Page 1

PLASMA TV

SERVICE MANUAL

CAUTION

BEFORE SERVICING THE CHASSIS,

READ THE SAFETY PRECAUTIONS IN THIS MANUAL.

CHASSIS :PA75C

MODEL : 42PC5DH 42PC5DH-UL

website:http://biz.LGservice.com

Internal Use Only

Page 2

SAFETY PRECAUTIONS

Many electrical and mechanical parts in this chassis have special safety-related characteristics. These parts are identified by in the

Schematic Diagram and Replacement Parts List.

It is essential that these special safety parts should be replaced with the same components as recommended in this manual to prevent

X-RADIATION, Shock, Fire, or other Hazards.

Do not modify the original design without permission of manufacturer.

General Guidance

An lsolation Transformer should always be used during the

servicing of a receiver whose chassis is not isolated from the AC

power line. Use a transformer of adequate power rating as this

protects the technician from accidents resulting in personal injury

from electrical shocks.

It will also protect the receiver and it's components from being

damaged by accidental shorts of the circuitary that may be

inadvertently introduced during the service operation.

If any fuse (or Fusible Resistor) in this monitor is blown, replace it

with the same specified type.

When replacing a high wattage resistor (Oxide Metal Film Resistor,

over 1W), keep the resistor 10mm away from PCB.

Keep wires away from high voltage or high temperature parts.

Leakage Current Cold Check(Antenna Cold Check)

With the instrument AC plug removed from AC source, connect an

electrical jumper across the two AC plug prongs. Place the AC

switch in the on positioin, connect one lead of ohm-meter to the AC

plug prongs tied together and touch other ohm-meter lead in turn to

each exposed metallic parts such as antenna terminals, phone

jacks, etc.

If the exposed metallic part has a return path to the chassis, the

measured resistance should be between 1MΩ and 5.2MΩ.

When the exposed metal has no return path to the chassis the

reading must be infinite.

An other abnormality exists that must be corrected before the

receiver is returned to the customer.

Leakage Current Hot Check (See below Figure)

Plug the AC cord directly into the AC outlet.

Do not use a line Isolation Transformer during this check.

Connect 1.5K/10watt resistor in parallel with a 0.15uF capacitor

between a known good earth ground (Water Pipe, Conduit, etc.)

and the exposed metallic parts.

Measure the AC voltage across the resistor using AC voltmeter

with 1000 ohms/volt or more sensitivity.

Reverse plug the AC cord into the AC outlet and repeat AC voltage

measurements for each esposed metallic part. Any voltage

measured must not exceed 0.75 volt RMS which is corresponds to

0.5mA.

In case any measurement is out of the limits sepcified, there is

possibility of shock hazard and the set must be checked and

repaired before it is returned to the customer.

Leakage Current Hot Check circuit

CANADA: LG Electronics Canada, Inc. 550 Matheson

Boulevard East Mississauga, Ontario L4Z 4G3

USA : LG Customer Interactive Center

P.O.Box 240007, 201 James Record Road Huntsville,

AL 35824

Digital TV Hotline 1-800-243-0000

IMPORTANT SAFETY NOTICE

0.15uF

To Instrument's

exposed

METALLIC PARTS

AC Volt-meter

Good Earth Ground

such as WATER PIPE,

CONDUIT etc.

1.5 Kohm/10W

Page 3

Copyright © 2007 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

SPECIFICATIONS.................................................................4

ADJUSTMENT INSTRUCTIONS ..........................................5

BLOCK DIAGRAM ..............................................................11

EXPLODED VIEW...............................................................20

EXPLODED VIEW PARTS LIST .........................................21

REPLACEMENT PARTS LIST............................................22

SCHEMATIC DIAGRAM..........................................................

PRINTED CIRCUIT BOARDS.................................................

TABLE OF CONTENTS

Page 4

Copyright © 2007 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

SPECIFICATIONS

-

The specifications shown above may be changed without prior notice for quality improvement.

MODELS

Dimensions

(Width x Height x Depth)

Weight

Power requirement

Television System

Program Coverage

External Antenna Impedance

Environment condition

Including stand

Excluding stand

including stand

excluding stand

Operating Temperature

Operating Humidity

Storage Temperature

Storage Humidity

42PB4DA

(42PB4DA-UA)

44.5 x 30.2 x 12.2 inches

1130.0 x 768.1 x 310.4mm

44.5 x 28.1 x 3.3 inches

1130.0 x 715.0 x 85.0 mm

75.8 pounds / 34.4 kg

68.0 pounds / 30.8 kg

NTSC-M, ATSC, 64 & 256 QAM

VHF 2-13, UHF 14-69, CATV 1-135, DTV 2-69, CADTV 1-135

50PB4DA

(50PB4DA-UA)

51.5 x 35.7 x 14.6 inches

1308.0 x 906.1 x 370.0 mm

51.5 x 33.3 x 3.5 inches

1308.0 x 845.0 x 89.5 mm

93.5 pounds / 42.4 kg

83.1 pounds / 37.7 kg

AC100-240V ~ 50/60Hz

75 ohm

32 ~ 104°F (0 ~ 40°C)

Less than 80%

-4 ~ 140°F (-20 ~ 60°C)

Less than 85%

60PB4DA

(60PB4DA-UA)

60.9 x 41.8 x 17.6 inches

1548.0 x 1061.0 x 448.0 mm

60.9 x 38.9 x 3.9 inches

1548.0 x 988.0 x 98.5 mm

163.1 pounds / 81.0 kg

135.6 pounds / 61.5 kg

Page 5

Copyright © 2007 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

1. Application Range

This spec sheet is applied all of the PDP TV, PA75C chassis.

2. Specification

(1) Because this is not a hot chassis, it is not necessary to use

an isolation transformer. However, the use of isolation

transformer will help protect test equipment.

(2) Adjustments must be done in the correct order.

(3) The adjustments must be performed in the circumstance of

25±5°C of temperature and 65±10% of relative humidity if

there is no specific designation.

(4) The input voltage of the receiver be must kept 110V, 60Hz

when adjusting.

(5) The receiver must be operational for about 15 minutes

prior to the adjustments.

1) After receiving 100% white pattern, the receiver must be

operated prior to adjustment. (Or 8. Test Pattern

condition in EZ - Adjust)

2) Enter into White Pattern

- Press POWER ON Key on the Service Remote

Control (S R/C)

- Enter the Ez - Adjust by pressing ADJ Key on the

Service Remote Control (S R/C).

- Select 10. Test Pattern using the CH +/- Key and

select the White by pressing the direction Key.

Display the 100% Full White Pattern.

[ Set is activated HEAT-RUN without signal generator in

this mode.

O HEAT RUN

Preliminary action is applied to the test for afterimage

discharge detection, and 100% FULL WHITE PATTERN

must be operated automatically.

O Test for afterimage discharge detection

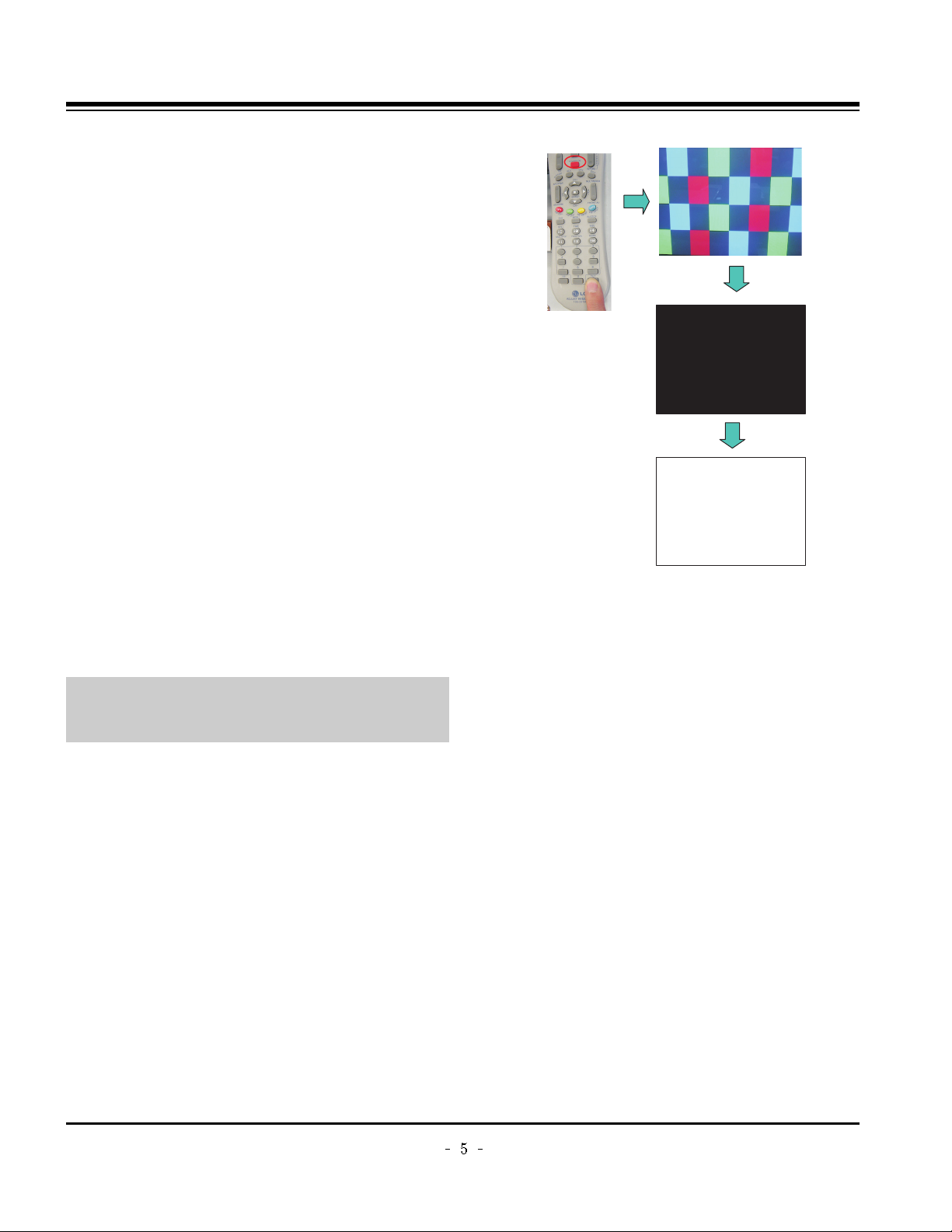

1) Pressing Power On key

- Only operating by pressing Power On key

2) Full Test Pattern(2 min 30sec) --> Full Black

Pattern(30sec) --> Full White Pattern(maintenance)

- Full White Pattern when the main power is turned on

again after being turned off

3) Pattern Mode is deselected by pressing CH +/-, Exit Key.

[ Set is activated HEAT-RUN without signal generator in this

mode.

ADJUSTMENT INSTRUCTIONS

If you turn on a still screen more than 20 minutes (Especially

Digital pattern(13 CH), Cross Hatch Pattern), an afterimage

may occur in the black level part of the screen.

Test Pattern 2min 30sec

Test Pattern 30sec

Page 6

Copyright © 2007 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

3. PSU(Power Supply Unit) Voltage

Adjustment

(Va, Vs Voltage Adjustment)

Adjust the voltages Va and Vs supplied from the PSU to the

module within the specified range of each module to supply

the stable power

3-1. Test Equipment

(1) D.M.M 1EA

(2) Voltage adjustment bar

3-2. Adjustment(60”)

(1) Va Voltage Adjustment

1) Connect + terminal of D.M.M to Va pin of P812 and

connect – terminal to GND pin of P812.

2) Adjust VR901 voltage to match that of the label on the

Top/Right of the panel. (Deviation : ±0.5V)

(2) Vs Voltage Adjustment

1) Connect + terminal of D.M.M to Vs pin of P812 and

connect – terminal to GND pin of P812.

