LG ARWN072BAS4 INSTALLATION MANUAL

http://www.lghvac.com

www.lg.com

Please read this installation manual completely before installing the product.

Installation work must be performed in accordance with the national wiring

standards by authorized personnel only.

Please retain this installation manual for future reference after reading it

thoroughly.

INSTALLATION MANUAL

AIR

CONDITIONER

P/NO : MFL68100308

Copyright © 2014 - 2018 LG Electronics Inc. All Rights Reserved.

ENGLISH

ESPAÑOL

FRANÇAIS

PORTUGUÊS

2

TIPS FOR SAVING ENERGY

Here are some tips that will help you minimize the power consumption

when you use the air conditioner. You can use your air conditioner

more efficiently by referring to the instructions below:

IMPORTANT SAFETY INSTRUCTIONS

READ ALL INSTRUCTIONS BEFORE USING THE APPLIANCE.

Always comply with the following precautions to avoid dangerous situations and ensure peak performance of your product

WARNING

It can result in serious injury or death when the directions are ignored

CAUTION

It can result in minor injury or product damage when the directions are

ignored

WARNING

• Installation or repairs made by unqualified persons can result in hazards to you and othersInstallation of all field wiring and components

MUST conform with local building codes or, in the absence of local

codes, with the National Electrical Code 70 and the National Building Con-struction and Safety Code or Canadian Electrical code and

National Building Code of Canada.

• Installation or repairs made by unqualified persons can result in hazards to you and others.

• The information contained in the manual is intended for use by a

qualified service technician familiar with safety procedures and

equipped with the proper tools and test instruments.

• Failure to carefully read and follow all instructions in this manual can

result in equipment malfunction, property damage, personal injury

and/or death.

Installation

• Have all electric work done by a licensed electrician according to "Electric Facility Engineering Standard" and "Interior Wire Regulations" and the

instructions given in this manual and always use a special circuit.

- If the power source capacity is inadequate or electric work is per-

formed improperly, electric shock or fire may result.

• Ask the dealer or an authorized technician to install the air conditioner.

- Improper installation by the user may result in water leakage, electric

shock, or fire.

• Always ground the product.

- There is risk of fire or electric shock.

• Always intstall a dedicated circuit and breaker.

- Improper wiring or installation may cause fire or electric shock.

• For re-installation of the installed product, always contact a dealer or an

Authorized Service Center.

- There is risk of fire, electric shock, explosion, or injury.

• Do not install, remove, or re-install the unit by yourself (customer).

- There is risk of fire, electric shock, explosion, or injury.

• Do not store or use flammable gas or combustibles near the air conditioner.

- There is risk of fire or failure of outdoors.

• Use the correctly rated breaker or fuse.

- There is risk of fire or electric shock.

• Do not install the unit at the outdoor.

- Otherwise it may cause fire, electric shock and trouble.

• Do not install the product on a defective installation stand.

- It may cause injury, accident, or damage to the product.

• Use a vacuum pump or Inert(nitrogen) gas when doing leakage test or

air purge. Do not compress air or Oxygen and do not use Flammable

gases. Otherwise, it may cause fire or explosion.

- There is the risk of death, injury, fire or explosion.

• When installing and moving the air conditioner to another site, do not

charge it with a different refrigerant from the refrigerant specified on

the unit.

- If a different refrigerant or air is mixed with the original refrigerant, the

refrigerant cycle may malfunction and the unit may be damaged.

• Do not reconstruct to change the settings of the protection devices.

- If the pressure switch, thermal switch, or other protection device is

shorted and operated forcibly, or parts other than those specified by

LGE are used, fire or explosion may result.

• Ventilate before operating air conditioner when gas leaked out.

- It may cause explosion, fire, and burn.

• Securely install the cover of control box and the panel.

- If the cover and panel are not installed securely, dust or water may

enter the outside unit and fire or electric shock may result.

• If the air conditioner is installed in a small room, measures must be

taken to prevent the refrigerant concentration from exceeding the safety

limit when the refrigerant leaks.

- Consult the dealer regarding the appropriate measures to prevent the

safety limit from being exceeded. Should the refrigerant leak and cause

the safety limit to be exceeded, harzards due to lack of oxygen in the

room could result.

Operation

• Do not damage or use an unspecified power cord.

- There is risk of fire, electric shock, explosion, or injury.

• Use a dedicated outlet for this appliance.

- There is risk of fire or electrical shock.

• Be cautious that water could not enter the product.

- There is risk of fire, electric shock, or product damage.

• Do not touch the power switch with wet hands.

- There is risk of fire, electric shock, explosion, or injury.

• When the product is soaked (flooded or submerged), contact an Authorized

Service Center.

- There is risk of fire or electric shock.

• Be cautious not to touch the sharp edges when installing.

- It may cause injury.

• Take care to ensure that nobody could step on or fall onto the outside unit .

- This could result in personal injury and product damage.

• Do not open the inlet grille of the product during operation. (Do not touch the

electrostatic filter, if the unit is so equipped.)

- There is risk of physical injury, electric shock, or product failure.

!

!

!

ENGLISH

• Do not cool excessively indoors. This may be harmful for your health

and may consume more electricity.

• Block sunlight with blinds or curtains while you are operating the air

conditioner.

• Keep doors or windows closed tightly while you are operating the air

conditioner.

• Adjust the direction of the air flow vertically or horizontally to circulate

indoor air.

• Open windows regularly for ventilation as the indoor air quality may

deteriorate if the air conditioner is used for many hours.

• Clean the air filter once every 2 weeks. Dust and impurities collected

in the air filter may block the air flow or weaken the cooling / dehumidifying functions.

For your records

Staple your receipt to this page in case you need it to prove the date of

purchase or for warranty purposes. Write the model number and the

serial number here:

Model number :

Serial number :

You can find them on a label on the side of each unit.

Dealer’s name :

Date of purchase :

3

CAUTION

Installation

• Always check for gas (refrigerant) leakage after installation or repair of product.

- Low refrigerant levels may cause failure of product.

• Do not install the product where the noise or hot air from the outside unit could

damage the neighborhoods.

- It may cause a problem for your neighbors.

• Keep level even when installing the product.

- To avoid vibration or water leakage.

• Do not install the unit where combustible gas may leak.

- If the gas leaks and accumulates around the unit, an explosion may result.

• Use power cables of sufficient current carrying capacity and rating.

- Cables that are too small may leak, generate heat, and cause a fire.

• Do not use the product for special purposes, such as preserving foods, works of

art, etc. It is a consumer air conditioner, not a precision refrigeration system.

- There is risk of damage or loss of property.

• When installting the unit in a hospital, communication station, or similar place,

provide sufficient protection against noise.

-

The inverter equipment, private power generator, high-frequency medical

equipment, or radio communication equipment may cause the air conditioner to operate erroneously, or fail to operate. On the other hand, the air

conditioner may affect such equipment by creating noise that disturbs medical treatment or image broadcasting.

Operation

• Do not use the air conditioner in special environments.

-

Oil, steam, sulfuric smoke, etc. can significantly reduce the performance of the air

conditioner or damage its parts.

• Do not block the inlet or outlet.

- It may cause failure of appliance or accident.

• Make the connections securely so that the outside force of the cable may not be

applied to the terminals.

- Inadequate connection and fastening may generate heat and cause a fire.

• Be sure the installation area does not deteriorate with age.

- If the base collapses, the air conditioner could fall with it, causing property

damage, product failure, or personal injury.

•

Install and insulate the drain hose to ensure that water is drained away properly

based on the installation manual.

- A bad connection may cause water leakage.

• Be very careful about product transportation.

- Only one person should not carry the product if it weighs more than 20 kg.

-

Some products use PP bands for packaging. Do not use any PP bands for a means

of transportation. It is dangerous.

- Do not touch the heat exchanger fins. Doing so may cut your fingers.

- When transporting the outside unit , suspending it at the specified positions on

the unit base. Also support the outside unit at four points so that it cannot slip

sideways.

• Safely dispose of the packing materials.

-

Packing materials, such as nails and other metal or wooden parts, may cause stabs

or other injuries.

-

Tear apart and throw away plastic packaging bags so that children may not play with

them. If children play with a plastic bag which was not torn apart, they face the risk

of suffocation.

• Turn on the power at least 6 hours before starting operation.

- Starting operation immediately after turning on the main power switch can re-

sult in severe damage to internal parts. Keep the power switch turned on during the operational season.

• Do not touch any of the refrigerant piping during and after operation.

- It can cause a burn or frostbite.

• Do not operate the air conditioner with the panels or guards removed.

- Rotating, hot, or high-voltage parts can cause injuries.

• Do not directly turn off the main power switch after stopping operation.

- Wait at least 5 minutes before turning off the main power switch. Otherwise it

may result in water leakage or other problems.

•

Auto-addressing should be done in condition of connecting the power of all indoor and

outdoour units. Auto-addressing should also be done in case of changing the indoor

unit PCB.

• Use a firm stool or ladder when cleaning or maintaining the air conditioner.

- Be careful and avoid personal injury.

!

