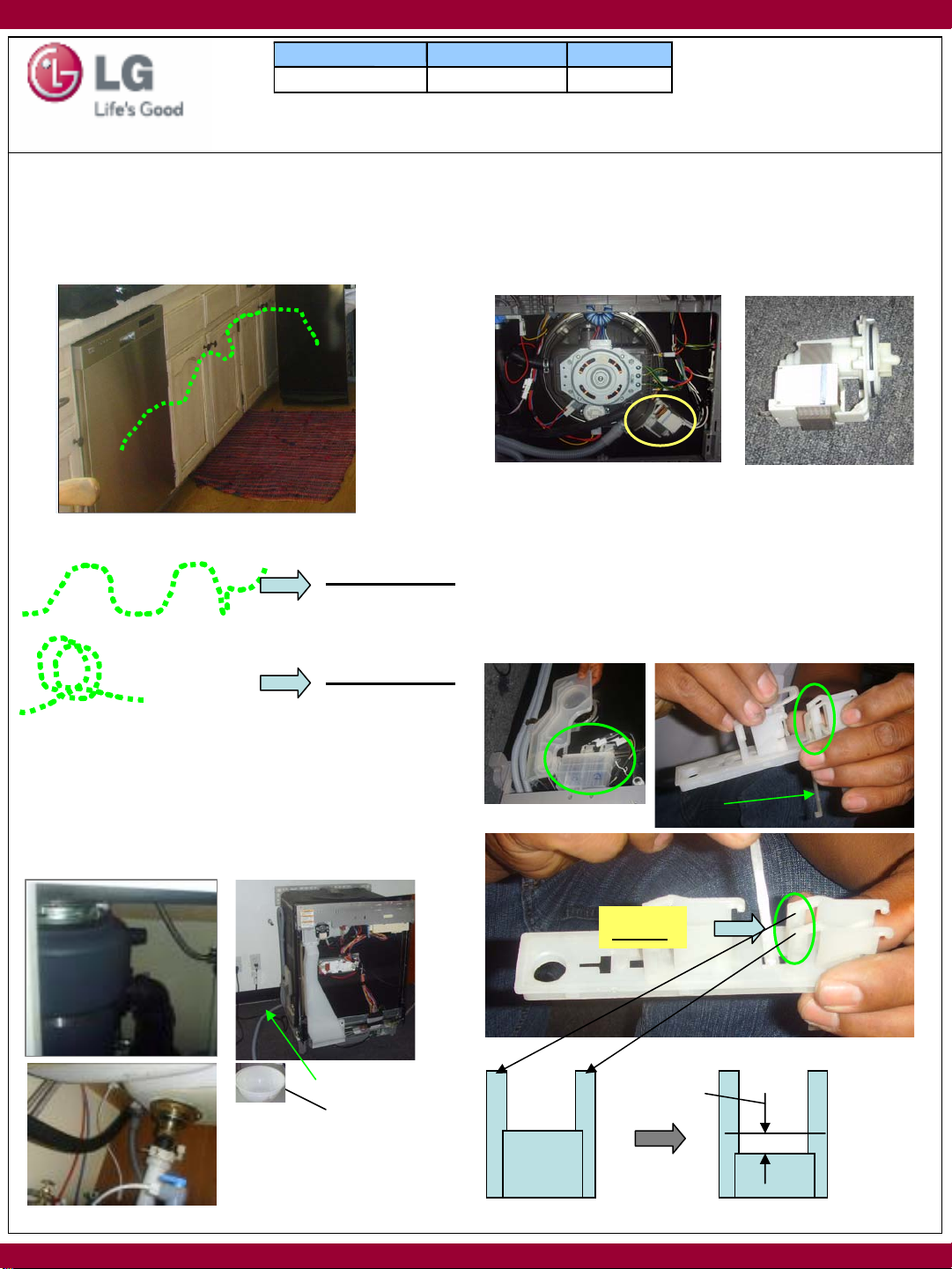

3) Too long extension hose ( over 6ft, installation )

8

.If the length of extension hose is longer than 6ft,

Can not drain water properly

Î Make the length of extension hose shorter than 6ft

Sink pipe

Drain hose + Extension hose

Dishwasher

2. Error Mode

- Run the drain pump by test mode – 3 ,or run the any course

& Check the water drain ( If there is no operation noise

or not drain )

Î Replace the drain pump, be careful the assemble direction

and 3 points of fastening 3 screws

[ Reference Assembly of drain pump ----- Page ---- ]

5) Float hinge stuck [ S/no : 501 ~ 706, especially 704~706]

Symptom : There is no water in the Tub (Drain ok)

But OE happen sometimes

( Sensing error of water drain )

Î Replace the Float assembly (float cover) or

cut 1.5 mm at hinge guide area in float cover ,

but we should pull dishwasher from sink cabinet.

