Page 1

MODEL : BH100

SERVICE MANUAL

P/NO : AFN33673316

http://biz.lgservice.com

MARCH, 2007

Super Multi Blue Player

SERVICE MANUAL

MODEL : BH100

CAUTION

BEFORE SERVICING THE UNIT, READ THE “SAFETY PRECAUTIONS”

IN THIS MANUAL.

Page 2

CONTENTS

SECTION 1.........SUMMARY

SECTION 2.........CABINET & MAIN CHASSIS

SECTION 3.........ELECTRICAL

SECTION 4.........HL-01P LOADER PART

SECTION 5.........REPLACEMENT PARTS LIST

Page 3

1-2

SECTION 1

SUMMARY

CONTENTS

PRODUCT SAFETY SERVICING GUIDELINES FOR SUPER MULTI BLUE PLAYER

PRODUCTS

....................................................................................................................................................1-3

SERVICING PRECAUTIONS....................................................................................................................1-4

• GENERAL SERVICING PRECAUTIONS

• INSULATION CHECKING PRODEDURE

• ELECTROSTATICALLY SENSITIVE (ES) DEVICES

SERVICE INFORMATION FOR EEPROM IC SETTING..................................................................1-5

DISC UPGRADE ...........................................................................................................................................1-6

SPECIFICATIONS ........................................................................................................................................1-7

Page 4

1-3

PRODUCT SAFETY SERVICING GUIDELINES FOR

SUPER MULTI BLUE PLAYER PRODUCTS

IMPORTANT SAFETY NOTICE

This manual was prepared for use only by properly trained audio-video service

technicians.

When servicing this product, under no circumstances should the original design be

modified or altered without permission from LG Corporation. All components should

be replaced only with types identical to those in the original circuit and their physical

location, wiring and lead dress must conform to original layout upon completion of

repairs.

Special components are also used to prevent x-radiation, shock and fire hazard.

These components are indicated by the letter “x” included in their component

designators and are required to maintain safe performance. No deviations are

allowed without prior approval by LG Corporation.

Circuit diagrams may occasionally differ from the actual circuit used. This way,

implementation of the latest safety and performance improvement changes into the

set is not delayed until the new service literature is printed.

CAUTION

: Do not attempt to modify this product in any way. Never perform

customized installations without manufacturer’s approval. Unauthorized

modifications will not only void the warranty, but may lead to property damage or user

injury.

Service work should be performed only after you are thoroughly familiar with these

safety checks and servicing guidelines.

GRAPHIC SYMBOLS

The exclamation point within an equilateral triangle is intended to alert

the service personnel to important safety information in the service

literature.

The lightning flash with arrowhead symbol within an equilateral

triangle is intended to alert the service personnel to the presence of

noninsulated “dangerous voltage” that may be of sufficient magnitude

to constitute a risk of electric shock.

The pictorial representation of a fuse and its rating within an equilateral

triangle is intended to convey to the service personnel the following

fuse replacement caution notice:

CAUTION : FOR CONTINUED PROTECTION AGAINST RISK OF

FIRE, REPLACE ALL FUSES WITH THE SAME TYPE AND

RATING AS MARKED NEAR EACH FUSE.

SERVICE INFORMATION

While servicing, use an isolation transformer for protection from AC line shock. After

the original service problem has been corrected, make a check of the following:

FIRE AND SHOCK HAZARD

1. Be sure that all components are positioned to avoid a possibility of adjacent

component shorts. This is especially important on items trans-ported to and from

the repair shop.

2. Verify that all protective devices such as insulators, barriers, covers, shields, strain

reliefs, power supply cords, and other hardware have been reinstalled per the

original design. Be sure that the safety purpose of the polarized line plug has not

been defeated.

3. Soldering must be inspected to discover possible cold solder joints, solder

splashes, or sharp solder points. Be certain to remove all loose foreign particles.

4. Check for physical evidence of damage or deterioration to parts and components,

for frayed leads or damaged insulation (including the AC cord), and replace if

necessary.

5. No lead or component should touch a high current device or a resistor rated at 1

watt or more. Lead tension around protruding metal surfaces must be avoided.

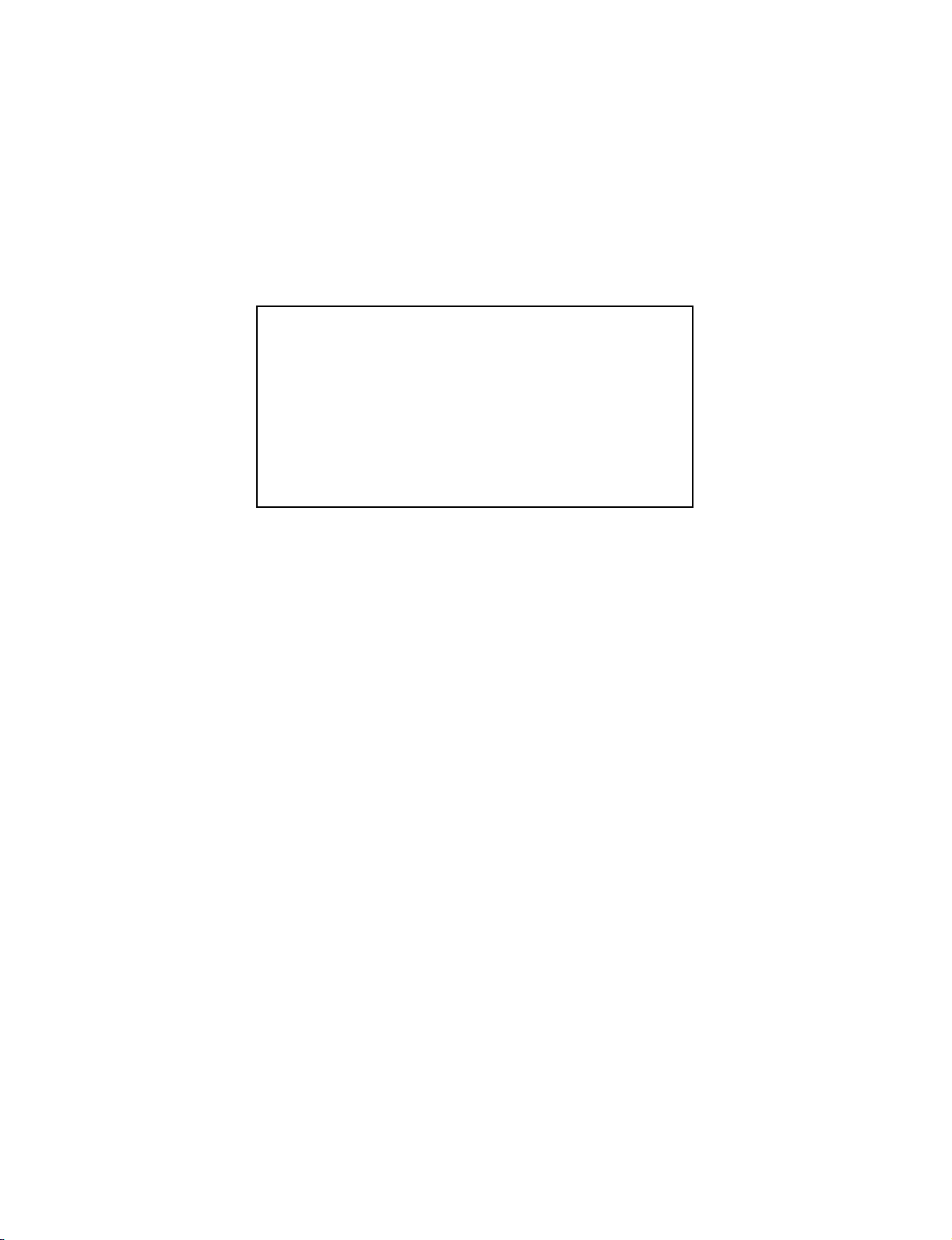

6. After reassembly of the set, always perform an AC leakage test on all exposed

metallic parts of the cabinet (the channel selector knobs, antenna terminals,

handle and screws) to be sure that set is safe to operate without danger of

electrical shock. DO NOT USE A LINE ISOLATION TRANSFORMER DURING

THIS TEST. Use an AC voltmeter having 5000 ohms per volt or more sensitivity

in the following manner: Connect a 1500 ohm, 10 watt resistor, paralleled by a .15

mfd 150V AC type capacitor between a known good earth ground water pipe,

conduit, etc.) and the exposed metallic parts, one at a time. Measure the AC

voltage across the combination of 1500 ohm resistor and .15 mfd capacitor.

Reverse the AC plug by using a non-polarized adaptor and repeat AC voltage

measurements for each exposed metallic part. Voltage measured must not

exceed 0.75 volts RMS. This corresponds to 0.5 milliamp AC. Any value

exceeding this limit constitutes a potential shock hazard and must be corrected

immediately.

TIPS ON PROPER INSTALLATION

1. Never install any receiver in a closed-in recess, cubbyhole, or closely fitting shelf

space over, or close to, a heat duct, or in the path of heated air flow.

2. Avoid conditions of high humidity such as: outdoor patio installations where dew

is a factor, near steam radiators where steam leakage is a factor, etc.

3. Avoid placement where draperies may obstruct venting. The customer should also

avoid the use of decorative scarves or other coverings that might obstruct

ventilation.

4. Wall- and shelf-mounted installations using a commercial mounting kit must follow

the factory-approved mounting instructions. A product mounted to a shelf or

platform must retain its original feet (or the equivalent thickness in spacers) to

provide adequate air flow across the bottom. Bolts or screws used for fasteners

must not touch any parts or wiring. Perform leakage tests on customized

installations.

5. Caution customers against mounting a product on a sloping shelf or in a tilted

position, unless the receiver is properly secured.

6. A product on a roll-about cart should be stable in its mounting to the cart.

Caution the customer on the hazards of trying to roll a cart with small casters

across thresholds or deep pile carpets.

7. Caution customers against using extension cords. Explain that a forest of

extensions, sprouting from a single outlet, can lead to disastrous consequences to

home and family.

Page 5

1-4

SERVICING PRECAUTIONS

CAUTION: Before servicing the Super Multi Blue Player

covered by this service data and its supplements and

addends, read and follow the SAFETY PRECAUTIONS.

NOTE: if unforeseen circumstances create conflict between

the following servicing precautions and any of the safety

precautions in this publications, always follow the safety

precautions.

Remember Safety First :

General Servicing Precautions

1.Always unplug the Super Multi Blue Player AC power cord

from the AC power source before:

(1) Removing or reinstalling any component, circuit board,

module, or any other assembly.

(2) Disconnecting or reconnecting any internal electrical

plug or other electrical connection.

(3) Connecting a test substitute in parallel with an

electrolytic capacitor.

Caution : A wrong part substitution or incorrect polarity

installation of electrolytic capacitors may result in an

explosion hazard.

2.Do not spray chemicals on or near this Super Multi Blue

Player or any of its assemblies.

3.Unless specified otherwise in this service data, clean

electrical contacts by applying an appropriate contact

cleaning solution to the contacts with a pipe cleaner,

cotton-tipped swab, or comparable soft applicator.

Unless specified otherwise in this service data, lubrication

of contacts is not required.

4.Do not defeat any plug/socket B+ voltage interlocks with

whitch instruments covered by this service manual might

be equipped.

5.Do not apply AC power to this Super Multi Blue Player and

/ or any of its electrical assemblies unless all solidstate

device heat sinks are correctly installed.

6.Always connect the test instrument ground lead to an

appropriate ground before connecting the test instrument

positive lead. Always remove the test instrument ground

lead last.

Insulation Checking Procedure

Disconnect the attachment plug from the AC outlet and turn

the power on. Connect an insulation resistance meter (500V)

to the blades of the attachment plug. The insulation

resistance between each blade of the attachment plug and

accessible conductive parts (Note 1) should be more than

1Mohm.

Note 1 : Accessible Conductive Parts include Metal panels,

Input terminals, Earphone jacks,etc.

Electrostatically Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged

easily by static electricity. Such components commonly are

called Electrostatically Sensitive (ES) Devices. Examples of

typical ES devices are integrated circuits and some field

effect transistors and semiconductor chip components.

The following techniques should be used to help reduce the

incidence of component damage caused by static electricity.

1.Immediately before handling any semiconductor

component or semiconductor-equipped assembly, drain off

any electrostatic charge on your body by touching a known

earth ground. Alternatively, obtain and wear a

commercially available discharging wrist strap device,

which should be removed for potential shock reasons prior

to applying power to the unit under test.

2.After removing an electrical assembly equipped with ES

devices, place the assembly on a conductive surface such

as aluminum foil, to prevent electrostatic charge buildup or

exposure of the assembly.

3.Use only a grounded-tip soldering iron to solder or

unsolder ES devices.

4.Use only an anti-static solder removal device. Some solder

removal devices not classified as “anti-static” can generate

electrical charges sufficient to damage ES devices.

5.Do not use freon-propelled chemicals. These can generate

an electrical charge sufficient to damage ES devices.

6.Do not remove a replacement ES device from its

protective package until immediately before you are ready

to install it. (Most replacement ES devices are packaged

with leads electrically shorted together by conductive

foam, aluminum foil,or comparable conductive material).

7.Immediately before removing the protective material from

the leads of a replacement ES device, touch the protective

material to the chassis or circuit assembly into which the

device will be installed.

Caution: Be sure no power is applied to the chassis or

circuit, and observe all other safety precautions.

8.Minimize bodily motions when handling unpackaged

replacement ES devices. (Normally harmless motion such

as the brushing together of your clothes fabric or the lifting

of your foot from a carpeted floor can generate static

electricity sufficient to damage an ES device.)