ENGLISH

TABLE OF CONTENTS

2 TIPS FOR SAVING ENERGY

2 IMPORTANT SAFETY INSTRUCTIONS

4 INSTALLATION PROCESS

4 OUTSIDE UNITS INFORMATION

4 ALTERNATIVE REFRIGERANT R410A

4 SELECT THE BEST LOCATION

5 INSTALLATION SPACE

5 WATER CONTROL

6 LIFTING METHOD

6 INSTALLATION

9 REFRIGERANT PIPING INSTALLATION

10 INSTALLATION OF WATER PIPE

11 DEVICE PROTECTION UNIT

20 ELECTRICAL WIRING

29 TEST RUN

33 CAUTION FOR REFRIGERANT LEAK

34 COOLING TOWER APPLIED METHOD

34 WATER SOLENOID VALVE CONTROL

4

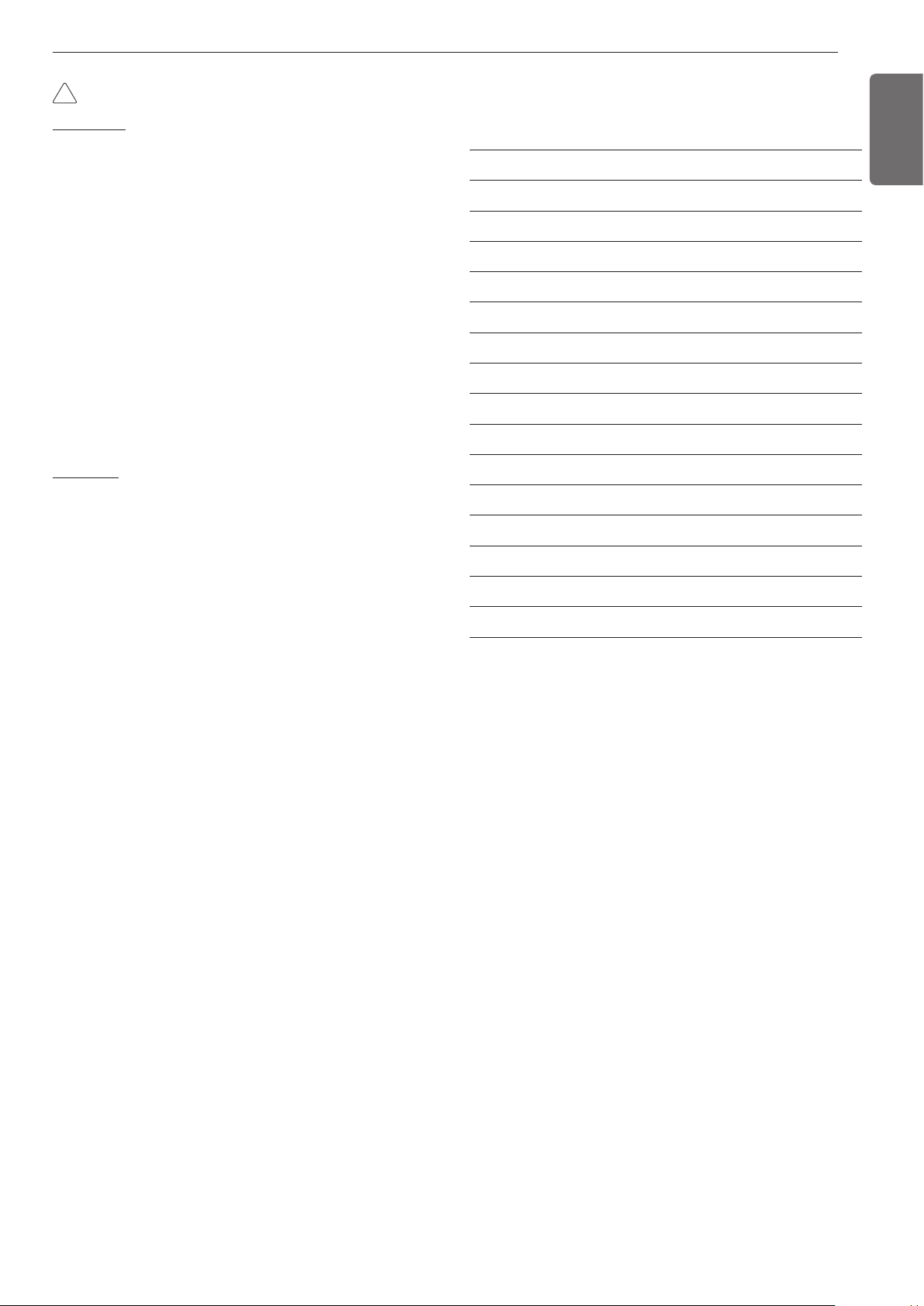

INSTALLATION PROCESS

ENGLISH

The foundation must be level even

Outside unit foundation work

Avoid short circuits and ensure

sufficient space is allowed for service

Installation of outside unit

Refer to automatic addressing flowchart

Automatic addressing of indoor unit

In the final check for 24hours at 3.8 MPa(38.7 kgf/cm

2

) there

must be no drop in pressure.

Airtight test

Multiple core cable must not be used.

(suitable cable should be selected)

Electrical work

(connection circuits and drive circuits)

Make sure no gaps are left where

the insulating materials are joined

Heat insulation work

Make sure airflow is sufficient

Duct work

Adjust to downward gradient

Drain pipe work

Special attention to dryness,

cleanness and tightness

Refrigerant piping work

Check model name to

make sure the fitting

is made correctly

Installation of indoor unit

Take account of gradient

of drain piping

Sleeve and insert work

Make connection clearly between outside, indoor,

remote controller and option.

Preparation of contract drawings

Indicate clearly who will be responsible for switch setting.

Determination of division work

The vacuum pump used must have a capacity of reaching at least

5 torr, more than 1 hour

Vacuum drying

Recharge correctly as calculated in this manual. and record the

amount of added refrigerant

Additional charge of refrigerant

Make sure there are no gaps left between the facing materials

used on the ceiling

Fit facing panels

Run each indoor unit in turn to make sure the pipe work

has been fitted correctly

Test run adjustment

Explain the use of the system as clearly as possible to your customer and

make sure all relevant documentation is in order

Transfer to customer with explanation

Preheat the crank case with the electrical heater for more than 6 hours.

CAUTION

• The above list indicates the order in which the individual work operations are normally carried out but this order may be varied where

local conditions warrants such change.

• The thickness of the piping should comply with the relevant local and

national regulations for the designed pressure 3.8Mpa(551.1psi).

• Since R410A is a mixed refrigerant, the required additional

refrigerant must be charged in its liquid state.(If the refrigerant is

charged in its gaseous state, its composition changes and the system will not work properly.)

!

CAUTION

Notes: *

We can guarantee the operation only within 130% Combination. If you want to connect more than 130% combination,

please contact us and discuss the requirement like below.

• If the operation of indoor unit is more than 130%, low airflow

operation is recommended in all the indoor units.

• If the operation of indoor unit is more than 130%, additional re-

frigerant is needed according to the Aheadquarter guidance.

• Over 130%, capacity is same as capacity of 130%, Same re-

mark is valid for power input.

•

Ratio of the running Indoor Units to the Outside: Within 10 ~ 100%

•

A combination operation over 100% cause to reduce each indoor unit capacity.

Combination Ratio(50~200%)

Outside Unit Number Connection Ratio

Single outside unit s 200%

Double outside unit s 160%

More than Triple outside unit s

130%

!

OUTSIDE UNITS INFORMATION

ALTERNATIVE REFRIGERANT R410A

The refrigerant R410A has the property of higher operating pressure in

comparison with R22.

Therefore, all materials have the characteristics of higher resisting

pressure than R22 ones and this characteristic should be also considered during the installation.

R410A is an azeotrope of R32 and R125 mixed at 50:50, so the ozone

depletion potential (ODP) of R410A is 0.

These days the developed countries have approved it as the environment-friendly refrigerant and encouraged to use it widely to prevent

environment pollution.

CAUTION

• The wall thickness of the piping should comply with the relevant

local and national regulations for the designed pressure

3.8Mpa(551.1psi).

• Since R410A is a mixed refrigerant, the required additional

refrigerant must be charged in its liquid state.

If the refrigerant is charged in its gaseous state, its composition

changes and the system will not work properly.

• Do not place the refrigerant container under the direct rays of the

sun to prevent it from exploding.

• For high-pressure refrigerant, any unapproved pipe must not be

used.

• Do not heat pipes more than necessary to prevent them from

softening.

• Be careful not to install wrongly to minimize economic loss

because it is expensive in comparison with R22.

!

SELECT THE BEST LOCATION

Select space for installing outside unit , which will meet the following

conditions:

• With strength which bears weight of unit

• With space for air passage and service work

Don't install the unit at the space where generation, inflow, stagnation, and leak of combustible gas is expected.

• Avoid unit installation in a place where acidic solution and spray (sulfur) are often used.

• Location with no leakage of combustible gas

• Recommend the outside unit to be installed within

0~40°C(32~104°F).

• Location with installation or service work space (Refer to required

space)

• Do not use the outside unit under any special environment where oil,

steam and sulfuric gas exist.

• Install in a separate machine room not exposed to external air

- Establish an anti-freeze plan for the water supply when the product

is stopped during the winter.

- Install the product so that the noise from the machine room is not

transferred outsides

• The floor of the machine room must be water proof.

• Drainage must be installed in the machine room to process the water

drainage.

• Install a floor slope to make the drainage smooth.

• Avoid installing the outside unit in the location with following conditions.

• Location where corrosive gas such as acidic gas is generated.

(It may cause the refrigerant leakage by corrosion of the pipe.)

• Location where electromagnetic waves happen.

(It may cause the abnormal operation by control parts disorder.)

• Location to be able to leak the combustible gas

• Location with carbon fiber or combustible dust.

• Location with the combustible material like thinner or gasoline.

(It may cause a fire by leaking the gas near the product.)

CAUTION

• Do not install Multi V water outside. Always install indoor like

machine room.

• Inverter product may generate electric noise. Keep the body

from computer, stereo etc. at enough distance. Specially leave

space from indoor remote controller to shoes electric devices at

the above 3m in weak electric wave area. Insert the power

cable and other wire into separate conduit.

!

