Page 1

INSTALLATION MANUAL

AIR

CONDITIONER

[Representative] LG Electronics Inc. EU Representative :

LG Electronics European Shared Service Center B.V.

Krijgsman 1, 1186 DM Amstelveen, The Netherlands

[Manufacturer] LG Electronics Inc. Changwon 2nd factory 84, Wanam-ro,

Seongsan-gu, Changwon-si, Gyeongsangnam-do, KOREA

MFL67855536

Rev.02_040319

Copyright © 2016 - 2019 LG Electronics Inc. All Rights Reserved.

Please read this installation manual completely before installing the product.

Installation work must be performed in accordance with the national wiring

standards by authorized personnel only.

Please retain this installation manual for future reference after reading it thoroughly.

CEILING CASSETTE

Original instruction

www.lg.com

РУССКИЙ ЯЗЫК

ENGLISH

УКРАÏНСЬКА

ITALIANO ESPAÑOL

ҚАЗАҚ ТІЛІ

БЕЛАРУСКАЯ МОВА

FRANÇAIS DEUTSCH

OʻZBEK TILI

ΕΛΛΗΝΙΚΆ

ČEŠTINA

NEDERLANDS

POLSKI

LIMBA ROMÂNĂ

Page 2

2

ENGLISH

MODEL DESIGNATION

MODEL DESIGNATION

Product information

- Product Name : Air conditioner

- Model Name :

SQSM N B 015

- Additional Information : serial number is

refer to the barcode on the product.

- Max allowable pressure High side :

4.2 MPa / 4.32 MPa (it can be different by

model)

- Max allowable pressure Low side :

2.4 MPa

- Refrigerant : R32 / R410A

Serial number

Chassis name

Indoor Unit / Outdoor Units

N : Indoor Unit

U : Outdoor Unit

Detailed product type only

for M- series models

AQ : Wall mounted Libero-R

SQ : Wall mounted Libero-E

AH* : ARTCOOL

AW* : ART COOL Mirror

AH : Ceiling Cassette

AHL : Ceiling Concealed Duct

(Low Static)

R : Refrigerant R32/R410A

PC : Standard plus (S)

Detailed product type for

U- / C- series models

L : Low Static

H : High COP

C : Econo

R : Refrigerant R32 / R410A

Nominal Capacity

Ex) 7 000 Btu/h Class → '07',

18 000 Btu/h Class → '18'

Product type

S : Wall mounted /

ARTCOOL mirror

J : Wall mounted

A : ARTCOOL

T : Ceiling Cassette

B, M : Ceiling Concealed Duct

V : Ceiling Suspended & floor

Q : Console

P : Floor Standing

Connectable Outdoor unit type

M : Indoor units only for

Multi systems

U : Indoor units only for

Single A systems

C : Common Indoor Unit for

Multi and Single CAC

Airborne Noise Emission

The A-weighted sound pressure emitted by

this product is below 70 dB.

** The noise level can vary depending on the

site.

The figures quoted are emission level and are

not necessarily safe working levels.

Whilst there is a correlation between the

emission and exposure levels, this cannot be

used reliably to determine whether or not

further precautions are required.

Factor that influence the actual level of

exposure of the workforce include the

characteristics of the work room and the other

sources of noise, i.e. the number of

equipment and other adjacent processes and

the length of time for which an operator

exposed to the noise. Also, the permissible

exposure level can vary from country to

country.

This information, however, will enable the

user of the equipment to make a better

evaluation of the hazard and risk.

Limiting concentration

Limiting concentration is the limit of Freon gas

concentration where immediate measures can

be taken without hurting human body when

refrigerant leaks in the air. The limiting

concentration shall be described in the unit of

kg/m3(Freon gas weight per unit air volume)

for facilitating calculation

Limiting concentration: 0.44 kg/m3(R410A)

n Calculate refrigerant concentration

Refrigerant

concentration

(kg/m3)

Total amount of replenished

refrigerant in refrigerant facility (kg)

=

Capacity of smallest room where

indoor unit is installed (m3)

Page 3

TIPS FOR SAVING ENERGY

TIPS FOR SAVING ENERGY

Here are some tips that will help you minimize the power consumption when you use the air

conditioner. You can use your air conditioner more efficiently by referring to the instructions

below:

• Do not cool excessively indoors. This may be harmful for your health and may consume more

electricity.

• Block sunlight with blinds or curtains while you are operating the air conditioner.

• Keep doors or windows closed tightly while you are operating the air conditioner.

• Adjust the direction of the air flow vertically or horizontally to circulate indoor air.

• Speed up the fan to cool or warm indoor air quickly, in a short period of time.

• Open windows regularly for ventilation as the indoor air quality may deteriorate if the air

conditioner is used for many hours.

• Clean the air filter once every 2 weeks. Dust and impurities collected in the air filter may block the

air flow or weaken the cooling / dehumidifying functions.

3

ENGLISH

For your records

Staple your receipt to this page in case you need it to prove the date of purchase or for warranty

purposes. Write the model number and the serial number here:

Model number :

Serial number :

You can find them on a label on the side of each unit.

Dealer’s name :

Date of purchase :

Page 4

IMPORTANT SAFETY INSTRUCTIONS

4

ENGLISH

IMPORTANT SAFETY INSTRUCTIONS

The following symbols are displayed on indoor and outdoor units.

Read the precautions in this manual

carefully before operating the unit.

This symbol indicates that the

Operation Manual should be read

carefully.

READ ALL INSTRUCTIONS BEFORE USING THE APPLIANCE.

Always comply with the following precautions to avoid dangerous

situations and ensure peak performance of your product.

WARNING

!

It can result in serious injury or death when the directions are ignored.

CAUTION

!

It can result in minor injury or product damage when the directions are

ignored.

WARNING

!

This appliance is filled with

flammable refrigerant (R32)

This symbol indicates that a service

personnel should be handling this

equipment with reference to the

Installation Manual.

• Installation or repairs made by unqualified persons can result in

hazards to you and others.

• The information contained in the manual is intended for use by a

qualified service technician familiar with safety procedures and

equipped with the proper tools and test instruments.

• Failure to carefully read and follow all instructions in this manual can

result in equipment malfunction, property damage, personal injury

and/or death.

• Compliance with national gas regulations shall be observed.

Installation

• Always perform grounding.

- Otherwise, it may cause electrical shock.

• Don’t use a power cord, a plug or a loose socket which is damaged.

- Otherwise, it may cause a fire or electrical shock.

• For installation of the product, always contact the service center or a

professional installation agency.

- Otherwise, it may cause a fire, electrical shock, explosion or injury.

Page 5

IMPORTANT SAFETY INSTRUCTIONS

5

ENGLISH

• Securely attach the electrical part cover to the indoor unit and the

service panel to the outdoor unit.

- If the electrical part cover of the indoor unit and the service panel of

the outdoor unit are not attached securely, it could result in a fire or

electric shock due to dust, water, etc.

• Always install an air leakage breaker and a dedicated switching board.

- No installation may cause a fire and electrical shock.

• Do not keep or use flammable gases or combustibles near the air

conditioner.

- Otherwise, it may cause a fire or the failure of product.

• Ensure that an installation frame of the outdoor unit is not damaged

due to use for a long time.

- It may cause injury or an accident.

• Do not disassemble or repair the product randomly.

- It will cause a fire or electrical shock.

• Do not install the product at a place that there is concern of falling

down.

- Otherwise, it may result in personal injury.

• Use caution when unpacking and installing.

- Sharp edges may cause injury.