Page 6

1-5

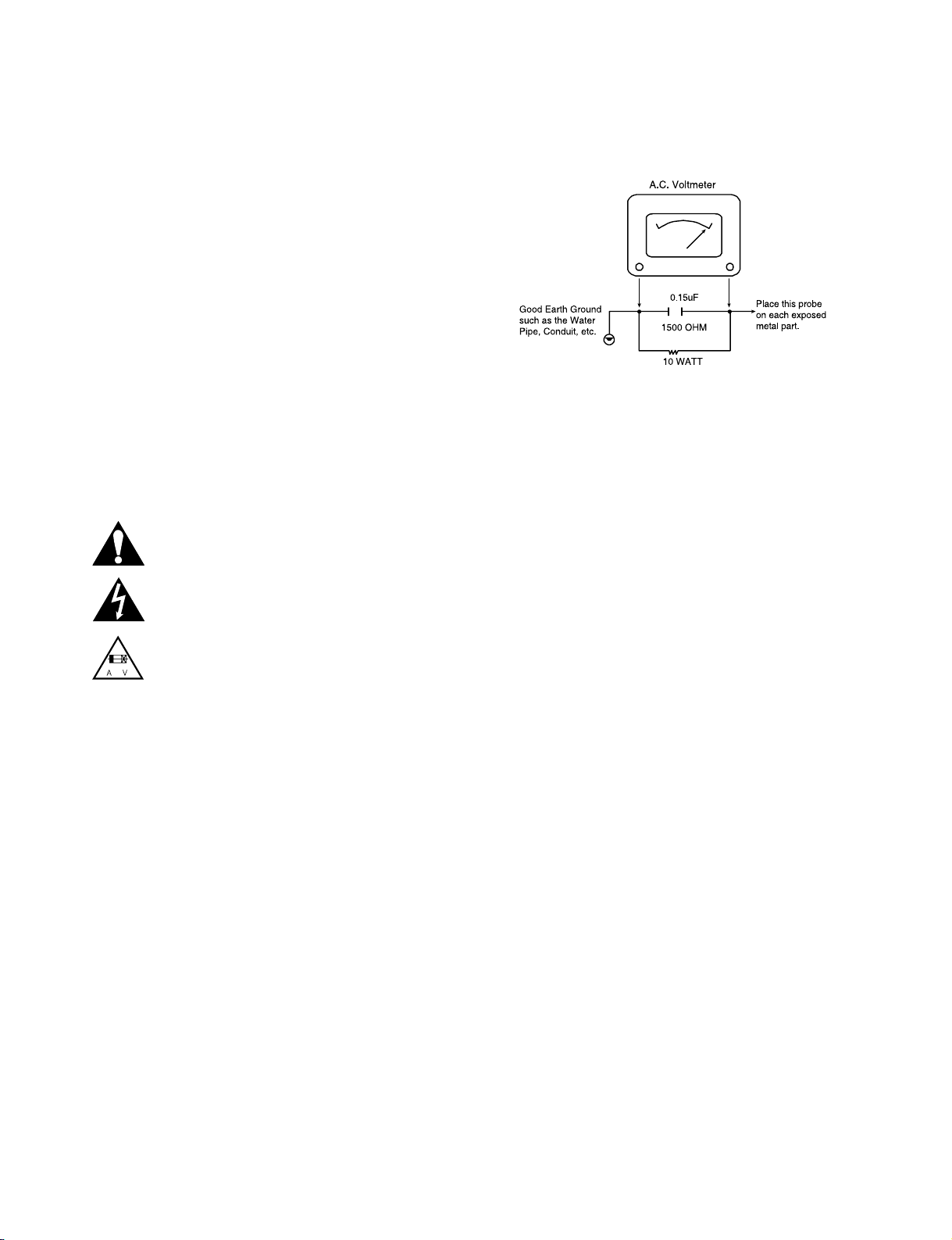

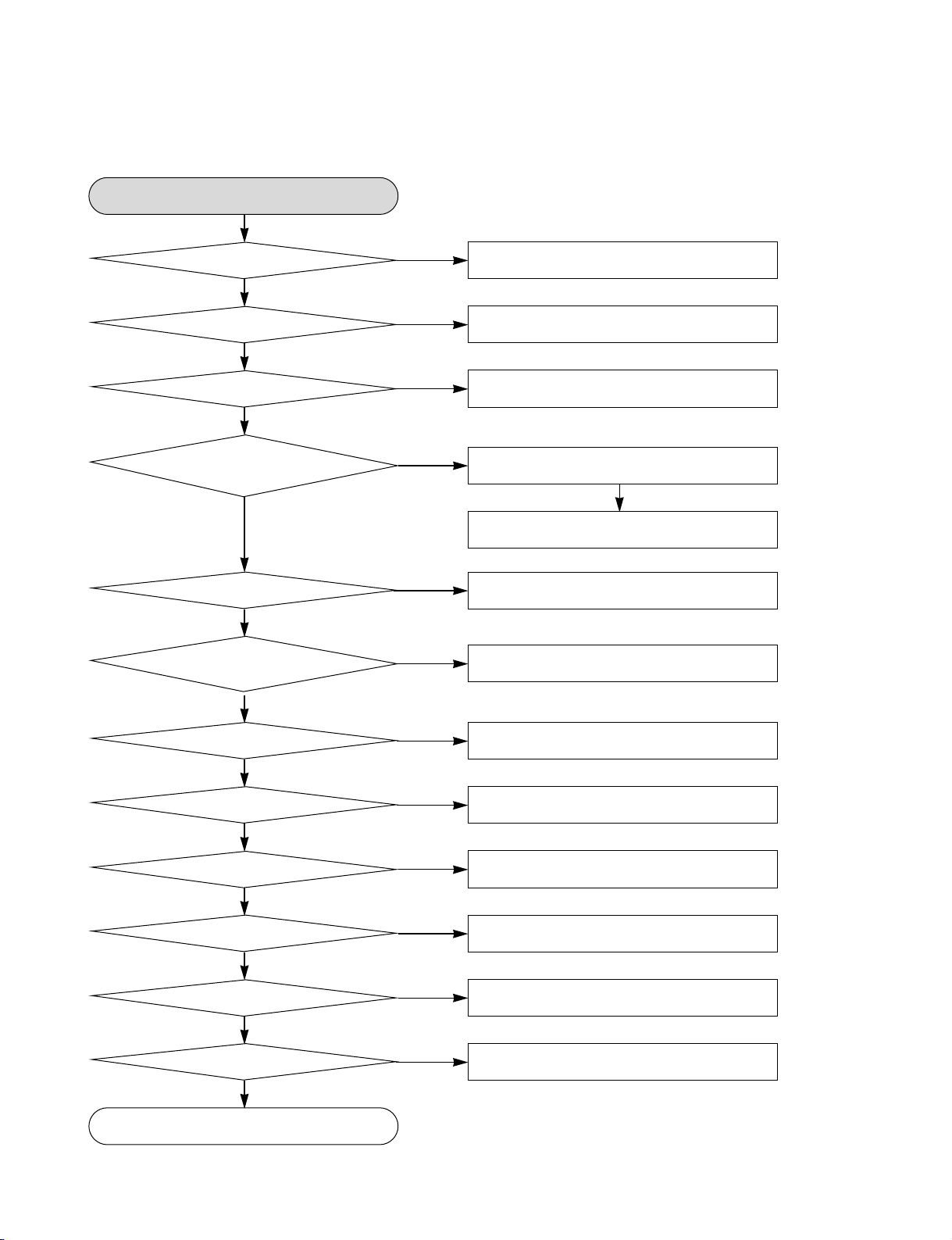

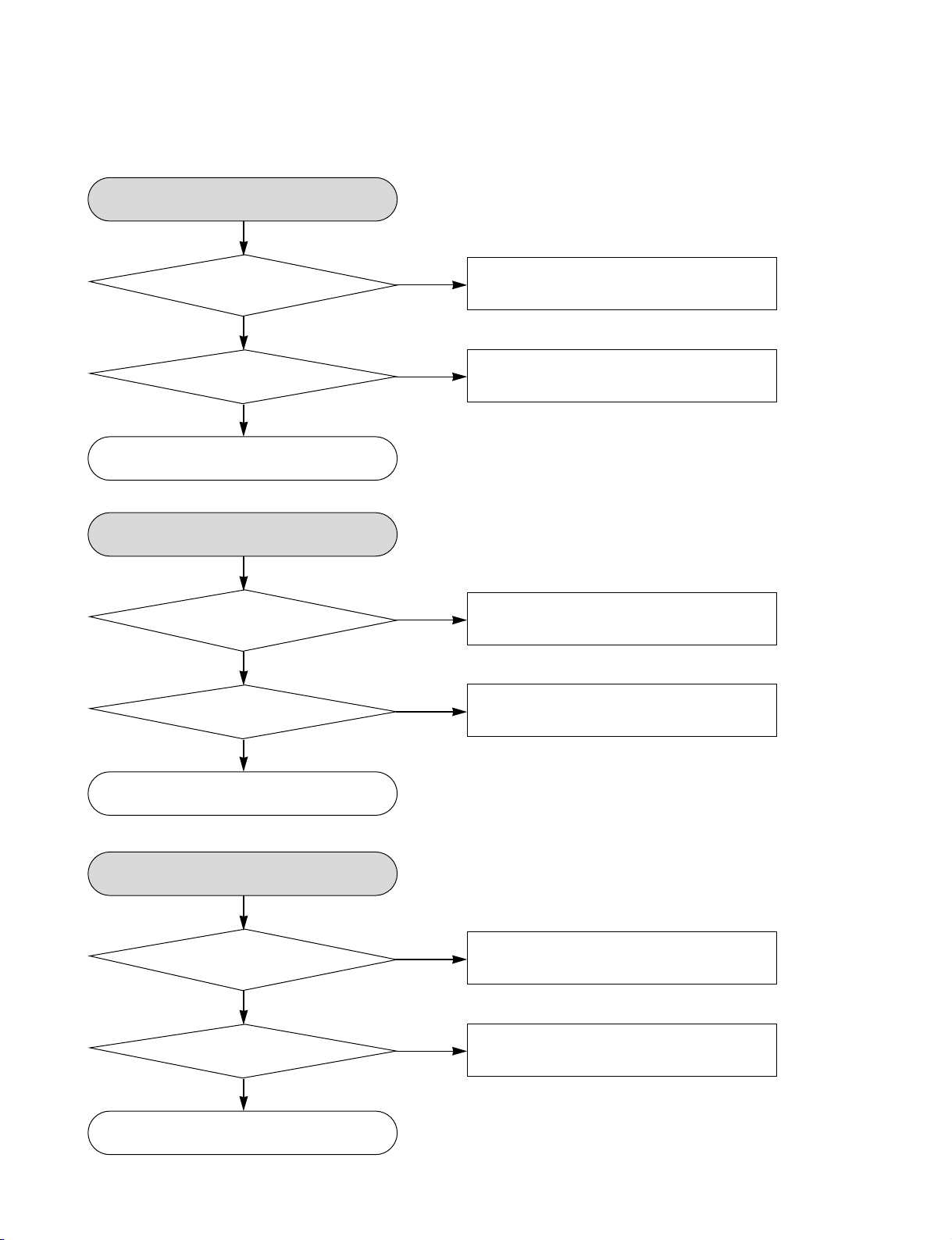

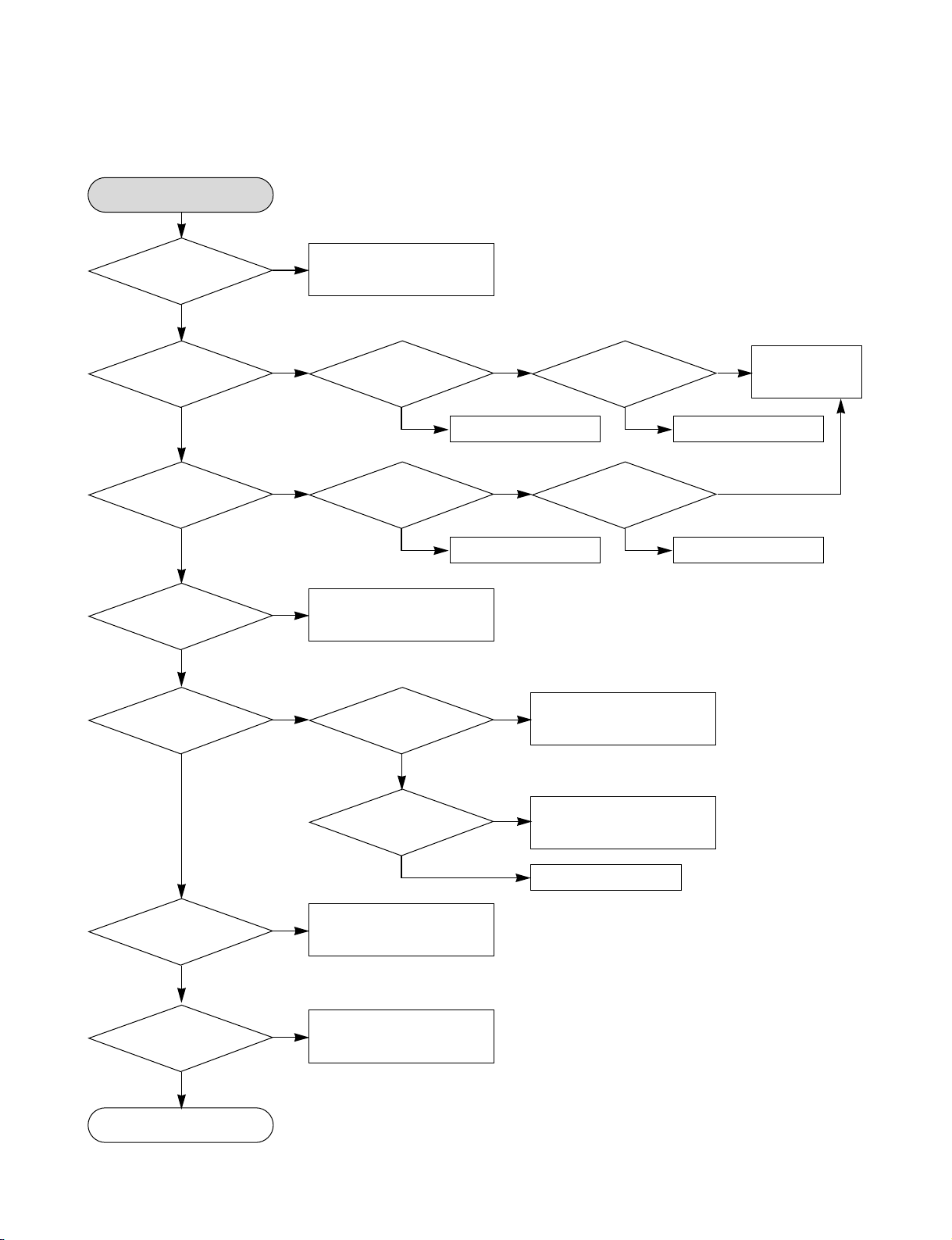

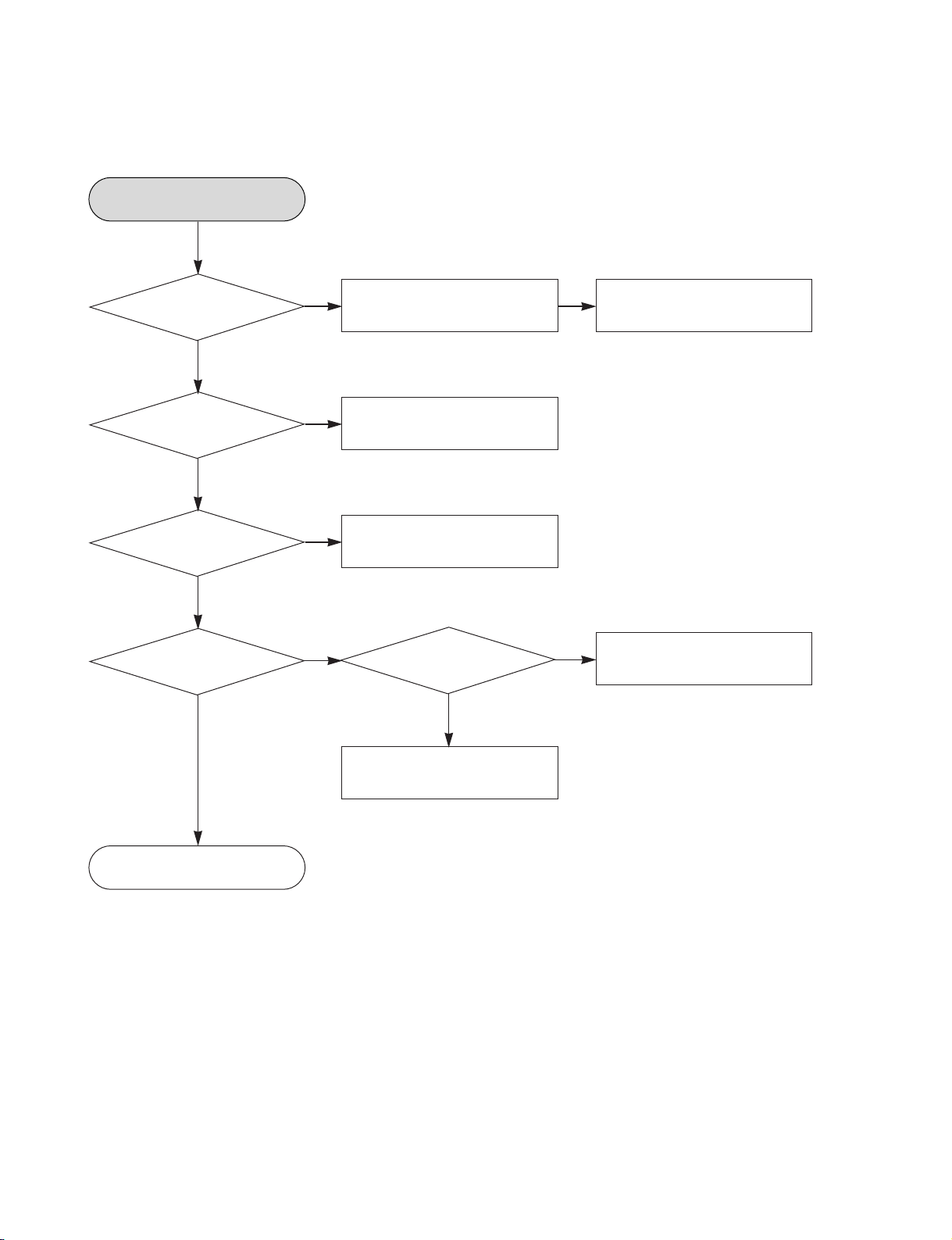

SERVICE INFORMATION FOR EEPROM IC SETTING

Option data read

YES

EEPROM ID check

(Whether a filename of

“eepromif.txt” exists or not)

YES

YES

Check the player set is

“No Disc” or “STOP” state.

Press the “PAUSE” key

and also press orderly

“1472” of number key.

Program start

*** EEPROM initial ***

- Check the player set is “No Disc” or “OPEN” state.

Move hightlight to SETUP --> Display --> TV Aspect --> 16:9 Wide.

And press orderly “1397139” + “ENTER” key of remocon.

Option confirmation mode

MICOM normal

operation start

NO

NO

EEPROM edit table

00 00 00 00 00 00 00 00

UP/DOWN key : Change the

EEPROM data

LEFT/RIGHT key : Move the

Cursor

PAUSE key : Store the

changeddata and

Exit the EEPROM

Edit Table

Detect new EEPROM

(Option edit screen)

Page 7

1-6

•Burn a DVD recordable disc using UDF format with a file that is named to “LG_BH_LX100000BN.ROM”.

• Insert a upgrading disc that was burned to UDF format only.

• Show help message for disc upgrade as follows.

<in the case of Back End Only or Front End Only burned on DISC>

Firmware Upgrade Mode [Back End]

Current Version : Vxxx.xx

New Version : Vxxx.xx

Press “PLAY” key to upgrade.

• Press play key to upgrade and it will show progress information

(Display percent[%] at VFD panel)

• After completing upgrade then it re-boot by auto.

Firmware Upgrade Mode [Back End]

Current Version : Vxxx.xx

New Version : Vxxx.xx

Upgrading ... Please Wait !!!

DISC UPGRADE

Page 8

1-7

SPECIFICATIONS

• GENERAL

Power requirements : AC 200-240V, 50/60Hz

Power consumption : 30W

Dimensions (W x H x D) : Approx. 430 x 78 x 250 mm (17 x 3.1 x 9.9 inches) without foot

Weight (Approx.) : 4.1kg (9.1 lbs)

Operating temperature : 5°C to 35°C (41°F to 95°F)

Operating humidity : 5% to 90%

• OUTPUTS

VIDEO OUT : 1.0V (p-p), 75Ω, sync negative, RCA jack x 1/SCART(TO TV)

COMPONENT VIDEO OUT : (Y) 1.0V (p-p), 75Ω,negative sync, RCA jack x 1

(Pb)/(Pr) 0.7V (p-p), 75Ω, RCA jack x 2

HDMI OUT (video/audio) : 19pin (HDMI standard, Type A)

ANALOG AUDIO OUT : 2CH : 2.0Vrms (1kHz, 0dB), 600Ω, RCA jack (L, R) x 1/SCART(TO TV)

6CH : 2.0Vrms (1kHz, 0dB), 600Ω, RCA jack x 6

DIGITAL OUT (COAXIAL) : 0.5V (p-p), 75Ω, RCA jack x 1

DIGITAL OUT (OPTICAL) : 3V (p-p), 75Ω, Optical jack x 1

• SYSTEM

Laser : Semiconductor laser, wavelength : 405nm/650nm/780nm

Signal system : Standard NTSC Color TV system

Frequency response : 8Hz to 44kHz (96 kHz Sampling)

8Hz to 22kHz (48 kHz Sampling)

Signal-to-noise ratio : More than 100dB (ANALOG OUT connectors only)

Harmonic distortion : Less than 0.008%

Dynamic range : More than 95dB

Accessories : Video cable (1), Audio cable (1), Remote control (1), Batteries (2)

Note : Design and specifications are subject to change prior notice.