5

ENGLISH

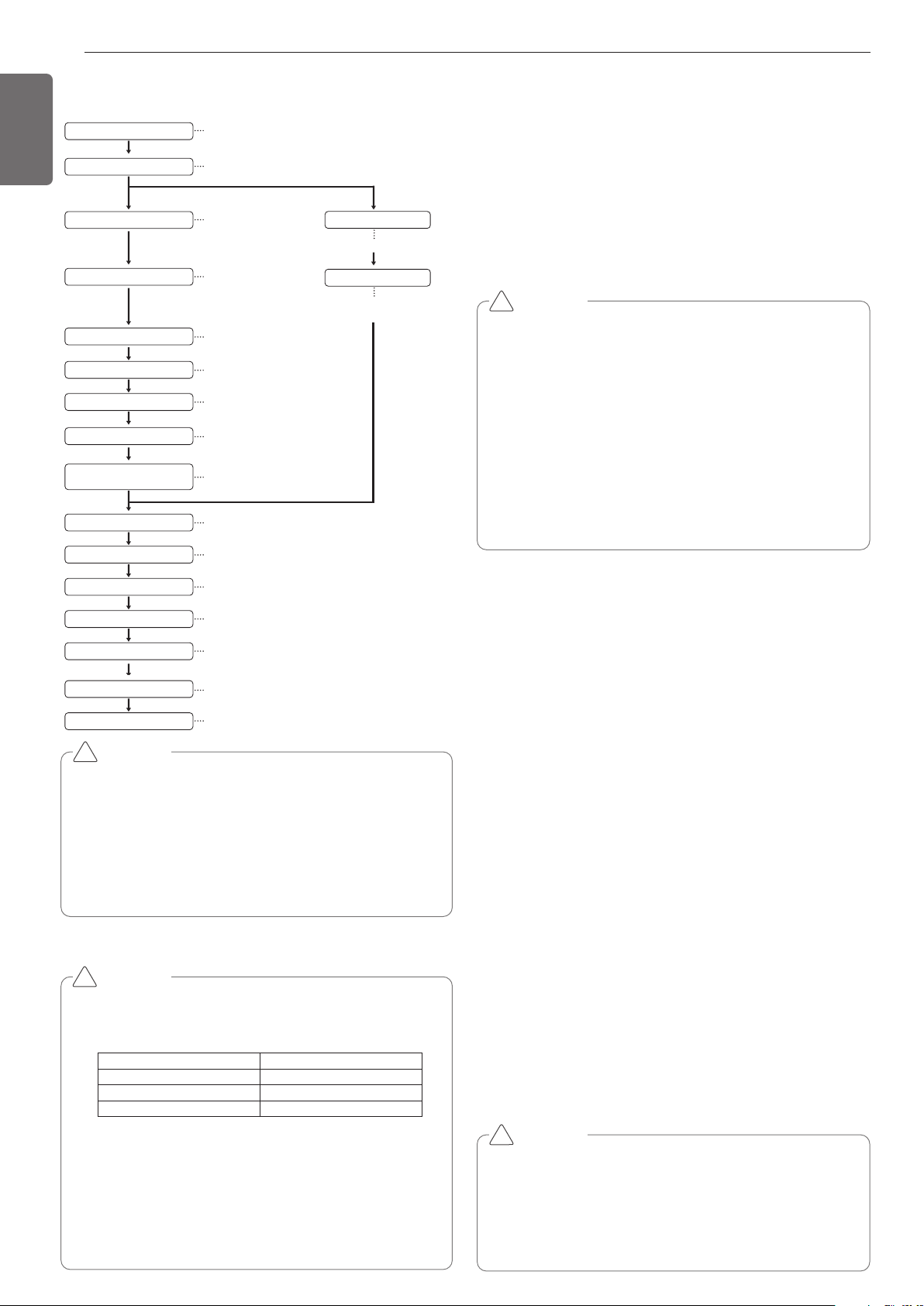

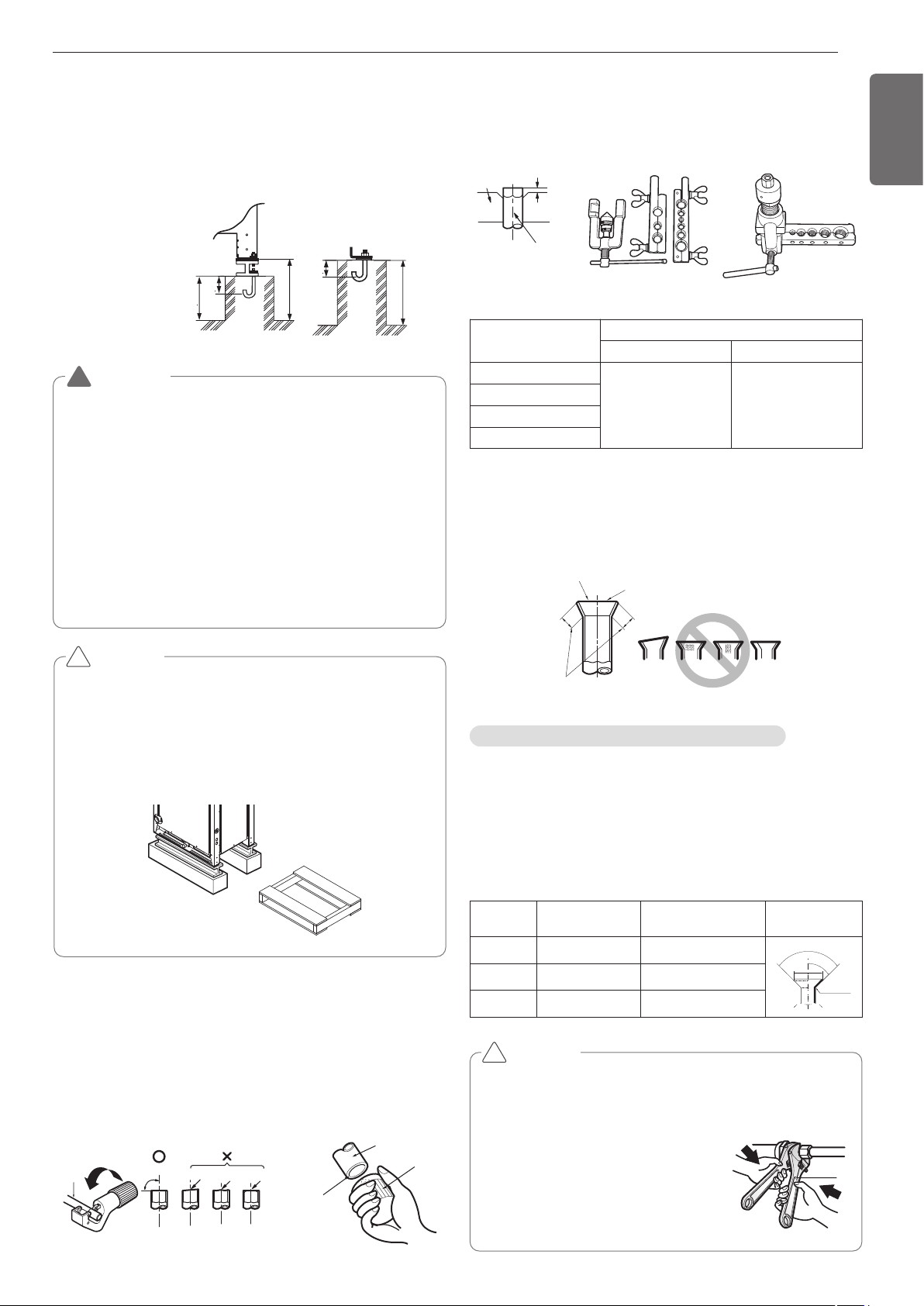

Individual Installation Water control

Collective / Continuous Installation

During the installation of the unit, consider service, inlet, and outlet

acquire the minimum space as shown in the figures below.

: Service area

* In case of the water pipe passing side product, please make suffi-

cient service place to avoid occurring between water pipe and product side.

Space required for collective installation and continuous installation as

shown below considering passage for air and people.

: Service area

Two Layer Installation

Space required for two layer installation as shown below considering

passage for air and people.

: Service area

• Keep the water temperature between 10~45°C(50~113°F). Other it

may cause the breakdown.

- Standard water supply temperature is 30°C(86°F) for Cooling and

20°C(68°F) for heating.

• Properly control the water velocity. Otherwise it may cause the

noise, pipe vibration or pipe contraction, expansion according to the

temperature. Use the same water pipe size connected with the product or more.

• Refer to the water source pipe diameter and water velocity table

below. As the water velocity is fast, air bubble will increase.

• Be careful of the water purity control. Otherwise it may cause the

breakdown due to water pipe corrosion.

(Refer to 'Standard Table for Water Purity Control')

• In case the water temperature is above 40°C(104°F), it is good to prevent the corrosion by adding the anticorrosive agent.

• Install the pipe, valve and gauge sensor in the space where it is easy

to maintain. Install the water valve in the low position for drain, if required.

• Be careful not to let air in. If so, the water velocity will be unstable in

the circulation, pump efficiency will also decrease and may cause the

piping vibration. Therefore, install the air purge where it may generate the air.

• Choose the following anti freezing methods. Otherwise, it will be

dangerous for the pipe to break in the winter.

- Circulate the water with the pump before dropping the temperature.

- Keep the normal temperature by boiler.

- When the cooling tower is not operated for a long time, drain the

water in the cooling tower.

- Use an anti-freeze. (For using an anti freeze, change the DIP switch

on main PCB in outside unit.)

- Refer to the additive amount about freezing temperature as in the

table given below.

• In addition to anti freeze, it may cause the change of the pressure in

the water system and the low performance of the product.

• Make sure to use the closed cooling type tower.

When applying the open type cooling tower, use a 2nd heat exchanger to make the water supply system a closed type system.

Service area

(Front)

Standard table for water purity control

The water may contain many foreign substances and hence may influence the performance and lifetime of the product due to the corrosion

of the condenser and water pipe. (Use water source that complies

with the below standard table for water purity control.)

If you use water supply other than the tap water to supply the water

for the cooling tower, you must do a water quality inspection.

