Lexmark4226 Printer

• Table of Contents

• Start Diagnostics

• Safety and Notices

• Trademarks

4226-XXX

•Index

• Manuals Menu

Lexmark and Lexmark with diamond

design are trademarks of Lexmark

International, Inc., registered in the

United States and/or other countries.

4226-001

First Edition (May, 1997)

The Following Paragraph Does Not Apply To The United Kingdom Or Any Country

Where Such Provisions Are Inconsistent With Local Law: LEXMARK

INTERNATIONAL, INC.PROVIDESTHIS PUBLICATION“ASIS” WITHOUT WARRANTY

OF ANY KIND, EITHER EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO,

THE IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE. Some states do not allow disclaimer of express or implied

warranties in certain transactions, therefore, this statement may not apply to you.

This publication could include technical inaccuracies or typographical errors. Changes are

periodically made to the information herein; these changes will be incorporated in later

editions of the publication. Improvements or changes in the products or the programs

described in this publication may be made at any time. Publications are not stocked at the

address given below; requests for publications should be made to your point of purchase.

Comments may be addressed to Lexmark International, Inc., Department D22A/035-3,

740 New Circle Road NW, Lexington, Kentucky 40550, U.S.A. Lexmark may use or

distribute any of the information you supply in any way it believes appropriate without

incurring any obligation to you.

Lexmark is a trademark of Lexmark International, Inc., registered in the United States

and/or other countries.

Other trademarks are the property of their respective owners

Copyright Lexmark International, Inc. 1991, 1997

All rights reserved.

UNITED STATES GOVERNMENT RESTRICTED RIGHTS

This software and documentation are provided with RESTRICTED RIGHTS. Use,

duplication or disclosure by the Government is subject to restrictions as set forth in

subparagraph (c)(1)(ii) of the Rights in Technical Data and Computer Software clause at

DFARS252.227-7013 and in applicable FAR provisions: Lexmark International, Inc.,

Lexington, KY 40550.