• The appliance shall be stored in a room without continuously

operating ignition sources

(for example: open flames, an operating gas appliance or an operating

electric heater.)

• Two or more people must lift and transport the product. Avoid

personal injury.

• Do not use means to accelerate the defrosting process or to clean,

other than those recommended by the manufacturer.

• Do not pierce or burn refrigerant cycle part.

• Be aware that refrigerants may not contain an odour.

• Keep any required ventilation openings clear of obstruction.

• The appliance shall be stored in a well-ventilated area where the room

size corresponds to the room area as specified for operation.(for R32)

• Refrigerant tubing shall be protected or enclosed to avoid damage.

• Flexible refrigerant connectors (such as connecting lines between the

indoor and outdoor unit) that may be displaced during normal

operations shall be protected against mechanical damage.

Page 6

IMPORTANT SAFETY INSTRUCTIONS

6

ENGLISH

• A brazed, welded, or mechanical connection shall be made before

opening the valves to permit refrigerant to flow between the

refrigerating system parts.

• Mechanical connections shall be accessible for maintenance

purposes.

• The appliance shall be installed in accordance with national wiring

regulations.

Operation

• Do not share the outlet with other appliances.

- It will cause an electric shock or a fire due to heat generation.

• Do not use the damaged power cord.

- Otherwise, it may cause a fire or electrical shock.

• Do not modify or extend the power cord randomly.

- Otherwise, it may cause a fire or electrical shock.

• Take care so that the power cord may not be pulled during operation.

- Otherwise, it may cause a fire or electrical shock.

• Unplug the unit if strange sounds, smell, or smoke comes from it.

- Otherwise, it may cause electrical shock or a fire.

• Keep the flames away.

- Otherwise, it may cause a fire.

• Take the power plug out if necessary, holding the head of the plug

and do not touch it with wet hands.

- Otherwise, it may cause a fire or electrical shock.

• Do not use the power cord near the heating tools.

- Otherwise, it may cause a fire and electrical shock.

• Do not open the suction inlet of the indoor/outdoor unit during

operation.

- Otherwise, it may electrical shock and failure.

• Do not allow water to run into electrical parts.

- Otherwise, it may cause the failure of machine or electrical shock.

• Hold the plug by the head when taking it out.

- It may cause electric shock and damage.

• Never touch the metal parts of the unit when removing the filter.

- They are sharp and may cause injury.

• Do not step on the indoor/outdoor unit and do not put anything on it.

- It may cause an injury through dropping of the unit or falling down.

Page 7

IMPORTANT SAFETY INSTRUCTIONS

7

ENGLISH

• Do not place a heavy object on the power cord.

- Otherwise, it may cause a fire or electrical shock.

• When the product is submerged into water, always contact the

service center.

- Otherwise, it may cause a fire or electrical shock.

• Take care so that children may not step on the outdoor unit.

- Otherwise, children may be seriously injured due to falling down.

• Use a vacuum pump or inert (nitrogen) gas when doing leakage test or

air purge. Do not compress air or oxygen, and do not use flammable

gases. Otherwise, it may cause fire or explosion.

- There is the risk of death, injury, fire or explosion.

• Do not turn on the breaker or power under condition that front panel,

cabinet, top cover, control box cover are removed or opened.

- Otherwise, it may cause fire, electric shock, explosion or death.

• Turn off all devices that cause fire when the refrigerant leaks.,

ventilate the room (example : opening window or using ventilation

unit), and contact with dealer who you purchased the unit.

• The installation of pipe-work shall be kept to a minimum.

• When mechanical connectors are reused indoors, sealing parts shall

be renewed.(for R32)

• When flared joints are reused indoors, the flare part shall be refabricated.(for R32)

CAUTION

!

Installation

• Install the drain hose to ensure that drain can be securely done.

- Otherwise, it may cause water leakage.

• Install the product so that the noise or hot wind from the outdoor unit

may not cause any damage to the neighbors.

- Otherwise, it may cause dispute with the neighbors.

• Always inspect gas leakage after the installation and repair of product.

- Otherwise, it may cause the failure of product.

• Keep level parallel in installing the product.

- Otherwise, it may cause vibration or water leakage.

• Any person who is involved with working on or breaking into a

refrigerant circuit should hold a current valid certificate from an

Page 8

IMPORTANT SAFETY INSTRUCTIONS

8

ENGLISH

industry-accredited assessment authority, which authorises their

competence to handle refrigerants safely in accordance with an

industry recognised assessment specification.(for R32)

• Wear adequate personal protection equipment (PPE) when installing,

maintaining or servicing the product.

• Pipe-work shall be protected from physical damage.

Operation

• Avoid excessive cooling and perform ventilation sometimes.

- Otherwise, it may do harm to your health.

• Use a soft cloth to clean. Do not use wax, thinner, or a strong

detergent.

- The appearance of the air conditioner may deteriorate, change color,

or develop surface flaws.

• Do not use an appliance for special purposes such as preserving

animals vegetables, precision machine, or art articles.

- Otherwise, it may damage your properties.

• Do not place obstacles around the flow inlet or outlet.

- Otherwise, it may cause the failure of appliance or an accident.

• The appliance shall be stored so as to prevent mechanical damage

from occurring.

• Servicing shall only be performed as recommended by the equipment

manufacturer. Maintenance and repair requiring the assistance of

other skilled personnel shall be carried out under the supervision of

the person competent in the use of flammable refrigerants. (for R32)

• Dismantling the unit, treatment of the refrigerant oil and eventual

parts should be done in accordance with local and national standards.

• Periodic ( more than once/year ) cleaning of the dust or salt particles

stuck on the heat exchanger by using water.

• Means for disconnection must be incorporated in the fixed wiring in

accordance with the wiring rules.

