Page 1

INSTALLATION MANUAL

AIR

CONDITIONER

www.lg.com

Hydro Kit (For High Temperature)

For more information, Refer to the CD or LG Web site (www.lg.com).

Original instruction

Please read this installation manual completely before installing the product.

Installation work must be performed in accordance with the national wiring

standards by authorized personnel only.

Please retain this installation manual for future reference after reading it

thoroughly.

[

Representative

] LG Electronics Inc. EU Representative : LG Electronics European Shared

Service Center B.V. Krijgsman 1, 1186 DM Amstelveen, The Netherlands

[Manufacturer] LG Electronics Inc. Changwon 2nd factory 84, Wanam-ro, Seongsan-gu,

Changwon-si, Gyeongsangnam-do, KOREA

P/NO : MFL67798102

ENGLISH

ITALIANO

ESPAÑOL FRANÇAIS

DEUTSCH

ΕΛΛΗΝΙΚΆ

ČEŠTINA

NEDERLANDS

POLSKI

LIMBA ROMÂNĂ

Page 2

Hydro Kit

Installation Manual

TABLE OF CONTENTS

1. SAFETY PRECAUTIONS..............................................................................................................3

2. INSTALLATION PARTS ................................................................................................................8

3. GENERAL INFORMATION ...........................................................................................................9

MODEL INFORMATION ................................................................................................................9

4. INSTALLATION...........................................................................................................................10

TRANSPORTING THE UNIT.......................................................................................................10

SELECTION OF THE BEST LOCATION .....................................................................................11

INSTALLATION SPACE ...............................................................................................................11

FOUNDATION FOR INSTALLATION...........................................................................................12

WATER PIPING AND WATER CIRCUIT CONNECTION ............................................................13

SANITARY WATER TANK AND SANITARY WATER TANK KIT..................................................16

INSTALLATION SCENES............................................................................................................18

REFRIGERANT PIPING..............................................................................................................20

HOW TO CONNECT WIRINGS...................................................................................................22

WIRING CONNECTION ..............................................................................................................22

CONNECTING CABLES .............................................................................................................23

5. ACCESSORIES INSTALLATION ................................................................................................24

LOCATION OF ACCESSORIES AND EXTERNAL PARTS CONNECTION ................................24

MAIN PUMP CONNECTION .......................................................................................................27

WATER TANK TEMPERATURE SENSOR CONNECTION.........................................................27

THERMOSTAT.............................................................................................................................28

REMOTE TEMPERATURE SENSOR .........................................................................................31

3WAY VALVE ...............................................................................................................................32

DRY CONTACT ...........................................................................................................................34

6. SYSTEM SET-UP........................................................................................................................35

DIP SWITCH SETTING ...............................................................................................................35

GROUP CONTROL SETTING.....................................................................................................36

INSTALLER SETTING.................................................................................................................40

7. TEST RUN...................................................................................................................................48

CAUTION BEFORE OPERATION TEST.....................................................................................48

OPERATION TEST OF WATER PIPE .........................................................................................48

TROUBLESHOOTING.................................................................................................................49

2

Hydro Kit

Page 3

Safety Precautions

1. Safety Precautions

To prevent injury to the user or other people and property damage, the following instructions must be followed.

■

Be sure to read before installing the unit.

■

Be sure to observe the cautions specified here as they include important items related to safety.

■

Incorrect operation due to ignoring instruction will cause harm or damage. The seriousness is classified

by the following indications.

■ Meanings of symbols used in this manual are as shown below.

WARNING

CAUTION

This symbol indicates the possibility of death or serious injury.

This symbol indicates the possibility of injury or damage to properties only.

WARNING

Be sure not to do.

Be sure to follow the instruction.

Hydro Kit Installation Manual 3

ENGLISH

■ Installation

Do not use a defective

or underrated circuit

breaker. Use this appliance on a dedicated

circuit.

• There is risk of fire or

electric shock.

For electrical work,

contact the dealer,

seller, a qualified electrician, or an Authorized Service Center.

• There is risk of fire or

electric shock.

Always ground the unit.

• There is risk of fire or

electric shock.

Install the panel and

the cover of control

box securely.

• There is risk of fire or

electric shock.

Always install a dedicated circuit and

breaker.

• Improper wiring or installation may cause fire or

electric shock.

Use the correctly rated

breaker or fuse.

• There is risk of fire or

electric.

Page 4

Safety Precautions

4

Hydro Kit

Be sure the installation

area does not deteriorate with age.

• If the base collapses, the

unit could fall with it,

causing property damage, unit failure, and personal injury.

Do not install the water

pipe system as Open

loop type.

• It may cause failure of

unit.

Do not install the unit

outside.

• It may cause damage to

the unit.

The refrigerant of this

unit is R134a and the

unit is connected to the

outdoor unit where

R410A refrigerant is

used.

• The installation tool such

as manifold gauge

should comply with

R410A.

For installation, always

contact the dealer or an

Authorized Service

Center.

• There is risk of fire, electric shock, explosion, or

injury.

Do not install the unit

on a defective installation stand.

• It may cause injury, accident, or damage to the

unit.

Do not modify or extend the power cable.

• There is risk of fire or

electric shock.

Do not install, remove,

or reinstall the unit by

yourself (customer).

• There is risk of fire, electric shock, explosion, or

injury.

For antifreeze, always

contact the dealer or an

authorized service center.

• Almost the antifreeze is

a toxic product.

Use a vacuum pump or inert (nitrogen) gas when doing leakage test or purging air. Do not compress air or oxygen and do not use flammable gases.

• There is the risk of death, injury, fire or explosion.

Page 5

Hydro Kit Installation Manual 5

Safety Precautions

ENGLISH

Take care to ensure

that power cable could

not be pulled out or

damaged during operation.

• There is risk of fire or

electric shock.

Do not place anything

on the power cable.

• There is risk of fire or

electric shock.

Do not plug or unplug

the power supply plug

during operation.

• There is risk of fire or

electric shock.

Do not touch (operate)

the unit with wet hands.

• There is risk of fire or

electric shock.

Do not place a heater

or other appliances

near the power cable.

• There is risk of fire or

electric shock.

Do not allow water to

run into electric parts.

• There is risk of fire, failure of the unit, or electric

shock.

■ Operation

Do not store or use

flammable gas or combustibles near the unit.

• There is risk of fire or

failure of unit.

Do not use the unit in a

tightly closed space for

a long time.

• It may cause damage to

the unit.

When flammable gas

leaks, turn off the gas

and open a window for

ventilation before turning the unit on.

• There is risk of explosion

or fire.

If strange sounds, or

small or smoke comes

from unit, turn the

breaker off or disconnect the power supply

cable.

• There is risk of electric

shock or fire.

Stop operation and

close the window in

storm or hurricane. If

possible, remove the

unit from the window

before the hurricane arrives.

• There is risk of property

damage, failure of unit,

or electric shock.

Do not open the front

cover of the unit while

operation. (Do not

touch the electrostatic

filter, if the unit is so

equipped.)

• There is risk of physical

injury, electric shock, or

unit failure.

Page 6

Safety Precautions

6

Hydro Kit

If the unit is not used

for long time, we

strongly recommend

not to switch off the

power supply to the

unit.

• There is risk of water

freezing.

Turn the main power off

when cleaning or maintaining the unit.

• There is risk of electric

shock.

Take care to ensure

that nobody could step

on or fall onto the unit.

• This could result in personal injury and unit

damage.

For installation, always

contact the dealer or an

Authorized Service

Center.

• There is risk of fire, electric shock, explosion, or

injury.

When the unit is

soaked (flooded or submerged), contact an

Authorized Service

Center.

• There is risk of fire or

electric shock.

Be cautious that water

could not be poured to

the unit directly.

• There is risk of fire, electric shock, or unit damage.

Ventilate the unit from

time to time when operating it together with a

stove, etc.

• There is risk of fire or

electric shock.

Page 7

Safety Precautions

Hydro Kit Installation Manual 7

ENGLISH

■ Installation

Always check for gas

(refrigerant) leakage

after installation or repair of unit.

• Low refrigerant levels

may cause failure of unit.

Keep level even when

installing the unit.

• To avoid vibration or

water leakage.

Use two or more people

to lift and transport the

unit.

• Avoid personal injury.

■ Operation

Do not use the unit for

special purposes, such

as preserving foods,

works of art, etc.

• There is risk of damage

or loss of property.

Use a soft cloth to

clean. Do not use harsh

detergents, solvents,

etc.

• There is risk of fire, electric shock, or damage to

the plastic parts of the

unit.

Do not step on or put

anything on the unit.

• There is risk of personal

injury and failure of unit.

Use a firm stool or ladder when cleaning or maintaining the unit.

• Be careful and avoid personal injury.

CAUTION

Page 8

Installation Parts

8

Hydro Kit

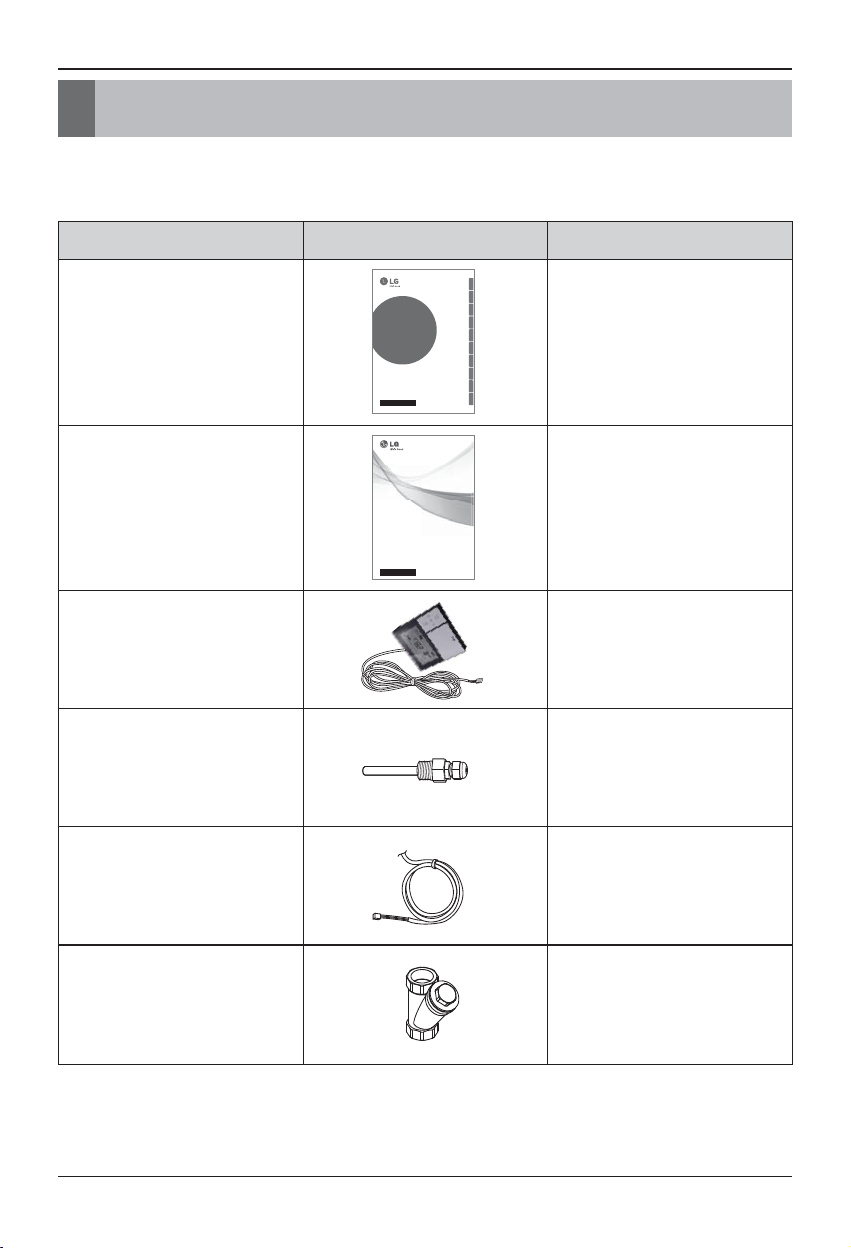

2. Installation Parts

Thank you for choosing LG Electronics Hydro Kit.

