Page 1

PLASMA TV

SERVICE MANUAL

CAUTION

BEFORE SERVICING THE CHASSIS,

READ THE SAFETY PRECAUTIONS IN THIS MANUAL.

CHASSIS : PP78D

MODEL : 32PC5DVC 32PC5DVC-UG

CANADA : http//biz.lgservice.com

USA : http//www.lgservice.com

: http//biz.lgservice.com

Internal Use Only

Page 2

- 2 -

Copyright©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

SAFETY PRECAUTIONS

Many electrical and mechanical parts in this chassis have special safety-related characteristics. These parts are identified by in the

Schematic Diagram and Replacement Parts List.

It is essential that these special safety parts should be replaced with the same components as recommended in this manual to prevent

X-RADIATION, Shock, Fire, or other Hazards.

Do not modify the original design without permission of manufacturer.

General Guidance

An lsolation Transformer should always be used during the

servicing of a receiver whose chassis is not isolated from the AC

power line. Use a transformer of adequate power rating as this

protects the technician from accidents resulting in personal injury

from electrical shocks.

It will also protect the receiver and it's components from being

damaged by accidental shorts of the circuitary that may be

inadvertently introduced during the service operation.

If any fuse (or Fusible Resistor) in this monitor is blown, replace it

with the same specified type.

When replacing a high wattage resistor (Oxide Metal Film Resistor,

over 1W), keep the resistor 10mm away from PCB.

Keep wires away from high voltage or high temperature parts.

Leakage Current Cold Check(Antenna Cold Check)

With the instrument AC plug removed from AC source, connect an

electrical jumper across the two AC plug prongs. Place the AC

switch in the on positioin, connect one lead of ohm-meter to the AC

plug prongs tied together and touch other ohm-meter lead in turn to

each exposed metallic parts such as antenna terminals, phone

jacks, etc.

If the exposed metallic part has a return path to the chassis, the

measured resistance should be between 1MΩ and 5.2MΩ.

When the exposed metal has no return path to the chassis the

reading must be infinite.

An other abnormality exists that must be corrected before the

receiver is returned to the customer.

