Page 1

SERVICE MANUAL

SERVICE MANUAL

CAUTION

BEFORE SERVICING THE UNIT, READ THE “SAFETY PRECAUTIONS”

IN THIS MANUAL.

Internal Use Only

MODEL: CM9760 (CM9650, CMS9760F)

MODEL: CM9760

(CM9760, CMS9760F)

MINI HI-FI SYSTEM

P/NO : AFN77552431

JULY, 2016

Page 2

CONTENTS

SECTION 1 ........GENERAL

SECTION 2 ........CABINET & MAIN CHASSIS

SECTION 3 ........ELECTRICAL

SECTION 4 ........MECHANISM (DM14AA)

SECTION 5 ........REPLACEMENT PARTS LIST

1-1

Page 3

SECTION 1

SUMMARY

CONTENTS

SERVICING PRECAUTIONS ............................................................................................................................ 1-3

ESD PRECAUTIONS .........................................................................................................................................1-5

HIDDEN KEY MODE .........................................................................................................................................1-6

SERVICE INFORMATION FOR EEPROM ........................................................................................................ 1-7

PROGRAM DOWNLOAD GUIDE ...................................................................................................................... 1-8

FOTA UPDATE ................................................................................................................................................1-11

SPECIFICATIONS ...........................................................................................................................................1-13

1-2

Page 4

SERVICING PRECAUTIONS

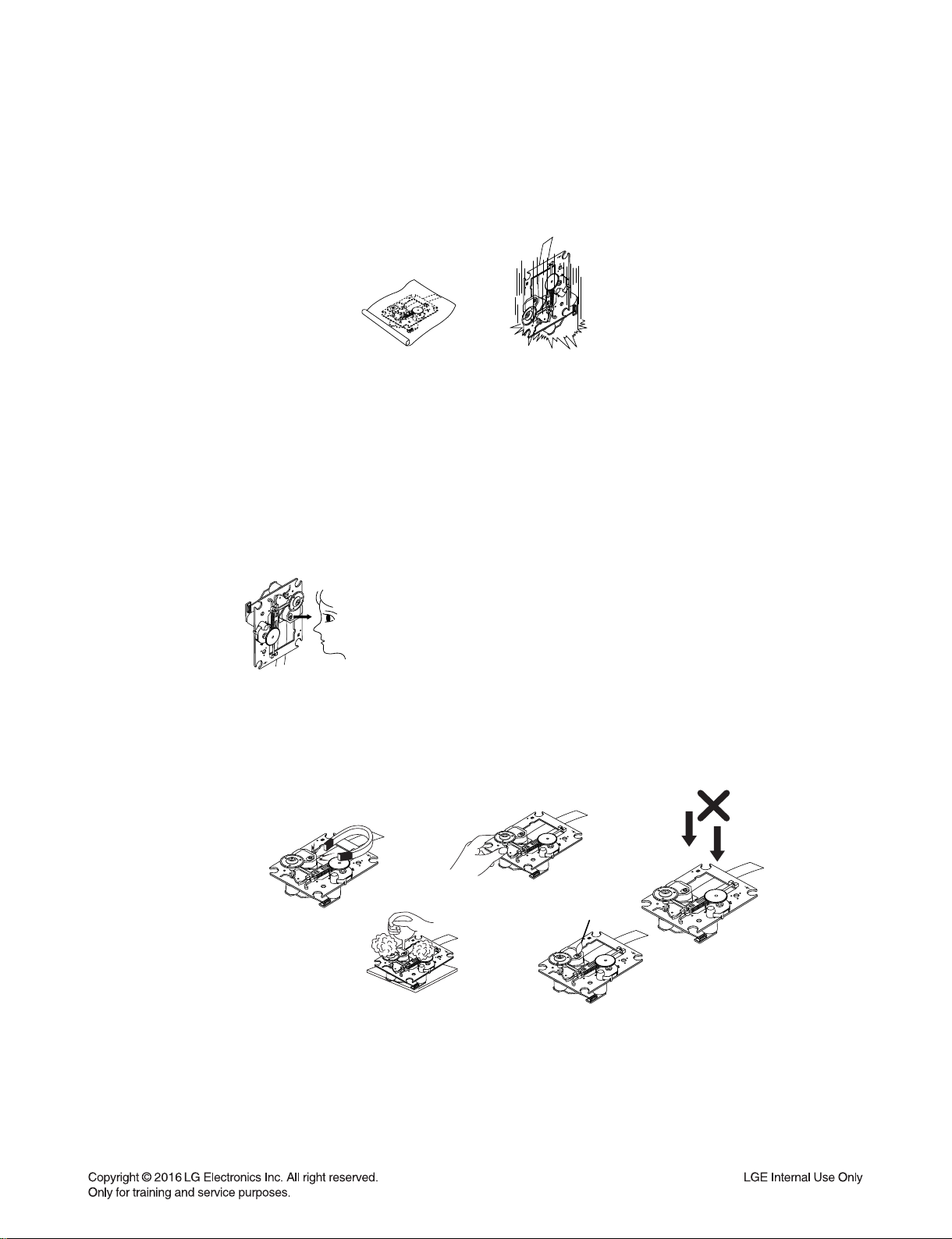

NOTES REGARDING HANDLING OF THE PICK-UP

1. Notes for transport and storage

1) The pick-up should always be left in its conductive bag until immediately prior to use.

2) The pick-up should never be subjected to external pressure or impact.

Storage in conductive bag

Drop impact

2. Repair notes

1) The pick-up incorporates a strong magnet, and so should never be brought close to magnetic materials.

2) The pick-up should always be handled correctly and carefully, taking care to avoid external pressure and

impact. If it is subjected to strong pressure or impact, the result may be an operational malfunction and/or

damage to the printed-circuit board.

3) Each and every pick-up is already individually adjusted to a high degree of precision, and for that reason

the adjustment point and installation screws should absolutely never be touched.

4) Laser beams may damage the eyes!

Absolutely never permit laser beams to enter the eyes!

Also NEVER switch ON the power to the laser output part (lens, etc.) of the pick-up if it is damaged.

NEVER look directly at the laser beam, and don’t allow

contact with fingers or other exposed skin.

5) Cleaning the lens surface

If there is dust on the lens surface, the dust should be cleaned away by using an air bush (such as used

for camera lens). The lens is held by a delicate spring. When cleaning the lens surface, therefore, a cotton swab should be used, taking care not to distort lens.

Pressure

Magnet

How to hold the pick-up

Cotton swab

Conductive Sheet

6) Never attempt to disassemble the pick-up.

Spring has excess pressure. If the lens is extremely dirty, apply isopropyl alcohol to the cotton swab.

(Do not use any other liquid cleaners, because they will damage the lens.) Take care not to use too much

of this alcohol on the swab, and do not allow the alcohol to get inside the pick-up.

1-3

Pressure

Page 5

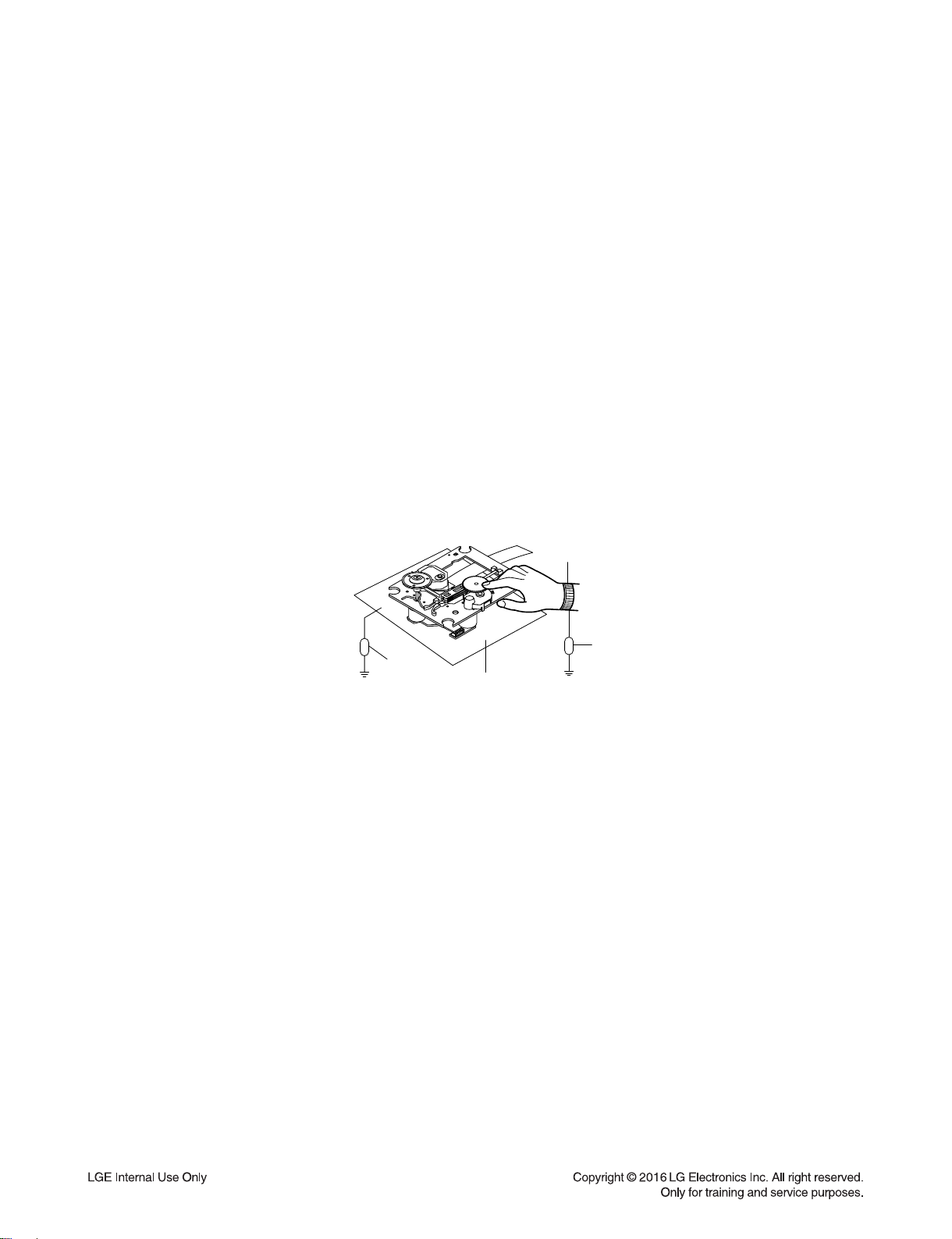

NOTES REGARDING COMPACT DISC PLAYER REPAIRS

1. Preparations

1) Compact disc players incorporate a great many ICs as well as the pick-up (laser diode). These components

are sensitive to, and easily affected by, static electricity. If such static electricity is high voltage, components

can be damaged, and for that reason components should be handled with care.

2) The pick-up is composed of many optical components and other high-precision components. Care must be

taken, therefore, to avoid repair or storage where the temperature or humidity is high, where strong magnetism is present, or where there is excessive dust.

2. Notes for repair

1) Before replacing a component part, first disconnect the power supply lead wire from the unit

2) All equipment, measuring instruments and tools must be grounded.

3) The workbench should be covered with a conductive sheet and grounded.

When removing the laser pick-up from its conductive bag, do not place the pick-up on the bag. (This is

because there is the possibility of damage by static electricity.)

4) To prevent AC leakage, the metal part of the soldering iron should be grounded.

5) Workers should be grounded by an armband (1 M)

6) Care should be taken not to permit the laser pick-up to come in contact with clothing, in order to prevent

static electricity changes in the clothing to escape from the armband.

7) The laser beam from the pick-up should NEVER be directly facing the eyes or bare skin.

Armband

Resistor

(1 M)

Resistor

(1 M)

Conductive

Sheet

1-4

Page 6

ESD PRECAUTIONS

Electrostatically Sensitive Devices (ESD)

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such components

commonly are called Electrostatically Sensitive Devices (ESD). Examples of typical ESD devices are integrated

circuits and some field-effect transistors and semiconductor chip components. The following techniques should

be used to help reduce the incidence of component damage caused by static electricity.

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off

any electrostatic charge on your body by touching a known earth ground. Alternatively, obtain and wear a

commercially available discharging wrist strap device, which should be removed for potential shock reasons

prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ESD devices, place the assembly on a conductive surface

such as aluminum foil, to prevent electrostatic charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ESD devices.

4. Use only an anti-static solder removal device. Some solder removal devices not classified as "anti-static" can

generate electrical charges sufficient to damage ESD devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ESD

devices.

6. Do not remove a replacement ESD device from its protective package until immediately before you are

ready to install it. (Most replacement ESD devices are packaged with leads electrically shorted together by

conductive foam, aluminum foil or comparable conductive materials).

7. Immediately before removing the protective material from the leads of a replacement ESD device, touch the

protective material to the chassis or circuit assembly into which the device will by installed.

CAUTION : BE SURE NO POWER IS APPLIED TO THE CHASSIS OR CIRCUIT, AND OBSERVE ALL OTHER

SAFETY PRECAUTIONS.

8. Minimize bodily motions when handing unpackaged replacement ESD devices. (Otherwise harmless motion

such as the brushing together of your clothes fabric or the lifting of your foot from a carpeted floor can generate

static electricity sufficient to damage an ESD device).

CAUTION. GRAPHIC SYMBOLS

THE LIGHTNING FLASH WITH APROWHEAD SYMBOL. WITHIN AN EQUILATERAL TRIANGLE, IS

INTENDED TO ALERT THE SERVICE PERSONNEL TO THE PRESENCE OF UNINSULATED

“DANGEROUS VOLTAGE” THAT MAY BE OF SUFFICIENT MAGNITUDE TO CONSTITUTE A RISK OF

ELECTRIC SHOCK.

THE EXCLAMATION POINT WITHIN AN EQUILATERAL TRIANGLE IS INTENDED TO ALERT THE

SERVICE PERSONNEL TO THE PRESENCE OF IMPORTANT SAFETY INFORMATION IN SERVICE

LITERATURE.