4) Drain pump problem

( If not 1), 2), 3) check the drain pump )

-Disconnect drain hose form sink pipe or garbage disposal

or Air-gap & release the drain hose to big pots ,

Prepare towel for protect floor wet from drain hose

Disconnect

Garbage disposal

Release drain hose

X

Air gap

Drain hose

Big Pot or bowl

X

Left side

Float assembly

Float cover

Hinge

View

Cut 1.5mm

Customer Model Factory Model Suffix

LDF6920XX D1608

Page

6) Drain pressure drop from the gap in drain cover ,can happen serial no : 612~711

9

. Drain pump operation ( No problem )

. We can see some water is drain to drain hose, sometimes Not OE error but too much water remain

. But after drain process, there is too much water remain in the sump assembly ( 800cc ~ 1000 cc)

Î Replace sump assembly (S/no: 901~, production date is from 2009.1 ~ )

2. Error Mode

Water remain near by sump filter

hole

If the Gap between drain pump case ~ drain cover

Is too much, drain pressure would be drop down.

So not drain, too much water remain in sump

Î New ( No gap : S/no 901~ )

Customer Model Factory Model Suffix

LDF6920XX D1608

Page

10

E1 means that there is not enough or very little water in the tub ( dishwasher )

Î Generally a lot of leakage or water drain out by siphon effect can display E1

1) Water automatic drain out by siphon effect [ Installation ]

9

ÎCheck the drain hose, If the end of drain hose location was

below than 10”(250mm) or deep into the water pipe,

the water can be drain out automatically and make air sucking

noise [ S/no 901~, we improved this issue by applying siphon protect, but not perfect ]

2. Error Mode

Drain hose

H

Lie drain hose on the floor

ÎHose position is below

than 10”(250mm)

2) Logistic damage ( Inner area broken or leakage )

ÎCheck the damage or leaking in Tub or Bottom sump area.

: If the parts are broken, replace the parts, but tub damage, we can’t repair

Water pipe

Change the end of drain hose position

Over 10” (250mm) and fixing

ÎCheck sump after service, miss hose connecting

: Reconnecting hose

Customer Model Factory Model Suffix

LDF6920XX D1608

Page

11

FE means that water supply can’t stop so there is excessive water in the tub

If the over flow float s/w is on and off 1 0 times, display FE e rror

ÎGenerally inlet valve and dirty water supply ( tiny particle or steel po wder) problem

So ask the customer lock the water tap connecting to D/W, and dispatch service

1) Water condition

9

Check that there is much steel stain powder or other dirty material in water pipe especially new house or after remodeling

This tiny material can block a small hole in inlet valve, if then even though no power supply to inlet valve,

the water supply is going on infinite until locking water tap.

Î Disassemble water supply connection between water supply hose & water tap

Open the water tap fully, and hold on for 1 minute or until you can see clean water , and assemble again.

Î Disassemble water supply hose with inlet valve

Open the water tap fully, and hold on for 1 minute or until you can see clean water , and assemble again

Î Next : Clean or replace inlet valve [ Next step ]

2. Error Mode

2) Clean or replace inlet valve ( Recommend replace inlet valve )

Remove filter in inlet valve Wash inlet valve

OR

Replace inlet valve

Customer Model Factory Model Suffix

LDF6920XXD D1608

Page

12

HE can be displayed if the circuit of heater has problems ( short or cut off )

ÎNot heating [ S/no 812~ , HE error can be displayed ]

ÎBefore s/no 812, Even though heater has some problem, the main board can not

display HE error, so you can check the heater status by checking power supply

at test mode [6] for 10 seconds or measure the heater resistance directly.

1) Customer Environment

If the temperature of water supply is very hot (higher than 140 F(60℃)) or rated voltage is low

Depending on surrounding condition,

dishwasher will display HE error code intermittently

and stop without drain, even though there is no defect in heater assembly.

Replace the PCB Main board without exception (Refer to the Service Bulletin)

2. Error Mode

2) Heater problem

Check power supply at test mode[6] for 10 seconds or heater resistance

If the Heater is open, HE error will occur every cycle.