Page 9

TABLE OF CONTENTS

TABLE OF CONTENTS

2 MODEL DESIGNATION

3 TIPS FOR SAVING ENERGY

4 IMPORTANT SAFETY INSTRUCTIONS

10 INSTALLATION PLACES

12 THE INDOOR UNIT INSTALLATION

13 Indoor Unit Drain Piping

14 Wiring Connection

16 Flaring Work

19 REMOTE CONTROLLER INSTALLATION

21 Wired remote controller installation

22 INSTALLATION OF DECORATIVE PANEL(ACCESSORY)

9

ENGLISH

24 TEST RUNNING

25 OPTIONAL OPERATION

25 Installer Setting - Test Run Mode

26 Installer Setting - Setting Address of Central Control

27 Installer Setting - Thermistor

28 Installer Setting - Ceiling Height Selection

29 Installer Setting - Group Setting

30 Installer Setting -Dry Contact Mode Setting

31 Installer Setting - Celsius / Fahrenheit Switching

32 Installer Setting - Optional Function Setting

33 Installer Setting - Remote controller Mode Lock

34 HOW TO SET E.S.P?

Page 10

INSTALLATION PLACES

Annexed sheet

Or

Packing corrugated

cardboard on the

bottom

10

ENGLISH

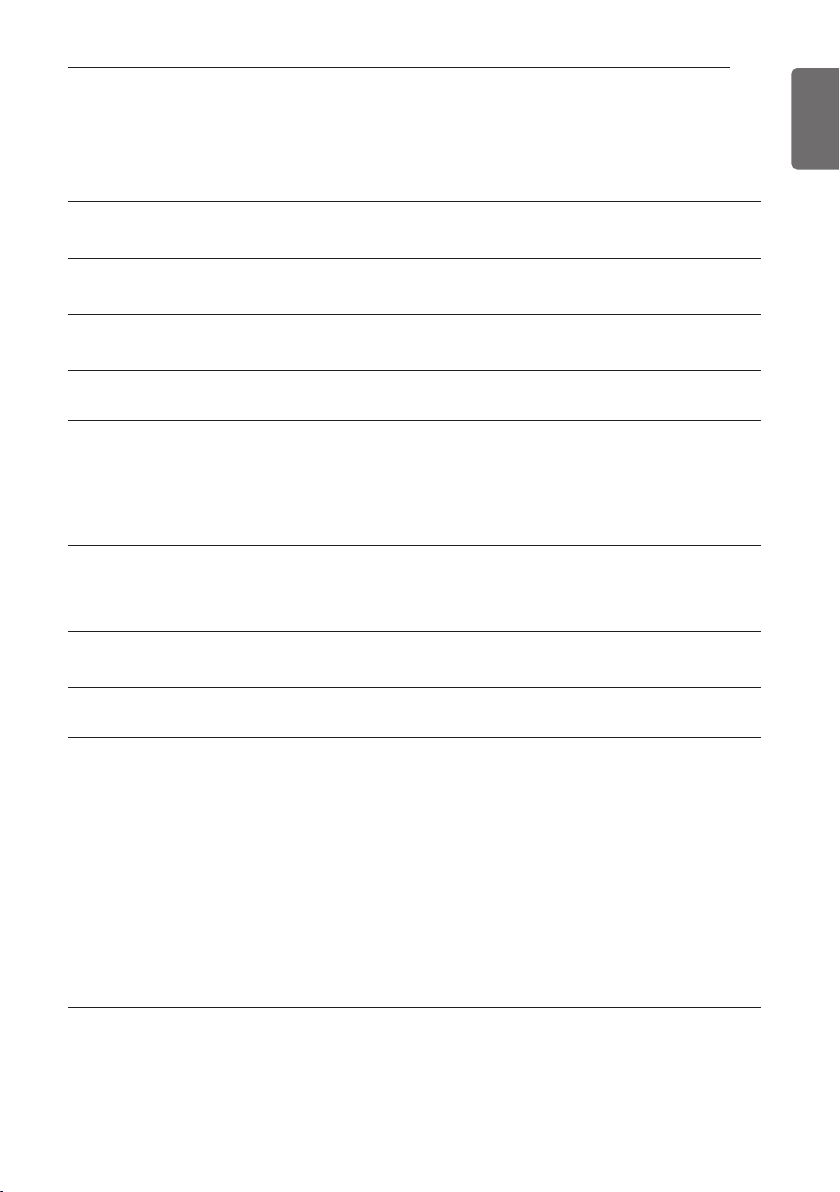

INSTALLATION PLACES

- There should not be any heat source or steam near the unit.

- There should not be any obstacles to prevent the air circulation.

- A place where air circulation in the room will be good.

- A place where drainage can be easily obtained.

- A place where noise prevention is taken into consideration.

- Do not install the unit near the door way.

- Ensure the spaces indicated by arrows from the wall, ceiling, or other obstacles.

- The indoor unit must keep the maintenance space.

10 or

Ceiling

Ceiling Board

more

Ceiling Board

500 or

more

* Please use an annexed sheet or the

corrugated cardboard on the bottom of

packing as installation sheet.

500 or

1 000

or more

Chassis

H

Floor

more

H

TU 3 300

TQ/TR/TP 3 600

TN/TM 4 200

* When using the bottom sheet, please use it

after separating the installation sheet from

packing of the product floor by using a knife

etc as a picture below.

Unit : mm

300 or less

At least 1 800

H or less

Page 11

INSTALLATION PLACES

11

ENGLISH

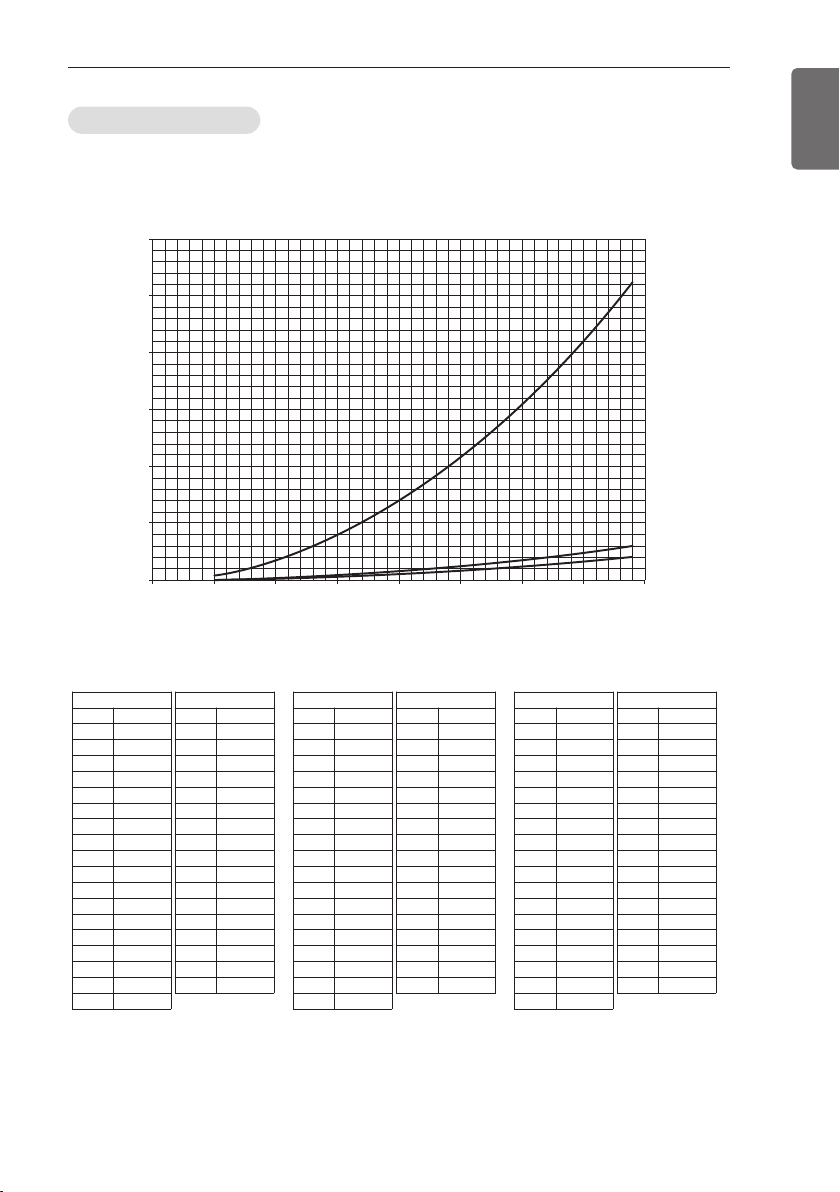

Minimum floor area

(for R32)

- The appliance shall be installed, operated and stored in a room with a floor area larger than the

minimum area.

- Use the graph of table to determine the minimum area.

