Lexmark 4227 - Forms Printer B/W Dot-matrix, 4227-300 Service Manual

Edition: January 15, 2007

Lexmark™ Forms Pr inter

• Table of contents

4227-300

• Start diagnostics

• Safety and notices

• Trademarks

•Index

Lexmark and Lexmark with diamond

design are trademarks of Lexmark

International , I nc., register ed in the

United States and/or other countries .

4227-300

Edition: January 15, 2007

The following paragraph does not apply to any country where such provisions are

inconsistent with local law: LEXMARK INTER N ATIONAL, INC. PROVIDES THIS

PUBLICATION “AS IS” WITHOUT WARRANTY OF ANY KIND, EITHER EXPRESS OR

IMPLIED, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. Some states do

not allow disclaimer of express or implied warranties in certain transactions, therefore,

this statement may not apply to you.

This publication could include technical inac curacies or typographical err ors. Changes

are periodically made to the information herein; these changes will be incorporated in

later editions. Improvements or changes in the products or the programs described may

be made at any ti m e.

Comments may be addressed to Lexmark International, Inc., Department D22/035-3,

740 New C ircle Road N .W., Lexington, Kentucky 40550, U.S .A. Lexm ark may use or

distribute any of the information you supply i n any way it believes appropriate without

inc urring any obligation to you.

Lexmark and Lexmark with diamond design are trademarks of Lexmark International,

Inc., registered in the Uni ted States and/or other countries.

Color Jetprinter is a trademark of Lexmark International, Inc.

All other trad emarks are the property of their respective owners.

© 1996, 2006 Lexmark International, Inc.

All rights reserved.

UNITED STATES GOV E RNMENT RIGHTS

This software and any accompanying documentation provided under this agreement are

commercial compu ter software and d ocumentation developed exclusively at private

expense.

12G9625

4227-300

Table of contents

Table of contents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ii

Safety info rmation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-vi

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xi

Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-xi

General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Voltage, ground, and continuity readings . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Voltage readings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Ground checks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Continuity rea dings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Maintenance appr oach . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Using the operator panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