4226-001

Contents 1

Notices..............................................vii

SafetyInformation................................... vii

Preface..............................................xii

GeneralInformation...................................1-1

Description....................................... 1-1

Maintenance Approach.............................. 1-2

Power Supply Specifications ......................... 1-2

PrinterCables..................................... 1-3

Tools............................................ 1-3

Abbreviations..................................... 1-4

Using the Operator Panel . . .......................... 1-5

DisplayFormat................................. 1-5

Buttons....................................... 1-7

Indicators.................................... 1-10

Display...................................... 1-10

Alarm....................................... 1-11

DiagnosticInformation ................................2-1

Power-OnSelfTest(POST).......................... 2-1

Start............................................ 2-3

ErrorIndicationTable............................... 2-4

SensorTest1.................................. 2-7

SensorTest2.................................. 2-7

ButtonTest.................................... 2-7

SymptomTable.................................... 2-8

iii

4226-001

ServiceChecks.................................. 2-14

AbnormalNoiseServiceCheck................... 2-14

AbnormalPrintServiceCheck.................... 2-16

CamDriveFailureServiceCheck................. 2-17

CarrierDriveFailureServiceCheck............... 2-20

EOFServiceCheck............................ 2-22

IntermittentProblemServiceCheck............... 2-23

Operator Panel Service Check ................... 2-24

Paper Feed Service Check ...................... 2-25

POSTFailureServiceCheck..................... 2-28

PowerFailureServiceCheck.................... 2-30

PrintQualityServiceCheck...................... 2-32

PrintTest.................................... 2-32

PrintWireDriveFailureServiceCheck............. 2-36

ResistanceTable1............................ 2-37

ResistanceTable2............................ 2-37

Ribbon Drive Service Check ..................... 2-38

DiagnosticAids ......................................3-1

Offline Test (Resident Non-Automatic Tests) . . . ...... 3-1

SensorTest1................................. 3-2

SensorTest2................................. 3-2

ButtonTest................................... 3-2

LCDTest..................................... 3-2

BAT Loop Test................................. 3-3

FactorySetting ................................ 3-3

LogClear..................................... 3-3

PrintTest..................................... 3-4

PrintTestSample.............................. 3-6

Trace (Hexadecimal Print). . . ........................ 3-7

Hexadecimal Print Sample (Wide Width) ............ 3-8

RepairInformation....................................4-1

Handling ESD-Sensitive Parts........................ 4-1

Adjustments...................................... 4-2

CarrierAssemblyAdjustment..................... 4-2

CarrierBeltAdjustment.......................... 4-3

CharacterAlignmentAdjustment................... 4-5

EOFSwitchAdjustment.......................... 4-6

Printhead to Platen Adjustment.................... 4-6

Printhead Cable to Carrier Shaft Gap Adjustment...... 4-7

TractorAdjustment............................. 4-7

iv

4226-001

RemovalProcedures............................... 4-8

AccessCoverRemoval.......................... 4-8

BottomPlateandGroundSheetRemoval............ 4-9

CamAssemblyRemoval........................ 4-11

CamMotorandCamSensorRemoval ............. 4-12

CarrierFrameAssemblyRemoval................. 4-13

CarrierMotorandBeltRemoval................... 4-16

EOFSwitchandJamSensorRemoval............. 4-18

FeedFrameAssemblyRemoval.................. 4-19

FeedGearsandFrictionBlocksRemoval........... 4-20

FeedUnitAssemblyRemoval.................... 4-21

FormsMotorRemoval.......................... 4-23

FormsThicknessLeverRemoval.................. 4-24

FrontCoverRemoval........................... 4-25

GapSensorAssemblyRemoval.................. 4-26

GearCoverRemoval........................... 4-27

Logic Board Removal. . ......................... 4-28

LowerPressureRollerAssemblyRemoval.......... 4-30

Operator Panel Removal ........................ 4-31

Pin Feeds Removal . . . ......................... 4-33

Power Supply Removal ......................... 4-35

Printhead Removal............................. 4-37

Printhead Cable Removal ....................... 4-39

PrintUnitAssemblyRemoval..................... 4-41

Ribbon Drive Assembly Removal. . ................ 4-44

Ribbon Drive Gears Removal..................... 4-45

Ribbon Drive Motor Assembly Removal............. 4-46

TensionPulleyAssemblyRemoval................ 4-47

TOFSensorRemoval........................... 4-49

TopCoverAssemblyRemoval.................... 4-51

TractorAssemblyRemoval...................... 4-53

Upper and Lower Feed Roller Shafts Removal ....... 4-55

Upper Pressure Roller Assembly Removal . . . ....... 4-57

v

4226-001

ConnectorLocations..................................5-1

Main Logic Board Connectors..................... 5-4

Carrier Motor Connector CP1 ..................... 5-5

FormsMotorConnectorCP2...................... 5-5

Cam Motor Connector CP3....................... 5-6

Printhead Connector CJ4 ........................ 5-7

Cam Initial Position Sensor Connector CP5 .......... 5-8

Ribbon Feed Motor Connector CP6 . ............... 5-9

Power Connector CP9. . . ....................... 5-10

Operator Panel Connector CP10.................. 5-11

TOFSensorConnectorCP11.................... 5-12

JamSensorConnectorCP12.................... 5-13

CM Encoder Connector CP13.................... 5-14

EOF Switch Connector CP14 .................... 5-14

GapPositionSensorConnectorCP15............. 5-15

Parallel/Serial Interface Signal Connector CJ17 . ..... 5-16

Printhead Connector CJ18 ...................... 5-17

Cover Open Connector CJ19 .................... 5-18

C/M Heat Sensor Connector CJ20 . . .............. 5-18

Carrier Motor Fan Connector CJ21 . . .............. 5-18

WiringDiagrams ................................. 5-19

4226 Printer Block Diagram...................... 5-19

Power Supply Wiring Diagram.................... 5-20

IBM 4226 Printer dc Grounding Diagram ........... 5-20

PreventiveMaintenance ...............................6-1

Lubrication....................................... 6-1

Lubrication Points .............................. 6-2

PartsCatalog ........................................7-1

HowtoUseThisPartsCatalog....................... 7-1

Assembly1:CoverandElectricalParts................. 7-2

Assembly2:PrintUnit.............................. 7-4

Assembly3:FeedUnit.............................. 7-6

Index...............................................X-1

vi

4226-001

Notices

Safety Information

•

The maintenance information for this product has been

prepared for use by a professional service person and is not

intended to be used by others.

• There may be an increased risk of electric shock and

personal injur y during disassembly and servicing of this

product. Professional service personnel should understand

this and take necessary precautions.

• The safety features of some parts may not always be

obvious. Therefore, replacement parts must have the

identical or equivalent characteristics as the original parts.

Sicherheitshinweise

•

Die Wartungsinformationen für dieses Produkt wurden zur

Verwendung durch einen Wartungsfachmann entwickelt und

sollten nicht von anderen benützt werden.

• Zusätzliches Risiko eines elektrischen Schlags und

körperlicher Verletzung existiert während des

Auseinandernehmens und der Wartung des Geräts.

Fachpersonal sollte im vollen Verständnis der Lage

entsprechende Vorsichtsmaßnahmen ergreifen.

• Ersatzteile müssen gleiche oder gleichwertige Merkmale wie

die Or iginalteile aufweisen, da Sicherheitsvorkehrungen nicht

immer offensichtlich sind.

Notices vii

4226-001

Consignes de Sécurité

•

Les consignes d'entretien et de réparation de ce produit

s'adressent uniquement à un personnel de maintenance

qualifié.

• Le démontage et l'entretien de ce produit pouvant présenter

certains risques électriques, le personnel d'entretien qualifié

devra prendre toutes les précautions nécessaires.

• Les normes de sécurité de certaines pièces n'étant pas

toujours explicites, les pièces de rechange doivent être

identiques ou conformes aux caractéristiques des pièces

d'origine.

Norme di sicurezza

•

Le informazioni riguardanti la manutenzione di questo

prodotto sono indirizzate soltanto al personale

dell'assistenza autorizzato.

• Durante lo smontaggio e il manutenzionamento di questo

prodotto, è possibile il rischio accresciuto di scosse elettriche

e danni personali. Il personale di assistenza autorizzato,

consapevole di ciò, deve adottare le precauzioni necessarie.

viii

• È possibile che le funzioni di sicurezza di alcuni elementi non

siano così ovvie, quindi, i pezzi di ricambio devono avere

caratteristiche identiche o equivalenti a quelle dei pezzi

originali.

4226-001

Pautas de Seguridad

•

La información sobre el mantenimiento de este producto fue

escrita para el personal de mantenimiento cualificado y no

para cualquier otro usuario.

• Existen mayores riesgos de descargas eléctricas y daños

personales durante el desmontaje y la reparación de la

máquina. El personal cualificado comprende esto y toma las

precauciones necesarias.

• Los dispositivos de seguridad de algunas partes quizá no

siempre puedan ser reconocidas a simple vista. Por lo tanto,

las partes de reemplazo deben poseer características

idénticas o equivalentes a las partes originales.

Sikkerhedsoplysninger

•

Oplysningerne om vedligeholdelse af dette produkt er

forberedt med henblik på professionelt servicepersonale, og

bør derfor ikke benyttes af andre.

• Risikoen for elektrisk stød øges under demontering og

service af dette produkt, hvorfor der børtages de nødvendige

forholdsregler.

• Sikkerhedsforanstaltningerne er ikke altid lige åpenbare for

alle reservedele. Der bør derfor kun anvendes originale

reservedele eller reservedele med samme egenskaber som

de oprindelige.

Notices ix

4226-001

Informações de Segurança

•

As informações de segurança relativas a este produto

destinam-se a profissionais destes serviços e não devem ser

utilizadas por outras pessoas.

• Risco de choques eléctricos e ferimentos graves durante a

desmontagem e manutenção deste produto. Os profissionais

destes serviços devem estar avisados deste facto e tomar os

cuidados necessários.

• Os dispositivos de segurança de algumas peças poderão

não ser sempre suficientemente evidentes. Assim, as peças

sobressalentes devem possuir características idênticas ou

equivalentes às peças originais.

Chinese Safety Information

x

4226-001

Korean Safety Information

Notices xi

4226-001

Preface

This manual is divided into the following chapters:

• General Information contains a general description of the

printer and the maintenance approach used to repair it. Special

tools and test equipment are listed in this chapter, as well as

general environmental and safety instructions.

• Diagnostic Information contains error code table, symptom

table,and service checks used to isolate failing field replaceable

units (FRUs).

• Diagnostic Aids contains tests and checks used to locate or

repeat symptoms of printer problems.

• Repair Information provides instructions for making printer

adjustments and removing and installing FRUs.

• Connector Locations uses illustrations to identify the major

components and test points on the printer.

• Preventive Maintenance contains lubrication specifications,

and maintenance information to prevent problems and maintain

optimum performance.

• Parts Catalog contains illustrations and part numbers for

individual FRUs.

xii

4226-001

1. General Information

Description

The IBM 4226 Printer is a dot matrix impact printer that prints 1-byte

code (alphanumeric, symbol) and attaches to the following as an

output device:

• Personal System/2

• RISC System/6000

• AS/400

• 9370 System

General Information 1-1

4226-001

Maintenance Approach

The diagnostic information in this manual leads you to the correct

field replaceable unit (FRU) or part. Use the error indication table,

symptom/check table, service checks and diagnostic aids to

determine the symptom and repair the failure.

Begin with “Start” on page 2-3.