2) Adjust VR951 voltage to match that of the label on the

Top/Right of the panel. (Deviation : ±0.5V)

3-3. Adjustment (50”)

(1) Va Adjustment

1) Connect + terminal of D.M.M to Va pin of P12 and

connect – terminal to GND pin of P12.

2) Adjust VR951 voltage to match that of the label on the

Top/Right of the panel. (Deviation : ±0.5V)

(2) Vs Adjustment

1) Connect + terminal of D.M.M to Vs pin of P12 and

connect – terminal to GND pin of P12.

2) Adjust VR901 voltage to match that of the label on the

Top/Right of the panel. (Deviation : ±0.5V)

3-4. Adjustment(42”)

(1) Va Voltage Adjustment

1) Connect + terminal of D.M.M to Va pin of P812 and

connect – terminal to GND pin of P812.

2) Adjust VR901 voltage to match that of the label on the

Top/Right of the panel. (Deviation : ±0.5V)

(2) Vs Voltage Adjustment

1) Connect + terminal of D.M.M to Vs pin of P812 and

connect – terminal to GND pin of P812.

2) Adjust VR951 voltage to match that of the label on the

Top/Right of the panel. (Deviation : ±0.5V)

ADJUSTMENT INSTRUCTIONS

Each PCB assembly must be checked by check JIG set.

(Because power PCB Assembly damages to PDP Module,

especially be careful)

Connection Diagram of Power Adjustment for Measuring

(Power Board): 60”

Connection Diagram of Power Adjustment for Measuring

(Power Board): 50”

Connection Diagram of Power Adjustment for Measuring

(Power Board): 42”(EAY32808901)

Page 7

Copyright © 2007 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

4. Component 480i/1080p RGB

1080p Adjustment

Component 480i/1080p RGB 1080p adjustment to set the

black level and the Gain to optimum.

4-1. Test Equipment

(1) Service R/C

(2) 801GF(802B, 802F, 802R) or MSPG925FA Pattern

Generator (480i/1080i The Horizontal 100% Color Bar

Pattern adjust to within 0.7±0.1Vp-p)

[ Because the above pattern can differ by the model and

pattern for each device, you must check the pattern first.

4-2. ADC 480i Component1 Adjustment

(1) Check the connection Component1 to the Test Equipment.

(MSPG-925FA => Model: 209, Pattern: 65)

(2) Select Component1 as the input with 100% Horizontal

Color Bar Pattern(HozTV31Bar) in 480i Mode and select

‘Normal’ in screen.

(3) After receiving signal for at least 1 second, press the ADJ

Key on the Service R/C to enter the ‘Ez - Adjust’ and select

the ‘3. ADC 480i Comp1’.

Pressing the Enter Key to adjust automatically.

(4) When the adjustment is over, 'ADC Component1 Success’

is displayed.

(5) If the adjustment has errors, 'ADC Component1 480i Fail’

is displayed. And error massage(‘Component1 Not

Connected’ or ‘Not Valid Format’ or ‘Check Signal Status’)

is displayed for 1 second.

4-3. ADC 1080i Component1/RGB

Adjustment

(1) Check the connection Component1, RGB to the Test

Equipment (MSPG-925FA => Model: 225, Pattern: 65)

(2) Select Component1 as the input with 100% Horizontal

Color Bar Pattern(HozTV31Bar) in 1080i Mode and select

‘Normal’ in screen.

(3) After receiving signal for at least 1 second, press the ADJ

Key on the Service R/C to enter the ‘Ez - Adjust’ and select

the ‘4. ADC 1080i Comp1/RGB’.

Pressing the Enter Key to adjust automatically component1.

(4) When the adjustment is over, 'ADC Component1 Success’

is displayed. If the adjustment has errors, 'ADC

Component1 1080i Fail’ is displayed.

(5) After the Component1 adjustment is over, convert the

RGB-DTV Mode and start RGB adjustment.

When the adjustment is over, 'ADC RGB 1080P Success’

is displayed.

(6) Readjust after confirming the case Pattern or adjustment

condition where the adjustment errors.

Error massage is ‘Component1 Not Connected’ or ‘Not

Valid Format’ or ‘Check Signal Status’.

(7) After adjustment is complete, exit the adjustment mode by

pressing the ADJ KEY.

5. EDID(The Extended Display

Identification Data)/DDC

(Display Data Channel) Download

It is the feature to implement the “Plug and Play” which

automatically reconfigures the user’sl environment to directly

use by exchanging information without any command directly

to the PC or the monitor by the user, which is established by

the VESA

5-1. HDMI EDID Data Input

(1) Required Test Equipment

1) PC, Jig for adjusting DDC. (PC serial to D-sub

Connection equipment)

2) S/W for writing DDC(EDID data write & read)

3) D-Sub cable

4) Jig for HDMI Cable connection

(2) Preparation for Adjustments &

Setting of Device

1) Set devices as below and turn on the PC and JIG.

2) Open S/W for writing DDC (EDID data write & read).

(operated in DOS mode)

ADJUSTMENT INSTRUCTIONS

<Fig. 1> Adjustment Pattern: 480i/1080i 60Hz Pattern

LCD TV SET

(or Digital Board)

Page 8

Copyright © 2007 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

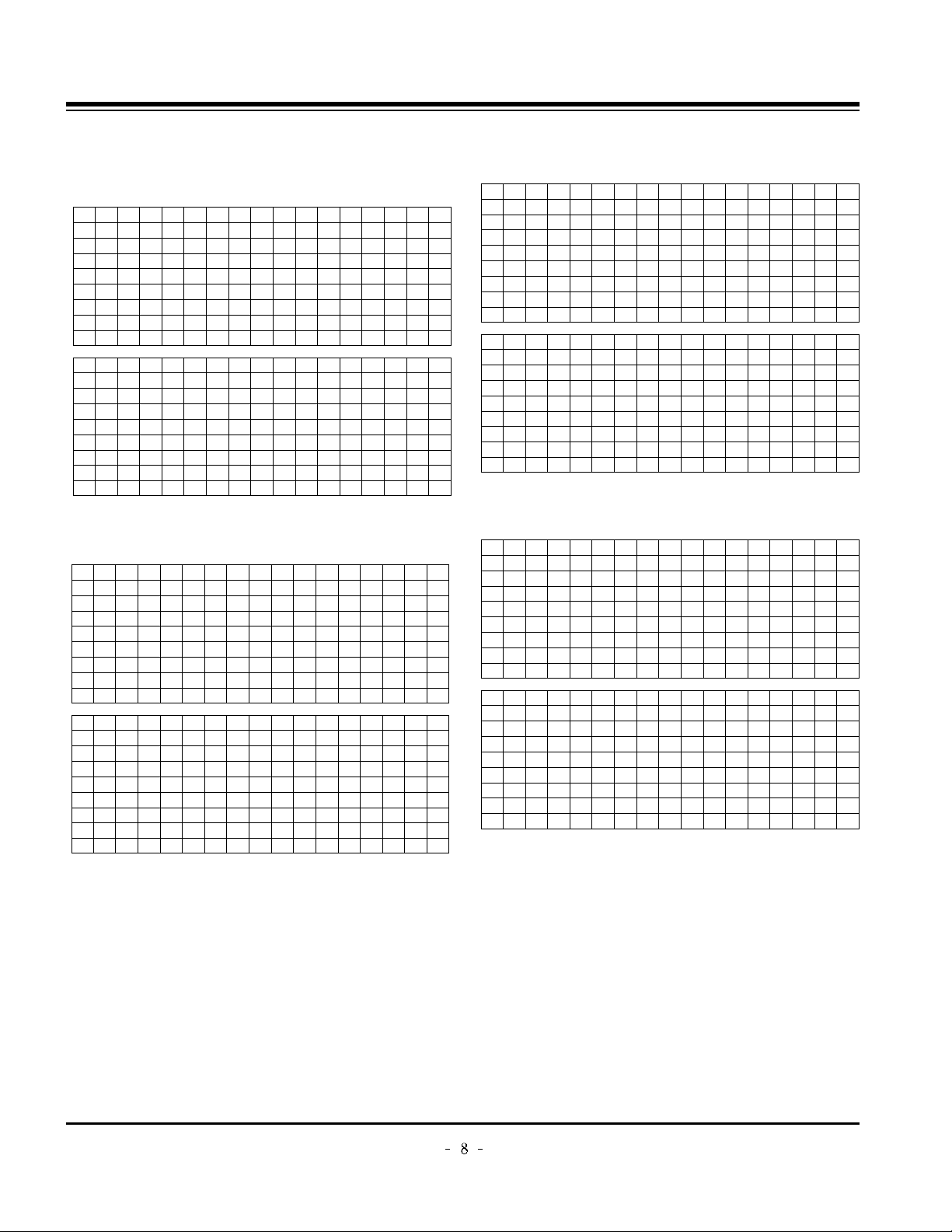

5-2. EDID DATA for PA75C

: EDID for HDMI-1 (DDC (Display Data Channel) Data)

EDID table =

: EDID for HDMI-2 (DDC (Display Data Channel) Data)

EDID table =

: EDID for HDMI-3 (DDC (Display Data Channel) Data)