Î Replace the heater assembly or Sump assembly

Heater assembly

Pull D/W from sink cabinet and Replace the heater assembly

Thermistor

Heater assemble area

In Sump assembly

Customer Model Factory Model Suffix

LDF6920XX D1608

Page

13

tE means that Main board doesn’t check the resistor of thermistor in heater assembly

2. Error Mode

★ if only thermistor has problem, change heater assembly.

not replace only thermistor

Customer Model Factory Model Suffix

LDF6920XX D1608

Page

14

LE means that the main board can not sense the rotation of washing motor

We can check the washing motor operation by using Test mode “2” in page 2 , Test 2 in page 3

※ Be careful, water supply must be done before running washing motor to protect water seal

1) In test mode , washing motor doesn’t rotate

Î Change washing motor

2. Error Mode

After remove bad washing motor ,

Sump

2) In test mode , washing motor doesn’t rotate

Î Change sump assembly [ Not only Washing motor but also Water seal have problems ]

! Must use new sump gasket for perfect sealing

Don’t use the gasket in old sump assembly, when you change

sump assembly

! Must add some lubricant liquid to out area of sump gasket

for better replacement ( hand wash liquid detergent or … )

Sump gasket

Sump assembly

You must check the water seal condition.

If it’s not good! Change sump assembly

! You must see the white grease is in

Water seal

Customer Model Factory Model Suffix

LDF6920XX D1608

Page

15

2. Error Mode

PF : This message is not a error message,

Just display the reason of stop washing is because of

not dishwasher but sudden power failure

( There was power supply stop in the dishwasher )

Î Open and close the door

or Power off and run D/W again.

Customer Model Factory Model Suffix

LDF6920XX D1608

Page

16

3. Trouble shooting guide

Leakage

Customer Model Factory Model Suffix

LDF6920XX D1608

Page

17

3. Trouble shooting guide

• Check the electric outlet

<1> Re- connect the power connection

Loose connection

※ Wire spec : UL AWG16

Under or over sized wire nuts (melting)

Insulator diameter : Φ

3.12mm

(0.123 inch )

YES

( Next page )

Electric conductor diameter :Φ

<2> Check the electricity is failed or not

BK

WH

Green/yellow

Check power supply

<3> Check the electric outlet

Check power supply

1.49mm

(0.059inch )

Customer Model Factory Model Suffix

LDF6920XX D1608

Page

18

YES

( Next page )