Amin (m2)

- m : Total refrigerant amount in the system

- Total refrigerant amount : factory refrigerant charge + additional refrigerant amount

- Amin : minimum area for installation

600

500

400

300

200

100

0

Floor location

m (kg) Amin (m

< 1.224

1.224

12.9

1.4 16.82

1.6 21.97

1.8 27.80

2 34.32

2.2 41.53

2.4 49.42

2.6 58.00

2.8 67.27

3 77.22

3.2 87.86

3.4 99.19

3.6 111.20

3.8 123.90

4 137.29

4.2 151.36

4.4 166.12

0 1.224 2 3 4 5 6 7 8

2

)

-

Floor location

m (kg) Amin (m

4.6 181.56

4.8 197.70

5 214.51

5.2 232.02

5.4 250.21

5.6 269.09

5.8 288.65

6 308.90

6.2 329.84

6.4 351.46

6.6 373.77

6.8 396.76

7 420.45

7.2 444.81

7.4 469.87

7.6 495.61

7.8 522.04

2

)

Wall mounted

m (kg) Amin (m

< 1.224

1.224

1.43

1.4 1.87

1.6 2.44

1.8 3.09

2 3.81

2.2 4.61

2.4 5.49

2.6 6.44

2.8 7.47

3 8.58

3.2 9.76

3.4 11.02

3.6 12.36

3.8 13.77

4 15.25

4.2 16.82

4.4 18.46

2

)

-

Wall mounted

m (kg) Amin (m

4.6 20.17

4.8 21.97

5 23.83

5.2 25.78

5.4 27.80

5.6 29.90

5.8 32.07

6 34.32

6.2 36.65

6.4 39.05

6.6 41.53

6.8 44.08

7 46.72

7.2 49.42

7.4 52.21

7.6 55.07

7.8 58.00

2

)

Ceiling Mounted

m (kg) Amin (m

< 1.224

1.224

0.956

1.4 1.25

1.6 1.63

1.8 2.07

2 2.55

2.2 3.09

2.4 3.68

2.6 4.31

2.8 5.00

3 5.74

3.2 6.54

3.4 7.38

3.6 8.27

3.8 9.22

4 10.21

4.2 11.26

4.4 12.36

2

)

-

Floor standing

Wall mounted

Ceiling mounted

m (kg)

Ceiling Mounted

m (kg) Amin (m

4.6 13.50

4.8 14.70

5 15.96

5.2 17.26

5.4 18.61

5.6 20.01

5.8 21.47

6 22.98

6.2 24.53

6.4 26.14

6.6 27.80

6.8 29.51

7 31.27

7.2 33.09

7.4 34.95

7.6 36.86

7.8 38.83

2

)

Page 12

THE INDOOR UNIT INSTALLATION

12

ENGLISH

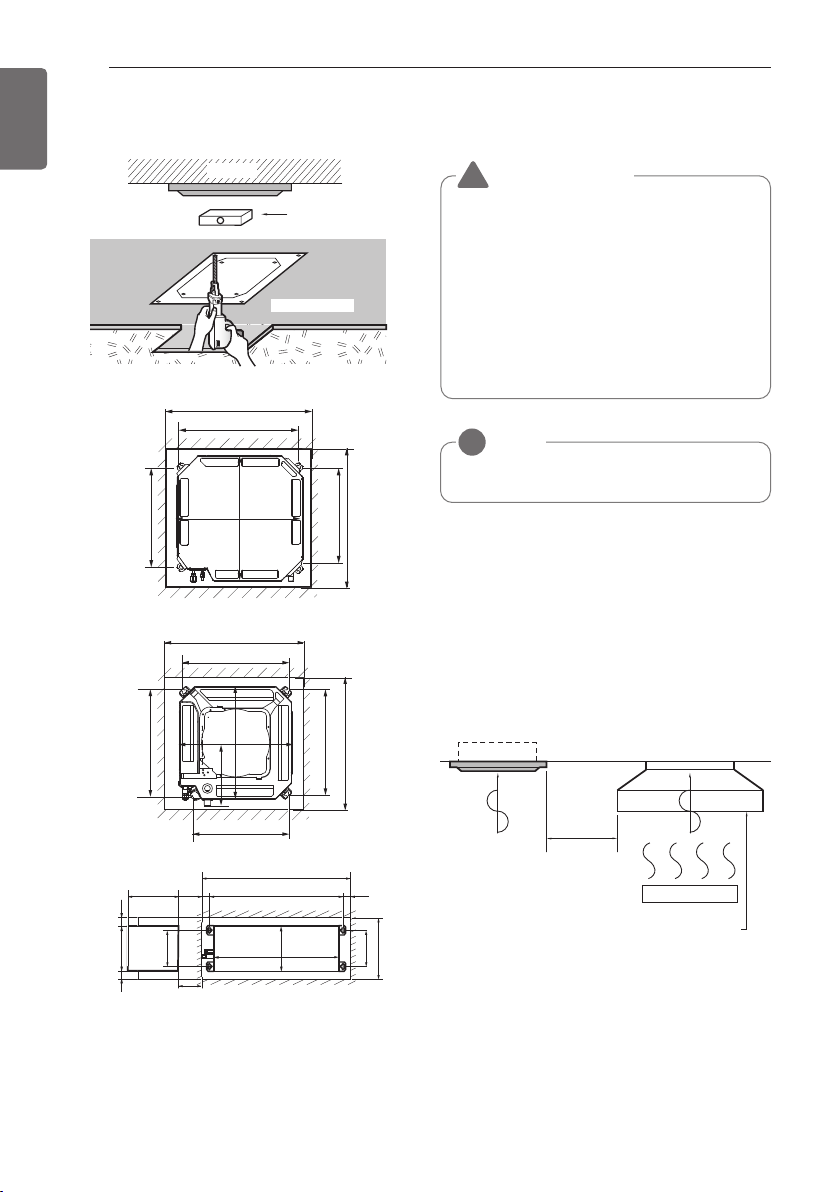

THE INDOOR UNIT INSTALLATION

TP/TN/TM Series

875(Ceiling opening)

787(Hanging bolt)

840 Unit size

671

523

Ceiling

840 Unit size

TQ/TR Series

585~660

517

570

570

319

Level gauge

Ceiling board

(Hanging bolt)

684

Unit:mm

517

875(Ceiling opening)

585~660

CAUTION

!

• This air-conditioner uses a

drain pump.

• Install the unit horizontally

using a level gauge.

• During the installation, care

should be taken not to damage

electric wires.

NOTE

!

Avoid the following installation location.

1

Such places as restaurants and kitchen

where considerable amount of oil steam

and flour is generated. These may cause

heat exchange efficiency reduction, or

water drops, drain pump mal-function. In

these cases, take the following actions;

-

Make sure that ventilation fan is enough to

cover all noxious gases from this place.

- Ensure enough distance from the cooking

room to install the air conditioner in such a

place where it may not suck oily steam.

Air conditioner

1 065

965

448

Unit:mm

50

354

466

400 4040

600

306

461

TU Chassis

50

860

250

- Select and mark the position for fixing bolts

and piping hole.

- Decide the position for fixing bolts slightly

tilted to the drain direction after considering

the direction of drain hose.

- Drill the hole for anchor bolt on the wall.

Take enough

distance

Cooking table

Use the ventilation fan

for smoke-collecting

hood with sufficient

capacity.

2 Avoid installng air conditioner in such

places where cooking oil or iron powder is

generated.

3 Avoid places where inflammable gas is

generated.

4 Avoid place where noxious gas is

generated.

5 Avoid places near high frequency

generators.

Page 13

THE INDOOR UNIT INSTALLATION

Ceiling board

Maintenance

drain port

Upward

routing

not allowed

Pipe clamp

Indoor unit

Ceiling

Keep the length of the bolt

from the bracket to 40 mm

Air Conditioner body

Keep the length of 15~18 mm

between the air conditioner

bottom surface and the ceiling

surface

Paper model

for installation

Keep the length of 20~22 mm

between the air conditioner bottom

surface and the ceiling surface

Paper model

for installation

Set screw of

paper model (4 pieces)

Open the ceiling board

along the outer edge of the

paper model

Ceiling

Air conditioner body

Set screw of

paper model (4 pieces)

Open the ceiling board

along the outer edge of the

paper model

Ceiling board

Ceiling board

Hanging bolt

(W3/8 or M10)

Nut

(W3/8 or M10)

Spring washer

(M10)

Flat washer for M10

(accessory)

Flat washer for M10

(accessory)

Nut

(W3/8 or M10)

The following parts is option.