Page 9

2-1

SECTION 2

CABINET & MAIN CHASSIS

CONTENTS

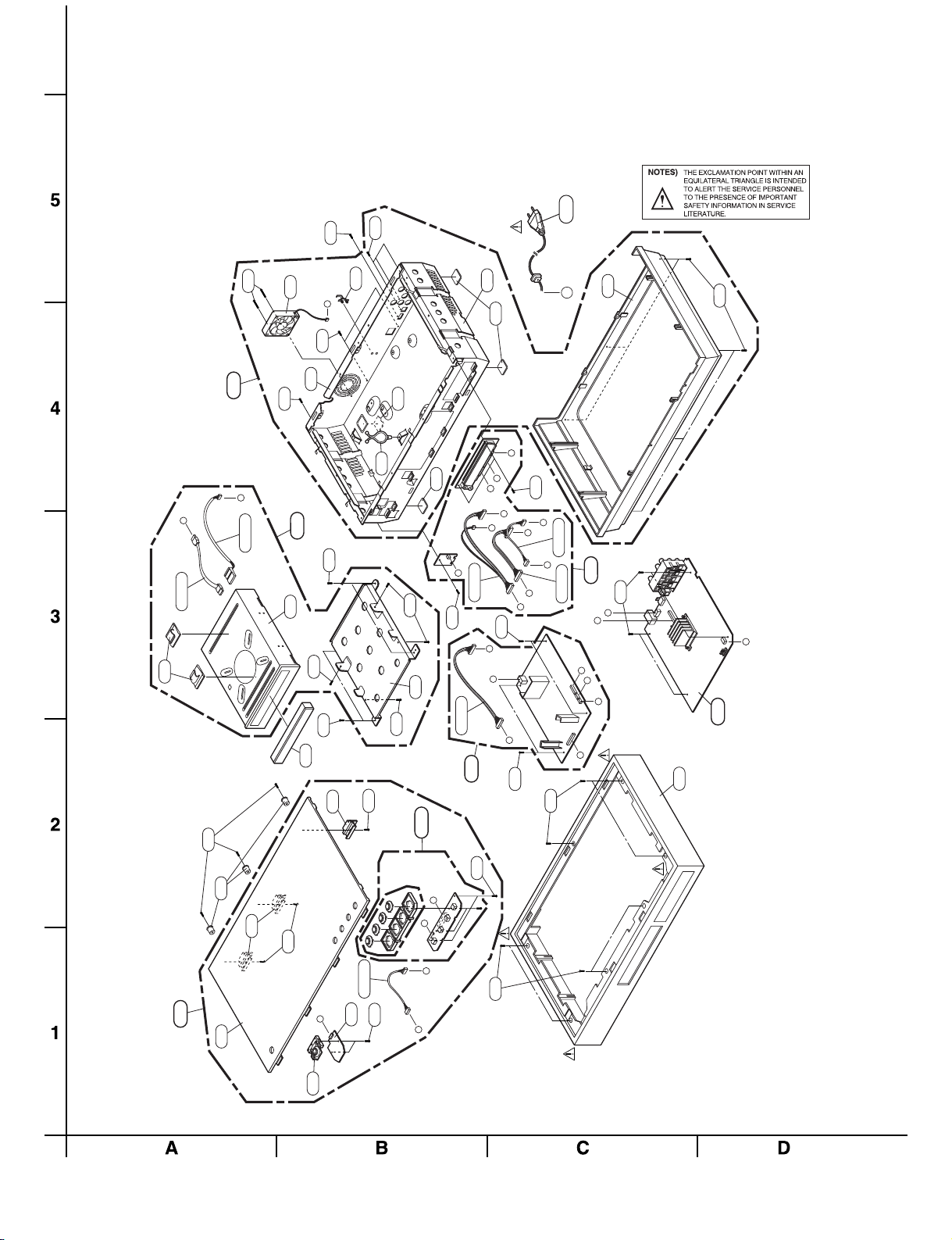

EXPLODED VIEWS .....................................................................................................................................2-2

1. CABINET AND MAIN FRAME SECTION ..................................................................................................2-2

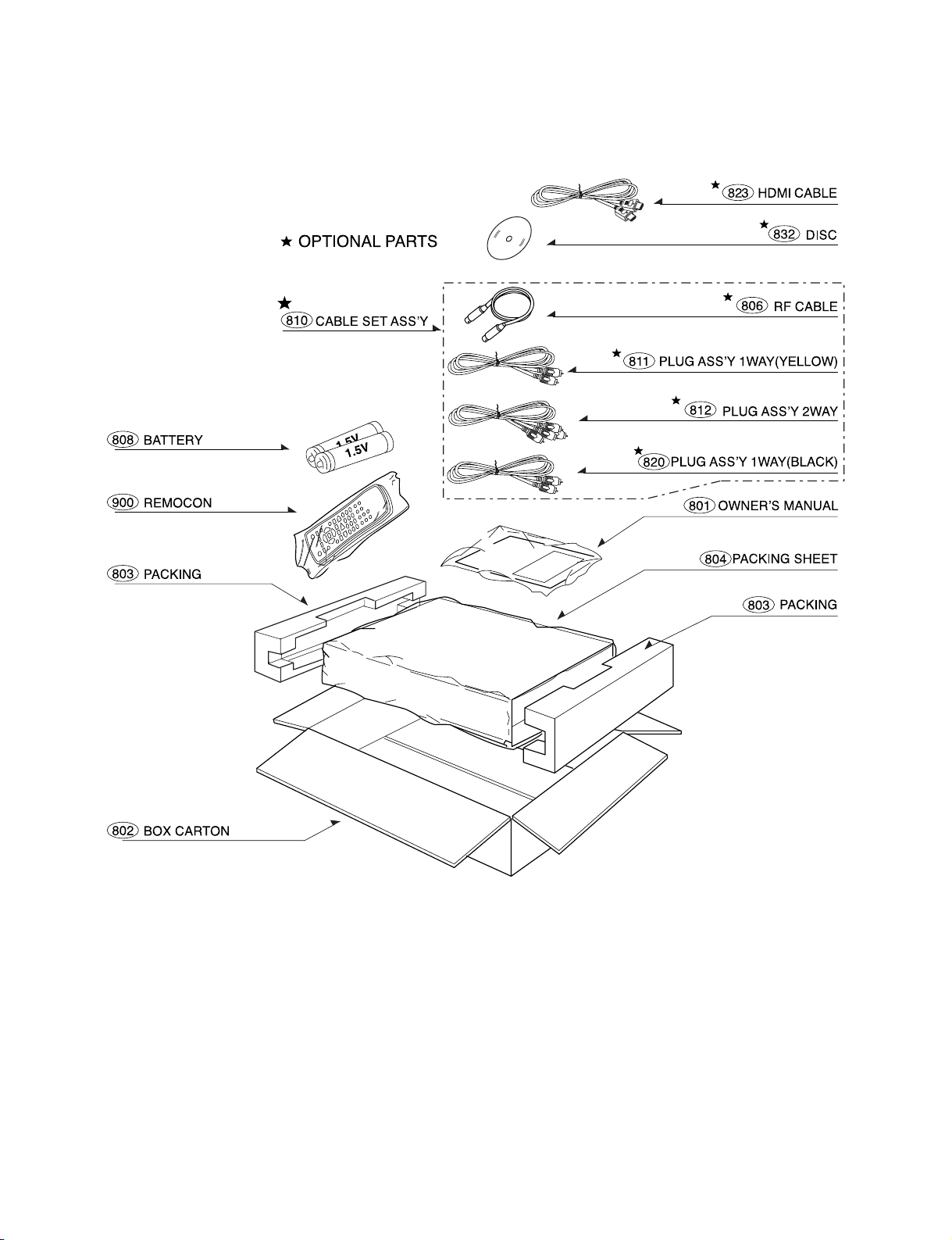

2. PACKING ACCESSORY SECTION...........................................................................................................2-3

Page 10

A

P

C

Q

E

R

P

B

J

D

R

G

K

G

H

J

Q

H

K

F

L

F

E

M

L

D

C

B

A

280

A43

284

286

469

283

253

468

330

260

465

320

265

267

467

465

465

465

466

468

468

468

261

261

261

468

468

285

468

A60

A44

A47

A50

A46

254

252

283

469

263

465

469

469

469

465

469

A43A

CABLE1

CABLE6

CABLE7

CABLE5

CABLE4

CABLE3

CABLE2

469

465

279

262

FRONT

BOARD

SMPS

BOARD

MAIN

BOARD

2-2

EXPLODED VIEWS

1. CABINET AND MAIN FRAME SECTION

M

300

Page 11

2-3

2. PACKING ACCESSORY SECTION

Page 12

3-1

SECTION 3

ELECTRICAL

CONTENTS

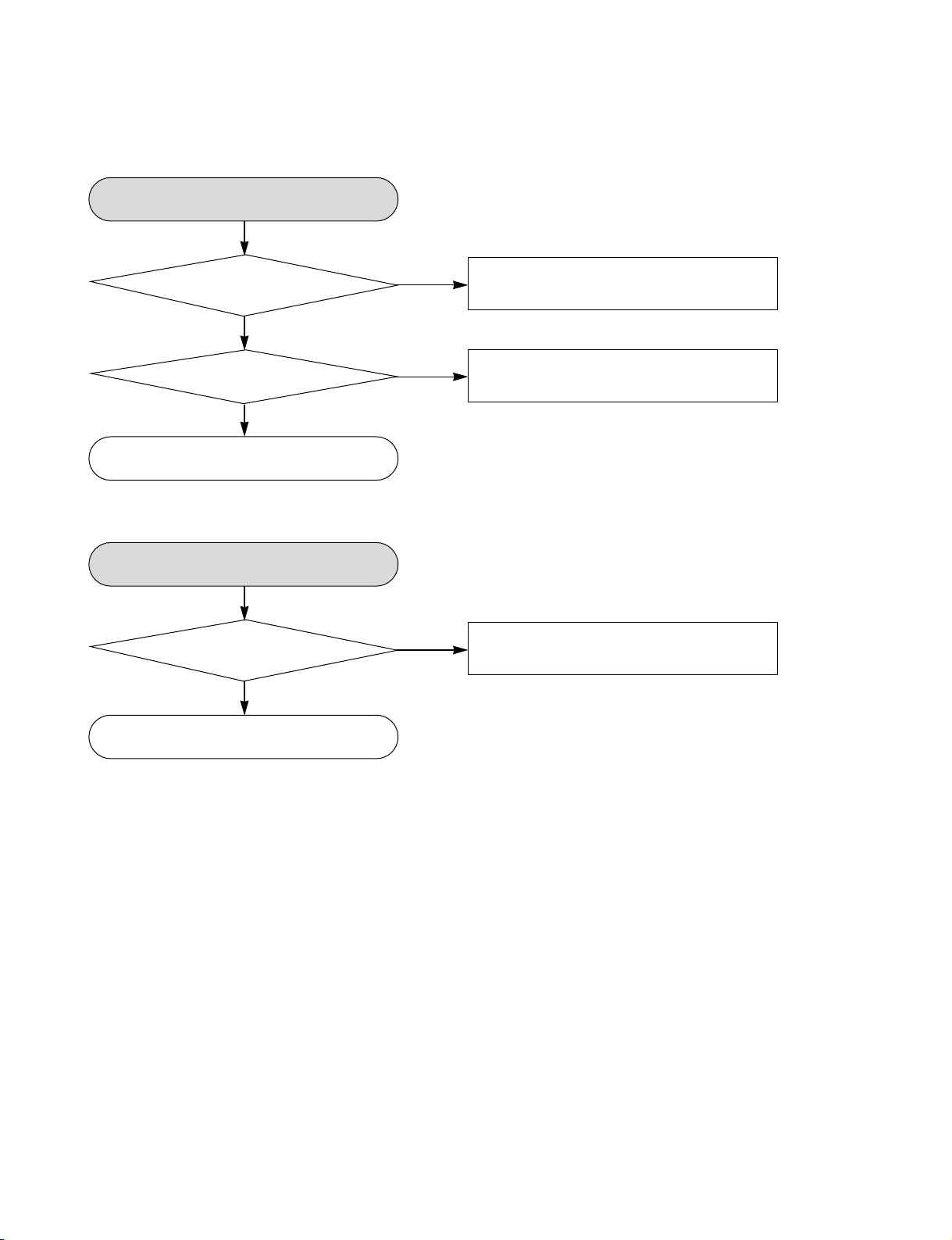

ELECTRICAL TROUBLESHOOTING GUIDE.....................................................................................3-2

1. POWER SUPPLY (SMPS).....................................................................................................................3-2

2. POWER ON ...........................................................................................................................................3-5

3. SYSTEM PART......................................................................................................................................3-6

4. VIDEO PART (COMMON) .....................................................................................................................3-7

5. COMPONENT (YPbPr) VIDEO OUT.....................................................................................................3-8

6. CVBS VIDEO OUT ................................................................................................................................3-9

7. AUDIO (ANALOG) ...............................................................................................................................3-10

8. AUDIO (S/PDIF) ...................................................................................................................................3-11

9. HDMI....................................................................................................................................................3-12

WAVEFORMS ..............................................................................................................................................3-13

1.SYSTEM PART-1..................................................................................................................................3-13

2.SYSTEM PART-2 (SYSTEM MEMORY) ..............................................................................................3-14

3.VIDEO PART-1 (100% FULL COLOR-BAR).........................................................................................3-15

4.VIDEO PART-2 (100% FULL COLOR-BAR).........................................................................................3-16

5.AUDIO PART-1 (ANALOG 5CH : 99Hz, -20dBFS / WOOFER : 30Hz, 0dBFS)...................................3-17

6.AUDIO PART-2 (S/PDIF) ......................................................................................................................3-18

7.HDMI PART...........................................................................................................................................3-19

8.FRONT I/F PART ..................................................................................................................................3-20

9.MPEG-4 DECODER PART-1................................................................................................................3-21

10.MPEG-4 DECODER PART-2................................................................................................................3-22

BLOCK DIAGRAMS ..................................................................................................................................3-23

1.OVERALL BLOCK DIAGRAM ..............................................................................................................3-23

2.SIGNAL PATH BLOCK DIAGRAM........................................................................................................3-24

3.WIRING BLOCK DIAGRAM..................................................................................................................3-25

4.FRONT BLOCK DIAGRAM...................................................................................................................3-26

5.SMPS BLOCK DIAGRAM.....................................................................................................................3-27

CIRCUIT DIAGRAMS................................................................................................................................3-29

1. SMPS (POWER) CIRCUIT DIAGRAM ................................................................................................3-29

2. DECODER-1 CIRCUIT DIAGRAM ......................................................................................................3-31

3. DECODER-2 CIRCUIT DIAGRAM ......................................................................................................3-33

4. MPEG-1 CIRCUIT DIAGRAM..............................................................................................................3-35

5. MPEG-2 CIRCUIT DIAGRAM..............................................................................................................3-37

6. 512MB SDRAM CIRCUIT DIAGRAM ..................................................................................................3-39

7. ROM, IDE, ETHERNET JTAG, UART, FP I/F CIRCUIT DIAGRAM ....................................................3-41

8. AUDIO FPGA CIRCUIT DIAGRAM......................................................................................................3-43

9. AUDIO & VIDEO CIRCUIT DIAGRAM.................................................................................................3-45

10. POWER CIRCUIT DIAGRAM..............................................................................................................3-47

11. FRONT/TIMER CIRCUIT DIAGRAM ...................................................................................................3-49

12. LOGO CIRCUIT DIAGRAM .................................................................................................................3-51

CIRCUIT VOLTAGE CHART...................................................................................................................3-53

PRINTED CIRCUIT DIAGRAMS............................................................................................................3-55

1. MAIN P.C.BOARD..................................................................................................................................3-55

2. FRONT P.C.BOARD ..............................................................................................................................3-57

3. LOGO P.C.BOARD ................................................................................................................................3-58

4. POWER P.C.BOARD.............................................................................................................................3-59

Page 13

Is the D121 normal?

3-2

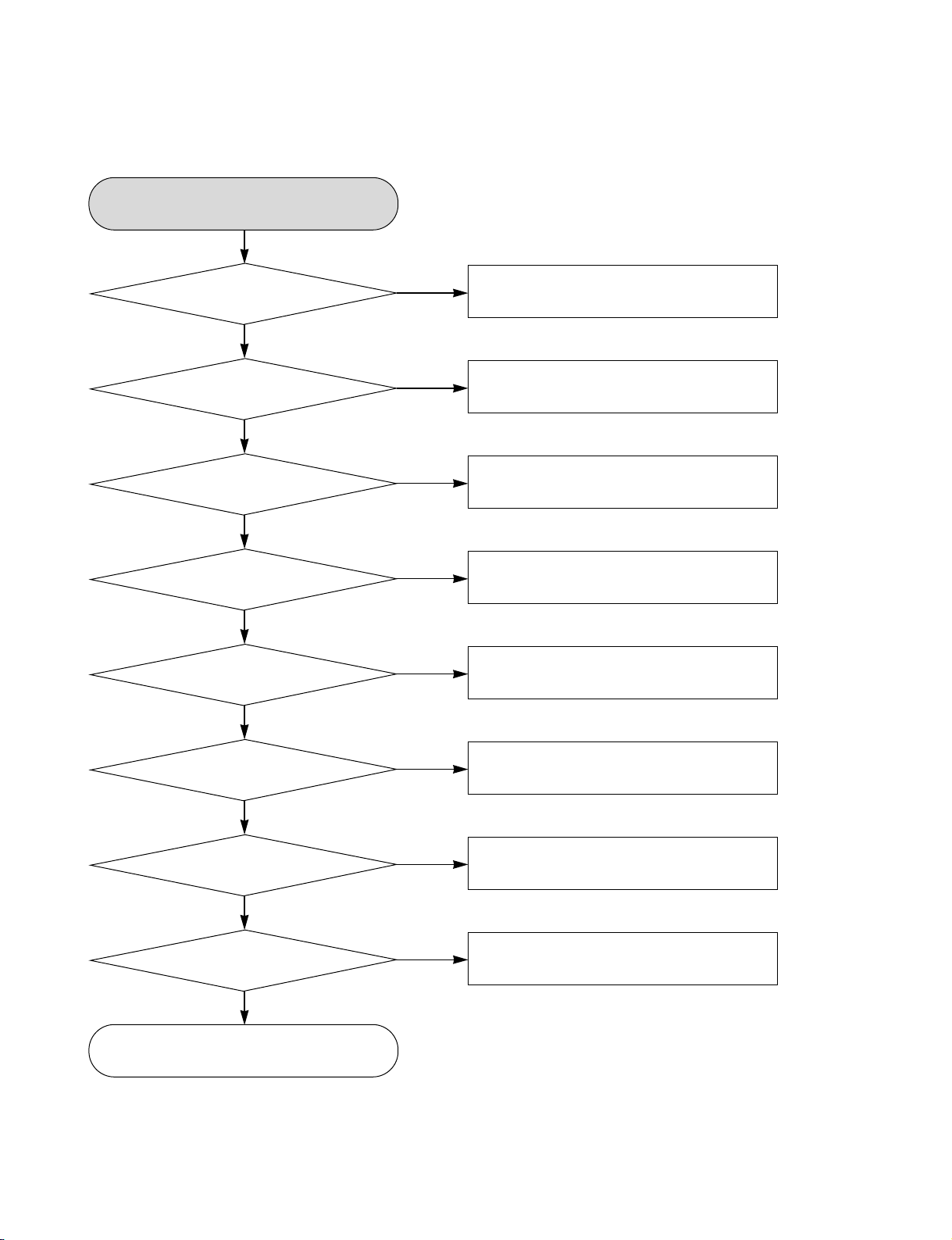

ELECTRICAL TROUBLESHOOTING GUIDE

1. POWER SUPPLY (SMPS)

No .5.3VA

YES

Is the F101 normal? Replace the F101 (Use the same fuse)

YES

NO

Is the BD101 normal? Replace the BD101

YES

NO

Is the R101 normal? Replace the R101

YES

NO

Is Vcc (9V - 18V) supplied

to IC101 Pin2?