3. Trouble shooting guide

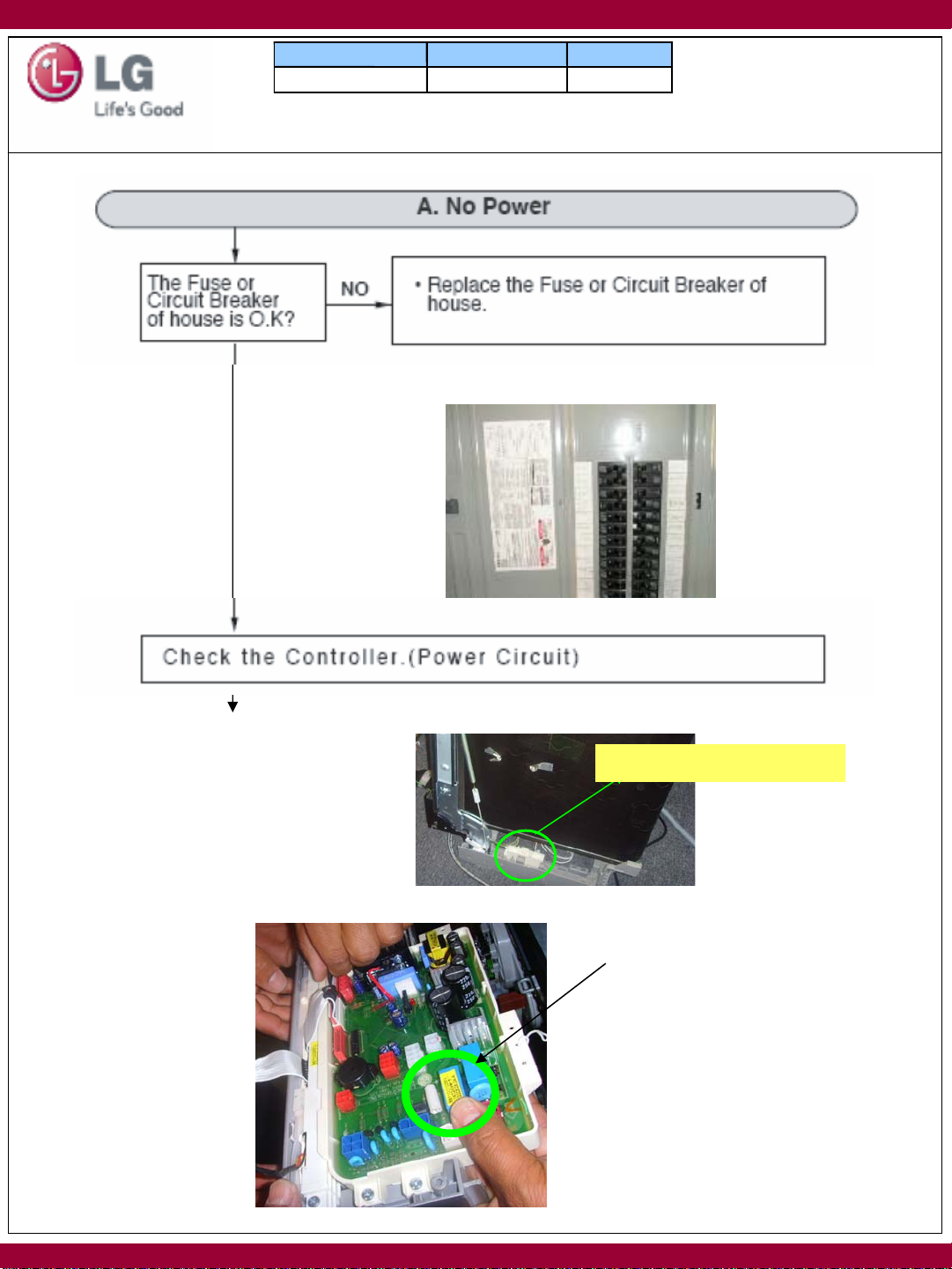

<1> Check the circuit breaker S/W : On / Off

<1> Check the noise filter

Check the power supply

<2> Check PCB main board

Part number is correct ?

Change Main PCB

( See SVC part lists )