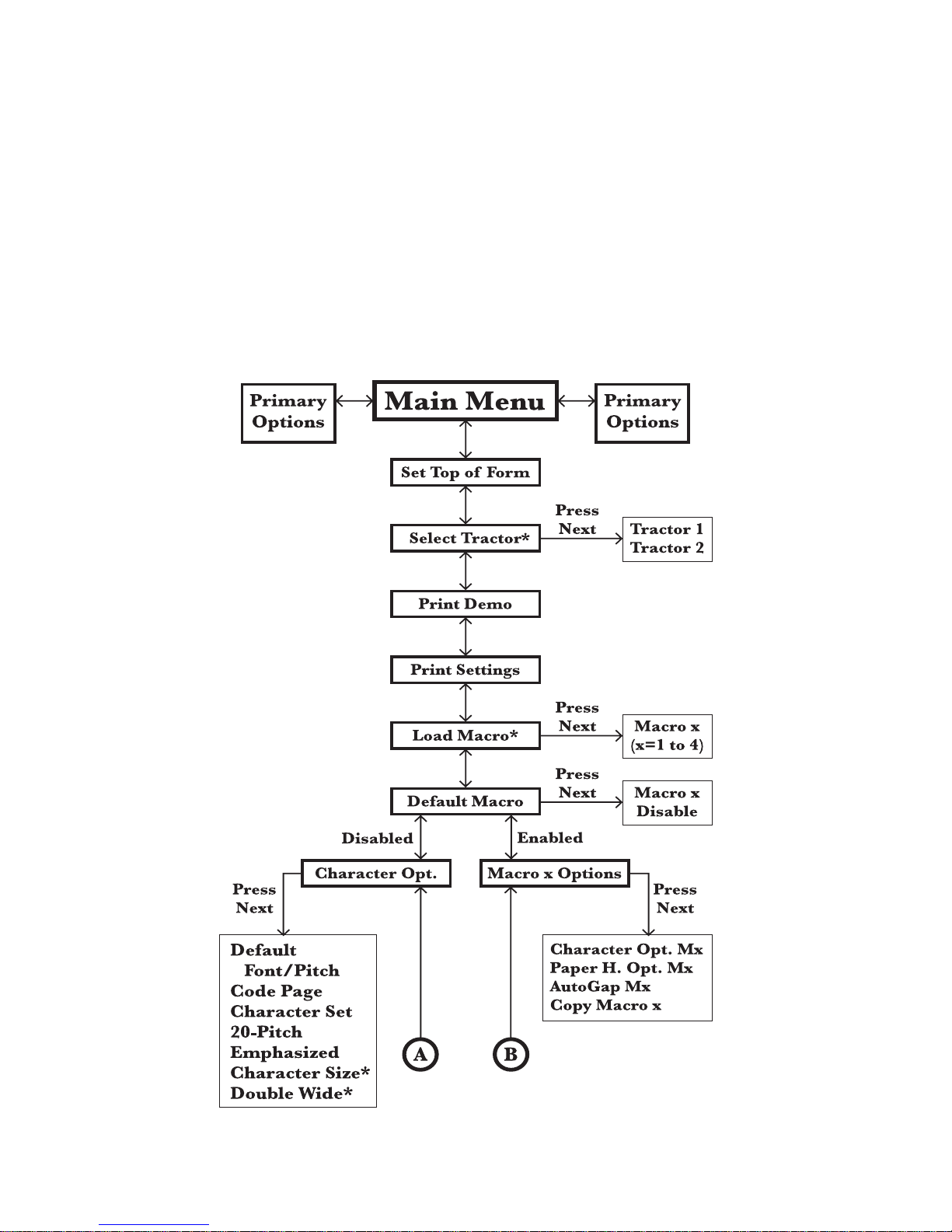

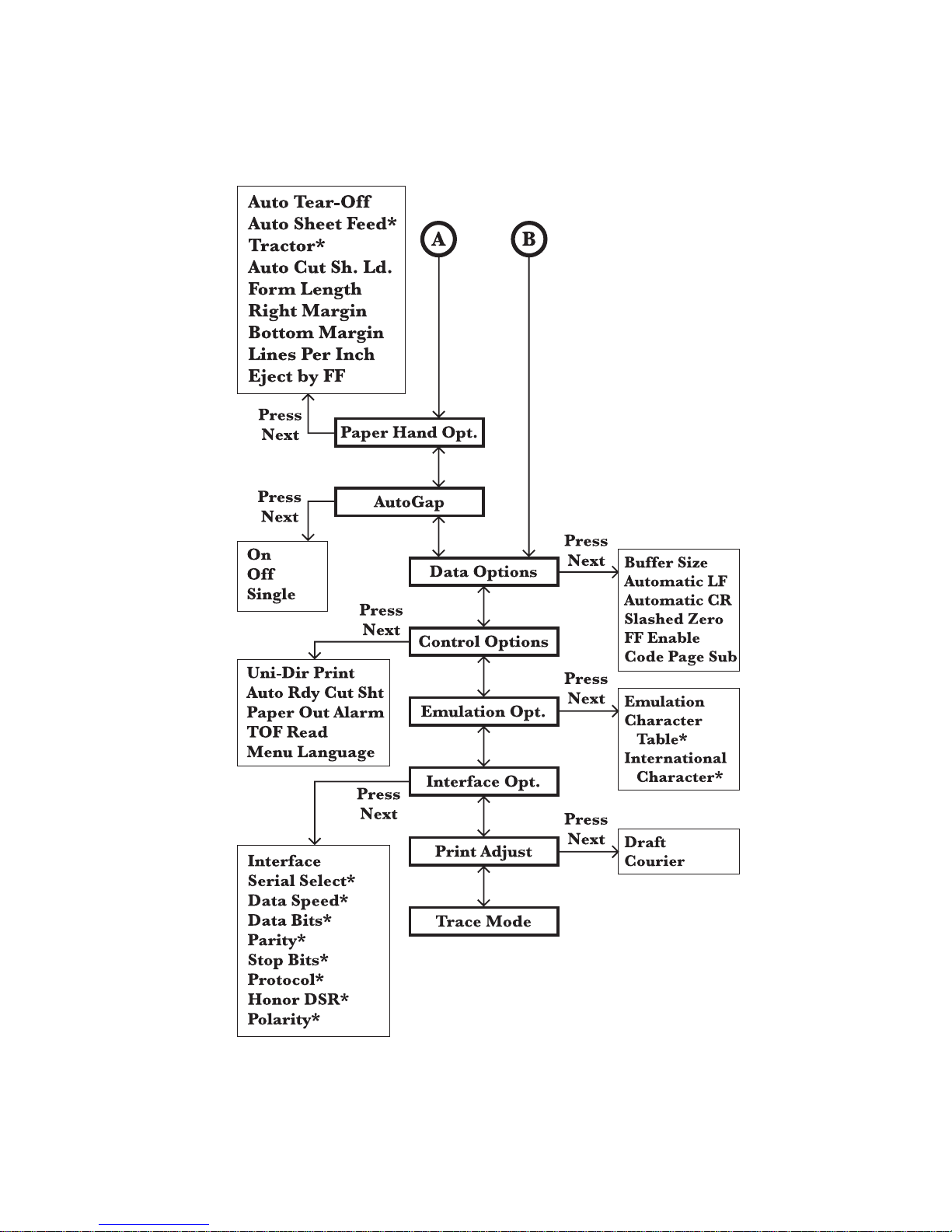

Using the function menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Setting print er f unctions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Overview of function menus. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Buttons. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Lights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

Diagnostic infor ma ti on . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Error indication table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Symptom tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Abnormal Indications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Abnormal print operation problem s . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Auto Sheet Feeder problems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

6XX Error indications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Paper feed problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Operator panel problems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Power Problems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Print quality problems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Ribbon feed problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Service checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Auto Gap service che ck. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Auto Sheet Feeder (ASF) ser vice check . . . . . . . . . . . . . . . . . . . . . 2-13

Auto Sheet Feeder princ iples of operation. . . . . . . . . . . . . . . . . . . . 2-13

Carrier drive service check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

Intermittent problem service check . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

No print or abnormal pr int service check . . . . . . . . . . . . . . . . . . . . . 2-19

Table of contents

ii

4227-300

Operator panel service che ck . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-20

Paper feed ser vice check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-21

POST service chec k . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-24

Powe r fa ilu r e s erv ice check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-25

Print quality service check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-27

Print wire drive failure servi ce check . . . . . . . . . . . . . . . . . . . . . . . . .2-28

Ribbon drive service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-30

Tractor 2 servi ce check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-31

Diagnostic aids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

Power-On Self Test (POST) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

Hex trace mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Hex trace mode sample . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Interface selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

Operation with the top cover removed . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

Service Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

Button Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

Factory Setting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

Printhead Bank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

Jam/PSet Sensor Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

Impac t fo rc e. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

Log clear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

Print Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

Other prin t te sts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

Error log. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

Repai r in fo r m a t io n . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

Handling ESD-sensitive parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

Printhead installation adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

Printhead-to-platen gap adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

Bidirecti onal print adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

Removals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

Top cover removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

Auto Ga p mo to r re m o v al . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-8

Auto Sheet Feeder gears removal. . . . . . . . . . . . . . . . . . . . . . . . . . . .4-9

Auto Sheet Feeder pick-up roller removal. . . . . . . . . . . . . . . . . . . . .4-10

Belt tension pul ley plate assem bly removal. . . . . . . . . . . . . . . . . . . .4-11

Base assembly removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-11

Carr ie r re mo val . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-12

Carr ie r motor ass e m b ly re m o va l . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-15

Carrier plate removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-16

Label jam removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-16

Lower feed roller removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-17

Lower pinch roll er removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-21

Main logic board r em oval. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-21

Memory Module removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-22

iii Service Manual

4227-300

Operator panel assembly removal. . . . . . . . . . . . . . . . . . . . . . . . . . 4-22

Paper Empty sensor/TO F sensor removal. . . . . . . . . . . . . . . . . . . . 4-22

Paper feed motor removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-25

Paper guide removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-25

Paper guide/platen assembly removal . . . . . . . . . . . . . . . . . . . . . . . 4-25

Paper Select lever removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-25

Paper Select sensor re mo val. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-26

Paper separator removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-27

Power suppl y remo val . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-29

Power sup p ly fan removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-29

Print unit removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-29

Printhead removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-32

Printhead cables removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-33

Ribbon drive motor assembly removal. . . . . . . . . . . . . . . . . . . . . . . 4-34

Right side frame removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-35

Sub logic board removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-37

Upper feed roller removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-38

Preventive maint enance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Specified lubricants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Lubrication poi nts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Locations and connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

4227-300 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Main Logic Board Connector s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Operator panel connectors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Component locat ions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Component location illustrations . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Component location illustrations (Continued) . . . . . . . . . . . . . . . . . . 6-6

Signal connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Main Logic Board<-->Paper Empty & TOF Sensors . . . . . . . . . . . . . 6 -9

Main Logic Board<-->Carrier Motor Cabl e #1 . . . . . . . . . . . . . . . . . . 6-9

Main Logic Board<-->Paper Feed Motor . . . . . . . . . . . . . . . . . . . . . . 6-9

Main Logic Board<-->Tractor 2 DIN . . . . . . . . . . . . . . . . . . . . . . . . 6-10

Main Logic Board<-->Ca rrier Motor Cooling Fan. . . . . . . . . . . . . . . 6-10

Main Logic Board<-->5 V dc Power . . . . . . . . . . . . . . . . . . . . . . . . 6-10

Main Logic Board<-->Operator Panel . . . . . . . . . . . . . . . . . . . . . . . 6-11

Main Logic Board<-->Tractor PSet & Jam Sensors . . . . . . . . . . . . 6-11

Main Logic Board<-->Ribbon Motor . . . . . . . . . . . . . . . . . . . . . . . . 6-12

Main Logic Board<-->Auto Gap Motor . . . . . . . . . . . . . . . . . . . . . . 6-12

Main Logic Board<-->Serial Board . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

Serial Board<-->Serial Cable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

Sub Logic Board<-->Printhead. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

Operator Panel Board<-->Ribbon Cover Sensor . . . . . . . . . . . . . . 6-14

Tractor 2 cable connectors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

Connector block diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-16

Table of contents iv

4227-300

Parts catalog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-1

How to use this parts catalog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-1

Assembly 1: Cover s and operator panel . . . . . . . . . . . . . . . . . . . . . . . . .7-2

Assembly 2: Paper feed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-4

Assemb ly 3: Carrier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-6

Assembly 4: Base and electronics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-8

Assembly 5: ASF side frame/covers . . . . . . . . . . . . . . . . . . . . . . . . . . .7-10

Assembly 6: ASF roller/ support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-12

Assembly 7: Tractor 2 option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-14

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I-1

Part number index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I-5

v Service Manual

Safety information

• The safety of this product is based on testing and approvals of the

original design and specific components. The manufacturer is not

responsib le f or safety in the event of use of unauthorized replacement

parts.

• The maintenance information fo r this product has bee n prepared f or

use by a prof essional service person and is not intended to be used by

others.

• There may be an increased ris k of el ectric shock and personal inj ury

during disassem bly and servicing of thi s product. Professional service

personnel sh ould understand thi s and take neces sary precautions.

• CAUTION: When you see this symbol, there is a danger

from hazardous voltage in the area of the product where

you are working. Unplug the product before you begin, or

use caution if the product must receive power in order to

perform the task.

