LG ARNH18GK1A4 INSTALLATION MANUAL

INSTALLATION MANUAL

AIR

CONDITIONER

ENGLISH

ITALIANO

ESPAÑOL FRANÇAIS DEUTSCH

ΕΛΛΗΝΙΚΆ

Please read this installation manual completely before installing the

product. Installation work must be performed in accordance with the

national wiring standards by authorized personnel only.

Please retain this installation manual for future reference after reading

it thoroughly.

Hydro Kit Wall mounted (medium temperature)

Original instruction (R32)

MFL67086714

Rev.00_072120

Copyright © 2020 LG Electronics Inc. All Rights Reserved.

www.lg.com

ČEŠTINA

NEDERLANDS

POLSKI

LIMBA ROMÂNĂ

TABLE OF CONTENTS

2

ENGLISH

TABLE OF CONTENTS

4 SAFETY INSTRUCTIONS

12 INSTALLATION PART

13 GENERAL INFORMATION

13 Model Information

13 Accessories

16 INSTALLATION

16 Transporting the Unit

16 Selection of the best location

20 INSTALLATION OF INDOOR UNIT

20 Conditions where Indoor Unit is Installed

23 PIPING AND WIRING FOR INDOOR UNIT

23 Water Piping and Water Circuit Connection

26 Water pump Capacity

26 Pressure Drop

28 Typical Installation Example

31 Water cycle (For R32)

33 Water Quality

33 Frost protection

34 Preparation for Piping

35 Electrical Wiring

36 Wiring Connection

39 Connecting Cables

40 ACCESSORIES INSTALLATION

40 Before Installation

40 Thermostat

44 DHW Tank

47 DHW Tank Kit

49 Solar Thermal Kit

50 Dry Contact

52 External Controller - Setting up programmable digital input operation

53 Remote Temperature Sensor

55 Solar pump

56 Wi-fi Modem

57 2Way Valve

58 3Way Valve(A)

59 3Way Valve(B)

60 Final check

61 SYSTEM SET-UP

61 DIP Switch Setting

66 SERVICE SETTING

66 How to enter service setting

66 Service setting

67 Service contact

68 Model information

69 RMC version lnformation

70 Open source license

71 Installer setting

73 3 Minutes Delay

74 Select Temperature Sensor

75 Dry Contact Mode

76 Pump test run

77 Air cooling set temp.

78 Water cooling set temp.

79 Air heating set temp.

80 Water heating set temp.

81 DHW set temp.

82 Water supply off temp. during cooling

84 Heater priority

85 DHW time setting

86 TH on/off Variable, heating air

87 TH on/off Variable, heating water

88 TH on/off Variable, cooling air

89 TH on/off Variable, cooling water

90 Heating temp. setting

91 Cooling temp. setting

92 Pump setting in heating

93 Pump setting. in cooling

94 Forced operation

95 CN_CC

96 Pump frequency setting (RPM)

97 Pump Capacity

98 CN_EXT

99 Anti-freezing Temperature

100 Pump Prerun/Overrun

101 Solar Thermal System

103 Current flow rate

104 Data logging

105 Password Initialization

106 Troubleshooting

TABLE OF CONTENTS

3

ENGLISH

SAFETY INSTRUCTIONS

4

ENGLISH

SAFETY INSTRUCTIONS

Read the precautions in this

manual carefully before

operating the unit.

This symbol indicates that

the Operation Manual should

be read carefully.

The following safety guidelines are intended to prevent

unforeseen risks or damage from unsafe or incorrect operation

of the appliance. The guidelines are separated into ‘WARNING’

and ‘CAUTION’ as described below.

This symbol is displayed to indicate matters and

!

operations that can cause risk. Read the part with this

symbol carefully and follow the instructions in order to

avoid risk.

WARNING

!

This indicates that the failure to follow the instructions can

cause serious injury or death.

This appliance is filled with

flammable refrigerant (R32)

This symbol indicates that a

service personnel should be

handling this equipment with

reference to the Installation

Manual.

CAUTION

!

This indicates that the failure to follow the instructions can

cause the minor injury or damage to the product.

WARNING

!

Installation

• Compliance with national gas regulations shall be observed.

• Do not use a defective or underrated circuit breaker. Use this

appliance on a dedicated circuit.

- There is risk of fire or electric shock.

SAFETY INSTRUCTIONS

• For electrical work, contact the dealer, seller, a qualified

electrician, or an Authorized Service Center.

- There is risk of fire or electric shock.

• Always ground the unit.

- There is risk of fire or electric shock.

• Install the panel and the cover of control box securely.

- There is risk of fire or electric shock.

• Always install a dedicated circuit and breaker.

- Improper wiring or installation may cause fire or electric

shock.

• Be cautious when unpacking and installing the product.

- Sharp edges could cause injury. Be especially careful of the

case edges and the fins on the condenser and evaporator.

• Use the correctly rated breaker or fuse.

- There is risk of fire or electric.

• Do not modify or extend the power cable.

- There is risk of fire or electric shock.

5

ENGLISH

• Do not install, remove, or reinstall the unit by yourself

(customer).

- There is risk of fire, electric shock, explosion, or injury.

• For antifreeze, always contact the dealer or an authorized

service center.

- Almost the antifreeze is a toxic product.

• For installation, always contact the dealer or an Authorized

Service Center.

- There is risk of fire, electric shock, explosion, or injury.

• Do not install the unit on a defective installation stand.

- It may cause injury, accident, or damage to the unit.

• Do not turn on the breaker or power under condition that front

panel, cabinet, top cover, control box cover are removed or

opened.

- Otherwise, it may cause fire, electric shock, explosion or

death.

SAFETY INSTRUCTIONS

6

ENGLISH

• Be sure the installation area does not deteriorate with age.

- If the base collapses, the unit could fall with it, causing

property damage, unit failure, and personal injury.

• Do not install the unit outdoor.

- It may cause damage to the unit.

• Use a vacuum pump or inert (nitrogen) gas when doing

leakage test or purging air. Do not compress air or oxygen and

do not use flammable gases.

- There is the risk of death, injury, fire or explosion.

• The appliance shall be stored in a well-ventilated area where

the room size corresponds to the room area as specified for

operation. (for R32)

• Ducts connected to an appliance shall not contain an ignition

source. (for R32)

• The appliance shall be stored in a room without continuously

operating ignition sources (for example: open flames, an

operating gas appliance or an operating electric heater.)

• Means for disconnection must be incorporated in the fixed

wiring in accordance with the wiring rules.

• This equipment shall be provided with a supply conductor

complying with the national regulation.

• Have all electric work done by a licensed electrician according

to "Electric Facility Engineering Standard" and "Interior Wire

Regulations" and the instructions given in this manual and

always use a special circuit.

- If the power source capacity is inadequate or electric work is

performed improperly, electric shock or fire may result.

• Always install a dedicated circuit and breaker.

- Improper wiring or installation may cause fire or electric

shock.

• Keep any required ventilation openings clear of obstruction.

• Mechanical connections shall be accessible for maintenance

purposes.

SAFETY INSTRUCTIONS

• To prevent the mixing of different types of refrigerants, be

sure to check the type of refrigerant used in the outdoor unit.

• When mechanical connectors are reused indoors, sealing parts

shall be renewed. (for R32)

• When flared joints are reused indoors, the flare part shall be refabricated. (for R32)

Operation

• Do not let the air conditioner run for a long time when the

humidity is very high and a door or a window is left open.

- Moisture may condense and wet or damage furniture.

• Take care to ensure that power cable could not be pulled out

or damaged during operation.

- There is risk of fire or electric shock.

• Do not place anything on the power cable.

- There is risk of fire or electric shock.

7

ENGLISH

• Do not plug or unplug the power supply plug during operation.

- There is risk of fire or electric shock.

• Do not touch (operate) the unit with wet hands.

- There is risk of fire or electric shock.

• Do not place a heater or other appliances near the power

cable.

- There is risk of fire or electric shock.

• Do not allow water to run into electric parts.

- There is risk of fire, failure of the unit, or electric shock.

• Do not store or use flammable gas or combustibles near the

unit.

- There is risk of fire or failure of unit.

• Do not use the product in a tightly closed space for a long

time.

- Oxygen deficiency could occur.

SAFETY INSTRUCTIONS

8

ENGLISH

• When flammable gas leaks, turn off the gas and open a

window for ventilation before turning the unit on.

- There is risk of explosion or fire.

• If strange sounds, or smell or smoke comes from unit, turn the

breaker off or disconnect the power supply cable.

- There is risk of electric shock or fire.

• Stop operation and close the window in storm or hurricane. If

possible, remove the unit from the window before the

hurricane arrives.

- There is risk of property damage, failure of unit, or electric

shock.

• Do not open the front cover of the unit while operation. (Do

not touch the electrostatic filter, if the unit is so equipped.)

- There is risk of physical injury, electric shock, or unit failure.

• When the unit is soaked (flooded or submerged), contact an

Authorized Service Center.

- There is risk of fire or electric shock.

• Be cautious that water could not enter the product.

- There is risk of fire, electric shock, or product damage.

• Ventilate the unit from time to time when operating it together

with a stove, etc.

- There is risk of fire or electric shock.

• Turn the main power off when cleaning or maintaining the unit.

- There is risk of electric shock.

• Take care to ensure that nobody could step on or fall onto the

unit.

- This could result in personal injury and unit damage.

• For installation, always contact the dealer or an Authorized

Service Center.

- There is risk of fire, electric shock, explosion, or injury.

• If the unit is not used for long time, we strongly recommend

not to switch off the power supply to the unit.

- There is risk of water freezing.

SAFETY INSTRUCTIONS

• Periodic ( more than once/year ) cleaning of the dust or salt

particles stuck on the heat exchanger by using water.

• Do not use means to accelerate the defrosting process or to

clean, other than those recommended by the manufacturer.

• Do not pierce or burn refrigerant cycle part.

• Be aware that refrigerants may not contain an odour.

CAUTION

!

Installation

• Always check for gas (refrigerant) leakage after installation or

repair of unit.

- Low refrigerant levels may cause failure of unit.

• Keep level even when installing the unit.

- To avoid vibration or water leakage.

• Use two or more people to lift and transport the unit.

- Avoid personal injury.

9

ENGLISH

•

Any person who is involved with working on or breaking into a

refrigerant circuit should hold a current valid certificate from an

industry accredited assessment authority, which authorises

their competence to handle refrigerants safely in accordance

with an industry recognised assessment specification. (for R32)

• The appliance shall be stored so as to prevent mechanical

damage from occurring.

• If anyone other than a licensed Professional installs, repairs, or

alters LG Electronics Air Conditioning Products, the warranty is

voided.