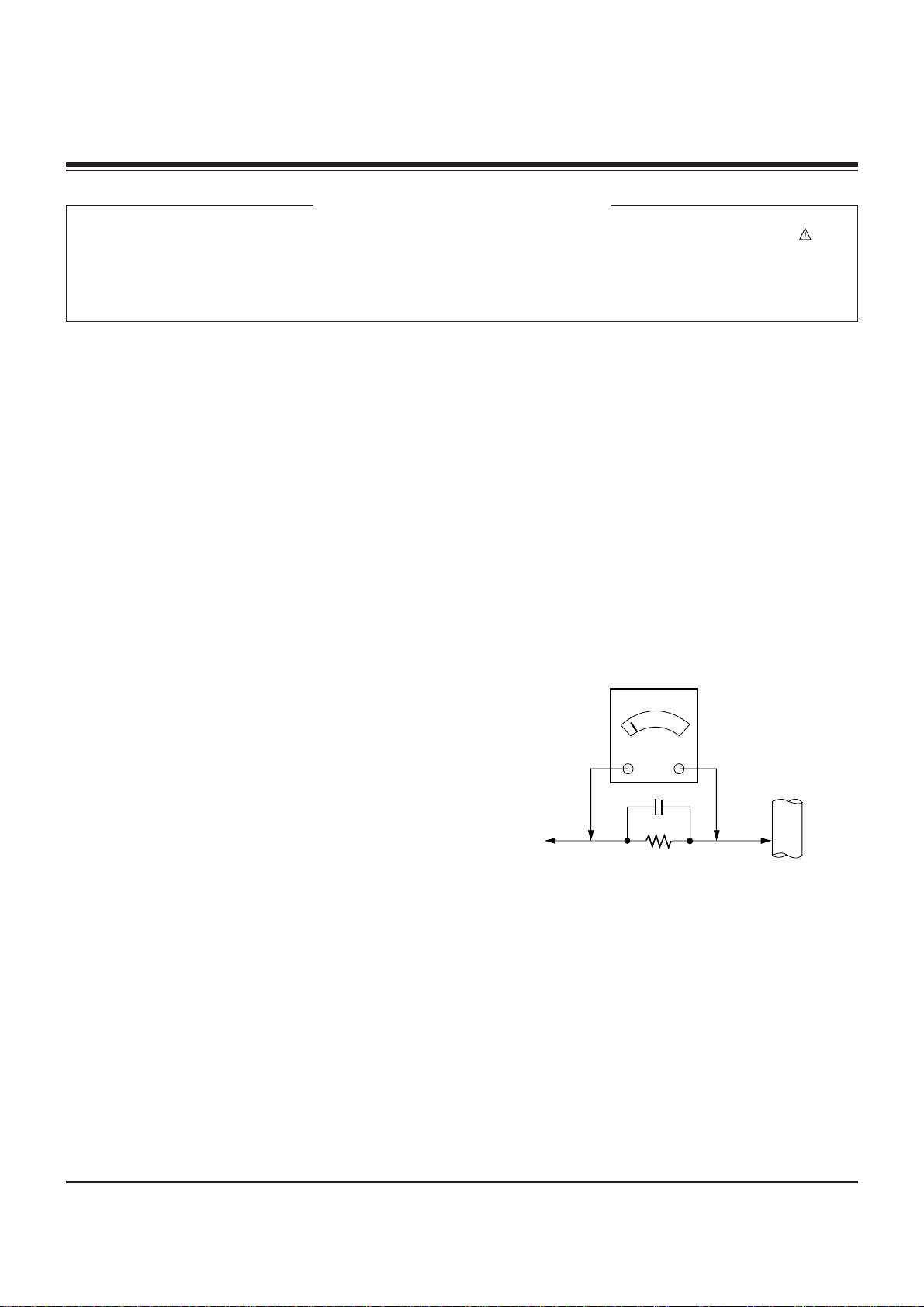

Leakage Current Hot Check (See below Figure)

Plug the AC cord directly into the AC outlet.

Do not use a line Isolation Transformer during this check.

Connect 1.5K/10watt resistor in parallel with a 0.15uF capacitor

between a known good earth ground (Water Pipe, Conduit, etc.)

and the exposed metallic parts.

Measure the AC voltage across the resistor using AC voltmeter

with 1000 ohms/volt or more sensitivity.

Reverse plug the AC cord into the AC outlet and repeat AC voltage

measurements for each esposed metallic part. Any voltage

measured must not exceed 0.75 volt RMS which is corresponds to

0.5mA.

In case any measurement is out of the limits sepcified, there is

possibility of shock hazard and the set must be checked and

repaired before it is returned to the customer.

Leakage Current Hot Check circuit

CANADA: LG Electronics Canada, Inc. 550 Matheson

Boulevard East Mississauga, Ontario L4Z 4G3

USA : LG Customer Interactive Center

P.O.Box 240007, 201 James Record Road Huntsville,

AL 35824

Digital TV Hotline 1-800-243-0000

1.5 Kohm/10W

To Instrument's

exposed

METALLIC PARTS

Good Earth Ground

such as WATER PIPE,

CONDUIT etc.

AC Volt-meter

IMPORTANT SAFETY NOTICE

0.15uF

Page 3

- 3 -

Copyright©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

SPECIFICATIONS.................................................................4

ADJUSTMENT INSTRUCTIONS ..........................................5

BLOCK DIAGRAM...............................................................10

EXPLODED VIEW...............................................................11

EXPLODED VIEW PARTS LIST.........................................12

SCHEMATIC DIAGRAM..........................................................

PRINTED CIRCUIT BOARDS.................................................