1-5

Page 7

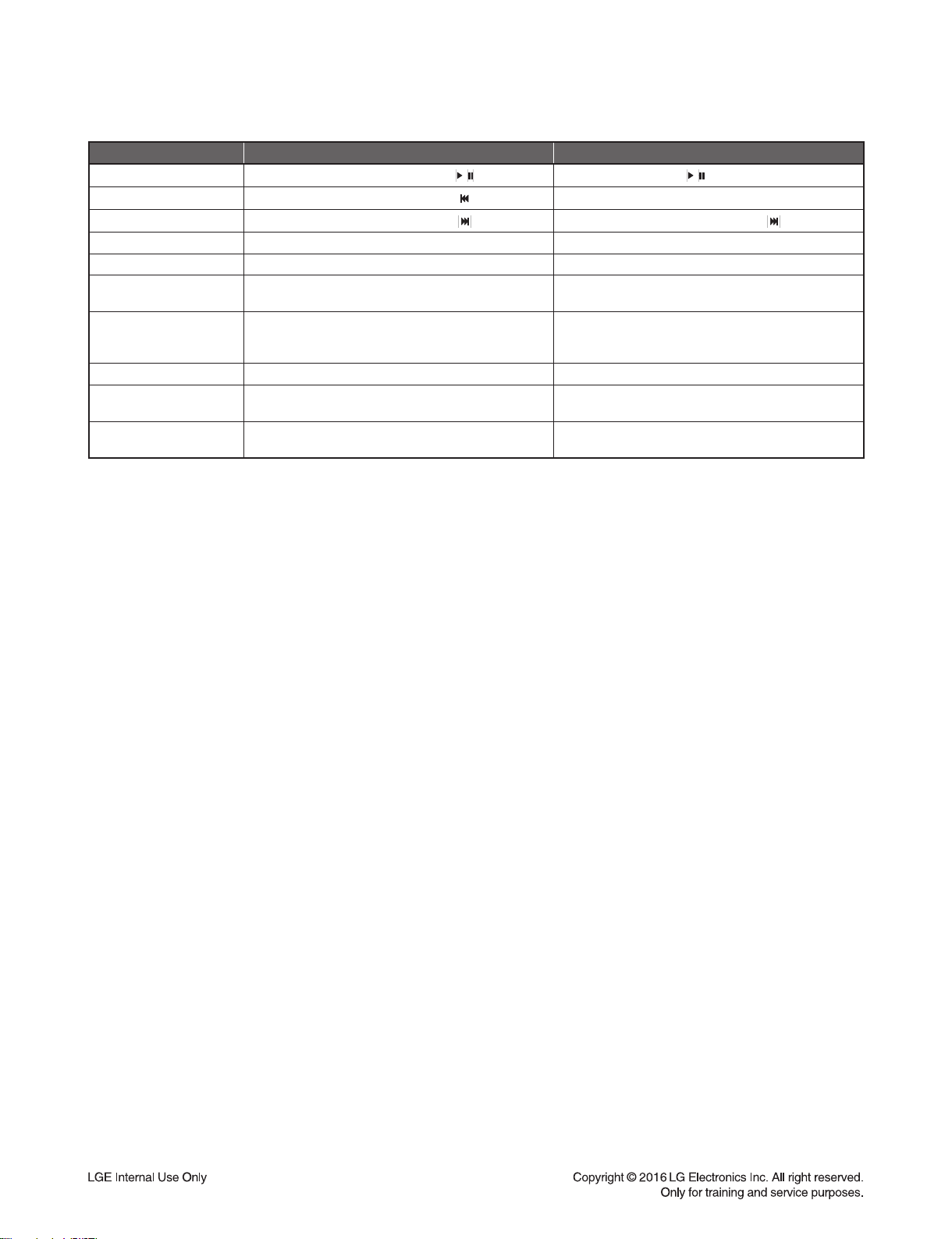

HIDDEN KEY MODE

HIDDEN MODE ENTRANCE KEY EXIT KEY

Version Check

EEPROM Initial

Option EDIT

APD Test Display Front ‘Stop’ + Remote Control Key ‘3’ for 5 s Auto Exit

Clip Front ‘Stop’ + Remote Control Key ‘Mute’ for 5 s Auto Exit

Disc Lock

On/ Off

Power Disc Lock

On/ Off

Demo All Key Lock Front ‘Stop’ + Remote Control Key ‘9’ for 5 s Front ‘Stop’ + Remote Control Key ‘9’ for 5 s

Bluetooth Auto Power

On/ Off

Child Safe

On/ Off

Front ‘Stop’ + Remote Control Key ‘

Front ‘Stop’ + Remote Control Key ‘

Front ‘Stop’ + Remote Control Key ‘

Front ‘Stop’ + Remote Control Key ‘Stop’ for 5 s Front ‘Stop’ + Remote Control Key ‘Stop’ for 5 s

Front ‘Stop’ + Remote Control Key ‘Region EQ’ for 5 s

or

Front ‘Stop’ + Front ‘Open’ for 5 s

Front/ Remote Control Key ‘Power’ for 5 s

Volume 0 (Min) + Front ‘Enter’ for 3 s Volume 0 (Min) + Front ‘Enter’ for 3 s

/ /

for 5 s Remote Control Key ‘ ’ for 1.5 s

’ for 5 s

Auto Exit

’ for 5 s Front ‘Stop’ + Remote Control Key ‘ ’

Front ‘Stop’ + Remote Control Key ‘Region EQ’ for 5 s

Front ‘Stop’ + Front ‘Open’ for 5 s

Front/ Remote Control Key ‘Power’ to SET ‘Power Off’

or

1-6

Page 8

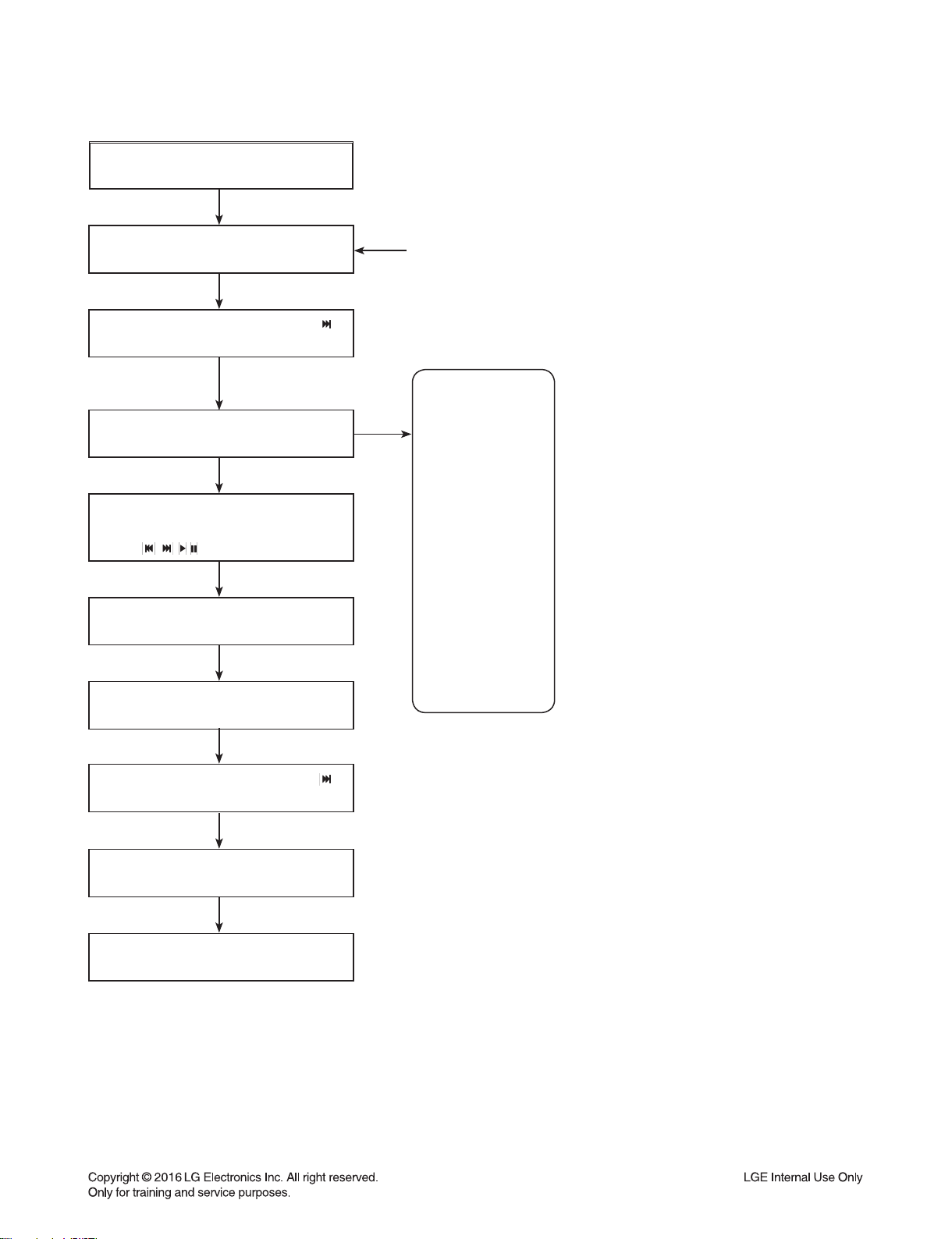

SERVICE INFORMATION FOR EEPROM

POWER ON

VFD “NO DISC” status

It is possible at any function.

(ex. It is possible at VFD “NO USB” status, too.)

This is an example.

Front ‘Stop’ + Remote control ‘ ’

push same timing during 5 s

FLD “OP00-…..”

Move to appropriate position

And make changes with remote control

“ , , , REPEAT” key.

/

Press ‘Stop’ Key

VFD “WRITE OK”

DETECT NEW EEPROM

(OPTION EDIT SCREEN)

NAME

OPT0

OPT1

OPT2

OPT3

OPT4

OPT5

OPT6

OPT7

OPT8

OPT9

OPT10

OPT11

OPT12

OPT13

OPT14

HEX

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

Front ‘Stop’ + Remote control ‘ ’

push same timing during 5 s

VFD “E2P CLR”

Completed

1-7

Page 9

PROGRAM DOWNLOAD GUIDE

1. AUDIO PROGRAM

Download program file name must be MICOM_CM9760_YYMMDDX.HEX

If security program(Water Wall) is activated on PC, you must save the file to the USB storage device

and disable the security software, then download the file to your set.

Downloading file proceeds in the same way at USB1 function and USB2 function.

Caution:

When downloading the file, you should neither unplug the USB device, change to the other function,

nor power off the device. USB device must be unplugged when the downloading process is completed.

ON VFD DISPLAY SCREEN

NO USB

Insert USB device at USB function.

SEARCH

MICOM UP

FINISH

AUTO POWER OFF

1) (Fast) Format USB device.

2) Copy Firmware file to USB device.

1-8

Page 10

2. CD PROGRAM

Download program file name must be HG690_CM9760_YYMMDDX.bin

If security program(Water Wall) is activated on PC, you must save the file to the USB storage device

and disable the security software, then download the file to your set.

Downloading file proceeds in the same way at USB1 function and USB2 function.

Caution:

When downloading the file, you should neither unplug the USB device, change to the other function,

nor power off the device. USB device must be unplugged when the downloading process is completed.

ON VFD DISPLAY SCREEN

NO USB

Insert USB device at USB function.

SEARCH

FIRMWARE

FINISH

AUTO POWER OFF

1) (Fast) Format USB device.

2) Copy Firmware file to USB device.

1-9

Page 11

3. EQ PROGRAM

Download program file name must be EQ_PRG.BIN

If security program(Water Wall) is activated on PC, you must save the file to the USB storage device

and disable the security software, then download the file to your set.

Downloading file proceeds in the same way at USB1 function and USB2 function.

Caution:

When downloading the file, you should neither unplug the USB device, change to the other function,

nor power off the device. USB device must be unplugged when the downloading process is completed.

ON VFD DISPLAY SCREEN

NO USB

Insert USB device at USB function.

SEARCH

EQ UP

FINISH

AUTO POWER OFF

1) (Fast) Format USB device.

2) Copy Firmware file to USB device.