- All costs associated with repair are then the full responsibility

of the owner.

• Do not install the product where it will be exposed to sea wind

(salt spray) directly.

- It may cause corrosion on the product. Corrosion, particularly

on the condenser and evaporator fins, could cause product

malfunction or inefficient operation.

SAFETY INSTRUCTIONS

10

ENGLISH

• Refrigerant tubing shall be protected or enclosed to avoid

damage.

• Flexible refrigerant connectors (such as connecting lines

between the indoor and outdoor unit) that may be displaced

during normal operations shall be protected against mechanical

damage.

• The installation of pipe-work shall be kept to a minimum.

• Pipe-work shall be protected from physical damage.

• A brazed, welded, or mechanical connection shall be made

before opening the valves to permit refrigerant to flow

between the refrigerating system parts.

• Dismantling the unit, treatment of the refrigerant oil and

eventual parts should be done in accordance with local and

national standards.

• Do not install the unit in potentially explosive atmospheres.

Operation

• Do not lay on the cooled floor for long time when the unit is in

cooling operation.

- This could harm to your health.

• Do not use the unit for special purposes, such as preserving

foods, works of art, etc.

- There is risk of damage or loss of property.

• Use a soft cloth to clean. Do not use harsh detergents,

solvents, etc.

- There is risk of fire, electric shock, or damage to the plastic

parts of the unit.

• Do not step on or put anything on the unit.

- There is risk of personal injury and failure of unit.

• Use a firm stool or ladder when cleaning or maintaining the

unit.

- Be careful and avoid personal injury.

SAFETY INSTRUCTIONS

• Servicing shall only be performed as recommended by the

equipment manufacturer. Maintenance and repair requiring the

assistance of other skilled personnel shall be carried out under

the supervision of the person competent in the use of

flammable refrigerants. (for R32)

• Do not unplug the power supply plug of Hydro Kit when

stopping Hydro Kit operation. Always turn Hydro Kit off, using

the wired remote controller.

- A plate heat exchanger burst may happen because of

disconnection of communication between Hydro Kit and the

outdoor unit.

11

ENGLISH

INSTALLATION PART

12

ENGLISH

INSTALLATION PART

Thank you for choosing LG Electronics Air-to-Water Heat Pump

Before starting installation, please make it sure that all parts are found inside the product box.

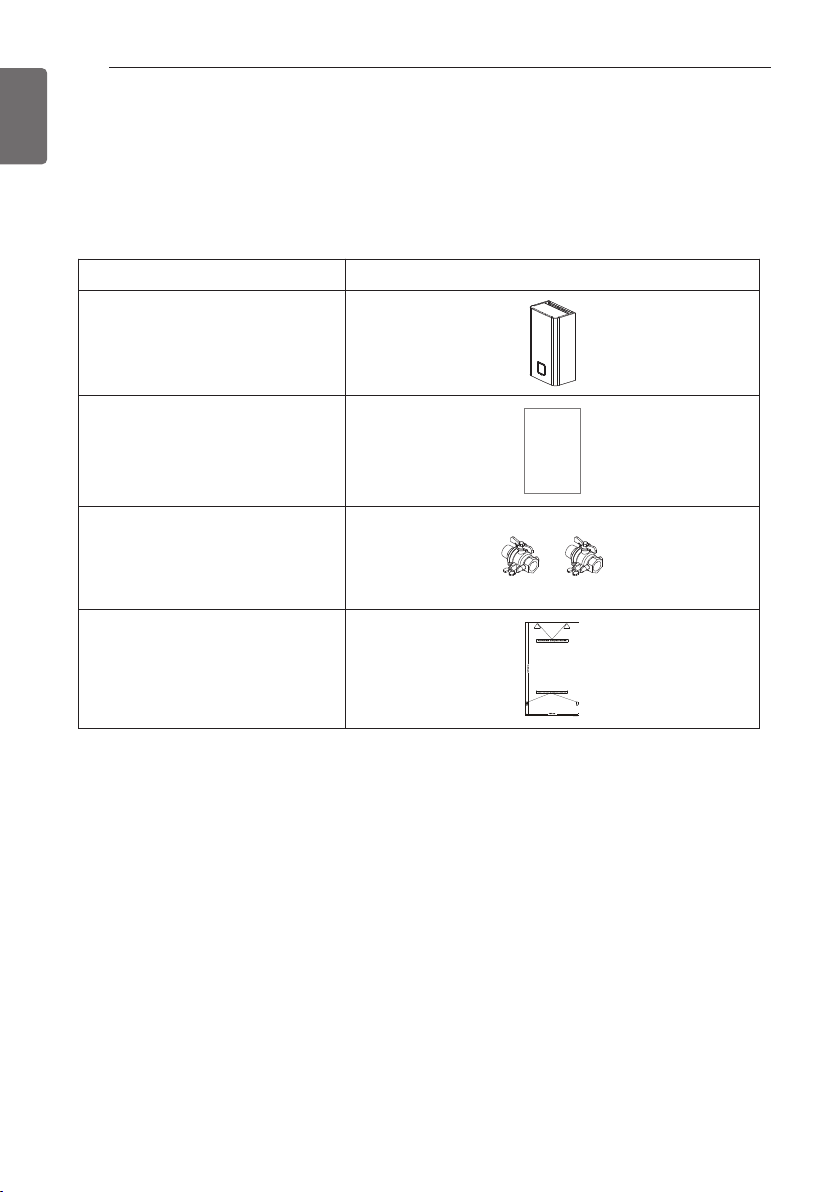

INDOOR UNIT BOX

Item Image

Indoor unit

Owner's / Installation manual

Shut-off valve

Installation Sheet

Hydro Kit

GENERAL INFORMATION

GENERAL INFORMATION

13

ENGLISH

With advanced inverter technology,

Hydro Kit

is suitable for applications like under floor heating,

and hot water generation. By Interfacing to various accessories user can customize the range of

the application.

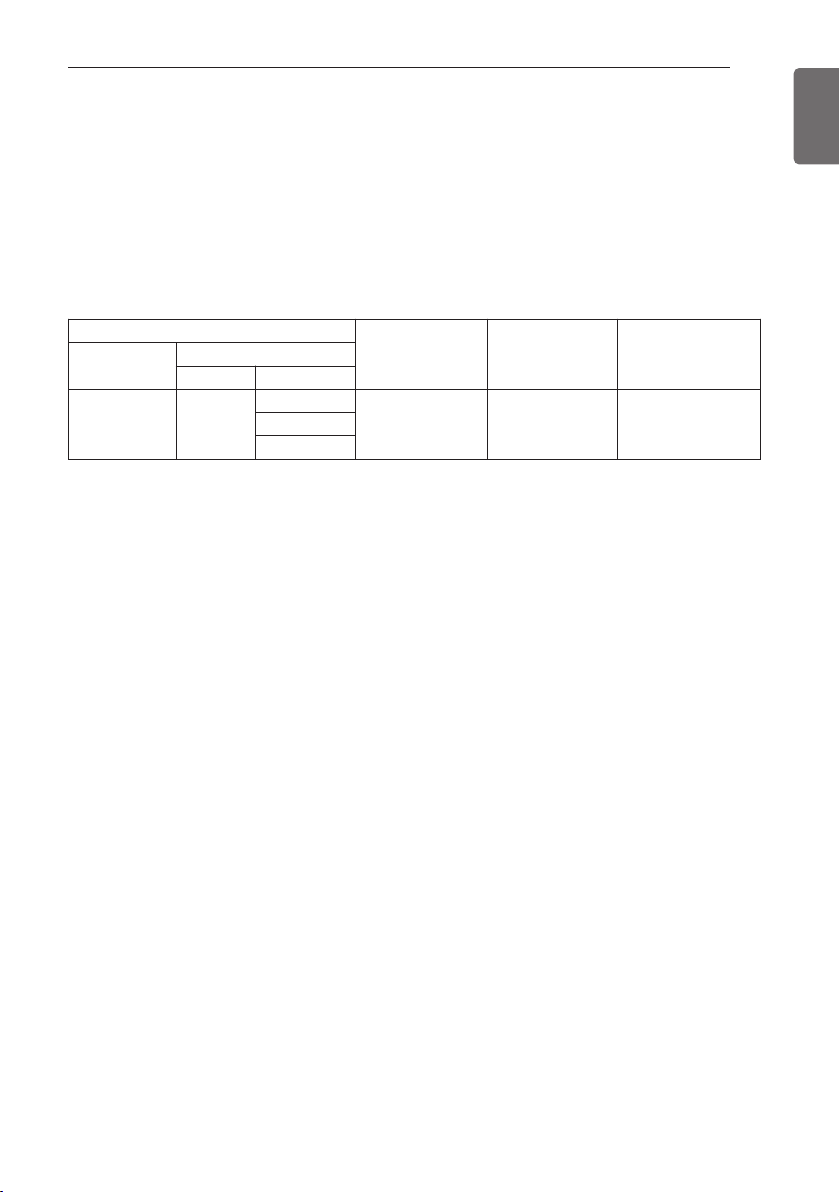

Model Information

Model name and related information

Model Name

Refrigerant

R32 1Ø

Indoor Unit

Phase Capacity (kW)

5.6

7.1

9.0

Built-In Electric

Heater(kW)

6 (3+3)

Power Source

(Electric Heater)

220-240 V~

50 Hz

Power

Source (Unit)

220-240 V~

50 Hz

Accessories

To extend the functionality of

"accessories".

They are classified by "accessories" and "3rd party accessories" according to the manufacturer.

Accessories are presented LG Electronics, and 3rd party accessories are presented by related

manufacturers.