TABLE OF CONTENTS

Page 4

- 4 -

Copyright©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

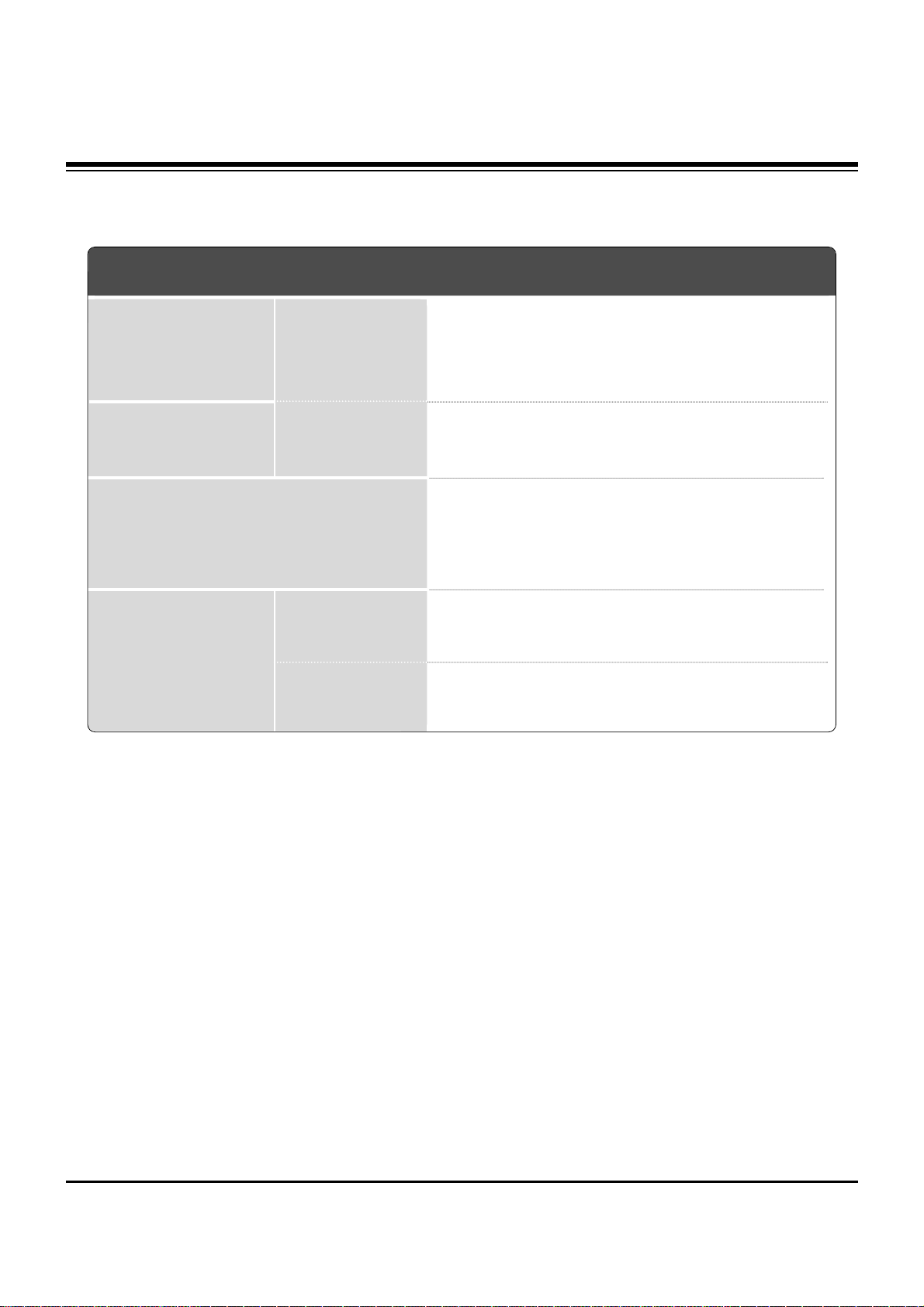

The specifications shown above may be changed without prior notice for quality improvement.

32PC5DVC

(32PC5DVC-UG)

MODELS

32.3 x 23.8 x 10.1 inches

819.9 x 603.8 x 255.4 mm

32.3 x 21.8 x 3.1 inches

819.9 x 554.2 x 78.1 mm

36.8 pounds / 16.7 kg

34.8 pounds / 15.8 kg

AC100-240V ~ 50/60Hz

NTSC-M, ATSC, 64 & 256 QAM

VHF 2-13, UHF 14-69, CATV 1-135, DTV 2-69, CADTV 1-135

75 ohm

32 ~ 104°F (0 ~ 40°C)

Less than 80%

-4 ~ 140°F (-20 ~ 60°C)

Less than 85%

Dimensions

(Width x Height x Depth)

Weight

Power requirement

Television System

Program Coverage

External Antenna

Impedance

Environment condition

Including stand

Excluding stand

including stand

excluding stand

Operating

Temperature

Operating Humidity

Storage Temperature

Storage Humidity

SPECIFICATIONS

Page 5

- 5 -

Copyright©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

ADJUSTMENT INSTRUCTIONS

1. Application Range

This spec sheet is applied to all of the PP78D chassis .