1-10

Page 12

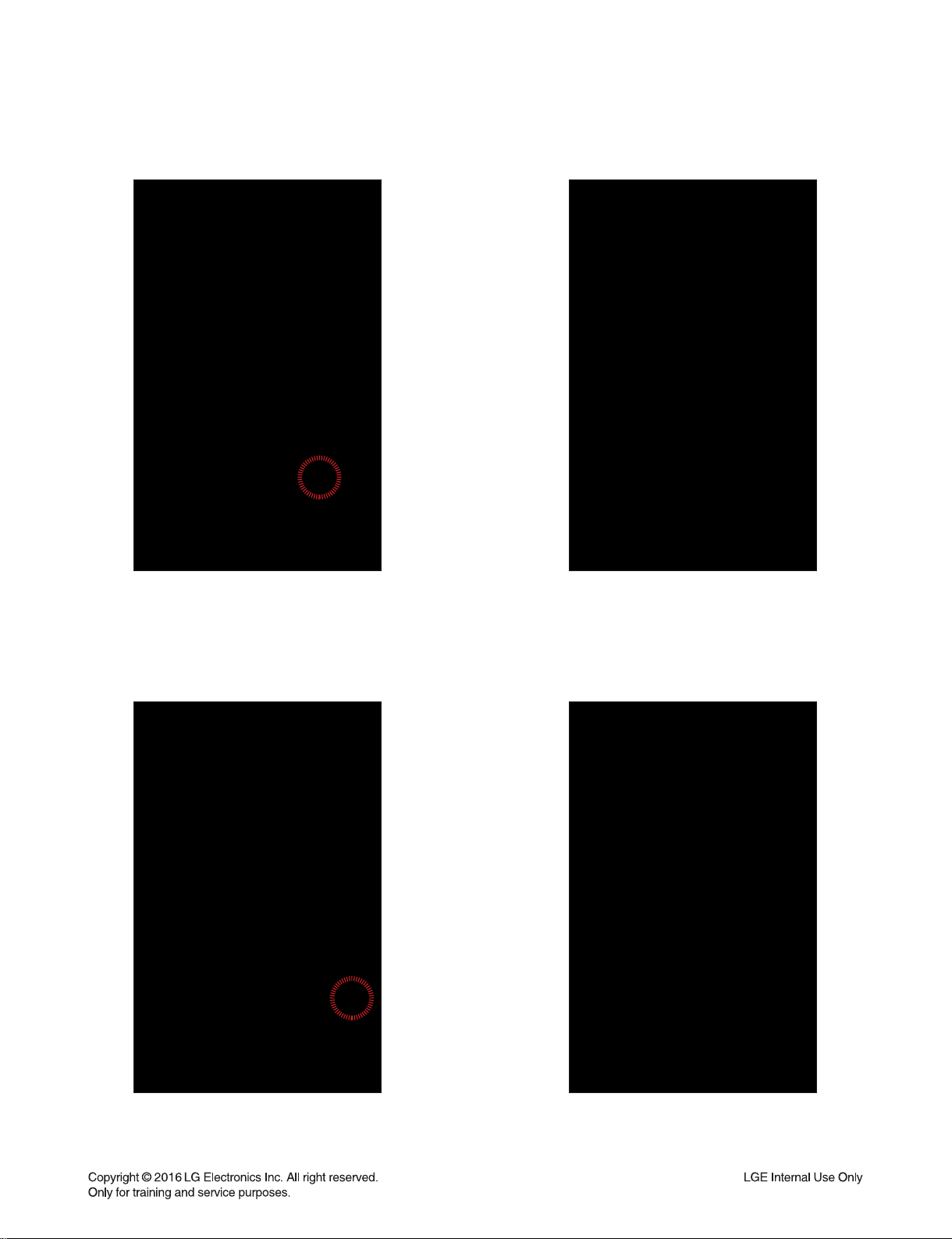

FOTA UPDATE

Step1. App Connecting

After connecting the bluetooth APP with SET,

the user could fi nd the “Device Version info”

on Setting tab.

Step2. Device version info

When touch the “Device Version info” button,

user could fi nd the current and latest SET

version on pop-up menu.

Step3. Select update button

When touch the UPDATE button, user could

update the SET fi rmware using FOTA.

Step4. Download from CDN server

Step1 is download from CDN server to smart

phone. The progress bar is displayed on

bluetooth APP.

1-11

Page 13

Step5. Transfer FW

Step6. FW fl ash writing

After completed the download from server,

smart phone start to transfer the fi rmware to

the SET. The progress bar is displayed on

bluetooth APP.

Step7. FOTA complete

After completed the download from the smart

phone, the SET overwrite the fi rmware to

fl ash memory.

When fi nishing the fl ash memory writing,

pop-up message about fi nish is displayed

and the SET auto power off.

1-12

Page 14

SPECIFICATIONS

• GENERAL

Power requirements Refer to the main label on the unit.

Power consumption Refer to the main label on the unit.

Networked standby : 0.5 W (If all network ports are activated.)

Dimensions (W x H x D) Approx. 450 mm x 160 mm x 355 mm

Net Weight Approx. 6,2 kg

Operating temperature 5 °C to 35 °C (41 °F to 95 °F)

Operating humidity 60 %

• INPUTS

Analog audio in (AUX IN) 2.0 Vrms (1 kHz, 0 dB), 600 Ω, RCA jack (L, R)

Portable in (PORT. IN) 1.2 Vrms (3.5 mm stereo jack) x 1

Microphone (MIC 1/2) Sensitivity 20 mV (1 kHz), 6.3 mm jack x 2

• TUNER

FM Tuning Range 87.5 to 108.0 MHz or 87.50 to 108.00 MHz

• SYSTEM

Frequency Response 40 to 20,000 Hz

Signal-to-noise ratio More than 75 dB

Dynamic range More than 80 dB

Bus Power Supply (USB) 5 V 500 mA

• AMPLIFIER (RMS OUTPUT POWER)

Total output 3,300 W

HIGH 560 W X 2 (6 Ω at 5 kHz, 25 % THD)

MID 560 W X 2 (6 Ω at 1 kHz, 25 % THD)

LOW 530 W X 2 (6 Ω at 70 Hz, 25 % THD)

• FRONT SPEAKER

Type HIGH : 2 Way 2 Speaker

MID : 1 Way 1 Speaker

LOW : 1 Way 1 Speaker

Impedance HIGH : 6 Ω

MID : 6 Ω

LOW : 6 Ω

Rated Input Power HIGH : 560 W

MID : 560 W

LOW : 530 W

Max. Input power HIGH : 1,120 W

MID : 1,120 W

LOW : 1,060 W

Net Dimensions (W x H x D) Approx. 454 mm x 652 mm x 400 mm

Net Weight Approx. 22 kg

• Design and specifications are subject to change without notice.

1-13

Page 15

1-14

Page 16

SECTION 2

CABINET & MAIN CHASSIS

CONTENTS

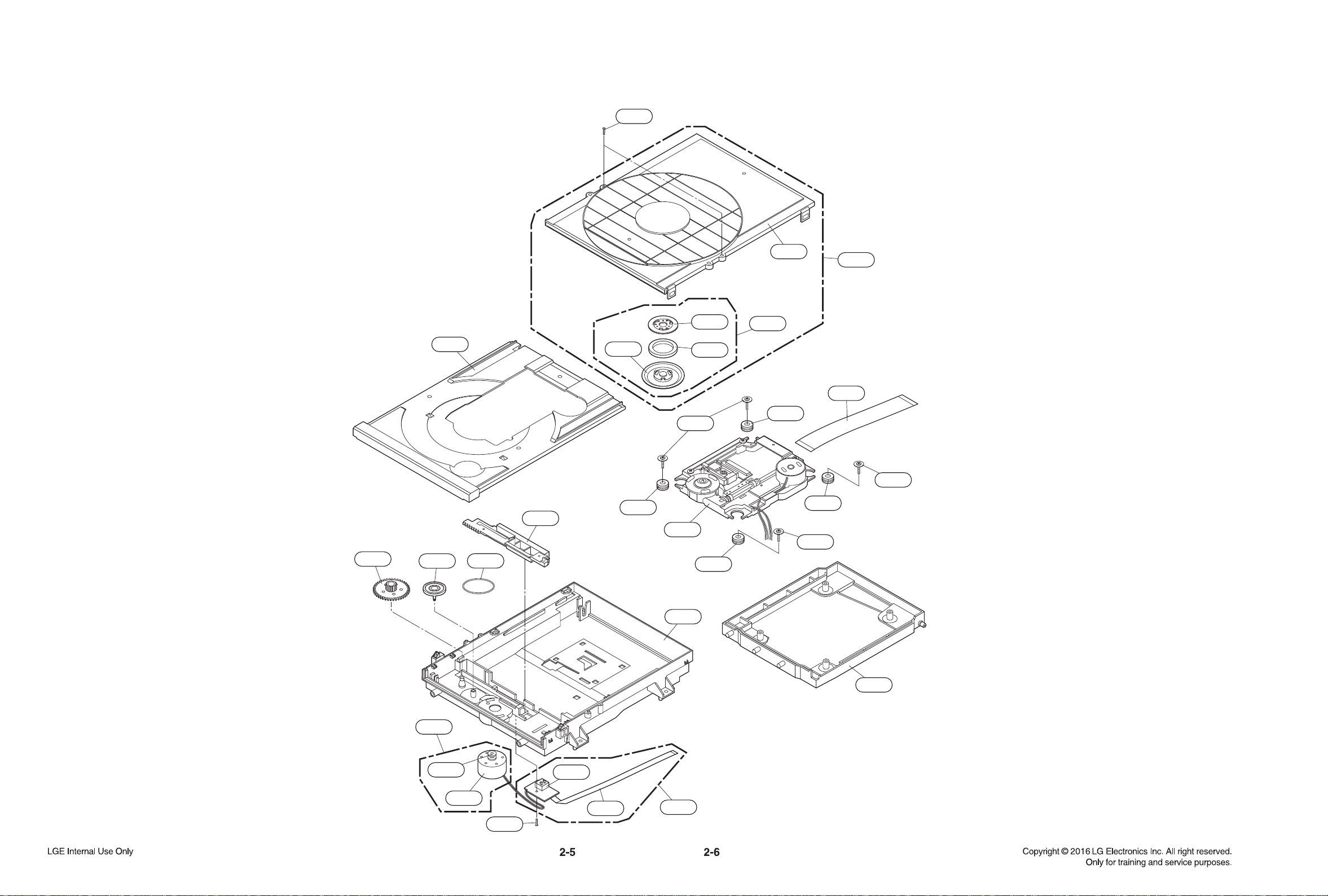

EXPLODED VIEWS .........................................................................................................................................2-3

1. CABINET AND MAIN FRAME SECTION ................................................................................................. 2-3

2. MECHANISM DECK SECTION ................................................................................................................ 2-5

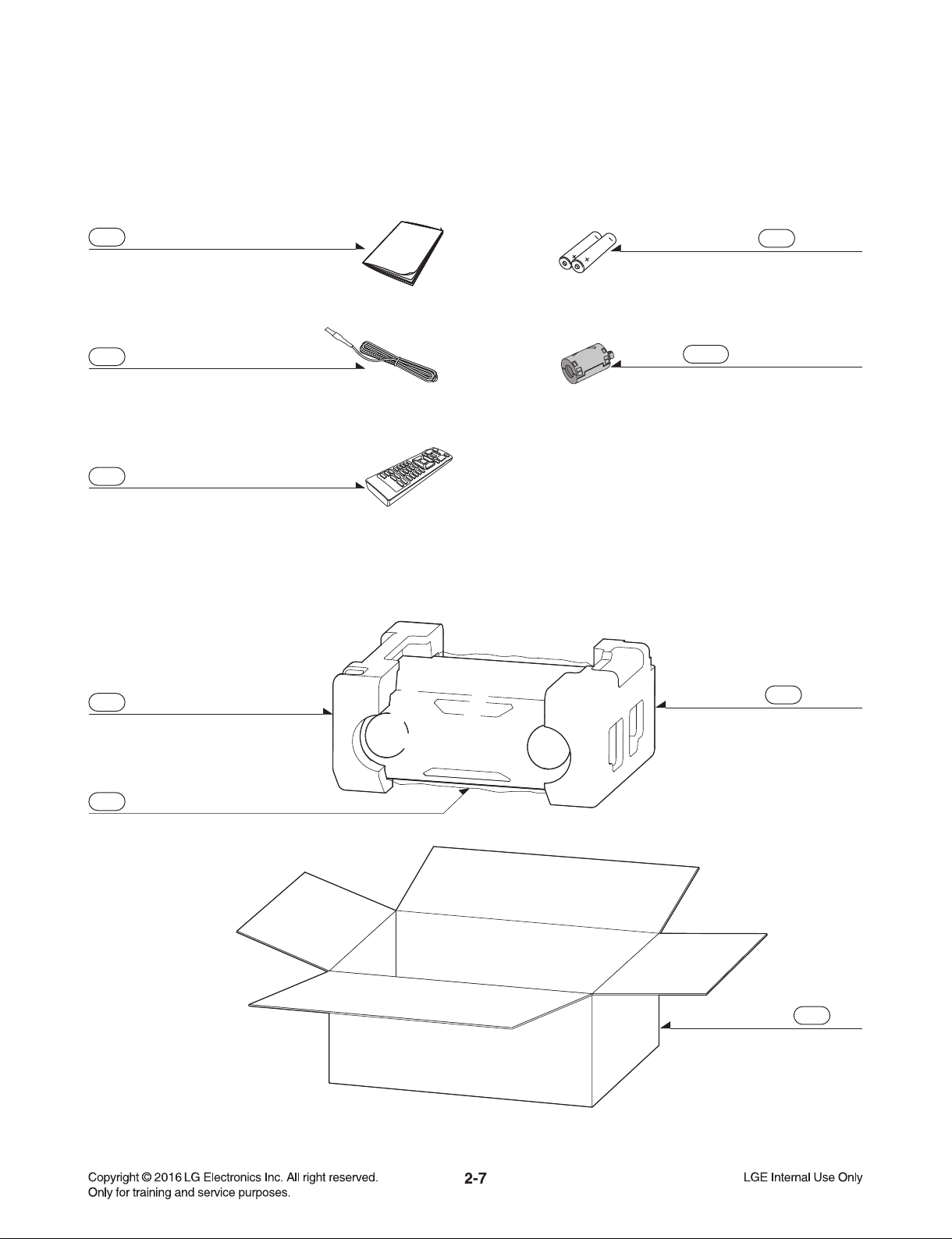

3. PACKING ACCESSORY SECTION .........................................................................................................2-7