Before starting installation, please make it sure that all parts are found inside the unit box.

Item Image Quantity

Installation Manual

1

Owner's Manual 1

Remote Controller

/ Cable

1

Sensor Holder 1

Water Tank

Temperature Sensor

1

Strainer 1

OWNER’S MANUAL

AIR CONDITIONER

Please read this manual carefully before operating

your set and retain it for future reference.

P/NO : MFL67212703

www.lg.com

TYPE :

Hydro Kit (For High Temperature)

ENGLISH

ITALIANO ESPAÑOL FRANÇAIS DEUTSCH

INSTALLATION MANUAL

AIR

CONDITIONER

Please read this installation manual completely before installing the product.

Installation work must be performed in accordance with the national wiring

standards by authorized personnel only.

Please retain this installation manual for future reference after reading it

thoroughly.

Hydro Kit (For High Temperature)

Original instruction

P/NO : MFL67798102

ΕΛΛΗΝΙΚΆ

ČEŠTINA

NEDERLANDS

POLSKI

LIMBA ROMÂNĂ

www.lg.com

Page 9

General Information

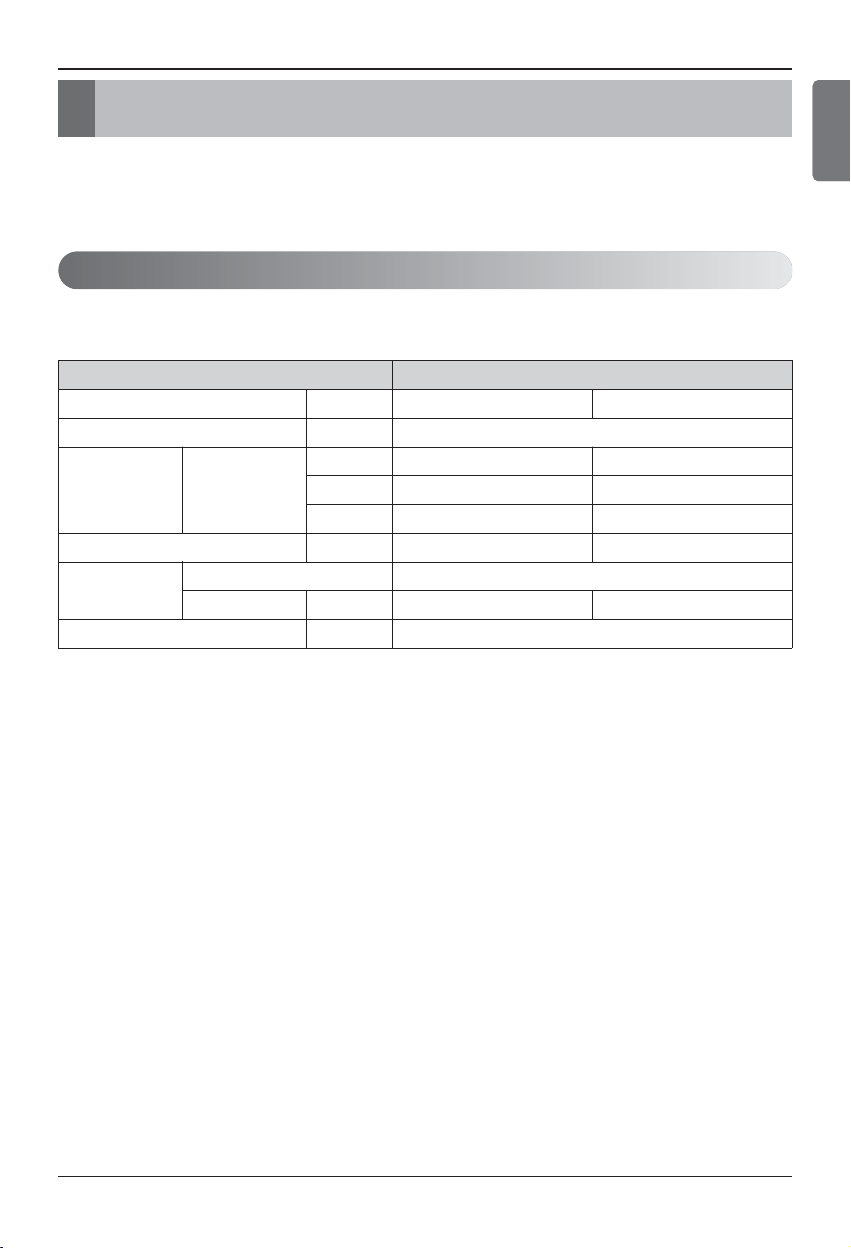

Model Information

With advanced inverter technology, Hydro Kit is suitable for applications like under floor heating, and hot water generation. By Interfacing to various accessories user can customize the range

of the application.

Hydro Kit Installation Manual 9

Model name and related information

*1 : Tested under Eurovent Heating condition

(Water temperature 55℃(131℉) 65 ℃(149 ℉) at outdoor ambient temperature

7℃(44℉) / 6℃(42℉))

ENGLISH

Type

Hydro Kit

(For High Temperature)

Model Unit

Power Supply Ø, V, Hz

Capacity Heating

kW

kcal/h

Btu/h

Net Weight kg(lbs)

Refrigerant

Type

Quantity kg(lbs)

Noise Level dB

ARNH08GK3A2 ARNH04GK3A2

1, 220-240, 50

25 13.8

21500 11870

85300 47000

94(207) 88(194)

R134a

3(6.61) 2.3(5.07)

43

3. General Information

Page 10

10

Hydro Kit

Installation

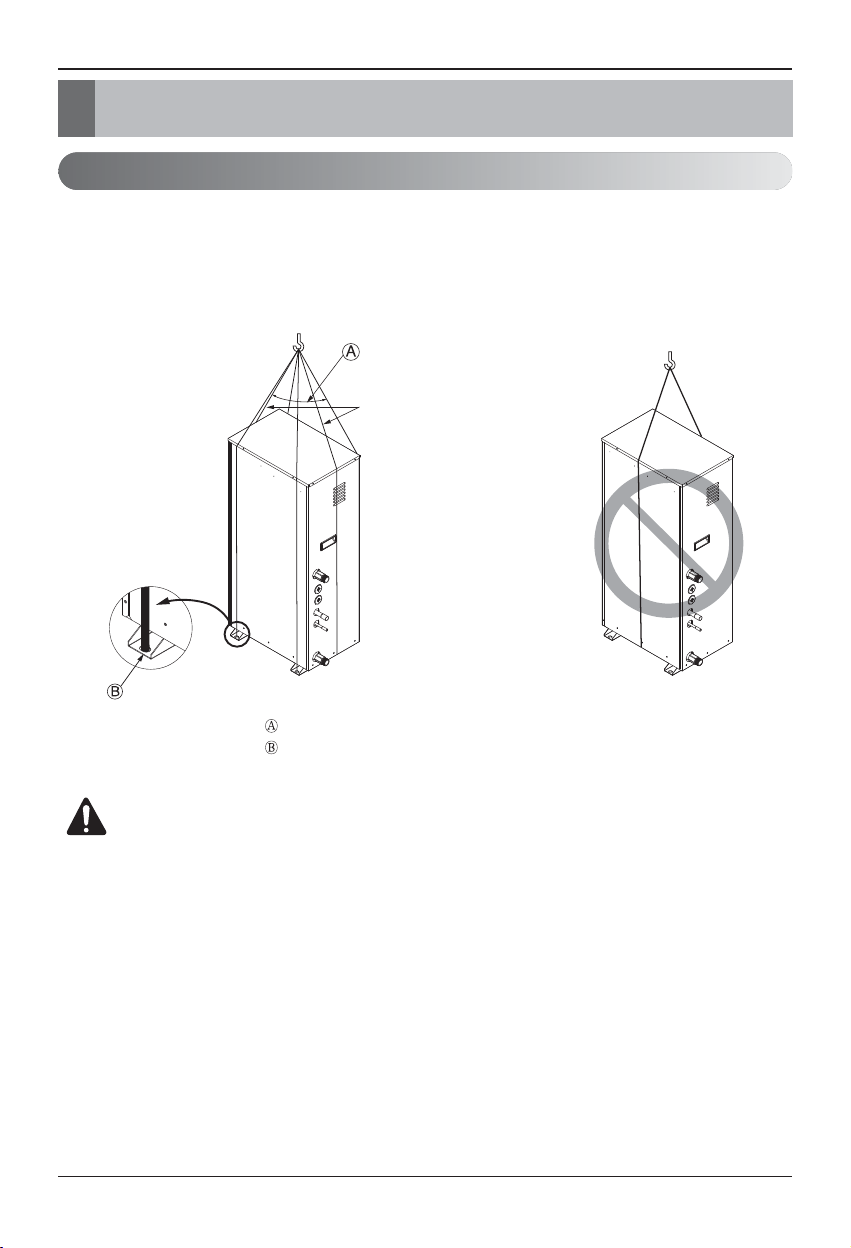

Transporting the Unit

• When carrying the suspended unit, pass the ropes between legs of base panel under the unit.

• Always lift the unit with ropes attached at 6 points so that impact is not applied to the unit.

• Attach the ropes to the unit at an angle Ⓐ of 40° or less.

• Use only accessories and parts which are of the designated specification when installing.

CAUTION

Be very careful while carrying the unit.

- Do not have only one person carry the unit if it is more than 20 kg (44.1 lbs).

- PP bands are used to pack some products. Do not use them as a mean for transportation because

they are dangerous.

- Tear plastic packaging bag and scrap it so that children cannot play with it. Otherwise plastic packaging bag may suffocate children to death.

- When carrying the unit, be sure to support it at 6-points. Carrying and lifting the unit with 4-point

support may make it unstable, resulting in a fall.

4. Installation

Sub line

40º or less

Line supporter

Page 11

Installation

Hydro Kit Installation Manual 11

1. Select space for installing the unit, which will meet the following conditions:

• The place where the unit shall be installed inside.

• The place shall easily bear a load exceeding four times of the unit weight.

• The place where the unit shall be leveled.

• The place shall allow easy water drainage.

• The place where the unit shall be connected to the outdoor unit.

• The place where the unit is not affected by an electrical noise.

• The place where there should not be any heat source or steam near the unit.