Is the D102 normal?

YES

NO

NO

Check or replace the D102

IS the D123 normal? Replace the D123

YES

NO

Is there about 2.5V

at the IC103 Pin1?

Replace the IC103

YES

NO

Is the IC102 normal? Replace the IC102

YES

NO

Is the D124 normal? Replace the D124

YES

NO

Is the D127 normal? Replace the D127

YES

NO

Is the D128 normal? Replace the D128

YES

NO

Replace the D121

YES

NO

Is the D122 normal? Replace the D122

YES

NO

Power line of main PCB is short

Page 14

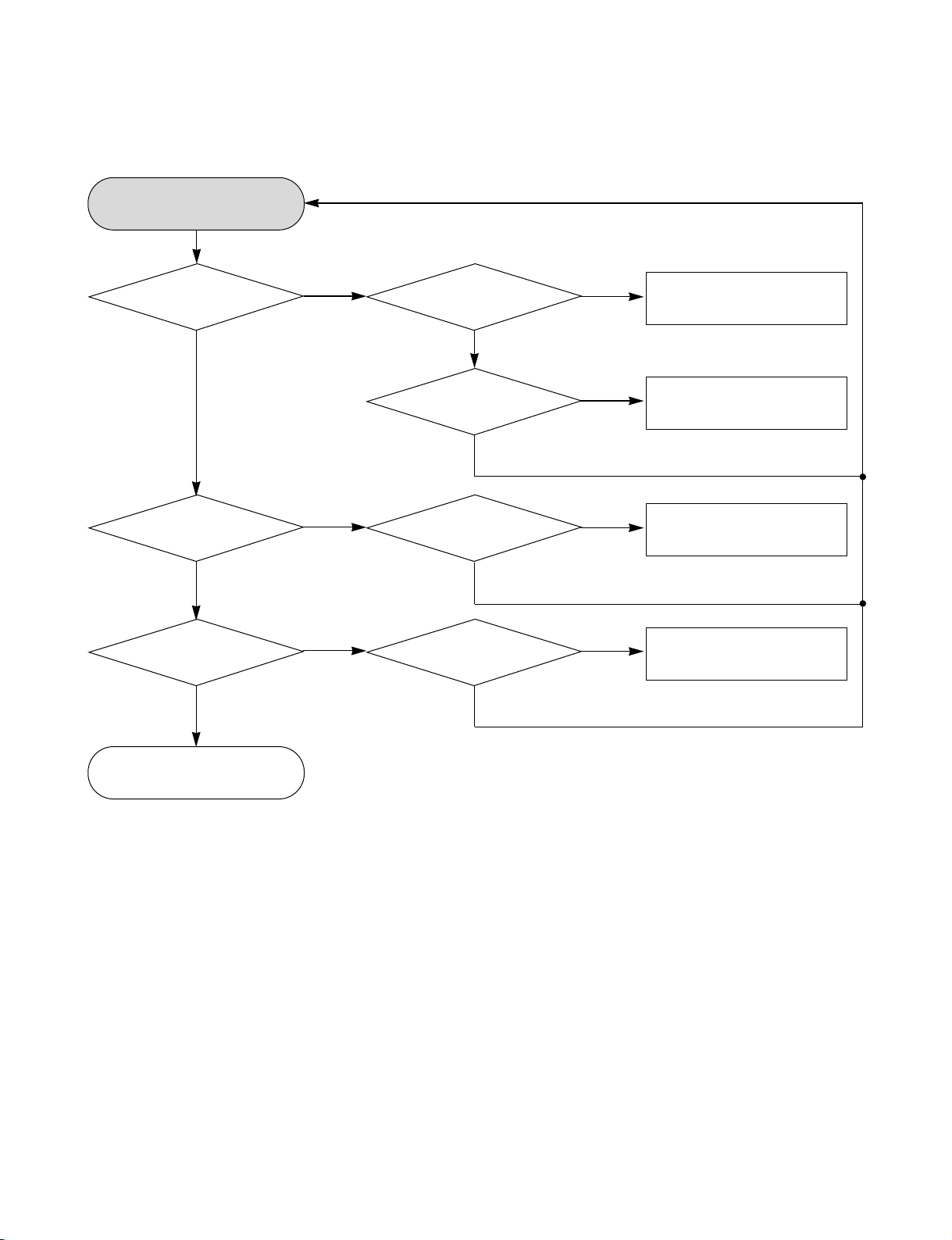

3-3

ELECTRICAL TROUBLESHOOTING GUIDE

No 5.0 Loader

Is the Vcc

(5.3V) supplied to

IC156 Pin1?

Check or Replace the D128

YES

NO

NO

Is the IC156 pin4 “H”?

Check the PWR CTL

“H” signal from µ-com

YES

Check or replace the IC156

No 3.3V

Is the Vcc

(3.8V) supplied to

IC153 Pin1?

Check or replace the D127

YES

NO

NO

Is the IC153 Pin4 “H”?

Check the PWR CTL

“H” signal from µ-com

YES

Check or replace the IC153

No 12V (Main)

Is the Vcc

(13.5V) supplied to

IC152 Pin1?

Check or replace the D124

YES

NO

NO

Is the IC152 Pin4 ‘H’?

Check the PWR CTL

“H” signal from µ-com

YES

Check or replace the IC152

Page 15

3-4

No 12 (Fan, Loader)

Is the Vcc

(13.5V) supplied to

IC155 Pin1?

Check or replace the D124

YES

NO

NO

Is the IC155 Pin4 “H”?

Check the PWR CTL

“H” signal from µ-com

YES

Check or replace the IC155

No VF+

Is the ZD121 normal?

Replace the ZD121

YES

NO

Replace the R121

ELECTRICAL TROUBLESHOOTING GUIDE

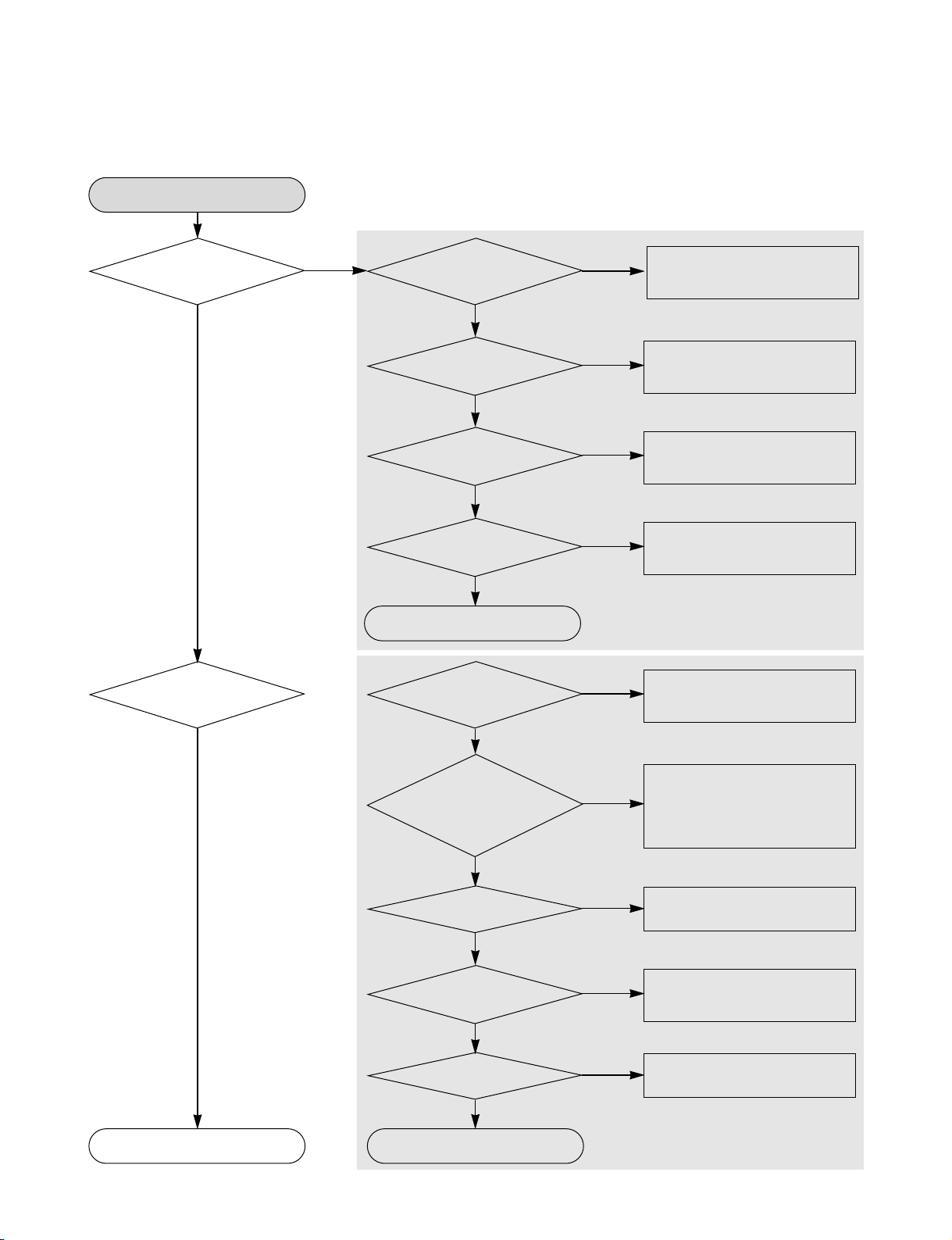

Page 16

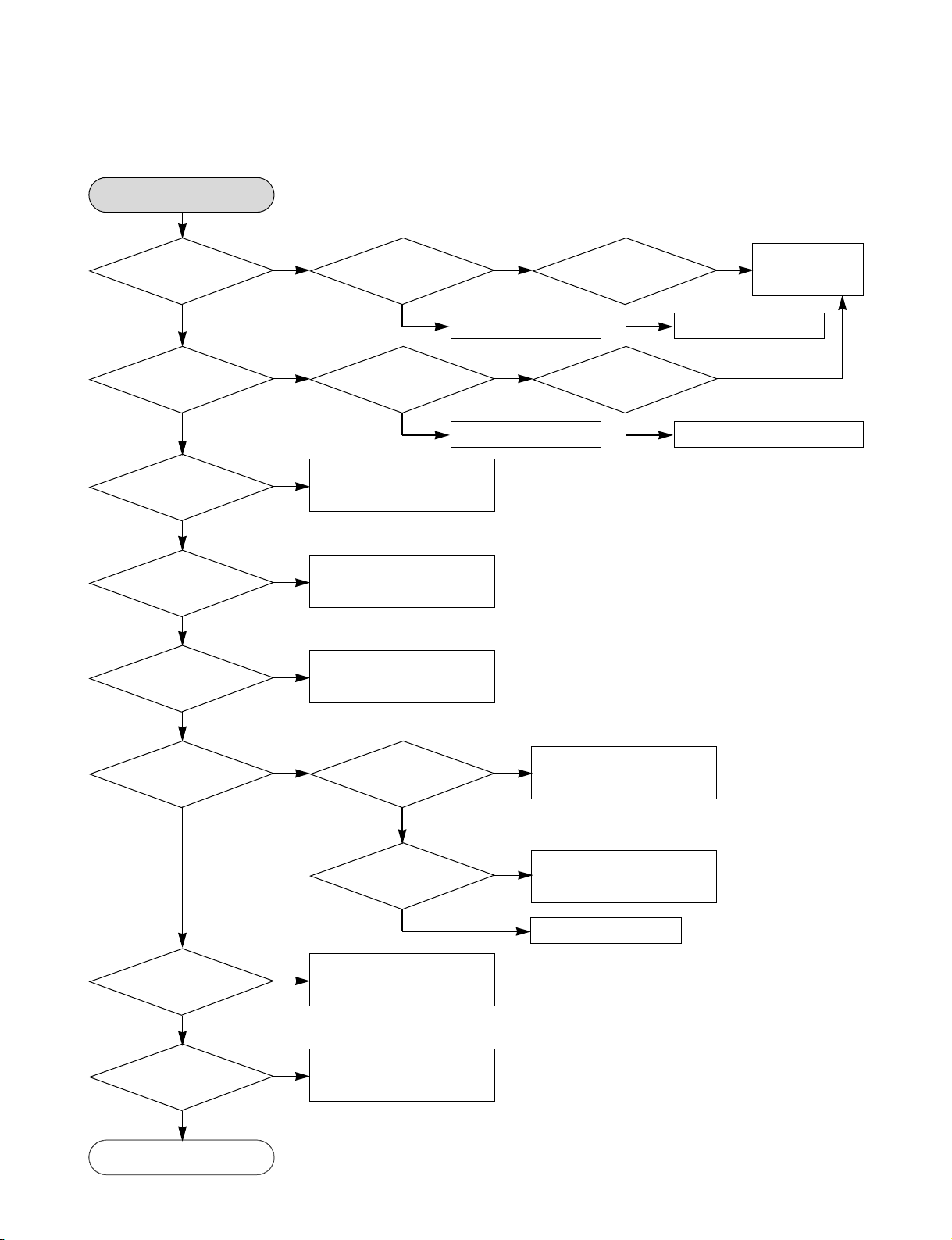

3-5

POWER on

Normal TV

function OK

Front I/F cable connect

"HELLO PLEASE WAIT"

Display on VFD OK?

Front I/F

cable connection

OK?

NO

NO

YES

VFD power cable connect

VFD power

cable connection

OK?

NO

YES

YES

YES

YES

Touch-Pad I/F

cable connect

"LED ON"

on Touch-Pad OK?

Touch-Pad I/F

cable connection OK?

NO NO

YES

Proper display

cable connect

"LG LOGO"

display on monitor OK?

Display

cable connection

OK?

NO NO

YES

2. POWER ON

ELECTRICAL TROUBLESHOOTING GUIDE

Page 17

3-6

POWER on

Main Board

Timer Board

Check SMPS

"HELLO PLEASE WAIT"

Display on VFD OK?

P602, 8 pin; +5V,

3 pin; -28V, 4 pin; -32V,

5 pin; -36V ?

NO

NO

YES

YES

YES

X602 change

X602 10MHz OK?

NO

YES

IC600 change

R613 About 625kHz

serial Clock OK?

NO

YES

IC601 change

R611

about 3MHz

OK?

NO

YES

DIS600 change

Check SMPS

“READING”

Display on VFD OK?

P901,

11pin; 12V, 9 pin; 5V,

4 pin; 3.3V?

YES

IC904 Change,

IC901 Change

IC905 or IC903 or

IC908 Change, IC907

Change, IC902

C971; 2.6V,

C972 ; 1.3V C962, C967,

C9F5 ; 1.2V, C9F3 ; 2.5V,

C9E3; 1.8V ?

NO

NO

YES

X402 change

X402

54.000MHz OK?

NO

X401 Change

X401

25.000MHz OK?

NO

YES

IC605 change

IC402

Pin 2, 3, 5, 7 27MHz

OK?

NO

YES

YES

Check IC301System part OK

3. SYSTEM PART

ELECTRICAL TROUBLESHOOTING GUIDE

Page 18

3-7

No display

Video part OK

C863

(Pin 2) +3.3V

OK?

IC907

(Pin 2) +3.3V

OK?

NO

P901

(Pin 3, 4) +3.3V

OK?

NO NO

YES

YES

YES

Check main

power cable

L803 Re-soldering

YES

L904, L906 Re-soldering

C327

(Pin 2) +2.5V

OK?

C970

(Pin 2) +2.6V

OK?

NO

IC904

(Pin 2) +5.0V

OK?

NO NO

YES

L304 Re-soldering

YES

IC904 Change

C968

(Pin 2) +1.2V

OK?

NO

IC903 Re-soldering

C8F9, C8G0,

C8G1, C8F6 (Pin 2)

signal OK?

L816, L811, L813,

L820 soldering OK?

NO NO

Re-soldering

Re-soldering

L812, L819, L815

soldering OK?

NO

YES

Check IC301

CF804,

CF802, CF806, CF803

(Pin 1) signal OK?

NO

C8F9 ~ C8F6

Re-soldering

YES

YES

YES

YES

JK803

(Pin 1, 3, 5, 7)

signal OK?

NO

CF804 ~ CF803

Re-soldering

YES

YES

VIDEO cable

connection

OK?

NO

Check VIDEO cable

4. VIDEO PART (COMMON)

ELECTRICAL TROUBLESHOOTING GUIDE

Page 19

3-8

Component video no display

Component video cable connect

YES

NO

5. COMPONENT (YPbPr) VIDEO OUT

Video cable

connection OK?

Video part (Common) check

YES

NO

TP782 ~ TP784 video

signal input OK?

Re-soldering

YES

NO

L812, L819, L815

soldering OK?

Re-soldering

YES

NO

L818, L814, L809

soldering OK?

Re-soldering

YES

NO

L811, L813, L820

soldering OK?

Re-soldering

YES

NO

C8G0, C8G1, C8F6

soldering OK?

Re-soldering

YES

NO

CF802, CF806, CF803

soldering OK?