4227-300

Consig n es de sécu ri té

• La sécurité de ce produit repose sur des tests et des

agréations portant sur sa conception d'origine et sur des composants

particuliers . Le fabricant n'assume aucune responsabili té concernant

la sécurité en cas d'utilisation de pièces de rechange non agréées.

• Les consignes d'entreti en et de répara ti on de ce produit s'adr essent

uniquement à un pers onnel de maintena nce qualifié.

• Le démontage et l'entreti en de ce produit pouvant présenter certains

risques électriques, le personnel d'entre tien qualifié devra prendre

toutes les précautions nécessaires.

• ATTENTION : Ce symbole indique la présence

d'une tension dangereuse dans la partie du produit sur

laquelle vous tra vaillez. Débranchez le produit av ant de

commencer ou faites preuve de vigilance si l'e xécuti on de

la tâche exige que le produit reste sous tension.

vi

4227-300

Norme di sicurezza

• La sicurezza del prodotto si basa sui test e sull'approvazione del

progetto origin ale e dei componenti specifici. Il produttore non è

responsabil e per la sicurezza in caso di sostituzione non autorizzata

delle parti.

• Le informazioni riguardanti la manutenzione di questo prodotto sono

indirizzate sol tanto al personale di assistenza autorizzato .

• Durante lo smont aggio e la manuten zione di questo prodotto,

il rischio di subi re sc osse elett riche e dan ni al la per sona è più e le v ato . Il

personale di assistenza autori zzato deve, quindi, adottare le

precauzioni necessarie .

• ATTENZIONE: Questo simbolo indica la presenza

di tensione pericolosa nell'area del prodot to. Scollegare il

prodotto prima di inizi are o usare cautela se il prodott o dev e

essere alimentato per eseguire l'intervento.

Sicherheitshinweise

• Die Sicherheit dieses Produkts basiert auf Tests und Zulassungen des

ursprünglichen Modells und bestimmter Bauteil e. Bei Verwendung

nicht genehmigter Ersatzt eile wird v om Hersteller keine Verantwortung

oder Haftung für die Sicherheit übernommen.

• Die Wartungsin formationen für d ieses Produkt sin d ausschließlich für

die Verwendung durch einen Wartungsfachmann bestimmt.

• Während des A useinandernehmens und der Wartung des Geräts

besteht ein zusätzliches Risi ko eines el ektrischen Schlags und

körperlicher Verletzung. Das zuständige Fach personal sollt e

entsprechende Vorsichtsmaßnahmen treffen.

• ACHTUNG: Dies es Sym bol weist auf ei ne gefährliche

elektrische Spannung hin, die in diesem Bereich des

Produkts auftreten kann. Ziehen Sie vor den Arbeiten am

Gerät den Netzstecker des Geräts, bzw. arbei ten Sie mit

großer Vorsicht, wenn das Produkt für die Ausführung der

Arbeiten an den Strom angeschlossen sein muß.

vii Servi c e M a nual

Pautas de Seguridad

• La seguridad de este producto se basa en pruebas y aprobac iones del

diseño original y componentes específicos. El fabricante no es

responsable de la seguridad en ca so de uso de piez as de repuest o no

autorizadas.

• La información sobre el man tenimiento de este producto está di rig ida

exclusivam ente al personal cualificado de ma ntenimiento.

• Existe mayor ri esgo de descarga eléctri ca y de daños personales

durante el desm ontaje y la repar ación de la máquina . El personal

cualificado debe ser consc iente de este peli gro y tomar las

precaucio nes necesarias .

• PRECAUCIÓN: este símbolo indica que el voltaje de la

parte del equipo con la que está trabajando es peligroso.

Antes de empezar, desenchufe el equipo o tenga cuidado

si, para trabajar con él, debe conectarlo.

4227-300

Informações de Segurança

• A segurança deste produto baseia-se em testes e aprovações do

modelo original e de componentes espec íficos. O fabricante não é

responsável pela segunrança, no caso de uso de peças de

substituição não autorizadas.

• As informações de segurança relati vas a este produto destinam- se a

profissionais destes servi ços e não devem ser utilizadas por outras

pessoas.

• Risco de choques eléctricos e ferimentos grav es durant e a

desmontagem e man utenção deste produto. Os profissionai s destes

serviços devem estar avisados deste facto e tomar os cuidados

necessários.

• CUIDADO: Quando vir este sí mb olo, existe a possível

presença de uma potencial tensão perigosa na zona do

produto em que está a trabalhar. Antes de começar,

desligue o produto da tomada eléctrica ou seja cuidadoso

caso o produto te nha de estar ligado à corrente eléctric a

para real izar a taref a necessária.

viii

4227-300

Informació de Seguretat

• La seguretat d'aquest producte es basa en l'avaluació i aprovació del

disseny original i els components específics.

El fabricant no es fa responsable de les qüestions de

seguretat si s' utilitz en peces de recanvi no autoritzades.

• La informació pel manteniment d’aquest producte està orientada

exclusi vame nt a professionals i no està dest inada

a ningú que no ho sigui.

• El risc de xoc elèctric i de dan ys personals pot augm entar duran t el

procés de desmuntatge i de servei d’aquest producte. El personal

professional ha d’estar-ne assabentat i prendre

le s m e s ures co nve nien t s.

• PRECAUCIÓ: aquest símbol indica que el voltatge de la

part de l'equip amb la qual esteu treballant és perillós.

Abans de començar, desendolleu l'equip o extremeu les

precaucions si, per treballar amb l'equip, l'heu de

connectar.

ix Service Manual

4227-300

x

4227-300

Preface

This manual contains maint enance procedur es for service personne l. It is

divided into the following chapters:

1. General information con tains a general description of the MFP and

the maintenance approach used to repair it. Special tools and test

equipment are listed, as well as general environmental and safety

instructions.

2. Diagnostic information contain s an error indicator table, symptom

tables , and service checks used t o isolate failing field replaceab le units

(FRUs).

3. Diagnostic aids contai ns tests and checks used to locate or repeat

symptoms of MFP problems.

4. Repair inf o rmat ion pr o vides i nstruct ions f or maki ng MFP adj ustm ents

and removing and i nstalling FRUs.

5. Connector locations uses illustrations to identi fy the connector

locations and test points on the printer.

6. Preventive maintenance contai ns the lubrication specifications and

recommendations to prevent prob lems.

7. Parts catalog contains illustrations and part numbers for individual

FRUs.

Definitions

Note: A note provid es additional information.

Wa rning: A warning identifies something that might damage the product

hardware or software.

CAUTION: A caution identifies something that might cause a servicer

harm.

CAUTION: When you see th is symb ol, the re is a danger from

hazardous voltage in the area of the product where you are

working. Unplug th e product bef ore you begin, or use caution

if the product must receive power in ord er to perform the tas k.

xi Service Manual

4227-300

1. Ge n e r a l inform a tion

Description

The Lexmark™ Form Printer 4227-300 is a dot matr ix, electromechanical prin ter that forms characters on a print media using a

printhead and fabric ribbon. The printhead is composed of 18

miniature solenoids containing print wires and operates on

electromagnetic pr inciple s. When a solenoid is energized, the small

print wire pin is “fired” toward the ribbon to make a dot on the paper.

The printer receives commands in the form of an electronic data

stream from the PC through the parallel or serial port connector. The

printer logic receives and translates the electronic data stream into

carrier returns, line spacing, characters, or graphics as instructed.