Hydro Kit

, there are various external auxiliary apparatus called as

GENERAL INFORMATION

14

ENGLISH

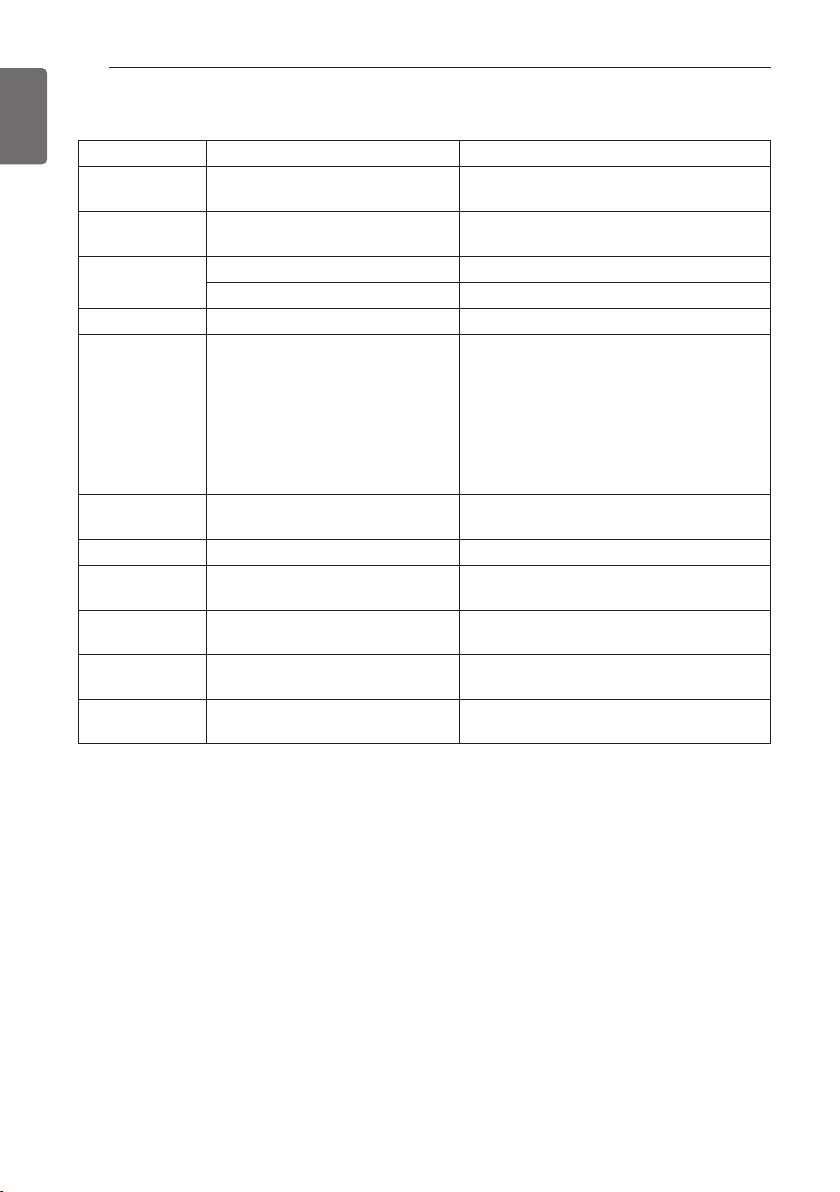

Accessories supported by LG Electronics

Item Purpose Model

DHW Tank Kit To operate with DHW tank

Remote Air

Sensor

Dry Contact

Solar Thermal Kit To operate with solar heating system PHLLA(Limit temperature : 96 °C)

DHW Tank To generate and store hot water

Thermistor for

DHW Tank

Drain Pan To prevent drain water drop PHDPB

Central Controller

Wi-Fi Modem

Extension wire

Cover Plate

To control by air temperature PQRSTA0

To receive on & off external signal PDRYCB500

Dry Contact For Thermostat PDRYCB300

To control hot water temperature of

DHW tank

Multiple installed products into one

central control

To enable remote system operation

from smartphone

To connect remote controller with

Indoor PCB for communication

To relocate remote controller from

indoor unit

PHLTA : 1Ø

PHLTC : 3Ø

PHS02060310 : 200 liter, Single Heating Coil,

1Ø 230 V 50 Hz 3 kW Electric Heater

PHS02060320 : 200 liter, Double Heating Coil,

1Ø 230 V 50 Hz 3 kW Electric Heater

PHS03060310 : 300 liter, Single Heating Coil,

1Ø 230 V 50 Hz 3 kW Electric Heater

PHS03060320 : 300 liter, Double Heating Coil,

1Ø 230 V 50 Hz 3 kW Electric Heater

PHRSTA0

PWFMDD200

PZCWRC1

PDC-HK10

Accessories supported by 3rd party Companies

Item Purpose Specification

Solar Heating System

Thermostat To control by air temperature

3rdParty Controller

3way valve and actuator

2way valve and actuator To control water flow for Fan Coil Unit

To generate auxiliary heating energy

for water tank

To connect external controller using

modbus protocol

(A) : To control water flow for hot

water heating or floor heating / To

control water flow when installing

3rd party boiler

(B) : To control close/open mode of

solar circuit

GENERAL INFORMATION

• Solar collector

• 3way valve(B)

Heating-Only type (230 V AC)

Cooling/Heating type (230 V AC with

Mode selection switch)

3 wire, SPDT (Single Pole Double Throw)

type, 230 V AC

2 wire,NO(Normal Open) or NC(Normal

Closed) type, 230 V AC

15

ENGLISH

INSTALLATION

16

ENGLISH

INSTALLATION

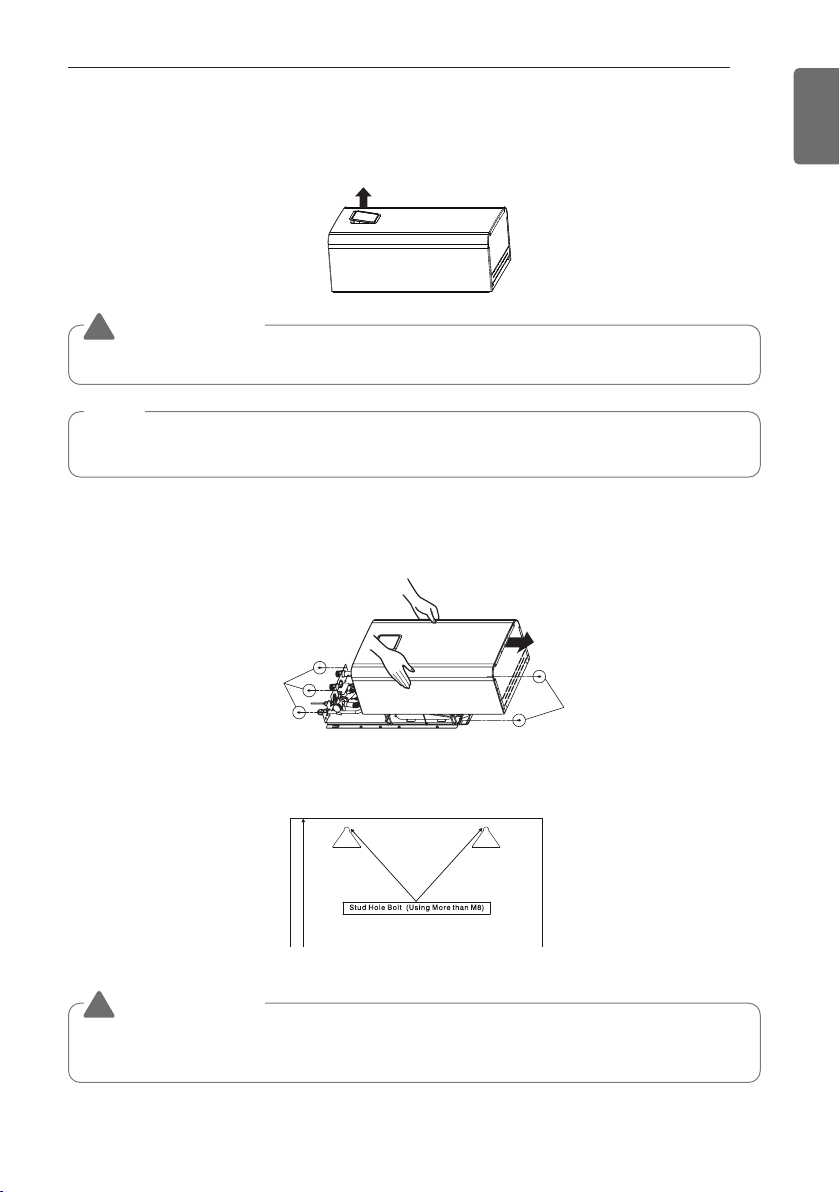

Transporting the Unit

CAUTION

!

Be very careful while carrying the unit.

• Do not have only one person carry the unit if it is more than 20 kg (44.1 lbs).

• PP bands are used to pack some products. Do not use them as a mean for transportation

because they are dangerous.

• Tear plastic packaging bag and scrap it so that children cannot play with it. Otherwise

plastic packaging bag may suffocate children to death.

• When carrying the unit, be sure to support it at 6-points. Carrying and lifting the unit with 4point support may make it unstable, resulting in a fall.

Selection of the best location

Select space for installing the unit, which will meet the following conditions:

The place where the unit shall be installed inside.

The place shall easily bear a load exceeding four times of the unit weight.

The place where the unit shall be leveled.

The place shall allow easy water drainage.

The place where the unit shall be connected to the outdoor unit.

The place where the unit is not affected by an electrical noise.

The place where there should not be any heat source or steam near the unit.