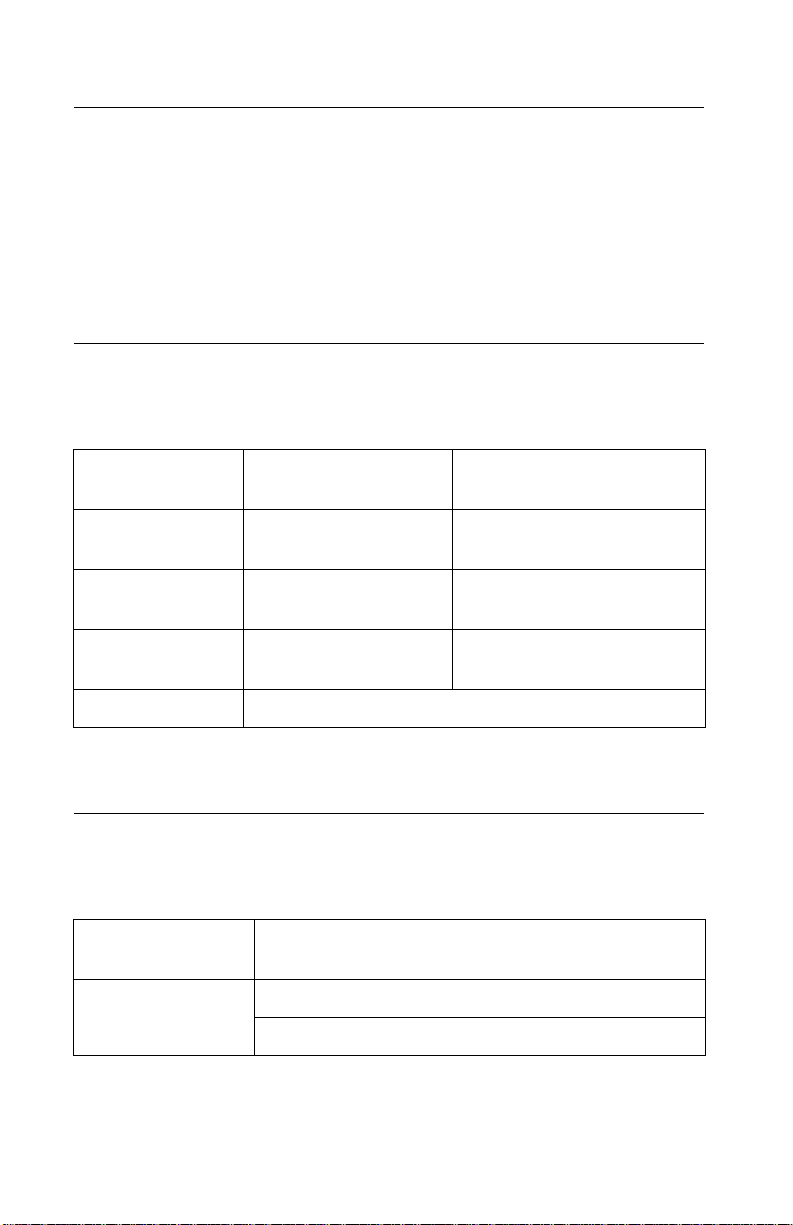

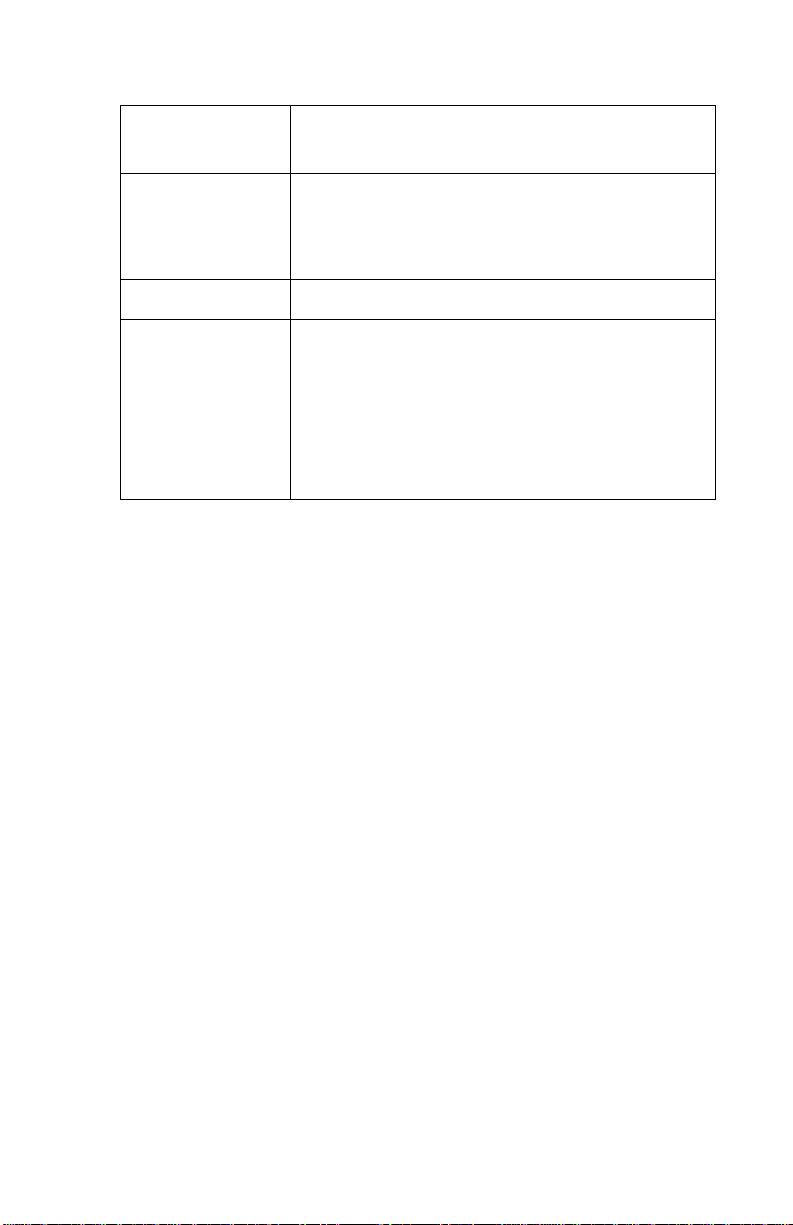

Print Specifications

Character Size 1-byte code character

(Alphanumeric, symbol)

Character Spacing 1-byte code character

(Alphanumeric, symbol)

Print Speed 1-byte code character

(10 CPI)

Maximum Print

Width

Line Spacing Variable in multiples of 1/144 in.