This is a versatile printer that combines excellent print quality along

with the ability to print several print styles and graphics. Some of the

features and functions included with this printer are:

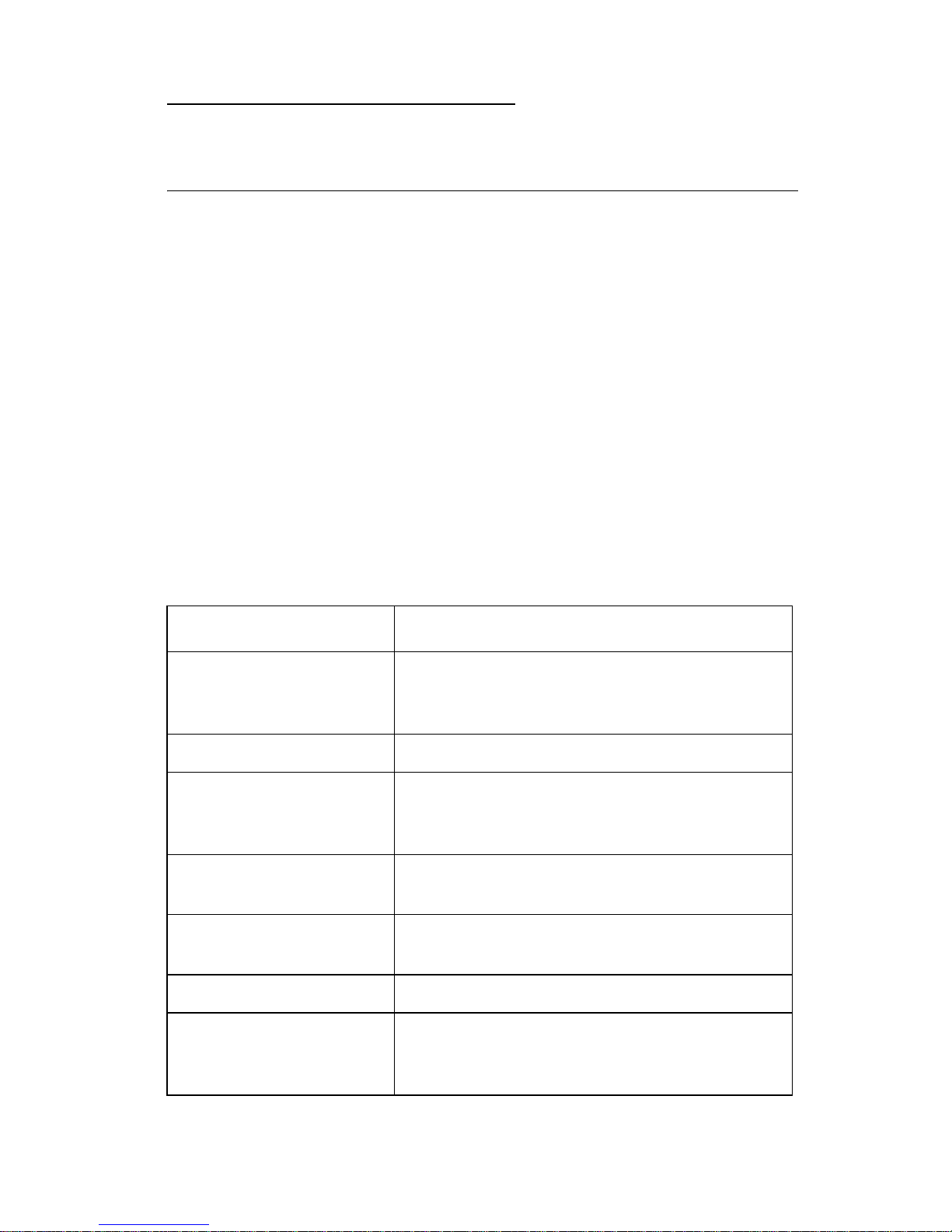

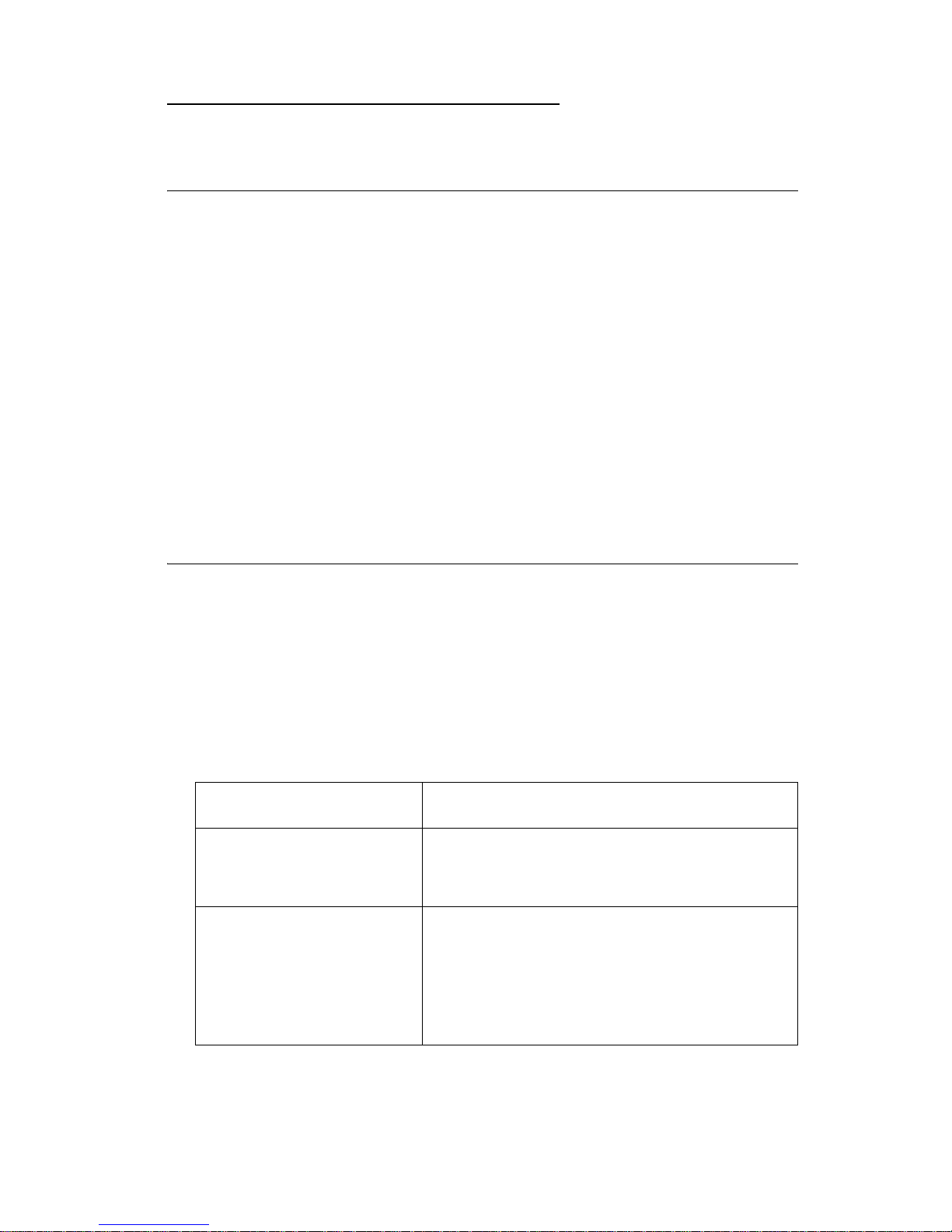

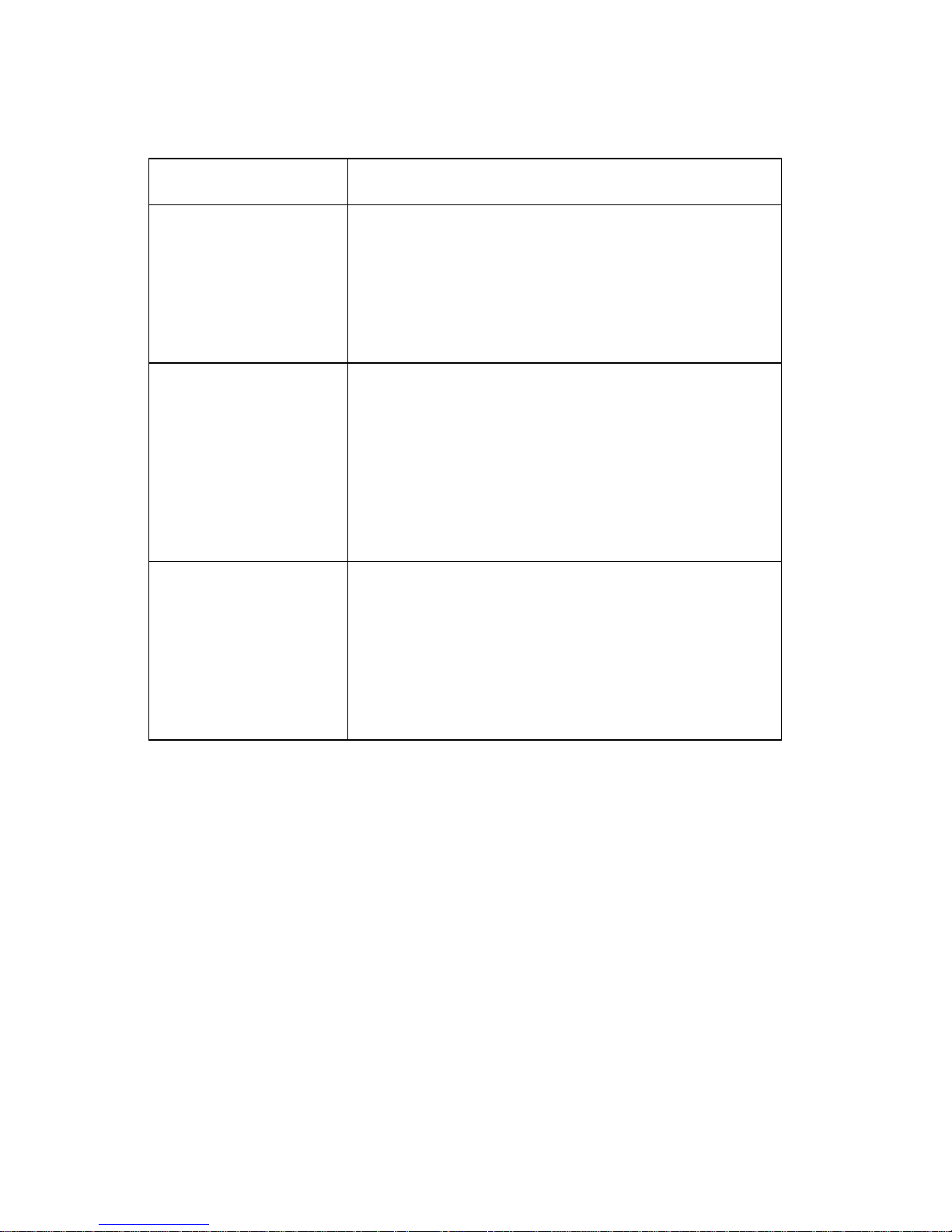

Feature Function

Multi-speed Prin ti ng FastDraft - 720 cps

Draft - 600 cps

Courier and Gothic ( NL Q) - 150 cps

Resident F onts FastDraft, Draft, Courier, and Gothic

Forms Handling Forms (straight paper path)

Automatic tear-off

Automatic paper loading/unloading

Cut Sheets Manual

Optional Auto Sheet F eeder

Multiple Par t Forms 6-part Forms (carbon and carbonless)

(4227-300 - up to 8-part Forms)

Interface Connection Parallel, Serial RS-422, Serial RS-232

Auto Gap When Aut o Gap is set to On, the printer

automatically adjusts to the thickness of paper

you are using.

General information 1-1

4227-300

Voltage, ground, and continuity read ings

Voltage readings

All DC voltages must be within +5% through -10% of the values to

be considered correct. Unless stated otherwise, all connectors

should be connected norm ally when a voltage measurement is

done.

When a “line voltage” measurement is to be done, the voltage on

United States and Canada machines should be between 100 V ac

and 127 V ac. On World Trade machines, the voltage is according to

each country’s specification.

Ground checks

To check for a correct ground, measure the voltage