INSTALLATION

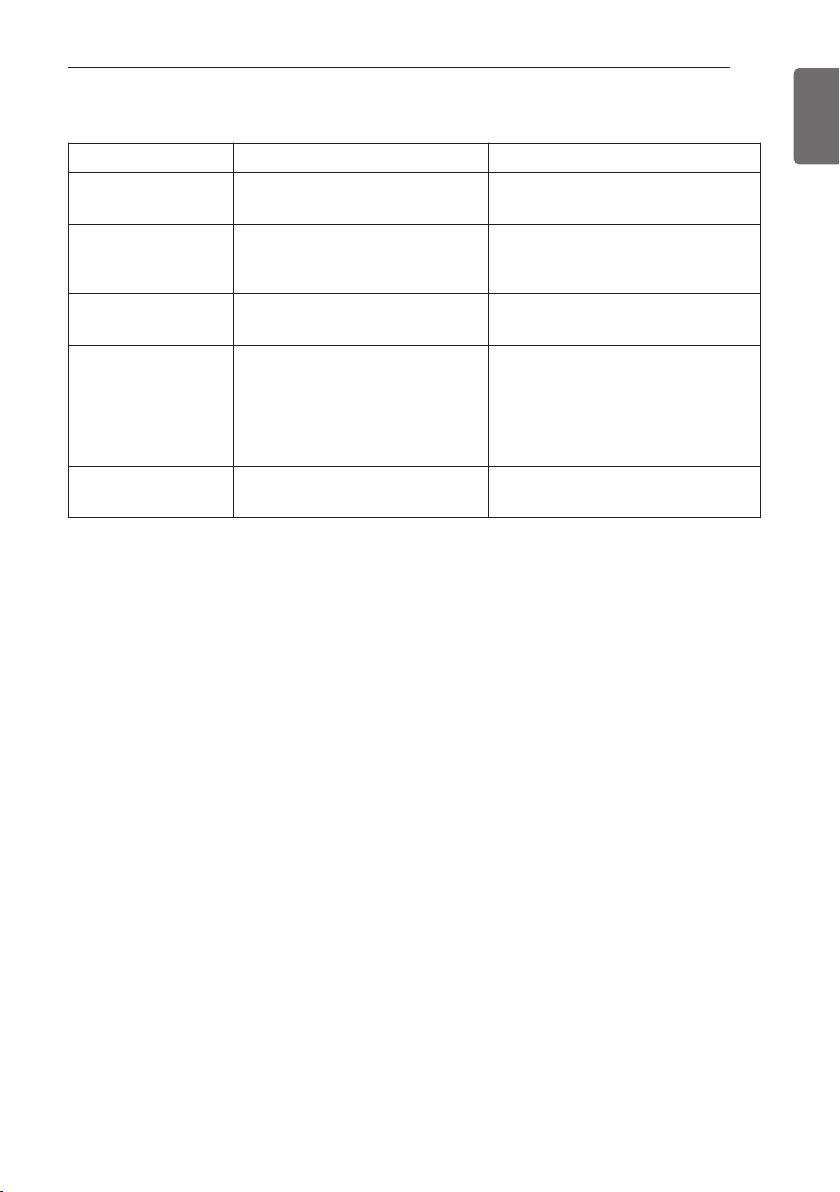

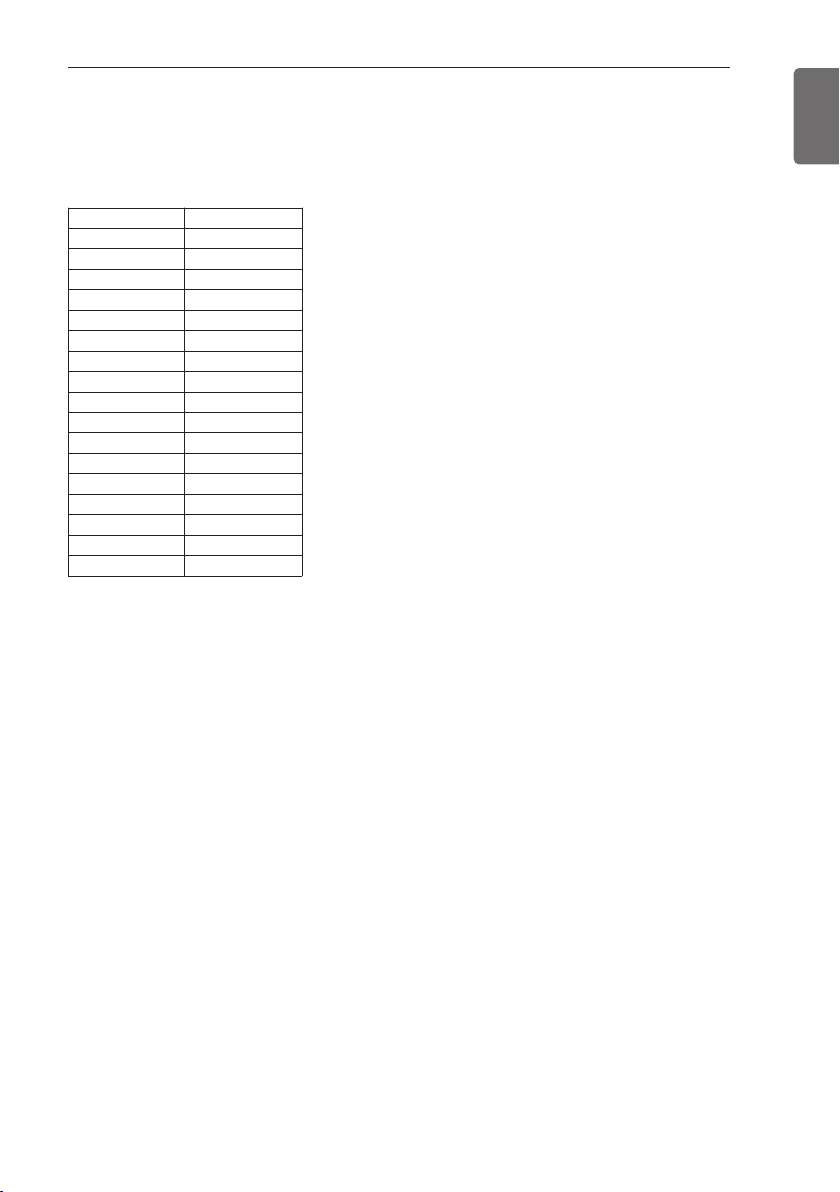

Minimum floor area(for R32)

- The appliance shall be installed, operated and stored in a room with a floor area larger than the

minimum area.

- Use the graph of table to determine the minimum area.

600

Amin (m2)

17

ENGLISH

500

400

300

200

100

0

0 1.224 2 3 4 5 6 7 8

- m : Total refrigerant amount in the system

- Total refrigerant amount : factory refrigerant charge + additional refrigerant amount

- Amin : minimum area for installation

Floor standing

m (kg) Amin (m

< 1.224

1.224 12.9

1.4 16.82

1.6 21.97

1.8 27.80

2 34.32

2.2 41.53

2.4 49.42

2.6 58.00

2.8 67.27

3 77.22

3.2 87.86

3.4 99.19

3.6 111.20

3.8 123.90

4 137.29

4.2 151.36

4.4 166.12

2

)

-

Floor standing

m (kg) Amin (m

4.6 181.56

4.8 197.70

5 214.51

5.2 232.02

5.4 250.21

5.6 269.09

5.8 288.65

6 308.90

6.2 329.84

6.4 351.46

6.6 373.77

6.8 396.76

7 420.45

7.2 444.81

7.4 469.87

7.6 495.61

7.8 522.04

2

)

Wall mounted

m (kg) Amin (m

< 1.224

1.224 1.43

1.4 1.87

1.6 2.44

1.8 3.09

2 3.81

2.2 4.61

2.4 5.49

2.6 6.44

2.8 7.47

3 8.58

3.2 9.76

3.4 11.02

3.6 12.36

3.8 13.77

4 15.25

4.2 16.82

4.4 18.46

2

)

-

Wall mounted

m (kg) Amin (m

4.6 20.17

4.8 21.97

5 23.83

5.2 25.78

5.4 27.80

5.6 29.90

5.8 32.07

6 34.32

6.2 36.65

6.4 39.05

6.6 41.53

6.8 44.08

7 46.72

7.2 49.42

7.4 52.21

7.6 55.07

7.8 58.00

2

)

Ceiling Mounted

m (kg) Amin (m

< 1.224

1.224 0.956

1.4 1.25

1.6 1.63

1.8 2.07

2 2.55

2.2 3.09

2.4 3.68

2.6 4.31

2.8 5.00

3 5.74

3.2 6.54

3.4 7.38

3.6 8.27

3.8 9.22

4 10.21

4.2 11.26

4.4 12.36

2

)

-

Floor standing

Wall mounted

Ceiling mounted

m (kg)

Ceiling Mounted

m (kg) Amin (m

4.6 13.50

4.8 14.70

5 15.96

5.2 17.26

5.4 18.61

5.6 20.01

5.8 21.47

6 22.98

6.2 24.53

6.4 26.14

6.6 27.80

6.8 29.51

7 31.27

7.2 33.09

7.4 34.95

7.6 36.86

7.8 38.83

2

)

INSTALLATION

18

ENGLISH

If this product is installed in the a room smaller than minimum floor area, there shall be

continuously operated mechanical ventilation system or natural ventilation openings.

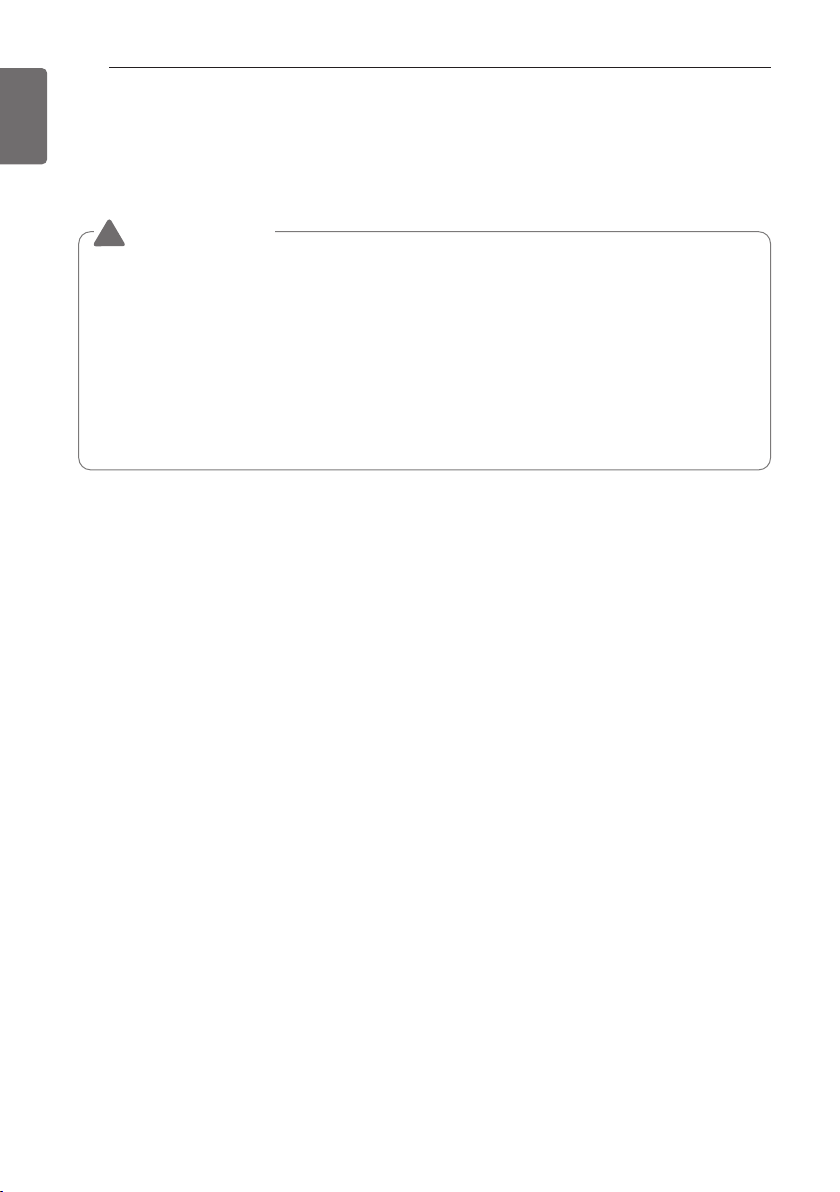

Natural ventilation

[Room A]

→ ≥ 50 % of Anv

[Room B]

min

≥ 1.5 m

Unit

→ ≥ 100 % of Anv

min

The floor area of “Room A + Room B” is considered as floor area instead of “Room A” for

min

complying with minimum floor area “A

” if :

- Openings are permanent openings which cannot be closed.