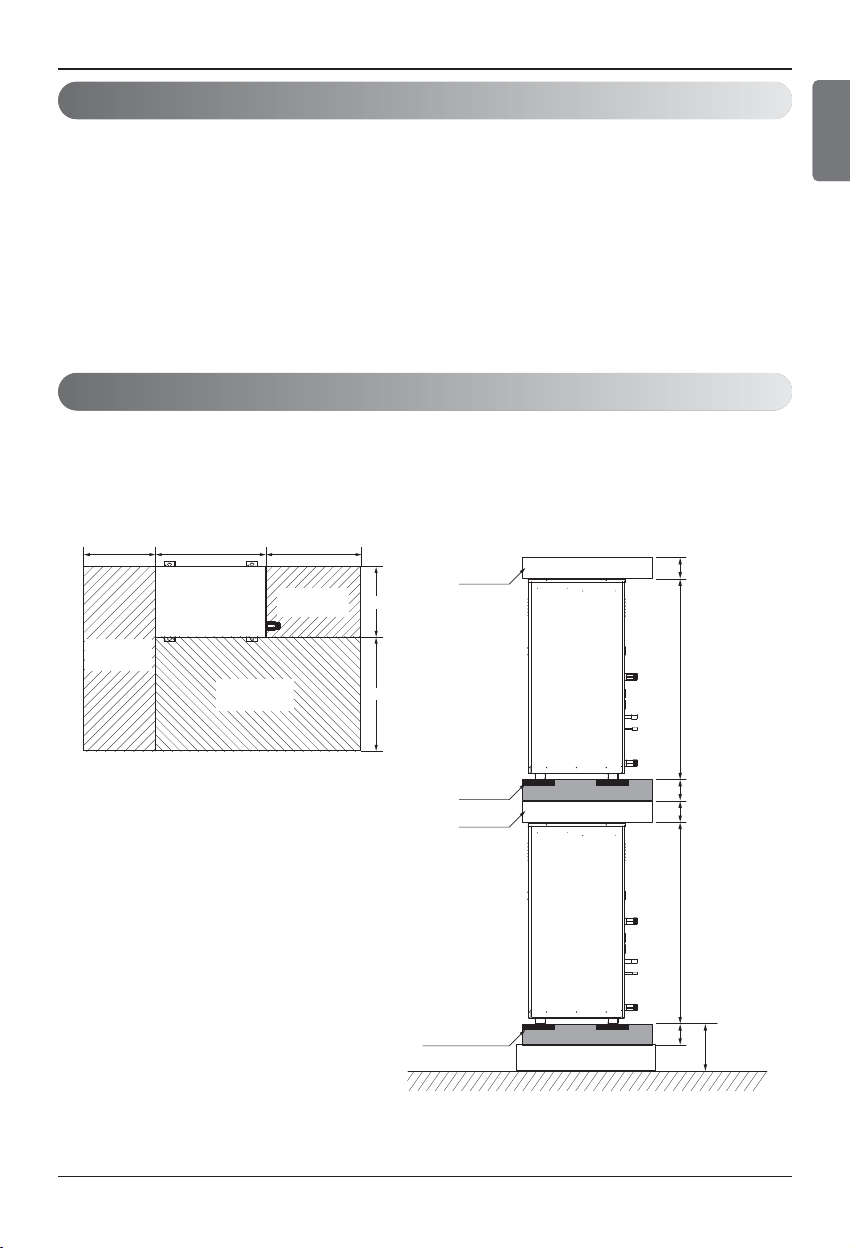

Installation Space

• The following values are the least space for installation.

If any service area is needed for service according to field circumstance, obtain enough service

space.

• The unit of values is mm.

ENGLISH

Selection of the best location

(Unit: mm)

100100100100

10801080

Service space

(left side)

Service space

(front side)

400520300

Piping space

(front side)

space

330

600

(Unit: mm)

Anti Vibration

material

space

H-Beam supporter

Concrete supporter

200

Page 12

Installation

12

Hydro Kit

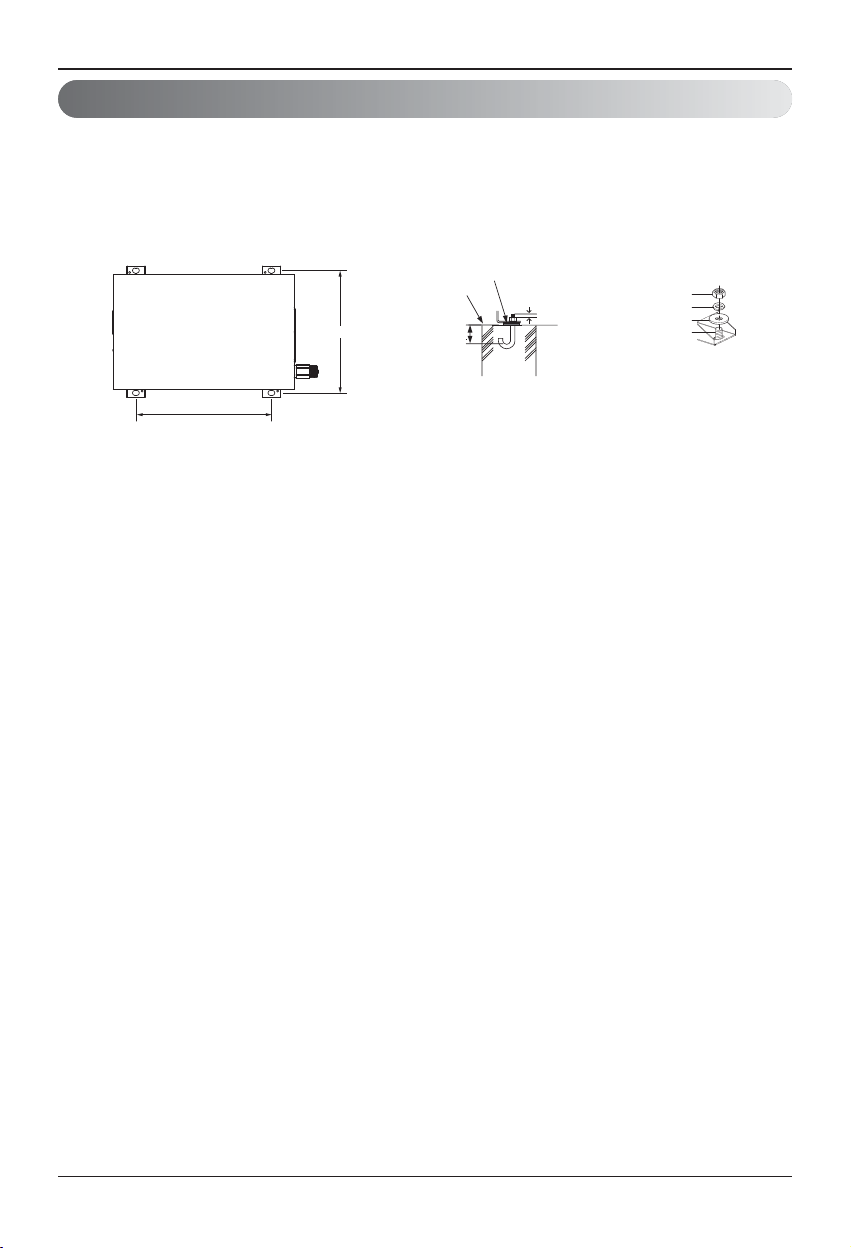

Foundation for Installation

• Fix the unit tightly with bolts as shown below so that the unit will not fall down due to earthquake.

• Noise and vibration may occur from the floor or wall since vibration is transferred through the installation part depending on installation status. Thus, use anti-vibration materials (cushion pad)

fully (The base pad shall be more than 200 mm (7-7/8 inch)).

Anti-vibration material

354

Concrete

base

Support

75

3 or more screw

threads of the

2 bolts must be

shown

Nut

Spring washer

Flat washer

Anchor bolt

392

(Unit: mm)

Page 13

Installation

Hydro Kit Installation Manual 13

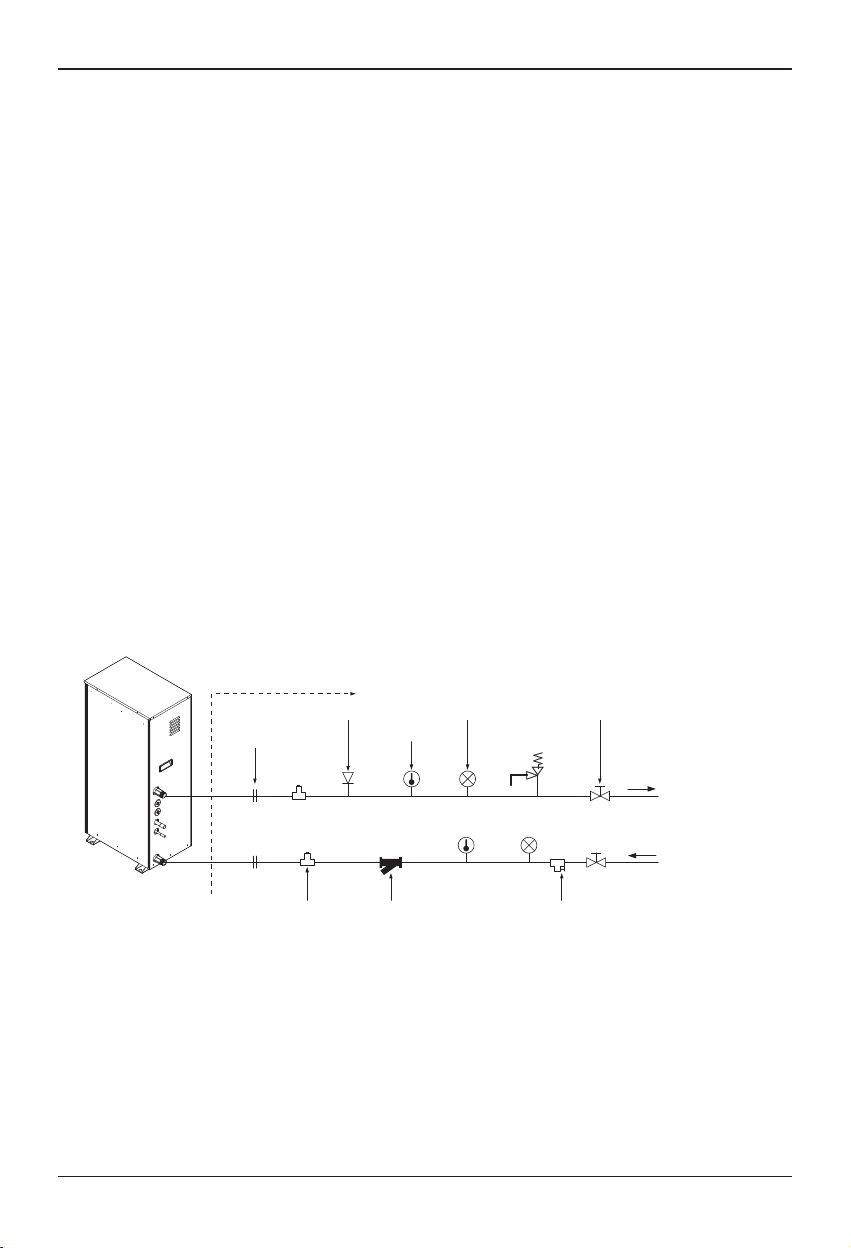

General Considerations

Followings should be considered before beginning water circuit connection.

• Service space should be secured.

• Water pipes and connections should be cleaned using water.