between the ground and a known good voltage source.

The voltage measurement must be the same as the

source voltage to consider the ground is correct.

Continuity measurements may be used to check grounds; however ,

be sure to measure to a known good ground using the lowest ohms

scale and check for zero ohms.

WARNING: Always unplug the power cord before doing any continuity measurement.

Continuity readings

When measuring continuity, be sure no back circuits affect the

measurement. If necessary , unplug connectors to remove any back

circuits. Zero the ohm range on the lowest scale (X1). An open

circuit will read infinity. A circuit with correct co ntinuity will r ead zero

ohms.

1-2 S ervice Manual

4227-300

Mai nt en an ce ap proa ch

The diagnostic information in this manual leads you to the correct

field replaceable unit (FRU) or part. Use the error indication table,

symptom/check table, service checks and diagnostic aids to

determine the symptom and repair the failure. Begin with “Power-On

Self Test (POST)” on page 3-1.

Options

The following options may be installed:

• Automatic Sheet Feeder (ASF)

• Tractor 2

• Extended Cut-sheet Paper Guides

• 32kb Memor y Module

• Extended National Language S upport modules (Non-U.S. only)

Tools

The basic tools needed are:

• Basic CE tool kit

• #1 magnetic Phillips screwdriver

• #2 magnetic Phillips screwdriver

• Feeler gauges 0.35 mm (0.014 in.) 0.4 mm (0.016 in.)