① Hanging Bolt - W 3/8 or M10

② Nut - W 3/8 or M10

③ Spring Washer - M10

④ Plate Washer - M10

4Way

Keep the length of the bolt

from the bracket to 40 mm

1Way

Ceiling board

Adjust the

same height

Ceiling board

Adjust the same height

Drill the piping hole on the wall slightly tilted to the outdoor side using a Ø 70 hole-core drill.

13

150 mm

Ceiling

board

70 mm

ENGLISH

CAUTION

!

Tighten the nut and bolt to

prevent unit falling.

Wall

Indoor

Outdoor

5~7 mm

Indoor Unit Drain Piping

- Drain piping must have down-slope (1/50 to

1/100): be sure not to provide up-and-down

slope to prevent reversal flow.

- During drain piping connection, be careful

not to exert extra force on the drain port on

the indoor unit.

- The outside diameter of the drain connection

on the indoor unit is 32 mm.

Piping material: Polyvinyl chloride pipe VP25 and pipe fittings

- Be sure to execute heat insulation on the

drain piping.

- Install the drain raising pipes at a right

angle to the indoor unit and no more than

300 mm from the unit.

Page 14

THE INDOOR UNIT INSTALLATION

700 or less

1 -1.5 m

Clamp metal(attached) Drain hose(attached)

Drain raising pipe

300 mm or less300 mm or less300 mm or less

Remote

controller

cord

1

1

Connection

cord

between the

indoor unit and

the outdoor

unit

Control box cover

(On which the

Electric Wiring

Connection is put)

14

ENGLISH

Heat insulation material: Polyethylene

foam with thickness more than 8 mm.

Drain test

The air conditioner uses a drain pump to drain

water.

Use the following procedure to test the drain

pump operation:

- Connect the main drain pipe to the exterior

and leave it provisionally until the test comes

to an end.

- Feed water to the flexible drain hose and

check the piping for leakage.

- Be sure to check the drain pump for normal

operating and noise when electrical wiring is

complete.

- When the test is complete, connect the

flexible drain hose to the drain port on the

indoor unit.

Feed water

Drain Pump

Drain pan

Flexible drain hose

(accessory)

Drain

port

Drain hose connection

Use the clip (accessory)

Main drain pipe

Glue the joint

HEAT INSULATION

- Use the heat insulation material for the

refrigerant piping which has an excellent

heat-resistance (over 120 °C).

- Precautions in high humidity circumstance:

This air conditioner has been tested

according to the "KS Standard Conditions

with Mist" and confirmed that there is not

any default. However, if it is operated for a

long time in high humid atmosphere (dew

point temperature: more than 23 °C), water

drops are liable to fall. In this case, add heat

insulation material according to the following

procedure:

Indoor

unit

- Heat insulation material to be prepared...

Adiabatic EPDM or NBR with thickness 10 to

20 mm.

- Stick glass wool on all air conditioners that

are located in ceiling atmosphere.

Fastening band

(accessory)

Refrigerant

piping

Thermal insulator

(accessory)

Wiring Connection

- Open the control box cover and connect the

Remote controller cord and Indoor power

wires.

- Remove the control box cover for electrical

connection between the indoor and outdoor

unit. (Remove screws ①)

- Use the cord clamper to fix the cord.

CAUTION

!

The supplied flexible drain hose

should not be curved, neither

screwed. The curved or screwed

hose may cause a leakage of water.

Max 300 mm

Metal

clamp

Insulation

Hanger

distance

Hanger Bracket

1~1.5 m

1/50~1/100 slope

Flexible drain hose

Max 700 mm

Page 15

THE INDOOR UNIT INSTALLATION

NORMAL

CROSS-SECTIONAL

AREA 0.75 mm

2

20 mm

35±5 mm

GN/YL

10±3 mm

Power wire

Round pressure terminal

Connect same thickness

wiring to both sides.

It is forbidden to

connect two to one

side.

It is forbidden to

connect wiring of

different thicknesses.

15

ENGLISH

CAUTION

!

The connecting cable connected to

the indoor and outdoor unit should

Precautions when laying power

wiring

Use round pressure terminals for connections

to the power terminal block.

be complied with the following

specifications (This equipment shall

be provided with a cord set

complying with the national

regulation).

When none are available, follow the

instructions below.

- Do not connect wiring of different

thicknesses to the power terminal block.

(Slack in the power wiring may cause

abnormal heat.)

- When connecting wiring which is the same

thickness, do as shown in the figure below.

If the supply cord is damaged, it

must be replaced by a special cord

or assembly available from the

manufacturer of its service agent.

CAUTION

!

The Power cord connected to the

unit should be selected according

to the following specifications.

- For wiring, use the designated power wire

and connect firmly, then secure to prevent

outside pressure being exerted on the

terminal block.

- Use an appropriate screwdriver for tightening

the terinal screws. A screwdriver with a

small head will strip the head and make

proper tighterning impossible.

- Over-tightening the terminal screws may

break them.

Page 16

16

Pipe

Reamer

Point down

Flare nut

Copper tube

ENGLISH

THE INDOOR UNIT INSTALLATION

Flaring Work

Main cause for gas leakage is due to defect of

flaring work. Carry out correct flaring work in

the following procedure.

Cut the pipes and the cable

1 Use the piping kit accessory or the pipes

purchased locally.

2 Measure the distance between the indoor

and the outdoor unit.

3 Cut the pipes a little longer than measured

distance.

4 Cut the cable 1.5 m longer than the pipe

length.

Copper

pipe

Burrs removal

1. Completely remove all burrs from the cut

cross section of pipe/tube.

2. While removing burrs put the end of the

copper tube/pipe in a downward direction

while removing burrs location is also

changed in order to avoid dropping burrs

into the tubing.

90 °

Slanted Uneven Rough

Putting nut on

- Remove flare nuts attached to indoor and

outdoor unit, then put them on pipe/tube

having completed burr removal.

(not possible to put them on after finishing

flare work)

Flaring work

1

Firmly hold copper pipe in a bar with the

dimension shown in below table table below.

2 Carry out flaring work with the flaring tool.

Pipe diameter

Inch (mm)

Ø 1/4 (Ø 6.35)

Ø 3/8 (Ø 9.52)

Ø 1/2 (Ø 12.7)

Ø 5/8 (Ø 15.88)

Ø 3/4 (Ø 19.05)

Bar

<Wing nut type>

0.04~0.05 (1.1~1.3)

0.06~0.07 (1.5~1.7)

0.06~0.07 (1.6~1.8)

0.06~0.07 (1.6~1.8)

0.07~0.08 (1.9~2.1)

A inch (mm)

Wing nut type Clutch type

0~0.02

(0~0.5)

"A"

Copper pipe

<Clutch type>

CAUTION

!

Copper in contact with refrigerants

shall be oxygen-free or de-oxidized,

for example Cu-DHP as specified in

EN 12735-1 and EN 12735-2.

CAUTION

!

• The installation of pipe-work shall be

kept to a minimum.

• Flared joint shall be restricted to use

with annealed pipe only, and to pipe

sizes not exceeding a diameter of 20

mm outside diameter.