• If you use the closed cooling tower, the water quality must be controlled in accordance with the following standard table.

If you do not control the water quality in accordance with the following standard water quality table, it can cause performance deterioration to the air conditioner and severe problem to the product

WATER CONTROL INSTALLATION SPACE

Anti freeze type

Minimum temperature for anti freezing [°C(°F)]

0 -5(23) -10(14) -15(5) -20(-4) -25(-13)

Ethylene glycol (%) 0 12 20 30 - -

Propylene glycol (%) 0 17 25 33 - -

Methanol (%) 0 6 12 16 24 30

Diameter [mm(inch)] Velocity range (m/s)

< 50(1-31/32) 0.6 ~ 1.2

50(1-31/32) ~ 100(5-7/8) 1.2 ~ 2.1

100100(5-7/8) < 2.1 ~ 2.7

(Unit: mm(inch))

H-Beam Support

<Front View><Top View>

997(39-1/4)

100(3-15/16) 100(3-15/16)

Water pipe

installation

space

20(25/32)

Product

(Outside unit)

Service area

Service area

(Front)

(Front)

350(13-25/32)

755(29-23/32)

20

(25/32)

100(3-15/16)

600(23-5/8) 500(19-11/16)

(Unit: mm(inch))

20

(25/32)

600(23-5/8) 500(19-11/16)

100(3-15/16)

20

(25/32)

350(13-25/32)

Product

(Outside unit)

Service area

(Front)

755(29-23/32)

100(3-15/16)

Product

(Outside unit)

Service area

(Front)

350(13-25/32)

755(29-23/32)

(Outside unit)

350(13-25/32)

100(3-15/16)

<Top view>

Product

Service area

(Front)

755(29-23/32)

350(13-25/32)

100(3-15/16)

Product

(Outside unit)

Service area

(Front)

755(29-23/32)

(Unit: mm(inch))

100(3-15/16)

H-Beam Support

<Front View>

997(39-1/4)

100(3-15/16)

100(3-15/16)

997(39-1/4)

100(3-15/16)

6

ENGLISH

Items

pH(25C)

Conductivity[25C](mS/m)

Chlorine ion(mg CI-/l)

Sulfuric acid ion(mg SO

2

-

/l)

Acid demand[pH 4.8] (mg SiO

2/l)

Total hardness(mg SiO

2/l)

Ca hardness(mg CaCO

3/l)

Ion silica(mg SiO

2/l)

Fe(mg Fe/l)

Copper(mg Cu/l)

Sulfuric acid ion(mg S

2

/l)

Ammonium ion(mg NH

4/l)

Residual chlorine(mg Cl/l)

Free carbon dioxide(mg CO

2/l)

Stability index

7.0~8.0

Below 30

Below 50

Below 50

Below 50

Below 70

Below 50

Below 30

Below 1.0

Below 1.0

Must not be detected

Below 0.3

Below 0.25

Below 0.4

-

Below 0.3

Below 0.1

Must not be detected

Below 0.1

Below 0.3

Below 4.0

-

7.0~8.0

Below 30

Below 50

Below 50

Below 50

Below 70

Below 50

Below 30

O

O

O

O

-

-

-

-

O

O

O

O

O

O

O

O

-

-

-

-

-

O

O

O

O

O

O

O

O

Closed type

Basic Item

Reference Item

Effect

Circulating water Supplemented water Corrosion Scale

4

+

Reference

• The "O" mark for corrosion and scale means that there is possibility of occurrence.

• When the water temperature is 40°C(104°F) or above or when

uncoated iron is exposed to the water, it can result in corrosion.

Therefore adding anti-corrosion agent or removing the air can be

very effective.

• In case of using the closed type cooling tower, the cooling water

and supplementing water must satisfy the water quality criteria

of closed type system in the table.

• Supplementing water and supplied water must be supplied with

tap water, industrial water and underground water excluding filtered water, neutral water, soft water etc.

• 15 items in the table are general causes of corrosion and scale.

The location of the Anchor bolts

• Install at places where it can endure the weight and vibration/noise

of the outside unit .

• The outside unit supports at the bottom shall have width of at least

100mm(3-15/16inch) under the Unit’s legs before being fixed.

• The outside unit supports should have minimum height of 200mm

(7-7/8inch).

• Anchor bolts must be inserted at least 75mm(2-15/16 inch).

At least 100mm

(3-15/16 inch)

At least 100mm

(3-15/16 inch)

At least 100mm

(3-15/16 inch)

At least 100mm

(3-15/16 inch)

Foundation for Installation

• Fix the unit tightly with bolts as shown below so that unit will not fall

down due to earthquake or gust.

• Use the H-beam support as a base support

• Noise and vibration may occur from the floor or wall since vibration is

transferred through the installation part depending on installation status. Thus, use anti-vibration materials (cushion pad) fully (The base

pad shall be more than 200mm(7-7/8inch)).

At least

200mm

(7-7/8inch)

INSTALLATION

LIFTING METHOD

- When carrying the unit suspended, pass the ropes under the unit and

use the two suspension points each at the front and rear.

- Always lift the unit with ropes attached at fours points so that impact

is not applied to the unit.

- Attach the ropes to the unit at an angle of 40° or less

CAUTION

Be very careful while carrying the product.

• Do not have only one person carry product if it is more than 20

kg(44lbs).

• PP bands are used to pack some products. Do not use them as a

mean for transportation because they are dangerous.

• Tear plastic packaging bag and scrap it so that children cannot

play with it. Otherwise plastic packaging bag may suffocate children to death.

• When carrying in Outdoor Unit, be sure to support it at four

points. Carrying in and lifting with 3-point support may make Outdoor Unit unstable, resulting in a fall.

• Use 2 belts of at least 8m(26.2ft) long.

• Place extra cloth or boards in the locations where the casing

comes in contact with the sling to prevent damage.

• Hoist the unit making sure it is being lifted at its center of gravity.

!

Sub line

A

40° or less

Rope supporter

B

Unit: mm(inch)

62(2-7/16)

The location of

anchor bolt

62(2-7/16)

500(19-11/16)

472(18-19/32)

755(29-23/32)

631(24-27/32)

7

ENGLISH

Unit: mm(inch)

200(7-7/8)

75(2-15/16)

75(2-15/16)

200(7-7/8)

100(3-15/16)

Ⓐ The corner part must be fixed firmly. Otherwise, the support for the

installation may be bent.

Ⓑ Get and use M10 Anchor bolt.

Ⓒ Put Cushion Pad between the outside unit and ground support for

the vibration protection in wide area.

Ⓓ Space for pipes and wiring (Pipes and wirings for bottom side)

Ⓔ H-beam support

Ⓕ Concrete support

CAUTION

• Be sure to remove the Pallet(Wood Support) of the bottom

side of the outside unit Base Pan before fixing the bolt. It

may cause the unstable state of the outdoor settlement,

and may cause freezing of the heat exchanger resulting in

abnormal operations.

• Be sure to remove the Pallet(Wood Support) of the bottom

side of the outside unit before welding. Not removing Pallet(Wood Support) causes hazard of fire during welding.

WARNING

• Install where it can sufficiently support the weight of the outside unit .

If the support strength is not enough, the outside unit may

drop and hurt people.

• Install where the outside unit may not fall in strong wind or

earthquake.

If there is a fault in the supporting conditions, the outside unit

may fall and hurt people.

• Please take extra cautions on the supporting strength of the

ground, water outlet treatment(treatment of the water flowing

out of the outside unit in operation), and the passages of the

pipe and wiring, when making the ground support.

• Do not use tube or pipe for water outlet in the Base pan. Use

drainage instead for water outlet. The tube or pipe may freeze

and the water may not be drained.

Pallet(Wood Support)

- Remove before Installation

!

!