• Space for installing external water pump should be provided.

• Never connect electric power while proceeding water charging.

Water Piping and Water Circuit Connection

While installing water pipes, followings should be considered :

•

While inserting or putting water pipes, close the end of the pipe with pipe cap to avoid dust entering.

• When cutting or welding the pipe, always be careful that inner section of the pipe should not be

defective. For example, no weldments or no burrs are found inside the pipe.

• Pipe fittings (e.g. L-shape elbow, T-shape tee, diameter reducer, etc) should be tightened

strongly to be free from water leakage.

• Connected sections should be leakage-proof treatment by applying tefron tape, rubber bushing,

sealant solution, etc.

•

Appropriate tools and tooling methods should be applied to prevent mechanical breakage of the connections.

• Operation time of flow valve(e.g. 3way valve) should be less than 90 seconds.

• Pipe is insulated to prevent heat loss to external environment.

Water Piping and Water Circuit Connection

ENGLISH

Page 14

Installation

14

Hydro Kit

Water cycle

* For the water pipe system, use the closed loop type.

1. For the parts of the water pipe system, use the parts above the design water pressure.

2. For the water pipe, do not use steel pipe.

3. To replace the connected device easily, install the union joint (2).

4.

Install the service port (3) to clean the heat exchanger at each inlet and outlet of the water pipe.

5. Always install a strainer (4) at the inlet of the water pipe.

- For the strainer, use one with 50 mesh or above with measurement diameter of 0.4mm or

less. (Exclude other net)

- Always install the strainer on the horizontal pipe.

(When dirt, trash, rusted pieces get into the water pipe system, it can cause problems to the

product by corroding the metallic material.)

6. Install the air vent (5) at the top of the water pipe.

7. Install a thermometer (6) and pressure gauge (7) at the inlet and outlet of the water pipe.

8. Install the drain valve (8) that can be used for draining the water inside when replacing the part

or providing service.

9. Install the shut-off valve (9) to block the water by closing the valve when replacing the part or

cleaning.

10. Apply insulated treatment on the exterior of the water pipe so that water drops do not form.

11. Install excessive pressure safety valve (10) that meets the design water pressure to prevent

unit or water pipe damage at the pressure increase inside the water pipe system.

12. There is a drain hole at the bottom of the Hydro Kit to prevent risk of electric shock caused by

leakage of water.

Hydro kit

(For High Temperature)

On-site installation (1)

Air vent (5)

Union joint (2) Thermometer (6) Excessive pressure

Pressure gauge(7) Shut-off valve (9)

safety valve(10)

Outlet Water

Inlet water

Drain valve(8)Strainer(4)P/T Service port(3)

[Install water tank]

or

[Install floor heating]

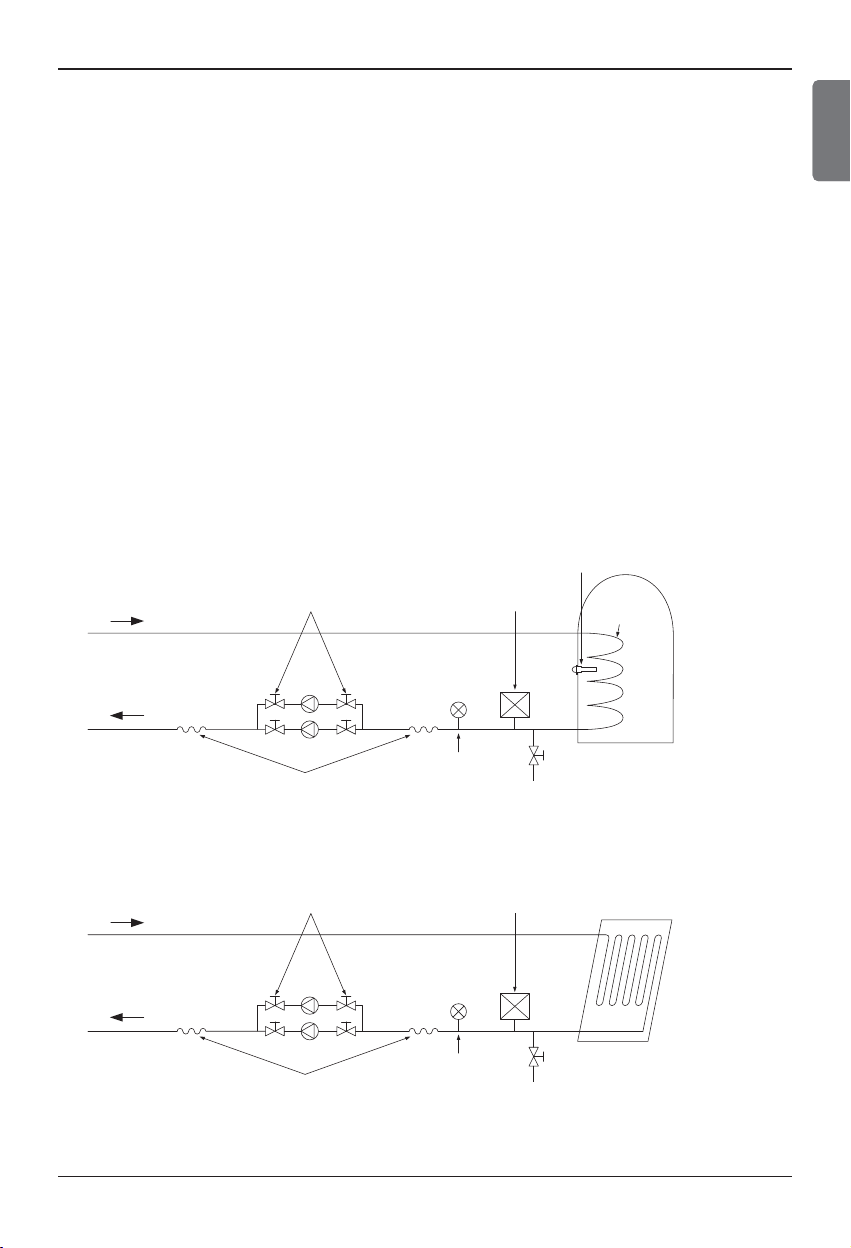

Page 15

Installation

Hydro Kit Installation Manual 15

* Water tank & Floor heating installation

1. Use the pump (1) with sufficient capacity to assure loss of overall water pressure and to supply

water to the

Hydro Kit

.

2. Install the shut-off valve (2) on both sides of the pump to clean and repair the pump.

3. Install the flexible joint (3) to prevent noise and vibration transferred from the pump.

4. Install the pressure gauge (4) to monitor the water pressure from water tank. (Option)

5. Install the expansion tank (5) to accommodate the water contracted or expanded from the temperature difference and to supply the water.

6. After the installation of water pipe system is completed, open the water supply valve (6) and supply the water.

7. When installing the water tank, insert the water tank temperature sensor (7) to measure the temperature of the water inside the tank.

- For the water tank temperature sensor, use the sensor supplied on the product.

- When heating the floor, measure the temperature by using the remote controller or remote tem-

perature sensor (Separately sold).

8. Use the water tank (9) with the heat exchange coil (8) installed so that the heat can be exchanged

sufficiently inside the tank.

Installation of water tank

Installation of floor heating

ENGLISH

water tank

temperature sensor (7)

shut-off valve (2)

Expansion tank (5)

Heat

exchange

coil (8)

Pump (1)

Flexible joint (3)

shut-off valve (2)

Pump (1)

Flexible joint (3)

Pressure gauge (4)

Water supply valve (6)

Expansion tank (5)

Pressure gauge (4)

Water supply valve (6)

water tank (9)

(Indirect heating type)

Floor heating coil

(Radiator, FCU can be used)

Page 16

Installation Condition

Installing sanitary water tank requires following considerations :

• Sanitary water tank should be located at the flat place.

• Water quality should comply with EN 98/83 EC Directives.

• As this water tank is sanitary water tank (indirect heat exchange), do not use anti water-freezing

treatment like ethylene grycol.

• It is highly recommend to wash out inside of the sanitary water tank after installation. It ensures

generating clean hot water.

• Near the sanitary water tank, there should be water supply and water drain for easy access and

maintenance.

Sanitary Water Tank and Sanitary Water Tank Kit

Sanitary

Water Tank

Water Tank

Temperature Sensor

Water In

Water Out

Installation

16

Hydro Kit

Strainer

- Use the 50 mesh strainer.

(Exclude scale diameter of 0.4mm or less and other net)

- Check the strainer direction and assemble on the inlet hole (Refer to picture)

- Wrap the Teflon tape on the screw thread of the water pipe for more than 15 times for assembly.

- Install the service port facing downward. (Within left/right 45 degrees)

- Check if there is any leakage on the connecting part.

- Clean the strainer periodically. (Once a year or more frequent)

Water In

Strainer

Front Side

45°

Page 17

Installation

Hydro Kit Installation Manual 17

PT 1/2 inch

Process PT 1/2 inch

female bolt

Inside water tank

Water tank outer wall

Water Tank

Temperature Sensor

Sensor

holder

• If hot water mode is used, make sure to install

sensor to water tank.

• Make PT15A female bolt hole in the water tank,

and install sensor in the water tank.

• Push the sensor into the hole of the sensor holder

cap.

• Lock the sensor holder cap.

Water tank temperature sensor connection

ENGLISH

WARNING :

Installing recirculation pump

When Hydro Kit is used with the sanitary water tank, it is STRONGLY recommended to install

recirculation pump to prevent cold water at the end of hot water supply flooding out and to

stabilize the water temperature inside the sanitary water tank.

- The recirculation pump should be operated when sanitary water demand is not required.

Therefore, external time scheduler to determine when the recirculation pump should turn on

and turn off is required.

- The operating duration time of the recirculation pump is calculated as follow :

Duration time [minute] = k * V / R

k : 1.2 ~ 1.5 is recommended.

(If distance between pump and tank is far, then choose high number.)

V : Volume of sanitary water tank [liter]

R : Water flow rate of pump [liter per minute], which is determined by pump performance

curve.

- The pump operating start time should be prior to the sanitary water demand.