Page 17

THE INDOOR UNIT INSTALLATION

17

ENGLISH

Check

1 Compare the flared work with the figure

by.

2 If a flared section is defective, cut it off

and do flaring work again.

Smooth all round

Even length

all round

Inside is shiny without scratches

= Improper flaring =

Inclined

Surface

Cracked Uneven

damaged

thickness

Connecting the installation pipe

and drain hose to the indoor unit

1 Align the center of the pipes and

sufficiently tighten the flare nut by hand.

Indoor unit tubing Flare nut Pipes

2 Tighten the flare nut with a wrench.

Outside diameter

mm inch kgf.m

Ø 6.35 1/4 1.8~2.5

Ø 9.52 3/8 3.4~4.2

Ø 12.7 1/2 5.5~6.5

Ø 15.88 5/8 6.3~8.2

Ø 19.05 3/4 9.9~12.1

Torque

CAUTION

!

(for R32)

• When mechanical connectors are

reused indoors, sealing parts

shall be renewed.

• When flared joints are reused

indoors, the flare part shall be

re-fabricated.

3 When needed to extend the drain hose of

indoor unit, assembly the drain pipe as

shown on the drawing.

Drain pipe

Indoor unit drain hose

Vinyl tape(narrow)

Adhesive

Wrap the insulation material

around the connecting portion

1 Overlap the connection pipe insulation

material and the indoor unit pipe insulation

material. Bind them together with vinyl

tape so that there may be no gap.

Insulation material

Torque wrench

Indoor unit tubing

Open-end wrench

(fixed)

Flare nut

Connection pipe

Page 18

THE INDOOR UNIT INSTALLATION

Gas Pipe

Liquid Pipe

Cutting Line

Cutting Line

Good Case Bad Case

* Tubing cutting line have to be upward.

Vinyl tape(narrow)

Connection pipe

Connecting cable

Vinyl tape (wide)

Wrap with vinyl tape

Indoor unit pipe

Pipe

18

ENGLISH

2 Set the tubing cutting line upward.

Wrap the area which accommodates the

rear piping housing section with vinyl tape.

3 Bundle the piping and drain hose together

by wrapping them with vinyl tape sufficient

enough to cover where they fit into the

rear piping housing section.

Wrap with vinyl tape

Pipe

Drain hose

Vinyl tape(wide)

Page 19

REMOTE CONTROLLER INSTALLATION

1

2

3

2

3

<Wire guide grooves>

REMOTE CONTROLLER INSTALLATION

Please fix tightly using provided screw after placing remote controller setup

board on the place where you like to setup.

- Please set it up not to bend because poor setup could take place if setup board bends.

Please set up remote controller board fit to the reclamation box if there is a reclamation box.

- Install the product so as not to make a gap with the wall side and to prevent shaking after the

installation.

19

ENGLISH

Can set up Wired remote controller cable into three directions.

- Setup direction: the surface of wall reclamation, upper, right

- If setting up remote controller cable into upper and right side, please set up after removing

remote controller cable guide groove.

* Remove guide groove with long nose.

① Reclamation to the surface of the wall

② Upper part guide groove

③ Right part guide groove

Page 20

REMOTE CONTROLLER INSTALLATION

Wall

Side

Wall

Side

Wall

Side

Wall

Side

<Connecting order>

<Separating order>

Please check if connector is normally connected.

Connecting cable

Indoor

Unit side

20

ENGLISH

Please fix remote controller upper part

into the setup board attached to the

surface of the wall, as the picture below,

and then, connect with setup board by

pressing lower part.

- Please connect not to make a gap at the remote

controller and setup board’s upper and lower, right

and left part.

- Before assembly with the installation board, arrange

the Cable not to interfere with circuit parts.

When separating remote controller from

setup board, as the picture below, after

inserting into the lower separating hole

using screw driver and then, spinning

clockwise, remote controller is separated.

- There are two separating holes. Please individually

separate one at a time.

- Please be careful not to damage the inside

components when separating.

Please connect indoor unit and remote controller using connection cable.

Please use extension cable if the distance between wired remote controller

and indoor unit is more than 10 m.

CAUTION

!

When installing the wired remote controller, do not bury it in the wall. (It can

cause damage in the temperature sensor.) Do not install the cable to be 50 m

or above. (It can cause communication error.)

• When installing the extension cable, check the connecting direction of the

connector of the remote controller side and the product side for correct

installation.

• If you install the extension cable in the opposite direction, the connector will

not be connected.

• Specification of extension cable: 2547 1007 22# 2 core 3 shield 5 or above.

Page 21

REMOTE CONTROLLER INSTALLATION

no

Wired remote controller installation

Since the room temperature sensor is in the remote controller, the remote controller box should

be installed in a place away from direct sunlight, high humidity and direct supply of cold air to

maintain proper space temperature. Install the remote controller about 5 ft(1.5 m) above the floor

in an area with good air circulation at an average temperature.

Do not install the remote controller where it can be affected by:

- Drafts, or dead spots behind doors and in corners.

- Hot or cold air from ducts.

- Radiant heat from sun or appliances.

- Concealed pipes and chimneys.

- Uncontrolled areas such as an outside wall behind the remote controller.

- This remote controller is equipped with a seven segment LED. display. For proper display of the

remote controller LED's, the remote controller should be installed properly as shown in Fig.1.

(The standard height is 1.2~1.5 m from floor level.)

Direct

Sun ray contact area

yes

no

21

ENGLISH

no

5 feet

(1.5 meters)

no

no

Page 22

INSTALLATION OF DECORATIVE PANEL(ACCESSORY)