Re-soldering

YES

NO

JK803 soldering OK?

Component Video OK

ELECTRICAL TROUBLESHOOTING GUIDE

Page 20

3-9

CVBS video no display

Composite cable connect

YES

NO

6. CVBS VIDEO OUT

Video cable

connection OK?

Video part (Common) check

YES

NO

TP871

Video signal input OK?

Re-soldering

YES

NO

C806 soldering OK?

Re-soldering

YES

NO

L816 soldering OK?

Re-soldering

YES

NO

C8F9 soldering OK?

Re-soldering

YES

NO

CF804 soldering OK?

Re-soldering

YES

NO

JK803 soldering OK?

CVBS video OK

ELECTRICAL TROUBLESHOOTING GUIDE

Page 21

3-10

No audio

Audio part OK

IC804 ~ IC806

(Pin 8) +11.5V

OK?

C9E7

(Pin 2) +12.0V

OK?

NO

P901

(Pin 11) +12.0V

OK?

NO NO

YES

YES

YES

Check main

power cable

R882 Re-soldering

YES

L905 Re-soldering

IC802

(Pin 28) +5.0V

OK?

C8F5

(Pin 2) +5.0V

OK?

NO

P901

(Pin 9, 8, 7) +5.0V

OK?

NO NO

YES

R855 Re-soldering

YES

L901 ~ 903 Re-soldering

R854, R839, R836

R878~R880 Soldering

OK?

NO

Re-soldering

TP847

LOW = GND

OK?

R884, R814

soldering OK?

NO NO

Re-soldering

Re-soldering

Q806

soldering OK?

NO

YES

Check IC701

C8E1 ~ C8E6

soldering

OK?

NO

Re-soldering

YES

IC802 (Pin 7, 8, 9)

I2S input signal

OK?

NO

Check IC701

YES

YES

YES

TP816 ~ TP821

audio out signal

OK?

NO

Check IC802

YES

YES

YES

JK803 (Pin 11 ~ 21)

audio out signal

OK?

NO

Change IC804 ~ 806

7. AUDIO (ANALOG)

ELECTRICAL TROUBLESHOOTING GUIDE

Page 22

3-11

No audio

S/PDIF audio OK

IC801

(Pin 5) +3.3V

OK?

P901

(Pin 3,4) +3.3V

OK?

NO NO

YES

YES

YES

YES

Check IC301

main power cable

Check main

power cable

L904, L906 Re-soldering

Change IC801

YES

Change JK802

YES

L901 ~ L903

Re-soldering

IC801 (Pin 4)

Digital Audio Out

OK?

IC801

soldering OK?

NO NO

YES

Re-soldering

JK802

Red Lighting

OK?

JK802

(Pin 2) +5.0V

OK?

NO NO

NO

P901

(Pin 9, 8, 7) +5.0V

OK?

TP8A0

digital audio input

OK?

NO

Check IC301

YES

8. AUDIO (S/PDIF)

ELECTRICAL TROUBLESHOOTING GUIDE

Page 23

3-12

No A/V

HDMI OK

JK801

Pin 19 (HPD)

OK?

NO

YES

Check IC301

JK801

Pin 15 (SCL), 16 (SDA)

OK?

NO

YES

Check IC301

Check IC301

JK801

Pin 18 +5V

OK?

NO

P901 Pin 7, 8, 9 Check

NO

Re-soldering

YES

JK801

Pin 1, 3, 4, 6, 7, 9, 10,

12 OK?

NO

NO

Re-soldering

YES

Check

CF807~810

OK?

YES

9. HDMI

ELECTRICAL TROUBLESHOOTING GUIDE

Page 24

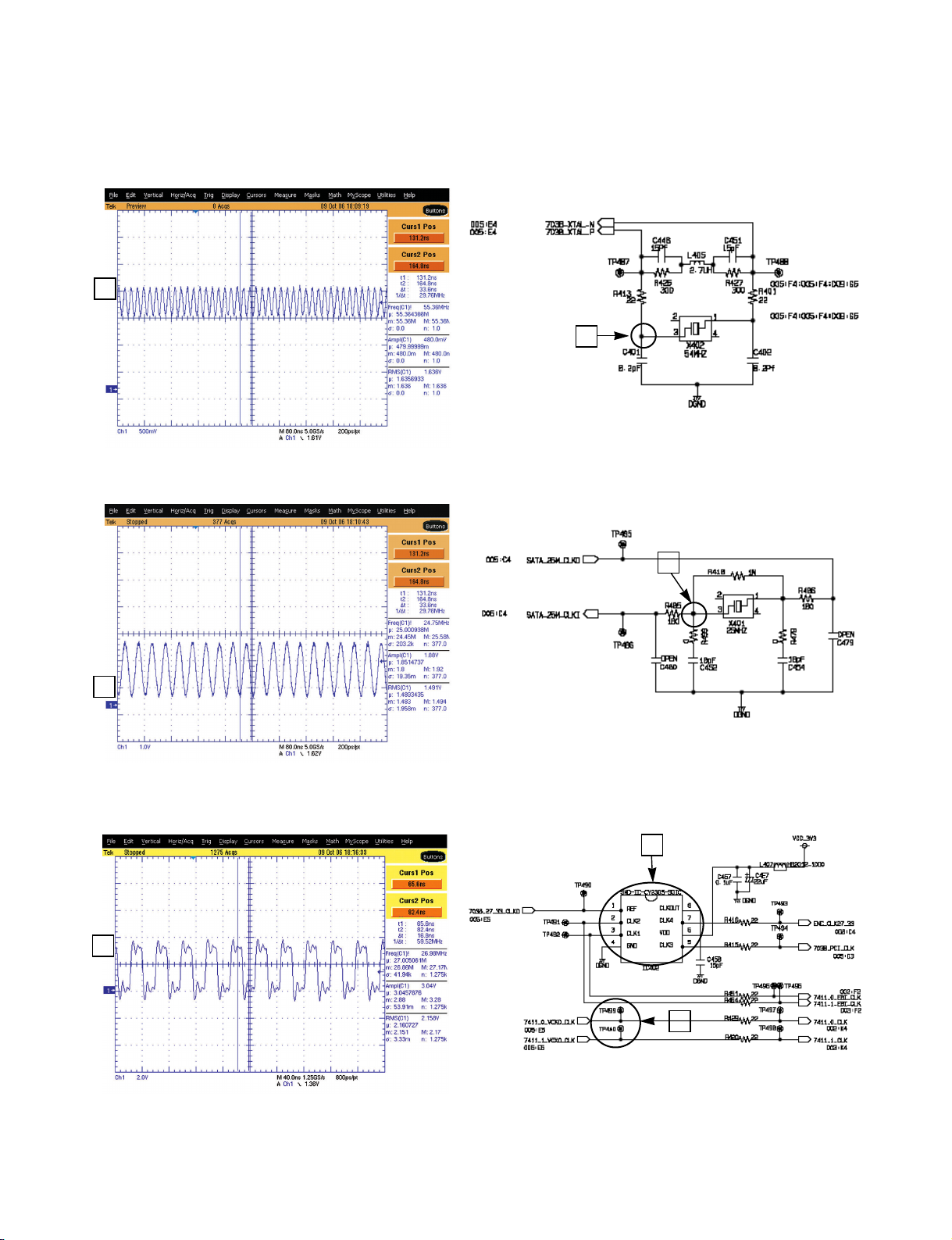

3-13

WAVEFORMS

1. SYSTEM PART-1

7438 XTAL (54MHz)

1

1

7438 XTAL for SATA loader (25MHz)

2

2

7438 CLK(27MHz), 7438 PCI CLK(27MHz)

7438 FPGA CLK(27MHz), 7412_0 CLK(27MHz)

7412_1 CLK(27MHz)