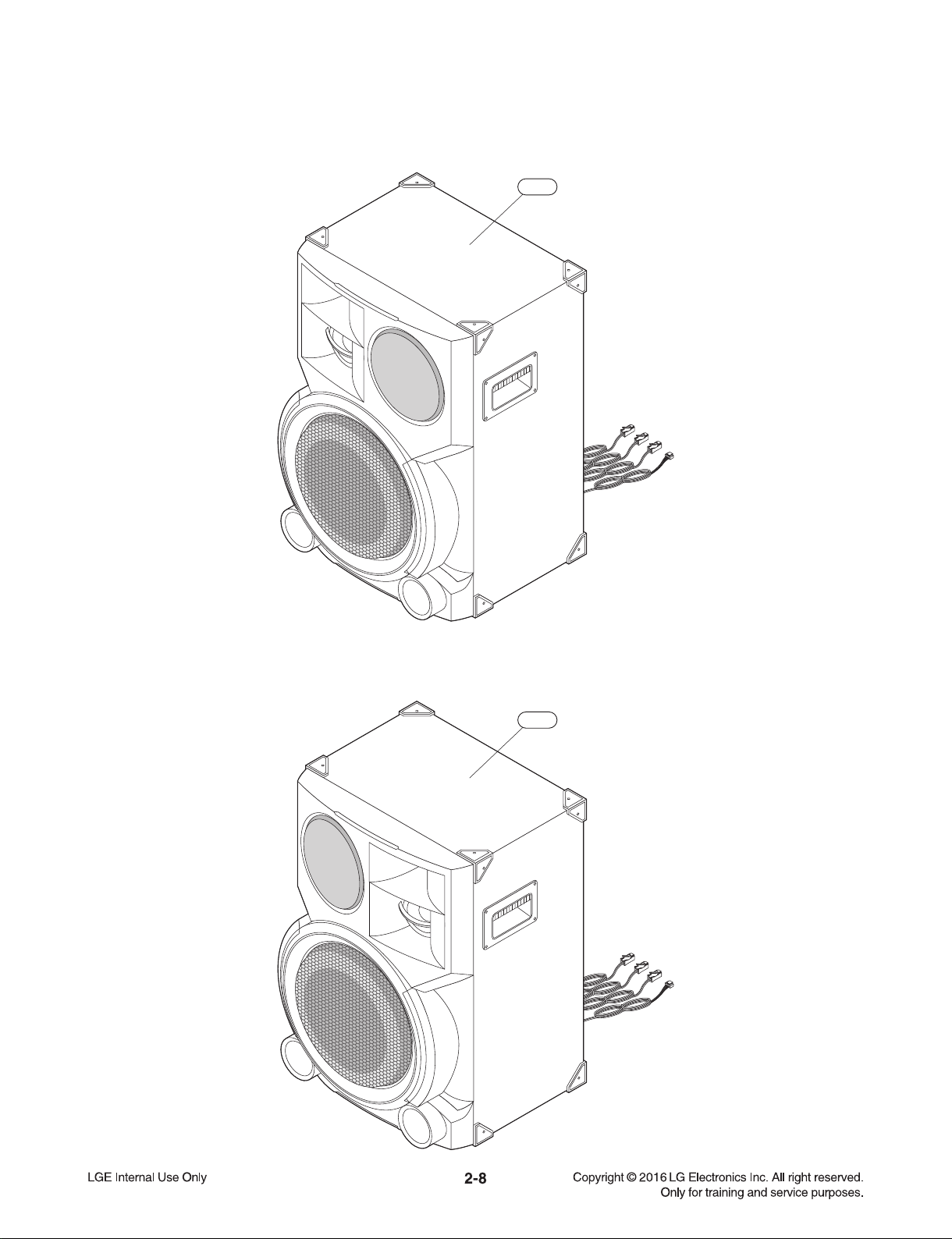

4. SPEAKER SECTION ................................................................................................................................2-8

2-1

Page 17

2-2

Page 18

E

G

H

B

E

C

I

K

H

D

F

A

MAIN

F

G

C

D

I

A46

443

443

274

266

443

443

468

468

262

FRONT

FRONT_CTRL

498

498

271

498

443

443

271

271

271

BT

CABLE1

A52

443

A45

443

443

467

263

265

265

443

CABLE2

272

252

252

A42

250

251

251

270

254

K

263

467

264

443

273

275

468

468

A

B

J

SMPS

A47

498

L

L

300

J

A43

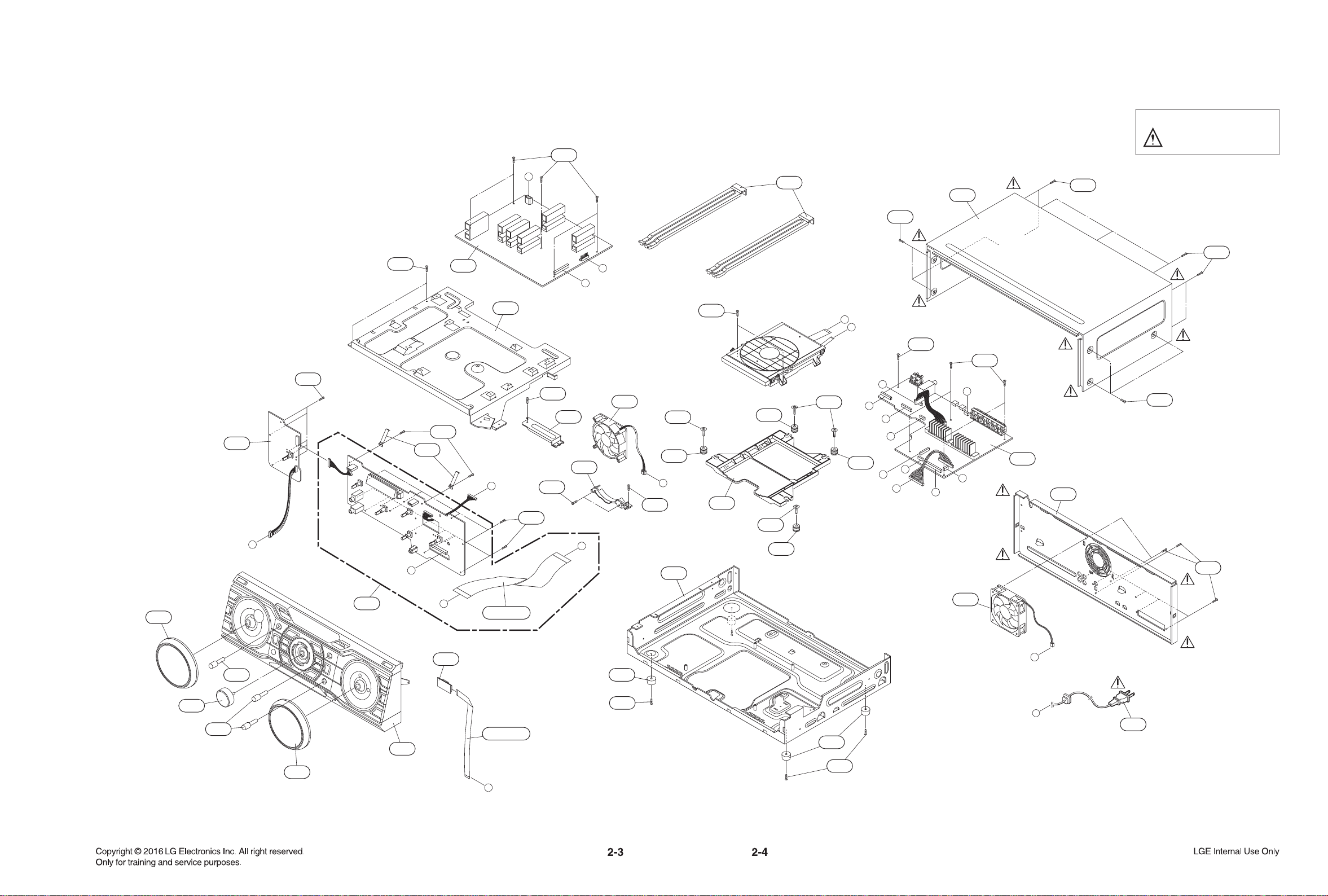

EXPLODED VIEWS

1. CABINET AND MAIN FRAME SECTION

NOTES) THE EXCLAMATION POINT WITHIN AN

EQUILATERAL TRIANGLE IS INTENDED

TO ALERT THE SERVICE PERSONNEL

TO THE PRESENCE OF IMPORTANT

SAFETY INFORMATION IN SERVICE

LITERATURE.

Page 19

1439

A001

1002

1005

1001

1049

1437

1437

1024

1024

1024

1024

1003

1011

1437

1004

1026

1030

1043

1045

A005

A006

1016

1013

1015

1020

1439

1018

1019

1012

2. MECHANISM DECK SECTION

Page 20

3. PACKING ACCESSORY SECTION

801 Owner’s manual

825 FM Antenna

900 Remote Control

Filter, Ferrite Core

826A

808 Batteries

803 Packing

804 Bag

Packing803

802 Box

Page 21

4. SPEAKER SECTION

A60L

A60R

Page 22

SECTION 3

ELECTRICAL

CONTENTS

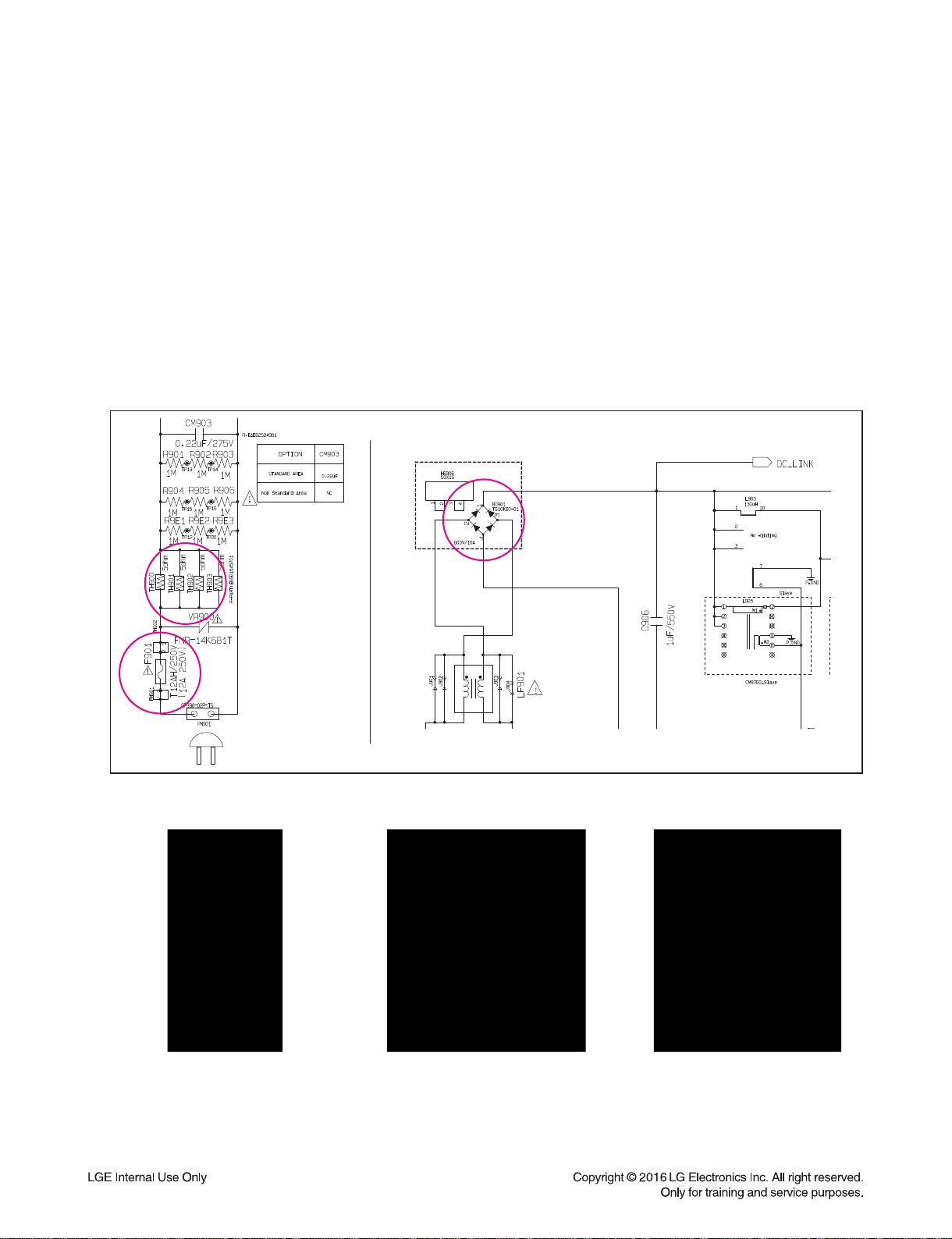

ONE POINT REPAIR GUIDE ............................................................................................................................3-2

1. NO POWER ............................................................................................................................................3-2

2. NO AMP POWER ...................................................................................................................................3-3

3. NO BOOTING WHEN POWER ON THE SET........................................................................................3-4

4. VFD IS NOT DISPLAYED WHEN POWER ON THE SET ..................................................................... 3-5

5. AUDIO OUTPUT IS SMALL OR NO AUDIO OUTPUT ..........................................................................3-6

6. NO POWER ON (STANDBY LED IS BLINKING) ................................................................................... 3-7

7. SPEAKER NO AUDIO ............................................................................................................................3-8

8. NO BOOTING IN CD/USB FUNCTION .................................................................................................. 3-9

9. NO OPERATION OF MD ...................................................................................................................... 3-14

10. NO SOUND ........................................................................................................................................... 3-19

ELECTRICAL TROUBLESHOOTING GUIDE .................................................................................................3-25

1. POWER SUPPLY ON SMPS BOARD ..................................................................................................3-25

2. SYSTEM PART ..................................................................................................................................... 3-28

3. NO AUDIO CHECK ...............................................................................................................................3-29

WAVEFORMS OF MAJOR CHECK POINT ....................................................................................................3-34

1. DSP (IC501) .......................................................................................................................................... 3-34

2. PWM (IC202) ........................................................................................................................................ 3-35

3. SERVO (IC401) .....................................................................................................................................3-36

4. MOTOR DRIVER (IC400) ..................................................................................................................... 3-37

5. ADC (IC201) ..........................................................................................................................................3-38

6. USB (CN502) ........................................................................................................................................3-38

7. BLUETOOTH (CN504) ..........................................................................................................................3-39

WIRING DIAGRAM ..........................................................................................................................................3-41

BLOCK DIAGRAMS ........................................................................................................................................3-43

1. SYSTEM BLOCK DIAGRAM ................................................................................................................3-43

2. SMPS BLOCK DIAGRAM .....................................................................................................................3-45

CIRCUIT DIAGRAMS ......................................................................................................................................3-47

1. SMPS - POWER #1 CIRCUIT DIAGRAM ............................................................................................3-47

2. SMPS - POWER #2 CIRCUIT DIAGRAM ............................................................................................3-49

3. MAIN - CD DSP CIRCUIT DIAGRAM ...................................................................................................3-51

4. MAIN - ADC/ TUNER/ AUX/ MICOM CIRCUIT DIAGRAM ..................................................................3-53

5. MAIN - RF SERVO CIRCUIT DIAGRAM .............................................................................................. 3-55

6. MAIN - PWM/ AMP LPF CIRCUIT DIAGRAM ...................................................................................... 3-57

7. MAIN - AMP #1 CIRCUIT DIAGRAM ................................................................................................... 3-59

8. MAIN - AMP #2 CIRCUIT DIAGRAM ................................................................................................... 3-61

9. MAIN - SPEAKER LED/ FAN CONTROL CIRCUIT DIAGRAM ...........................................................3-63

10. MAIN - DC_DC/ LDO CIRCUIT DIAGRAM .......................................................................................... 3-65

11. FRONT CIRCUIT DIAGRAM ................................................................................................................3-67

12. FRONT CONTROL CIRCUIT DIAGRAM ..............................................................................................3-69

CIRCUIT VOLTAGE CHART ...........................................................................................................................3-71

1. CAPACITOR VOLTAGE .......................................................................................................................3-71

PRINTED CIRCUIT BOARD DIAGRAMS .......................................................................................................3-73

1. SMPS P.C.BOARD ...............................................................................................................................3-73

2. MAIN P.C.BOARD ................................................................................................................................ 3-77

3. FRONT P.C.BOARD ............................................................................................................................. 3-81

4. FRONT CONTROL P.C.BOARD ..........................................................................................................3-85

3-1

Page 23

ONE POINT REPAIR GUIDE

1. NO POWER

If the unit doesn’t work by no power problem, repair the set according to the following guide.