1-byte code character

(10 CPI)

9(H)X12(V)dots

9(H)X 9(V)dots

10, 12, 15, 17.1, 20 CPI,

Proportional Spacing

Draft Print...........400 cps

FastDraft Print....533 cps

80/136 characters

8 inch/13.6

Power Supply Specifications

Input Voltage Single phase: 90 to 132 V ac (LV), 50/60Hz

180 to 265 V ac (HV), 50/60Hz

Power Consumption Operating:.276 VA (all character print)

Idling:.......... 70 VA

1-2

4226-001

Printer Cables

When connecting the printer to a host personal computer, use the

following cables:

• Parallel Cable P/N 1525612 or its equivalent.

• Serial Interface Cable RS-232 P/N 6486685.

• Serial Adapter Plug P/N 1319143 - when using a non-IBM serial

printer cable.

Note: The RS-422 serial interface cable may also be used.

Tools

The jumper wire is used to put the cover sensor in a closed condition

(jumper CJ19-1 to CJ19-2 on the operator panel card) and is

contained in the parts packet.

The Push-Pull gauge is used for weight ranges between

400g (0.88 lb) and 500g (1.1 lb).

General Information 1-3

4226-001

Abbreviations

ASIC Application-Specific Integrated Circuit

CSU Customer Setup

DRAM Dynamic Random Access Memory

EPROM Erasable Programmable Read-Only Memory

ESD Electrostatic Discharge

FRU Field Replaceable Unit

HVPS High Voltage Power Supply

LCD Liquid Crystal Display

LED Light-Emitting Diode

LVPS Low Voltage Power Supply

NVRAM Nonvolatile Random Access Memory

OEM Original Equipment Manufacturer

POR Power-On Reset

POST Power-On Self Test

ROS Read-Only Storage

UPR Used Parts Replacement

V ac Volts alternating current

V dc Volts direct current

1-4

4226-001

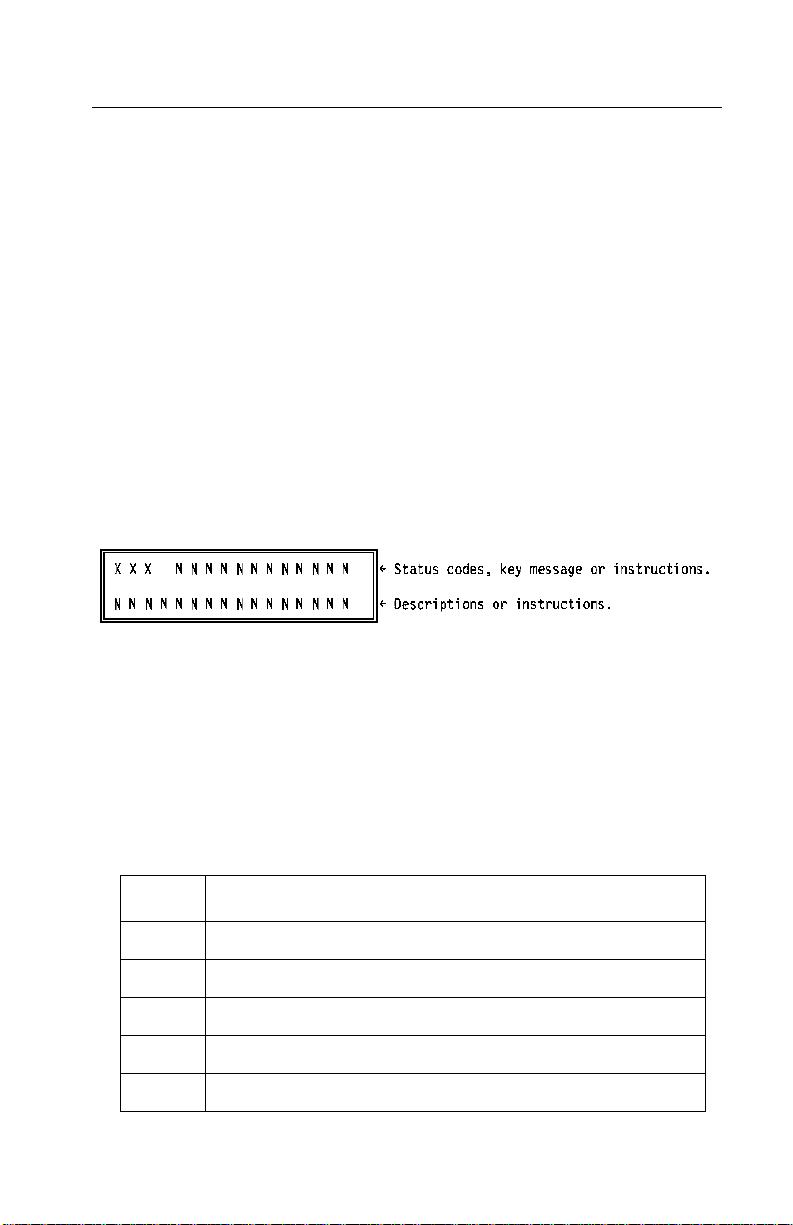

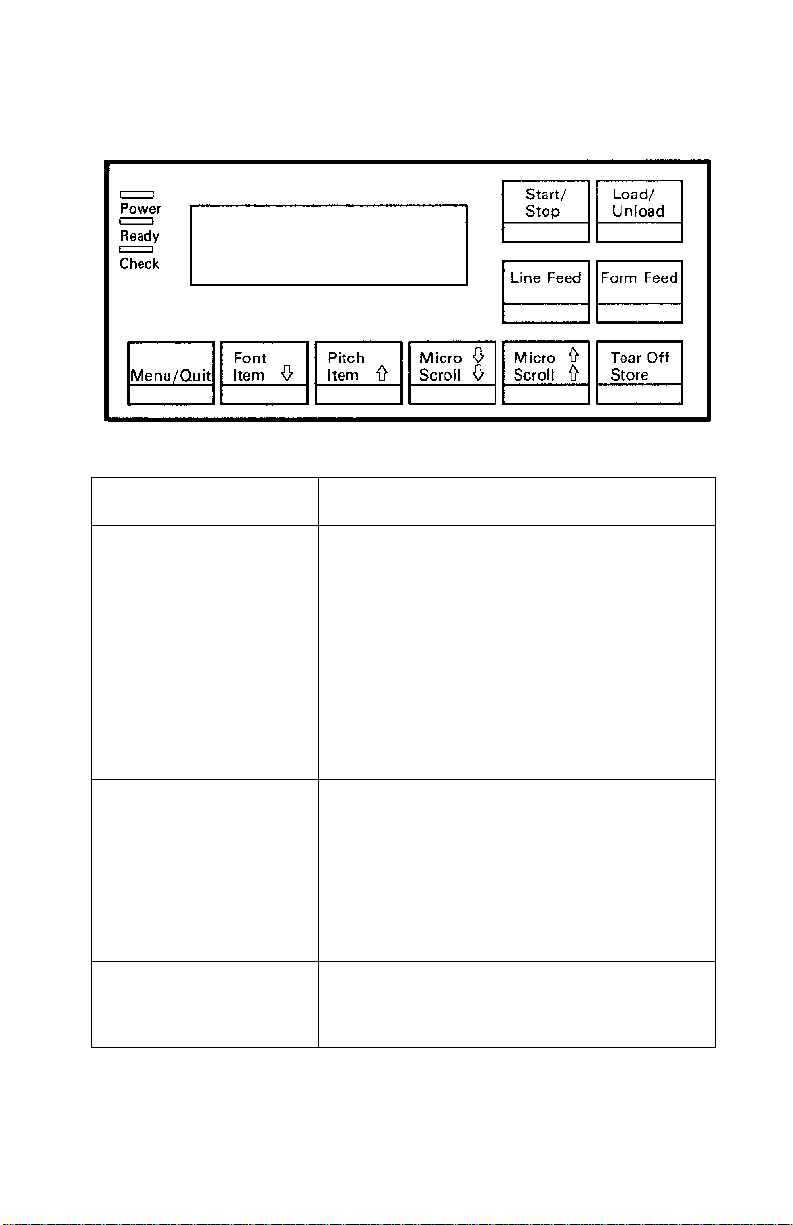

Using the Operator Panel

This section provides a brief description of the operator panel

buttons, lights and settings. Refer to the User’s Guide for additional

information.

The operator panel has three LED indicator lights (Power, Ready

and Check) and an LCD message display. The display presents the

printer status, instructions and messages. When an error occurs, a

code and a message are automatically displayed and an alarm

sounds. Pressing Start/Stop will stop the alarm.

Display Format

There are two kinds of status codes:

1. Intervention Request Code (IRC) - IRC “00X” is displayed in

three digit hexadecimal with five additional codes as follows:

Code Meaning

001 Paper Out

002 Paper Jam

005 Cover Open

007 Data error in serial interface

00D I/F error (Check interface mode)

General Information 1-5

4226-001

2. Error code “6xx” is displayed in three digit hexadecimal.

• 6 - Classification Code - 6 for all printers

• x - Function Code - Error function code

• x - Detailed Code - Error part code

The following table shows error codes and their associated meaning.

Code Meaning

631 Display RAM Read/Write Error

632 System RAM Read/Write Error

633 Timer Interrupt Controller Error