Customer Model Factory Model Suffix

LDF6920XX D1608

Page

19

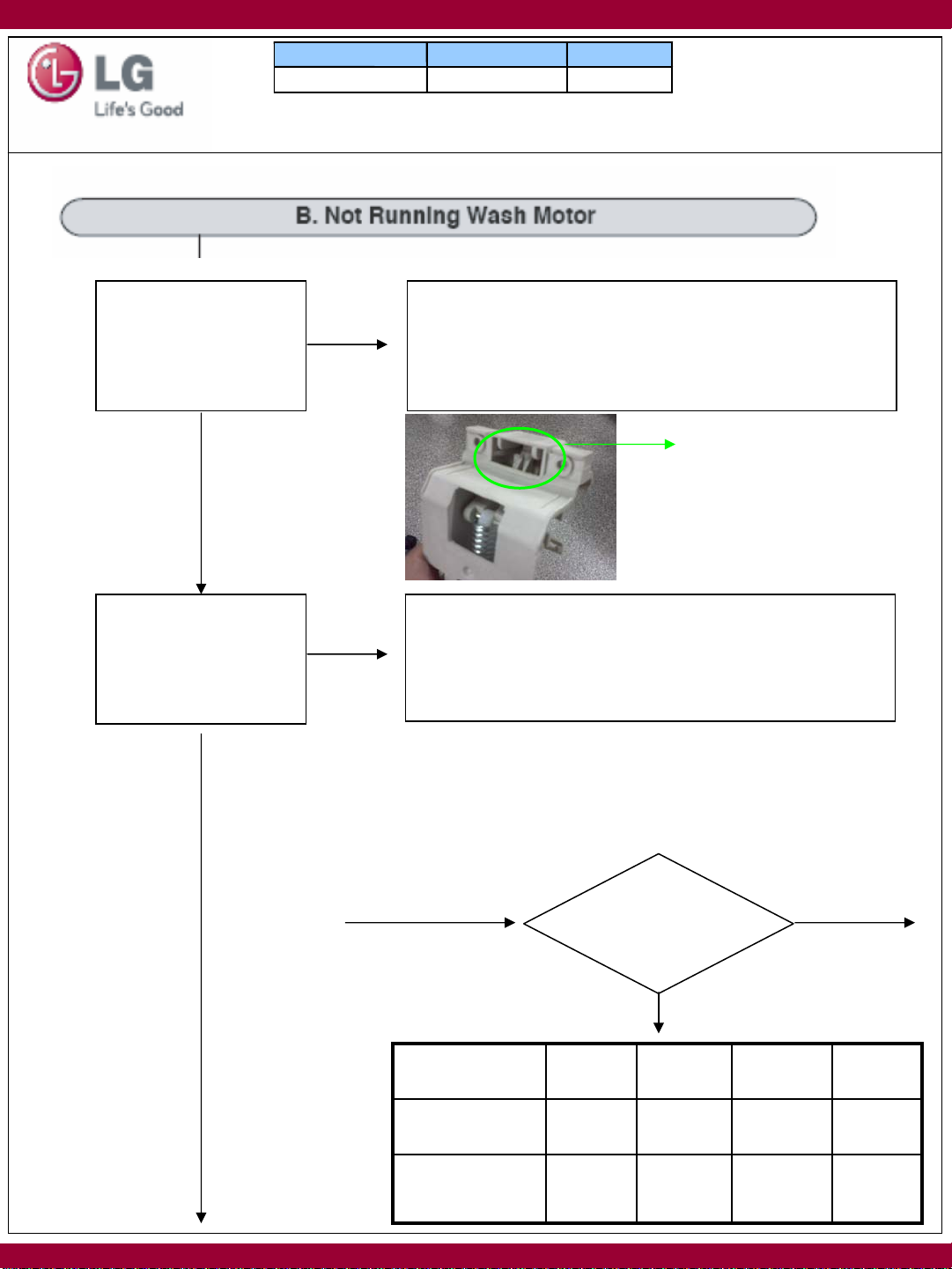

The door is tightly

closed

YES

3. Trouble shooting guide

NO

NO

Close the door tightly

Check the latch assembly in door

If you open the door,

, the latch is closed

position like left

ÎReposition the

Latch by closing the

Door tightly

Normal operation ( Serial no: 901 ~ 905 )

Error message ?

YES

In cold water supply condition, after water supply process

Heater heat the water to 95F (35℃).

At this time washing motor runs for 1 minutes

when the temperature rise up every 9F(5℃) by

target temperature.

Water supply

¾ Only Pre wash process

Temperature 70F 79F 88F 95F

Heater ON ON ON Off~

Y

Temperature >95F(35℃)

N

Washing

Motor

Off On for

1 min

On for

1 min

On~

Customer Model Factory Model Suffix

LDF6920XX D1608

Page

20

Checking by test

Mode [Chapter 1]

YES

PF

3. Trouble shooting guide

NO

NO

FE ( Over flow error )

E1 ( Leak or siphon error )

※ Refer : Chapter 2 – error mode

IE ( No water supply error )

OE ( No drain error )

HE ( Can’t heat : Heater error: S/no 901~ )

tE ( Thermister error :

Can’t check the temperature )

LE ( Washing motor error :

Washing motor do not rotate or

Can’t check motor rotation )