1-1. FUSE/ THERMISTOR/ BRIDGE DIODE

1-1-1. Solution

Please check and replace TH900 ~ TH903, BD901 on SMPS board.

1-1-2. How to troubleshoot (Countermeasure)

1) Check if the fuse F901 is open or short-circuit.

2) Check if the NTC thermistor TH900 ~ TH903 is normal or open.

3) Check if the bridge diode BD901 is short-circuit by over current with a digital multimeter.

1-1-3. Service hint (Any picture/ Remark)

< F901 >

If F901 is not short-circuit,

replace it with a same

specifi cations one.

<TH900 ~ TH903 >

If TH900 ~ TH903 is open,

replace it with a new one.

3-2

< BD901 >

If BD901 is short-circuit,

replace it with a new one.

Page 24

ONE POINT REPAIR GUIDE

2. NO AMP POWER

If the unit doesn’t work by no ±PVDD problem, repair the set according to the following guide.

2-1. FUSE/ FET

2-1-1. Solution

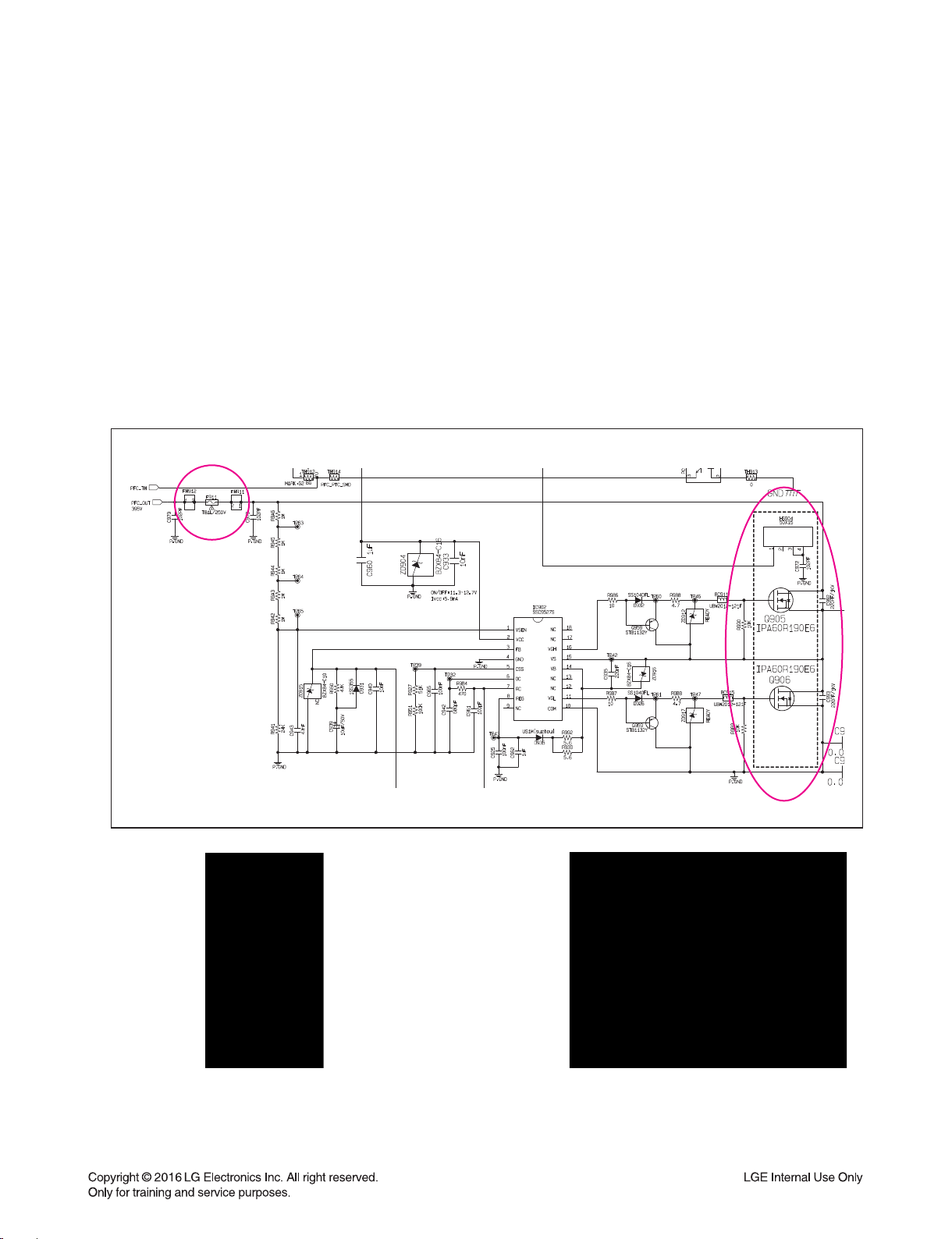

Please check and replace F911, Q905, Q906 on SMPS board.

2-1-2. How to troubleshoot (Countermeasure)

1) Check if the fuse F911 is open or short-circuit.

2) Check the Drain-Source or Drain-Gate, Gate-Source Resistance of Q905, Q906 with a digital multimeter.

If it is short condition, it’s destroyed. Replace it with a new one.

(Please replace 2 FET at the same time although several FET is OK).

2-1-3. Service hint (Any picture/ Remark)

< F911 >

If F911 is not short-circuit,

replace it with a same specifi cations one.

< Q905, Q906 >

If Q905, Q906 is short-circuit,

replace it with a new one.

3-3

Page 25

ONE POINT REPAIR GUIDE

X500

(24 MHz)

X501

(32.768 kHz)

KEY2

(R526)

PWR_CTRL

R522

3. NO BOOTING WHEN POWER ON THE SET

The set doesn’t work when press the power button on the FRONT board or the remote control.

3-1. IC501

3-1-1. Solution

Replace IC501 on MAIN board.

3-1-2. How to troubleshoot (Countermeasure)

1) Check the 5.6 VA (CN106) and DVCC 3.3 V (IC505) in standby mode.

If there is no 5.6 VA, check the SMPS and if doesn’t appear 3.3 V, check IC505.

2) Check 5.6 VA, +12 V, DVCC_5 and VCC_3.3V when power on the set.

If the set doesn’t work regardless of what the KEY1 changes HIGH to LOW.

while pressing the power button. X500 and X501 work normally but, if you can not power on the set,

replace the IC501 with a new one on the MAIN board.

3-1-3. Service hint (Any picture/ Remark)

X501

(32.768 kHz)

KEY2

(R526)

< MAIN board top view >

PWR_CTRL

R522

X500

(24 MHz)

< MAIN board bottom view >

3-4

Page 26

ONE POINT REPAIR GUIDE

VFD_STB,

VFD_CLK,

V D_DO

4. VFD IS NOT DISPLAYED WHEN POWER ON THE SET

When power on the set, any icons or characters on VFD are not displayed.

4-1. VFD (VFD301)

4-1-1. Solution

Please check and replace VFD301 on FRONT board.

4-1-2. How to troubleshoot (Countermeasure)

1) Check if 12 V, VCC_3.3V and DVCC_5V are output from SMPS to VFD via the MAIN board.

2) Check if the IC501 outputs VFD_CLK, VFD_STB, and VFD_DO to the FRONT board.

3) Check if the VFD grid current amplifier circuit on the FRONT board.

Check the drive signal to the transistor’s base.

If the control signals from VFD (DGND, VDD) isn’t output, replace VFD with a new one.

4-1-3. Service hint (Any picture/ Remark)

R327 (TP304)

VFD_STB,

VFD_CLK,

VFD_DO

< MAIN-CD DSP circuit > < Waveform of the grid current driver>

Q3 0 1 E m i tter

About

30 Vp-p

3-5

Page 27

ONE POINT REPAIR GUIDE

IC700

IC701

IC705

IC704

IC703

IC702

5. AUDIO OUTPUT IS SMALL OR NO AUDIO OUTPUT

Audio signal output is small or not. when you power on the middle power mini system.

5-1. AMP IC (IC700 ~ IC705)

5-1-1. Solution

Replace IC700 ~ IC705 on MAIN board.

5-1-2. How to troubleshoot (Countermeasure)

1) Please check if this system is on bass blast mode.

FL, FR, RL, RR, SW1, SW2 make sound only on bass blast mode.

2) Check the IC700 ~ IC705 on your eyes.

3) Check the audio signal output check (pin13 of IC700 ~ IC705).

First, check the PWM data input (pin3 of IC700 ~ IC705).

4) If the audio signal output has no output, try to change IC which has no output.

5) Lastly, check speaker terminal (TM700).

5-1-3. Service hint (Any picture/ Remark)

IC700

IC701

< MAIN board top view >

IC705

3-6

IC704

IC703

IC702

Page 28

ONE POINT REPAIR GUIDE

AMP FETs

6. NO POWER ON (STANDBY LED IS BLINKING)

It doesn’t turn on, and blinks standby LED (RED).

6-1. AMP FETs

6-1-1. Solution

Replace AMP FET on MAIN board.

6-1-2. How to troubleshoot (Countermeasure)

1) This symptom occurs, when DC protection is detected. MAIN reasons are like below.

- When some of AMP FETs dead.

6-1-3. Service hint (Any picture/ Remark)

AMP FET : IRF6775

< MAIN board top view >

Notice for FET service

- In case of RF6775, Metal case, FET Drain,

has electric potential. So be careful when you

deal with it.

AMP FETs

* You can see FET after removing heatsink.

* Notice for Service

Before repair MAIN Assy, you need to discharge SMPS.

After then, open the connector.

You should try to change both of +/- FET and Driver IC

as a pair.

3-7

Page 29

ONE POINT REPAIR GUIDE

CN110

pin1, 2 : +66 V

pin3, 4 : PGND

pin5, 6 : -66 V

pin5 of IC700

CSD

7. SPEAKER NO AUDIO

Speaker no audio.

7-1. AMP IC (IC700, IC701, IC705)

7-1-1. Solution

Replace IC700, IC701, IC705 on MAIN board.

7-1-2. How to troubleshoot (Countermeasure)

1) Check supply voltage of AMP (CN110) & PWM signal.

Normal supply voltage and signal Check AMP IC.

Poor supply voltage Check SMPS.

Poor signal Check PWM IC.

2) Check CSD of FET driver IC (IRS2092 : EAN60778301).

CSD has about 5 V on normal state.

When AMP has problem, CSD is LOW state or keep change LOW to HIGH.

7-1-3. Service hint (Any picture/ Remark)

CN110

pin1, 2 : +66 V

pin3, 4 : PGND

pin5, 6 : -66 V

< MAIN board top view >

pin5 of IC700

< MAIN board top view > < MAIN - AMP circuit >

CSD

3-8

Page 30

ONE POINT REPAIR GUIDE

IC505

IC500

8. NO BOOTING IN CD/USB FUNCTION

After you turn on power key and displayed message in the following order (HELLO VOL XX

CD or USB) on VFD, it will not display other message on VFD, and it will not boot-up normally.

8-1. NO DVCC_3.3V, 1.2 VA

8-1-1. Solution

Please check and replace IC505, IC500 on MAIN board.

8-1-2. How to troubleshoot (Countermeasure)

1) Check voltage of IC505 pin3 on MAIN board.

If IC505 pin3 (about 4.9 V) & D500 Input 5.6 VA doesn’t come out, check 5.6 VA from SMPS board.

2) If IC505 pin3 (about 4.9 V) is normal, check the PWR_CTRL(IC505 pin2) is HIGH (about 3.3 V).

If PWR_CTRL isn’t HIGH, check pin B2 of IC501 & R559, R522.

3) If PWR_CTRL is HIGH, check R559 and if there’s no defective component then replace IC505.

4) If 3.3 V (DVCC_3.3V) is normal, check 1.2 V output (pin2) voltage of IC500.

If 1.2 V of IC500 pin2 doesn’t come out, then replace IC500.

8-1-3. Service hint (Any picture/ Remark)

IC500

< MAIN board top view >

IC505

< MAIN board bottom view >

3-9

Page 31

ONE POINT REPAIR GUIDE

XO

IC501

X500

8. NO BOOTING IN CD/USB FUNCTION

After you turn on power key and displayed message in the following order (HELLO VOL XX

CD or USB) on VFD, it will not display other message on VFD, and it will not boot-up normally.

8-2. CRYSTAL (X500)

8-2-1. Solution

Replace X500 on MAIN board.

8-2-2. How to troubleshoot (Countermeasure)

1) If 3.3 V & 1.2 V is normal, check reset ‘HIGH’ of IC501 pin T12 on MAIN board.

If MAIN_RESET isn’t HIGH, check MICOM (IC101) pin40.