Separate the link from the front grill

Coner

cover

Hook

clip

Hook

22

ENGLISH

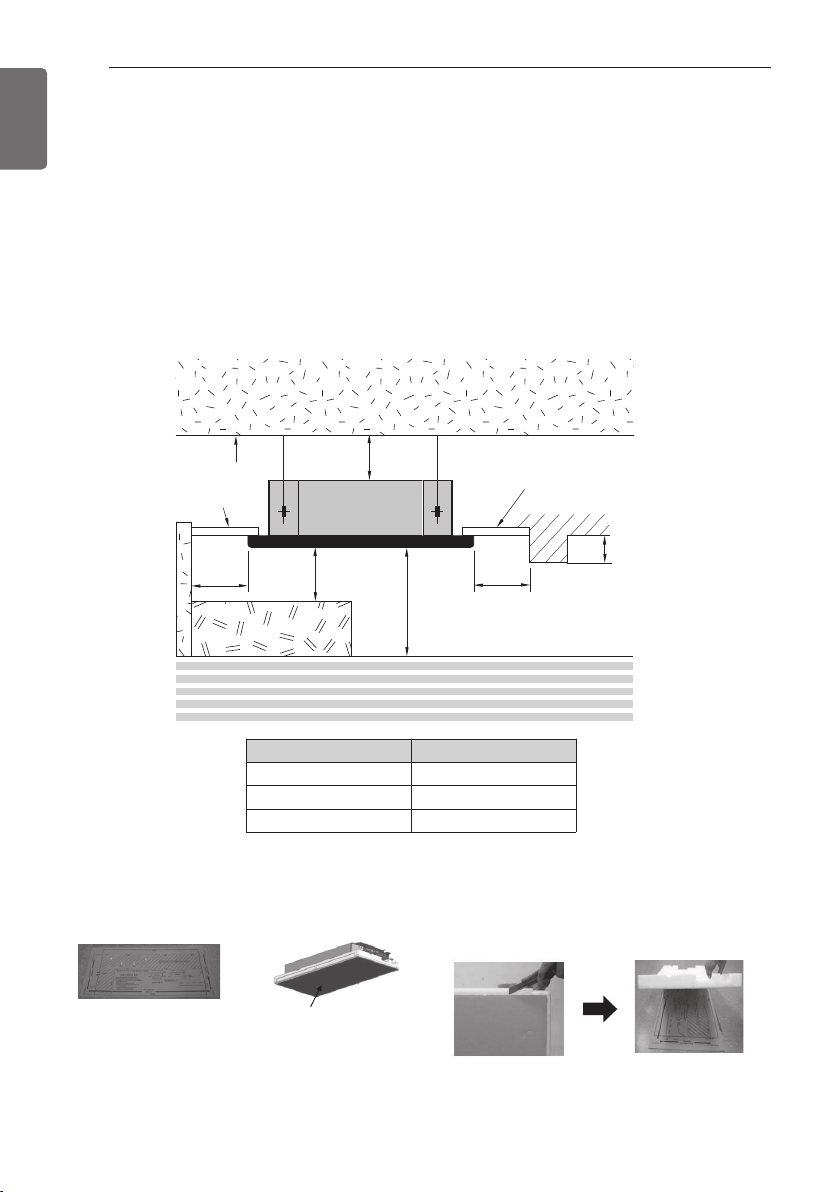

INSTALLATION OF DECORATIVE PANEL(ACCESSORY)

The decorative panel has its installation

direction.

Before installing the decorative panel,

always remove the paper template.

1 Remove the packing and take out air inlet

grille from front panel.

3 Fit the panel on the unit by inserting hooks

as shown in picture.

4 Insert two screws on diagonal corners of

panel. Do not tighten the bolts completely.

(The fixing screws are included in the

indoor unit box.)

Check the alignment of panel with the

ceiling. Height can be adjusted using

hanging bolts as shown in picture. Insert

the other two screws and tighten all

screws completely.

2 Remove the Corner covers of the panel.

Page 23

INSTALLATION OF DECORATIVE PANEL(ACCESSORY)

Screw

Installing the grill link on the panel body

Inserting the edge into the panel body

Closing the door lock

Check the left, right and central sections

CN_VANE 1,2

CN_DISPLAY

23

ENGLISH

5 Fit the corner covers.

6 Open two screws of control panel cover.

7 Connect one display connector and two

vane control connectors of front panel to

indoor unit PCB.

The position marking on PCB is as:

Display connector : CN_DISPLAY

Vane control connector: CN_VANE 1,2

9 Install the air inlet grille and Filter on the

panel.

- After inserting the edge of the grill into

the panel body, close the door lock and

press on the left, right, and center

sections.

8 Close the cover for control box.

Page 24

24

Air conditioner

unit

Decorative panel

Fit the insulator (this part) and

be careful for cool air leakage

Good example

Ceiling

board

Ceiling

board

Decorative

panel

Air

Cool air leakage

(no good)

Bad example

Air conditioner unit

ENGLISH

TEST RUNNING

CAUTION

!

Install certainly the decorative panel.

Cool air leakage causes sweating.

Water drops fall.

TEST RUNNING

PRECAUTIONS IN TEST RUN

- The initial power supply must provide at least

90 % of the rated voltage.

Otherwise, the air conditioner should not be

operated.

CAUTION

!

• For test run, carry out the cooling

operation firstly even during heating

season. If heating operation is

carried out firstly, it leads to the

trouble of compressor. Then

attention must be paid.

• Carry out the test run more than 5

minutes without fail.

(Test run will be cancelled 18

minutes later automatically)

- To cancel the test run, press any button.

CHECK THE FOLLOWING ITEMS WHEN

INSTALLATION IS COMPLETED

- After completing work, be sure to measure and

record trial run properties, and store measured

data, etc.

- Measuring items are room temperature,

outside temperature, suction temperature,

blow out temperature, wind velocity, wind

volume, voltage, current, presence of abnormal

vibration and noise, operating pressure, piping

temperature, compressive pressure.

- As to the structure and appearance, check

following items.

* Is the circulation of air adequate?

* Is the draining smooth?

* Is the heat insulation complete

(refrigerant and drain piping)?

* Is there any leakage of refrigerant?

* Is the remote controller switch operated?

* Is there any faulty wiring?

* Are not terminal screws loosened?

M4......118 N.cm{12 kgf.cm}

M5......196 N.cm{20 kgf.cm}

M6......245 N.cm{25 kgf.cm}

M8......588 N.cm{60 kgf.cm}

Connection of power supply

- Connect the power supply cord to the

independent power supply.

Circuit breaker is required.

- Operate the unit for 15 minutes or more.

Evaluation of the performance

- Measure the temperature of the intake and

discharge air.

- Ensure the difference between the intake

temperature and the discharge one is more

than 8 °C (Cooling) or reversely (Heating).

Thermometer

Page 25

OPTIONAL OPERATION

Installer Setting - Test Run Mode

After installing the product, you must run a Test Run mode.

For details related to this operation, refer to the product manual.

If pressing button long for 3 seconds, it

1

enters into remote controller setter setup

mode.

- If pressing once shortly, it enters into user

setup mode. Please press more than 3

seconds for sure.

- Please cancel the right and left of wind

direction for RAC product.

Function Code Set

Setup figure '01' blinks at the lower part of

2

indication window.

OPTIONAL OPERATION

25

ENGLISH

Press button to start.

3

During the test run, pressing the below

4

button will exit the test run.

- Select operation, temperature up/down,

wind flow control, wind direction,

start/stop button.

Page 26

OPTIONAL OPERATION

26

ENGLISH

Installer Setting - Setting Address of Central Control

It's the function to use for connecting central control.

Please refer to central controller manual for the details

If pressing button long for 3

1

seconds, it enters into remote controller

setter setup mode.

- If pressing once shortly, it enters into

user setup mode. Please press more

than 3 seconds for sure.

If entering into address setup mode by using

2

button, it indicates as picture below.

Set Group No. by pressing

3

button.(0~F)

Indoor No.

Group No

Function Code

Move to Indoor No. setting option

4

by pressing button.

Set Indoor No. by pressing

5

button.

Press button to save.

6

Pressing button will exit settings mode.

7

❈ After setup, it automatically gets out of setup

mode if there is no button input for 25

seconds.

❈ When exiting without pressing set button, the

manipulated value is not reflected.

Page 27

Installer Setting - Thermistor

OPTIONAL OPERATION

If pressing button long for 3

1

seconds, it enters into remote controller

setter setup mode.

- If pressing once shortly, it enters into

user setup mode. Please press more

than 3 seconds for sure.

If moving to room temperature perception sensor

2

selection menu by pressing button, it

indicates as picture below.

Set Thermistor value by pressing

3

button. (01: Remote Controller,

02: Indoor, 03: 2TH)

27

ENGLISH

Function Code Thermistor setting

Press button to save.

4

Pressing button will exit settings mode.

❈ After setup, it automatically gets out of setup

5

mode if there is no button input for 25

seconds.

❈ When exiting without pressing set button, the

manipulated value is not reflected.

<Thermistor Table>

Temperature sensor selection Function

01 Remote controller Operation in remote controller temperature sensor

02 Indoor unit Operation in indoor unit temperature sensor

03 2 TH

Cooling

Heating

* The function of 2 TH has different operation characteristics according to the product.

Operation of higher temperature by comparing indoor unit's and wired

remote controller’s temperature.

(There are products that operate at a lower temperature.)

Operation of lower temperature by comparing indoor unit's and wired

remote controller's temperature.