634 + 40 V dc Power Failure

635 Cam Position Error

636 Non-Volatile Memory (NVM) Read/Write Error

637 - 639 Carrier Drive Error

63A Font ROM Error

63B Button Scanning Error

1-6

4226-001

Buttons

Button Description

Start/Stop • Used to return to Ready and to Start/Stop.

• Thisisthe only active button when the printer

is printing. Printing continues until the

current line is completed.

•WhenStart/Stop is pressed at the tear-off

position in manual tear-off mode, the forms

are retracted to the line 1 position.

• Loads the forms to line 1 position with the

Ready indicator on.

• Turns off the printer alarm.

Load/Unload • Loads forms to line position 1.

• Retractsthe forms to the tractor position.

When the printer detects an end-of-form

condition, pressing this button ejects the

forms from the printer.

• Opens the pinch rollers when held for more

than two seconds.

FormFeed • Advances the forms to line 1 position of the

next page.

• Loads the forms to the line 1 position.

General Information 1-7

4226-001

Button Description

LineFeed • Advances the forms one line.

• When this button is held for more than one

second in the offline (not ready state), the

forms move continuously until the button is

released.

↑ Micro ↓ • Advance the forms down 0.35 mm (1/72 in.)

Micro

in either direction.

• When this button is held for more than one

second, the forms move continuously until

the button is released.

Tear Off • Advance the forms to the tear-off position.

• Retractstheformstoline1positionwhenthe

forms are at the tear-off position.

Pitch • Advances the pitch to the next setting when

pressed.

• The following pitches can be selected:

10, 12, 15, 17.1, 20, PS

Each pitch can be locked which prevents your

software from changing pitch settings at the

operator panel.

When pressing Pitch, the printer goes offline

and displays the current pitch and font.

When a font conflicts with a selected pitch, the

Invalid Pitch message appears on the display.

Font • Advances the font to the next setting when

pressed.

• The following fonts can be selected:

FastDraft, Draft, Gothic, Courier

• The following Epson Emulation Modes can

be selected:

Draft (Fast & Normal), Gothic, Courier)

Each font can be locked which prevents your

software from changing font settings at the

operator panel.

When pressing Font, the printer goes offline

and displays the current pitch and font.

When a font conflicts with a selected pitch, the

Invalid Pitch message appears on the display.

1-8

4226-001

Button Description

Menu/Quit • Enters the function mode and the printer

goes offline.

• Exits the function mode and the printer

performs the Power-On Self Test (POST).

↑ / Item ↓ Scrolls up or down to display the desired

Item

function.

↑ / Scroll ↓ Scrolls up or down to display the desired value

Scroll

intheselectedfunctionmenu.

Store Saves the values selected in the menus.