2) If MAIN_RESET is HIGH, check the soldering status of 24 MHz crystal (X500).

3) If the crystal (X500) doesn’t oscillate, check R508, C502, C503 around crystal (X500).

If there’s no defective component, then replace X500.

8-2-3. Service hint (Any picture/ Remark)

XX

IC501

< MAIN board top view >

X500

X500

< Signal waveform >

3-10

Page 32

ONE POINT REPAIR GUIDE

VCC

CLK

DO

CS#

IC503

8. NO BOOTING IN CD/USB FUNCTION

After you turn on power key and displayed message in the following order (HELLO VOL XX

CD or USB) on VFD, it will not display other message on VFD, and it will not boot-up normally.

8-3. SERIAL FLASH (IC503)

8-3-1. Solution

Please check and replace IC503 on MAIN board.

8-3-2. How to troubleshoot (Countermeasure)

1) If the crystal (X500) does oscillate, check Serial Flash (IC503) on MAIN board.

Check pin8 (VCC), pin6 (CLK), pin1 (CS), pin2 (DO), pin5 (DI) of below waveform

2) If pin1, 2, 5, 6, 8 doesn’t come out, check damping resistor (R563, R564, R535, R534, R536) of IC503.

If damping resistor of IC503 is OK, then replace IC503. (it need to download program)

3) After change IC503, if It is still not below waveform, check IC501 (DSP IC).

8-3-3. Service hint (Any picture/ Remark)

V

IC503

< MAIN board bottom view >

< Signal waveform >

3-11

Page 33

ONE POINT REPAIR GUIDE

VCC

Reset

Address

Data

/CS

RAS

/WE

CAS

IC502

8. NO BOOTING IN CD/USB FUNCTION

After you turn on power key and displayed message in the following order (HELLO VOL XX

CD or USB) on VFD, it will not display other message on VFD, and it will not boot-up normally.

8-4. SDRAM (IC502)

8-4-1. Solution

Please check and replace IC502 on MAIN board.

8-4-2. How to troubleshoot (Countermeasure)

1) Check below waveform & soldering status of SDRAM (IC502) on MAIN board.

If pin17 (#CAS), pin18 (#RAS), pin19 (#CS), pin38 (CLK), pin29 (address), pin2 (DQ) doesn’t come out,

check damping resistor (R568, R570, R544, R547, R510).

2) If resistor is OK, then replace IC502 (SDRAM).

3) After change IC502, if It is still not below waveform, check IC501 (DSP IC).

8-4-3. Service hint (Any picture/ Remark)

V

IC502

< MAIN board bottom view >

< Signal waveform >

3-12

Page 34

ONE POINT REPAIR GUIDE

IC501

8. NO BOOTING IN CD/USB FUNCTION

After you turn on power key and displayed message in the following order (HELLO VOL XX

CD or USB) on VFD, it will not display other message on VFD, and it will not boot-up normally.

8-5. DSP (IC501)

8-5-1. Solution

Please check and replace IC501 on MAIN board.

8-5-2. How to troubleshoot (Countermeasure)

1) After check them by previous pages about no booting, if the set is still no booting,

Check soldering status of IC501.

2) If below bootstrap waveform doesn’t come out, then replace IC501 (DSP IC).

8-5-3. Service hint (Any picture/ Remark)

R594

PGPB12

(YELLOW)

R598

PAD19

IC501

(GREEN)

< MAIN board top view >

R597

PAD20

(PINK)

< Bootstrap waveform >

3-13

Page 35

ONE POINT REPAIR GUIDE

SP-

pin8 of CN401

SP+

pin6 of CN401

IC400

9. NO OPERATION OF MD

When no sound output in the CD function, you can not listen to music reading data from a CD

disc if the servo motors in MD don’t work. This step is for checking the spindle motor among

them.

9-1. SPINDLE MOTOR

9-1-1. Solution

Replace IC401 or IC400 on MAIN board.

9-1-2. How to troubleshoot (Countermeasure)

1) Check the SPDO signal from pin16 of IC401.

If no signal, check 3.3 V (RF) and X400.

2) Check the SP- & SP+ from IC400 to CN401 for driving SPINDLE motor. It is about 3.6 Vp-p.

If no signal, check +1.8 V and DVCC+5 V for IC400.

3) Check if the FFC cable is solidly connected between CN401 and MD.

4) Check the MD.

If the spindle motor is short-circuit or has any trouble, it can not rotate CD discs.

Please check the function after changing another MD.

9-1-3. Service hint (Any picture/ Remark)

zwR

zwT

< Waveform of SP- & SP+

for driving SPINDLE motor >

SP+

pin6 of CN401

SP-

pin8 of CN401

IC400

< MAIN board top view >

3-14

Page 36

ONE POINT REPAIR GUIDE

SL-

pin9 of CN401

SL+

pin7 of CN401

IC400

9. NO OPERATION OF MD

When no sound output in the CD function, you can not listen to music reading data from a CD

disc if the servo motors in MD don’t work. This step is for checking the sled motor among them.

9-2. SLED MOTOR

9-2-1. Solution

Replace IC401 or IC400 on MAIN board.

9-2-2. How to troubleshoot (Countermeasure)

1) Check the SLDO signal from pin23 of IC401.

If no signal, check 3.3 V (RF) and X400.

2) Check the SLED+ & SLED- from IC400 to CN401 for driving SPINDLE motor. It is about 2.9 Vp-p.

If no signal, check +1.8 V and +5 V for IC400.

3) Check if the FFC cable is solidly connected between CN401 and MD.

4) Check the MD.

If the sled motor is sort-circuit or has any trouble, it can not move the pickup module.

Please check the function after changing another MD.

9-2-3. Service hint (Any picture/ Remark)

zsR

zsT

< Waveform of SL- & SL+

for driving SLED motor >

SL+

pin7 of CN401

SL-

pin9 of CN401

IC400

< MAIN board top view >

3-15

Page 37

ONE POINT REPAIR GUIDE

LO-

pin2 of CN401

LO+

pin4 of CN401

MOT_CLOSE

pin6 of IC400

MOT_OPEN

pin7 of IC400

9. NO OPERATION OF MD

When no sound output in the CD function, you can not listen to music reading data from a CD

disc if the servo motors in MD don’t work. This step is for checking the tray open/close motor

among them.

9-3. TRAY OPEN/ CLOSE MOTOR

9-3-1. Solution

Replace IC401 or IC400 on MAIN board.

9-3-2. How to troubleshoot (Countermeasure)

1) Check MOT_OPEN & MOT_CLOSE signals from pin K4 & L4 of IC501 to IC400.

If no signal, check +1.8 V & + 5 V to IC400.

2) Check LOAD ± from IC400 to CN401 for driving the tray open/ close motor. It is about 3.85 Vp-p.

If no signal, check +5 V to IC401. If it has any trouble, replace it with a new one.

3) Check if the FFC cable is solidly connected between CN401 and MD.

4) Check the MD.

If the tray motor is short-circuit or has any trouble, it can not open or close the tray.

Please check the function after changing another MD.

9-3-3. Service hint (Any picture/ Remark)

sv

svROylkP

tv{ v w lu

tv{ jsvz l

< Waveform

for driving tray open/ close motor >

MOT_OPEN

pin7 of IC400

MOT_CLOSE

pin6 of IC400

LO+

pin4 of CN401

< MAIN board top view >

LO-

pin2 of CN401

3-16

Page 38

ONE POINT REPAIR GUIDE

TR-

pin17 of CN400

TR+

pin16 of CN400

9. NO OPERATION OF MD

When no sound output in the CD function, you can not listen to music reading data from a CD

disc if the pickup module in MD doesn’t work. This step is for checking the laser tracking actuator.

9-4. LASER TRACKING ACTUATOR

9-4-1. Solution

Replace IC401 or IC400 on MAIN board.

9-4-2. How to troubleshoot (Countermeasure)

The tracking actuator makes the laser beam be positioned in the center of a track on CD disc.

1) Check the TRD signal from pin14 of IC401.

If no signal, check 3.3 V (RF) and X400.

2) Check TR- & TR+ from IC400 to CN400 for driving the tracking actuator.

If no signal, check +1.8 V and +5 V for IC400.

3) Check if the FFC cable is solidly connected between CN400 and MD.

4) Check the MD.

If the pickup module has any trouble, it can not move the laser beam on the left or right side.

Please check the function after changing another MD.

9-4-3. Service hint (Any picture/ Remark)

{y ju[W[

{y R ju[W[

< Waveform of TR±

for driving tracking actuator >

TR-

pin17 of CN400

pin16 of CN400

< MAIN board top view >

TR+

3-17

Page 39

ONE POINT REPAIR GUIDE

F-

pin18 of CN400

F+

pin15 of CN400

9. NO OPERATION OF MD

When no sound output in the CD function, you can not listen to music reading data from a CD disc

if the pickup module in MD doesn’t work. This step is for checking the laser focusing actuator.

9-5. LASER FOCUSING ACTUATOR

9-5-1. Solution

Replace IC401 or IC400 on MAIN board.

9-5-2. How to troubleshoot (Countermeasure)

The focusing actuator makes the laser beam keep a regular interval with the surface of a CD disc.

1) Check the FDO signal from pin21 of IC401.

If no signal, check 3.3 V (RF) and X400.

2) Check F- & F+ from IC400 to CN400 for driving the focusing actuator.

If no signal, check +1.8 V and +5 V for IC400.

3) Check if the FFC cable is solidly connected between CN400 and MD.

4) Check the MD.

If the pickup module has any trouble, it can not move the laser beam on the top or bottom side.

Please check the function after changing another MD.

9-5-3. Service hint (Any picture/ Remark)

mR ju[W[

m ju[W[

< Waveform of F±

for driving focusing actuator >

F-

pin18 of CN400

pin15 of CN400

< MAIN board top view >

F+

3-18

Page 40

ONE POINT REPAIR GUIDE

D+

D-

10. NO SOUND

There is no sound output in the USB function, repair the set according to the following

10-1. USB FUNCTION

10-1-1. Solution

Replace IC501 on MAIN board, ICA201 on FRONT board.

10-1-2. How to troubleshoot (Countermeasure)

1) Check +5 VU to FRONT board.

If +5.6 VA to pin1 of ICA201 (LDO) doesn’t come out, check pin7, pin8 of CN106.

If +5.6 VA is normal & +5 VU of ICA201 pin3 doesn’t come out, then replace ICA201.

2) Check “Digital audio AMP block”.

10-1-3. Service hint (Any picture/ Remark)

D

D

guide.

< USB function signal fl ow diagram >

USB D-/ D+ (CN502 pin5, pin6, pin8, pin9)

< Waveform of USB D± signal >

3-19

Page 41

ONE POINT REPAIR GUIDE

IC201

ADC/ MIC_DATA

MCS_BCK

MCS_LRCK

MCS_MCLK

AUX_R to R209

AUX_L to R210

10. NO SOUND

There is no sound output in the AUX function, repair the set according to the following guide.

10-2. AUX FUNCTION

10-2-1. Solution

Replace IC201 on MAIN board.

10-2-2. How to troubleshoot (Countermeasure)

1) Check AUX_L/ R signals to IC201 (pin7, pin8).

2) Check if MCS_BCK, MCS_LRCK, & MCS_MCLK are entered from IC501 to IC201.

3) Check if ADC/ MIC_DATA is entered from IC201 to IC501.

If no signal, check +5 V & +3.3 V (ADC) for IC201. If is NG, replace it a new one.

4) Check the following I2S signal flow from IC501 to IC202.

If there is any trouble, check the power for each IC. The power is normal but, if the signal waveform to

the IC is distorted or no signal, replace it with a new one.

5) Check if the digital audio AMP block is okay.

If AMP is damaged, replace it with a new one.

10-2-3. Service hint (Any picture/ Remark)

AUX_R to R209

AUX_L to R210

ADC/ MIC_DATA

MCS_BCK

MCS_LRCK

MIX_DATA_OUT

AUX_L/ R

AUX

IC202

PS9860

PWM

IR AMP

IRS2092

+

IRF6775

ADC/ MIC_DATA

MCS_BCK

MCS_LRCK

MCS_MCLK

IC201

IC201

CS5346

MCS_MCLK

IC501

MLC3730

< AUX function signal fl ow diagram >

< MAIN board bottom view >

3-20

Page 42

IC201

PT_L to pin9

PT_R to pin10

ONE POINT REPAIR GUIDE

10. NO SOUND

There is no sound output in the PORT. IN function, repair the set according to the following guide.

10-3. PORT. IN FUNCTION

10-3-1. Solution

Replace IC201 on MAIN board.

10-3-2. How to troubleshoot (Countermeasure)

1) Check PT_L/ R signal from FRONT board to MAIN board.

2) Check if PT_L/ R is entered pin1 & pin3 of CN201.

3) Check PT_L/R signals to IC201 (pin9, 10).

4) Check if ADC_BCK, ADC_LRCK & DAC_MCLK are entered from IC501 to IC201.

5) Check if ADC_DATA is entered from IC201 to IC501.

If no signal, check +5 V & +3.3 V (ADC) for IC201. If is NG, replace it a new one.

6) Check the following I2S signal flow from IC501 to IC202.

If there is any trouble, check the power for each IC. The power is normal but, if the signal waveform to

the IC is distorted or no signal, replace it with a new one.

7) Check if the digital audio AMP block is okay.

If AMP is damaged, replace it with a new one.

10-3-3. Service hint (Any picture/ Remark)

IC202

PWM

PORT. IN

IR AMP

IRS2092

IRF6775

+

MCS_MCLK

MLC3730

IC201

CS5346

ADC/ MIC_DATA

IC501

POT_L/ R

MCS BCK

MCS_LRCK

MIX_DATA_OUT

VOLUME

Board

PS9860

< PORT. IN function signal fl ow diagram >

IC201

PT_L to pin9

PT_R to pin10

< MAIN board bottom view >

3-21

Page 43

ONE POINT REPAIR GUIDE

IC201

ADC/ MIC_DATA

MCS_BCK

MCS_LRCK

MCS_MCLK

TUNER_R to pin27

TUNER_L to pin26

10. NO SOUND

There is no sound output in the TUNER function, repair the set according to the following guide.