Water Out

Water In

Hot water supply

Sanitary

Water Tank

Shower

(End of Hot

water supply)

Recirculation

Pump

External

Time Scheduler

City water

Page 18

Installation

18

Hydro Kit

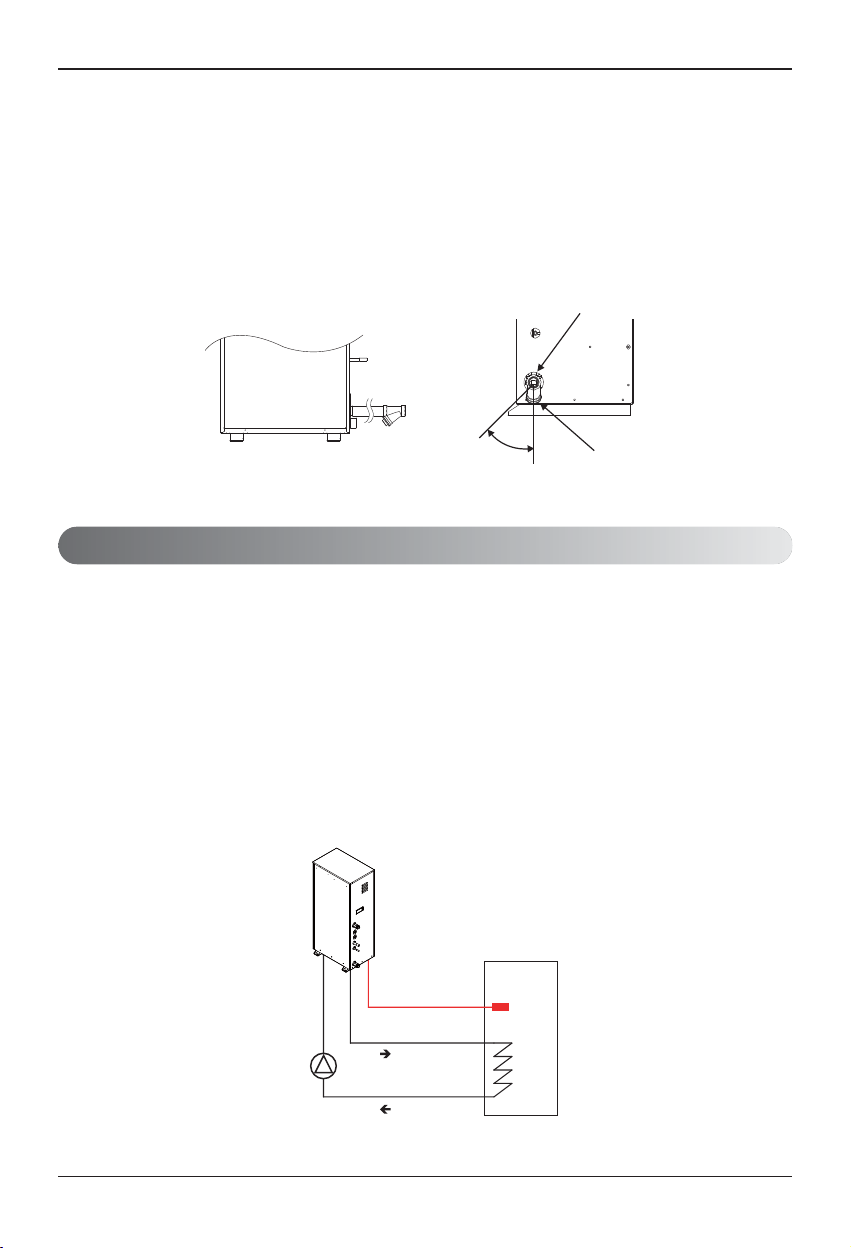

Installation Scenes

Some installation scenes are presented for example. As these scenes are conceptual figures, installer should optimize the installation scene according to the installation conditions.

1) Floor Heating only (Without mixing tank)

3) Floor Heating + Hot water

4) Hot water only

Floor heating loopFan coil unit

Radiator

2) Floor Heating only (With mixing tank)

Floor heating loopFan coil unit

Radiator

Floor heating loopFan coil unit

Sanitary

water

tank

Hot water

City water

Radiator

Sanitary

water

tank

Hot water

City water

Pump

3way valve

Bypass valve

Page 19

Installation

Hydro Kit Installation Manual 19

Water Quality

Water quality should comply with EN 98/83 EC Directives. Requirement for resolved chemical ingredients is following table. Detailed water quality condition can be found in EN 98/83 EC Directives.

Frost protection

In areas of the country where entering water temperatures drop below 0℃(32℉), the water pipe must

be protected by using an approved antifreeze solution. Consult your

Hydro Kit

unit supplier for locally approved solutions in your area. Calculate the approximate volume of water in the system. (Except the

Hydro Kit

unit.)

And add antifreeze solution to the total volume to allow for the water

contained in

Hydro Kit

unit.

Parameter Value

Acrylamide 0.10 μg/l

Antimony 5.0 μg/l

Arsenic 10 μg/l

Benzene 1.0 μg/l

Benzo(a)pyrene 0.010 μg/l

Boron 1.0 mg/l

Bromate 10 μg/l

Cadmium 5.0 μg/l

Chromium 50 μg/l

Copper 2.0 mg/l

Cyanide 50 μg/l

1.2-dichloroethane 3.0 μg/l

Epichlorohydrin 0.10 μg/l

Parameter Value

Fluoride 1.5 mg/l

Lead 10 μg/l

Mercury 1.0 μg/l

Nickel 20 μg/l

Nitrate 50 mg/l

Nitrite 0.50 mg/l

Pesticides 0.10 μg/l

Pesticides — Total 0.50 μg/l

Polycyclic aromatic hydrocarbons 0.10 μg/l

Selenium 10 μg/l

Tetrachloroethene and Trichloroethene 10 μg/l

Trihalomethanes — Total 100 μg/l

Vinyl chloride 0.50 μg/l

CAUTION

• If the unit is installed at existing hydraulic water loop, it is important to clean hydraulic pipes to remove

sludge and scale.

• Installing sludge strainer in the water loop is very important to prevent performance degrade.

• Chemical treatment to prevent rust should be performed by installer.

CAUTION

1. Use only one of the above antifreeze.

2. If a antifreeze is used, pressure drop and capability degradation of the system can occur.

3. If one of antifreezes is used, corrosion can occur. So please add corrosion inhibitor.

4. Please check the concentration of the antifreeze periodically to keep same concentration.

5. When the antifreeze is used (for installation or operation), take care to ensure that antifreeze

must not be touched.

6. Ensure to respect all laws and norms of your country about Anti-freeze usage.

7. When hydro kit is applied for heating, the antifreeze never added in the water circuit.

Type of Antifreeze

Minimum Temperature for Freeze Protection

0℃(32℉) -5℃(23℉) -10℃(14℉) -15℃(5℉) -20℃(-4℉) -25℃(-13℉)

Ethylene glycol 0% 12% 20% 30% - -

Propylene glycol 0% 17% 25% 33% - -

Methanol 0% 6% 12% 16% 24% 30%

ENGLISH

Page 20

Installation

20

Hydro Kit

Cut the pipes and the cable

- Use the accessory piping kit or the pipes

purchased locally.

- Measure the distance between the indoor

and the outdoor unit.

- Cut the pipes a little longer than measured

distance.

-

Cut the cable 1.5m longer than the pipe length.

Burrs removal

- Completely remove all burrs from the cut

cross section of pipe/tube.

- Put the end of the copper tube/pipe to downward direction as you remove burrs in order

to avoid to let burrs drop in the tubing.

Pipe welding

- Insert and weld the pipe.

- Always make sure to flow Nitrogen at

0.2kgf/cm

2

within the pipe when welding.

-

If the welding is done without flowing Nitrogen,

it can generate a thick oxidized coating within

the pipe to interfere with normal operation of

valve and compressor etc.

Insulation

- Use rubber foamed insulation material

(EPDM, NBR) with high thermal resistance.

- When installed in humid environment, use

thicker insulation material than usual.

- Insert the insulation material within the product as deep as possible.

❈

The thickness of the above insulation material is

based on thermal conduction rate of 0.036W/m°C.

Nitrogen

Refrigerant Piping

Classification Thickness

Gas pipe(Ø15.88 – 4HP)

(Ø22.2 - 8HP)

t19 above

CAUTION

There is no pump-down function because

Hydro Kit

is the only heating unit. After vacuum drying,

recharge the refrigerant.

Copper

tube

Point down

Copper tube

90°

Direction of Nitrogen

Slanted Uneven Rough

Pipe

Reamer

Regulator

Taping

Valve

Nitrogen

Nitrogen

Inside product

Panel

Insulation

Copper

tube

Page 21

Installation

Hydro Kit Installation Manual 21

Precaution when connecting Heat Recovery systems

Pipe searching process

1. When Pipe searching process is performed,

- Use ‘Mode 1’ if water temperature is higher than 30℃(86℉)

- Use ‘Mode 2’ if water temperature is lower than 30℃(86℉)

2. When Pipe searching process is not performed,

- Check whether ‘CH14’ error occurs in the Hydro Kit.

*Refer to the installation manual of HR unit

(When two

Hydro Kit are

installed)

-

One connection of refrigerant pipe for HR unit is insufficient

for the flow of refrigerant. Join two pipes with a branch pipe

when connecting the

Hydro Kit

(Up to 16kW (54kBut/h) capacity model: ARNH08GK3A2).

- The pipe number of the connected gas pipe and

liquid pipe must be same.

- Flow water in the Hydro Kit when pipe-searching process is performed.

- Pipe-searching process error may occur if the

pipe temperature does not increase.

- It is recommended that Hydro Kit is connected

to No.1 valve and No.2 valve.

Recaution when connecting to synchronous type outdoor unit

ENGLISH

Gas pipe

Liquid pipe

Welding type

No.1, 2 Valve

Ø15.88

Ø9.52

Not control

Control

Hydro kit

Gas pipe

Liquid pipe

DIP S/W setting

Ø22.2

Ø9.52

4

3

2

1

4

3

2

1

Example

Indoor Unit

Indoor Unit

Indoor Unit

Indoor Unit

Indoor Unit

Indoor Unit

Hydro kit

No.2, 3 Valve

Control

No.3, 4 Valve

Control

No.1, 2 Valve

/

No.3, 4 Valve

4

2

4

2

4

2

Control

Indoor Unit

3

Hydro kit

1

Indoor Unit

Hydro kit

3

Indoor Unit

1

Indoor Unit

Hydro kit

3

Hydro kit

1

Page 22

Installation

22

Hydro Kit

Connect the wires to the terminals on the control board individually according to the outdoor unit connection.

*Ensure that the wire color of the outdoor unit and terminal No. are same as those of the indoor unit

respectively.

Communication cable

Power cable

Earth

3(A) 4(B)

Terminal block

of indoor unit

Terminal block

of indoor unit

Terminal block of outdoor unit

Outdoor unit

Indoor unit

DRY2DRY1

WARNING : Make sure that the screws of the terminal are free from

looseness.

Remove the box cover of electric parts and connect the wiring

CAUTION

After checking the above status, prepare for the following wiring :

1)

Use individual power for the unit and refer to the circuit diagram posted on the inside of the control cover.

2) Make sure to install 30A capacity circuit breaker when power is connected to the unit.

3) The bolts used for cable connection may become loose by the vibration generated during the transportation. Make sure to check again and fasten them tightly. (If they are loose, it may cause fire.)

4) Make sure to check power specification.

5) Electrical capacity shall be sufficient.

6) The initial voltage shall be maintained at 90% of the rated voltage on the name plate.

7) The thickness of the power cable complies with the designated specification. (length and thickness of

the power cable)

8) Do not install the circuit breaker in the place where there is a lot of moisture or where it is wet.

9) The following problems may be the cause of voltage drop.

-

Magnetic switch vibration, defective contact, fuse damage, malfunction of overload protection device

❈ Based on the owner’s manual, teach how to operate and use the unit to the user.

(temperature setting, etc.)

Wiring Connection

Communication cable

Power cable

Communication cable

Power cable

CAUTION

When connecting the power and communication

cable, always use the terminal connector (Oring, Y-ring).

Make sure to tighten so that the screw of the terminal does not get loose.

ARNH08GK3A2 ARNH04GK3A2

How to connect wirings

Page 23

Installation

Hydro Kit Installation Manual 23

Connecting Cables

Types of the cables

The distance between communication cable and power cable

- If the power cable and communication cable are tied together, system malfunction may occur with

electrostatic, electromagnetic combination effect causing the interference signal. If communication

cable is connected along with power cable, secure at least 50mm distance between indoor unit

power cable and communication cable.