EDID table =

: EDID DATA for RGB

EDID table =

ADJUSTMENT INSTRUCTIONS

0123456789ABCDEF

000FFFFFFFFFFFF001E6D010001010101

10 00 11 01 03 80 73 41 96 0A CF 74 A3 57 4C B0 23

20 09 48 4C AF CF 00 31 40 45 40 61 40 81 80 A9 40

30 01 01 01 01 01 01 66 21 50 B0 51 00 1B 30 40 70

40 36 00 C4 8E 21 00 00 1E 02 3A 80 18 71 38 2D 40

50 58 2C 45 00 C4 8E 21 00 00 1E 00 00 00 FD 00 30

60 58 1F 64 11 00 0A 20 20 20 20 20 20 00 00 00 FC

70 00 4C 47 20 54 56 0A 20 20 20 20 20 20 20 01 8A

0123456789ABCDEF

0020316F1478405030220221023150750

10 65 03 0C 00 10 00 01 1D 00 72 51 D0 1E 20 6E 28

20 55 00 C4 8E 21 00 00 1E 01 1D 80 18 71 1C 16 20

30 58 2C 25 00 C4 8E 21 00 00 9E 8C 0A D0 8A 20 E0

40 2D 10 10 3E 96 00 C4 8E 21 00 00 18 8C 0A D0 8A

50 20 E0 2D 10 10 3E 96 00 13 8E 21 00 00 18 26 36

60 80 A0 70 38 1F 40 30 20 25 00 C4 8E 21 00 00 1A

70 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 10

0123456789ABCDEF

000FFFFFFFFFFFF001E6D010001010101

10 00 11 01 03 80 73 41 96 0A CF 74 A3 57 4C B0 23

20 09 48 4C AF CF 00 31 40 45 40 61 40 81 80 A9 40

30 01 01 01 01 01 01 66 21 50 B0 51 00 1B 30 40 70

40 36 00 C4 8E 21 00 00 1E 02 3A 80 18 71 38 2D 40

50 58 2C 45 00 C4 8E 21 00 00 1E 00 00 00 FD 00 30

60 58 1F 64 11 00 0A 20 20 20 20 20 20 00 00 00 FC

70 00 4C 47 20 54 56 0A 20 20 20 20 20 20 20 01 8A

0123456789ABCDEF

0020316F1478405030220221023150750

10 65 03 0C 00 20 00 01 1D 00 72 51 D0 1E 20 6E 28

20 55 00 C4 8E 21 00 00 1E 01 1D 80 18 71 1C 16 20

30 58 2C 25 00 C4 8E 21 00 00 9E 8C 0A D0 8A 20 E0

40 2D 10 10 3E 96 00 C4 8E 21 00 00 18 8C 0A D0 8A

50 20 E0 2D 10 10 3E 96 00 13 8E 21 00 00 18 26 36

60 80 A0 70 38 1F 40 30 20 25 00 C4 8E 21 00 00 1A

70 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00

0123456789ABCDEF

000FFFFFFFFFFFF001E6D010001010101

10 00 11 01 03 80 73 41 96 0A CF 74 A3 57 4C B0 23

20 09 48 4C AF CF 00 31 40 45 40 61 40 81 80 A9 40

30 01 01 01 01 01 01 66 21 50 B0 51 00 1B 30 40 70

40 36 00 C4 8E 21 00 00 1E 02 3A 80 18 71 38 2D 40

50 58 2C 45 00 C4 8E 21 00 00 1E 00 00 00 FD 00 30

60 58 1F 64 11 00 0A 20 20 20 20 20 20 00 00 00 FC

70 00 4C 47 20 54 56 0A 20 20 20 20 20 20 20 01 8A

0123456789ABCDEF

0020316F1478405030220221023150750

10 65 03 0C 00 30 00 01 1D 00 72 51 D0 1E 20 6E 28

20 55 00 C4 8E 21 00 00 1E 01 1D 80 18 71 1C 16 20

30 58 2C 25 00 C4 8E 21 00 00 9E 8C 0A D0 8A 20 E0

40 2D 10 10 3E 96 00 C4 8E 21 00 00 18 8C 0A D0 8A

50 20 E0 2D 10 10 3E 96 00 13 8E 21 00 00 18 26 36

60 80 A0 70 38 1F 40 30 20 25 00 C4 8E 21 00 00 1A

70 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 F0

0123456789ABCDEF

000FFFFFFFFFFFF001E6D010001010101

10 00 11 01 03 18 73 41 96 0A CF 74 A3 57 4C B0 23

20 09 48 4C AF CF 00 31 40 45 40 61 40 81 80 A9 40

30 01 01 01 01 01 01 66 21 50 B0 51 00 1B 30 40 70

40 36 00 C4 8E 21 00 00 1A 02 3A 80 18 71 38 2D 40

50 58 2C 45 00 C4 8E 21 00 00 1E 00 00 00 FD 00 30

60 58 1F 64 11 00 0A 20 20 20 20 20 20 00 00 00 FC

70 00 4C 47 20 54 56 0A 20 20 20 20 20 20 20 01 F6

0123456789ABCDEF

0020304000E1F008051001E3040803700

10 C4 8E 21 00 00 1C F1 27 00 A0 51 00 25 30 50 80

20 37 00 C4 8E 21 00 00 1C 00 00 00 00 00 00 00 00

30 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00

40 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00

50 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00

60 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00

70 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 31

Page 9

Copyright © 2007 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

6. Adjustment of White Balance

6-1. Required Test Equipment

(1) Color Analyzer : CA-210 (CH 9)

=> To adjust color temperature of PDP, CS-1000 is the

Color Analyzer(CA-210) and should be set to use CH 9

in which white, red, green, and blue color are corrected.

Conduct the adjustment according to the coordinates for

White Balance adjustment in the table below.

(2) Computer for adjusting (necessary for the automatic

adjustment, possible to communicate with the RS-232C,

Baud Rate : 115200)

(3) Video Signal Generator MSPG-925F 720p, 216Gray

(Model :217, Pattern 78)

6-2. Connection Diagram of Equipment

for Measuring

(Automatic Adjustment)

6-3. White Balance Adjustment Method

Basically it uses the internal pattern but when internal pattern

is not possible, you can select HDMI input for adjustment.

Through the option at the most bottom part of the Ez Adjust

Menu 7.White Balance menu, you can select NONE, INNER

and HDMI, and the default is set to INNER. When the

adjustment cannot be done with the internal pattern, you can

select HDMI input for adjustment.

For manual adjustment, press the ADJ KEY of the adjustment

R/C to enter Ez Adjust 7.White-Balance, and the pattern is

automatically displayed. (When you set the Option to INNER,

the default is always set to INNER)

(1) Connect the set according to the internal pattern or HDMI

input in accordance with measuring device connection

diagram.

(2) Set the Baud Rate of RS-232C to 115200. It is set to

115200 as default.

(3) Connect the RS-232C Cable to the set.

(4) Connect the HDMI Cable to the set. (Limited to the set with

HDMI option)

(5) Select and adjust the model applicable to PA75C chassis

from the adjuster.

[RS-232C command used for the automatic adjustment]

Ô Wb 00 00-----white balance Automatic Adjustment Start

Ô Wb 00 10-----Gain Adjustment start (Internal pattern)

Ô Ja 00 ff------Adjustment Data

Ô Jb 00 c0

Ô ...

Ô Wb 00 1f-----Gain Adjustment End

Ô *(wb 00 20(Start), wb 00 2f(End))----- When adjust Off-set

Ô Wb 00 ff------White Balance Automatic Adjustment End

(Disappear Inside pattern)

[Adjustment Map]

ADJUSTMENT INSTRUCTIONS

Connection Diagram for Internal Pattern

Connection Diagram for HDMI Input

wb

wb

wb

wb

wb

wb

00

00

00

00

00

00

00

10

1f

20

2f

ff

White Balance Adjustment Start

Gain Adjustment Start(Internal white pattern)

Gain Adjustment End

Offset Adjustment Start(Internal white pattern)

Offset Adjustment End

White Balance Adjustment End

(Disappear Internal pattern)

RS-232C COMMAND

[CMD ID DATA]

Meaning

R Gain

G Gain

B Gain

R Cut

G Cut

B Cut

Jg

Jh

Ji

Cool

Ja

Jb

Jc

Mid

RS-232C COMMAND

[CMD ID DATA]

CENTER

(DEFAULT)

Jd

Je

Jf

00

00

00

192

192

192

127

127

127

Warm

Min Max

184

187

192

64

64

64

Cool

192

183

161

64

64

64

Mid

192

159

95

64

64

64

Warm

(internal pattern)

Page 10

Copyright © 2007 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

6-4. Automatic Adjustment

(1) Execute POWER ON(Â) of the adjustment R/C to execute

automatic adjustment.

(2) Set the Baud Rate to 115200.

(3) Always start adjustment with “wb 00 00” and end

adjustment with “wb 00 ff”

(4) Adjust the offset if necessary

6-5. Manual Adjustment

(1) Required Test Equipment: CA-210

=> To adjust color temperature of PDP, CS-1000 is the

Color Analyzer(CA-210) and should be set to use CH 9

in which white, red, green, and blue color are corrected.

Conduct the adjustment according to the coordinates for

White Balance adjustment in the table below.

(2) Enter the ‘Ez - Adjust’ by pressing the ADJ on the Service

R/C.

(3) Select 10.TEST PATTERN using the CH + / - KEY and

press the Enter KEY to execute a heat run for more than

30 minutes.

(4) Execute a Zero Calibration for CA-210 and put it at

distance of less than 10Cm from the PDP module surface

center during the adjustment.

(5) Select ‘7. White-Balance’ of ‘Ez - Adjust’ by pressing the

ADJ KEY on the Service R/C. Then enter adjustment mode

by pressing the Right KEY (

G

) .

(The internal pattern of full white appears by pressing

G

)

(6) The adjustment is conducted in three levels of color

temperature; COOL, MEDIUM, and WARM.

When the white balance is Cool,

Fix B Gain 192, fix R-Cut / G-Cut / B-Cut 64,

and use R Gain / G Gain to adjust the High Light.

When the white balance is Medium,

Fix R Gain 192, fix R-Cut / G-Cut / B-Cut 64,

and use G Gain / B Gain to adjust the High Light.

When the white balance is Warm,

Fix R Gain 192, fix R-Cut / G-Cut / B-Cut 64,

and use G Gain / B Gain to adjust High Light.

(7) Use the Vol. +, - key for adjustment.

(8) When the adjustment is completed, press the ENTER (

Á

KEY) button to move to the Ez –Adjust screen. Press the

ADJ KEY to exit the adjustment mode.

Full White 216gray

[Cool]

X; 0.276±0.002 Y; 0.283±0.002

Color temperature: 11000°K

9uv: 0.000

[Medium]

X; 0.285±0.002 Y; 0.293±0.002

Color temperature: 9300°K

9uv: 0.000

[Warm]

X; 0.313±0.002 Y; 0.329±0.002

Color temperature: 6500°K

9uv: 0.000

ADJUSTMENT INSTRUCTIONS

Page 11

Copyright © 2007 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

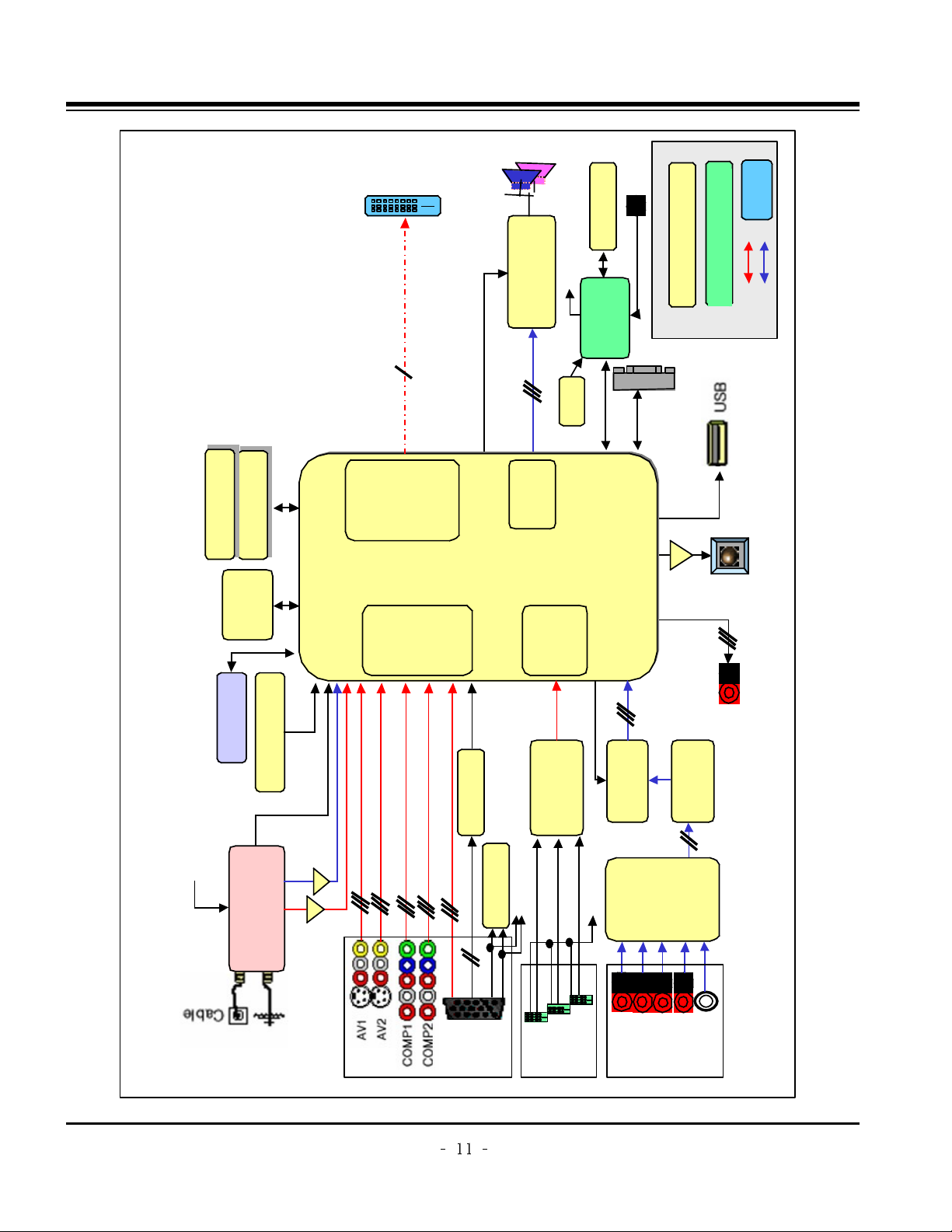

BLOCK DIAGRAM

Block Diagram - Overview

Audio L/R

Flash

(16MB)

DDR(64MB)

DDR(64MB)