General Information 1-9

4226-001

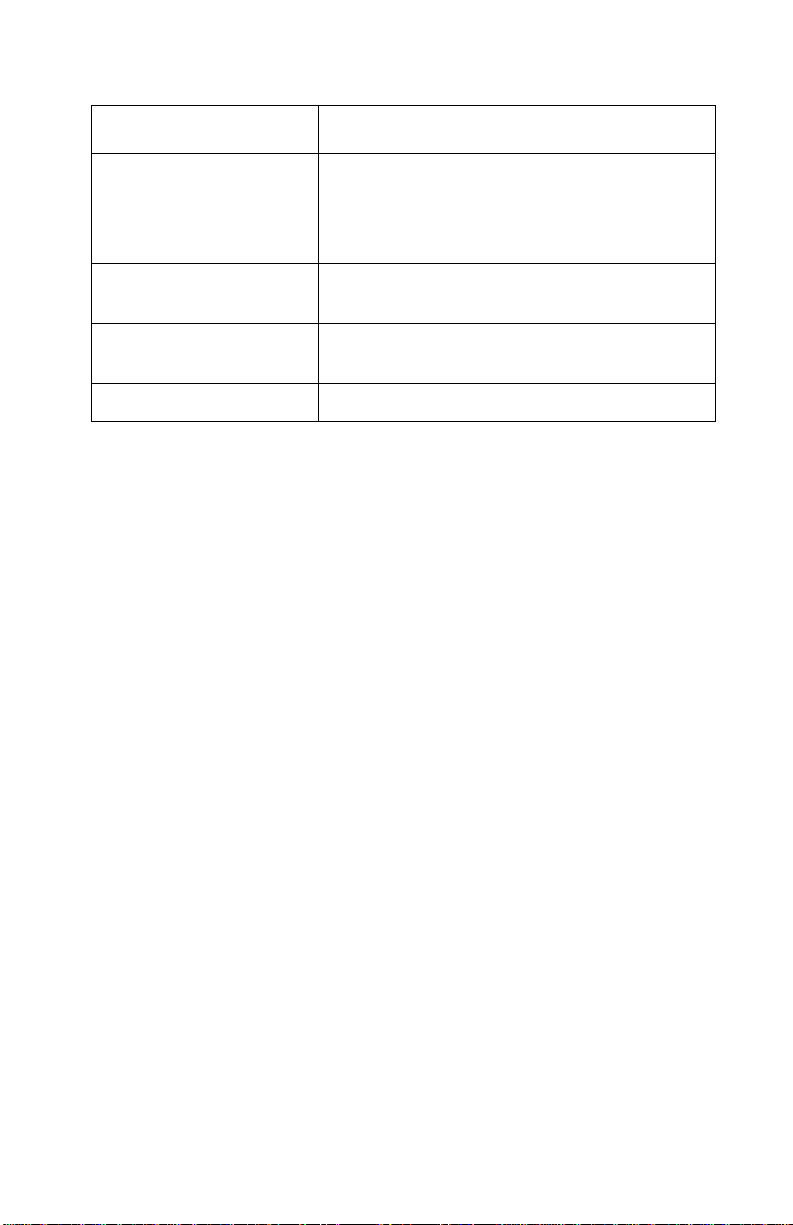

Indicators

Indicator

Power (Green) Indicates the printer power is on.

Ready (Green) The printer is on-line and ready to print.

Check (Yellow) Any of the following conditions may have

Description

The following conditions cause the Ready light

to turn off:

•PressingStart/Stop

•End-of-form(EOF)

• Paper jam

• Cover open

• Hardware error

• Power-On Self Test failure

occurred:

•End-of-form(EOF)

• Paper jam

• Cover open

• Hardware error

• Data transmission error

• Interface mode error

• Power-On Self Test (POST) failure

Display

The display shows error status codes, function menus and optional

values when the printer is in the printer function setting mode.

1-10

4226-001

Alarm

The alarm sounds to indicate the printer status or an error condition

when:

• A cover is opened.

• An end-of-form (EOF) condition is detected.

• A paper jam.

• A data transmission error.

• An interface mode error.

• A hardware error.

To stop the alarm, press Start/Stop.

General Information 1-11

4226-001

2. Diagnostic Information

Power-On Self Test (POST)

The Power-On Self Tests diagnose the basic hardware printer

functions and initialize the default value settings. POST starts

automatically when power to the printer is turned on, or when the

printer receives an INIT signal from the controller.

• Display and Indicator Function Test - Checks LCD functions and

LED indicators.

• RAM Test - Checks that the CPU can write/read the RAM.

• Font ROS Test - Calculates the check-sum value.

• Drive Voltage (+40 V dc) Test - Checks the voltage of the motors

and printhead.

• Button Scan Test - Scans all operator panel buttons.

• NVRAM Test - Checks that the NVRAM data is correct.

• Button Scan Test - Checks all buttons on the operator panel.

• Cover Open Check - Checks if any covers are open.

• Carrier Drive Check and Initialization - Checks the carrier

positioning.

• Cam Drive Check and Initialization - Checks the cam motor and

cam sensor.

If the POST completes successfully, the Power and Ready indicators

are on associated with a blank display. If any errors occur during

POST, an error indicator shows which test failed.

See “Start” on page 2-3.

2-1

4226-001

Diagnostic Information 2-2

4226-001

Start

Make a quick visual check for defects (loose or broken parts,

unplugged connectors, or paper jams).

If there is no power after turning the printer on, go to the “Power

Failure Service Check” on page 2-30.

To prevent the printer from starting while service is performed,

disconnect the interface cables.

Unload paper from the tractor.

The cover open interlock can be bypassed by placing a jumper on

the rear of the operator panel.

If the printer displays an error indication code go to the “Error

Indication Table” on page 2-4.

Run the “Print Test” on page 3-4 and refer to the Error Log for details

of error indication information. If no error indication appears, refer to

the “Symptom Table” on page 2-8.

2-3

4226-001

Error Indication Table

The following table describes the service check entries for the printer

error indication codes.

When an error indication changes after you have entered a service

check, you have an intermittent problem. If this occurs, leave the

service c heck and go to “Intermittent Problem Service Check” on

page 2-23.

Display

Indication

Blank LCD busy condition.

Replace the following in the order listed:

1. Operator panel assembly

2.Logic board.

Go to the “Operator Panel Ser vice Check”

on page 2-24.

001 EOF state is detected, or the EOF switch

fails to operate.

Go to the “EOF Service Check” on page

2-22.

002 Frequent jams occur, or the jam sensor fails

to make contact.

Go to the “Paper Feed Service Check” on

page 2-25.

005 Cover open condition is not detected, or is

not reset.

Go to the “POST Failure Service Check” on

page 2-28.

Description / Action

007 Data error.

Go to the “Abnormal Print Service Check” on

page 2-16.

Diagnostic Information 2-4

4226-001

Display

Indication

Description / Action

00D Statusof the interface mode switches do not

match the setting in the NVM.

Go to the “Abnormal Print Service Check” on

page 2-16.

631 Display RAM Read/Write Error. This error is

detected only in the Display Test.

Replace the following in the order listed:

1. Operator panel assembly

2.Logic board.

Go to the “Operator Panel Service Check”

on page 2-24.

632 System RAM Read/Write Error.

Replace the logic board.

633 Timer and Interrupt Controller Error.

Replace the logic board.

634 / 638 + 40 V dc power failed to drop.

Go to the “Power Failure Service Check” on

page 2-30.

2-5

635 Cam Positioning Error.

Go to the “Cam Drive Failure Service Check”

on page 2-17.

636 Non-Volatile Memory (NVM) Read/Write

Error. Replace the logic board.

637 Carrier Drive Timeout Error.

Go to the “Carrier Drive Failure Service

Check” on page 2-20.

638 No Emitter Pulse Error.

Go to the “Carrier Drive Failure Service

Check” on page 2-20.

4226-001

Display

Indication

Description / Action

639 Carrier Positioning Error.

Go to the “Carrier Drive Failure Service

Check” on page 2-20.

63A Font ROM Error. Replace the logic board.

63B Button Scanning Error.

Replace the following in the order listed:

1. Operator panel assembly

2.Logic board.

Go to the “Operator Panel Ser vice Check”

on page 2-24.

Diagnostic Information 2-6

4226-001

Sensor Test 1

For the offline test procedure, do the following:

1. POR the printer.

2. Press and hold Menu/Quit during POST until the message

“Sensor Test 1” is displayed.

3. Press Item↑until “Print Test” is displayed.

4. Press Start/Stop to start printing. The message changes to

“Printing”.