It is the value with the assumption of the length of the parallel cable as 100 m. If it is longthan 00m,

it shall be calculated again with proportional to the added length.

If the distance is secured as the previous page, and the distortion in the waveform of the power still

occurs, increase the distance.

※ When several power cables are inserted into the transmission line, or tied together, make sure to

consider the following issues.

- Power cables and communication lines shall not be in the same transmission line.

- Power cables and communication lines shall not be tied together.

Classification types Cable cross section

Power cable(CV) mm2 x cores 4.0 x 3

Communication cable(VCTF-SB) mm2 x cores 1.0~1.5 x 2

WARNING

• Are all of the indoor units and outdoor units grounded?

• If grounding is not properly done, there is a risk of electric shock. Grounding must be done by a

qualified technician.

• Consider the surrounding conditions(surrounding temperature, direct sunlight, rain water, etc.)

when wiring the cable.

• The thickness of the power cable is the minimum thickness of metal conductor cable. Use

thicker cable considering the voltage drop.

It is the value with the assumption of the length of the parallel cable as 100 m.

If it is longer than 100m, it shall be calculated again with proportional to the added length.

If the distortion in the waveform of the power still occurs despite securing the distance, increase

the distance.

※ When several power cables are inserted into the transmission line, or tied together, make sure

to consider the following issues.

- Power cables and communication cable shall not be in the same transmission line.

- Power cables and communication cable shall not be tied together.

ENGLISH

Page 24

Accessories Installation

24

Hydro Kit

Location of Accessories and External Parts Connection

• Connect 3way valve, if both floor heating and hot water is used.

• Connect the separately purchased thermostat.

• Dry contact is an accessory supplied by LG and installed by referring to the attached installation

manual.

• 3way valve, thermostat and pump are external parts for installation, which are not supplied by LG.

After checking each part carefully, install external parts respectively.

• Connect the cable of each accessory to the terminal block of the control box in the Hydro Kit.

• Check the label attached on the terminal block to prevent wrong connection.

• Use the pump of 220-240 voltage and maximum operation current of 4A or less.

• Select a suitable relay for pump capacity when connecting the pump to the unit.

WARNING:

• Install the unit after turning off the main power.

• Do not connect the products out of range specified in the manual.

• Do not work with wet hand.

5. Accessories Installation

Dry contact board attachment location

Dry contact board locking location (CN-CC)

Remote controller locking location (CN-REMO)

Water tank temperature sensor locking location (CN-TH4)

L N L L1 N L N L1 L2

PUMP

(A)

3WAY VALVE

(A)

THERMOSTAT

(Default : 230V AC)

Page 25

Accessories Installation

Hydro Kit Installation Manual 25

2

2

1

3

3

<Wire guide grooves>

Wall

Side

Wall

Side

Wall

Side

Wall

Side

<Connecting order>

<Separating order>

Installation of Wired Remote Controller

1. Please fix tightly using provided screw after

placing remote controller setup board on the

place where you like to setup.

- Please set it up not to bend because poor

setup could take place if setup board bends.

Please set up remote controller board fit to the

reclamation box if there is a reclamation box.

2. Can set up Wired remote controller cable

into three directions.

- Setup direction: the surface of wall reclamation, upper, right

- If setting up remote controller cable into upper

and right side, please set up after removing

remote controller cable guide groove.

❈

Remove guide groove with long nose.

①

Reclamation to the surface of the wall

②

Upper part guide groove

③

Right part guide groove

3. Please fix remote controller upper part into

the setup board attached to the surface of

the wall, as the picture below, and then, connect with setup board by pressing lower

part.

- Please connect not to make a gap at the

remote controller and setup board’s upper and

lower, right and left part.

When separating remote controller from

setup board, as the picture below, after

inserting into the lower separating hole

using screw driver and then, spinning clockwise, remote controller is separated.

- There are two separating holes. Please individually separate one at a time.

- Please be careful not to damage the inside

components when separating.

ENGLISH

Page 26

Accessories Installation

26

Hydro Kit

4. Please connect indoor unit and remote controller using connection cable.

5. Please use extension cable if the distance between wired remote controller and indoor

unit is more than 10m.

Extension cable(10m) model name : PZCWRC1

When installing the wired remote controller, do not bury it in the wall.

(It can cause damage in the temperature sensor.)

Do not install the cable to be 50m or above. (It can cause communication error.)

• When installing the extension cable, check the connecting direction of the connector of the

remote controller side and the product side for correct installation.

•

If you install the extension cable in the opposite direction, the connector will not be connected.

• Specification of extension cable: 2547 1007 22# 2 core 3 shield 5 or above.

CAUTION

Male plug ends

Please check if connector

is normally connected.

Hydro Kit

Female plug ends

Optional extension cable

(purchased separately)

Page 27

Accessories Installation

Hydro Kit Installation Manual 27

Water tank temperature sensor Connection

• Select the suitable pump by referring to the flow rate table with water temperature difference between the entrance and the exit.

*It is recommended that the flow rate is 36LPM.

• Use the pump with enough capacity to guarantee the loss of entire water

pressure and to supply the Hydro Kit with water.

• Select a suitable relay for pump capacity when connecting the pump to the

unit.

• Connect the relay to the terminal block 11 and 12 of the control box.

• Connect sensor housing to PCB‘CN-TH4’ connector (red).

CAUTION

• Make sure to supply external power with the pump.

CAUTION

• If water tank temperature sensor is not connected, error will occur.

(CH08) Exclude the case of using floor heating.

ENGLISH

Main Pump Connection

Pump

(main)

12

LN

Relay

Pump

CN-TH4

Housing

Water tank

thermistor

Page 28

Accessories Installation

28

Hydro Kit

Installation Condition

Thermostat

Thermostat is generally used to control the unit by air temperature. When thermostat is connected to

the unit, the unit operation is controlled by the thermostat.

Following location should be avoid to secure proper operation :

• Height from floor is approximately 1.5 m.

• Thermostat can not be located where the area may be hidden when door is open.

• Thermostat can not be located where external thermal influence may be applied. (such as

above heating radiator or open window)

CAUTION

1. USE 1~230 V Thermostat.

2. Some electro-mechanical type thermostat has internal delay time to protect compressor. In that case,

mode change can takes time more than user's expectation. Please read thermostat manual carefully

if the unit does not response quickly.

3. Setting temperature range by thermostat can be different with that of the unit. The heating set temperature should be chosen within the setting temperature range of the unit.

4. It is highly recommended that the thermostat should be installed where space heating is mainly applied.

Direct

Sun ray contact area

yes

no

no

1.5 m

no

Page 29

Accessories Installation

Hydro Kit Installation Manual 29

General Information

Hydro Kit

supports following thermostats.

(1) There is no electric circuit inside the thermostat and electric power supply to the thermostat is not

required.

(2) Electric circuit such as display, LED, buzzer, etc is included in the thermostat and electric power

supply is required.

(3) Thermostat generates "Heating ON or Heating OFF" signal according to user"s heating target

temperature.

Type Power Operating Mode Supported

Mechanical (1) 1~ 230 V Heating Only (3) Yes

Electrical (2) 1~ 230 V Heating Only (3) Yes

How to Wire Thermostat

Follow below procedures Step 1 ~ Step 4.

Step 1. Uncover front cover of the unit and open the control box.

Step 2. Identify the power specification of the thermostat.

1~230V thermostat is used in the Hydro Kit (For High Temperature).

Step 3. If it is Heating Only Thermostat, go to step 4.

Step 4. Find terminal block and connect wire as below.

WARNING :

Mechanical type Thermostat.

Do not connect wire (N) as mechanical type thermostat does not require electric power supply.

CAUTION

Do not connect external electric loads.

Wire (L) and (N) should be used only for operation Electric type thermostat.

Never connect external electric loads such as valves, fan coil units, etc.

If connected, Main PCB Assembly 1 can be seriously damaged.

(L) : Live signal from PCB to Thermostat

(N) : Neutral signal from PCB to Thermostat

(H) : Heating signal from Thermostat to PCB

ENGLISH

THERMOSTAT

(Default : 1~ 230 V)

7

8

9

10

L

N

L1

L2

BR

BL

(L) (N) (H)

WH

BK

Thermostat

Page 30

Accessories Installation

30

Hydro Kit

Final Check

• DIP switch setting :

Set DIP switch No. 8 to ‘ON’. Otherwise, the unit can not recognize the thermostat.

• Remote Controller :

- ‘Thermostat’ icon is displayed on the remote controller.

- Button input is prohibited.

Thermostat Operation with Remote Controller

Following features are permitted when thermostat is installed :

• SET TEMP button

• VIEW TEMP button

• Temperature adjusting button(*)

• Sanitary water heating button

(*) : The unit is not turned on/off according to the setting temperature at the remote controller.

It is turned on/off according to the thermostat signal.

Following features are NOT permitted when thermostat is installed :

• Operating mode (heating/ weather-dependent) selection

• Time scheduling

• Operation On / Off

NOTICE

?)<-:?)< -:

78- :

0-)<16/0-) <1 6/

57, -

78-:78- :

57,-57, -

<-58<-58

78-:

57,-

Sequence of thermostat operation

- How to set the heating temperature when thermostat is connected to the Hydro Kit.

Set thermostat

to the heating mode

Adjust the heating temperature,

using the remote controller

Thermostat Icon

Page 31

Accessories Installation

Remote Temperature Sensor

Remote temperature sensor can be installed any place a user wants to detect the temperature.

How to Install Remote Temperature Sensor

Step 1. After deciding where the remote temperature sensor is in-

stalled, decide the location and height of the fixing screws.

(Interval between the screws : 60mm)

Step 2. Insert the connector of the connection wire into the space

for the connector in place of the room temperature sensor.(CN_ROOM)

Step 3. Separately, set the option code of the attached controller

on the indoor unit.

In detail, refer to "installer setting mode".

Step 4. The Connection wire does not matter if you change the color of the wire because of non-

polar.

Fixing screws 60mm

Fixing the

Remote Sensor

2

1

CAUTION

1. Choose the place where the average temperature can be measured for the indoor unit operates.

2. Avoid direct sunlight.

3. Choose the place where the heating devices do not affect the remote sensor.

4. Choose the place where the outlet of the cooling fan do not affect the remote sensor.

5. Choose the place where the remote sensor isn't affected when door is open.

Step 5. Integrate the remote temperature sensor with the screws as the order of arrows.

Hydro Kit Installation Manual 31

ENGLISH

Page 32

Accessories Installation

32

Hydro Kit

WARNING :

• 3way valve should select water tank loop when electric power is

supplied to wire (W) and wire (N).

• 3way valve should select under floor loop when electric power is

supplied to wire (U) and wire (N).

WARNING :

Mice can not be appeared to prevent entering the unit or attacking wires.

3way valve is required to operate sanitary water tank. Role of 3way valve is flow switching between

under floor heating loop and water tank heating loop.

General Information

Hydro Kit

supports following 3way valve.

(1) SPDT = Single Pole Double Throw. Three wires consist of Live (for selecting Flow A), Live 1 (for

selecting Flow B), and Neutral (for common).

(2) Flow A means ‘water flow from the unit to sanitary water tank’

(3) Flow B means ‘water flow from the unit to under floor water circuit’

How to Wire 3Way Valve

Follow below procedures Step 1 ~ Step 2.