- Room A shall be larger than 0.64 m

2

Bottom opening:

- The area of any openings above 300 mm from the floor shall not be considered in determining

compliance with Anv

- At least 50 % of the required opening area Anv

min

.

min

shall be below 200 mm from the floor.

- The bottom of the lowest openings shall not be higher than 100 mm from the floor.

- If the openings starts from the floor, the height must be higher than 20 mm.

Top opening:

- The total size of the top opening shall not be less than 50 % of minimum opening area for

min

Anv

and shall be at least 1.5 m above the floor.

min

- Anv

: the minimum opening for natural ventilation

m (kg) A

min

1.224 51.2

1.4 73.5

1.6 98.8

1.8 124.1

2.0 149.4

2.2 174.7

2.4 200.0

2.6 225.3

2.8 250.6

3.0 275.9

(cm2)

m (kg) A

3.2 301.2

3.4 326.5

3.6 351.8

3.8 377.1

4.0 402.4

4.2 427.7

4.4 453.0

4.6 478.3

4.8 503.6

5.0 528.9

min

(cm2)

INSTALLATION

Mechanical ventilation

If there is a mechanical ventilation system that satisfies with minimum air flow, a product can be

installed in the room smaller than the minimum floor area.

• The room shall comply with machinery room’s requirements of ISO 5149.

m (kg) A

min

(m2)

< 1.224 -

1.224 1.43

1.3 1.61

1.4 1.87

1.5 2.15

1.6 2.44

1.7 2.76

1.8 3.09

1.9 3.44

2 3.81

2.1 4.20

2.2 4.61

2.3 5.04

2.4 5.49

2.5 5.96

2.6 6.44

2.7 6.95

19

ENGLISH

INSTALLATION OF INDOOR UNIT

20

ENGLISH

INSTALLATION OF INDOOR UNIT

The indoor unit of

and refrigerant pipe from the outdoor unit are accessible at the same time.

In this chapter conditions for installation place is described. In addition, considerations when

installing accessories or 3rd party accessories are described, too.

Conditions where Indoor Unit is Installed

Specific conditions are required for installation place such as service space, wall mounting, water

pipe length and height, total volume of water, adjusting expansion vessel, and water quality.

General Considerations

Followings are should be considered before the installation of the indoor unit.

- The installation place should be free from outdoor weather conditions such as rain, snow, wind,

frost, etc.

- Choose the place where is water-resistant or good drainage.

- Service space should be secured.

- No flammable materials around the indoor unit.

- Mice can not be appeared to prevent entering the indoor unit or attacking wires.

- Do not place anything in front of the indoor unit to ensure air circulation around the indoor unit.

- Do not locate anything under the indoor unit to be free from unexpected water out.

- In case of water pressure increasing to 3 bar, water drainage should be treated when water is

drained by safety valve.

Hydro Kit

is installed inside where terminal of under floor water pipe cycle

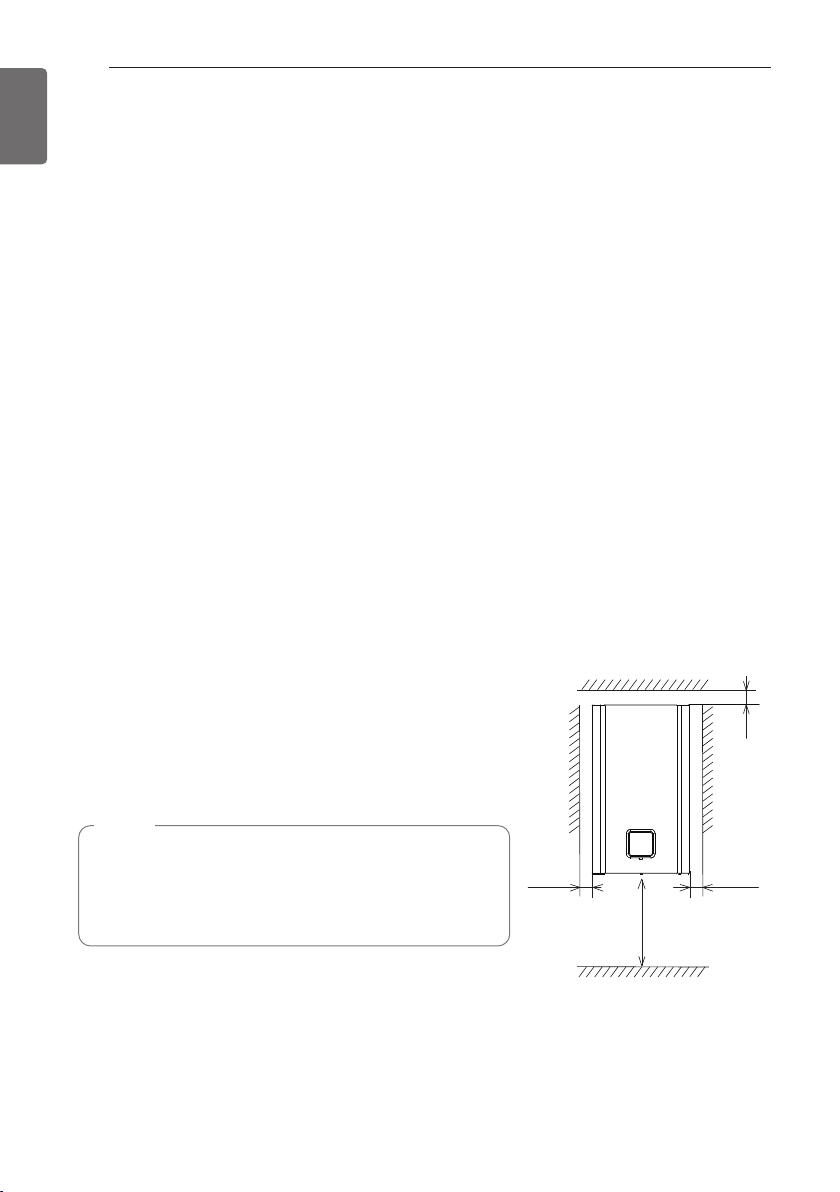

Service Space

- Ensure that the spaces indicated by arrows around bottom,

side, and top side.

- Wider spaces are preferred for easy maintenance and piping.

- If minimum service space is not secured, air circulation can

be troubled and internal parts of the indoor unit can be

damaged by overheating.

NOTE

• The default setting of the product is for heating only.

To use the cooling system together, DIP S / W 4

should be turned ON and additional drain pan

accessory should be installed.

200

1 300

Minimum service space

(unit : mm)

250

200

INSTALLATION OF INDOOR UNIT

Bottom screws

Upper screw

Mounting to Wall

Step 1. Disconnect the remote control case from the front panel and disconnect the remote

control cable.

CAUTION

!

After installation is completed, return the remote control to its original state.

NOTE

Use a flat-blade screwdriver or a coin to remove the remote control case.

Step 2. After releasing five screws, detach front cover from the indoor unit. While detaching the

front cover, grab the left and right sides of the front cover. Then pull into upward

direction.

21

ENGLISH

Step 3. Attach "Installation Sheet" to the wall and mark the location of bolts.

This sheet helps to find correct location to the bolts.

CAUTION

!

The sheet should be attached level. If not, the supporting plate and the indoor unit will not

be mounted correctly.

INSTALLATION OF INDOOR UNIT

22

ENGLISH

Step 4. Detach the Installation sheet. Screw bolts at the hole marks on the wall.

When screwing bolts, use M8 ~ M11 anchor bolts to secure hanging the indoor unit.

NOTE

Self drilling screw can be used as alternatives of M8 ~ M11 anchor bolts. But M8 ~ M11

anchor bolts are more preferred.

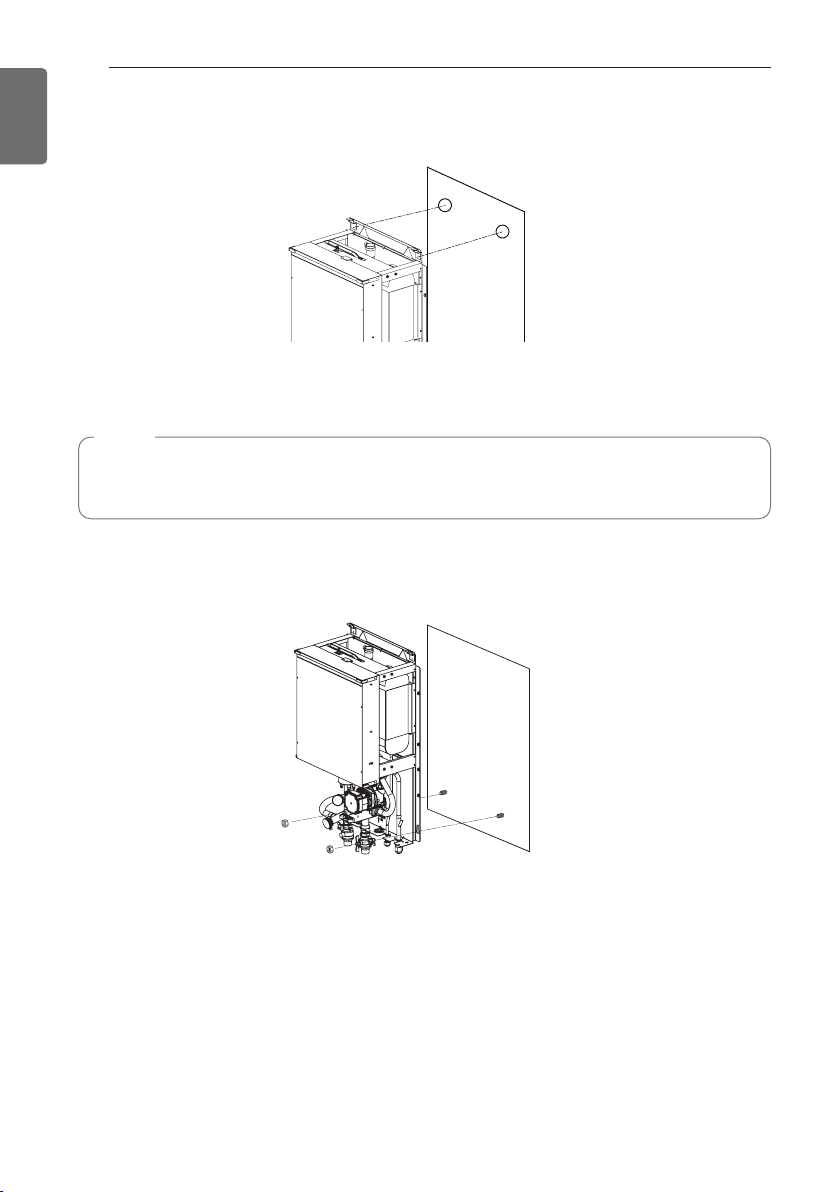

Step 5. Hang the indoor unit at the supporting plate.