• Analog or digital volt-ohmmeter

General information 1-3

4227-300

Abbreviations

ASF Automatic Sheet Feeder

ASIC Application-Specific Integrated Circuit

CSU Customer Setup

DRAM Dynamic Random Access Memory

EPROM Erasable Programmable Read-Only Memory

ESD Electrostatic Discharge

FRU Field Replaceable Unit

HVPS High Voltage Power Supply

LAN Local Area Network

LCD Liquid Crystal Display

LED Light-Emitting Diode

LVPS Low Voltage Power Supply

NVRAM Nonvolatile Random Access Memory

OEM Original Equipment Manufacturer

POR Power-On Reset

POST Power-On Self Test

PQET Print Quality Enhancem ent Technology

ROS Read-Only Storage

SRAM Static Random Access Memory

UPR Used Parts Replacement

V ac Volts alternating current

V dc Volts direct current

1-4 S ervice Manual

4227-300

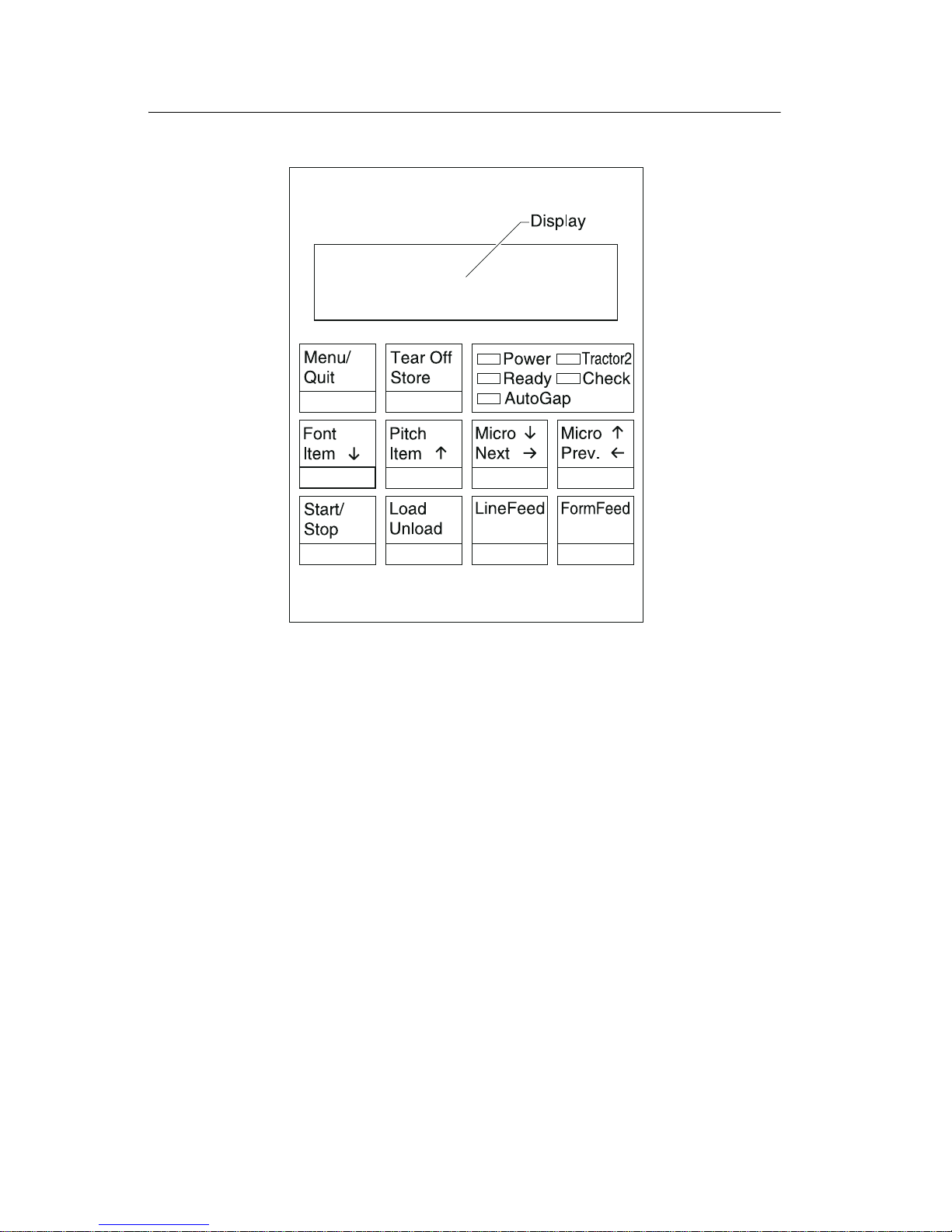

Using the operator p anel

This section provides a brief description of the operator panel

buttons, lights, and settings. Refer to the User’s Guide for additional

information.

Note: Application software may allow the user to operate the printer

from a computer. Changes made to the printer settings from a

software application override settings made from the operator panel,

with the exception of the Font and Pitch Lock features.

Changeable printer functions include:

• Set Top of Form

• Tractor selecti o n

• Character options

• Paper handling options

• Interface options

• Emulation options

• Macro definition and selection

• Print tests

• Auto Gap functions

General information 1-5

4227-300

Using the function menus

Use the Item ↓ and Item ↑ buttons to move through the menu and

option directories. Press Next → to move away from the Main Menu

to the subordinate directories and choices. Press Prev. ← if you want

to go back in a menu or return to the Main Menu.

1-6 S ervice Manual

4227-300

Setting printer functions

1. Press Start/Stop.

2. Press Menu to enter the function menu.

3. Press Item ↓ or Item ↑ until the function menu you want

appears on the display.

Note: The selectable function menu is different depending on the

selected data stream mode (IBM PPDS or Epson emulation) and the

Interface mode (Parallel, RS-232 or RS-422).

4. Press Next → to enter th at menu ite m.

5. Press Item ↓ or Item ↑ until the v alue you want appears on the

display.

6. Press Store to save the selected value.

Note: The currently selected default value is displayed with an

asterisk (*).

If you want to change the optional value in another function menu,

repeat steps 3 through 5. Otherwise, go to the next step.

7. To print the function setting, press It e m ↓ or Item ↑ until the

Print Settings message appears on the display.

8. Press Start/Stop to print the current setting values.

9. Press Quit to exit the function menus.

Note: If you have changed any settings, the printer performs a

Power-On Self Test. For more information, see “Power-On Self Test

(POST)” on page 3-1. If you did not change any settings, the printer

enters the not-ready state.

General information 1-7

4227-300

Overview of function menus

Use the Item ↑ and Item ↓ buttons to move through the menu and

option directories. Press Next → to move away from the Main Menu

to the subordinate directories and choices. Press Prev. ← if y o u w a nt

to go back in a menu or return to the Main Menu.

Menu items marked with an asterisk (*) may not appear on the

operator panel, depending on the printer settings or what printer

options are installed.

1-8 S ervice Manual

4227-300

General information 1-9

4227-300

Buttons

When using the function menus, press Item ↓ or Item ↑ to scr o l l

through the menu items. Press Next → or Prev. ← to mov e to th e

next, or previous menu level.

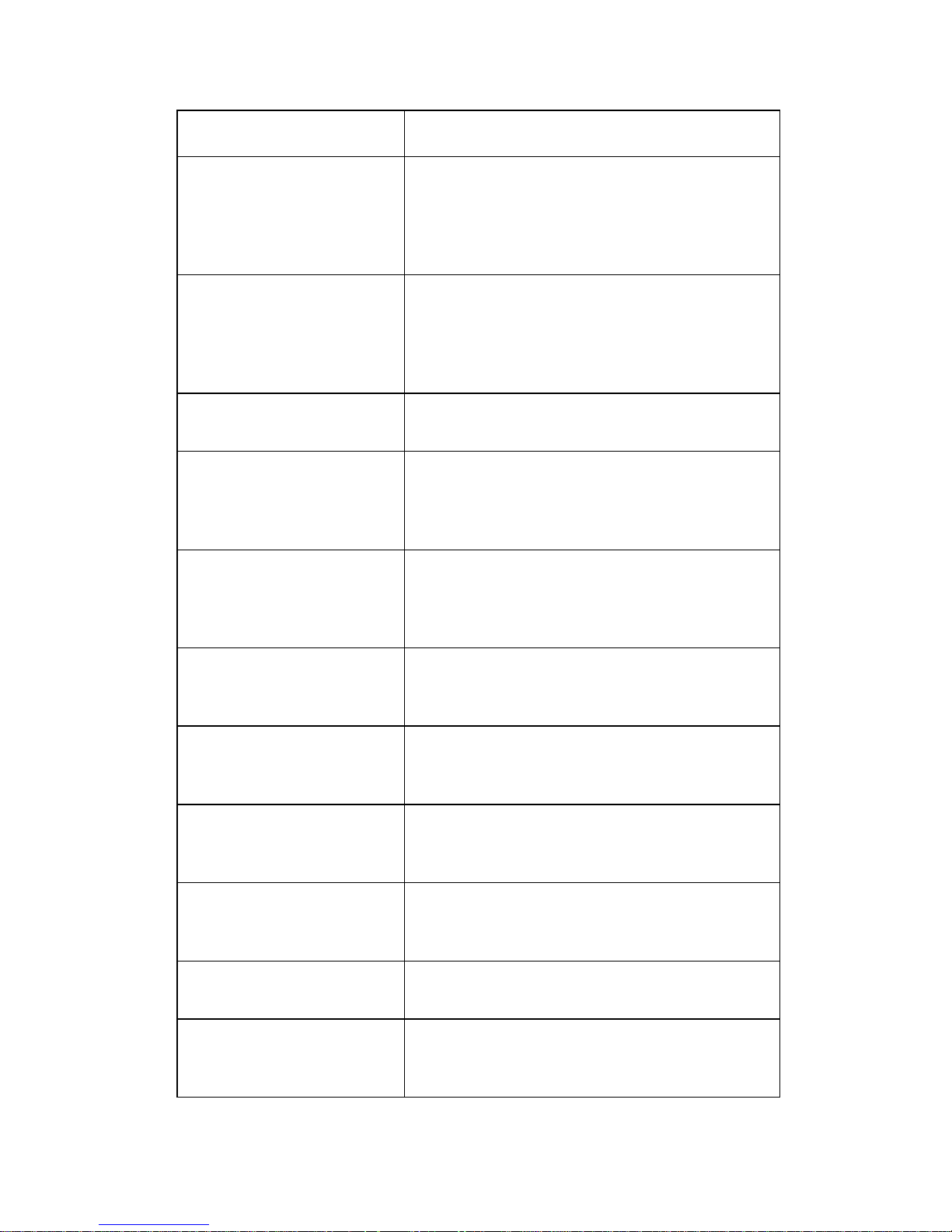

Press To

Menu Enter the function m enu. The printer goes

offline.