5. Press and hold Start/Stop to stop printing.

6. Turn the power off to exit this test mode.

Sensor Test 2

1. POR the printer.

2. Press and hold Menu/Quit during POST until the message

“Sensor Test 2” is displayed.

3. Press Item↑until “Print Test” is displayed.

4. Press Start/Stop to start printing. The message changes to

“Printing”.

5. Press and hold Start/Stop to stop printing.

6. Turn the power off to exit this test mode.

Button Test

1. POR the printer.

2. Press and hold Menu/Quit during POST until the message

“Button Test” is displayed.

3. Press Item↑until “Print Test” is displayed.

4. Press Start/Stop to start printing. The message changes to

“Printing”.

5. Press and hold Start/Stop to stop printing.

6. Turn the power off to exit this test mode.

2-7

4226-001

Symptom Table

1. Select the symptom that best describes the problem.

2. Perform the appropriate action before you go to the indicated

service check.

Abnormal Indications

Symptom Action

All indicators turn on, but do not turn

off.

Machine model “IBM 4226” is displayed

on the message display, the printer

stops and an alarm sounds.

Abnormal Print Operation Problems

Symptom Action

Printer will not print, or become Ready.

Abnormal operation, incorrect

characters, or incorrect line width.

Printer is ready but will not print from

the computer correctly.

Undefined or incorrect characters.

Intermittent Problems

Symptom Action

Go to the “POST Failure

Service Check” on page

2-28.

Be sure the interface

cable is connected

properly.

Go to the “Abnormal

Print Service Check” on

page 2-16.

Problem appears to be intermittent. Go to the “Intermittent

Problem Service Check”

on page 2-23.

Diagnostic Information 2-8

4226-001

6XX Error Indications

Symptom Action

6XX Machine Check is displayed. Turn the printer off and

then on.

Go to “Error Indication

Table” on page 2-4.

Paper Feed Problems

Symptom Action

Pressing any feed function does not

feed paper.

Go to the “Paper Feed

Service Check” on page

2-25.

Pressing Load/Unload does not

move paper down to park.

Paper stops at the tractor and does

not feed.

Frequent jams, paper skews or

creases.

Forms do not travel to TOF or travel

past TOF.

Line spacing problems.

Error “001 paper Out” cannot be

cleared.

Go to the “EOF Service

Check” on page 2-22.

EOF condition occurs with paper on

the tractor.

No EOF condition occurs with the

end of paper.

Paper did not move. Check the configuration

data for an incorrect paper

length setting.

2-9

4226-001

Operator Panel Problems

Symptom Action

Missing dotted characters, or

unreadable characters displayed.

Ready does not turn off when

Start/Stop is pressed.

Turn the printer off and

then on.

Go to the “Operator

PanelService Check” on

page 2-24.

Only the Power light turns on.

One or more buttons do not function.

Power light does not come on but

carrier moves.

One or more lights do not function.

Blank display.

Cover open displayed.

Power Problems

Symptom Action

No Power indicator on and no carrier

movement.

Check the continuity of

the power cord and the

voltage of the electrical

outlet.

Carrier does not move during POST.

Go to the “Power Failure

Service Check” on page

2-30.

Diagnostic Information 2-10

4226-001

Print Quality Problems

Symptom Action

No print, but carrier moves as if

printing.

Be sure the printhead

cables are not loose or

damaged.

Carrier moves slowly or stops at

every line.

Be sure the interface cable

is connected properly.

Check the ribbon cartridge

for binds or damage.

Go to the “Print Wire Drive

Failure Service Check” on

page 2-36.

Print density is light. If the ribbon has reached

its end of life or is worn,

the ribbon cartridge needs

to be replaced. Check the

“Printhead to Platen

Adjustment” on page 4-6.

Go to the “Ribbon Drive

Service Check” on page

2-38.

2-11

4226-001

Symptom Action

Uneven print density across the print

line.

Specific dots missing.

Scattered ink smearing, blurred

characters.

Fuzzy print.

Be sure the printhead

cables are connected

correctly to the printhead.

Clean the printhead.

Run the Print Test, see

“Test Execution” on page

3-1.Iftheprintislightat

one edge and uniformly

gets darker across the

page to the other edge,

perform the “Printhead to

Platen Adjustment” on

page 4-6.

Go to the “Print Wire Drive

Failure Service Check” on

page 2-36.

Clean the printhead.

Clean the ribbon guide.

If the ribbon has reached

its end of life or is worn,

the ribbon cartridge needs

to be replaced.

Wavy vertical lines, uneven left

margin or character width is reduced.

Go to the “Print Quality

Service Check” on page

2-32.

Clean and lubricate the

carrier shaft.

Check the“Character

Alignment Adjustment” on

page 4-5.

Go to the “Carrier Drive

Failure Service Check” on

page 2-20.

Diagnostic Information 2-12

4226-001

Ribbon Feed Problems

Symptom Action

Ribbon comes off, becomes loose or

folded, or jams.

Ribbon feeds correctly but is noisy.

Check the ribbon cartridge

for binds or damage.

Go to the “Ribbon Drive

Service Check” on page

2-38.

Noise

Symptom Action

Printer is noisy during idle.

Go to the “Abnormal Noise

Service Check” on page

Abnormal sounds when feeding

2-14.

paper, printing or during POST.

2-13

4226-001

Service Checks

Abnormal Noise Service Check

FRU Action

1Covers

Ribbon

Cartridge

2PrintUnit

Assembly

Be sure that all covers are correctly

mounted with no loose screws or latches.

Be sure the ribbon cartridge is installed

correctly.

If the pri nter makes noise during POST or

idling, perform a POR and wait a few

minutes to complete POST.

If the printer continues to make noise

during POST, but not idling, turn the

printer off and disconnect CP6 from the

logic board.

If the printer continues to make noise

during POST, turn the power off,

reconnect CP6 to the logic board,

disconnect CP3 from the logic board and

turn the power on.

If the printer continues to make noise, turn

the power off, reconnect CP3 to the logic

board, disconnect CP1 from the logic

board and turn power on.

If the printer continues to make noise,

replace the print unit assembly.

3 Ribbon

Cartridge

Feed Unit

Assembly

If the ribbon cartridge is installed correctly,

load paper on the tractor and press Form

Feed.

If the printer makes noise during paper

loading, replace the feed unit assembly.

Diagnostic Information 2-14

4226-001

FRU Action

4 Printhead

Ribbon

Cartridge

Disconnect CP4 (Printhead) from the logic

board and perform the “Print Test” on

page 2-32. If the printer makes noise while

performing the print test, check for broken

print wires or a dirty printhead nose. If

there are broken print wires or if the

printhead nose is dirty, replace the

printhead.

If the printer did not make noise during the

print test, replace the ribbon cartridge.