2. Specification

(1) Because this is not a hot chassis, it is not necessary to use

an isolation transformer. However, the use of isolation

transformer will help to protect test instruments.

(2) Adjustment must be done in the correct sequence.

(3) The adjustment must be performed at 25±5°C temperature

and 65±10% relative humidity if there is no specified

designation.

(4) The input voltage of the receiver must be kept between

100~220V, 50/60Hz.

(5) Before adjustment, execute Heat-Run for 30 minutes at RF

no signal.

3. ADC Calibration

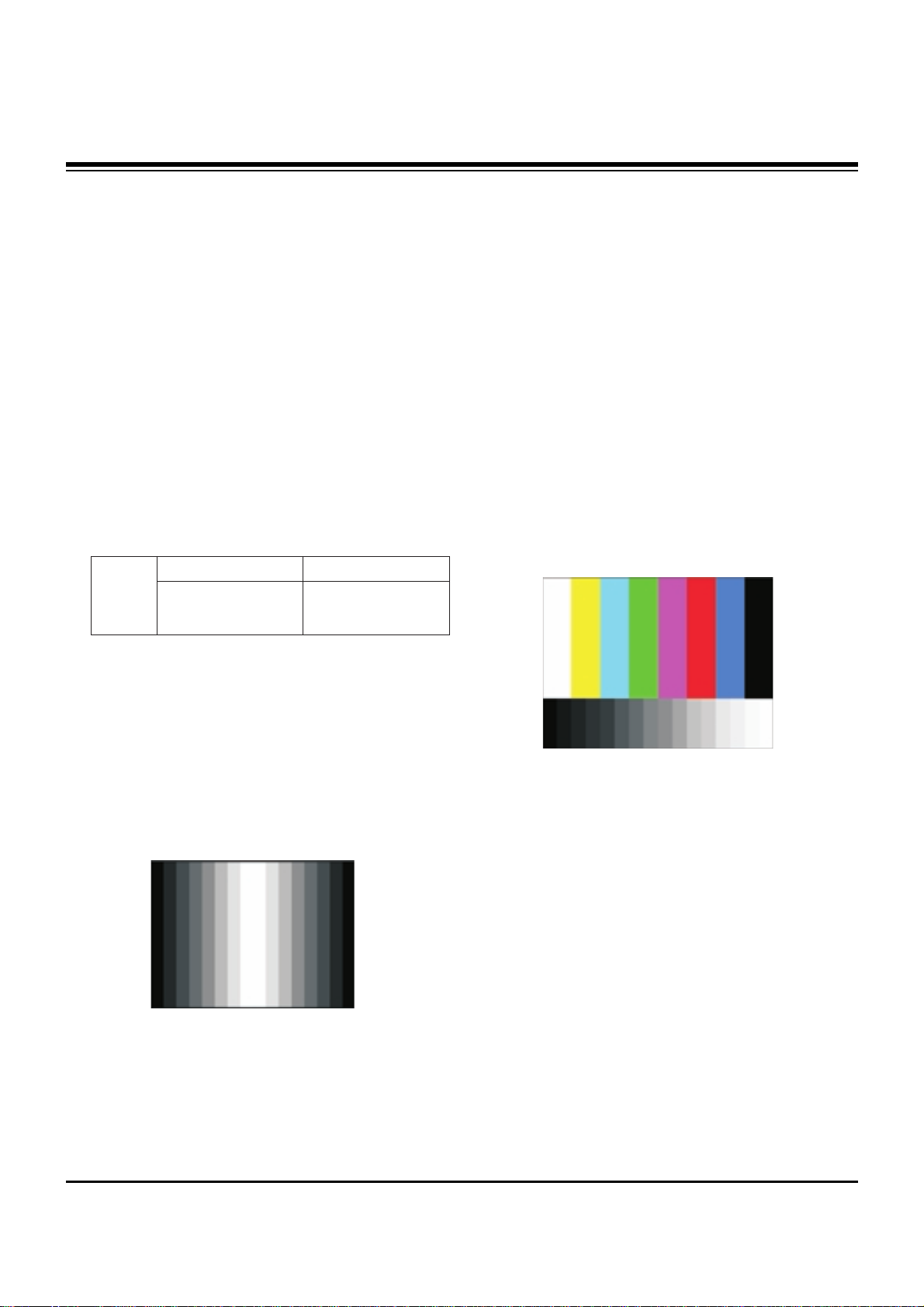

3-1. PC input ADC

(1) Auto RGB Gain/Offset Adjustment

1) Convert to PC in Input-source

2) Signal equipment displays

Output Voltage : 700 mVp-p

Impress Resolution XGA (800 x 600 @ 60Hz)

Model : 46 in Pattern Generator

Pattern : 29 in Pattern Generator (MSPG-925 SERISE)

[gray pattern that left & right is black and center is white

signal (Refer below picture)]

3) Adjust by commanding AUTO_COLOR_ADJUST(0xF1)

0x00 0x02 instruction.

(2) Confirmation

1) We confirm whether “0xB6(RGB)” address of EEPROM

“0xA2” is “0xAA” or not.

2) If “0xB6(RGB)” address of EEPROM “0xB2” isn’t “0xAA”,

we adjust once more

3) We can confirm the ADC values from

“0xB0~0xB5(RGB)” addresses in a page “0xA2”

[ Manual ADC process using Service Remocon. After enter

Service Mode by pushing “ADJ” key, execute “ADC Adjust”

by pushing “

G” key at “Adjust-RGB”.

3-2. COMPONENT input ADC

(1) Component Gain/Offset Adjustment

1) Convert to Component in Input-source