Quit • Exit the function menus.

• Run a Powe r-On Self Test ( P O S T).

Tear Off • Adv ance the forms to the tear-off posi tion.

• Retract the forms to the Top-of-Form (TOF)

position when the forms are at the tear-off

position.

Store Save the values select ed in the menus.

Font Select a font.

Item

↓ Scroll down.

Pitch Select a pitch.

Item

↑ Scroll up.

Micro

Next

Micro

Prev.

Start/Stop • To return to Ready and to Start/Stop.

Load/Unload • Load paper (cut or continuous f orms) to t he

↓ Advance the forms down 0.35 mm (1/72 in.).

→ Scroll forward.

↑ Advance the forms up 0.35 mm (1/72 in.).

← Return to the previ ous function menu.

• Load the forms to TOF position with the

ready light on.

TO F position.

• Retract the forms to the tractor position.

LineFeed Advance the paper to the nex t line.

FormFeed • Advance the paper to the T O F position on

1-10 Service Manual

the next page.

• Load the forms to the TOF position.

4227-300

Lights

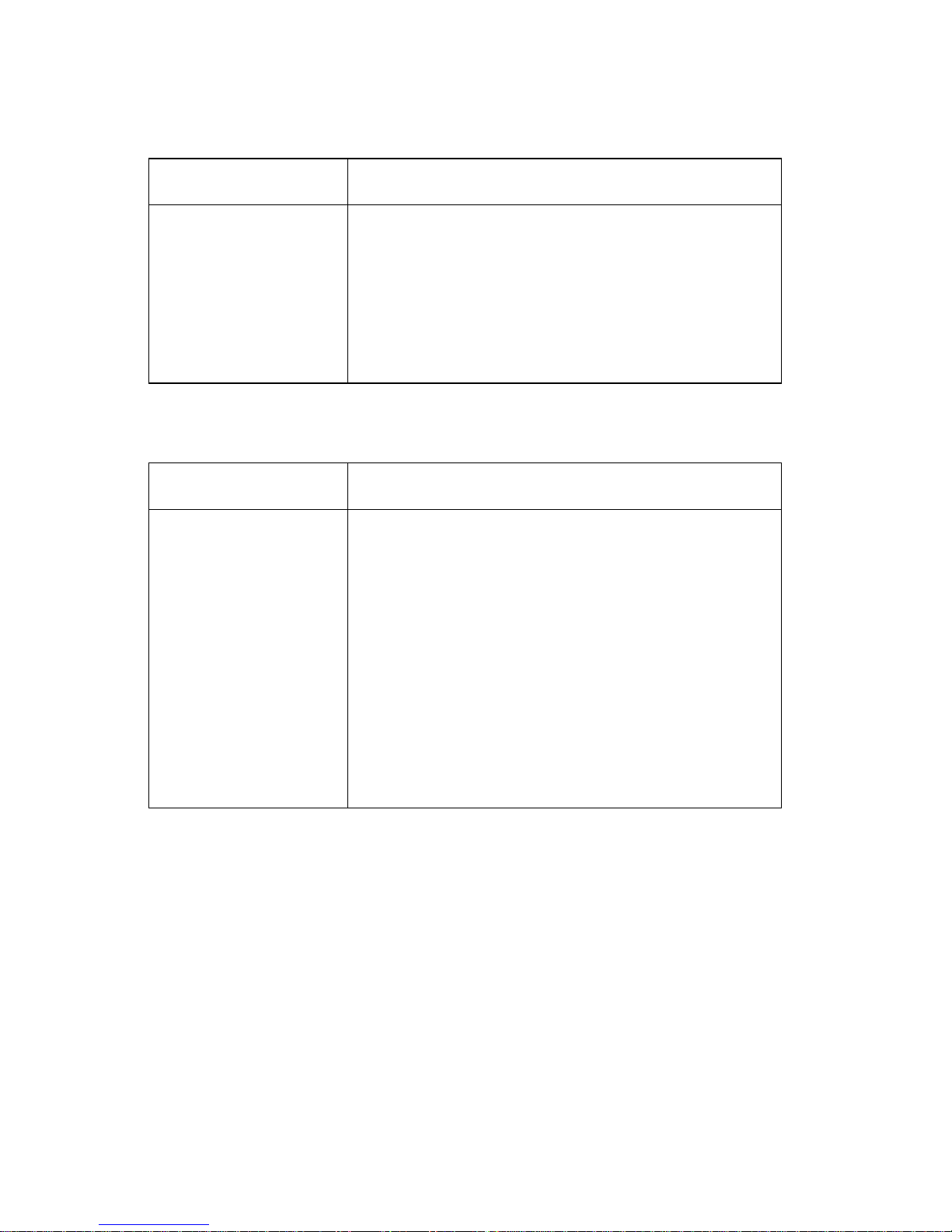

Light

Power (Green) The printer power is on.

Ready (Green) The printer is online and ready to print.

Check (Yellow) Any of the following conditions may have

Description

The fol lowing con dit ions cause the Ready light

to turn off:

• Pressing Start/Stop

• An end-of-form (EOF)

• A paper jam

• A cover open

• A ha r dw a re er ro r

• A Power-On Self Test failure

• The printer is offline.

occurred:

• An end-of-form (EOF)

• A paper jam

• A cover open

• A ha r dw a re er ro r

• A data transmission error

• An interface mode error

• A Power-On Self Test (POST)

failure

Aut o G ap (Green) Auto Gap is on. Auto Gap automatically adjusts

the printer according to the th ickness of the

paper you ar e u sing.

Tractor 2 (Green) The Tractor 2 Feeder is select ed. (The Tractor

2 Feeder option must be installed. )

General information 1-11

4227-300

1-12 Service Manual

4227-300

2. Diagnostic information

Start

Make a quick visual check for defects (loose or broken part s,

unplugged connectors, or paper jams).

If there is no power after turning the printer on, go to the “Power

failure service check” on page 2-25.

If an error indicator appears, go to the “Error indication table” on

page 2-1 and take the indicated action.

Run the “Print Test” on page 3-5 and refer to the “Error log” on page

3-5 for details of error indication information. If no error indication

appears, refer to “Symptom tables” on page 2-3.

Error indication table

The following table describes the serv ice check entries for the

printer error indication codes.

When an error indication changes after you have entered a service

check, you have an intermittent problem. If this occurs, leave the

servi ce check and go to “Symptom tables” on page 2-3.