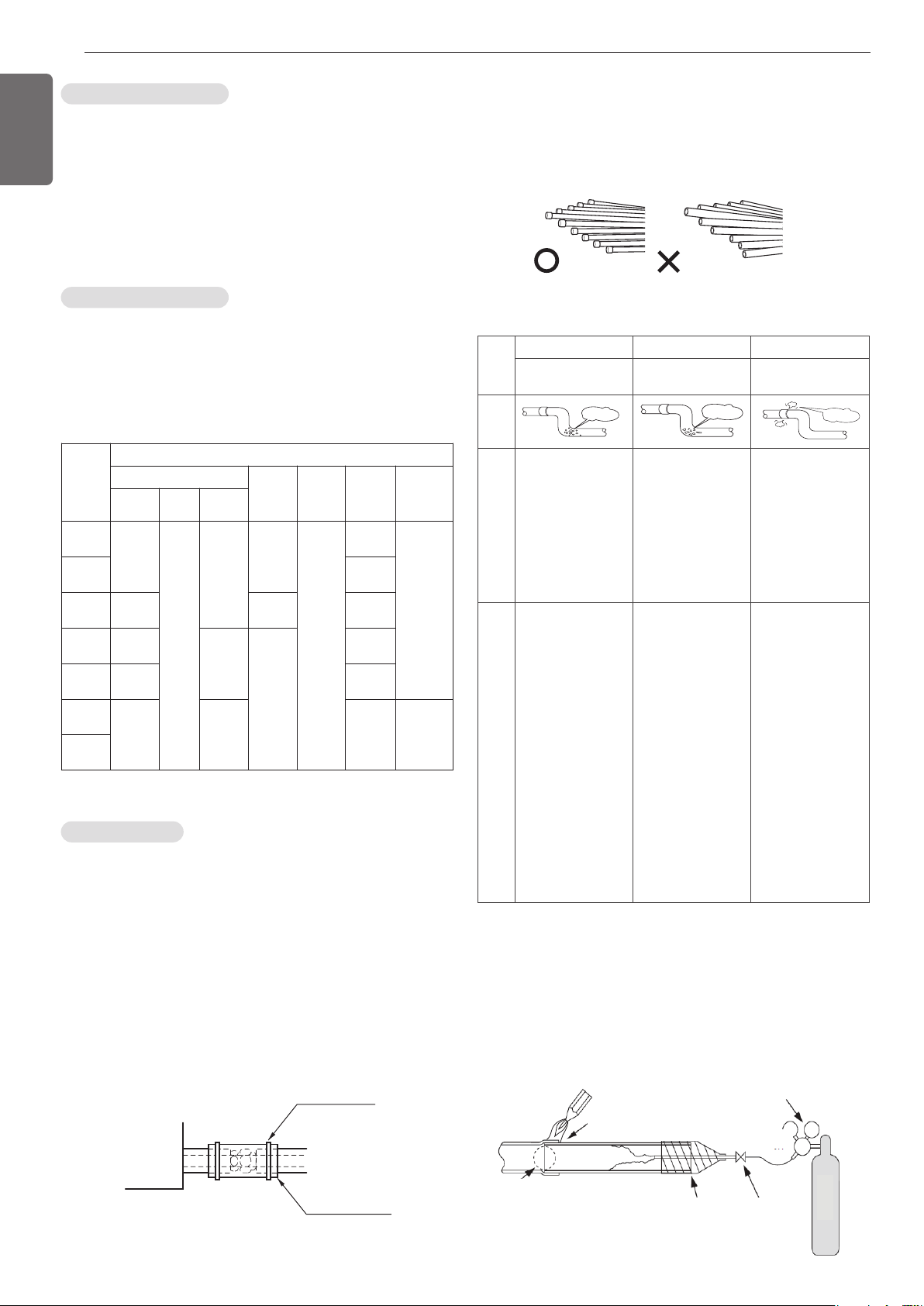

Main cause of gas leakage is defect in flaring work. Carry out correct

flaring work in the following procedure.

Cut the pipes and the cable

- Use the accessory piping kit or the pipes purchased locally.

- Measure the distance between the indoor and the outside unit .

- Cut the pipes a little longer than measured distance.

- Cut the cable 1.5m(4.92ft) longer than the pipe length.

Pipe

Reamer

Point down

Copper

tube

90

Slanted Uneven Rough

Preparation of Piping

Burrs removal

- Completely remove all burrs from the cut cross section of pipe/tube.

- Put the end of the copper tube/pipe to downward direction as you remove burrs in order to avoid to let burrs drop in the tubing.

Flaring work

- Carry out flaring work using flaring tool as shown below.

Firmly hold copper tube in a bar(or die) as indicated dimension in the

table above.

Check

- Compare the flared work with figure below.

- If flare is noted to be defective, cut off the flared section and do flaring work again.

Inclined

Inside is shining without scratches.

Smooth all round

Even length

all round

Surface

damaged

Cracked Uneven

thickness

= Improper flaring =

Flare shape and flare nut tightening torque

Precautions when connecting pipes

- See the following table for flare part machining dimensions.

- When connecting the flare nuts, apply refrigerant oil to the inside and

outside of the flares and turn them three or four times at first. (Use

ester oil or ether oil.)

-

See the following table for tightening torque.(Applying too much torque may

cause the flares to crack.)

- After all the piping has been connected, use nitrogen to perform a

gas leak check.

CAUTION

• Always use a charge hose for service port connection.

•

After tightening the cap, check that no refrigerant leaks are present

.

• When loosening a flare nut, always use two wrenches in

combination, When connecting the piping,

always use a spanner and torque wrench

in combination to tighten the flare nut.

• When connecting a flare nut, coat the

flare(inner and outer faces) with oil for

R410A(PVE) and hand tighten the nut

3 to 4 turns as the initial tightening.

Union

!

pipe size

[mm(inch)]

Tightening Torque

N·m(lbs ·ft)

A [mm(inch)] Flare shape

Ø9.52(3/8) 38±4(28±3.0) 12.8(0.5)~13.2(0.52)

Ø12.7(1/2) 55±6(41±4.4) 16.2(0.64)~16.6(0.65)

Ø15.88(5/8) 75±7(55±5.2) 19.3(0.76)~19.7(0.78

Pipe diameter

Inch (mm)

A inch (mm)

Wing nut type Clutch type

Ø1/4 (Ø6.35)

0.04~0.07 (1.1~1.8) 0~0.02 (0~0.5)

Ø3/8 (Ø9.52)

Ø1/2 (Ø12.7)

Ø5/8 (Ø15.88)

<Wing nut type> <Clutch type>

Bar

"A"

Copper pipe

2

90

45

2

A

R=0.4~0.8

8

ENGLISH

Opening shutoff valve

1 Remove the cap and turn the valve counter clockwise with the

wrench.

2 Turn it until the shaft stops.

Do not apply excessive force to the shutoff valve. Doing so may

break the valve body, as the valve is not a backseat type. Always

use the special tool.

3 Make sure to tighten the cap securely.

Heat insulation

1 Use the heat insulation material for the refrigerant piping which has

an excellent heat-resistance (over 248°F).

2 Precautions in high humidity circumstance:

This air conditioner has been tested according to the "ISO Conditions with Mist" and confirmed that there is not any default. However, if it is operated for a long time in high humid atmosphere

(dew point temperature: more than 73.4°F), water drops are liable

to fall. In this case, add heat insulation material according to the following procedure:

- Heat insulation material to be prepared... EPDM (Ethylene Propylene Diene Methylene)-over 248°F the heat-resistance temperature.

- Add the insulation over 10mm(0.39 inch) thickness at high humid-

ity environment.

Closing shutoff valve

1 Remove the cap and turn the valve clockwise with the wrench.

2 Securely tighten the valve until the shaft contacts the main body seal.

3 Make sure to tighten the cap securely.

* For the tightening torque, refer to the table on the below.

Tightening torque

Plumbing materials and storage methods

Pipe must be able to obtain the specified thickness and should be

used with low impurities.

Also when handling storage, pipe must be careful to prevent a fracture, deformity and wound.

Should not be mixed with contaminations such as dust, moisture.

Shut off

valve size

[mm(inch)]

Tightening torque N·m(lbs ·ft)(Turn clockwise to close)

Shaft(valve body)

Cap

(Valve lid)

Service

port

Flare nut

Gas line piping attached

to unit

Closed Opened

Hexagonal

wrench

Ø6.35

(1/4)

6.0 ±0.6

(4.4±0.4)

5.0 ±0.0

(3.7±0.4)

4mm

(0.16inch)

17.6±2.0

(13.0±1.5)

12.7±2

(9.4±1.5)

16±2

(12±1.5)

-

Ø9.52

(3/8)

38±4

(28±3.0)

Ø12.7

(1/2)

10.0 ±1.0

(7.4±0.7)

20.0±2.0

(14.8±1.5)

55±6(

41±4.4)

Ø15.88

(5/8)

12.0 ±1.2

(8.9±0.9)

5mm

(0.24inch)

25.0±2.5

(18.4±1.8)

75±7

(55±5.1)

Ø19.05

(3/4)

14.0 ±1.4

(10.3±1.0)

110±10

(81.1±7.4)

Ø22.2

(7/8)

30.0 ±3.0

(22.1±2.2)

8mm

(0.31inch)

-

25±3.0

(18.5±2.2)

Ø25.4

(1.0)

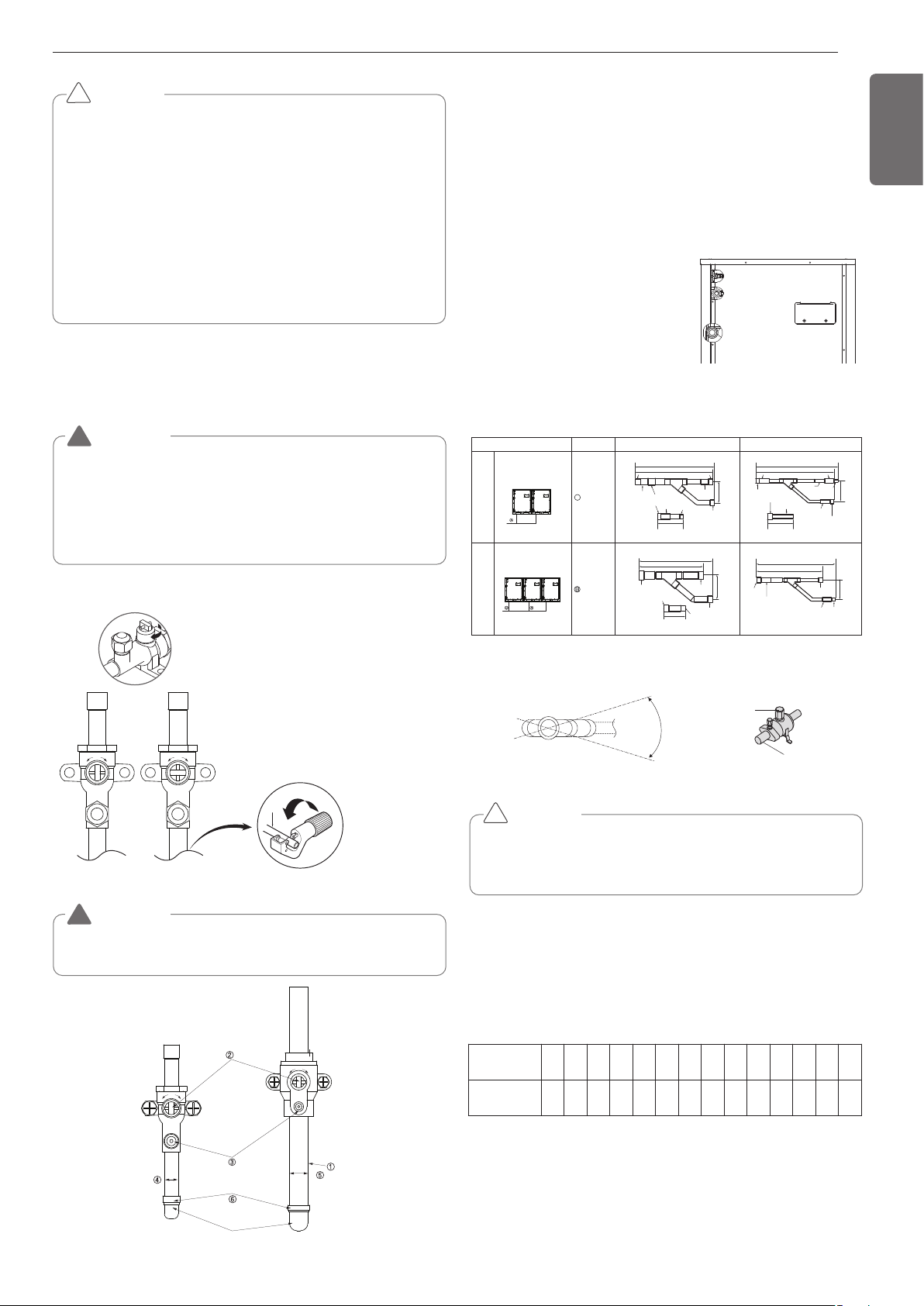

Refrigerant piping on three principles

Drying Cleanliness Airtight

Should be no moisture

inside

No dust inside.