2) Signal equipment displays

Impress Resolution 720P

MODEL : 216 in Pattern Generator(720P Mode)

PATTERN : 08 in Pattern Generator(MSPG-925 SERISE)

3) Adjust by commanding AUTO_COLOR_ADJUST(0xF1)

0x00 0x02 instruction

(2) Confirmation

1) We confirm whether “0xC8(720P)” address of EEPROM

“0xA2” is “0xAA” or not.

2) If “0xC8(720P)” address of EEPROM “0xA2” isn’t

“0xAA”, we adjust once more

3) We can confirm the ADC values from “0xB9~

0xBE(480i)/0xC2~(1080i)” addresses in a page “0xA2”

MSPG-

925FA

Component

Model: 216

(720p@60Hz)

Model: 46

(800x600@60Hz)

RGB

Adjustment pattern (PC)

Adjustment pattern (COMPONENT)

Page 6

- 6 -

3-3. Function Check

(1) Check display and sound

1) Check Input and Signal items. (cf. work instructions)

1. TV

2. AV (CVBS/ S-Video)

3. COMPONENT (480i)

4. RGB (PC : 1024 x 768 @ 60hz)

5. HDMI

6. PC Audio In and H/P Out

* Display and Sound check is executed by Remote

controller.

4. EDID

[

Caution

(1) Use the proper signal cable for EDID Download

- Analog EDID : Pin3 exists

- Digital EDID : Pin3 exists

(2) Never connect HDMI & DVI-D & DVI-A Cable at the same

time.

(3) Use the proper cables below for EDID Writing

4-1. EDID Data

(1) 32PC5DV ANALOG(128 Bytes )

O BLOCK1 (128BYTE)

(2) 32PC5DV HDMI(256 Bytes)

O BLOCK1 (128BYTE)

O BLOCK2 (128BYTE)

(2) 32PC5DVC HDMI(256 Bytes)

O BLOCK1 (128BYTE)

O BLOCK2 (128BYTE)

Copyright©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

ADJUSTMENT INSTRUCTIONS

Caution: Each PCB assembly must be checked by check JIG set.