74LVC14APW

TEA6420

(Audio

SW)

MC33078

(AMP)

CS5340

(A/D)

MTV416

(Micom)

NTP3000

(Digital AMP)

X-tal(54M)

TMDS341A

(3x1,S/W)

74F08D

EEPROM

AT/NT

Tuner

64Bit I/F

Reset

CVBS

CVBS/Y/C

Y/Cb/Cr

R/G/B

H/V Sync

RGB-PC

HDMI

0/1/2

COMP 1

COMP 2

AV 1

AV 2

RGB-PC

Audio L/R

I2S

MNT out

( L/R)

SPDIF OUT

I2S

RS-232C

Dead IC when Standby

Option

Alive IC when Standby

Video

Audio

Video

Front

End

Dual

HDMI

Rx

HD/SD

Video

Encoder

Audio

DSP

BCM3553

MCLK

MCLK

HDMI CEC

HDMI CEC

(To Micom)

To Micom

SDA

SCL

SIF

IF(AT)

Buffer

Single LVDS

Connector

Digital out (W)XGA

Local KEY

IR

Buffer Buffer

24C16

AGC CTL (From BCM)

USB2.0

I2S Audio Input

VSB/QAM/NTSC/SIF

DDR(128MB)

DDR(128MB)

Page 12

Copyright © 2007 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

BLOCK DIAGRAM

Signal path for CVBS, Component, RGB

Comp1_Y

H Sync

V Sync

BCM3553

Comp1_Pb

Comp1_Pr

74F08D

Component 1

Input

Component 2

Input

RGB Input

RGB H_Sync

Side AV CVBS

Rear AV

Rear S_Video Y/C

Side S_Video

Y/C

CVBS

CVBS 2

L1/C1

CVBS 3

L2/C2

ANT/ Cable

TUNER

IF_P

IF_N

IF_P from TUNER for DTV

IF_N from TUNER for DTV

CVBS 1

EEPROM

FOR EDID

DDC SDA

DDC SCL

RGB V_Sync

LVDS_Tx

Out

Only for HD

Component_1 S/W

Component_2 S/W

Rear_CVBS_ S/W

RGB S/W

GPIO[0:6]

Comp2_Y

Comp2_Pb

Comp2_Pr

RGB_G

RGB_B

RGB_R

DDC SCL to Micom

for Download

LPF 6 Mhz

LPF 30Mhz

LPF 30Mhz

LPF 30Mhz

LPF 30Mhz

LPF 30Mhz

LPF 30Mhz

LPF 6 Mhz

LPF 6 Mhz

LPF 6 Mhz

DDC SDA to Micom

for Download

DVO Out[0:29]

Rear_S-Video_ S/W

Side_CVBS_ S/W

Side_S-Video_ S/W

31p

LVDS

Con.

31p

LVDS

Con.

Page 13

Copyright © 2007 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

BLOCK DIAGRAM

Signal path for HDMI

BCM3553

TMDS0 RX0+/-

TMDS0 RX1+/-

TMDS0 RX2+/-

TMDS0 RXCLK+/-

DDC SDA0

DDC SCL0

EEPROM

For EDID

HDCP SDA

HDCP SCL

NDA

NCL

HDMI 0

HDMI 1

HDMi — CEC

+5V Power_0

Hot Plug Detect_0

TMDS1 RX0+/-

TMDS1 RX1+/-

TMDS1 RX2+/-

TMDS1 RXCLK+/-

DDC SDA1

DDC SCL1

EEPROM

For EDID

HDMi — CEC

+5V Power_1

Hot Plug Detect_1

LVDS_Tx

Out

HDMI 2

TMDS2 RX0+/-

TMDS2 RX1+/-

TMDS2 RX2+/-

TMDS2 RXCLK+/-

DDC SDA2

DDC SCL2

EEPROM

For EDID

HDMi — CEC

+5V Power_2

Hot Plug Detect_2

TMDS341A

TMDS0

INPUT

DDC SDA

DDC SCL

TMDS1

INPUT

TMDS2

INPUT

TMDS RX0+/-

TMDS RX1+/-

TMDS RX2+/-

TMDS RXCLK+/-

Hot Plug Detect_0

TMDS

Out

TMDS_Rx

Input

HDMi_Sel_0

HDMi_Sel_1

HDMi_Sel_2

Hot Plug Detect_1

Hot Plug Detect_2

+5V Power_0

+5V Power_1

+5V Power_2

GPIO[0:8]

Switch

Selection

DDC

INPUT

MTV416

MTV416

Micom

HDMi — CEC

Parallel connections with

HDMi 0,1,2

Only for HD 31P

LVDS

Con.

31P

LVDS

Con.

DVO Out[0:29]

EEPROM

for HDCP

EEPROM

for HDCP

DDC SDA0

DDC SCL0

DDC SDA1

DDC SCL1

DDC SDA2

DDC SCL2

DDC

OUT

Page 14

Copyright © 2007 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

BLOCK DIAGRAM

AV1_Audio

AV2_Audio

MNT_Audio

HDMI

(PC/DTV)

Comp2_Audio

RGB_Audio

Comp1_Audio

[L1 / R1]

[L2 / R2]

[L3 / R3]

[L4 / R4]

[L5 / R5]

Switch

Switch

[Rout/Lout]

I2C SCL/SDA

Audio

Switch

[TEA6420]

AUDIO ADC

[CS5340]

I2S_CLK_IN/DATA_IN

/LR IN

(I2S_MCLK)

SPDIF OUT

Buffer

Buffer

OP AMP

[MC33078]

PWM MODULATOR/

POWER AMP

[NTP3000]

SIF IN

Broadcom

[BCM3553]

AUD_SPDIF

ANA L/R IN

ANA L/R

(MC33078)

ANA L/R

ANA L/R OUT

(CS5340)

BCM_MCLK

BCM_MCLK

I2S_CLK_IN

I2S_DATA_IN

I2S_LR_IN

RESET

RESET

I2S_CLK_OUT

I2S_DATA_OUT

I2S_LR_OUT

(NTP3000)

I2S_CLK_OUT/

DATA_OUT/

LRCH OUT

I2C SCL/SDA

OUT1A/B

OUT2A/B

SPK R

SPK L

MNT_L/R OUT

HDMI Rx

Built in

Internal

I2S/SPDIF

Convert

HDMI_TMDS 0/1/2/CLK

TUNER (ATSC/NTSC )

I2C SCL/SDA

Buffer

Buffer

SIF

IF_P

IF_N

AUD_LEFT/RIGHT P

HDMI_RX_DATA/CLK

ANA L/R OUT

BTSC

Decoder

MPEG2

Dolby

AUDIO

Processor

Signal path for AUDIO/ IF

SPDIF OUT(coaxial)

BCM_MCLK

IF AGC

CVBS

FRONT END

Page 15

Copyright © 2007 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

BLOCK DIAGRAM

BCM3553

AUDIO S/W(TEA6420)

NTP3000

NVRAM

4.7K‰

5.0V

I2C_Channel 0

I2C_Channel 1

ATSC/NTSC Tuner

I2C_Channel 2

I2C_Channel 3

I2C0_5V

I2C1_5V

I2C2_2.5V

I2C2_3.3V

I2C3_3.3V

MTV416

4.7K‰

3.3VST

1K‰

3.3V

M62320

4.7K‰

5.0V

LM57(DS1621)

HDCP Key EEPROM

Address

0xC2

0x9A

0x74

0xA6

0x94

0x1C

0x54

0x??

0xD4

PDP MODULE

0x50

I2C MAP

CAT6431 Ready

(only S/W mode)

Page 16

Copyright © 2007 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

BLOCK DIAGRAM

Block Diagram Power Sequence and Flow Diagram

P_+19V

P_+19V

IC501

NTP3000

(Sound IC)

BIAS

Speaker R/L

+12.0V

+12.0V

IC806

KA7809

IC500

TEA6420D

(Audio SW)

+9V

IC504

MC33078

(OP AMP)

Digital eye

LCD control B/D

IC901,902

KIA78R09F

(FAN REG)

FAN

FAN

REG IC BIAS Side power

Page 17

Copyright © 2007 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

BLOCK DIAGRAM

Block Diagram Power Sequence and Flow Diagram

ST_5V

ST_5V

REG IC BIAS Side power

Local key/IR power

IC202

ICL3232

RS-232C RX/TX

IC404

AZ1117H-3.3

IC406

AT24C16AN

(EEPROM)

+3.3VST_MICOM

IC407

MTV416GMF

( micom )

BIAS

HDMI CEC

Inv/RL/live-on

3.3V->5V

BIAS

Page 18

Copyright © 2007 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

BLOCK DIAGRAM

Block Diagram Power Sequence and Flow Diagram

+6.0V

+6.0V

REG IC BIAS Side power

IC800

PQ05DZ1U

TUNER

+5V_TU

Power_CTL_3.3V

Tuner SIF

IC801

PQ05DZ1U

+5.0V

IC102

CAT24WC

(HDCP KEY EEPROM)

BIAS

BCM PCI 단

BCM SCL/SDA0~1

BCM DS-AGC,AUD_VDD

BIAS

IC200

TPS2052

(USB power CTL

analog SW)

IC403

AT24C512W

(EEPROM NVRAM)

Inv/RL/live-on

3.3V->5V

IC502

CS5340

(Audio ADC)

입력단자 HPD

IC601/602/603/701

AT24C02BN

(EEPROM EDID)

EDID EEPROM

W/P

IC600

3:1HDMI SW

SCL/SDA

IC700

74F08D

(RGB HV AND GATE)

IC808

FMS6400

(Tuner video buffer)

IC900

M62320FP

(FAN driver)

IC903

LM75CIMX-3

(FAN 온도센서)

IC804

AZ1117H-3.3

IC802

AZ1117H-3.3

D3.3V_BCM

IC101

Flash MEM 32M

Reset SWBCM3553

IC401

74LVC14ADW

Reset 슈미트트리거

A3.3V_BCM

BCM3553

DAC/USB,AGC,HDMI

BOOT

STRAP

IC600

PICHDMI341

HDMI 3:1 SW

3.3V_TMDS_SW

Page 19

Copyright © 2007 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

BLOCK DIAGRAM

Block Diagram Power Sequence and Flow Diagram

+3.3V

+3.3V

REG IC BIAS Side power

Power_CTL_2.6V_1.2V

IC803

SC1566I5M

D2.6V_BCM

BCM3553

IC300,301,302,303

DDR IC 전원

IC200,201

TPS2052BD

(USB analog SW)

IC501

NTP3000

(sound IC)

IC502

CS5340

(Audio ADC)

IC503

TC74VHC04FT

(coxial SPDIF IC)

JK501

SPDIF power

IC407

MTV416GMF

+3.3V detect signal

BIAS

LVDS Tuner CTR

IC304

5C25955TR

DDR Memory

DDR0_VTT

DDR0_REF

BCM3553

A2.6V_BCM

IC805

SC4519STRT

DC-DC converter

BCM3553

D1.2V_BCM

A1.2V_BCM

Power_CTL_2.6V_1.2V

IC807

AZ1117H-1.8

IC501

NTP3000

(sound IC)