There is no refrigerant

leakage

Items

Moisture

Dust

Leakage

Cause

failure

- Significant hydrolysis of refrigerant oil

- Degradation of refrigerant oil

- Poor insula’tion of

the compressor

- Do not cold and

warm

- Clogging of EEV,

Capillary

- Degradation of refrigerant oil

- Poor insulation of

the compressor

- Do not cold and

warm

- Clogging of EEV,

Capillary

- Gas shortages

- Degradation of refrigerant oil

- Poor insulation of

the compressor

- Do not cold and

warm

Coun-

termea-

sure

-

No moisture in the pipe

- Until the connection is completed,

the plumbing pipe

entrance should be

strictly controlled.

- Stop plumbing at

rainy day.

- Pipe entrance

should be taken

side or bottom.

-

When removal burr

after cutting pipe, pipe

entrance should be

taken down.

- Pipe entrance

should be fitted cap

when pass through

the walls.

- No dust in the pipe.

- Until the connection is completed,

the plumbing pipe

entrance should be

strictly controlled.

- Pipe entrance

should be taken

side or bottom.

- When removal burr

after cutting pipe,

pipe entrance

should be taken

down.

- Pipe entrance

should be fitted cap

when pass through

the walls.

- Airtightness test

should be.

- Brazing operations

to comply with

standards.

- Flare to comply

with standards.

- Flange connections

to comply with

standards.

Nitrogen substitution method

Welding, as when heating without nitrogen substitution a large

amount of the oxide film is formed on the internal piping.

The oxide film is a caused by clogging EEV, Capillary, oil hole of accumulator and suction hole of oil pump in compressor.

It prevents normal operation of the compressor.

In order to avoid this problem, Welding should be done after replacing

air by nitrogen gas.

When welding plumbing pipe, the work is required.

Regulator

Nitrogen gas Pressure

0.02Mpa (2.9psi) less

Auxiliary valve

Taping

(Should not

contain air)

Welding Point

Note) should not block the outlet side.

When the internal pressure in pipe is abo

ve the atmospheric pressure, pinhole is o

ccurred and it is a leakage cause.

Oxide scale

Nitrogen

Fastening band

(accessory)

Indoor unit

Thermal insulator

(accessory)

Refrigerant piping

1

Always use the nitrogen.(not use oxygen, carbon dioxide, and a

Chevron gas): Please use the following nitrogen pressure

0.02Mpa (2.9psi) Oxygen – Promotes oxidative degradation of refrigerant oil. Because it is flammable, it is strictly prohibited to

use Carbon dioxide – Degrade the drying characteristics of gas

Chevron Gas – Toxic gas occurs when exposed to direct flame.

2 Always use a pressure reducing valve.

3 Please do not use commercially available antioxidant.

The residual material seems to be the oxide scale is ob-

served. In fact, due to the organic acids generated by oxida-

tion of the alcohol contained in the anti-oxidants, ants nest

corrosion occurs. (causes of organic acid

’

alcohol + copper

+ water + temperature)

CAUTION

!

9

ENGLISH

Liquid pipe

Gas pipe

Liquid pipe

Gas pipe

Cautions in pipe connection/valve operation

WARNING

After completing work, securely tighten both service ports and

caps so that gas does not leak.

!

WARNING

Always use extreme care to prevent the refrigerant gas (R410A)

from leakage while using fire or flame. If the refrigerant gas

comes in contact with the flame from any source, such as a gas

stove, it breaks down and generates a poisonous gas which can

cause gas poisoning. Never perform brazing in an unventilated

room. Always conduct an inspection for gas leakage after installation of the refrigerant piping has been completed.

!

Elbow

Ball Valve(Gas Pipe)

Ball Valve

(Liquid Pipe)

Liquid pipe

Gas pipe

REFRIGERANT PIPING INSTALLATION

① Pipe joint (auxiliary parts): Securely perform brazing with a nitrogen

blow into the service port.(Releasing pressure : 0.02 MPa(2.9psi) or

less)

② Cap: Remove caps and operate valve, etc. After operation, always

reattach caps (tightening torque of valve cap: 25Nm (250kg-cm) or

more). (Don't remove the internal part of the port)

③ Service port: Make the refrigerant pipe vacuum and charge it using

the service port. Always reattach caps after completing work (tightening torque of service cap: 14Nm (140kg-cm) or more).

④ Liquid pipe

⑤ Gas pipe

⑥ Elbow joint (field supply)

Connection of Outside units

* Install the branch pipe between outside units so that the outlet pipe

is parallel to the surface.

Viewed from point A

in direction of arrow

Within +/- 10°

Do not cut for

70mm(2-3/4”) or less

Execute the

welding while

pouring

nitrogen

When installing the branch pipe vertically between the outside

units, the refrigerant can be uneven between the outside units,

leading to compressor burn and reduced capacity.

CAUTION

!

CAUTION

1 Use the following materials for refrigerant piping.

• Material: Seamless phosphorous deoxidized copper pipe

• Wall thickness : Comply with the relevant local and national regulations for the designed pressure

3.8MPa(551.14psi). We recommend the following table as the minimum wall thickness.

2 Commercially available piping often contains dust and other materi-

als. Always blow it clean with a dry inert gas.

3 Use care to prevent dust, water or other contaminants from enter-

ing the piping during installation.

4 Reduce the number of bending portions as much as possible, and

make bending radius as big as possible.

5 Always use the branch piping set shown below, which are sold sep-

arately.

Outer diameter

[mm(inch)]

6.35

(1/4)

9.52

(3/8)

12.7

(1/2)

15.88

(5/8)

19.05

(3/4)

22.2

(7/8)

25.4

(1)

28.58

(1-1/8)

31.8

(1-1/4)

34.9

(1-3/8)

38.1

(1-1/2)

41.3

(1-5/8)

44.45

(1-3/4)

53.98

(2-1/8)

Minimum thickness

[mm(inch)]

0.8

(1/32)

0.8

(1/32)

0.8

(1/32)

0.99

(5/128)

0.99

(5/128)

0.99

(5/128)

0.99

(5/128)

0.99

(5/128)

1.1

(3/64)

1.21

(3/64)

1.35

(7/128)

1.43

(7/128)

1.55

(1/16)

2.1

(11/128)

h Remove the front panel before pipe

connection

h Must check the pipe (liquid pipe, gas

pipe) before pipe connection

Unit : mm(inch)

Open status when both the pipe and the valve are

in a straight line.

Outside units Model

AB

(Master) (Slave1)

2 Unit

ABC

(Master) (Slave1) (Slave2)

3 Unit

A

ARCNN21

ARCNN31

Gas Pipe

416(16-3/8)

408(16-1/16)

I.D.28.58(1-1/8) I.D.28.58(1-1/8)

I.D.31.8(1-1/4)

I.D.34.9(1-3/8)

I.D.38.1

I.D.41.3(1-5/8)

(1-1/2)

130(5-1/8)

341(13-7/16)

298(11-23/32)

I.D.41.3(3/4)

I.D.41.3(1-5/8)

125(4-29/32)

I.D.22.2(7/8)

O.D.34.9(1-3/8)

I.D.34.9(1-3/8)

O.D.34.9(1-3/8)

111(4-3/8)

I.D.28.58(1-1/8)

111(4-3/8)

I.D.28.58(1-1/8)

Liquid Pipe

I.D.15.88(5/8) I.D.15.88(5/8)

I.D.19.05(3/4)

I.D.22.2(7/8)

O.D.19.05(3/4)

70(2-3/4)

281(11-1/16)

I.D.22.2

(7/8)

I.D.19.05(3/4)

331(13-1/32)

314(12-3/8)

334(13-5/32)

I.D.15.88(5/8)

I.D.12.7

(1/2)

I.D.12.7(1/2)

I.D.19.05(3/4)

I.D.9.52

(3/8)

I.D.15.88(5/8)

I.D.12.7(1/2)

83

(3-9/32)

83

(3-9/32)

Cut both the pipe and the valve with a cutter to

suit the length

[Don't cut the length of less than 70mm(2-3/4”)]

CLOSE OPEN

10

ENGLISH

9 The Multi V water will stop due to an abnormality like excessive or

insufficient refrigerant. At such a time, always properly charge the

unit. When servicing, always check the notes concerning both the

piping length and the amount of additional refrigerant.

10 Never perform a pump down. This will not only damage the com-

pressor but also deteriorate the performance.