3

3

3

Page 25

3-14

2. SYSTEM PART-2 (SYSTEM MEMORY)

4

4

7438 DDR BA0

5

7

6

5

7438 DDR WE

6

7438 DDR CAS

7

7438 DDR CLK0 (200MHz)

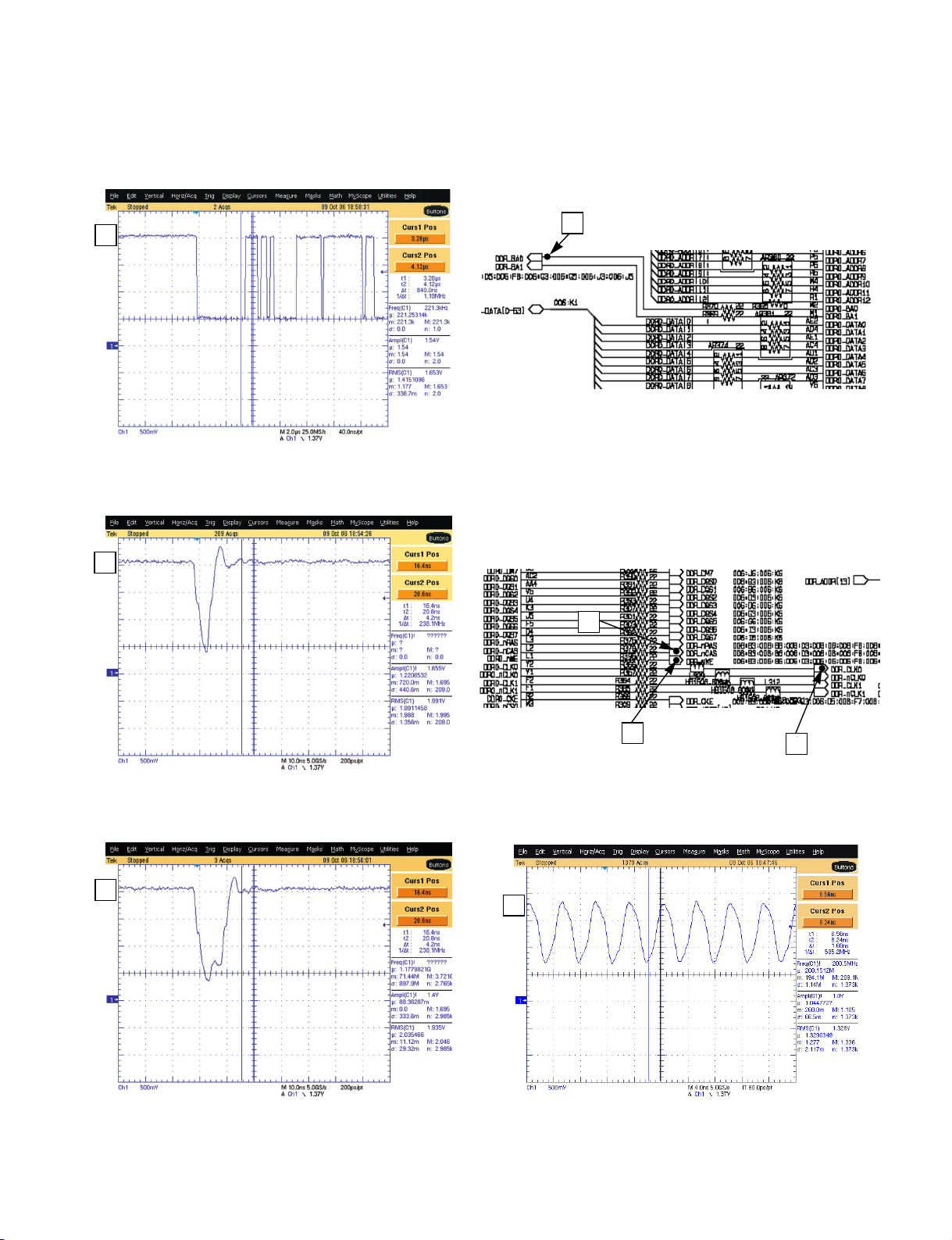

Page 26

3-15

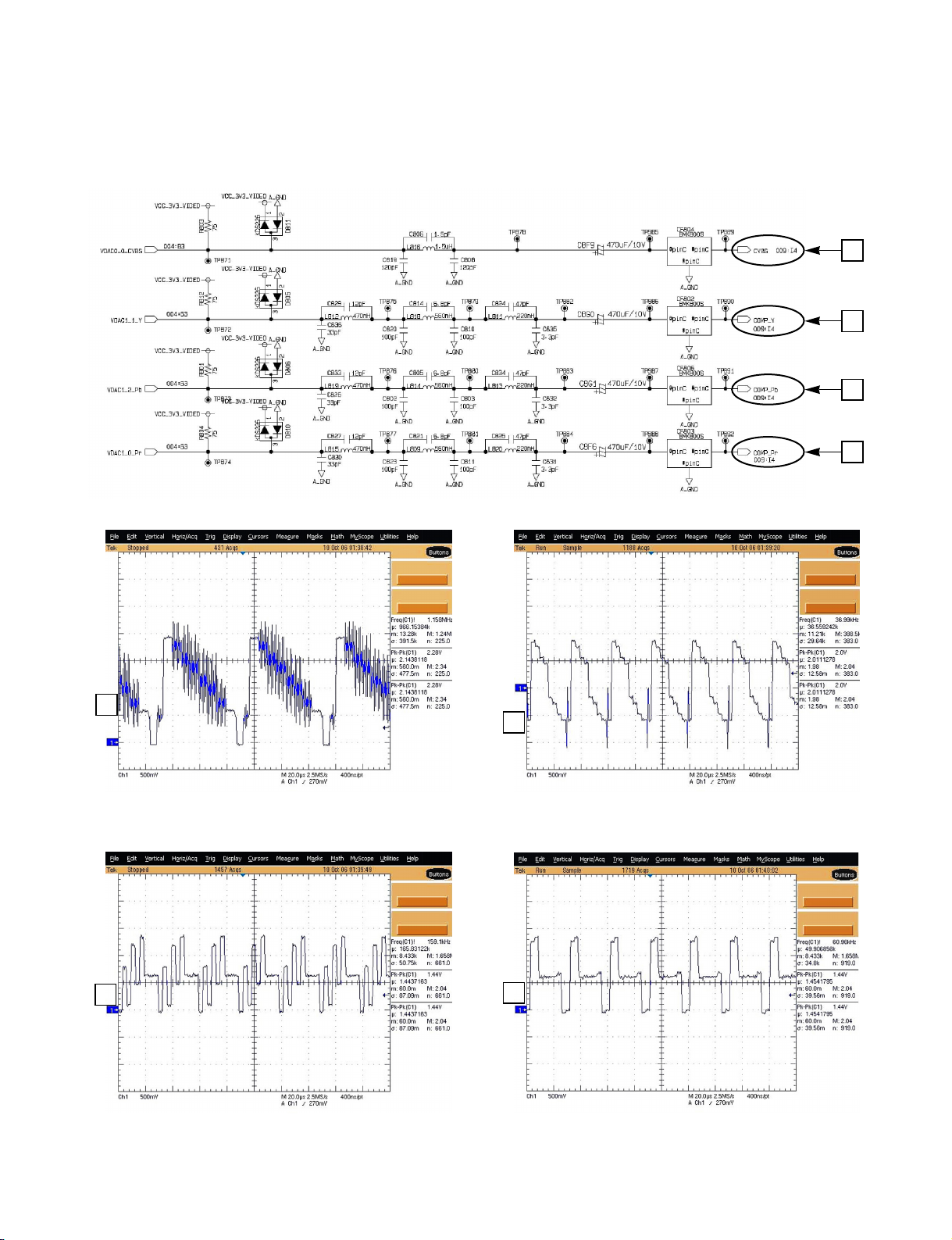

3. VIDEO PART-1 (100% FULL COLOR-BAR)

8

9

10

11

10

VDAC1_2_Pb

11

VDAC1_0_Pr

8

VDAC0_0_CVBS

9

VDAC1_1_Y

Page 27

3-16

4. VIDEO PART-2 (100% FULL COLOR-BAR)

12

13

14

15

14

COMP_Pb

15

COMP_Pr

12

CVBS

13

COMP_Y

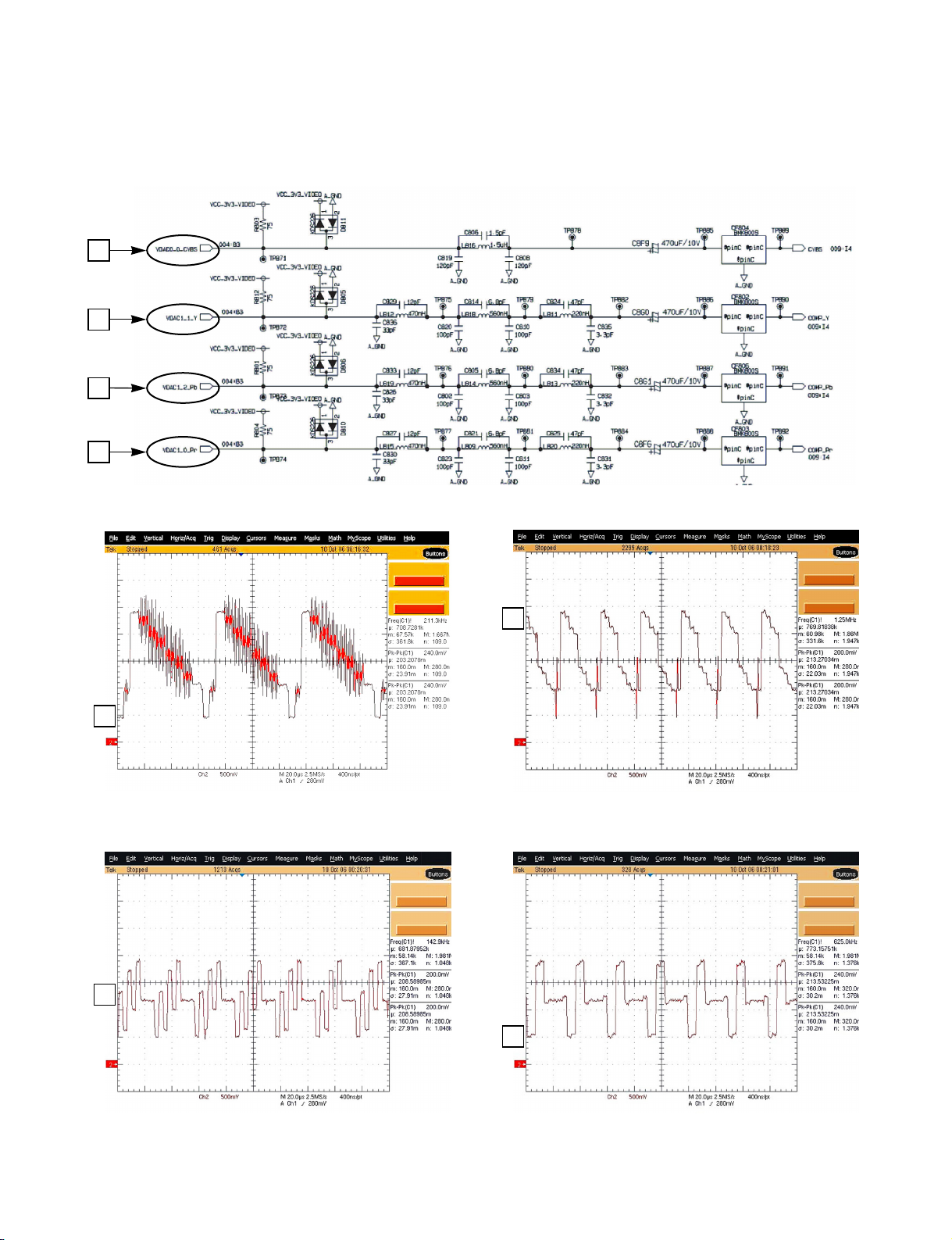

Page 28

3-17

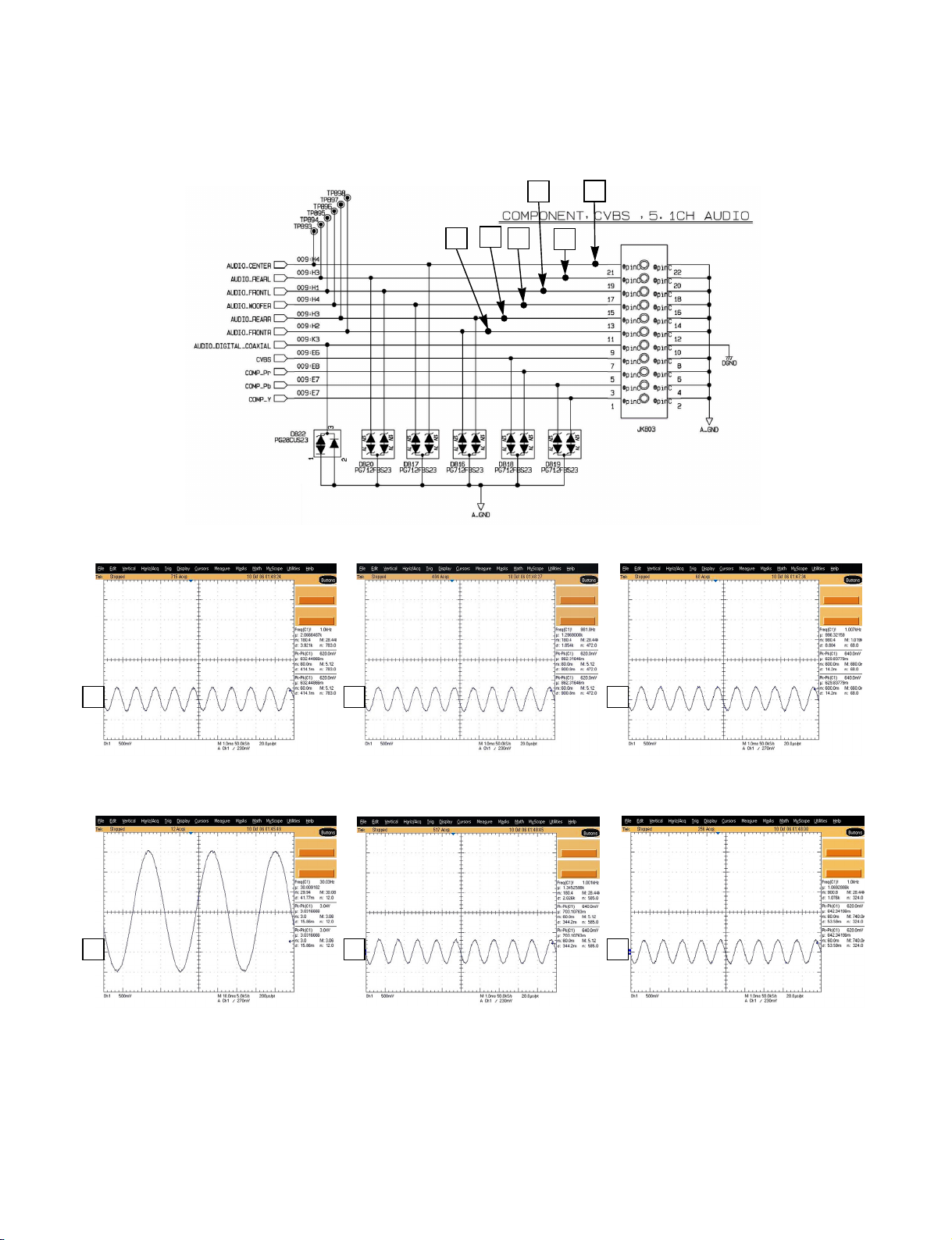

5. AUDIO PART-1 (ANALOG 5CH : 99Hz, -20dBFS / WOOFER : 30Hz, 0dBFS)

21

20

19

18

17

16

16

AUDIO_CENTER

17

AUDIO_REARL

18

AUDIO_FRONTL

19

AUDIO_WOOFER

20

AUDIO_REARR

21

AUDIO_FRONTR

Page 29

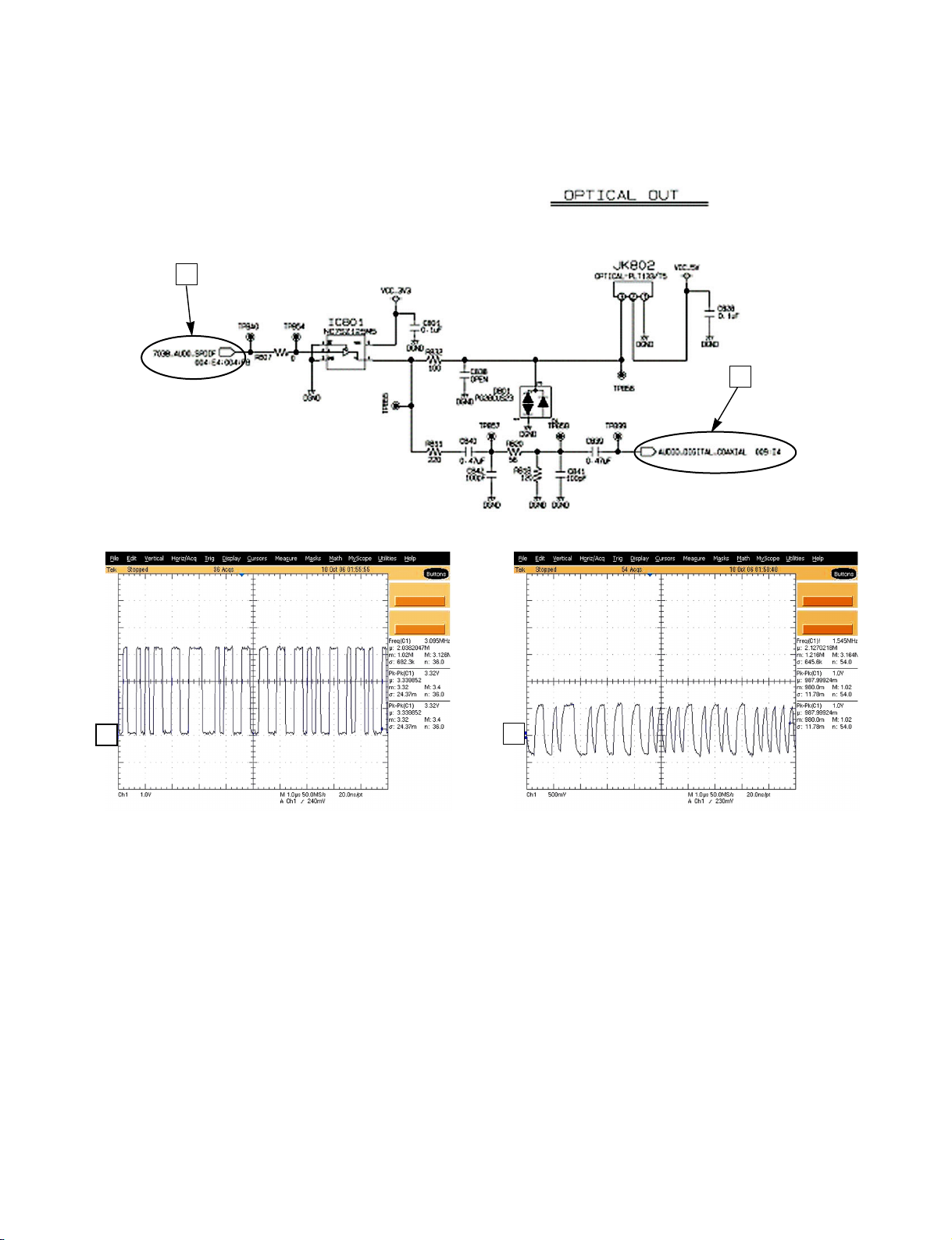

3-18

6. AUDIO PART-2 (S/PDIF)

22

23

22

7038_AUDIO_SPDIF

23

AUDIO_DIGITAL_COAXIAL

Page 30

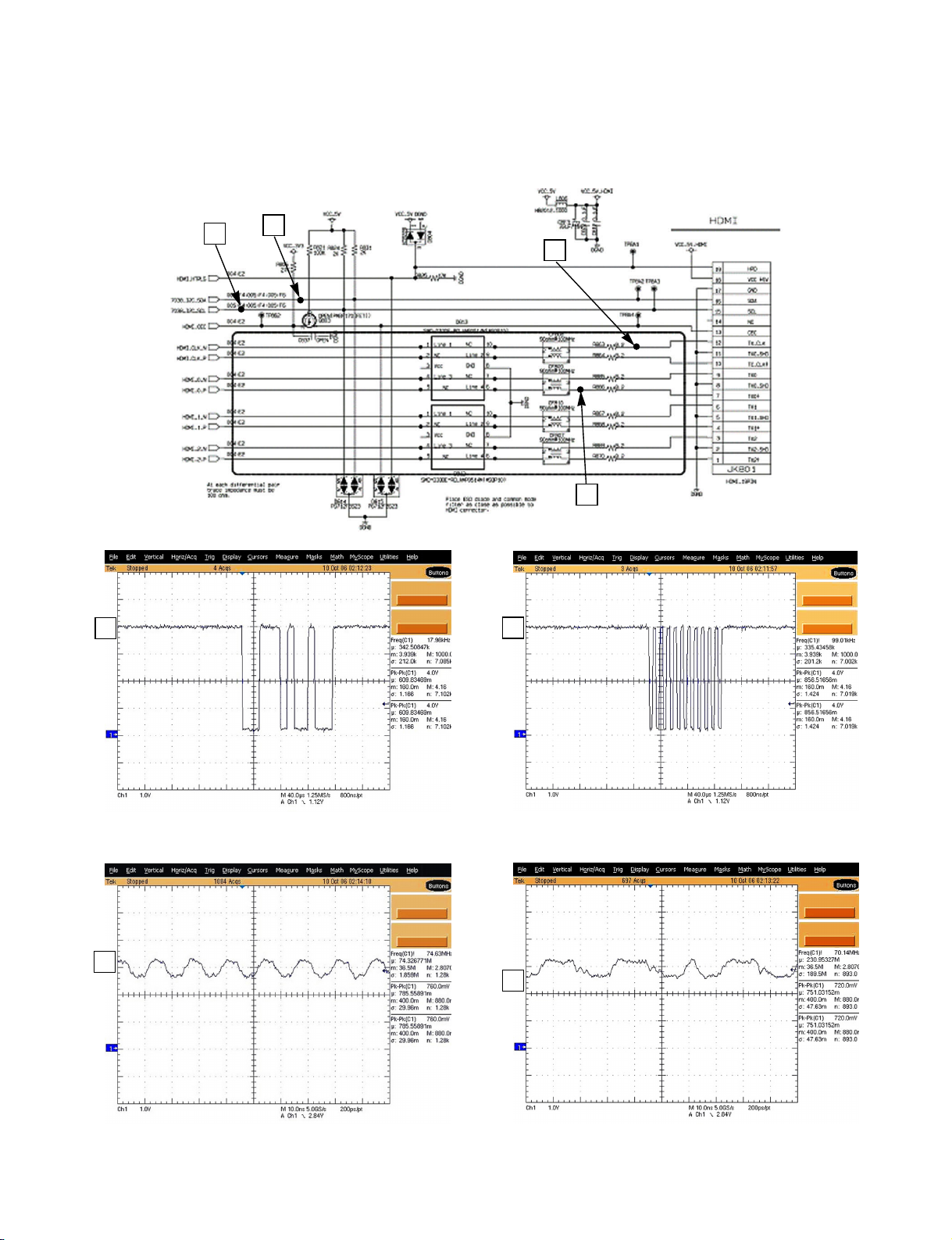

3-19

7. HDMI PART

25

26

HDMI_CLK

27

HDMI_DATA

24

7038_I2C_SDA

25

7038_I2C_SCL

24

26

27

Page 31

3-20

8. FRONT I/F PART

28

29

28

UART_TXD

29

UART_RXD

Page 32

3-21

9. MPEG-4 DECODER PART-1

32

7412 DDR CLK (200MHz)

33

7412 DDR WE

30

7412 DDR BAO

31

7412 DDR CAS

33

30

32

31

Page 33

3-22

10. MPEG-4 DECODER PART-2

36

7412_O I2S_DATAO

37

7412_O_I2S_CLKO

34

7412_HD_DVIO_CLK (74.25MHz)

35

7412_O_I2S_LRCLKO

34

35

36

37

Page 34

3-23

BLOCK DIAGRAMS

1. OVERALL BLOCK DIAGRAM

Page 35

3-24

2. SIGNAL PATH BLOCK DIAGRAM

Page 36

3-25

3. WIRING BLOCK DIAGRAM

Page 37

3-26

4. FRONT BLOCK DIAGRAM

Page 38

3-27

5. SMPS BLOCK DIAGRAM

Page 39

3-28

MEMO

Page 40

3-29 3-30

CIRCUIT DIAGRAMS

1. SMPS (POWER) CIRCUIT DIAGRAM

WHEN SERVICING THIS CHASSIS, UNDER NO

CIRCUMSTANCES SHOULD THE ORIGINAL DESIGN

BE MODIFIED OR ALTERED WITHOUT PERMISSION

FROM THE LG CORPORATION. ALL COMPONENTS

SHOULD BE REPLACED ONLY WITH TYPES

IDENTICAL TO THOSE IN THE ORIGINAL CIRCUIT.

SPECIAL COMPONENTS ARE SHADED ON THE

SCHEMATIC FOR EASY IDENTIFICATION. THIS

CIRCUIT DIAGRAM MAY OCCASIONALLY DIFFER

FROM THE ACTUAL CIRCUIT USED. THIS WAY,

IMPLEMENTATION OF THE LATEST SAFETY AND

PERFORMANCE IMPROVEMENT CHANGES INTO

THE SET IS NOT DELAYED UNTILTHE NEW SERVICE

LITERATURE IS PRINTED.

1. Shaded( ) parts are critical for safety. Replace only

with specified part number.

2. Voltages are DC-measured with a digital voltmeter

during Play mode.