(Because power PCB Assembly damages to PDP Module,

especially be careful)

Item

Manufacturer ID

Version

Revision

Condition

GSM

Digital : 1

Digital : 3

Hex Data

1E6D

01

03

For RGB EDID For HDMI EDID

Page 7

- 7 -

ⓐ Product ID

ⓑ Serial No

=> Controlled on production line

ⓒ Month, Year

=> Controlled on production line:

ex) Monthly: ‘11’ -> ‘0B’

Year: ‘2006’ -> ‘10’

ⓓ Model Name/Monitor Name

ⓔ Checksum(7EH)

=> Changeable by total EDID data

4-2. Required Test Equipment

(1) Adjusting PC with S/W for writing EDID Data.(S/W : EDID

TESTER Ver.2.5)

(2) A Jig for EDID Download

(3) Cable : Serial(9Pin or USB) to D-sub 15Pin cable, D-sub

15Pin cable, DVI to HDMI cable.

4-3. Preparation for Adjustment

(1) As above (Fig. 1), Connect the Set, EDID Download Jig,,

PC & Cable

(2) Turn on the PC & EDID Download Jig. And Execute the

S/W : EDID TESTER Ver.2.5

(3) Set up the S/W option

Repeat Number : 5

Device Address : A0

PageByte : 8

(4) Power on the Set

4-4. Sequence of Adjustment

DDC data of Analog-RGB

(1) Init the data

(2) Load the EDID data.(Open File).

(3) Set the S/W as below.

Copyright©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

ADJUSTMENT INSTRUCTIONS

TV set

or

Main B/D

(Fig. 1) Connection Diagram of DDC Download

Open FileOpen File

[Analog – RGB :

PP78D_RGB.ANA ]

[Digital – HDMI :

PP78D_HDMI.DVI ]

Page 8

- 8 -

(4) Push the “Write Data & Verify” button. And confirm “Yes”.

(5) If the writing is finished, you will see the “ OK” message.

5. HDCP(High-Bandwidth Digital Contents Protection)

(1) Connect D-sub Signal Cable to D-Sub Jack

(2) Input HDCP key with HDCP-key- in-program

(3) HDCP Key value is stored on EEPROM(AT24C512) which

is 80~A1 addresses of 0xA0~0xA2 page

(4) AC off/ on and on HDCP button of MSPG925 and confirm

whether picture is displayed or not of using MSPG925

(5) HDCP Key value is different among the sets

6. Adjustment of White Balance

6-1. Purpose and Principle for Adjustment

of the Color Temperature

(1) Purpose: Adjust the color temperature to reduce the

deviation of the module color temperature.

(2) Principle: To adjust the white balance without the

saturation, Fix the one of R/G/B gain to 80 and decrease

the others.

6-2. Adjustment Mode

Two modes of Cool and Warm

(Medium data is automatically calibrated by the cool data)

6-3. Required Equipment

(1) Remote controller for adjustment

(2) Color Analyzer : CA100, CA-100+, CA-210 or same

product

- PLASMA TV(ch : 10)

(3) Auto W/B adjustment instrument(only for Auto adjustment)

6-4. Connecting Diagram of Equipment

for Measuring

(For Automatic Adjustment)