+1.8V_NTP

Page 20

Copyright © 2007LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

EXPLODED VIEW

300

120

304

560

570

600

601

603

602

LV1

306

301

302

303

501

520

590

400

240

250

200

206

205

202

203

204

201

502

A2

900

901

Page 21

- 22 -

A1 MFL34797035 "Manual,Owners" PRINTING USER LA75C LG

A2 MKJ39927801 Remote Controller COMPLEX PA63E 50PC5D-U

A3 EAD36401701 Power Cord LP-31 + LS-13L LP-31 L

C103 0CE107SF6DC "Capacitor,AL,Chip" VMV107M016S0ANE010 100

C108 0CE107SF6DC "Capacitor,AL,Chip" VMV107M016S0ANE010 100

C241 0CE476WH6DC "Capacitor,AL,Chip" MVK8.0TP25VC47M 47uF 2

C242 0CE336WH6D8 "Capacitor,AL,Chip" MVK6.3TP25VC33M 33uF 2

C2601 0CH8106F691 "Capacitor,AL,Chip" MVK4.0TP16VC10M 10uF 2

C2665 0CE335WK6D8 "Capacitor,AL,Chip" MVK4.0TP50VC3.3M 3.3uF

C2666 0CE335WK6D8 "Capacitor,AL,Chip" MVK4.0TP50VC3.3M 3.3uF

C2667 0CE335WK6D8 "Capacitor,AL,Chip" MVK4.0TP50VC3.3M 3.3uF

C2668 0CE335WK6D8 "Capacitor,AL,Chip" MVK4.0TP50VC3.3M 3.3uF

C273 0CE476WH6DC "Capacitor,AL,Chip" MVK8.0TP25VC47M 47uF 2

C278 0CH8106F691 "Capacitor,AL,Chip" MVK4.0TP16VC10M 10uF 2

C300 0CE107WF6DC "Capacitor,AL,Chip" MVK6.3TP16VC100M 100uF

C320 0CE107WF6DC "Capacitor,AL,Chip" MVK6.3TP16VC100M 100uF

C338 0CE336WH6D8 "Capacitor,AL,Chip" MVK6.3TP25VC33M 33uF 2

C352 0CE107WF6DC "Capacitor,AL,Chip" MVK6.3TP16VC100M 100uF

C353 0CE107WF6DC "Capacitor,AL,Chip" MVK6.3TP16VC100M 100uF

C358 0CE107WF6DC "Capacitor,AL,Chip" MVK6.3TP16VC100M 100uF

C400 0CE106WFKDC "Capacitor,AL,Chip" MVK4.0TP16VC10M 10uF 2

C401 0CE106WFKDC "Capacitor,AL,Chip" MVK4.0TP16VC10M 10uF 2

C421 0CE106WFKDC "Capacitor,AL,Chip" MVK4.0TP16VC10M 10uF 2

C422 0CE476WF6DC "Capacitor,AL,Chip" MVK6.3TP16VC47M 47uF 2

C424 0CE476WF6DC "Capacitor,AL,Chip" MVK6.3TP16VC47M 47uF 2

C426 0CE106WFKDC "Capacitor,AL,Chip" MVK4.0TP16VC10M 10uF 2

C429 0CE107WF6DC "Capacitor,AL,Chip" MVK6.3TP16VC100M 100uF

C442 0CE476WF6DC "Capacitor,AL,Chip" MVK6.3TP16VC47M 47uF 2

C505 0CE106WFKDC "Capacitor,AL,Chip" MVK4.0TP16VC10M 10uF 2

C506 0CE106WFKDC "Capacitor,AL,Chip" MVK4.0TP16VC10M 10uF 2

C513 0CE337WJ6D8 "Capacitor,AL,Chip" MVK12.5TP35VC330M 330u

C519 0CE106WFKDC "Capacitor,AL,Chip" MVK4.0TP16VC10M 10uF 2

C527 0CE337WJ6D8 "Capacitor,AL,Chip" MVK12.5TP35VC330M 330u

C554 0CE107WF6DC "Capacitor,AL,Chip" MVK6.3TP16VC100M 100uF

C555 0CE226WF6DC "Capacitor,AL,Chip" MVK5.0TP16VC22M 22uF 2

C568 0CE226WF6DC "Capacitor,AL,Chip" MVK5.0TP16VC22M 22uF 2

C569 0CE226WF6DC "Capacitor,AL,Chip" MVK5.0TP16VC22M 22uF 2

C575 0CE107WF6DC "Capacitor,AL,Chip" MVK6.3TP16VC100M 100uF

C576 0CE226WF6DC "Capacitor,AL,Chip" MVK5.0TP16VC22M 22uF 2

C577 0CE226WF6DC "Capacitor,AL,Chip" MVK5.0TP16VC22M 22uF 2

C581 0CE105WK6DC "Capacitor,AL,Chip" MVK4.0TP50VC1M 1uF 20%

C583 0CE105WK6DC "Capacitor,AL,Chip" MVK4.0TP50VC1M 1uF 20%

C586 0CE105WK6DC "Capacitor,AL,Chip" MVK4.0TP50VC1M 1uF 20%

C587 0CE105WK6DC "Capacitor,AL,Chip" MVK4.0TP50VC1M 1uF 20%

C695 0CE107WF6DC "Capacitor,AL,Chip" MVK6.3TP16VC100M 100uF

C700 0CE105WK6DC "Capacitor,AL,Chip" MVK4.0TP50VC1M 1uF 20%

C701 0CE105WK6DC "Capacitor,AL,Chip" MVK4.0TP50VC1M 1uF 20%

C727 0CE476WF6DC "Capacitor,AL,Chip" MVK6.3TP16VC47M 47uF 2

C730 0CE105WK6DC "Capacitor,AL,Chip" MVK4.0TP50VC1M 1uF 20%

C731 0CE105WK6DC "Capacitor,AL,Chip" MVK4.0TP50VC1M 1uF 20%

C733 0CE107WH6DC "Capacitor,AL,Chip" MVK8.0TP25VC100M 100uF

C734 0CE105WK6DC "Capacitor,AL,Chip" MVK4.0TP50VC1M 1uF 20%

C735 0CE105WK6DC "Capacitor,AL,Chip" MVK4.0TP50VC1M 1uF 20%

C805 0CE476WF6DC "Capacitor,AL,Chip" MVK6.3TP16VC47M 47uF 2

C807 0CE107WF6DC "Capacitor,AL,Chip" MVK6.3TP16VC100M 100uF

C809 0CE107WF6DC "Capacitor,AL,Chip" MVK6.3TP16VC100M 100uF

C812 EAE30840201 "Capacitor,AL,Chip" 4SVPC330M 330uF 20% 4V

C813 EAE30840401 "Capacitor,AL,Chip" 25SVPD10M 10uF 20% 25V

C814 0CE476WF6DC "Capacitor,AL,Chip" MVK6.3TP16VC47M 47uF 2

C816 0CE476WF6DC "Capacitor,AL,Chip" MVK6.3TP16VC47M 47uF 2

C819 0CH8106F691 "Capacitor,AL,Chip" MVK4.0TP16VC10M 10uF 2

C824 0CE476WF6DC "Capacitor,AL,Chip" MVK6.3TP16VC47M 47uF 2

C828 0CE476WF6DC "Capacitor,AL,Chip" MVK6.3TP16VC47M 47uF 2

C829 0CE476WF6DC "Capacitor,AL,Chip" MVK6.3TP16VC47M 47uF 2

C831 0CE476WF6DC "Capacitor,AL,Chip" MVK6.3TP16VC47M 47uF 2

C837 0CE107WH6DC "Capacitor,AL,Chip" MVK8.0TP25VC100M 100uF

C841 EAE30840201 "Capacitor,AL,Chip" 4SVPC330M 330uF 20% 4V

C845 0CE105WK6DC "Capacitor,AL,Chip" MVK4.0TP50VC1M 1uF 20%

C846 0CE107WF6DC "Capacitor,AL,Chip" MVK6.3TP16VC100M 100uF

C851 0CE227WF6DC "Capacitor,AL,Chip" MVK8.0TP16VC220M 220uF

C854 0CE107WF6DC "Capacitor,AL,Chip" MVK6.3TP16VC100M 100uF

C860 0CE336WD6D8 "Capacitor,AL,Chip" RC1A336M05005VR 33uF 2

C862 0CE336WD6D8 "Capacitor,AL,Chip" RC1A336M05005VR 33uF 2

C863 0CE476WF6DC "Capacitor,AL,Chip" MVK6.3TP16VC47M 47uF 2

C865 0CE476WF6DC "Capacitor,AL,Chip" MVK6.3TP16VC47M 47uF 2

C867 0CE107WF6DC "Capacitor,AL,Chip" MVK6.3TP16VC100M 100uF

C868 0CE107WF6DC "Capacitor,AL,Chip" MVK6.3TP16VC100M 100uF

C9019 0CE106VF6DC "Capacitor,AL,Chip" VGV106M016S0ANB010 10u

C9020 0CE106VF6DC "Capacitor,AL,Chip" VGV106M016S0ANB010 10u

C9021 0CE106VF6DC "Capacitor,AL,Chip" VGV106M016S0ANB010 10u

C9023 0CE106VF6DC "Capacitor,AL,Chip" VGV106M016S0ANB010 10u

C907 0CE476WF6DC "Capacitor,AL,Chip" MVK6.3TP16VC47M 47uF 2

C914 0CE476WH6DC "Capacitor,AL,Chip" MVK8.0TP25VC47M 47uF 2

C100 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C101 0CH4471K416 "Capacitor,Ceramic,Chip" C2012C0G1H471JT 470pF

C101 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C102 0CH5101K416 "Capacitor,Ceramic,Chip" C2012C0G1H101JT 100pF

C102 0CK475CC94A "Capacitor,Ceramic,Chip" C1608Y5V0J475ZT 4.7uF

C103 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C104 0CH4471K416 "Capacitor,Ceramic,Chip" C2012C0G1H471JT 470pF

C105 0CH4471K416 "Capacitor,Ceramic,Chip" C2012C0G1H471JT 470pF

C105 0CH5101K416 "Capacitor,Ceramic,Chip" C2012C0G1H101JT 100pF

C105 0CK475CC94A "Capacitor,Ceramic,Chip" C1608Y5V0J475ZT 4.7uF

C106 0CH5101K416 "Capacitor,Ceramic,Chip" C2012C0G1H101JT 100pF

C106 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C108 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

LOC. NO. PART NO. DESCRIPTION / SPECIFICATION LOC. NO. PART NO. DESCRIPTION / SPECIFICATION

REPLACEMENT PARTS LIST

DATE: 2007. 10. 24.

CAPACITORs

ACCESSORY

Page 22

- 23 -

C109 0CK103BH56A "Capacitor,Ceramic,Chip" C1005X7R1E103KT- 10nF

C110 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C111 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C112 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C113 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C114 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C123 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C124 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C125 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C126 0CK475CC94A "Capacitor,Ceramic,Chip" C1608Y5V0J475ZT 4.7uF

C127 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C128 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C129 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C130 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C131 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C132 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C200 0CK475DD57A "Capacitor,Ceramic,Chip" C2012X5R1A475KT 4.7uF

C201 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C202 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C203 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C204 0CK475CC94A "Capacitor,Ceramic,Chip" C1608Y5V0J475ZT 4.7uF

C205 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C206 0CK475CC94A "Capacitor,Ceramic,Chip" C1608Y5V0J475ZT 4.7uF

C207 0CK101BK4EA "Capacitor,Ceramic,Chip" C1005C0G1H101JT 100pF

C208 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C209 0CK475CC94A "Capacitor,Ceramic,Chip" C1608Y5V0J475ZT 4.7uF

C210 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C211 0CK475CC94A "Capacitor,Ceramic,Chip" C1608Y5V0J475ZT 4.7uF

C212 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C213 0CK103BH56A "Capacitor,Ceramic,Chip" C1005X7R1E103KT- 10nF

C214 0CK102BK56A "Capacitor,Ceramic,Chip" 0402B102K500CT 1nF 10%

C215 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C216 0CK103BH56A "Capacitor,Ceramic,Chip" C1005X7R1E103KT- 10nF

C217 0CK102BK56A "Capacitor,Ceramic,Chip" 0402B102K500CT 1nF 10%

C218 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C219 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C220 EAE33970001 "Capacitor,Ceramic,Chip" CS1005X5R105K6R3NR 1uF