Step 1. Uncover front cover of the unit and open the control box.

Step 2. Find terminal block and connect wire as below.

(W) : Live signal (Water tank heating) from PCB to 3way valve

(U) : Live signal (Under floor heating) from PCB to 3way valve

(N) : Neutral signal from PCB to 3way valve

3Way Valve

3way valve

(W) (U) (N)

3WAY VALVE

(A)

BR WH BL

4

L5L1

6

N

Type Power Operating Mode Supported

SPDT

3-wire (1)

1~ 230 V

Selecting “Flow A” between

“Flow A” and “Flow B” (2)

Yes

Selecting “Flow B” between

“Flow A” and “Flow B” (3)

Yes

Page 33

Accessories Installation

Hydro Kit Installation Manual 33

Final Check

• Flow direction :

- Water should flow from water outlet of the unit to sanitary tank water inlet when sanitary tank

heating is selected.

- To verify the flow direction, check temperature at the water outlet of the unit and water inlet of

sanitary water tank.

- If correctly wired, these temperatures should be almost equivalent if thermal insulation of water

pipe is well performed.

• Noise or water pipe vibration while 3way valve operation

- Due to surging effect or cavitation effect, noise or water pipe vibration can be occurred while

3way valve is operating.

- In that case, check followings :

• Is water circuit (both under floor water loop and sanitary water tank loop) fully charged? If not,

additional water charging is required.

• Fast valve operation yields noise and vibration. Appropriated valve operating time is 60~90 seconds.

ENGLISH

Page 34

Accessories Installation

34

Hydro Kit

LG Dry Contact is a solution for automatic control of HVAC system at the owner's best.

In simple words, it's a switch which can be used to turn the unit On/Off after getting the signal from

external sources like key-in lock, door or window switch etc specially used in Hotel rooms.

How to Install Dry Contact

Connect CN_DRY with Control Unit.

- To apply power source through Dry Contact PCB.

Dry Contact

Dry contact

Controller

CN-CC

DRY CONTACT

PCB

DRY CONTACT

PCB

INPUT

220 - 240V

LG does not

supply this section

LG does not

supply this section

4 4

3 3

2 2

1 1

2 2

1 1

RY1

RY2

CN_DRY

NL

Operation Display

Error Check Display

Dry contact

Controller

CN_DRY

4

3

2

4

3

2

1 1

221

1

L

N

220 - 240V

RY1

RY2

CN-CC

DRY CONTACT

PCB

Operation Display

Error Check Display

- To apply power source directly to external source.

(unit : mm)

Page 35

System Set-Up

Hydro Kit Installation Manual 35

As

Hydro Kit

(For High Temperature) is designed to satisfy various installation environment, it is

important to set up system correctly. If not configured correctly, improper operation or degrade of performance can be expected.

DIP Switch Setting

• Turn off electric power supply before setting DIP switch,

There is risk of electric shock.

•

Dip switch is turned on when pulled right.

•

Always set dip switch #6 to ON and #7 to OFF.

•

Do not set dip switch #2 to ON and #3 to OFF.

•

If dip switch is not set as below, the unit may not operate

properly.

x

: OFF●: On

Description

Dip switch setting

Function Default

1 2 3 4 5 6 7 8

Group Control

x ○

●

Installation

Scene

x x

x ● ○

● ●

Emergency

operation

x ○

●

Water pump

control

x

● ○

Thermostat connection

x ○

●

ENGLISH

Master

Slave

Floor heating only

Floor heating + Hot water

Hot water only

High temperature operation

Low temperature operation

Water pump controlled with Hydro Kit

Water pump NOT controlled with Hydro Kit

Thermostat NOT installed

Thermostat installed

6. System Set-Up

Page 36

System Set-Up

36

Hydro Kit

Group Control Setting

Group Control

- Wired remote controller 1 + Many of

Hydro Kit

- Dip Switch in PCB

1. It is possible to connect 16 indoor units(Max) by one wired remote controller.

Set only one indoor unit to Master, set the others to Slave.

2. You can connect all the types of 2nd generation indoor units .

3. It is possible to use wireless remote controller at the same time.

4. It is possible to connect Dry Contact and Central controller at the same time.

- The Master indoor unit is possible to recognize Dry Contact and Central Controller only.

- In case of Central controller and Group controller at the same time, it is possible to connect standard 2series indoor units or later since Sep. 2012.

- In case of Central controller setting, the Central controller can control indoor units after setting

only the address of master indoor unit.

- Slave indoor unit will be operated like master indoor unit.

- Slave indoor unit can not be individually controlled by Central controller.

- Some remote controller can’t perform with Dry Contact and Central controller at the same time.

So contact us further information about it.

¿ Master Setting

- No. 1 Off

¡ Slave Setting

- No. 1 On

Master

Display Error Message

Master

Slave Slave

Only connect serial signal and GND lines

between slave indoor unit

Slave

GND

Signal

12 V

Page 37

System Set-Up

Hydro Kit Installation Manual 37

5. In case that the indoor unit has an abnormal problem an error code will be displayed on the wired

remote controller.

With the exception of the indoor unit with the error, you can control each indoor unit individually.

6. In case of Group Control, it is possible to use following functions.

- Selection of operation options (operation/stop/mode/set temperature)

- It is not possible at some functions.

h Master/Slave setting of indoor units be set possible using a PCB Dip Switch.

h It can be the cause of malfuctions when there is no setting of master and slave.

Accessories for group control setting

- Accessories for group control setting

ENGLISH

CAUTION

• Indoor unit(Hydro Kit)’s group setting is possible which connected same outdoor unit.

• To install Master and Slave indoor unit, the Dip Switch setting should be same.

• Group control is not possible between hydro kit and air conditioner.

• Group control is not possible between mid temperature hydro kit and high temperature hydro kit.

Indoor unit 2 EA +Wired remote controller

❈ PZCWRCG3 cable used for connection

Master

Slave

PZCWRCG3

Master

Page 38

System Set-Up

38

Hydro Kit

Emergency Operation

• Definition of terms

- Trouble : a problem which can stop system operation, and can be resumed temporally under

limited operation without certificated professional's assist.

- Error : problem which can stop system operation, and can be resumed ONLY after certificated

professional's check.

- Emergency mode : temporary heating operation while system met Trouble.

• Objective of introducing 'Trouble'

- Not like airconditioning unit,

Hydro Kit

is generally operated in whole winter season without any

system stopping.

- If system found some problem, which is not critical to system operating for yielding heating

energy, the system can temporarily continue in emergency mode operation with end user's decision.

• Classified Trouble

- Trouble is classified two levels according to the seriousness of the problem : Slight Trouble and

Heavy trouble

- Slight Trouble : Sensor trouble.

- Heavy trouble : Compressor cycle trouble.

- Option Trouble : a problem is found for option operation such as water tank heating. In this

trouble, the troubled option is assumed as if it is not installed at the system.

• Emergency operation level

- When the system is faced with trouble, it stops and waits for user’s decision. : Calling service

center or starting emergency operation.

- To start emergency operation, user simply push ON / OFF button once more.

- Two different levels are prepared for emergency operation : High temperature cycle and low

temperature cycle.

- In emergency operation mode, user can not adjust target temperature.

NOTICE

DIP Switch

(No. 4)

Target

Leaving Water

Temperature

Target

Room Air

Temperature

Target

Sanitary Water

Temperature

High temperature

cycle

OFF 70℃(158℉) 24℃(75℉) 70℃(158℉)

Low temperature

cycle

ON 50℃(122℉) 19℃(66℉) 50℃(122℉)

Page 39

System Set-Up

Hydro Kit Installation Manual 39

• Following features are permitted in emergency operation :

- Operation On/Off

- VIEW TEMP button(*)

- Temperature adjusting button(**)

- Sanitary water heating button

(*) : Temperature measured by failed sensor is displayed as ‘- -’.

(**) : The unit is not turned on/off according to the setting temperature at the remote controller.

It is turned on/off according to the thermostat signal.

• Following features are NOT permitted in emergency operation :

- Operating mode (heating/ weather-dependent) selection

- Time scheduling

- SET TEMP button

• Duplicated trouble : Option trouble with Slight or Heavy trouble

If option trouble is occurred with slight (or heavy) trouble at the same time, the system puts higher

priority to slight (or heavy) trouble and operates as if slight (or heavy) trouble is occurred.

Therefore, sometimes sanitary water heating can be impossible in emergency operation mode.

When sanitary water is not warming up while emergency operation, please check whether the sanitary water sensor and related wiring are connected well or not.

• Emergency operation is not automatically restarted after main electricity power is reset.

In normal condition, the unit operating information is restored and automatically restarted after main

electricity power is reset.

But in emergency operation, automatic re-start is prohibited to protect the unit.

Therefore, user must restart the unit after power reset when emergency operation has been running.

?)<-:?)< -:

78- :

0-)<16/0-) <1 6/

57, -

78-:78- :

57,-57, -

<-58<-58

78-:

57,-

ENGLISH

Page 40

System Set-Up

40

Hydro Kit

Installer Setting

How to enter installer setting mode

CAUTION

Installer setting mode is to set the detail function of the remote controller.

If the installer setting mode is not set correctly, it could cause problems to the unit, user injury or

property damage. This must be set by an certificated installer, and any installation or change that is

carried out by a non-certificated person should be responsible for the results. In this case, free

service cannot be provided.

?)<-:

<-58

78-:

0-)<16/

57,-

Press Function Setting button for 3 seconds

to enter the installer setting mode.

(When you enter the installer setting mode initially, function code is displayed on the bottom of

the LCD screen.)

Repeat pressing button, and the function code

will be changed.

Please refer the code table on the next page.

1

?)<-:

0-)<16/

<-58

78-:

57,-

Function Code Value

Page 41

System Set-Up

Hydro Kit Installation Manual 41

Summary

Function Default Value #1 Value #2 Remark

Disable 3 Min. Delay 02:01 01 -

Remote Air Sensor Connection 03:01

01 : NOT connected.

02 : connected.

-

Celsius/Fahrenheit Switching 04:01

01 : Celsius

02 : Fahrenheit

-

Setting Temp. Selection 05:02

01 : Air Temp.

02 : Leaving water Temp.

-

Auto Dry Contact 06:01

01 : Auto Start OFF

02 : Auto Start ON

-

Address Setting 07:00 00 ~ FF -

Override Setting 08:00

00 : Slave

01 : Master

-

Water Pump Test Run 09:00 01 : Set -

Setting Air Temp.

(Heating Mode)

13:030:016

24℃(75℉) ~ 30℃(86℉)

: Upper Limit of setting range

16℃(60℉) ~ 22℃(71℉)

: Lower Limit of setting range

Setting Leaving Waer Temp.

(Heating Mode)

14:080:046

50℃(122℉) ~ 80℃(176℉)

: Upper Limit of setting range

30℃(86℉) ~ 46℃(114℉)

: Lower Limit of setting range

Setting Sanitary Tank Water Temp.