10-4. TUNER FUNCTION

10-4-1. Solution

Replace IC201, TU500 on MAIN board.

10-4-2. How to troubleshoot (Countermeasure)

1) Check if TUNER_L/R is entered from pin1 & pin3 of TU500 to IC201 (pin26, 27).

If no signals, check +3.3 V for tuner power.

Check if the tuner control signals (CLK, DAT, CE, RST, GPO2) are entered from IC501 to TU500.

If it doesn’t work, replace TUNER with a new one.

2) Check if ADC_BCK, ADC_LRCK & DAC_MCLK are entered from IC501 to IC201.

3) Check if ADC_DATA is entered from IC201 to IC501.

If no signal, check +5 V & +3.3 V (ADC) for IC201. If is NG, replace it a new one.

4) Check the following I2S audio signal flow from IC501 to IC202.

If there is any trouble, check the power for each IC. The power is normal but, if the signal waveform to

the IC is distorted or no signal, replace it with a new one.

5) Check if the digital audio AMP block is okay.

If AMP is damaged, replace it with a new one.

10-4-3. Service hint (Any picture/ Remark)

TUNER

CS5346

MCS_MCLK

IC501

MLC3730

IC201

TUNER_L/ R

ADC/

MIC_DATA

MCS_BCK

MCS_LRCK

MIX_DATA_OUT

Jack

Board

IC202

PS9860

PWM

IR AMP

IRS2092

+

IRF6775

< TUNER function signal fl ow diagram >

TUNER_R to pin27

TUNER_L to pin26

ADC/ MIC_DATA

MCS_BCK

MCS_LRCK

MCS_MCLK

< MAIN board bottom view >

IC201

3-22

Page 44

ONE POINT REPAIR GUIDE

IC206

ADC/ MIC_DATA

MCS_BCK

MCS_LRCK

MCS_MCLK

10. NO SOUND

There is no sound output in the MIC IN function, repair the set according to the following guide.

10-5. MIC IN FUNCTION

10-5-1. Solution

Replace IC206 on MAIN board, IC30A1 on FRONT CONTROL board.

10-5-2. How to troubleshoot (Countermeasure)

1) Check MIC_SIG1 & MIC_SIG2 signal to pin5 & pin6 of CN201.

If no signal, check the signals to pin5 & pin6 of CN302 on the Control board.

Check if the signal is entered from pin5 & pin6 of CN302 to CN201.

2) Check if MIC_SIG is entered from pin6 & pin7 of CN301 to pin2, pin13 to IC30A1 (PRE AMP).

3) Check if the amplified signal comes out from pin3 & pin12 of IC30A1.

If no signal output, check +3.3 V for IC30A1, replace IC30A1 with a new one if it has a problem.

4) Check if MCS_BCK, MCS_MLCK & MCS_LRCK is entered from IC501 to IC206.

Check if MIC_DATA_IN is entered from pin9 of IC206 to pin T1of IC501.

If no signal, check +5 V & +3.3 V for IC206. If it is abnormal, change replace it a new one.

5) Check the following I2S signal flow from IC206 to IC501.

If there is any trouble, check the power for each IC. If the signals are abnormal, replace it a new one.

6) Check if the digital audio AMP block is okay.

If AMP is damaged, replace it with a new one.

10-5-3. Service hint (Any picture/ Remark)

< MIC IN function signal fl ow diagram >

IC206

ADC/ MIC_DATA

MCS_BCK

MCS_LRCK

MCS_MCLK

< MAIN board top view >

3-23

Page 45

ONE POINT REPAIR GUIDE

BT_TX. pin4

BT_RX. pin6

BT_RTS. pin7

BT_CTS. pin8

CN504

MIX_DATA2_OUT

MIX_DATA1_OUT

MIX_DATA0_OUT

MCS_LRCK

MCS_BCK

IC202

10. NO SOUND

There is no sound output in the Bluetooth function, repair the set according to the following

guide.

10-6. BLUETOOTH FUNCTION

10-6-1. Solution

Replace IC501 on the MAIN board or bluetooth module on the FRONT Panel.

10-6-2. How to troubleshoot (Countermeasure)

1) Check BT_RX, BT_TX signal to pin4, pin6 of CN504.

If no signal, check the signal to pin4, pin6 and pin10 (+3.3 V) of on the Bluetooth module and cable

connection state.

If there are no signal out from module, replace new module.

2) Check if BT_RX/ TX is entered from pin4, pin6 of CN504 to pin K1, pin L1 to IC501 (DSP).

3) Check if MCS_BCK, MCS_LRCK & MIX_DATAN is entered from IC501 to IC202.

If no signal, check VCC12 (+1.2 V) for IC501. If it is abnormal, change replace it a new one.

4) Check the following I2S signal flow from IC501 to IC202.

If there is any trouble, check the power for each IC. If the signals are abnormal, replace it a new one.

5) Check if the digital audio AMP block is okay.

If AMP is damaged, replace it with a new one.

10-6-3. Service hint (Any picture/ Remark)

Bluetooth

module

BT_RX,

BT_TX

IC501

MLC3730

MCS_BCK

MCS_LRCK

MIX_DATA_OUT

< Bluetooth function signal fl ow diagram >

IC202

PS9860

PWM

IR AMP

IRS2092

+

IRF6775

MIX_DATA2_OUT

MIX_DATA1_OUT

MIX_DATA0_OUT

MCS_LRCK

MCS_BCK

IC202

BT_TX. pin4

BT_RX. pin6

BT_RTS. pin7

BT_CTS. pin8

3-24

CN504

< MAIN board top view >

Page 46

ELECTRICAL TROUBLESHOOTING GUIDE

1. POWER SUPPLY ON SMPS BOARD

No output 5.6 VA

Is the F901 normal?

YES

Is BD901 normal?

YES

Is the VCC

(11 V ~ 25 V) supplied to IC901

pin4?

YES

Power line of MAIN PCB is short.

NO

NO

NO

Replace F901 (same fuse).

Replace BD901.

Is D960, D961 normal?

Check or replace D960, D961.

No 12 V

VCC 12 VA supplied to IC951

‘HIGH’ signal at IC951

check line of MAIN PCB is short or not.

Is the

pin1?

YES

Is there

pin4?

YES

Check IC951 and replace.

Or

NO

NO

Check or replace D963.

Check P_CTL from μ-com.

3-25

Page 47

ELECTRICAL TROUBLESHOOTING GUIDE

1. POWER SUPPLY ON SMPS BOARD

No -5 V

VCC -7 VA supplied to IC953

Check or replace Q953, Q957.

check line of MAIN PCB is short or not.

No output AMO gate line

Is the

pin2?

YES

Is there

‘H’ signal at Q953

Base?

YES

Or

NO

NO

Is the D967 normal?

YES

Check or replace Q951.

Check P_CTL

from μ-com.

NO

Check or replace D967.

Is the VCC

13 VA supplied to IC952

pin1 to pin3?

Check and replace IC952.

check line of MAIN PCB is short or not.

Or

NO

Is the R952 normal?

YESYES

Check or replace D952, D959.

3-26

NO

Check or replace R952.

Page 48

ELECTRICAL TROUBLESHOOTING GUIDE

1. POWER SUPPLY ON SMPS BOARD

No AMP output

Is the

C904 voltage

about 390 V?

YES

Is F911 normal?

NO

NO

YES

Is the

PFC P_CTL OK?

YES

Is the

VCC 12 V supplied to

IC904 pin16?

YES

Check or replace

IC904, Q907 ~ Q910.

Is the

AMP P_CTL OK?

YES

Is the

VCC 12 V supplied to

IC902 pin8?

NO

NO

NO

NO

Check PFC P_CTL

from μ-com.

Replace D908, Q955, PC903.

Check AMP P_CTL

from μ-com.

Replace D908, Q956, PC902.Replace F911.

NO

Is Q905, Q906 OK?

NO

Replace Q905, Q906.

YES

Check or replace IC902 and

check Q905, Q906 gate(pin1)

Components (Resistors, Diodes).

3-27

Check or replace D954, D955.

Check line of MAIN PCB is short or not.

Page 49

ELECTRICAL TROUBLESHOOTING GUIDE

2. SYSTEM PART

Power on.

“HELLO”

Display on FLD

OK?

YES

When turn

the volume, count is

change?

YES

NO

NO

CN605

cable connection

OK?

YES

CN605

pin7, 14, 16, 29 power

OK?

YES

CN605

pin8 ~ 10 data signal

OK?

YES

Check

CN605 pin5, 6

I2C data OK?

YES

NO

NO

NO

NO

NO

Check FFC cable.

Check SMPS board.

Check MAIN board.

Replace VFD301.FL+/-, VDD_3.3V voltage OK?

Check FFC cable.

FRONT, FRONT_CTRL board

OK.

Check MAIN board.

3-28

Page 50

ELECTRICAL TROUBLESHOOTING GUIDE

3. NO AUDIO CHECK

CD FUNCTION

Can

DISC insert?

YES

Disc reading OK?

YES

NO

NO

LOAD +, - OK?

YES

Is motor impedance

about 12 Ω?

OPU driving

(Focusing & Tracking) OK?

Check OPU.

(Pick-up module)

NO

NO

NO

NO

Is Motor_open/ close OK?

(IC400 pin6, 7)

YES

Check IC501.

Check loading motor.

Check IC400.

NO

Focusing/

Tracking/ Sled signal

OK?

YES

MON_MPD(CN400 pin22)

About 180 mV?

IC401 pin34 ~ 36

I2S output signal OK?

YES

IC501 pin N1, N2, N4

I2S input signal OK?

YES

A

NO

NO

IC401

RF & Servo signal

OK?

YES

Check IC501.

3-29

NO

Check FFC cable

to CN400, CN401.

Page 51

ELECTRICAL TROUBLESHOOTING GUIDE

3. NO AUDIO CHECK

USB FUNCTION

When insert USB,

IC501 pin U7, U8, A7, A8

USB_D signal OK?

YES

A

AUX FUNCTION

NO

IC312 USB Power

+5VU OK?

YES

NO

Replace IC312.

pin23, 24 AUX input signal

IC201

OK?

YES

IC201

pin42 ~ 44 I2S input signal

OK?

YES

IC201

pin41 ADC/ MIC_data output

signal OK?

YES

A

NO

NO

NO

Check audio cable.

Check IC501.

Replace IC201.

3-30

Page 52

ELECTRICAL TROUBLESHOOTING GUIDE

3. NO AUDIO CHECK

PORTABLE FUNCTION

pin9, 10 POT_IN input signal

IC201

OK?

YES

IC201

pin42 ~ 44 I2S input signal

OK?

YES

IC201 pin41

ADC_data_IN/ SDOUT output

signal OK?

YES

A

TUNER FUNCTION

NO

NO

NO

Check FRONT board.

Check IC501.

Replace IC201.

IC201 pin26, 27

TUNER_L/R input signal

OK?

YES

IC201

pin42 ~ 44 I2S input

signal OK?

YES

IC201

pin41 ADC data output

signal OK?

YES

A

NO

NO

NO

TU500

TUNER_L/R output

signal OK?

YES

Check IC501.

Replace IC201.

3-31

NO

Check +3.3 V of TU500.

Page 53

ELECTRICAL TROUBLESHOOTING GUIDE

3. NO AUDIO CHECK

A

YES

pin D1, D2, E1 I2S clock signal

IC501

OK?

YES

IC501

pin E2 I2S data signal

OK?

YES

IC202

PWM data output signal

OK?

YES

B

NO

NO

NO

Check IC501.

Check IC501.

Replace IC202.

3-32

Page 54

ELECTRICAL TROUBLESHOOTING GUIDE

3. NO AUDIO CHECK

B

pin37 ~ 40,

pin47 ~ 50 of IC202,

FL/FR/RL/RR signal

FL/FR/RL/RR signal

IC700, IC701, IC702, IC703

FL/FR audio signal OK?

OK?

YES

IC203, IC204

OK?

YES

Pin13 of

YES

Check IC700 ~ IC703.

NO

Check IC202.

NO

Check IC203, IC204.

NO

NO

Check IC202.

NO

Check IC205.

NO

Check IC704, IC705.

Pin41,42,45,46

of IC202, SW1±, SW2±

signal OK?

YES

IC205

SW1, SW2 audio signal

OK?

YES

Pin13 of IC704, IC705

SW1, SW2 audio signal OK?

YES

±66 V, -12 V, ±5 V

power voltage OK?

YES

Is Q705 ~ Q708,

Q717, Q718 OK?

YES

NO

Check SMPS.

NO

Check

Q705 ~ Q708,

Q711 ~ Q714

.

Check speaker cable connection.

OK

Check Q715 ~ Q718.

3-33

NO

Check SMPS.

NO

±66 V, -12 V, ±5 V

power voltage OK?

YES

Is Q715 ~ Q718

OK?