C221 EAE33970001 "Capacitor,Ceramic,Chip" CS1005X5R105K6R3NR 1uF

C222 EAE32479401 "Capacitor,Ceramic,Chip" CH1005CG471J500NR 470p

C223 EAE32479401 "Capacitor,Ceramic,Chip" CH1005CG471J500NR 470p

C224 0CK103BH56A "Capacitor,Ceramic,Chip" C1005X7R1E103KT- 10nF

C227 0CK475CC94A "Capacitor,Ceramic,Chip" C1608Y5V0J475ZT 4.7uF

C228 0CK105CD56A "Capacitor,Ceramic,Chip" C1608X7R1A105KT 1uF 10

C229 0CC120CK41A "Capacitor,Ceramic,Chip" C1608C0G1H120JT 12pF 5

C230 0CC120CK41A "Capacitor,Ceramic,Chip" C1608C0G1H120JT 12pF 5

C232 0CZZB00035A "Capacitor,Ceramic,Chip" GRM1555C1H330J 33pF 5%

C234 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C235 0CK475CC94A "Capacitor,Ceramic,Chip" C1608Y5V0J475ZT 4.7uF

C236 0CK102BK56A "Capacitor,Ceramic,Chip" 0402B102K500CT 1nF 10%

C237 0CK103BH56A "Capacitor,Ceramic,Chip" C1005X7R1E103KT- 10nF

C238 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C239 0CK106DC67A "Capacitor,Ceramic,Chip" JMK212JB106MG-T 10uF 2

C240 0CK106DC67A "Capacitor,Ceramic,Chip" JMK212JB106MG-T 10uF 2

C243 0CK102BK56A "Capacitor,Ceramic,Chip" 0402B102K500CT 1nF 10%

C244 0CK103BH56A "Capacitor,Ceramic,Chip" C1005X7R1E103KT- 10nF

C245 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C246 0CK475CC94A "Capacitor,Ceramic,Chip" C1608Y5V0J475ZT 4.7uF

C247 0CK102BK56A "Capacitor,Ceramic,Chip" 0402B102K500CT 1nF 10%

C248 0CK103BH56A "Capacitor,Ceramic,Chip" C1005X7R1E103KT- 10nF

C249 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C250 0CK475CC94A "Capacitor,Ceramic,Chip" C1608Y5V0J475ZT 4.7uF

C251 0CK102BK56A "Capacitor,Ceramic,Chip" 0402B102K500CT 1nF 10%

C252 0CK103BH56A "Capacitor,Ceramic,Chip" C1005X7R1E103KT- 10nF

C253 0CK475CC94A "Capacitor,Ceramic,Chip" C1608Y5V0J475ZT 4.7uF

C254 0CK102BK56A "Capacitor,Ceramic,Chip" 0402B102K500CT 1nF 10%

C255 0CK103BH56A "Capacitor,Ceramic,Chip" C1005X7R1E103KT- 10nF

C256 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C257 0CK475CC94A "Capacitor,Ceramic,Chip" C1608Y5V0J475ZT 4.7uF

C258 0CK102BK56A "Capacitor,Ceramic,Chip" 0402B102K500CT 1nF 10%

C259 0CK103BH56A "Capacitor,Ceramic,Chip" C1005X7R1E103KT- 10nF

C260 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C2600 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C2602 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C2603 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C2604 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C261 0CK106DC67A "Capacitor,Ceramic,Chip" JMK212JB106MG-T 10uF 2

C262 0CK102BK56A "Capacitor,Ceramic,Chip" 0402B102K500CT 1nF 10%

C263 0CK103BH56A "Capacitor,Ceramic,Chip" C1005X7R1E103KT- 10nF

C264 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C265 0CK475CC94A "Capacitor,Ceramic,Chip" C1608Y5V0J475ZT 4.7uF

C266 0CK102BK56A "Capacitor,Ceramic,Chip" 0402B102K500CT 1nF 10%

C2662 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C2663 0CC100BKF1A "Capacitor,Ceramic,Chip" 0402N100J500LT 10pF 5%

C2664 0CK106CC67A "Capacitor,Ceramic,Chip" C1608X5R0J106MT 10uF 2

C267 0CK103BH56A "Capacitor,Ceramic,Chip" C1005X7R1E103KT- 10nF

C268 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C269 0CK102BK56A "Capacitor,Ceramic,Chip" 0402B102K500CT 1nF 10%

C270 0CK103BH56A "Capacitor,Ceramic,Chip" C1005X7R1E103KT- 10nF

C271 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C272 0CK106DC67A "Capacitor,Ceramic,Chip" JMK212JB106MG-T 10uF 2

C274 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C275 0CK103BH56A "Capacitor,Ceramic,Chip" C1005X7R1E103KT- 10nF

C276 0CK475CC94A "Capacitor,Ceramic,Chip" C1608Y5V0J475ZT 4.7uF

C279 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C280 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C281 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C282 0CK105CD56A "Capacitor,Ceramic,Chip" C1608X7R1A105KT 1uF 10

C283 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C284 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C285 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C286 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C287 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C288 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C289 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C290 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C2900 0CC100BKF1A "Capacitor,Ceramic,Chip" 0402N100J500LT 10pF 5%

C2901 0CC100BKF1A "Capacitor,Ceramic,Chip" 0402N100J500LT 10pF 5%

C291 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C292 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C295 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

LOC. NO. PART NO. DESCRIPTION / SPECIFICATION LOC. NO. PART NO. DESCRIPTION / SPECIFICATION

Page 23

- 24 -

C3001 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C3002 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C301 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C302 0CK103BH56A "Capacitor,Ceramic,Chip" C1005X7R1E103KT- 10nF

C303 EAE32166101 "Capacitor,Ceramic,Chip" CS1005XR473K250CR 0.04

C304 0CK272BKF6A "Capacitor,Ceramic,Chip" 0402B272J500CT 2.7nF 5

C305 EAE32479401 "Capacitor,Ceramic,Chip" CH1005CG471J500NR 470p

C312 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C313 EAE32479401 "Capacitor,Ceramic,Chip" CH1005CG471J500NR 470p

C316 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C317 EAE32479401 "Capacitor,Ceramic,Chip" CH1005CG471J500NR 470p

C321 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C322 0CK103BH56A "Capacitor,Ceramic,Chip" C1005X7R1E103KT- 10nF

C323 EAE32166101 "Capacitor,Ceramic,Chip" CS1005XR473K250CR 0.04

C324 0CK272BKF6A "Capacitor,Ceramic,Chip" 0402B272J500CT 2.7nF 5

C325 EAE32479401 "Capacitor,Ceramic,Chip" CH1005CG471J500NR 470p

C332 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C333 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C334 EAE33970001 "Capacitor,Ceramic,Chip" CS1005X5R105K6R3NR 1uF

C335 EAE33970001 "Capacitor,Ceramic,Chip" CS1005X5R105K6R3NR 1uF

C336 EAE32479401 "Capacitor,Ceramic,Chip" CH1005CG471J500NR 470p

C337 EAE32479401 "Capacitor,Ceramic,Chip" CH1005CG471J500NR 470p

C339 0CK106DC67A "Capacitor,Ceramic,Chip" JMK212JB106MG-T 10uF 2

C340 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C341 0CK103BH56A "Capacitor,Ceramic,Chip" C1005X7R1E103KT- 10nF

C342 0CK102BK56A "Capacitor,Ceramic,Chip" 0402B102K500CT 1nF 10%

C344 0CK103BH56A "Capacitor,Ceramic,Chip" C1005X7R1E103KT- 10nF

C345 0CK102BK56A "Capacitor,Ceramic,Chip" 0402B102K500CT 1nF 10%

C346 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C347 0CK103BH56A "Capacitor,Ceramic,Chip" C1005X7R1E103KT- 10nF

C348 0CK102BK56A "Capacitor,Ceramic,Chip" 0402B102K500CT 1nF 10%

C349 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C350 0CK103BH56A "Capacitor,Ceramic,Chip" C1005X7R1E103KT- 10nF

C351 0CK102BK56A "Capacitor,Ceramic,Chip" 0402B102K500CT 1nF 10%

C354 0CK103CK56A "Capacitor,Ceramic,Chip" 0603B103K500CT 10nF 10

C355 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C356 0CK103CK56A "Capacitor,Ceramic,Chip" 0603B103K500CT 10nF 10

C357 0CK225DD66A "Capacitor,Ceramic,Chip" LMK212JB225MG-T 2.2uF

C359 0CK105CD56A "Capacitor,Ceramic,Chip" C1608X7R1A105KT 1uF 10

C360 0CK103CK56A "Capacitor,Ceramic,Chip" 0603B103K500CT 10nF 10

C361 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C362 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C368 0CK102BK56A "Capacitor,Ceramic,Chip" 0402B102K500CT 1nF 10%

C369 0CK102BK56A "Capacitor,Ceramic,Chip" 0402B102K500CT 1nF 10%

C370 0CK102BK56A "Capacitor,Ceramic,Chip" 0402B102K500CT 1nF 10%

C371 0CK102BK56A "Capacitor,Ceramic,Chip" 0402B102K500CT 1nF 10%

C372 0CK102BK56A "Capacitor,Ceramic,Chip" 0402B102K500CT 1nF 10%

C373 0CK102BK56A "Capacitor,Ceramic,Chip" 0402B102K500CT 1nF 10%

C374 EAE32479401 "Capacitor,Ceramic,Chip" CH1005CG471J500NR 470p

C375 EAE32479401 "Capacitor,Ceramic,Chip" CH1005CG471J500NR 470p

C376 0CK103BH56A "Capacitor,Ceramic,Chip" C1005X7R1E103KT- 10nF

C378 0CK103BH56A "Capacitor,Ceramic,Chip" C1005X7R1E103KT- 10nF

C380 0CK103BH56A "Capacitor,Ceramic,Chip" C1005X7R1E103KT- 10nF

C381 0CK103BH56A "Capacitor,Ceramic,Chip" C1005X7R1E103KT- 10nF

C382 0CK103BH56A "Capacitor,Ceramic,Chip" C1005X7R1E103KT- 10nF

C383 0CK103BH56A "Capacitor,Ceramic,Chip" C1005X7R1E103KT- 10nF

C384 0CK103BH56A "Capacitor,Ceramic,Chip" C1005X7R1E103KT- 10nF

C385 0CK103BH56A "Capacitor,Ceramic,Chip" C1005X7R1E103KT- 10nF

C386 0CK103BH56A "Capacitor,Ceramic,Chip" C1005X7R1E103KT- 10nF

C387 EAE32479401 "Capacitor,Ceramic,Chip" CH1005CG471J500NR 470p

C388 EAE32479401 "Capacitor,Ceramic,Chip" CH1005CG471J500NR 470p

C394 0CK103BH56A "Capacitor,Ceramic,Chip" C1005X7R1E103KT- 10nF

C396 0CK103BH56A "Capacitor,Ceramic,Chip" C1005X7R1E103KT- 10nF

C397 0CK475CC94A "Capacitor,Ceramic,Chip" C1608Y5V0J475ZT 4.7uF

C402 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C403 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C404 0CK104CF56A "Capacitor,Ceramic,Chip" 0603B104K160CT 100nF 1

C405 0CK104CF56A "Capacitor,Ceramic,Chip" 0603B104K160CT 100nF 1

C406 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C407 0CK104CF56A "Capacitor,Ceramic,Chip" 0603B104K160CT 100nF 1

C408 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C409 0CC221BKFAA "Capacitor,Ceramic,Chip" C1005C0G1H221JT 220pF

C410 0CC221BKFAA "Capacitor,Ceramic,Chip" C1005C0G1H221JT 220pF

C411 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C412 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C413 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C414 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C415 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C416 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C419 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C420 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C423 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C425 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C427 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C428 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C430 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C431 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C433 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C434 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C435 0CH5220K618 "Capacitor,Ceramic,Chip" 0402N220M500LT 22pF 5%

C436 0CH5220K618 "Capacitor,Ceramic,Chip" 0402N220M500LT 22pF 5%

C437 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C438 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C439 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C440 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C441 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C500 0CK101BK4EA "Capacitor,Ceramic,Chip" C1005C0G1H101JT 100pF

C501 0CK102BK56A "Capacitor,Ceramic,Chip" 0402B102K500CT 1nF 10%

C503 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C504 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C507 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C508 0CZZB00035A "Capacitor,Ceramic,Chip" GRM1555C1H330J 33pF 5%