IMPORTANT SAFETY NOTE :

Page 41

3-31 3-32

2. DECODER-1 CIRCUIT DIAGRAM

Page 42

3-33 3-34

3. DECODER-2 CIRCUIT DIAGRAM

Page 43

3-35 3-36

4. MPEG-1 CIRCUIT DIAGRAM

Page 44

3-37 3-38

5. MPEG-2 CIRCUIT DIAGRAM

Page 45

3-39 3-40

6. 512MB SDRAM CIRCUIT DIAGRAM

Page 46

3-41 3-42

7. ROM, IDE, ETHERNET JTAG, UART, FP I/F CIRCUIT DIAGRAM

Page 47

3-43 3-44

8. AUDIO FPGA CIRCUIT DIAGRAM

Page 48

3-45 3-46

9. AUDIO & VIDEO CIRCUIT DIAGRAM

Page 49

3-47 3-48

10. POWER CIRCUIT DIAGRAM

Page 50

3-49 3-50

11. FRONT/TIMER CIRCUIT DIAGRAM

Page 51

3-51 3-52

12. LOGO CIRCUIT DIAGRAM

Page 52

3-53 3-54

CIRCUIT VOLTAGE CHART

ALUMINUM CAPACITOR -1 : BY-PASS CAPACITOR

CAPACITOR VOLTAGE MEASUREMENT ON BH100 (VOLT)

NO LOC SPEC

EE MODE PLAYBACK

(+) (-) (+) (-)

1 C8E5 10uF/16V 5.48 0.90 5.48 1.10

2 C8E6 10uF/16V 5.47 1.30 5.47 0.50

3 C8E4 10uF/16V 5.46 0.00 5.42 1.40

4 C8E2 10uF/16V 5.44 0.00 5.46 0.60

5 C8E3 10uF/16V 5.46 0.00 5.45 0.60

6 C8E1 10uF/16V 5.44 1.60 5.43 0.50

7 C8G3 10uF/16V 2.22 0.00 2.20 0.00

8 C8F5 100uF/16V 4.83 0.00 4.80 0.00

9 C8F0 22uF/16V 10.65 0.00 10.65 0.00

10 C8F2 22uF/16V 10.65 0.00 10.65 0.00

11 C8F4 220uF/16V 11.87 0.00 11.87 0.00

12 C8G2 10uF/16V 4.42 0.00 4.42 0.00

13 C8E9 22uF/16V 3.18 0.00 3.18 0.00

14 C8G1 470uF/10V 1.92 0.00 1.80 0.00

15 C8G0 470uF/10V 1.92 0.00 1.13 0.00

16 C8F9 470uF/10V 1.12 1.05 1.27 1.12

17 C8F6 470uF/10V 1.75 0.00 1.77 0.00

18 C9E7 220uF/16V 11.87 0.00 11.87 0.00

19 C9E8 220uF/16V 4.83 0.00 4.83 0.00

20 C9F2 220uF/16V 3.18 0.00 3.18 0.00

21 C9F4 220uF/16V 11.87 0.00 11.87 0.00

22 C9E9 220uF/16V 4.83 0.00 4.81 0.00

23 C9F1 220uF/16V 3.18 0.00 3.18 0.00

24 C8F3 22uF/16V 4.83 0.00 4.82 0.00

25 C7E6 100uF/16V 3.18 0.00 3.18 0.00

26 C9E5 100uF/16V 3.18 0.00 3.18 0.00

27 C9F3 100uF/16V 2.55 0.00 2.55 0.00

28 C9E6 100uF/16V 2.55 0.00 2.55 0.00

29 C9F5 100uF/16V 1.25 0.00 1.25 0.00

30 C7E2 10uF/16V 2.55 0.00 2.55 0.00

31 C7E4 10uF/16V 1.25 0.00 1.25 0.00

32 C4E1 22uF/16V 3.18 0.00 3.18 0.00

33 C4E9 22uF/16V 3.18 0.00 3.18 0.00

34 C6E1 22uF/16V 3.18 0.00 3.18 0.00

35 C4E7 22uF/16V 3.17 0.00 3.17 0.00

36 C1E5 22uF/16V 3.18 0.00 3.18 0.00

38 C9E3 47uF/16V 1.81 0.00 1.81 0.00

40 C9E4 47uF/16V 3.18 0.00 3.18 0.00

41 C1E1 22uF/16V 1.16 0.00 1.16 0.00

42 C1E2 22uF/16V 1.13 0.00 1.13 0.00

NO LOC SPEC

EE MODE PLAYBACK

(+) (-) (+) (-)

43 C1E6 22uF/16V 1.15 0.00 1.15 0.00

44 C1E8 47uF/16V 1.18 0.00 1.18 0.00

45 C1E9 47uF/16V 1.18 0.00 1.18 0.00

46 C1E4 22uF/16V 2.57 0.00 2.57 0.00

47 C6E2 22uF/16V 4.82 0.00 4.82 0.00

48 C6E4 22uF/16V 4.82 0 4.82 0

49 C1E3 22uF/16V 2.57 0.00 2.57 0.00

50 C1E7 22uF/16V 2.57 0.00 2.57 0.00

51 C2E2 22uF/16V 2.57 0.00 2.57 0.00

52 C4E2 22uF/16V 3.18 0.00 3.18 0.00

53 C4F0 47uF/16V 3.18 0.00 3.18 0.00

54 C4E6 22uF/16V 1.17 0.00 1.17 0.00

55 C4E3 22uF/16V 1.18 0.00 1.18 0.00

56 C4F2 47uF/16V 1.18 0.00 1.18 0.00

57 C4E5 22uF/16V 1.18 0.00 1.18 0.00

58 C4E4 22uF/16V 1.18 0.00 1.18 0.00

59 C3E7 22uF/16V 1.29 0.00 1.29 0.00

60 C2E4 22uF/16V 3.12 0.00 3.12 0.00

61 C2E5 22uF/16V 1.16 0.00 1.16 0.00

62 C2E1 22uF/16V 1.13 0.00 1.13 0.00

63 C2E6 22uF/16V 1.14 0.00 1.14 0.00

64 C3E3 22uF/16V 2.58 0.00 2.58 0.00

65 C3E4 22uF/16V 1.17 0.00 1.17 0.00

66 C3E2 22uF/16V 1.18 0.00 1.18 0.00

67 C4E8 22uF/16V 2.58 0.00 2.58 0.00

68 C4F1 47uF/16V 2.58 0.00 2.58 0.00

69 C3E1 22uF/16V 1.29 0.00 1.29 0.00

70 C6E3 22uF/16V 2.58 0.00 2.58 0.00

71 C9E2 22uF/16V 2.58 0.00 2.58 0.00

72 C5E9 100uF/16V 2.58 0.00 2.58 0.00

73 C5E1 100uF/16V 2.58 0.00 2.58 0.00

74 C5E2 100uF/16V 2.58 0.00 2.58 0.00

75 C5E5 100uF/16V 2.58 0.00 2.58 0.00

76 C5E4 100uF/16V 2.58 0.00 2.58 0.00

77 C5E3 100uF/16V 2.58 0.00 2.58 0.00

78 C5E7 100uF/16V 2.58 0.00 2.58 0.00

79 C5E8 100uF/16V 2.58 0.00 2.58 0.00

80 C2E8 47uF/16V 1.18 0.00 1.18 0.00

81 C2E9 47uF/16V 1.18 0.00 1.18 0.00

82 C2E3 22uF/16V 2.58 0.00 2.58 0.00

Page 53

3-55 3-56

PRINTED CIRCUIT DIAGRAMS

1. MAIN P.C.BOARD

(TOP VIEW) (BOTTOM VIEW)

Page 54

3-57 3-58

2. FRONT P.C.BOARD

(TOP VIEW) (BOTTOM VIEW)

3. LOGO P.C.BOARD

(TOP VIEW) (BOTTOM VIEW)

Page 55

3-59 3-60

4. POWER P.C.BOARD

(TOP VIEW) (BOTTOM VIEW)

Page 56

4-1

SECTION 4

HL-01P LOADER PART

CONTENTS

ELECTRICAL

TROUBLESHOOTING GUIDE.....................4-2

THE DIFFERENCES OF BLUE-RAY & DVD

.....4-12

1. INTRODUCTION.......................................4-12

2. DISC SPECIFICATION .............................4-13

HOW TO USE TEST TOOL........................4-16

1. ALPC MEASUREMENT

SYSTEM COMPOSITION.........................4-16

2. ALPC PROGRAM COMPOSITION...........4-17

3. EXECUTE ALPC PROGRAM ...................4-18

4. LASER POWER SETTING .......................4-19

5. LASER POWER SETTING

PARAMETER CHECK...............................4-20

6. HOW TO MEASURE LASER POWER.....4-22

INTERNAL BLOCK DIAGRAM OF IC

........4-23

1. R2S30220SP ............................................4-23

2. R8J32700FPV...........................................4-24

3. R2S35003 .................................................4-25

WAVEFORMS .................................................4-31

1. POWER & RESET SIGNAL......................4-31

2.

MAIN CLOCK1 FOR IC301 (33.859MHz)

.......4-31

3.

MAIN CLOCK2 FOR IC707 (25.035MHz)

.......4-32

4. TRAY OPEN/CLOSE SIGNAL ..................4-32

5. TRAY OPEN/CLOSE SIGNAL A ...............4-33

6. TRAY OPEN/CLOSE SIGNAL B ...............4-33

7. TRAY OPEN/CLOSE SIGNAL C...............4-34

8. TRAY OPEN/CLOSE SIGNAL D...............4-34

9. SLED MOVE SIGNAL...............................4-35

10. ZOOM OF SLED MOVE SIGNAL.............4-35

11. SPINDLE WAVEFORM .............................4-36

12. ZOOM OF SPINDLE WAVEFORM...........4-36

13. DISC TYPE JUDGEMENT

WAVEFORM (DVD SERIES)....................4-37

14. DISC TYPE JUDGEMENT WAVEFORM

(DVD_SINGLE) .........................................4-37

15. DISC TYPE JUDGEMENT WAVEFORM

(DVD_DUAL).............................................4-38

16. DISC TYPE JUDGEMENT WAVEFORM

(BD SERIES) .............................................4-38

17. DISC TYPE JUDGEMENT WAVEFORM

(BD_SINGLE)............................................4-39

18. DISC TYPE JUDGEMENT WAVEFORM

(BD_DUAL) ...............................................4-39

19. DISC TYPE JUDGEMENT WAVEFORM

(HD SERIES) .............................................4-40

20. DISC TYPE JUDGEMENT WAVEFORM

(HD_SINGLE)............................................4-40

21. DISC TYPE JUDGEMENT WAVEFORM

(HD_DUAL) ...............................................4-41

22. FOCUS ON SIGNAL (DVD)......................4-41

23. FOCUS ON SIGNAL (BD).........................4-42

24. FOCUS ON SIGNAL (HD) ........................4-42

25. TRACK OFF SIGNAL (DVD).....................4-43

26. TRACK OFF SIGNAL (BD) .......................4-43

27. TRAKC OFF SIGNAL (HD).......................4-44

28. TILT DRIVER SIGNAL ..............................4-44

29. WOBBLE (DVD - R/RW)...........................4-45

30. WOBBLE (DVD + R/RW)..........................4-45

31. RF WAVEFORM (DVD) ............................4-46

32. RF WAVEFORM (BD) ...............................4-46

33. RF WAVEFORM (HD)...............................4-47

34.

LD ON SEQUENCES (BD -> DVD -> BD)

......4-47

BLOCK DIAGRAMS .....................................4-48

1. ALPC BLOCK DIAGRAM............................4-48

2. SERVO SYSTEM BLOCK DIAGRAM.........4-49

3. FOCUS, TRACKING, SLED

SERVO PROCESS .....................................4-50

4. SPINDLE SERVO PROCESS.....................4-51

CIRCUIT DIAGRAM ......................................4-53

CIRCUIT VOLTAGE CHART......................4-55

PRINTED CIRCUIT DIAGRAMS...............4-57

P.C.BOARD (TOP SIDE).................................4-57

P.C.BOARD (BOTTOM SIDE).........................4-59

Page 57

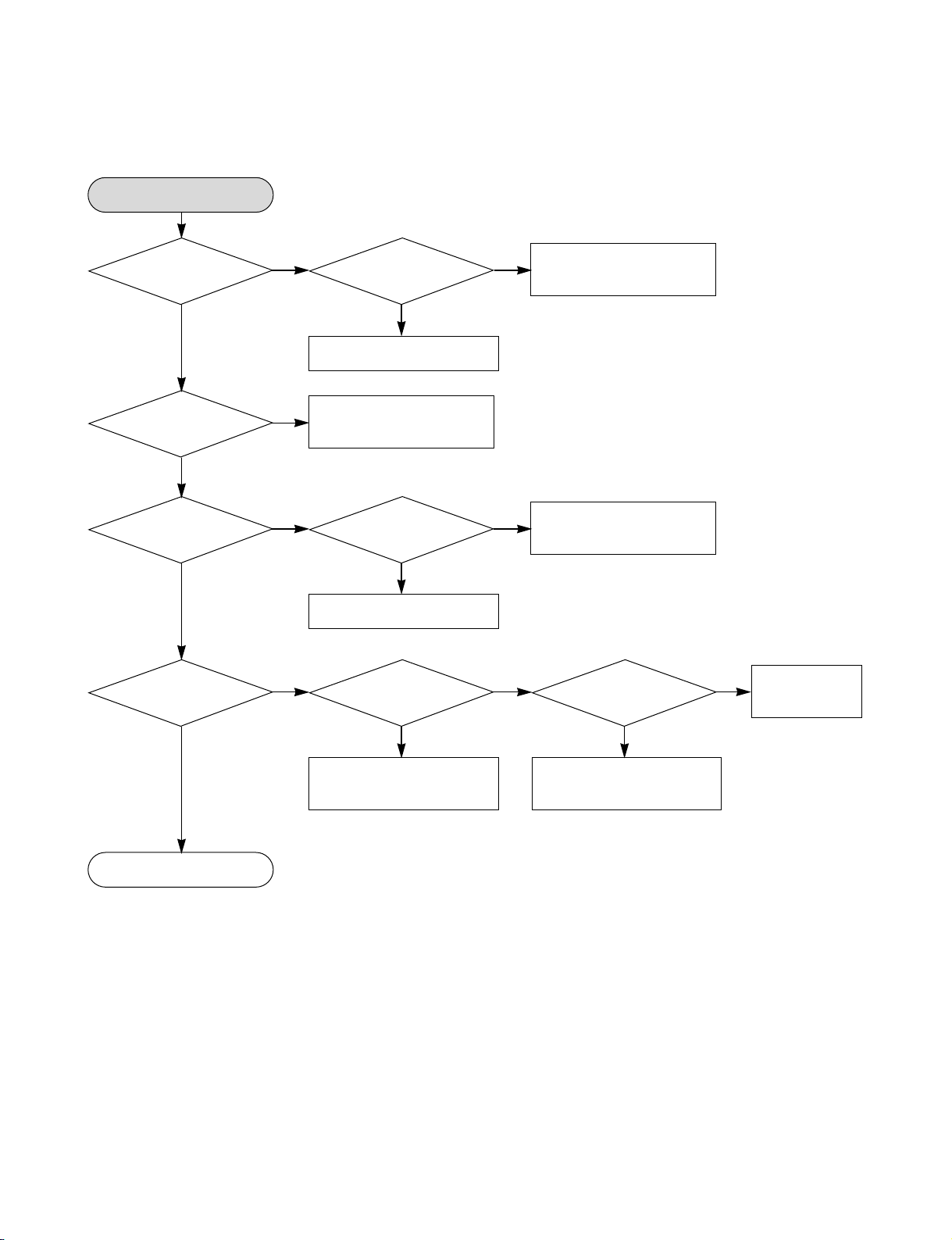

4-2

ELECTRICAL TROUBLESHOOTING GUIDE

Reset or power check.

OK

Check the power (5V/12V) short.

Repair the SMPS Block

NO

Are the pin47

of IC601+5V, pin5 of IC601+12V

respectively after the power cable

connecting?

Check the IC703 (3.3V & 1.5V regulator

& reset IC)

Check the IC301

NO

Does the pin88

(Reset) of IC301 change 0V to 3.3V

at the power supply initial input

mode?

Check the IC706

NO

Is the TP761 5V?

Check it after connecting the power cable only on

interface cable for NO Reset or Power ON.

YES

YES

Check the X301 (33.86MHz)

Check the IC301

NO

Are the X301 oscillating?

YES

Check the IC705

NO

Is the pin2, 3 of IC705 2.8V?

YES

Check the IC702

NO

Is the TP049 5.7V?

YES

Check the IC701

NO

Is the pin1 of IC701 9V?

YES

Check the IC703

NO

<Power>

Is the TP734 3.3V?

Is the TP737 1.5V?

YES

Check the IC101

NO

<Reference>

2.1V (VREF1) : Check pin83 of IC101?

2.5V (VC25) : Check pin81

of IC101?

YES

YES

YES

Page 58

4-3

ELECTRICAL TROUBLESHOOTING GUIDE

System check.

Go to “Tray operating is abnormal”

YES

YES

YES

YES

YES

YES

YES

YES

YES

NO

Does tray operate normally?

Go to “Sled operating is abnormal”

NO

Does pick-up

move to inside?

Go to “Focus actuator

operating is abnormal”

NO

Does pickup lens

move up/down?

Go to “Laser operating is abnormal”

NO

Does laser turn on?

Go to “Recognition fail case1

(DVD-ROM Disc)”

NO

Does Disc rotate

continuously and the drive

recognize the disc?

Go to “Recognition fail case2

(HD DVD-ROM)”

NO

Does Disc rotate

continuously and the drive

recognize the disc?

After eject tray, insert DVD-ROM Disc

and check rotation.

After eject the tray, insert HD DVD-ROM

disc and check rotation.

YES

YES

Go to “Recognition fail Case3

(DVD R/RW finalized disc)”

NO

Does disc rotate

continuously and the drive

recognize the disc?

After eject the tray, insert DVD R/RW

finalized disc and check rotation.

Load tray without inserting disc.

OK

Page 59

4-4

Tray operating is abnormal.

Tray open doesn’t work.

Replace the IC601.

Check the connctor (CN651)

Is there Tray

drive voltage output?

(IC601 pin38, 39)

When CN651 is

open, Is there Tray drive

signal output?

YES

YES

Is there Tray

control signal input?

(IC601 pin51)

NO

NO

NO

Check the connction of IC301 pin85

Check the communication line

(LD0 signal) between IC301 and IC601.

YES

YES

ELECTRICAL TROUBLESHOOTING GUIDE

Page 60

4-5

Sled operating is abnormal.

Check the connection

of IC301 pin7.

Check the R323, R325.

Replace the IC601.

Check the

Connection CN601

Is there

Sled drive voltage

output? (IC601 pin9,

10, 11, 12)

Is CTL1 signal “H”?

(IC601, pin27)

YES

YES

Replace the IC301.

YES

Is there

Sled drive voltage input?

(IC601 pin2, 3)

NO

NO

NO

Replace the IC301.

Is there Sled

control signal output?

(IC301 pin105, 106)

NO

YES

Replace the Sled Motor.

Is there Tray

control signal input?

(CN601 pin1, 2, 3, 4)

NO

YES

YES

ELECTRICAL TROUBLESHOOTING GUIDE

Page 61

4-6

Spindle

operating is abnormal.

Replace the IC301.

OK

Check the

connection CN602

Check the output of IC601

pin25.

Check the connector CN602.

Replace the IC301.

Is there

Spindle control DSP

output? (IC301

pin80)

YES

YES

Is there

Spindle drive voltage

output? (IC601 pin17,

18, 19)

Is there

FG signal input?

(IC301 pin78)

NO NO

NO

Replace the spindle motor.

Is there

Spindle drive voltage

output? (CN602

pin1, 2, 3)

YES

NO

YES

ELECTRICAL TROUBLESHOOTING GUIDE

Page 62

4-7

Focus servo is unstable

Replace the pick up.

Replace the IC301.

Replace the IC101.

Go to “Focus actuator

operating is abnormal”

* LIC121 pin25 is MOUT2(FEP Monitor2).

After disc recognition action, Monitor port

is off. So, please check FE signal during

disc recognition.

Is FE

signal output normal

in focusing Up/Down?

(IC101 pin4)

Check pickup

DVD read power is

1.0~1.5mW?

YES

YES

Is FDRV

signal output normal in

focusing Up/Down?

(IC301 pin108)

NO

NO

NO

YES

Focus actuator

operating is abnormal.

Check the connection of

IC301 pin7.

Replace the IC301.

Check the connection

CN101 pin49, 50.

Is there focus

search drive voltage output?

(IC601 pin45, 46)

Is

DRVMUTE2 signal “H”?

(IC601 pin27)

YES

Replace the pick-up.

Replace the IC601.

YES

Is there focus

search control signal input?