(1) Enter the adjustment mode of the white balance

1) Enter the white balance adjustment mode at the same

time heat-run mode when pushing the power on by

power only key

2) Maintain the white balance adjustment mode with same

condition of Heat-run -> Maintain after AC off/on in

status of Heat-run pattern display

(2) Release the white balance adjustment mode

1) Release the adjust mode after AC off/on or std-by off/on

in status of finishing the Hear-run mode

2) Release the Adjust mode when receiving the aging off

command(F3 00 00) from adjustment equipment

3) Need to transmit the aging off command to TV set after

finishing the adjustment

Copyright©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

ADJUSTMENT INSTRUCTIONS

Page 9

- 9 -

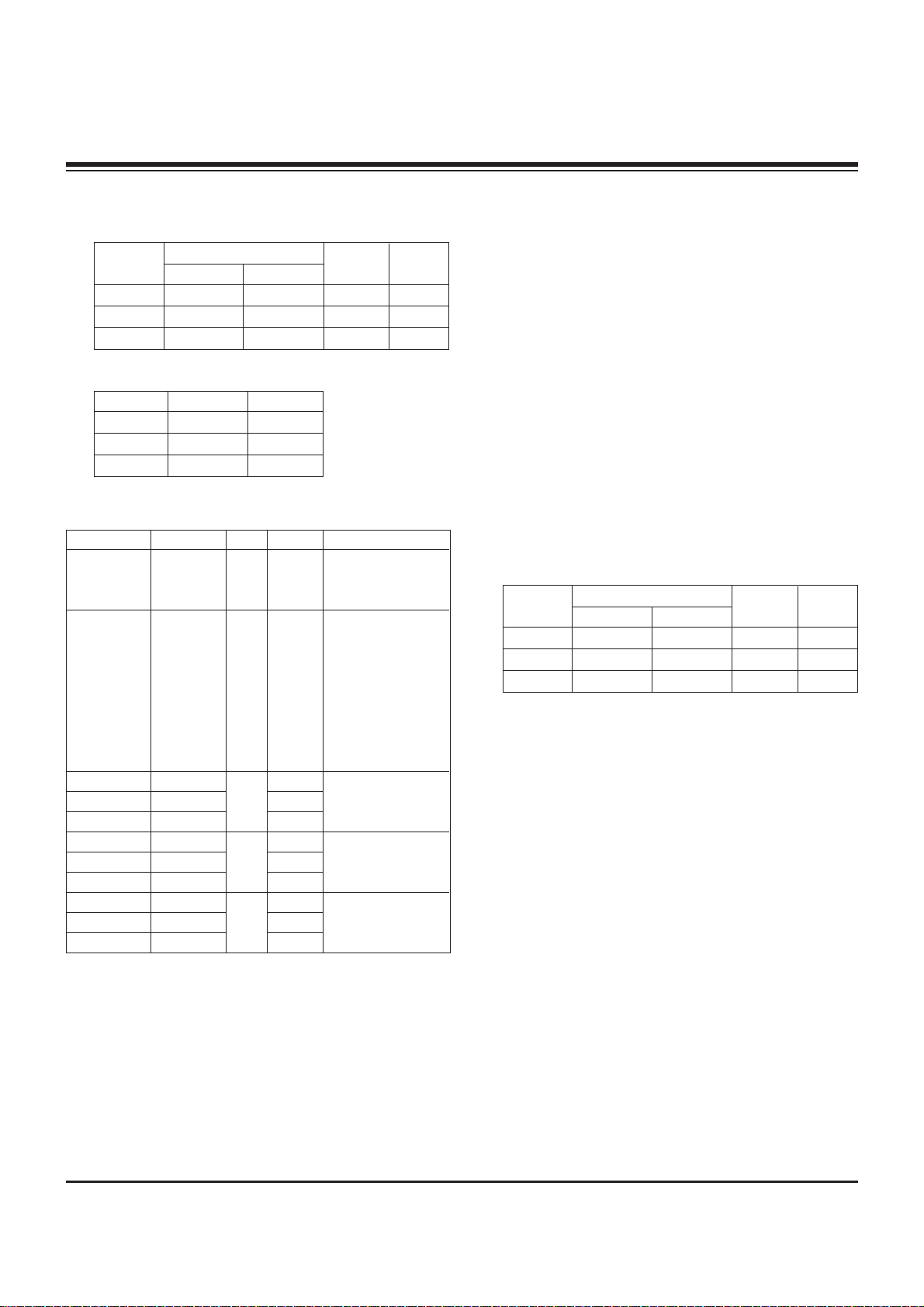

O

Standard color coordinate and temperature when using the

CA-100+ or CA210 equipment

O

Synchronization relation between PSM and CSM

(3) DDC adjustment Command set

[ R/G/B GAIN max value : 80

6-5. Adjustment of White Balance for

Manual Adjustment

(1) Adjustment mode: Two modes of Cool (Dynamic) and

Warm(Mild)

(Medium data is automatically calibrated by the cool data)

(2) Color analyzer(CA110) should be used in the calibrated ch

by CS-1000(PDP : CH10)

(3) Operate the zero-calibration of the CA-110 then stick

sensor to the module when adjusting.

(4) For manual adjustment, it is also possible by the following

sequence

1) Select white pattern of heat-run by pressing “POWER

ON” key on remote control for adjustment then operate

heat run longer than 15 minutes.