C509 0CK105CD56A "Capacitor,Ceramic,Chip" C1608X7R1A105KT 1uF 10

C510 0CZZB00035A "Capacitor,Ceramic,Chip" GRM1555C1H330J 33pF 5%

C511 0CZZB00035A "Capacitor,Ceramic,Chip" GRM1555C1H330J 33pF 5%

C512 0CK223CK56A "Capacitor,Ceramic,Chip" UMK107JB223KA-T 22nF 1

C514 0CK104CK56A "Capacitor,Ceramic,Chip" 0603B104K500CT 100nF 1

C515 0CK223CK56A "Capacitor,Ceramic,Chip" UMK107JB223KA-T 22nF 1

C516 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C517 0CK104CK56A "Capacitor,Ceramic,Chip" 0603B104K500CT 100nF 1

LOC. NO. PART NO. DESCRIPTION / SPECIFICATION LOC. NO. PART NO. DESCRIPTION / SPECIFICATION

Page 24

- 25 -

C518 0CK104CK56A "Capacitor,Ceramic,Chip" 0603B104K500CT 100nF 1

C520 0CK103CK56A "Capacitor,Ceramic,Chip" 0603B103K500CT 10nF 10

C521 0CK105CD56A "Capacitor,Ceramic,Chip" C1608X7R1A105KT 1uF 10

C522 0CK105CD56A "Capacitor,Ceramic,Chip" C1608X7R1A105KT 1uF 10

C523 0CK223CK56A "Capacitor,Ceramic,Chip" UMK107JB223KA-T 22nF 1

C524 0CK223CK56A "Capacitor,Ceramic,Chip" UMK107JB223KA-T 22nF 1

C525 0CK105CD56A "Capacitor,Ceramic,Chip" C1608X7R1A105KT 1uF 10

C526 0CK104CK56A "Capacitor,Ceramic,Chip" 0603B104K500CT 100nF 1

C528 0CK104CK56A "Capacitor,Ceramic,Chip" 0603B104K500CT 100nF 1

C529 0CK104CK56A "Capacitor,Ceramic,Chip" 0603B104K500CT 100nF 1

C530 0CK103CK56A "Capacitor,Ceramic,Chip" 0603B103K500CT 10nF 10

C535 0CK102CK56A "Capacitor,Ceramic,Chip" 0603B102K500CT 1nF 10%

C536 0CK102CK56A "Capacitor,Ceramic,Chip" 0603B102K500CT 1nF 10%

C537 0CK102CK56A "Capacitor,Ceramic,Chip" 0603B102K500CT 1nF 10%

C538 0CK102CK56A "Capacitor,Ceramic,Chip" 0603B102K500CT 1nF 10%

C539 0CK104CK56A "Capacitor,Ceramic,Chip" 0603B104K500CT 100nF 1

C540 0CK104CK56A "Capacitor,Ceramic,Chip" 0603B104K500CT 100nF 1

C541 0CK104CK56A "Capacitor,Ceramic,Chip" 0603B104K500CT 100nF 1

C542 0CK104CK56A "Capacitor,Ceramic,Chip" 0603B104K500CT 100nF 1

C543 0CK474DK56A "Capacitor,Ceramic,Chip" UMK212BJ474KG-T 470nF

C544 0CK474DK56A "Capacitor,Ceramic,Chip" UMK212BJ474KG-T 470nF

C545 0CK103CK56A "Capacitor,Ceramic,Chip" 0603B103K500CT 10nF 10

C546 0CK103CK56A "Capacitor,Ceramic,Chip" 0603B103K500CT 10nF 10

C547 0CK103CK56A "Capacitor,Ceramic,Chip" 0603B103K500CT 10nF 10

C548 0CK103CK56A "Capacitor,Ceramic,Chip" 0603B103K500CT 10nF 10

C556 0CK103CK56A "Capacitor,Ceramic,Chip" 0603B103K500CT 10nF 10

C566 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C567 0CK103CK56A "Capacitor,Ceramic,Chip" 0603B103K500CT 10nF 10

C570 0CH5470K618 "Capacitor,Ceramic,Chip" 0402N470M500LT 47pF 5%

C571 0CK104CK56A "Capacitor,Ceramic,Chip" 0603B104K500CT 100nF 1

C572 0CK104CK56A "Capacitor,Ceramic,Chip" 0603B104K500CT 100nF 1

C573 0CK104CK56A "Capacitor,Ceramic,Chip" 0603B104K500CT 100nF 1

C574 0CH5470K618 "Capacitor,Ceramic,Chip" 0402N470M500LT 47pF 5%

C578 0CK103CK56A "Capacitor,Ceramic,Chip" 0603B103K500CT 10nF 10

C579 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C580 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C582 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C584 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C585 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C588 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C589 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C590 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C591 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C592 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C600 0CK103BH56A "Capacitor,Ceramic,Chip" C1005X7R1E103KT- 10nF

C601 0CK103BH56A "Capacitor,Ceramic,Chip" C1005X7R1E103KT- 10nF

C602 0CK103BH56A "Capacitor,Ceramic,Chip" C1005X7R1E103KT- 10nF

C603 0CK103BH56A "Capacitor,Ceramic,Chip" C1005X7R1E103KT- 10nF

C604 0CK103BH56A "Capacitor,Ceramic,Chip" C1005X7R1E103KT- 10nF

C605 0CK103BH56A "Capacitor,Ceramic,Chip" C1005X7R1E103KT- 10nF

C606 0CK103BH56A "Capacitor,Ceramic,Chip" C1005X7R1E103KT- 10nF

C607 0CK103BH56A "Capacitor,Ceramic,Chip" C1005X7R1E103KT- 10nF

C608 0CK103BH56A "Capacitor,Ceramic,Chip" C1005X7R1E103KT- 10nF

C609 0CK103BH56A "Capacitor,Ceramic,Chip" C1005X7R1E103KT- 10nF

C610 0CK103BH56A "Capacitor,Ceramic,Chip" C1005X7R1E103KT- 10nF

C611 0CK103BH56A "Capacitor,Ceramic,Chip" C1005X7R1E103KT- 10nF

C618 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C620 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C621 0CK475CC94A "Capacitor,Ceramic,Chip" C1608Y5V0J475ZT 4.7uF

C622 0CK475CC94A "Capacitor,Ceramic,Chip" C1608Y5V0J475ZT 4.7uF

C623 0CK475CC94A "Capacitor,Ceramic,Chip" C1608Y5V0J475ZT 4.7uF

C625 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C626 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C627 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C628 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C629 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C630 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C631 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C632 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C633 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C634 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C635 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C636 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C637 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C638 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C639 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C640 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C641 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C642 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C644 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C645 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C646 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C647 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C648 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C649 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C650 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C651 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C652 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C653 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C654 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C655 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C656 0CK475CC94A "Capacitor,Ceramic,Chip" C1608Y5V0J475ZT 4.7uF

C657 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C658 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C659 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C660 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C661 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C663 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C664 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C665 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C667 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C668 0CK475CC94A "Capacitor,Ceramic,Chip" C1608Y5V0J475ZT 4.7uF

C669 0CK475CC94A "Capacitor,Ceramic,Chip" C1608Y5V0J475ZT 4.7uF

C670 0CK475CC94A "Capacitor,Ceramic,Chip" C1608Y5V0J475ZT 4.7uF

C671 0CK103BH56A "Capacitor,Ceramic,Chip" C1005X7R1E103KT- 10nF

C672 0CK103BH56A "Capacitor,Ceramic,Chip" C1005X7R1E103KT- 10nF

C673 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C677 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C678 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C679 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

LOC. NO. PART NO. DESCRIPTION / SPECIFICATION LOC. NO. PART NO. DESCRIPTION / SPECIFICATION

Page 25

- 26 -

C680 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C681 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C682 EAE33970001 "Capacitor,Ceramic,Chip" CS1005X5R105K6R3NR 1uF

C683 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C684 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C685 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C686 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C687 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C688 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C689 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C692 0CK103BH56A "Capacitor,Ceramic,Chip" C1005X7R1E103KT- 10nF

C693 0CK103BH56A "Capacitor,Ceramic,Chip" C1005X7R1E103KT- 10nF

C698 0CK105CD56A "Capacitor,Ceramic,Chip" C1608X7R1A105KT 1uF 10

C699 0CK103BH56A "Capacitor,Ceramic,Chip" C1005X7R1E103KT- 10nF

C7022 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C704 0CC270BK61A "Capacitor,Ceramic,Chip" C1005C0G1H270MT 27pF 5

C705 0CC270BK61A "Capacitor,Ceramic,Chip" C1005C0G1H270MT 27pF 5

C706 0CC270BK61A "Capacitor,Ceramic,Chip" C1005C0G1H270MT 27pF 5

C707 0CC270BK61A "Capacitor,Ceramic,Chip" C1005C0G1H270MT 27pF 5

C708 0CC270BK61A "Capacitor,Ceramic,Chip" C1005C0G1H270MT 27pF 5

C709 0CC270BK61A "Capacitor,Ceramic,Chip" C1005C0G1H270MT 27pF 5

C710 0CC270BK61A "Capacitor,Ceramic,Chip" C1005C0G1H270MT 27pF 5

C711 0CC270BK61A "Capacitor,Ceramic,Chip" C1005C0G1H270MT 27pF 5

C712 0CC270BK61A "Capacitor,Ceramic,Chip" C1005C0G1H270MT 27pF 5

C713 0CC270BK61A "Capacitor,Ceramic,Chip" C1005C0G1H270MT 27pF 5

C714 0CC270BK61A "Capacitor,Ceramic,Chip" C1005C0G1H270MT 27pF 5

C715 0CC270BK61A "Capacitor,Ceramic,Chip" C1005C0G1H270MT 27pF 5

C719 0CH5220K618 "Capacitor,Ceramic,Chip" 0402N220M500LT 22pF 5%

C720 0CH5220K618 "Capacitor,Ceramic,Chip" 0402N220M500LT 22pF 5%

C721 0CC150BK4AA "Capacitor,Ceramic,Chip" C1005C0G1H150JT 15pF 5

C725 0CC150BK4AA "Capacitor,Ceramic,Chip" C1005C0G1H150JT 15pF 5

C726 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C728 0CK101BK4EA "Capacitor,Ceramic,Chip" C1005C0G1H101JT 100pF

C729 0CK101BK4EA "Capacitor,Ceramic,Chip" C1005C0G1H101JT 100pF

C732 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C736 0CK105DH56A "Capacitor,Ceramic,Chip" C2012X7R105KFT 1uF 10%

C737 0CK105DH56A "Capacitor,Ceramic,Chip" C2012X7R105KFT 1uF 10%

C738 0CK105DH56A "Capacitor,Ceramic,Chip" C2012X7R105KFT 1uF 10%

C739 0CK105DH56A "Capacitor,Ceramic,Chip" C2012X7R105KFT 1uF 10%

C743 0CK103CK56A "Capacitor,Ceramic,Chip" 0603B103K500CT 10nF 10

C800 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C801 0CK103BH56A "Capacitor,Ceramic,Chip" C1005X7R1E103KT- 10nF

C802 0CC270BK61A "Capacitor,Ceramic,Chip" C1005C0G1H270MT 27pF 5

C803 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C804 0CC270BK61A "Capacitor,Ceramic,Chip" C1005C0G1H270MT 27pF 5

C806 0CK103BH56A "Capacitor,Ceramic,Chip" C1005X7R1E103KT- 10nF

C808 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C810 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C811 0CK103BH56A "Capacitor,Ceramic,Chip" C1005X7R1E103KT- 10nF

C815 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C817 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C818 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C820 0CC100BKF1A "Capacitor,Ceramic,Chip" 0402N100J500LT 10pF 5%

C821 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C822 0CK103BH56A "Capacitor,Ceramic,Chip" C1005X7R1E103KT- 10nF