Page 28

OPTIONAL OPERATION

28

ENGLISH

Installer Setting - Ceiling Height Selection

This function is to adjust FAN Airflow rate according to ceilingheight (only cassette model)

If pressing button long for 3

1

seconds, it enters into remote controller

setter setup mode.

- If pressing once shortly, it enters into

user setup mode. Please press more

than 3 seconds for sure.

If moving to ceiling height selection menu by

2

pressing button, it indicates as picture below.

Select ceiling height value by pressing

3

button. (01:Low, 02:Standard,

03:High, 04:Very high)

Function Code Thermistor setting

Press button to save.

4

Pressing button will exit settings mode.

❈ After setup, it automatically gets out of setup

5

mode if there is no button input for 25

seconds.

❈ When exiting without pressing set button, the

manipulated value is not reflected.

<Ceiling Height Selection Table>

Ceiling Height Level Description

01 Low Decrease the indoor airflow rate 1 step from standard level

02 Standard Set the indoor airflow rate as standard level

03 High Increase indoor airflow rate 1 step from standard level

04 Super high Increase indoor airflow rate 2 steps from standard level

* Ceiling height setting is available only for some products.

* Ceiling height of ‘Super high’ function may not exist depending on the indoor unit.

* Refer to the product manual for more details.

Page 29

OPTIONAL OPERATION

Installer Setting - Group Setting

It is a function for settings in group control, or 2-remote controller control.

If pressing button long for 3 seconds, it

1

enters into remote controller setter setup

mode.

- If pressing once shortly, it enters into

user setup mode. Please press more than

3 seconds for sure.

If pressing button repeatedly, it moves to

2

master/slave selection menu as picture below.

Select Master/ Slave by pressing

3

button.

(00: Slave, 01: Master)

Function Code Master/Slave value

29

ENGLISH

Press button to save.

4

Pressing button will exit settings mode.

5

❈ After setup, it automatically gets out of setup mode

if there is no button input for 25 seconds.

❈ When exiting without pressing set button, the

manipulated value is not reflected.

Remote controller Function

Master

Slave

* Refer to the 'group control' part for details.

- When controlling in groups, basic operation settings, airflow strength weak/medium/strong,

lock setting of the remote controller, time settings, and other functions may be restricted.

Indoor unit operates based on master remote controller at group control.

(Master is set when delivering from the warehouse.)

Setup all remote controllers except one master remote controller to slave

at group control

Page 30

OPTIONAL OPERATION

30

ENGLISH

Installer Setting - Dry Contact Mode Setting

Dry contact function is the function that is possible to use only when dry contact equipment is

separately purchased/setup.

If pressing button long for 3

1

seconds, it enters into remote controller

setter setup mode.

- If pressing once shortly, it enters into

user setup mode. Please press more

than 3 seconds for sure.

If pressing button repeatedly, it moves to

2

remote controller dry contact mode setup menu

as picture below.

Select Dry contact setting by

3

pressing button.

(00 : Automatic, 01 : manual)

Function Code Dry Contact

Press button to save.

setting value

4

Pressing button will exit settings mode.

5

❈ After setup, it automatically gets out of setup

mode if there is no button input for 25

seconds.

❈ When exiting without pressing set button, the

manipulated value is not reflected.

What is Dry Contact?

Like hotel card key and body perception sensor, it is the signal of the point of contact when using

air-conditioner by interlocking.

- Please refer to dry contact manual for more details.

Page 31

OPTIONAL OPERATION

Function Code conversion mode value

If pressing button long for 3

seconds, it enters into remote

controller setter setup mode.

- If pressing once shortly, it enters

into user setup mode.

Please press more than 3 seconds for

sure.

1

Press button to exit or system

will automatically exit after 25

seconds without any input.

5

Repeat pressing button to select

Function code 12.

Ex) Fahrengeit Setting

2

Select Temperature unit mode by pressing

button.

(00: Celsius, 01: Fahrenheit)

3

Press button to save or release.

4

Installer Setting-Celsius / Fahrenheit Switching

This function is used for switching the display between Celsius and Fahrenheit.

(Optimized only for U.S.A)

31

ENGLISH

h Whenever press button in Fahrenheit mode, the temperature will increase/drop 2

degrees.

Page 32

OPTIONAL OPERATION

32

ENGLISH

Installer Setting - Optional Function Setting

Setting feature for indoor unit when air cleaning / heater / humidifier / Up/down grill / Ventilation

KIT / Auxiliary Heater is newly installed, or installed unit is removed.

If pressing button long for 3

1

seconds, it enters into remote controller

setter setup mode.

- If pressing once shortly, it enters into

user setup mode. Please press more

than 3 seconds for sure.

If pressing button repeatedly, it moves to the

2

selected option function code as picture below.

Function

Plasma purification

Electric heater

Dehumidifier

Elevation grill

Ventilation kit

Auxiliary heater

Select existing condition of

3

each mode by pressing

button.

(00: not installed,

01 : installed)

Function Code Existing condition

Press button to save.

4

Pressing button will exit settings mode.

5

❈ After setup, it automatically gets out of setup

mode if there is no button input for 25

seconds.

❈ When exiting without pressing set button, the

manipulated value is not reflected.

Code

20

21

22

23

24

25

Page 33

OPTIONAL OPERATION

Installer Setting - Remote controller Mode Lock

This function is used to limit ‘operation-mode’ selection setting.

Press and hold button for

1

more than 3 seconds to enter the

installer settings mode.

Move to the installer code number 42 in the

2

menu using button.

Select the remote control master/slave

3

using button.

33

ENGLISH

Code value for mode

code Description

42:00

42:01

42:02

Press button to save the setting.

lock setting

Doesn’t limit operation mode setting.

User can setting to cooling mode only.

User can setting to heating mode only.

Set value

4

Press button to exit.

5

h It can limit only wired remote controller button. other controllers can change operation mode.

(for example wireless remote controller and central controller)

Page 34

HOW TO SET E.S.P?

34

ENGLISH

HOW TO SET E.S.P?

This is the function that decides the strength of the wind for each wind level and because this

function is to make the installation easier.

- If you set ESP incorrectly, the air conditioner may malfunction.

- This setting must be carried out by a certificated-technician.

If pressing button long for 3

1

seconds, it enters into remote controller

setter setup mode.

- If pressing once shortly, it enters into

user setup mode. Please press more

than 3 seconds for sure.

If entering into ESP setup mode by using

2

button, it indicates as the picture below.

Function Code ESP value

ESP step

Function code,

ESP code

ESP value

- When setting ESP value on the product without very weak wind or power wind function, it may

not work.

Select ESP fan step by pressing

3

button. (01: very low, 02: low, 03:

medium, 04: high, 05: power)

Move to ESP value setting by pressing

4

button.

(It is 000 when delivering

from the warehouse.)

Press button to setup ESP value.

5

(It is possible to setup ESP

value from 1 to 255, and 1 is the

smallest and 255 is the biggest.)

Page 35

HOW TO SET E.S.P?

Function code,

ESP code

ESP value

Press button to save.

7

Select ESP fan step again by using

button and setup ESP value, as No. 4 and 5,

that corresponds each wind flow

6

Press button to exit.

❈ After setup, it automatically gets out of

setup mode if there is no button input for

25 seconds.

❈ When exiting without pressing set button,

the manipulated value is not reflected.

8

- Please be careful not to change the ESP value for each fan step.

- It does not work to setup ESP value for very low/power step for some products.

- ESP value is available for specific range belongs to the product.

35

ENGLISH

Page 36

36

ENGLISH

Page 37

A

C

[

[

P

I

s

P

C

O

Loading...

Loading...