(If not executed this step, the condition for W/B will be

differ )

2) Changing to the av mode by remote control.(av mode)

3) Display the internal pattern of the Mstar IC by pushing

the ADJ.

4) Stick sensor to center of the screen and select each

items (Red/Green/Blue Gain and Offset) using

D/E

(CH

+/-) key on R/C.

5) Adjust R/ G/B Gain using

F/G (VOL +/-) key on R/C.

6) Adjust two modes of Cool(Dynamic) and Warm(Mild) as

below figure.

(Fix the one of R/G/B and change the others)

1. Push the one time the in-start key : Cool

2. Push the two more the in-start key : Warm

[ Refer to the below case to know what value is fixed.

[CASE]

First adjust the coordinate much away from the target

value (x, y).

1. x, y > target

Decrease the R, G.

2. x, y < target

1) First decrease the B gain,

2) Decrease the one of the others.

- In case of decreasing the x, decreasing the R : fix G

- In case of decreasing the y , decreasing the G : fix R

3. x > target , y < target

1) First decrease B, so make y a little more than the

target.

2) Adjust x value by decreasing the R

4. x < target , y > target

1) First decrease B, so make x a little more than the

target.

2) Adjust x value by decreasing the G

7) When adjustment is completed, Exit adjustment mode

using EXIT key on R/C

Copyright©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

ADJUSTMENT INSTRUCTIONS

Color Coordinate

XY

0.283±0.003

0.293±0.003

0.329±0.00

3

11,000K

9,300K

6,500K

0.000

0.000

0.003

0.276±0.003

0.285±0.003

0.313±0.00

3

Cool

Medium

Warm

Mode

Temp

3uv

CSM Remark

Cool

Normal

Warm

Dynamic

Standard

Mild

PSM

Adjustment

Aging On/Off

Input select

R GAIN

G GAIN

B GAIN

R GAIN

G GAIN

B GAIN

R GAIN

G GAIN

B GAIN

CMD(HEX)

F3

F4

16

18

1A

16

18

1A

16

18

1A

ADR

00

00

00

01

02

VALUE

255/00

00 - 255

00 - 255

00 - 255

00 - 255

00 - 255

00 - 255

00 - 255

00 - 255

00 - 255

Detail

OO : OFF

01 : ON

FF : WB Ready

0x10 : TV

0x20 : AV1

0x21 : AV2

0x23 : AV3

0x40 : Component1

0x50 : RGB DTV

0x60 : RGB PC

0x90 : HDMI1 DTV

GAIN adjustment

CSM COOL

GAIN adjustment

CSM NORMAL

GAIN adjustment

CSM WARM

Color Coordinate

XY

0.283±0.003

0.293±0.003

0.329±0.00

3

11,000K

9,300K

6,500K

0.000

0.000

0.003

0.276±0.003

0.285±0.003

0.313±0.00

3

Cool

Medium

Warm

Mode

Temp

3uv

Page 10

- 10 -

Copyright©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

BLOCK DIAGRAM

Page 11

- 11 -

LGE Internal Use Only

EXPLODED VIEW

A21

A2

300

570

560

120

301

302

303

304

305

200

240

580

400

520

590

201

202

203

900

* Option

250

204

Many electrical and mechanical parts in this chassis have special safety-related characteristics. These

parts are identified by in the Schematic Diagram and EXPLODED VIEW.

It is essential that these special safety parts should be replaced with the same components as

recommended in this manual to prevent X-RADIATION, Shock, Fire, or other Hazards.

Do not modify the original design without permission of manufacturer.

IMPORTANT SAFETY NOTICE

Page 12

Copyright©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

Page 13

Copyright©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

Page 14

Copyright©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

Page 15

Copyright©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

MAIN(TOP) MAIN(BOTTOM)

PRE-AMP(TOP)

CONTROL(TOP)

CONTROL(BOTTOM)

PRE-AMP(BOTTOM)

Page 16

July, 2008

Printed in KoreaP/NO : MFL41619201

CANADA: LG Electronics Canada, Inc. 550 Matheson

Boulevard East Mississauga, Ontario L4Z 4G3

USA : LG Electronics Alabama, Inc.

P.O.Box 240007, 201 James Record Road Bldg 3

Huntsville, AL 35824

Loading...

Loading...