YES

Page 55

WAVEFORMS OF MAJOR CHECK POINT

XI

XO

XI

XO

1. DSP (IC501)

X

1

3

X

4

2

Fig 1-1. X501

Crystal of RTC 32.768 MHz

(R5D6)

Crystal of system 24 MHz

( MAIN DSP : R508, C503 )

Fig 1-2. X500

3

2

1

4

3-34

Page 56

2. PWM (IC202)

XI

XO

X

5

7

8

6

9

Fig 2-1. X200

Crystal 24.576 MHz

(IC202 pin4, pin5)

Fig 2-2. IC202 pin26 ~ pin30

DSP to PWM I2S

9

7 8

6 5

3-35

Page 57

3. SERVO (IC401)

XI

XO

X

10

11

12

Fig 3-1. X400

Crystal 16.9344 MHz

Fig 3-2. CD-16M

(IC401 pin31)

11

10

12

3-36

Page 58

4. MOTOR DRIVER (IC400)

13

17

14

15

16

19

20

Fig 4-1. IC400 pin6, pin7, pin9, pin10

LO- & LO+/ MOT_OPEN & MOT_CLOSE

for Driving TRAY Motor

18

Fig 4-2. IC400 pin11, pin12

SL- & SL+ for Driving SPINDLE Motor

Fig 4-3. IC400 pin17, pin18

SP- & SP+ for Driving SPINDLE Motor

1614

1513

1817

2019

3-37

Page 59

5. ADC (IC201) 6. USB (CN502)

21

22

24

23

25

Fig 5. IC201 pin42 ~ pin44

ADC I2S

Fig 6. CN502 pin 5, pin6, pin8, pin9

USB D+/ D-

23

22

21

3-38

25

24

Page 60

7. BLUETOOTH (CN504)

BT_TX

BT_RX

BT_RST

26

27

28

Fig 7. CN504 pin4, pin6, pin9

BT_TX/ BT_RX/ BT_RST

26

27

28

3-39

Page 61

3-40

Page 62

3-41 3-42

IC501

MLC3730

IC401

RF IC

BU9546

IC202

PWM

PS9860

IC101

MICOM

R5F100G

IC201

ADC

CS5346

IC206

ADC

PCM1808

IC503

F/S 8M

W25Q64

IC502

SDRAM

W9812G

IC30A1

MIC AMP

DRV632

IC400

Motor DR

AM5890

IC603

EXPENDER

TLC5928

IC604

DRV632

IC602

DAC

PCM5101

TUNER

MIC

2

MIC

1

PTB

29 P

29 P

10 P

10 P

10 P

10 P

23 P

23 P

8 P

USB 1 USB 2

FRONT_CTRL

Board

MAIN Board

FRONT Board

8 P

10 P

BLUETOOTH

Module

AUX IN/ OUT

SPEAKER LED

IC203

4580

IC204

S4308

IC205

S4308

MD

15 P

6 P

15 P

6 P

SMPS

HARNESS CABLE

FFC CABLE

FL

RL FR

RRW1 W2

Q705

/ Q706

Q707

/ Q708

Q717

/ Q718

Q715

/ Q716

Q713

/ Q714

Q711

/ Q712

IC700

IC701 IC705

IC704

IC703

IC702

WIRING DIAGRAM

Page 63

3-43 3-44

BLOCK DIAGRAMS

1. SYSTEM BLOCK DIAGRAM

(±5V)

(±66V)

DRIVER

IRS2092

OP AMP

AZ4580

FET

IRF6775

X2

DRIVER

IRS2092

OP AMP

AZ4580

FET

IRF6775

X2

DRIVER

IRS2092

OP AMP

AZ4580

FET

IRF6775

X2

DRIVER

IRS2092

OP AMP

AZ4580

FET

IRF6775

X2

DRIVER

IRS2092

OP AMP

AZ4580

FET

IRF6775

X2

MLC3730

Main DSP

(+3.3 V_CD, VCC 1.2)

DECK

MECHANISM

M

P/ UP

(VCC50)

FRONT

IR

Receiver

VFD

8BT278INK

Volume/

Key/switch

(+3.3 VA, +12 V)

AM5890

Motor Drive

USB 1

USB 2

SERVO

BU9546

(4X Speed)

IC201

ADC

CS5346

PRE, AMP

DRV632

PS9860

PWM

E2PROM

CLK/ DAT

DRM_WEN/ CAS/

RAS/ SEL/ CLK/ CKE

Speaker Lighting

AMP_OSC

ADC_DATA

MCS_BCK/ LRCK/ MCLK

EEPROM

RL

FL

SW1

RR

FR

IR_IN_RL

RL_OUT_P/ N

FL_OUT_P/ N

RR_OUT_P/ N

FR_OUT_P/ N

M00_15

A00_16

SF_DI/ DO

SF_CS/ SCK

VFD_STB/ CLK/ DO/ RST,

VKK, FL+/ -

RMC

MAIN VOL_A/ B,

KEY 1/ 2

SE

OP_SW, CL_SW, UP_SW, DN_SW, D_SENSE

MOT_MUTE, CLOSE, OPEN

A, B, C, D, E, F,

PD

LD

SPDO/ SLDO

/ FOD/ TRD

LOAD±, SLED±,

SPIN±, T

R±, F±

D2S+/ -

IR_IN_FL

IR_IN_SW1

IR_IN_RR

IR_IN_FR

PWM_LRCK/ BCK/ DATA

DSP_O_DATA

EXP_DATA

CD_RW/ MCLK/ LR C K/

BCK, CD_DAT

CD_RST

UART_RX/TX

2

S

For AUX

For MIC

PGPC08

IC101

MICOM

PCM1808

SCRATCH A/ B,

M_VOL_A/ B,

FAN_CTRL 1/ 2,

Search_A / B, EQ HIGH/ LOW

R/ G/ B/ W x 2 ea

SW1_OUT_P/ N

SW2_OUT_P/ N

DRIVER

IRS2092

OP AMP

AZ4580

FET

IRF6775

X2

SW2

IR_IN_SW2

32 MB (256 Mb)

SDRAM

16 MB (128 Mb)

S/ Flash

Page 64

3-45 3-46

2. SMPS BLOCK DIAGRAM

Digital

Power

AMP

R_ L

R_R

SW

AC Line

Filter Block

(Varistor ,

X-Cap

Line Filter

Thermistor )

Half Bridge

LLC

Resonant IC

(SSC9527S)

FET

20.2 A

600 V

4 EA

12 V

5.6 VA

+PVDD

(66 V)

AC

MAIN SMPS IC

(STR-2A153D)

Flyback

MAIN

TRANS

u- co m / B T

USB / MPEG

Motor Dirve

FAN/LED/Mic

PFC

P-CTRL

-5 V

-PVDD

(-66 V)

GATE

Half

Bridge

LLC

TRANS

(AMP)

OPAMP

AMP

P-CTRL

Totem

pole

PFC IC

(R2A20112A)

Interleaved

DCM

FET

23.8 A

600 V

4 EA

Gate

Drive

+

PFC Out

(380 V)

Ǿ

+

Ǿ

Ǿ

Ǿ

Ǿ

Ǿ

Vcc

Vcc

On/ Off

On/ Off

On/ Off

On/ Off

F_R

F_L

14 VA VFD

Ǿ

Page 65

CIRCUIT VOLTAGE CHART

1. CAPACITOR VOLTAGE

3-71 3-72

Location Value Capacitor (uF) Voltage_Spec (V)

100 V - 10 % 240 V/ 50 Hz +10 %

Measured voltage (V) Measured voltage (V)

SMPS Board

C904

330 450 393 393

C926 47 50 15.7 16

C927 47 50 17 17.5

C930 68 450 138 336

C936 1000 16 5.65 5.65

C937 2200 16 5.67 5.67

C939 10 50 3.2 3.2

C944 1000 25 12.7 12.73

C948 220 25 7.24 7.24

C957 220 25 12.68 12.7

C963 3300 25 16.35 16.35

C964 220 25 12.05 12.05

C966 1000 80 66.46 66.45

C968 1000 80 65.9 65.9

MAIN/ FRONT Board

C231 100 16 4.89 4.89

C238 220 6.3 3.26 3.26

C240 220 6.3 1.24 1.24

C308 47 16 5.14 5.14

C347 470 10 3.37 3.37

C402 100 16 4.90 4.90

C404 47 16 3.28 3.28

C409 47 16 3.28 3.28

C416 47 16 1.63 1.63

C418 3.3 50 0.49 0.49

C427 220 16 4.91 4.91

C501 220 6.3 2.93 2.93

C5C9 1000 6.3 3.25 3.25

C707 2200 80 65.8 65.8

C728 2200 80 65.8 65.8

C752 1000 80 65.8 65.8

C752-*1 2200 80 65.8 65.8

C798 1000 80 65.8 65.8

C798-*1 2200 80 65.8 65.8

Page 66

3-73 3-74

PRINTED CIRCUIT BOARD DIAGRAMS

1. SMPS P.C.BOARD

(TOP VIEW)

Page 67

3-75 3-76

SMPS P.C.BOARD

(BOTTOM VIEW)

NOTE) Warning

Parts that are critical with respect to risk

of fire or electrical shock.

Page 68

3-77 3-78

2. MAIN P.C.BOARD

(TOP VIEW)

Page 69

3-79 3-80

MAIN P.C.BOARD

(BOTTOM VIEW)

Page 70

3-81 3-82

3. FRONT P.C.BOARD

(TOP VIEW)

Page 71

3-83 3-84

FRONT P.C.BOARD

(BOTTOM VIEW)

Page 72

3-85 3-86

4. FRONT CONTROL P.C.BOARD

(TOP VIEW)

(BOTTOM VIEW)

Page 73

3-87 3-88

Page 74

SECTION 4

MECHANISM (DM14AA)

CONTENTS

DECK MECHANISM DISASSEMBLY

1. Cover Top ............................................................................................................................................... 4-2

2. Clamp Assembly .....................................................................................................................................4-2

2-1. Plate ................................................................................................................................................. 4-2

2-2. Magnet ............................................................................................................................................. 4-2

2-3. Clamp ...............................................................................................................................................4-2

3. Tray Disc ................................................................................................................................................. 4-3

4. Pick Up Assembly ................................................................................................................................... 4-4

5. Base Up/Down ........................................................................................................................................4-4

6. Belt Loading ............................................................................................................................................4-5

7. Gear Pulley ............................................................................................................................................. 4-5

8. Gear Loading ..........................................................................................................................................4-5

9. Guide .......................................................................................................................................................4-5

10. Deck PCB Assembly ...............................................................................................................................4-5

11. Motor Assembly ...................................................................................................................................... 4-5

12. FFC Cable ............................................................................................................................................... 4-5

DECK MECHANISM EXPLODED VIEW (DM14AA) ......................................................................................... 4-6

4-1

Page 75

(S1)

DECK MECHANISM DISASSEMBLY

1

Cover Top

1

Clamp

Assembly

2

3

Clamp Assembly

Plate

Magnet

2

Clamp

(L1)

< Figure A >

1. Cover Top

1) Remove the 2 screws (S1).

2) Unhook the 4 Locking Tabs (L1) by using a

flat-head screwdriver.

3) Remove the Cover Top.

< Figure B >

2. Clamp Assembly

1) Place the Clamp Assembly as Figure B.

2) Bending the Cover Top in direction of

arrow (2) as Figure B.

3) Separate the Clamp Assembly from the

Cover Top.

2-1. Plate

1) Turn the Plate to a counterclockwise direction

and then lift up the Plate.

2) Remove the Plate.

2-2. Magnet

Remove the Magnet.

2-3. Clamp

Remove the Clamp.

4-2

Page 76

DECK MECHANISM DISASSEMBLY

Emergency eject hole

Tray Disc

2

1

< Bottom side view >

Tray Disc

< Figure C >

(H1)

MD Sub

Assembly

1 1

22

3

Tray Disc

< Figure D >

3) Grasp the both sides of the Tray Disc and lift

it up as Figure D, and then pull the Tray Disc

until it is separated from the MD Sub Assembly

completely.

3. Tray Disc

1)

Insert and push a flat-head screwdriver in the

Emergency eject hole (H1) at the right side, so

that the Tray Disc is ejected about 15 ~ 20 mm.

2) Pull the Tray Disc until it is locked.

Guide

Tray Disc

< Figure E >

Note

• When reassembling place the Guide as Figure E.

4-3

Page 77

DECK MECHANISM DISASSEMBLY

BLK

RED

BRN

ORN

RED

BK

Gasket Tape

Rubber

Damper

5

4

1

< Bottom side view >

FFC Cable

(S2)

2

Deck PCB

Assembly

3

Pick Up

Assembly

Base Up/Down

(L2)

Base Main

(D)

(B)

3

1

2

(H2)

Figure G-3

(A)

Figure G-2Figure G-1

(C)

Guide

(B)

Base

Up/Down

< Figure F >

4. Pick Up Assembly

1) Detach the Gasket Tape.

2) Disconnect the wires (BLK, RED, BRN, ORN)

from the Deck PCB Assembly by desoldering.

3) Remove the 4 screws (S2).

4) Disconnect the FFC Cable from the Pick Up

Assembly.

5) Remove the 4 Rubber Dampers.

< Figure G >

5. Base Up/Down

Unlock the Locking Tab (L2) in direction of arrow

and then lift up the Base Up/Down to separate it

from the Base Main.

Note

• When reassembling move the Guide in direction

of arrow (A) until it is positioned as Figure G-1.

• When reassembling insert the (B) portion of the

Base Up/Down in the (C) portion of the Guide as

Figure G-2.

• When reassembling insert the (D) portion of the

Base Up/Down in the Hole (H2) of the Base Main

as Figure G-3.

4-4

Page 78

DECK MECHANISM DISASSEMBLY

RE

BR

ORN

RED

BK

Gear Loading

Gear Pulley

(L3)

< Bottom side view >

Belt Loading

Base Main

(A)

Figure H-1

Guide

(B)

Base Main

(L4)

< Bottom side view >

6. Belt Loading

Remove the Belt Loading.

7. Gear Pulley

Unlock the Locking Tab (L3) in direction of arrow

and then separate the Gear Pulley from the Base

Main.

8. Gear Loading

Remove the Gear Loading.

9. Guide

1) Move the Guide in direction of arrow (A) as

Figure H-1.

2) Separate the Guide from the Base Main.

Motor

Assembly

(S3)

< Figure H >

10. Deck PCB Assembly

11. Motor Assembly

12. FFC Cable

Deck PCB

< Bottom side view >

Deck PCB

Assembly

Assembly

1) Disconnect the wires (RED, BK) form the

Deck PCB Assembly by desoldering.

2) Remove the 1 screw (S3).

3) Separate the Deck PCB Assembly from the

Base Main.

Unlock the Locking Tab (L4) in direction of

arrow and then separate the Motor Assembly

from the Base Main.

Remove the FFC Cable.

4-5

Page 79

DECK MECHANISM EXPLODED VIEW (DM14AA)

1439

1013

1026

1016

1015

1012

1003

1024

1437

1049

1020

1005

1004

1024

1001

1002

1024

A001

1030

1437

1024

1437

A006

1019

1018

1439

1043

1045

1011

A005

4-6

Loading...

Loading...