PIPING AND WIRING FOR INDOOR UNIT

PIPING AND WIRING FOR INDOOR UNIT

Procedures about water piping and electric wiring at the indoor unit are described in this chapter.

Water piping and water circuit connection, water charging, pipe insulations will be shown for

water piping procedures. For wiring, terminal block connection, connecting with the outdoor

unit, electric heater wiring will be introduced. Accessories connection, such as sanitary water

tank, thermostat, 3way or 2way valves, etc will be dealt in separated chapter.

Water Piping and Water Circuit Connection

CAUTION

!

General Considerations

Followings are should be considered before beginning water circuit connection.

- Service space should be secured.

- Water pipes and connections should be cleaned using water.

- Space for installing external water pump should be provided if internal water pump capacity

is not enough for installation field.

- Never connect electric power while proceeding water charging.

Water Piping and Water Circuit Connection

Definition of terms are as follow :

- Water piping : Installing pipes where water is flowing inside the pipe.

- Water circuit connecting : Making connection between the product and water pipes or between

pipes and pipes. Connecting valves or elbows are, for example, in this category.

23

ENGLISH

While installing water pipes, followings should be considered :

- While inserting or putting water pipes, close the end of the pipe with pipe cap to avoid dust

entering.

- When cutting or welding the pipe, always be careful that inner section of the pipe should not be

defective. For example, no weldments or no burrs are found inside the pipe.

- Drain piping should be provided in case of water discharge by the operation of the safety valve.

This situation can be happened when the internal pressure is over 3.0 bar and water inside the

indoor unit will be discharged to drain hose.

While connecting water pipes, followings should be considered.

- Pipe fittings (e.g. L-shape elbow, T-shape tee, diameter reducer, etc) should be tightened

strongly to be free from water leakage.

- Connected sections should be leakage-proof treatment by applying tefron tape, rubber bushing,

sealant solution, etc.

- Appropriate tools and tooling methods should be applied to prevent mechanical breakage of the

connections.

- Operation time of flow control valve(e.g. 3way valve or 2way valve) should be less than 90

seconds.

- Drain hose should be connected with drain piping.

24

ENGLISH

PIPING AND WIRING FOR INDOOR UNIT

WARNING

!

Installing shut-off valve

• While assembling two shut-off valves, that are found inside ‘AWHP Installation Kit

(AET69364401)’, pop sound will be heard when valve is open or close by rotating handles.

It is normal condition because the sound is due to leakage of charged nitrogen gas inside

the valve. The nitrogen gas is applied to secure quality assurance.

• Before starting water charging, these two shut-off valves should be assembled with water

inlet and outlet pipe of the indoor unit.

Water condensation on the floor

While cooling operation, it is very important to keep leaving water temperature higher than

16 °C. Otherwise, dew condensation can be occurred on the floor.

If floor is in humid environment, do not set leaving water temperature below 18 °C.

Water condensation on the radiator

While cooling operation, cold water may not flow to the radiator. If cold water enters to the

radiator, dew generation on the surface of the radiator can be occurred.

Drainage treatment

While cooling operation, condensed dew can drop down to the bottom of the indoor unit. In

this case, prepare drainage treatment (for example, vessel to contain condensed dew) to

avoid water drop.

PIPING AND WIRING FOR INDOOR UNIT

Water Charging

For water charging, please follow below procedures.

Step 1. Open all valves of whole water circuit. Supplied water should be charged not only inside

the indoor unit, but also in the under floor water circuit, sanitary water tank circuit, FCU

water circuit, and any other water circuits controlled by the product.

Step 2. Connect supply water into drain valve and fill valve located at the side of the shut-off

valve.

CAUTION

!

No water-leakage permitted at the drain and fill

valve. Leakage-proof treatment which is

described in previous section should be applied.

Water Out Water In

Step 3. Start to supply water. While supplying water, following should be kept.

- Pressure of supplying water should be 2.0 bar approximately.

- For supplying water pressure, time to be taken from 0 bar to 2.0 bar should be more

than 1 minute. Sudden water supply can yield water drain through safety valve.

- Fully open the cap of air vent to assure air purging. If air is exist inside the water circuit,

then performance degrade, noise at the water pipe, mechanical damage at the surface

of electric heater coil.

Step 4. Stop water supplying when the pressure gauge located in front of the control panel

indicates 2.0 bar.

Step 5. Close drain valve and fill valve. Then wait for 20~30 seconds to observe water pressure

being stabilized.

Step 6. If following conditions are satisfactory, then go to step 7(pipe insulation). Otherwise, go

to step 3.

- Pressure gauge indicates 2.0 bar. Note that sometimes pressure in decreased after step

5 due to water charging inside expansion vessel.

- No air purging sound is heard or no water drop are popping out from air vent.

25

ENGLISH

Pipe Insulation

Purpose of water pipe insulation is :

- To prevent heat loss to external environment

- To prevent dew generation on the surface of the pipe in cooling operation

PIPING AND WIRING FOR INDOOR UNIT

26

ENGLISH

Water pump Capacity

The water pump use variable type which is capable to change flow rate, so it may be required to

change default water pump capacity in case of noise by water flow. In most case, however, it is

strongly recommended to set capacity as

Rated flow-rate

.

NOTE

• To secure enough water flow rate, do not set water pump capacity as Minimum.

It can lead unexpected flow rate error CH14.