11 Never use refrigerant to perform an air purge. Always evacuate

using a vacuum pump.

12. Always insulate the piping properly. Insufficient insulation will result in a decline in heating/cooling performance, drip of condensate

and other such problems.

13. When connecting the refrigerant piping, make sure the service

valves of the Outside Unit is completely closed (the factory setting)

and do not operate it until the refrigerant piping for the Outside and

Indoor Units has been connected, a refrigerant leakage test has

been performed and the evacuation process has been completed.

14. Always use a non-oxidizing brazing material for brazing the parts

and do not use flux. If not, oxidized film can cause clogging or damage to the compressor unit and flux can harm the copper piping or

refrigerant oil.

Ⓐ To Outside Unit

Ⓑ Sealed Piping

WARNING

When installing and moving the air conditioner to another site, be

sure to make recharge refrigerant after perfect evacuation.

•

If a different refrigerant or air is mixed with the original refrigerant, the

refrigerant cycle may malfunction and the unit may be damaged.

• After selecting diameter of the refrigerant pipe to suit total capacity of the indoor unit connected after branching, use an appropriate

branch pipe set according to the pipe diameter of the indoor unit

and the installation pipe drawing.

!

CAUTION

Do not directly connect the drain outlet to the water pipe outlet.

(It can cause problems to the product.)

!

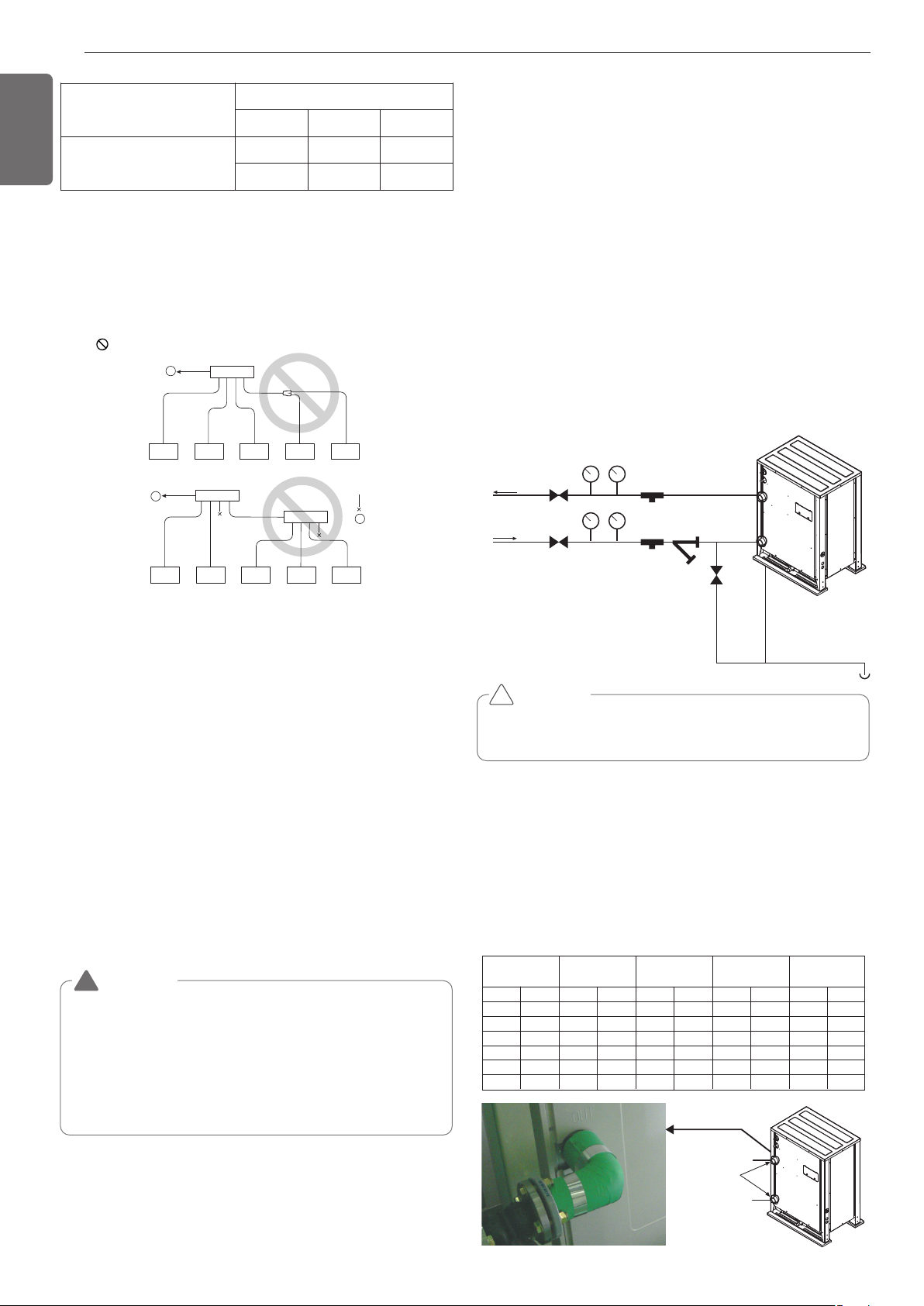

Water pipe connection

• The water pipe should be the same size of the connection on the

product or more.

• If necessary install the insulation material in the water pipe

inlet/outlet to prevent water drop, freeze and to save energy.

(Use the above 20mm(25/32inch) thickness PE insulation material.)

• Tightly connect the socket to the water pipe refer to below table

for recommended specification.

(Too much torque may cause the damage of the facility.)

Water pipe

connection

Water pipe inlet

Water pipe outlet

mm inch (kN) (kgf) (kN) (kgf) (N.m) (kgf.m)(N.m) (kgf.m)

12.7 1/2 3.5 350 2.5 250 20 23 5 3.5

19.05 3/4 12 1200 2.5 250 20 2 115 11.5

25.4 1 11.2 1120 4 400 45 4.5 155 15.5

31.8 1 1/4 14.5 1450 6.5 650 87.5 8.75 265 26.5

38.1 1 1/2 16.5 1.7 9.5 0.95 155 16 350 35.5

50.8 2 21.5 2.2 13.5 1.4 255 26 600 61

Pipe thickness Shear stress Tensile stress

Bending

moment

Torque

INSTALLATION OF WATER PIPE

Water pipe system diagram

• The water pressure resistance of the water pipe system of this

product is 1.98MPa(287.18psi).

• When the water pipe passes indoors, make sure to execute heat

insulation on the pipe so that water drops do not form on the

outer side of the water pipe.

• The size of the drain pipe must be equal to or larger than the diameter of the connecting product.

- Always install a trap so that the drained water does not back

flush.

•

Always install a strainer (50Mesh or above) at the entrance of the

water pipe. (When sand, trash, rusted pieces get mixed into the

water supply, it can cause problems to the product due to blocking)

- If On/Off valve is applied, by interlocking with outside unit, it can

save the energy consumption of pump by blocking the water

supply to the outside unit not operating. Select appropriate valve

and install on site if necessary.

• Install a pressure gauge and temperature gauge at the inlet and

outlet of the water pipe.

• Flexible joints must be installed not to cause any leakage from the

vibration of pipes.

• Install a service port to clean the heat exchanger at the each end

of the water inlet and outlet.

• For the components of the water pipe system, always use components above the designed water pressure.

6 If the diameters of the branch piping of the designated refrigerant

piping differs, use a pipe cutter to cut the connecting section and

then use an adapter for connecting different diameters to connect

the piping.

7 Always observe the restrictions on the refrigerant piping (such as

rated length, difference in height, and piping diameter).

Failure to do so can result in equipment failure or a decline in heating/cooling performance.

8 A second branch cannot be made after a header. (These are shown

by .)