(IC601 pin50)

NO

NO

NO

• Check the connection of IC301 pin108.

• Check the communication line between

IC101 and IC301.

YES

ELECTRICAL TROUBLESHOOTING GUIDE

Page 63

4-8

Track servo is unstable

Check the pick up FFC.

Replace the pick up.

Replace the LIC201.

Replace the IC101.

Check the Drive IC

(LIC301) and P/U

referring to “Focus actuator

operating is abnormal”.

* LIC121 pin24 is MOUT1(FEP Monitor1).

After disc recognition action, Monitor port is

off. So, please check TE signal during disc

recognition.

Is TE signal

output normal in focusing

ON and tracking OFF?

(IC101 pin6)

Is PICK UP

(E, F, G, H) output

normal? (CN101 pin2,

3, 4, 5)

YES

YES

Is there TDRV

signal output in tracking ON?

(LIC201 pin66)

NO

NO

NO

YES

ELECTRICAL TROUBLESHOOTING GUIDE

Page 64

4-9

Recognition fail case 1 :

DVD-ROM fail

Go to “LD CHECK”.

YES

NO

Check pick-up read power

was 1.0~1.5mW?

Go to “Focus servo is unstable”.

YES

NO

Does focus servo

operate normally?

Check the pick-up FFC and CN101.

Replace the pick-up.

YES

NO

Check pick-up

RF signal IC101 pin77

OCRFIP was 2~2.5V?

Replace IC101.

YES

NO

Check EQOP

waveform (IC101 pin66) was

1.75~2.3V?

Go to “Tracking servo is unstable”.

YES

NO

Check after replacing IC101.

It is OK?

OK

ELECTRICAL TROUBLESHOOTING GUIDE

Page 65

4-10

Recognition fail case 2 :

HD DVD-ROM disc

Go to “LD check”.

YES

NO

Check pick up read power

was 0.5~0.8mW.

Replace the pick up.

YES

NO

Is there RF signal

at IC101 pin77?

Replace the IC101.

YES

NO

Is there

RF signal at IC101 pin77 (DCRFIP)

and pin80 (DCRFIN)?

OK

Recognition fail case 3 :

DVD R/RW finalized disc

Replace IC301.

Replace IC101.

Is there WBL

(IC101 pin27)

signal?

Is there WBL

(IC301 pin196)

signal?

YES

Check the connection

between IC101 and IC301.

YES

NO

NO

ELECTRICAL TROUBLESHOOTING GUIDE

Page 66

4-11

LD check

(Laser operating is abnormal)

Change pick up module

YES

NO

Is ALPC parameters OK?

YES

YES

NO

Is LP setting result OK?

Perform 5. Optical power setting

parameter check from “How to use Test tool”.

Perform 4. Laser power setting from

“How to use test tool?

OK

ELECTRICAL TROUBLESHOOTING GUIDE

Page 67

4-12

THE DIFFERENCES OF BLUE-RAY & DVD

1. INTRODUCTION

Page 68

4-13

2. DISC SPECIFICATION

BD-ROM DVD-ROM

Single-Layer Dual-Layer Single-Layer Dual-Layer

Media Type Read only Read only Read only Read only

User data capacity 25GB 50GB 4.7GB 8.54GB

Wavelength 405nm 405nm 650nm 650nm

Reflectivity 35~70% 12~28% 45~85% 18~30%

Track pitch 0.32um 0.32um 0.74um 0.74um

Minimum pit length 74.5nm 74.5nm 0.4um 0.4um

Modulation 17PP(d=1, k=7) EFM+ (D=2, K=10)

Error correction LDC+BIS RS production code

Channel bit-rate 66MHz 66MHz 26.16MHz 26.16MHz

Addressing 66MHz 66MHz 26.16MHz 26.16MHz

Jitter <65% <65% <8% (L0) <8%

<8.5% (L1)

<6.5% (L1, 2T/2T

not included)

1 ECC data 32 Physical sector (64KB) 16 Physical sector (32KB)

Numerical Aperture 0.85 0.6

Protection Layer 0.1mm 0.1mm(L0) 0.6mm 0.6mm

(Cover Layer) 0.075mm(L1)

Hard coating Yes No

Data transfer rate(data) 36Mbps (1x) 11.08Mbps (1x)

Data transfer rate(A/V) 54Mbps (1.5x) 10.08Mbps (<1x)

Video resolution(max) 1920x1080 (1080p) 720x480/720x576 (480i/576i)

Video bit rate(max) 40.0Mbps 9.8Mbps

Video codecs MPEG-2 MPEG-2

MPEG-4AVC -

SMPTE VC-1 -

Audio codecs Linear PCM Linear PCM

Dolby Digital Dolby Digital

Dolby Digital Plus DTS Digital Surround

Dolby TrueHD -

DTS Digital Surround -

DTS-HD -

Interactivity BD-J DVD-Vide

Page 69

4-14

3. FORMAT OF THE INFORMATION ZONE

Page 70

4-15

BCA : Used to add information to the disc after completion of the manufacturing process

Protection zone1 : Protection area against overwriting of the PIC by the BCA

Protection zone2 : Changeover area for the track pitch(0.35um 0.32um)

PIC Zone : General information about the disc

INFO/reserved : Information zone/reserved

Data Zone : User Data Area

Page 71

4-16

HOW TO USE TEST TOOL

1. ALPC MEASUREMENT SYSTEM COMPOSITION

To measure and adjust the optical power of DVD, BD and HD-DVD, you must basically have the following

measuring device.

(1) Optical power meter & sensor (ADVANTEST, Q8230/Q82313 (RED), Q82312 (Blue) or equivalent product)

(2) Personal computer

(3) Program for adjustment (LP setting tool)

(4) USB-SATA interface (This is needed when using a notebook without SATA interface or when using USB

port on the PC.)

Optical power meter Personal computer

Loader ass'y USB-SATA interface

LP setting tool

Page 72

4-17

2. ALPC PROGRAM COMPOSITION

ALPC program is composed of two files.

LPSettingTool.exe

PCAL.CFG

These two files must be located in the same directory.

PSettingTool.exe is the execution file of the program and PCAL.CFG is the configuration file related to LP

Setting.

Decision of connection method

When you initially execute the LPSettingTool.exe file, you

will see a menu to select how to communicate with the

target system as shown in the left figure.

Use serial communication

Select Test LD

Display LP

setting results

Display execution

results OK/NG

Initialize button of

displayed results

Check execute results

Display HFM frequency

setting results

Laser power setting

start button

Disconnect communication

Use AAPI communication

Page 73

4-18

3. EXECUTE ALPC PROGRAM

(1) Execute the LPSettingTool.exe file.

(2) Click on the ATAPI icon to communicate with

the target system through ATAPI.

(3) Click on the Trigger button.

The results are displayed.

Page 74

4-19

4. LASER POWER SETTING

When replacing the Travers assembly including the pick-up or replacing the loader PCB, you must execute

the optical power setting to match the pick-up with the loader PCB.

When you click on the button in the condition shown above left, the optical power setting will be

executed in the order of DVD, BD and HD-DVD LD as shown on the right side to display whether OK/NG with

the results.

Trigger

Page 75

4-20

5. LASER POWER SETTING PARAMETER CHECK

Current defects can be realized but when the optical power setting result is OK, you need to check whether

the existing setting values are set correctly. In this case, when you press the button, the ALPC

Parameter Information window will be displayed to display the optical power setting value recorded in current

EEPROM. After taking note of this in a separate memo execute the optical power setting and press the

button again to display new optical power setting value. Compare the two parameters and if there is a big

gap, it means that either the initial optical power setting is done improperly or the optical output of the pick-

up has changed. If the pick-up is judged to be normal, you can reset the optical power to resolve the issue

without having to replace the pick-up. In order to delete the existing ALPC parameter from the ALPC

Parameter Info window, press the button on the bottom of the ALPC Parameter Info window.

Clear

Page 76

4-21

The PACL.CFG file in the directory where the execution file is located shows the valid range of the ALPC

parameter by LD.

Check whether each parameter value displayed in the ALPC Parameter Information window is regressing

within the low/high limit set in the PACL.CFG file, and if not the optical power setting is not done properly.

PACL.CFG file content

Page 77

4-22

6. HOW TO MEASURE LASER POWER

The optical power measurement is measuring the optical power actually emitted from the object lens with the

LD turned on. Therefore to measure the optical power, the LD must be turned on and the darker the better. If

needed, cover the top of the sensor with a dark paper or hand for measurement. Generally since the

florescent light is about 50 _W and sunlight about 100 _W, ignoring these lights can results in wrong setting

of the optical power. Therefore you must be careful.

Procedure for measuring the optical power

1. Set the _ (wave length) of the optical power meter to the DVD. (Generally 650nm)

2. Turn on the DVD LD.

3. Put the sensor within 3m from the object lens of the pick-up and locate the lens in a right angle.

Adjust the location so that the center of the object lens and the _ sign on the sensor are aligned.

4. Read the value on the monitor. (Read the maximum value while slightly moving the location.)

(Check the unit. The unit must be mW. When the LD is dead, you can mistakenly read the unit of _W or nW.)

5. Multiply 100 to the value on the monitor and round off to the nearest integer to write the integer part.)

6. Set the _ (wave length) of the optical power meter to the BD.

(Generally 405nm)

7. Turn on the BD LD.

8. Execute from 3 to 5 from the above.

9. Set the _ (wave length) of the optical power meter to the HD.

(Generally 405nm)

10.Turn on the HD-DVD LD.

11. Execute from 3 to 5 from the above.

Page 78

4-23

INTERNAL BLOCK DIAGRAM OF IC

1. R2S30220SP

1-1. BLOCK DIAGRAM

1-2. PIN FUNCTION

Termianl Symbol Termianl function Termianl Symbol Termianl function

1 SPIN Spindle control voltage input 27 EN1 Input terminal for enable 1

2 SL1IN Slide control voltage input 1 28 EN2 *1 Input terminal for enable 2

3 SL2IN Slide control voltage input 2 29 STES

Input terminal for Excitation off select ST

4 SPLIM

Input terminal for spindle current limit

30 ACTRST*2 Pickup protect Reset

5 VM2 Motor Power Supply 2 (for Slide12) 31 VM4 Power Supply£¥(for Stepper)

6 ST1IN Steppe control voltage input 1 32 ST1+ Steppe non-inverted output 1

7 ST2IN Steppe control voltage input £≤ 33 ST1- Steppe inverted output 1

8 LCIN Liquid crystal control voltage input 34 ST2+ Steppe non-inverted output 2

9 SL2+ Slide non-inverted output 2 35 ST2 Steppe inverted output 2

10 SL2 Slide inverted output 2 36 VM3 Power Supply3(for Loading)

11 GND GND 37 GND GND

12 SL1+ Slide non-inverted output 38 LO+ Loading non-inverted output

13 SL1- Slide inverted output 1 39 LO- Loading inverted output

14 LC+ Liquid crystal non-inverted output 40 TL+ Tilt non-inverted output

15 LC- Liquid crystal inverted output 41 TL- Tilt inverted output

16 GND GND 42 GND GND

17 U Motor drive output U 43 TO- Tracking inverted output

18 V Motor drive output V 44 TO+ Tracking non-inverted output

19 W Motor drive output W 45 FO+ Focus non-inverted output

20 COMMON Motor common 46 FO- Focus inverted output

21 VM5

Motor Power Supply5(for Liquid crystal)

47 5VCC 5V Power Supply (for FS,TS,TL)

22 STLIM

Input terminal for stepper current limit

48 TLIN Tilt control voltage input

23 SLLIM Input terminal for slide current limit 49 TOIN Tracking control voltage input

24 ACTFLG Pickup protect flag output 50 FOIN Focus control voltage input

25 FG Frequency generator output 51 LOIN Loading control input

26 VM1 Motor Power Supply 1(for Spindle) 52 REF Reference voltage input

Page 79

4-24

2. R8J32700FPV

2-1. PIN LAYOUT

Page 80

4-25

2-2. BLOCK DIAGRAM

Page 81

4-26

2-3. PIN FUNCTION

Page 82

4-27

3. R2S35003

3-1. PIN ASSIGNMENT

Page 83

4-28

3-2. BLOCK DIAGRAM

Page 84

4-29

3-3. PIN FUNCTIONS

Page 85

4-30

Page 86

4-31

WAVEFORMS

1. POWER & RESET SIGNAL

12V (CN803, PIN20, 21, 22)

5V(CN803, PIN14, 15, 16)

HRST (IC301, PIN209)

MRSTB (IC301, PIN88)

2. MAIN CLOCK1 FOR IC301 (33.859MHz)

X301 (IC301, PIN3)

Page 87

4-32

3. MAIN CLOCK2 FOR IC707 (25.035MHz)

X302 (IC707, PIN23)

Open sw (CN651 PIN3)

Close sw (CN651 PIN5)

Tray + (CN651 PIN2)

Tray - (CN651 PIN4)

4. TRAY OPEN/CLOSE SIGNAL

A

Open sw

Close sw

Tray +

Tray -

OPEN OPERATION

CLOSE OPERATION

B C D

Page 88

4-33

Open sw (CN651 PIN3) LDD (IC601 PIN51)

Tray + (CN651 PIN2) Tray - (CN651 PIN4)

5. TRAY OPEN/CLOSE SIGNAL A

6. TRAY OPEN/CLOSE SIGNAL B

Open sw (CN651 PIN3)

Open sw

LDO

Tray +

Tray -

ZOOM

A: STANDBY STATUS

Open sw (CN651 PIN3) LDD (IC601 PIN51)

Tray + (CN651 PIN2) Tray - (CN651 PIN4)

Open sw (CN651 PIN3)

Open sw

LDO

Tray +

Tray -

ZOOM

B : OPEN INITIAL STATUS

Page 89

4-34

Open sw (CN651 PIN3) LDD (IC601 PIN51)

Tray + (CN651 PIN2) Tray - (CN651 PIN4)

7. TRAY OPEN/CLOSE SIGNAL C

8. TRAY OPEN/CLOSE SIGNAL D

Open sw (CN651 PIN3)

Close sw

LDO

Tray +

Tray -

ZOOM

C : OPEN FINISHED STATUS

Open sw (CN651 PIN3) LDD (IC601 PIN51)

Tray + (CN651 PIN2) Tray - (CN651 PIN4)

Open sw (CN651 PIN3)

Close sw

LDO

Tray +

Tray -

ZOOM

D : CLOSE STATUS

Page 90

4-35

9. SLED MOVE SIGNAL

A+ (CN601 PIN4)

A- (CN601 PIN3)

B+ (CN601 PIN2)

B- (CN601 PIN1)

10. ZOOM OF SLED MOVE SIGNAL

A+ (CN601 PIN4)

A- (CN601 PIN3)

B+ (CN601 PIN2)

B- (CN601 PIN1)

Page 91

4-36

11. SPINDLE WAVEFORM

U (CN602 PIN3)

V (CN602 PIN2)

W (CN602 PIN1)

FG (IC601 PIN25)

12. ZOOM OF SPINDLE WAVEFORM

U (CN602 PIN3)

V (CN602 PIN2)

W (CN602 PIN1)

FG (IC601 PIN25)

Page 92

4-37

13. DISC TYPE JUDGEMENT WAVEFORM (DVD SERIES)

FE (IC101 PIN4)

FOD (IC601 PIN50)

TYPE JUGDEMENT

FOCUS ON

14. DISC TYPE JUDGEMENT WAVEFORM (DVD_SINGLE)

FE (IC101 PIN4)

FOD (IC601 PIN50)

Page 93

4-38

15. DISC TYPE JUDGEMENT WAVEFORM (DVD_DUAL)

FE (IC101 PIN4)

FOD (IC601 PIN50)

16. DISC TYPE JUDGEMENT WAVEFORM (BD SERIES)

FE (IC101 PIN4)

FOD (IC601 PIN50)

FOCUS ON

TYPE JUGDEMENT

Page 94

4-39

17. DISC TYPE JUDGEMENT WAVEFORM (BD_SINGLE)

FE (IC101 PIN4)

FOD (IC601 PIN50)

18. DISC TYPE JUDGEMENT WAVEFORM (BD_DUAL)

FE (IC101 PIN4)

FOD (IC601 PIN50)

Page 95

4-40

19. DISC TYPE JUDGEMENT WAVEFORM (HD SERIES)

FE (IC101 PIN4)

FOD (IC601 PIN50)

TYPE JUGDEMENT

FOCUS ON

20. DISC TYPE JUDGEMENT WAVEFORM (HD_SINGLE)

FE (IC101 PIN4)

FOD (IC601 PIN50)

Page 96

4-41

21. DISC TYPE JUDGEMENT WAVEFORM (HD_DUAL)

FE (IC101 PIN4)

FOD (IC601 PIN50)

22. FOCUS ON SIGNAL (DVD)

FE (IC101 PIN4)

FOD (IC601 PIN50)

TE (IC101 PIN5)

TRD (IC601 PIN49)

Page 97

4-42

23. FOCUS ON SIGNAL (BD)

FE (IC101 PIN4)

FOD (IC601 PIN50)

TE (IC101 PIN5)

TRD (IC601 PIN49)

24. FOCUS ON SIGNAL (HD)

FE (IC101 PIN4)

FOD (IC601 PIN50)

TE (IC101 PIN5)

TRD (IC601 PIN49)

Page 98

4-43

25. TRACK OFF SIGNAL (DVD)

TE (IC101 PIN5)

TZC (IC101 PIN43)

MIRR (IC101 PIN49)

26. TRACK OFF SIGNAL (BD)

TE (IC101 PIN5)

TZC (IC101 PIN43)

MIRR (IC101 PIN49)

Page 99

4-444-44

27. TRAKC OFF SIGNAL (HD)

TE (IC101 PIN5)

TZC (IC101 PIN43)

MIRR (IC101 PIN49)

28. TILT DRIVER SIGNAL

TLD (IC601 PIN48)

TILT+ (IC601 PIN40)

TILT- (IC601 PIN41)

Page 100

4-454-45

29. WOBBLE (DVD - R/RW)

AWOBSIG (IC101 PIN27)

LPPOUT (IC101 PIN51)

30. WOBBLE (DVD + R/RW)

WOBSIG (IC101 PIN48)

AWOBSIG (IC101 PIN27)

Loading...

Loading...