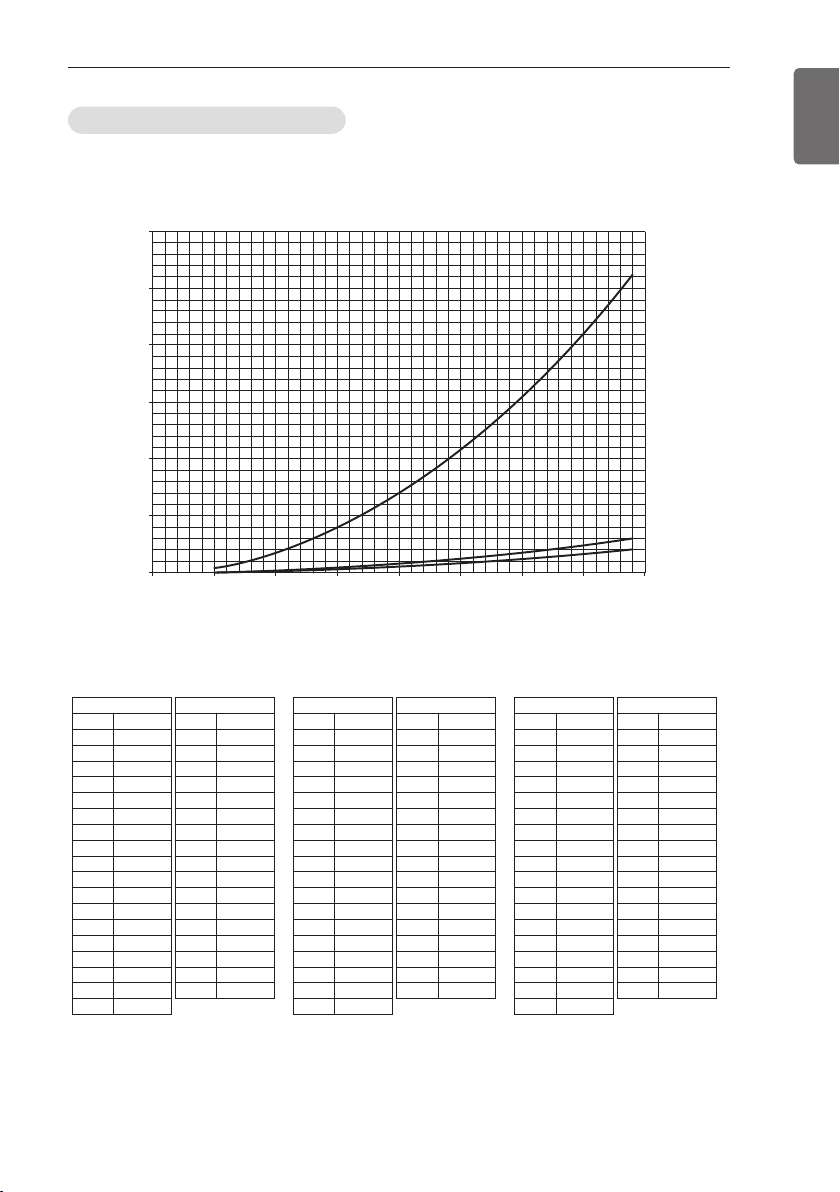

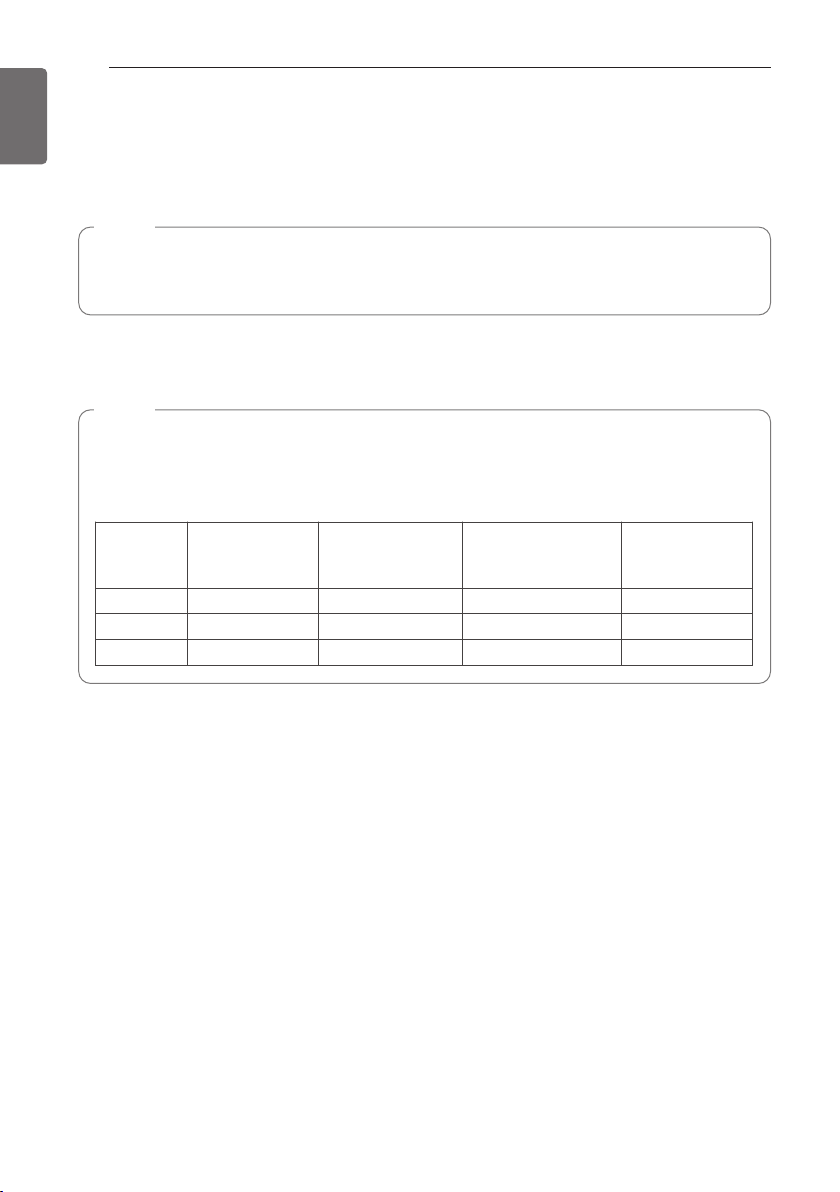

Pressure Drop

NOTE

When installing the product, install additional pump in consideration of the pressure loss and

pump performance.

If flow-rate is low, overloading of product can occur.

Capacity

[kW]

5.6 25.9 6.1 0.4 5.7

7.1 20.1 7.3 0.3 7.0

9.0 15.8 7.5 0.2 7.3

Rated flow-rate

[LPM]

Pump Head [m]

(at rated flow-rate)

Product pressure

drop [m]

(Plate heat exchanger)

Serviceable

Head [m]

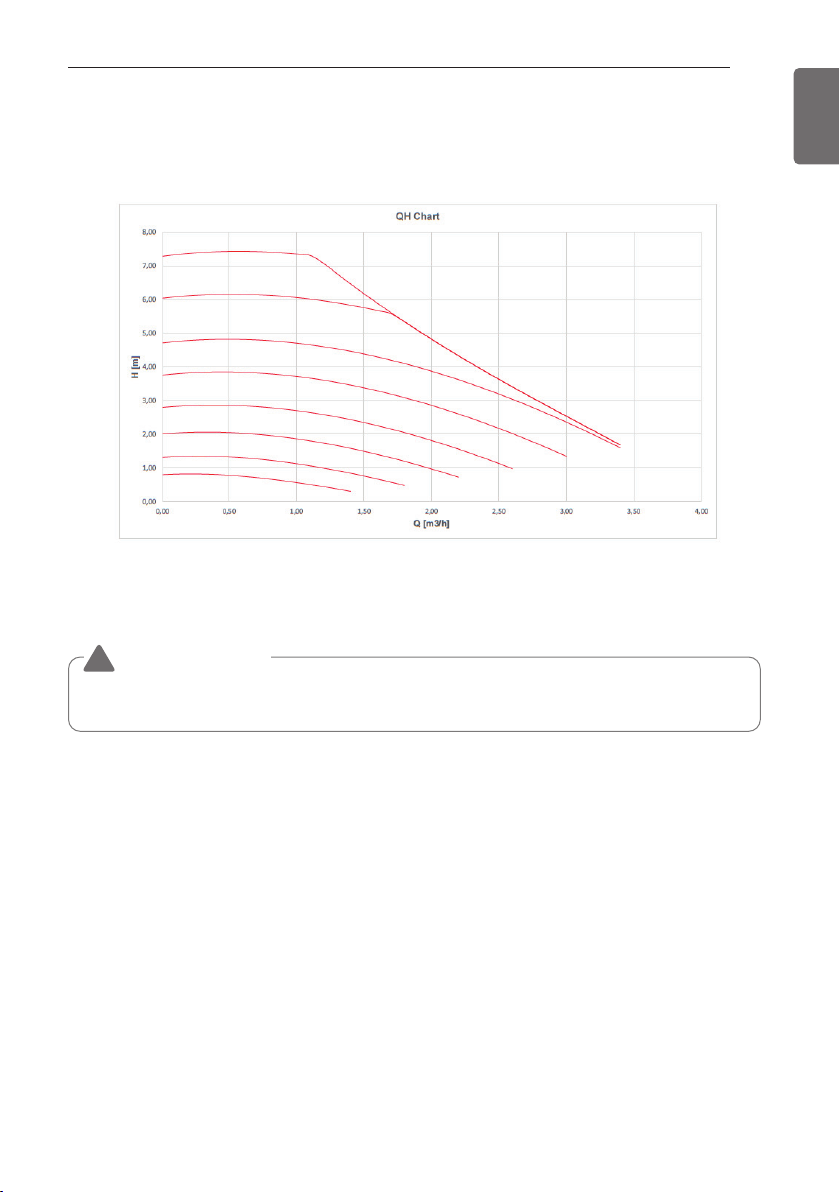

PIPING AND WIRING FOR INDOOR UNIT

MGQ62321902 : UPM3K GEO 20 - 75 CHBL

(5 kW, 7 kW, 9 kW / for R32)

Performance test based on standard ISO 9906 with pre-pressure 2.0bar and liquid temperature

20 °C.

27

ENGLISH

WARNING

!

Selecting a water flowrate outside the curves can cause damage to or malfunction of the

unit.

PIPING AND WIRING FOR INDOOR UNIT

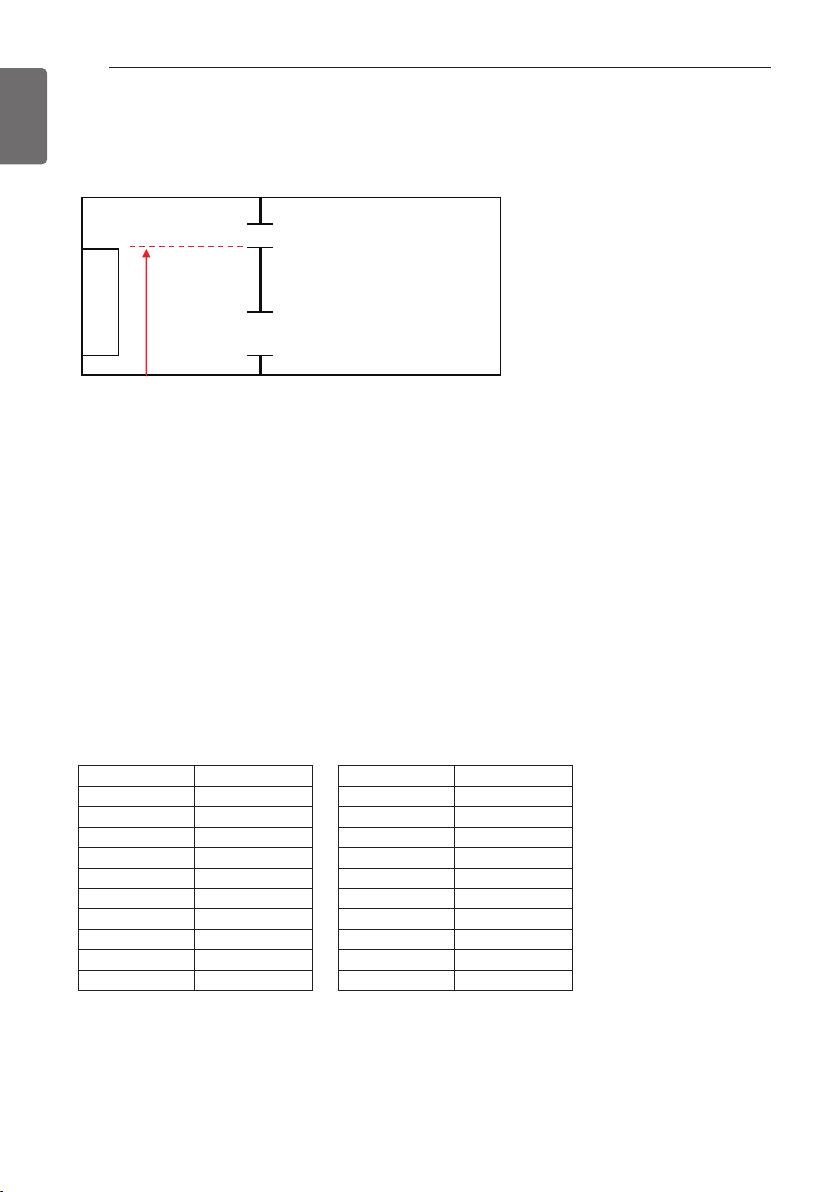

Outdoor Indoor

Outdoor Unit

Indoor Unit

Floor heating loop

Fan coil unit

Radiator

M / F

High Temperature Room Thermostat(Field supply)

2way valve (Field supply) By-pass valve(Field supply)Low Temperature

Magnetic Filter (Recommended)