Y branch

Header

4 branch 7 branch 10 branch

ARBLB01621, ARBLB03321,

ARBLB07121, ARBLB14521,

ARBLB23220

ARBL054 ARBL057 ARBL1010

ARBL104 ARBL107 ARBL2010

A

A

B

Water pipe

outlet

Water pipe

Inlet

Pressure gauge

Gate valve

Gate valve

Temperature gauge

Service port

Strainer

Service port

Drain line

Condensed

water drain

11

ENGLISH

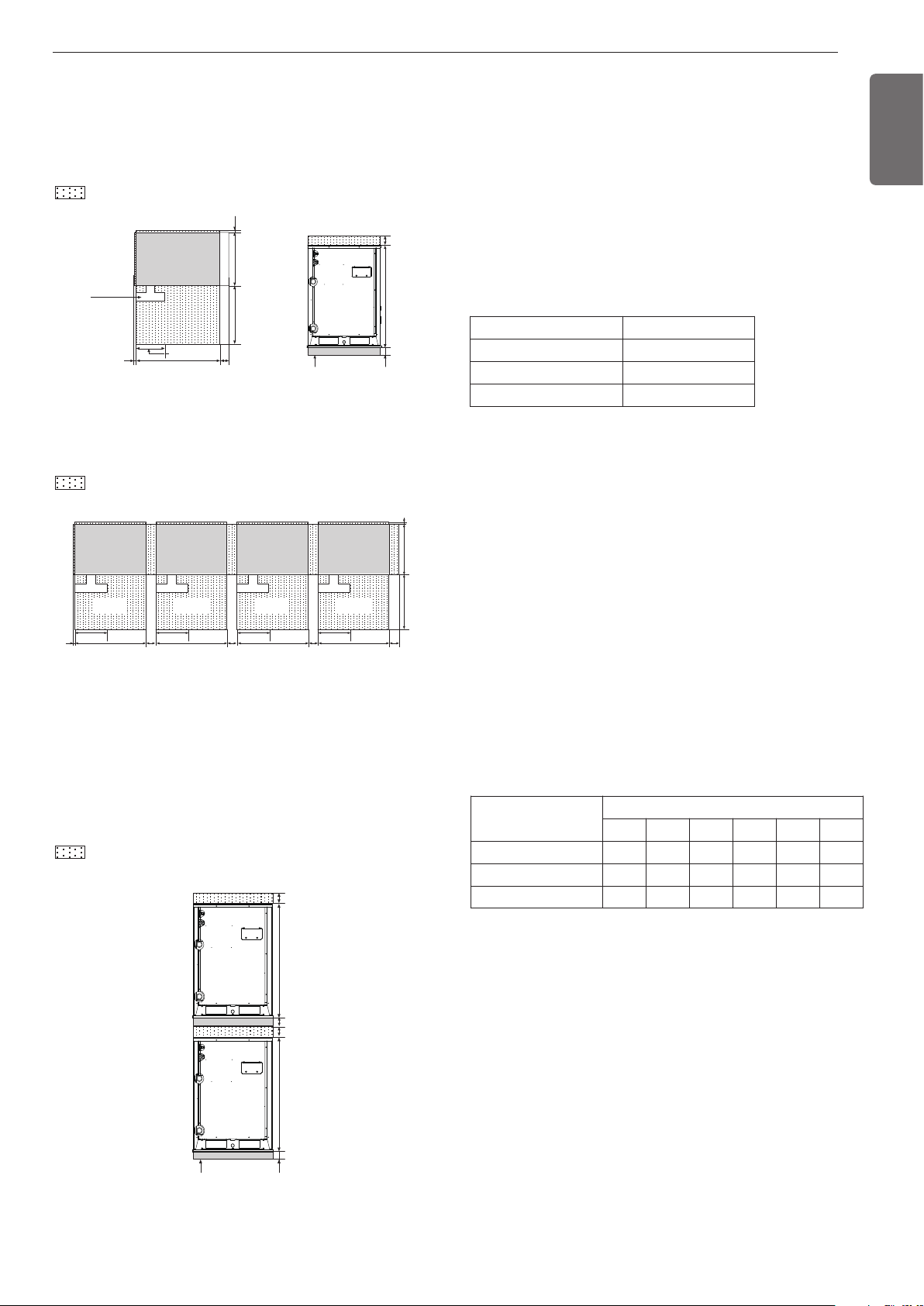

Upper graph is a theoretical value for selection and it may be different

according to specification of strainer.

Head loss of strainer on water pipe

ARWN121DAS4

ARWN121BAS4

ARWN192DAS4

Flow switch work

• It is recommended to install the flow switch to the water collection

pipe system connecting to the outside unit.

(Flow switch acts as the 1st protection device when the heat water

is not supplied. If a certain level of water does not flow after installing the flow switch, an error sign of CH24 error will be displayed

on the product and the product will stop operating.)

• When setting the flow switch, it is recommended to use the product

with default set value to satisfy the minimum flow rate of this product. (The minimum flow rate range of this product is 50%. Reference

flow rate : 10HP-25.4GPM, 20HP-50.7GPM

• Select the flow switch with the permitted pressure specification considering the pressure specification of the heat water supply system.

(Control signal from outside unit is AC 220V.)

Strainer on water pipe

To protect the water cooling type product, you must install a strainer

with 50 mesh or more on the heat water supply pipe.

If not installed, it can result in damage of heat exchanger by the following situation.

1 Heat water supply within the plate type heat exchanger is com-

posed of multiple small paths.

2 If you do not use a strainer with 50 mesh or more, alien particles

can partially block the water paths.

3 When running the heater, the plate type heat exchanger plays the

role of the evaporator, and at this time, the temperature of the

coolant side drops to drop the temperature of the heat water supply, which can result in icing point in the water paths.

4 And as the heating process progresses, the water paths can be par-

tially frozen to lead to damage in plate type heat exchanger.

5 As a result of the damage of the heat exchanger from the freezing,

the coolant side and the heat water source side will be mixed to

make the product unusable.

DEVICE PROTECTION UNIT

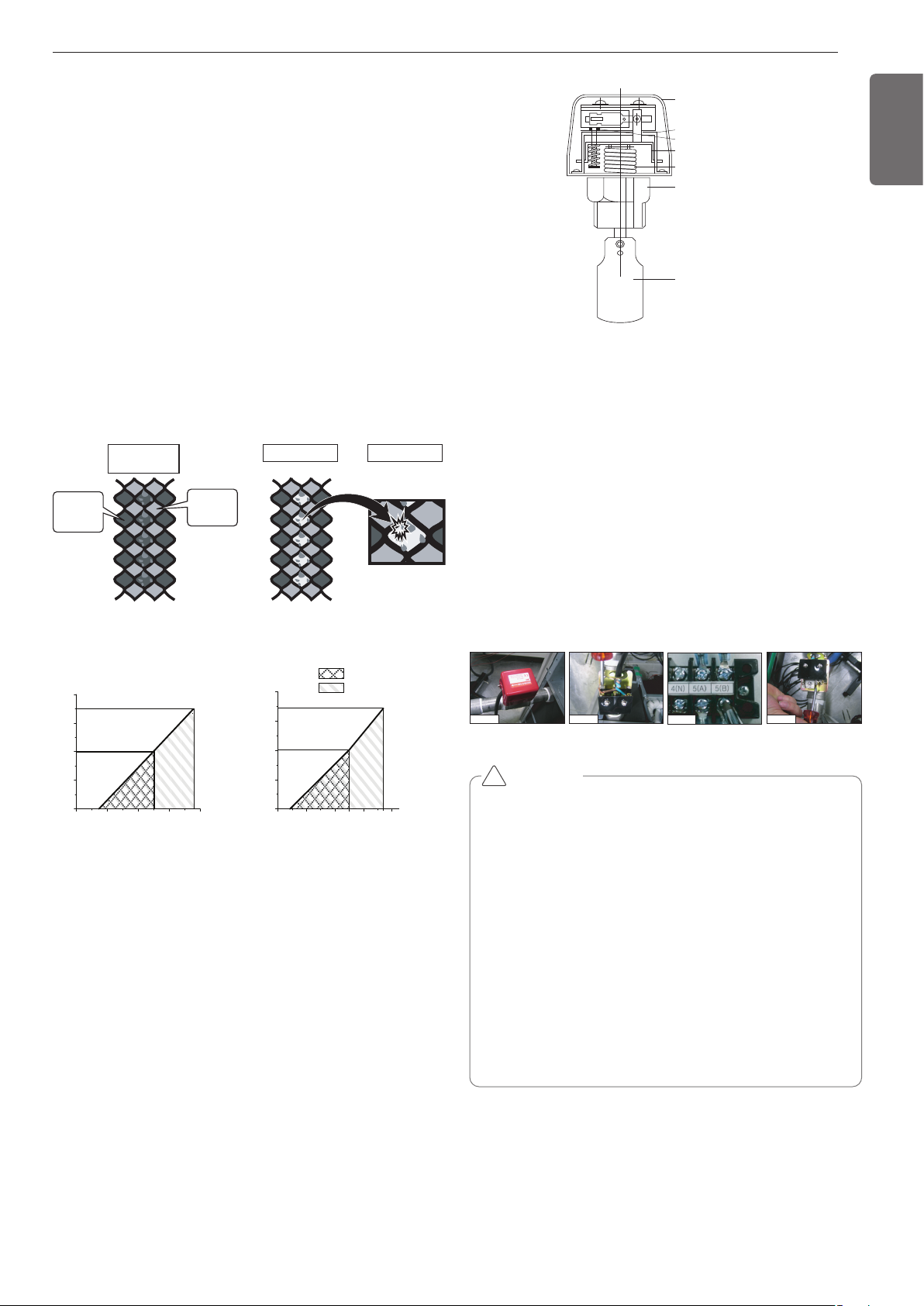

Installation of flow switch

• The flow switch must be installed at the horizontal pipe of the heat

water supply outlet of the product and check the direction of the heat

water flow before the installation. (Picture 1)

• When connecting the flow switch to the product, remove the jump

wire to connect to the communication terminal (5(A) and 5(B)) of the

outside unit control box. (Picture 2, 3) (Open the cover of the flow

switch and check the wiring diagram before connecting the wires.

The wiring method can differ by the manufacturer of the flow

switch.)

• If necessary, adjust the flow rate detection screw after consulting

with an expert and adjust to the minimum flow rate range. (Picture 4)

(Minimum flow rate range of this product is 50%. Adjust the flow

switch to touch the contact point when the flow rate reaches 50% of

the flow rate.)

- Reference flow rate : 10HP-25.4GPM, 20HP-50.7GPM

CAUTION

• If the set value does not satisfy the minimum flow rate or if the

set value is changed by the user arbitrarily, it can result in product performance deterioration or serious product problem.

• If the product is operated with the heat water supply not flowing smoothly, it can damage the heat exchanger or cause serious product problems.

• In case of CH24 or CH180 error, there is a possibility that the

plate type heat exchanger is partially frozen inside. In this case

resolve the issue of partial freezing and then operate the product again. (Cause of partial freezing : Insufficient heat water

flux, water not supplied, insufficient coolant, alien particle penetrated inside plate type heat exchanger)

• When the product operates while the flow switch touches the

contact point at the flow rate range out of the permitted range,

it can cause product performance deterioration or serious product problem.

• Must use the normal closed type flow switch

- Circuit of outside unit is normal closed type.

!

Cover

Heat Source

Water

1. Pollution of

Heat source

Refrigerant

2. Partially frozen

3. Damage

Micro-switch

Adjustment screw

Vibration plate

Bellows

1 inch or

3/4 inch

socket

Pad

: Suggestion range

8

6

4

psi

2

0

0 10 20

25 30 40

GPM

8

6

4

psi

2

0

02040

: Allowed range

50 60 80

GPM

Picture 1 Picture 2

Picture 3

Picture 4

Loading...

Loading...