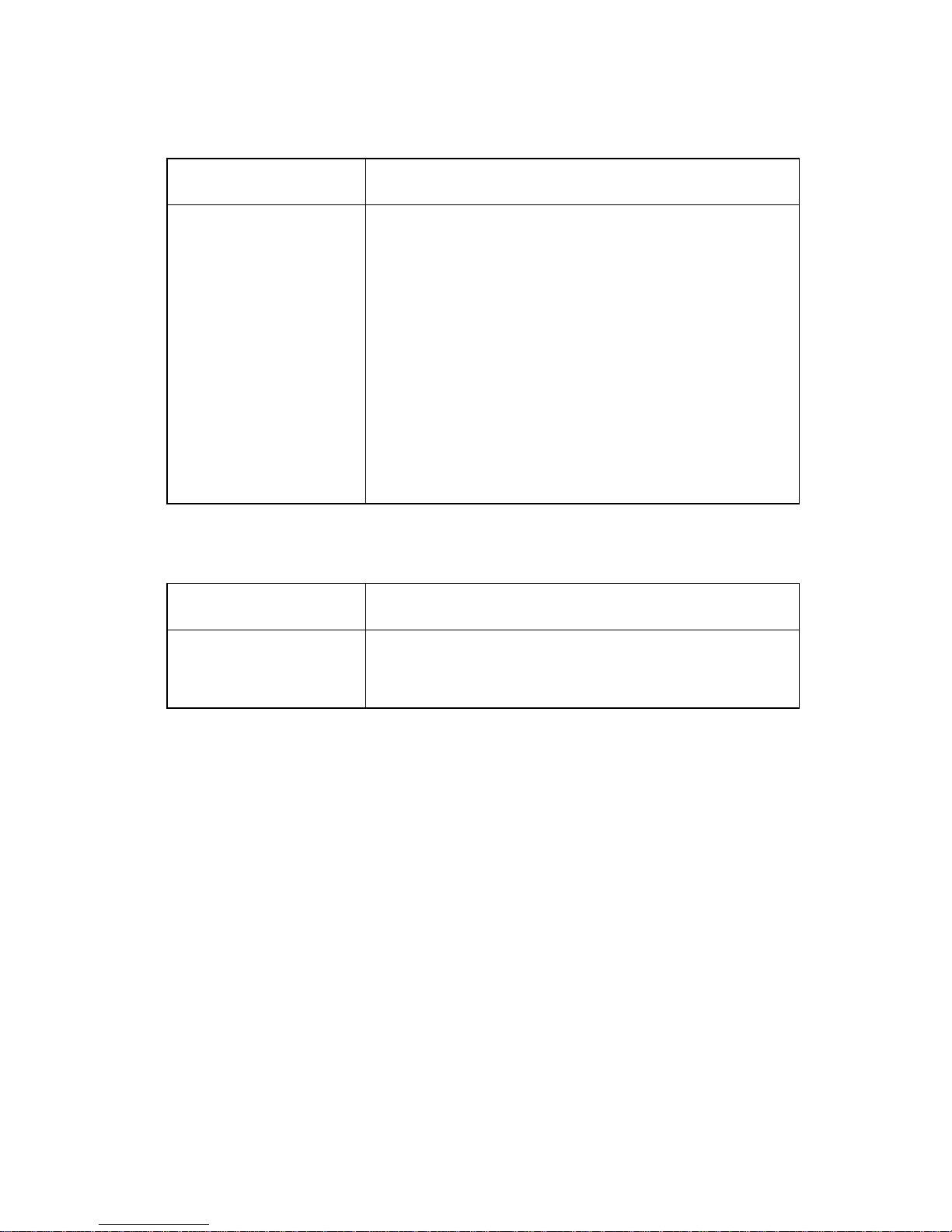

Display Indication Description/Action

631 Machine Check

Display RAM Error

632 Machine Check

System RAM Error

Display RAM Read/Write Error. This error

is detected only during POST. Replace the

operator panel.

System RAM Read/Write Error.

Replace the main logic board and

perform the

adjustment” on page 4-3

“Bidirectional print

. Check th e

“Printhead-to-platen gap adjustment”

on page 4-2

.

Diagnostic information 2-1

4227-300

Display Indication Description/ Action

633 Machine Check

Timer Inter r up t Error

636 Machine Check

NOVRAM Error

637 Machine Check

CA Drive Error

638 Machine Check

CA Drive Error

639 Machine Check

CA Drive Error

Timer Interrupt Controller Error. Replace

the main logic board and perform the

“Bidirectional print adjustment” on

page 4-3

platen gap adjustment” on page 4-2

Non-Volat ile Memory Read/Write E rror.

Replace the main log ic board and perform

the

“Bidirectional print adjustment” on

page 4-3

. Check th e “Printhead-to-

.

. Check th e “Printhead-to-

platen gap adjustment” on page 4-2.

Home Timeout Error. Go to the

“Carrier

drive service check” on page 2-15.

Carrier Drive Error.

No emitter pulse detected. Go to the

“Carrier drive service check” on page

2-15.

Carrier Drive Error.

Carrier positioning error. Go to the

“Carrier drive service check” on page

.

2-15

63B Machine Check

Key Scan Error

63C Machine Check

Auto Gap Error

63D Machine Check

Tractor 2 HP Error

63E Machine Check

Head Thermal Error

63F Machine Check

Option RAM Error

640 Machine Check

CA Thermal Error

Button Scann ing Error.

Go to the

check” on page 2-20

Auto Gap Err or.

Go to the

page 2-11

Tractor 2 Home Position Error.

Go to the

“Operator panel service

.

“Auto Gap service check” on

.

“Tractor 2 service check” on

page 2-31.

Head Thermal Sensor Error.

Go to the

service check” on page 2-28

Option RAM Read/Write Error.

Replace the 32Kb Memory Module.

Carrier Thermal Sensor Error.

Go to the

“Print wire drive failure

.

“Carrier drive service check”

on page 2-15.

2-2 S ervice Manual

4227-300

Symptom tables

1. Select the symptom that best describe s the problem.

2. Perform the appropriate action before you go to the indicated

service check.

Diagnostic information 2-3

4227-300

Abnormal Indications

Symptom Action

All LEDs turn on but

do not turn off.

The Power LED is

on, but POST will

not run.

Disconnect the in terf ace c ab le from t he print er and

turn the printer off and then back on. If POST now

runs correctly, the problem is in the computer or

interface cable.

Go to the

“POST serv ice check” on page 2-24.

Abnormal print operation problems

Symptom Action

Printer will not print,

or become Ready.

Abnormal opera ti on,

incorrec t chara cte rs ,

or incorrect line

width

Be sure the interf ace cable is connected pr operly.

Go to th e

“No print or abnormal print ser vice

check” on page 2-19.

Printer is ready but

will not print from the

computer correctly.

Undefined or

incorrect characters

2-4 S ervice Manual

4227-300

Auto Sheet Feeder problems

Symptom Action

Auto Sheet Feed er

will not feed paper.

Auto Sheet Feed er

double feeds.

Auto Sheet Feed er

has intermittent feed

problems.

Paper skews.

Be sure Auto Sheet Feed is set to On i n the Paper

Handling Option Menu.

Be sure the paper select le ver is in the cut sheet

position.

Go to the

2-11

Isolate the problem b y removing the A uto Sheet

Feeder and then feed paper using the man ual

feed tr ay . Go to th e

service check” on page 2-13

6XX Error indications

Symptom Action

6XX Machine

Check is display ed.

Turn the printer off and then on.

Go to

“Auto Gap service check” on page

.

“Auto Sheet Feeder (ASF)

.

“Error indication table” on page 2-1.

Diagnostic information 2-5

4227-300

Paper feed problems

Symptom Action

Paper Empty

Add Paper

is di splayed with

paper in the printe r.

Print operatio n starts

without paper.

Load/Unload

does not function.

Form feed length is

not correct.

Load/Unload

functions with cut

sheets i n use.

Paper feeds, but

Auto Loading does

not work.

Be sure the Pape r Empty Sensor is not blocked.

There may be a problem with the Paper Select

Sensor. Go to the

on page 2-21

Be sure the Paper Select lever is in th e corr ect

position.

There may be a problem with the Paper Select

Sensor. Go to the

“Paper feed service check”

.

“Paper feed service check”

on page 2-21.

Be sure the P a p er Select lev er is in the cut sh eet

position.

Be sure Auto Cut Sheet is enabled in the Paper

Handling Option Menu.

Go to th e

2-21.

“Paper f eed service check” on page

2-6 S ervice Manual

Loading...

Loading...