C823 0CK475CC94A "Capacitor,Ceramic,Chip" C1608Y5V0J475ZT 4.7uF

C825 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C827 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C830 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C832 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C833 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C834 0CK103BH56A "Capacitor,Ceramic,Chip" C1005X7R1E103KT- 10nF

C835 0CK475CC94A "Capacitor,Ceramic,Chip" C1608Y5V0J475ZT 4.7uF

C838 EAE33970001 "Capacitor,Ceramic,Chip" CS1005X5R105K6R3NR 1uF

C840 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C842 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C843 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C844 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C852 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C853 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C855 0CN475FH67A "Capacitor,Ceramic,Chip" TMK325BJ475MN-T 4.7uF

C856 0CK223BF5CA "Capacitor,Ceramic,Chip" 0402B223K160CT 22nF 10

C857 0CC561CK41A "Capacitor,Ceramic,Chip" C1608C0G1H561JT 560pF

C858 0CK153CK51A "Capacitor,Ceramic,Chip" 0603B153K500CT 15nF 10

C859 0CK476FD67A "Capacitor,Ceramic,Chip" LMK325BJ476MM-T 47uF 2

C861 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C864 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C866 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C871 0CK475DD57A "Capacitor,Ceramic,Chip" C2012X5R1A475KT 4.7uF

C872 0CK103BH56A "Capacitor,Ceramic,Chip" C1005X7R1E103KT- 10nF

C881 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C882 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C883 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C884 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C885 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C886 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C887 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C888 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C889 0CC100BKF1A "Capacitor,Ceramic,Chip" 0402N100J500LT 10pF 5%

C890 0CC100BKF1A "Capacitor,Ceramic,Chip" 0402N100J500LT 10pF 5%

C891 0CC100BKF1A "Capacitor,Ceramic,Chip" 0402N100J500LT 10pF 5%

C892 0CC100BKF1A "Capacitor,Ceramic,Chip" 0402N100J500LT 10pF 5%

C893 0CC100BKF1A "Capacitor,Ceramic,Chip" 0402N100J500LT 10pF 5%

C894 0CC100BKF1A "Capacitor,Ceramic,Chip" 0402N100J500LT 10pF 5%

C895 0CC100BKF1A "Capacitor,Ceramic,Chip" 0402N100J500LT 10pF 5%

C896 0CC100BKF1A "Capacitor,Ceramic,Chip" 0402N100J500LT 10pF 5%

C897 0CC100BKF1A "Capacitor,Ceramic,Chip" 0402N100J500LT 10pF 5%

C898 0CC100BKF1A "Capacitor,Ceramic,Chip" 0402N100J500LT 10pF 5%

C899 0CC100BKF1A "Capacitor,Ceramic,Chip" 0402N100J500LT 10pF 5%

C9022 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C905 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

C912 0CK104BF56A "Capacitor,Ceramic,Chip" C1005X7R104KET 100nF 1

D400 0DD184009AA Diode Assembly KDS184 KDS184 TP KEC -

D403 0DD184009AA Diode Assembly KDS184 KDS184 TP KEC -

D404 0DD184009AA Diode Assembly KDS184 KDS184 TP KEC -

D600 0DD184009AA Diode Assembly KDS184 KDS184 TP KEC -

D602 0DD184009AA Diode Assembly KDS184 KDS184 TP KEC -

LOC. NO. PART NO. DESCRIPTION / SPECIFICATION LOC. NO. PART NO. DESCRIPTION / SPECIFICATION

DIODEs

Page 26

- 27 -

D603 0DSON00138A "Diode,Schottky" MMBD301LT1G 600MV 30V

D801 0DR340009AA "Diode,Schottky" MBRS340 525MV 40V 4A 0

D800 0DS226009AA "Diode,Switching" KDS226 1.2V 85V 300MA

D401 0DRSE00038A "Diode,TVS" SDC15 1.3V 14.3VTO16.4

D402 0DRSE00038A "Diode,TVS" SDC15 1.3V 14.3VTO16.4

ZD732 EAH33945901 "Diode,TVS" CDS3C30GTH 30V 50V 120

ZD733 EAH33945901 "Diode,TVS" CDS3C30GTH 30V 50V 120

ZD101 0DZ560009DA "Diode,Zener" UDZS5.6B 5.6V 5.49TO5.

ZD102 0DZ560009DA "Diode,Zener" UDZS5.6B 5.6V 5.49TO5.

ZD600 0DZDI00078A "Diode,Zener" BZT52C3V3S-F 3.3V 3.1T

ZD700 0DZRM00178A "Diode,Zener" UDZS5.1B 5.1V 4.98TO5.

ZD701 0DZRM00178A "Diode,Zener" UDZS5.1B 5.1V 4.98TO5.

ZD702 0DZRM00178A "Diode,Zener" UDZS5.1B 5.1V 4.98TO5.

ZD703 0DZRM00178A "Diode,Zener" UDZS5.1B 5.1V 4.98TO5.

ZD704 0DZRM00178A "Diode,Zener" UDZS5.1B 5.1V 4.98TO5.

ZD705 0DZRM00178A "Diode,Zener" UDZS5.1B 5.1V 4.98TO5.

ZD706 0DZRM00178A "Diode,Zener" UDZS5.1B 5.1V 4.98TO5.

ZD707 0DZRM00178A "Diode,Zener" UDZS5.1B 5.1V 4.98TO5.

ZD708 0DZRM00178A "Diode,Zener" UDZS5.1B 5.1V 4.98TO5.

ZD709 0DZRM00178A "Diode,Zener" UDZS5.1B 5.1V 4.98TO5.

ZD710 0DZRM00178A "Diode,Zener" UDZS5.1B 5.1V 4.98TO5.

ZD711 0DZRM00178A "Diode,Zener" UDZS5.1B 5.1V 4.98TO5.

ZD712 0DZRM00178A "Diode,Zener" UDZS5.1B 5.1V 4.98TO5.

ZD713 0DZRM00178A "Diode,Zener" UDZS5.1B 5.1V 4.98TO5.

ZD714 0DZRM00178A "Diode,Zener" UDZS5.1B 5.1V 4.98TO5.

ZD715 0DZRM00178A "Diode,Zener" UDZS5.1B 5.1V 4.98TO5.

ZD717 0DZRM00178A "Diode,Zener" UDZS5.1B 5.1V 4.98TO5.

ZD719 0DZRM00218A "Diode,Zener" UDZS8.2B 8.2V 8.02TO8.

ZD720 0DZRM00218A "Diode,Zener" UDZS8.2B 8.2V 8.02TO8.

ZD721 0DZRM00218A "Diode,Zener" UDZS8.2B 8.2V 8.02TO8.

ZD722 0DZRM00218A "Diode,Zener" UDZS8.2B 8.2V 8.02TO8.

ZD723 0DZRM00218A "Diode,Zener" UDZS8.2B 8.2V 8.02TO8.

ZD724 0DZRM00178A "Diode,Zener" UDZS5.1B 5.1V 4.98TO5.

ZD725 0DZRM00178A "Diode,Zener" UDZS5.1B 5.1V 4.98TO5.

ZD726 0DZRM00178A "Diode,Zener" UDZS5.1B 5.1V 4.98TO5.

ZD729 0DZRM00178A "Diode,Zener" UDZS5.1B 5.1V 4.98TO5.

ZD730 0DZRM00178A "Diode,Zener" UDZS5.1B 5.1V 4.98TO5.

ZD731 0DZRM00178A "Diode,Zener" UDZS5.1B 5.1V 4.98TO5.

ZD734 0DZRM00178A "Diode,Zener" UDZS5.1B 5.1V 4.98TO5.

ZD735 0DZRM00178A "Diode,Zener" UDZS5.1B 5.1V 4.98TO5.

ZD736 0DZRM00178A "Diode,Zener" UDZS5.1B 5.1V 4.98TO5.

ZD737 0DZRM00178A "Diode,Zener" UDZS5.1B 5.1V 4.98TO5.

ZD738 0DZRM00178A "Diode,Zener" UDZS5.1B 5.1V 4.98TO5.

ZD739 0DZRM00178A "Diode,Zener" UDZS5.1B 5.1V 4.98TO5.

ZD746 0DZRM00218A "Diode,Zener" UDZS8.2B 8.2V 8.02TO8.

ZD747 0DZRM00218A "Diode,Zener" UDZS8.2B 8.2V 8.02TO8.

ZD748 0DZRM00218A "Diode,Zener" UDZS8.2B 8.2V 8.02TO8.

ZD749 0DZRM00178A "Diode,Zener" UDZS5.1B 5.1V 4.98TO5.

ZD750 0DZRM00178A "Diode,Zener" UDZS5.1B 5.1V 4.98TO5.

ZD751 0DZRM00178A "Diode,Zener" UDZS5.1B 5.1V 4.98TO5.

ZD752 0DZRM00178A "Diode,Zener" UDZS5.1B 5.1V 4.98TO5.

ZD753 0DZRM00178A "Diode,Zener" UDZS5.1B 5.1V 4.98TO5.

ZD754 0DZRM00178A "Diode,Zener" UDZS5.1B 5.1V 4.98TO5.

IC502 0IPRPCI013A "IC,A/D Converter" CS5340-CZZR 1.7TO5.25V

IC200 EAN38015402 "IC,Analog Switch" BD2051AFJ 2.7TO5.5V 10

IC600 EAN39310001 "IC,Analog Switch" PI3HDMI341ART 3.135 TO

IC501 EAN32404601 "IC,Audio Amplifier" NTP3000 7TO30V 5.5V 0.

IC500 0IPRP00665A "IC,Bus Controller" TEA6420D 8TO10.2V 8mA

IC401 0ISTLPH026A "IC,CMOS" 74LVC14APW 1.2TO3.6V 0

IC408 0ISTL00024A "IC,CMOS" MC14053BDR2G 3TO18V 0.

IC805 EAN31513601 "IC,DC,DC Converter" SC4519STRT 2.6V to 16V

IC300 0IMMRHY057E "IC,DDR SDRAM" HY5DU561622ETP-D43 256

IC302 0IMMRHY057E "IC,DDR SDRAM" HY5DU561622ETP-D43 256

IC102 0IMMRCS012D "IC,EEPROM" CAT24C08WI-GT3-26753 8

IC403 0IMCRAL021A "IC,EEPROM" AT24C512W-10SU-2.7 512

IC406 0IMCRAL006A "IC,EEPROM" AT24C16AN-10SU-2.7 16K

IC601 0IMMRAL014D "IC,EEPROM" AT24C02BN-SH-T 2KBIT 2

IC603 0IMMRAL014D "IC,EEPROM" AT24C02BN-SH-T 2KBIT 2

IC701 0IMMRAL014D "IC,EEPROM" AT24C02BN-SH-T 2KBIT 2

IC808 0IPRPFA015B "IC,Image Filter" "FMS6400CS1X,LF 4.75VTO"

IC404 0IPMGA0010A "IC,LDO Voltage Regulator" AZ1117H-3.3 4.75TO10V

IC802 0IPMGA0010A "IC,LDO Voltage Regulator" AZ1117H-3.3 4.75TO10V

IC803 0IPMGS1006B "IC,LDO Voltage Regulator" SC1566I5M25TRT 2.2V~5.

IC804 0IPMGA0010A "IC,LDO Voltage Regulator" AZ1117H-3.3 4.75TO10V

IC807 0IPMG00049A "IC,LDO Voltage Regulator" AZ1117H-1.8TR/E1[H13A]

IC901 0IPMGKE032A "IC,LDO Voltage Regulator" KIA78R09F 10TO25V 9V 8

IC504 0ISTL00029A "IC,OP Amplifier" MC33078DR2G +-5TO+-18V

IC402 EAN39038801 "IC,Tx/Rx" ADM3232EARNZ 3VTO5.5V

IC100 0IPRP00702C "IC,Video Processors" BCM3552KFEB5G 1.14VTO1

IC400 0IKE702900G "IC,Voltage Detector" KIA7029AF -0.3TO15V 2.

IC405 0IKE702900G "IC,Voltage Detector" KIA7029AF -0.3TO15V 2.