Shut-off valve

M / F

28

ENGLISH

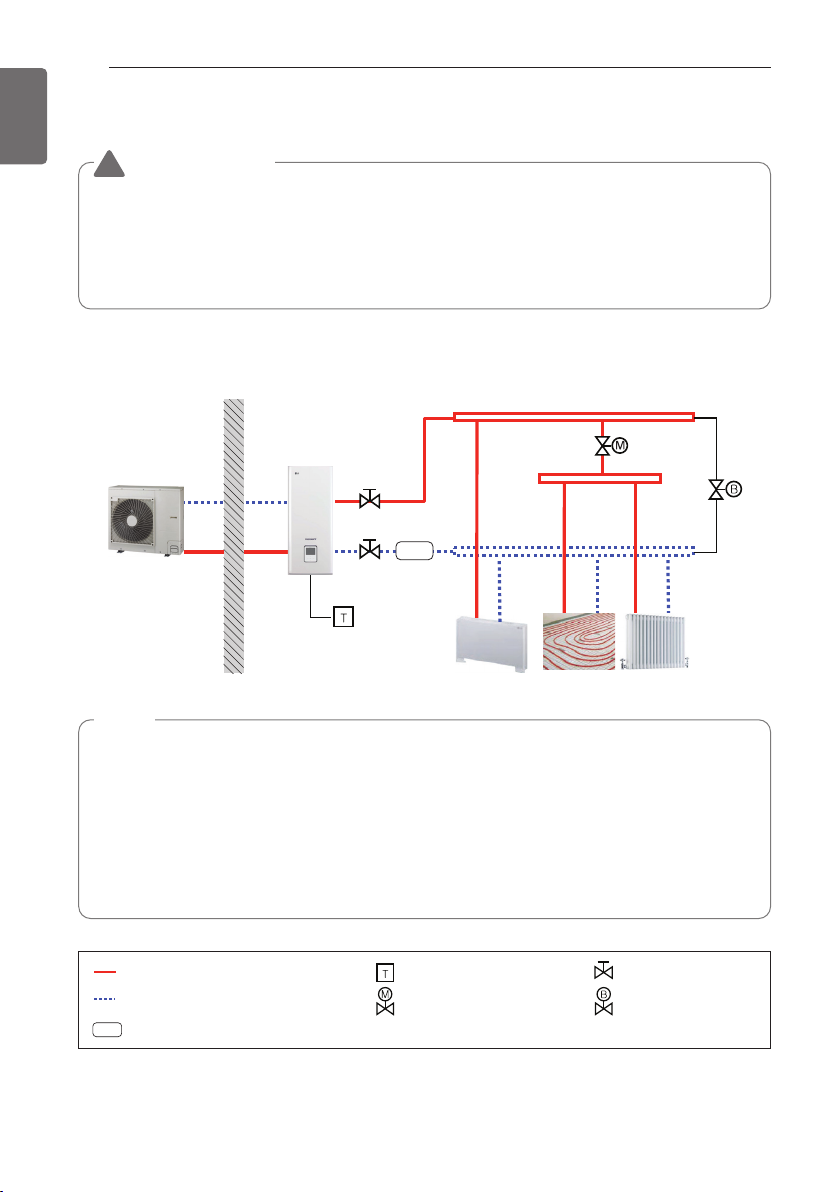

Typical Installation Example

CAUTION

!

If

Hydro Kit

operated together. If entering water temperature of

will stop operation to prevent mechanical damage of the product. For detailed electric wiring

and water piping, please contact authorized installer.

Some installation scenes are presented for example. As these scenes are conceptual figures,

installer should optimize the installation scene according to the installation conditions.

CASE 1: Connecting Heat Emitters for Heating and Cooling

is installed with pre-existing boiler, the boiler and

Hydro Kit

(Under floor loop, Fan Coil Unit, and Radiator)

Hydro Kit

is above 50 °C, the system

should not be

NOTE

• 2way valve

- It is important to install 2way valve to prevent dew condensation on the floor and radiator

while cooling mode.

- 2way valve should be installed at the supply side of the collector.

• By-pass valve

- To secure enough water flow rate, by-pass valve should be installed at the collector.

- By-pass valve should guarantee minimum water flow rate in any case. Minimum water

flow rate is described in water pump characteristics curve.

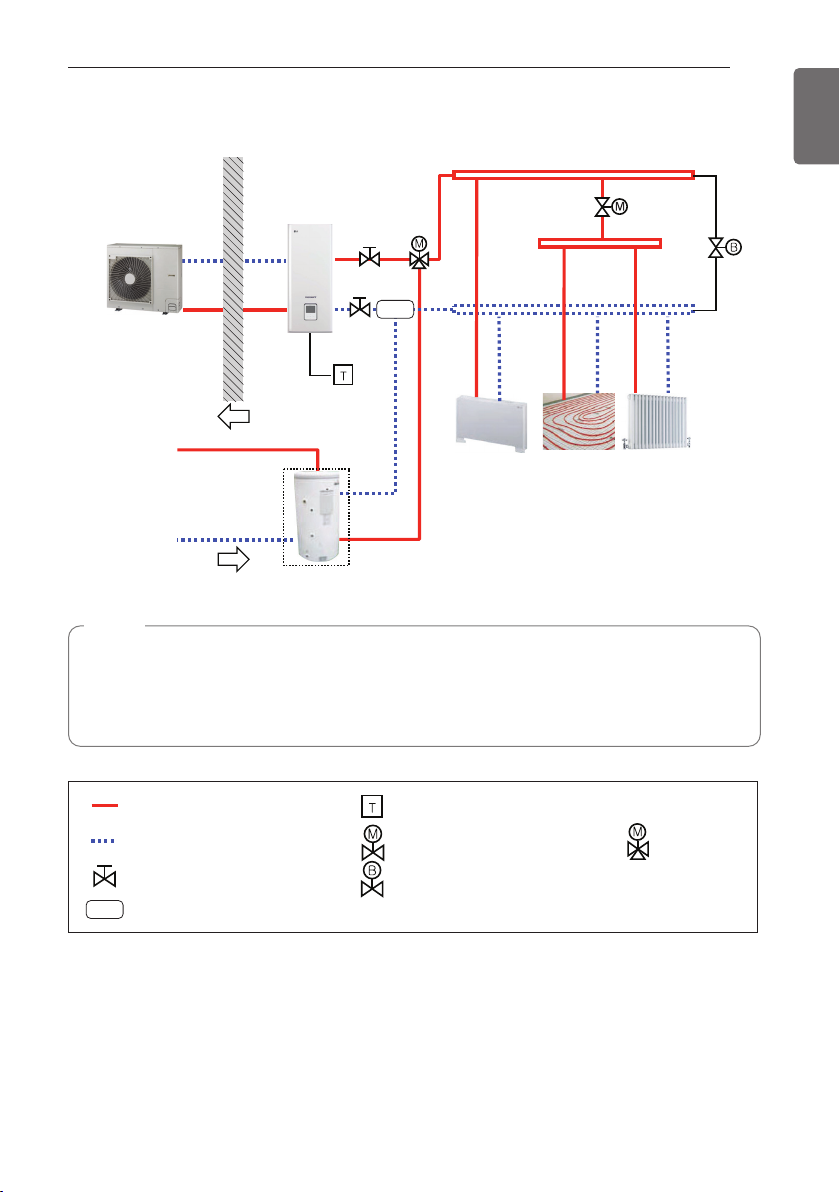

CASE 2: Connecting DHW Tank

Outdoor Indoor

Outdoor Unit

Indoor Unit

Floor heating loopFan coil unit

Hot water

City water

Radiator

M / F

DHWDHW

tanktank

DHW

tank

High Temperature

Room Thermostat(Field supply)

2way valve

(Field supply)

3way valve

(Field supply)

By-pass valve(Field supply)

Low Temperature

Shut-off valve

Magnetic Filter (Recommended)

M / F

DHW

tank

NOTE

PIPING AND WIRING FOR INDOOR UNIT

29

ENGLISH

• DHW tank

- It should be equipped with internal electric heater to generate sufficient heat energy in

very cold season.

- DHW : Domestic Hot Water

PIPING AND WIRING FOR INDOOR UNIT

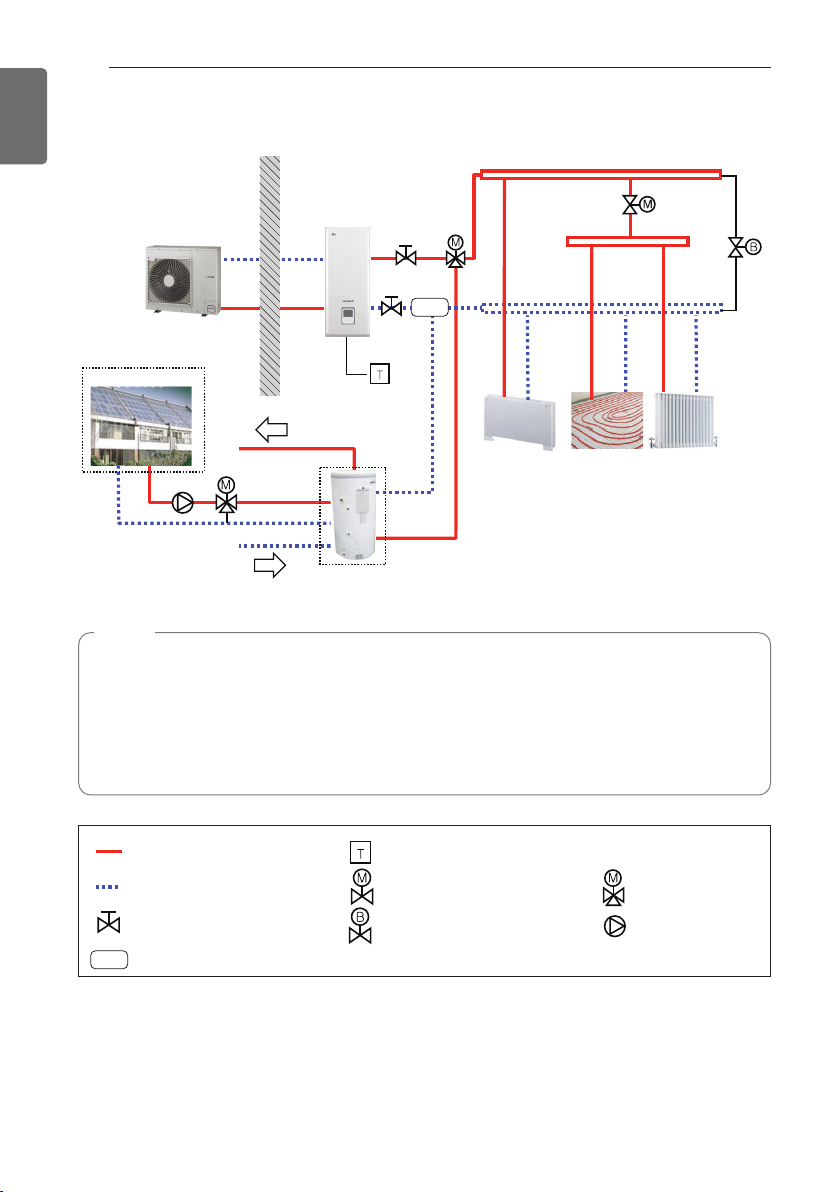

Solar heat source

Outdoor Indoor

Outdoor Unit

Indoor Unit

Floor heating loopFan coil unit

Hot water

City water

Radiator

M / F

DHWDHW

tanktank

DHW

tank

High Temperature

Room Thermostat(Field supply)

2way valve (Field supply)

3way valve

(Field supply)

By-pass valve(Field supply)

Low Temperature

Shut-off valve

Pump(Field supply)

Magnetic Filter (Recommended)

M / F

DHW

tank

30

ENGLISH

CASE 3: Connecting Solar thermal system

NOTE

• DHW tank

- It should be equipped with internal electric heater to generate sufficient heat energy in

very cold season.

- DHW : Domestic Hot Water

• Pump

- Maximum power consumption of pump should be less than 0.25 kW.

Loading...

Loading...