YES

PF is not error mode

Just display there was

Sudden power

failure

※ Refer :Chapter 1 – test mode

Chapter 2 – error mode

NO

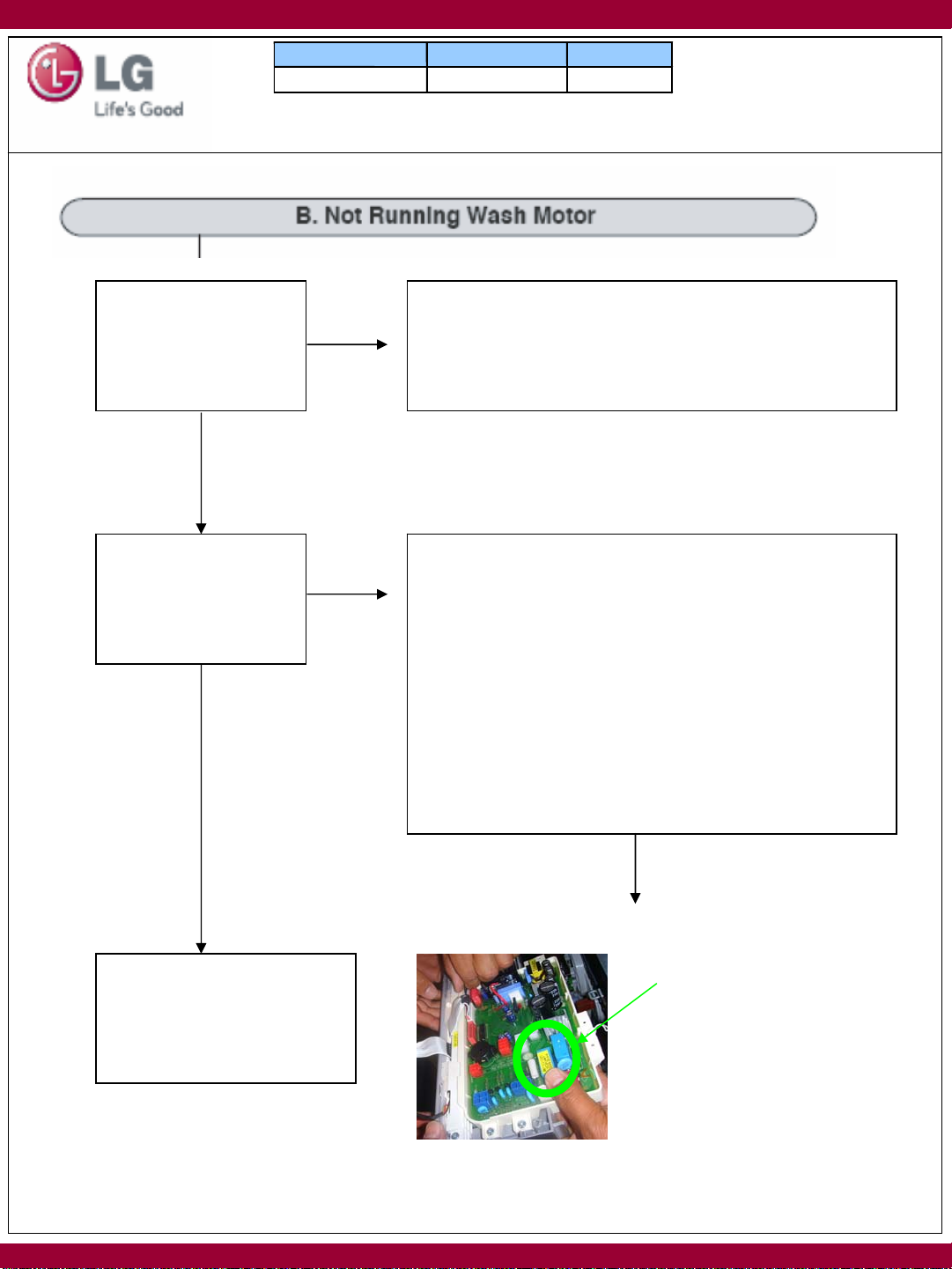

<2> Check PCB main board

Part number is correct ?

( See SVC part lists )

Change Main PCB

Customer Model Factory Model Suffix

LDF6920XX D1608

Page

21

Soil Spot

[Not washing]

3. Trouble shooting guide(5/13)

C. Poor wash

CIC

Soil spot or

white spot

(Hard water)

White

spot

Hard water is from the water supply, not the unit. If hard water is causing

white film or powder in unit .

1) Install a water softener can solve the problem cl e ar ly.

2) – A Run a cycle with an EXTRA RINSE option to minimize the effect of hard

water

* ~ S/no:906: Choose Extra rinse option Î + 1 rinse process in cycle

S/no:907~ : Choose Extra rinse option Î + 3 rinse process in cycle

* In Lab test +0 default : Score 0 / 5

2) – B Don’t put too much soap into dishwasher.

Put 0.7~ 1 ounce detergent into dishwasher : OK

Put over 1.4 ounces detergent into dishwasher : Not good

(if the customer choose EXTRA RINSE OPTION )

Hard water condition

. White spot on glasses, cups, tub

. White powder residue on cups or …

. Cloudy glasses

+1 rinse process : Score 3.5 / 5

+3 rinse process : Score 4.5 / 5 in Very high hardness

condition ( 400ppm )

Use glass magic to minimize the side effect of hard water

Glass magic has 20% of

Î Put 2 Tea spoons glass magic into the tub before starting

Î Put 0.7 ~ 1 ounce detergent into the dispenser

Î Run a cycle with an EXTRA RINSE option

Use White Vinegal

1) Remove all dishes and silverware from the dishwasher.

2) Only the racks should remain in the tub

3) Place about 1 cup ( 200ml ~ 500ml) of white vinegar into the Lower rack

( Don’t pour the vinegar to the bottom area )

Run a “Normal” cycle and select “Extra Rinse” and

“Sanitary”, then close the door. Do NOT USE ANY DETERGENT

Phosphorus (the material of water softener)

Loading...

Loading...