(Sanitary Water Heating)

15:080:046

50℃(122℉) ~ 80℃(176℉)

: Upper Limit of setting range

30℃(86℉) ~ 46℃(114℉)

: Lower Limit of setting range

Operation mode lock 17:00

00 : Off

01 : On

Setting outdoor Temp. range

(Weather-dependent operation)

23:-10:015

10℃(50℉) ~ 20℃(68℉)

: Upper Limit of setting range

-20℃(-4℉) ~ 05℃(41℉)

: Lower Limit of setting range

Setting indoor air Temp. range

(Weather-dependent operation)

24:021:016

20℃(68℉) ~ 30℃(86℉)

: Upper Limit of setting range

16℃(60℉) ~ 19℃(66℉)

: Lower Limit of setting range

Setting leaving water Temp.

(Weather-dependent operation)

25:080:046

65℃(149℉) ~ 80℃(176℉)

: Upper Limit of setting range

40℃(104℉) ~ 54℃(129℉)

: Lower Limit of setting range

Setting start/maintain time

(Disinfection Operation)

26:000

00 : Disable

01 : Enable

-

26:006:023

01~07 : Starting Date

(01:Sun, 02:Mon, ····, 07:Sat)

00~23 hours

: Starting Time in 24 hours

Setting Temp.

(Disinfection Operation)

27:070:010

40℃(104℉) ~ 70℃(129℉)70

: Maximum heating Temp.

05~60 min

: Maximum heating duration

Setting control parameter

(Sanitary water heating operation)

29:003:000 00~01 :Refer to 46p

Setting sanitary water heating timers

2b:030 5 ~ 95 min (step: 5 min) 2b:180:020 0 ~ 600 min (step: 30 min) 20 ~ 95 min (step: 5 min)

Changing thermal on/off room air Temp.

2E:00 00~03 : Refer to 45p -

Changing thermal on/off leaving water

Temp.

2F:00 00~03 : Refer to 45p -

Program version 30:00 Display Version number -

Changing thermal on/off sanitary tank water Temp.

33:00 00~03 : Refer to 47p -

Select entering/leaving water Temp mode

in Heating Mode

34:00

00 : Based on leaving water Temp

01 : Based on entering water Temp

-

Water Pump operation/delay time set

in Heating Mode

37:000:001

000: Operates according to OFF time setting

001 : Pump always on

001 ~ 060 : OFF Time (minutes)

Forced product operation 39:00

00 : Forced product operation in use

01 : Forced product operation not in use

Dry Contact installation set 41:00

00 : Dry Contact equipped decided on

01 : Dry Contact not installed

02 : Dry Contact installed

*Temp. = Temperature

ENGLISH

Example of Fuction Code Display

Function Code Value #1 Value #2

Page 42

System Set-Up

42

Hydro Kit

Common Setting

• Function Code 02 : Disable 3 minute Delay

Only used for an inspection in a factory.

• Function Code 03 : Remote Air Sensor Connection

If remote air sensor is connected to control the unit by room air temperature, the connection information should be notified to the unit.

Note : If remote air sensor is connected but this function code is not set correctly, the unit can not

be controlled by room air temperature.

• Function Code 04 : Celsius/Fahrenheit Switching

Temperature is displayed in Celsius or Fahrenheit.

• Function Code 05 : Setting Temperature Selection

The unit can be operated according to air temperature or leaving water temperature. The selection

for setting temperature as air temperature or leaving water temperature is determined.

Note : Air temperature as setting temperature is ONLY available when Remote Air Sensor

Connection is enabled and Function Code 03 is set as 02.

• Function Code 06 : Auto Dry Contact

This function enables the Dry Contact to operate under Auto Run mode or Manual mode with

remote controller.

If thermostat is used, value should be changed from "2" to "1".

• Function Code 07 : Address Setting

When Central Controller is installed, address assigning is set by this function.

• Function Code 08 : Override Setting

Override master/slave selection function is to prevent the unit’s different mode operation. If the unit

is set as the slave, it blocks a change of opposite operating mode(cooling/heating).

❈ To use override master/slave selection function is only possible when units are connected in

series to the outdoor unit.

• Function Code 09 : Water Pump Test Run

After water pipe work is done, Water Pump Test Run mode should be

performed to check whether water circulation is normal.

Page 43

System Set-Up

Hydro Kit Installation Manual 43

Temperature Range Setting

• Function Code 13 : Setting Air Temperature in Heating Mode

Determine heating setting temperature range when air temperature is selected as setting temperature.

CAUTION

Only available when remote air temperature sensor is connected.

• Accessory PQRSTA0 should be installed.

• Also, Function Code 03 should be set properly.

• Function Code 14 : Setting Leaving Water Temperature in Heating Mode

Determine heating setting temperature range when leaving water temperature is selected as setting temperature.

• Function Code 15 : Setting Sanitary Tank Leaving Water Temperature

Determine heating setting temperature range of water tank leaving water.

Only available when sanitary water tank temperature sensor is installed.

• Sanitary water tank and sanitary water tank kit should be installed.

• DIP switch No. 2 and 3 should be set properly.

• Function Code 17 : Setting Operation mode lock.

Set the Operation mode lock when Multi V Indoor unit is used only cooling mode in summer and

Hydro Kit is used only heating in winter.

CH51 error occur when Combination Ratio exceed limitation without setting operation

mode lock.

Multi V indoor unit can’t be operated heating mode and Hydro Kit can’t be operated cooling mode when operation mode lock is set.

It can’t be operated with Multi V Indoor unit and Hydro Kit simultaneously when operation

mode lock is set.

NOTICE

NOTICE

ENGLISH

Page 44

System Set-Up

44

Hydro Kit

Temperature Control Parameter Setting and Etc

• Function Code 23, 24, and 25 : Setting Weather-dependent operation

Weather-dependent operation is that the unit automatically adjusts target temperature (leaving

water or room air) according to the outdoor air temperature.

- Value #1 and Value #2 of Function Code 23 : range of outdoor air temperature

- Value #1 and Value #2 of Function Code 24 : range of auto-adjustable target room air temperature

- Value #1 and Value #2 of Function Code 25 : range of auto-adjustable target leaving water temperature

Note : Weather-dependent operation is applied for heating mode only.

Auto-Adjustable

Target Temperature

Value #1 of

Function Code

24 or 25

Value #2 of

Function Code

24 or 25

Temperature profile

of Weather-dependent

operation

Value #2 of

Function Code 23

Value #1 of

Function Code 23

Outdoor

air temperature

Page 45

System Set-Up

Hydro Kit Installation Manual 45

• Function Code 26 and 27 : Setting Disinfection operation

Disinfection operation is special sanitary tank operation mode to kill and to prevent growth of

viruses inside the tank.

- Value #1 of Function Code 26 : Selecting disinfection operation mode. ‘00’ for setting disinfection

mode off, and ‘01’ for setting disinfection mode on.

- Value #2 of Function Code 26 : Determining the date when the disinfection mode is running. ’01’

for Sunday, ’02’ for Monday, … , and ’06’ for Saturday.

- Value #3 of Function Code 26 : Determining the time when the disinfection mode is running. ’00’

for 0:00am, ’01’ for 01:00am, … , ’22’ for 10:00pm, and ’23’ for 11:00pm.

- Value #1 of Function Code 27 : Target temperature of disinfection mode.

- Value #2 of Function Code 27 : Duration of disinfection mode.

WARNING

Vales of Function Code 26

• If Value #1 of Function Code 26 is set as ’00’, Value #2 and Value #3 is not used.

• When Value #1 is set as ’01’, Value #2 is displayed at the position of Value #1 and Value #3 is

displayed at the position of Value #2 due to limited width of the control panel display.

CAUTION

Sanitary water heating should be enabled

• If sanitary water heating is disabled, the disinfection mode

will not be operated although Value #1 of Code 26 is set

as ’01’.

• To use disinfection mode, sanitary water heating should

be enabled.

Time

Value #2 of

Function Code 26

Value #1 of

Function Code

27

Value #2 of

Function Code 27

Water temperature

(Inside sanitary water tank)

Temperature profile

of Disinfection operation

Press repeatedly Button to enable sanitary

tank heating

<Sanitary Water Heating Disable>

<Sanitary Water Heating enable>

ENGLISH

Page 46

• Function Code 2B : Setting sanitary water heating timers

Determine time duration : Operation time and stop time of sanitary tank heating.

- Value #1 of Function Code 2B : This time duration defines how long sanitary tank heating

can be continued.

- Value #2 of Function Code 2B : This time duration defines how long sanitary tank heating

can be stopped. It is also regarded as time gap between

sanitary tank heating cycle.

- Example of timing chart :

System Set-Up

46

Hydro Kit

• Function Code 28 and 29 : Setting control parameter for Sanity water heating operation

Descriptions for each parameters are as following.

- Value #1 of Function Code 28 : temperature gap from Value #2 of Function Code 28.

- Value #2 of Function Code 28 : maximum temperature.

- Example : If Value #1 is set as ‘5’ and Value #2 is set as ’80’, then water tank heating will be

started when the water tank temperature is below 75°C(167°F).

- Value #1 of Function Code 29 : temperature gap from target sanitary water temperature.

- Value #2 of Function Code 29 : Determining heating demand priority between sanitary water

tank heating and under floor heating.

- Example : If user’s target temperature is set as ’50’ and Value #1 is set as ‘3’, then water

tank heating will be turned off when the water temperature is above 53°C(127°F).

Water tank heating will be turned on when the water temperature is below

50°C(122°F).

- Example : If Value #2 is set as ‘0’, that means heating priority is on sanitary water heating, In

this case the under floor can not be heated while sanitary water heating. On the

other hand, if the Value #2 is set as ‘1’, that means heating priority is on under

floor heating, sanitary tank can not be heated while under floor heating.

Sanitary water heating does not operate when it is disabled.

Enabling / Disabling sanitary water heating to operate is determined by pushing button.

When icon is displayed on the remote controller, sanitary water heating is enabled.

(by button input or scheduler programming)

NOTICE

Sanitary tank

heating is enabled

Sanitary tank

heating is required

2B.01 2B.012B.02 2B.022B.02

Time

Sanitary tank

heating operation

Page 47

System Set-Up

Hydro Kit Installation Manual 47

• Function Code 2E and 2F : Changing thermal on/off temperature

Select Thermal on/off Temperature gap.

• Function Code 30 : Remote Controller Program Version

Display Remote Controller Program Version.

• Function Code 33 : Changing thermal on/off temperature in Hot water Mode Select Thermal

on/off Temperature gap.

• Function Code 34 : Setting control parameter for Water flow temperature.

Select entering/leaving water Temp in Heating Mode.

• Function Code 37 : Water pump operation/delay time set in heating mode.

• Function Code 39 : Setting of Forced product operation.

• Function Code 41 : Setting of Dry Contact installation set.

Th On Th Off

0 -0.5°C 1.5°C

1 4°C 6°C

2 2°C 4°C

3 -1°C 1°C

2E : Room Air temperature

Th On Th Off

0 -2°C 2°C

1 -6°C 4°C

2 -2°C 4°C

3 -1°C 1°C

Function code 33 : Sanitary Tank water temperature

Th On Th Off

0 -2°C 2°C

1 -6°C 4°C

2 -2°C 4°C

3 -1°C 1°C

2F : Entering/Leaving Water temperature

ENGLISH

Page 48

Test Run

48

Hydro Kit

• Check whether water flow is smoothly supplied.

• Check whether the flow switch properly operates.

• Check whether the connection status is good.

• Check whether the power cable and communication cable are completely connected.

• Check whether it is 2.0MΩ or above, when insulation resistance between the terminal block