5 Form Feed

Mechanism

Turn power off and measure the

resistance of the following pins using the

lowest ohm range:

CP2-1 & CP2-5

CP2-2 & CP2-5

CP2-3 & CP2-6

CP2-4 & CP2-6

If the above resistances are not correct,

replace the forms motor assembly.

6 Logic Board Turn power off and remove the feed idler

gear. Check the following by rotating the

line feed motor gear by hand and

observing the parts; replace the

appropriate FRU as required:

2-15

• Broken gear teeth on the feed gears.

• Incorrect gear alignment.

• Foreign objects in the gears.

• No lubricants on the gear teeth.

• Lubrication, or excess wear of metal

bushing.

• Bent or worn feed roller shafts.

If the failure remains, replace the logic

board.

4226-001

Abnormal Print Service Check

FRU Action

1 Printer Interface

Cable

2 Logic Board Be sure the interface switch on the logic

If the printer interface cable is connected

correctly, check the continuity of all

connector signals. Replace the printer

interface cable if necessary.

board is correctly set and that the printer

emulation is consistent with the host

computer. If the problem remains, replace

the logic board.

Diagnostic Information 2-16

4226-001

Cam Drive Failure Service Check

Note: FRUs in this service check may be worn, broken, binding or

corroded.

FRU Action

1 Logic Board

Cam Assembly

Upper Pressure

Roller Assembly

Lower Pressure

Roller Assembly

If error code 635 is displayed, POR and

observe the upper and lower pressure

rollers.

If both pressure rollers move up and down

smoothly, POR again and observe the

cam motion.

If the cam motor moves smoothly, replace

the logic board.

If the cam motor does not move up and

down smoothly, check the following

mechanical connections:

• Linkage between the bracket of the upper

pressure roller and cam.

• Linkage between the bracket of the lower

pressure roller and cam.

If both linkage connections are good, POR

again and observe the cam motion. If the

cam motor moves smoothly, replace the

logic board. If the linkage connections are

incorrect, replace the appropriate FRU

(cam assembly, upper pressure roller

assembly, lower pressure roller

assembly).

2MetalBushing

Upper Pressure

Roller Assembly

Lower Pressure

Roller Assembly

2-17

The upper or lower feed roller shafts may

be binding or worn. Replace the

appropriate FRU.

4226-001

FRU Action

3 Cam Sensor Perform the “Sensor Test 2” on page 2-7.

Check that the cam position sensor status

changes correctly by using the blade of a

screw driver.

If the cam sensor status did not change

correctly, measure the voltage between

TP4 and GND,performingthe same check

as the previous step. If the cam sensor is

good, the voltage changes from + 5 V dc

to 0 V dc alternately.

• If the voltage changed correctly, replace the

cam sensor.

• If the voltage did not change correctly,

replace the logic board.

If the cam sensor status changed

correctly, POR and observe the cam

motion. If the cam motor moves smoothly,

replace the logic board.

If the cam motor does not move smoothly,

turn power off, disconnect CP3 and

remove the cam motor from the bracket.

Manually turn the cam drive gear to move

the cam one full revolution. If the cam

does not move smoothly, replace the cam

assembly.

Diagnostic Information 2-18

4226-001

FRU Action

4CamMotor

Assembly

Manually turn the cam drive gear to move

the cam one full revolution. If the cam

does move smoothly, measure the

resistance of the following pins using the

lowest ohm range of the meter:

CP3-1 & CP3-5

CP3-2 & CP3-5

CP3-3 & CP3-6

CP3-4 & CP3-6

The correct resistance of all

measurements is approximately 40 ohms.

If the above resistances are not correct,

replace the cam motor assembly.

• If the above resistances are correct, turn the

cam motor shaft by hand. It the motor shaft

turns smoothly, replace the logic board.

• If the motor shaft does not turn smoothly,

replace the cam motor assembly.

2-19

4226-001

Carrier Drive Failure Service Check

Note: When the printer detects an Error Code of 637 or 639, verify

the same error exists after removing the jammed paper.

FRU Action

1 Carrier Belt

Carrier Motor

Logic Board

If the error code is 637 or 639, or if there is

incorrect vertical print registration, check

for breakage, wear or loose tension of the

carrier belt.

If the belt is good, turn power off and

manually move the carrier to check for

smooth operation.

If the carrier moves smoothly, replace the

carrier motor assembly. If the problem

remains, replace the logic board.

If the carrier does not move smoothly,

adjust and lubricate the following parts:

• Gap between the printhead and the platen.

See “Printhead to Platen Adjustment” on

page 4-6. If the printhead gap is incorrect or

unevenright to left, reinstall the printhead or

replace the upper pressure roller assembly.

• Dirt or no oil on the carrier shaft or support.

• Binding or broken idler pulley.

If the above items are good, remove the

carrier belt from the carrier motor pulley

and move the carrier manually to check for

smooth carrier motion. If the carrier moves

smoothly, replace the carrier motor

assembly. If the carrier does not move

smoothly, replace the carrier frame

assembly.

Diagnostic Information 2-20

4226-001

FRU Action

2 Logic Board

Carrier Motor

3 Carrier Motor

Logic Board

If the error code is not 637 or 639, or if the

vertical print registration is ok, POR and

verify the carrier motor rotates. If the

carrier motor rotates slightly, POR and

observe the status of the following TPs,

using an ILP during carrier movement:

• TP9 and GND

•TP10andGND

Movecarrier slowly in both directionsIf the

status changes alternately on both

positions, replace the logic board.

If the failure re-occurs, reinstall the old

logic board and replace the carrier motor

assembly.

If the carrier motor does not rotate slightly,

measure the voltage between

TP1 (+40 V dc Motor) and GND.

• If the voltage is between +36 V dc and +42 V

dc, disconnect CP1 and measure the

resistance between pins 1 and 2 of CP1. If

the resistance is infinity, replace the carrier

motor assembly. If not, replace the logic

board.

• If the voltage is not between

+36 V dc and +42 V dc, go to the “Power

Failure Service Check” on page 2-30.

2-21

4226-001

EOF Service Check

FRU Action

1EOFSwitch

Assembly

2Tractor

Assembly

Logic Board

If the left tractor is loose or operating

incorrectly, replace the left pin feed.

If the left tractor is operating correctly,

perform “Sensor Test 1” on page 2-7.

If the status did not change correctly,

check the switching status using an ILP

between TP5 and GND. If the status did

change correctly, perform the Sensor Test

1 again and check the EOF switch on/off

operation when loading and removing

continuous forms. If it does not operate

correctly, adjust the locating position of the

EOF switch. If the problem remains after

adjusting, replace the EOF switch

assembly.

If the status did not change correctly,

replace the EOF switch assembly.

Check that the TOF sensor status

changes correctly by using a piece of

paper.

If the TOF sensor status does not change

correctly, measure the voltage between

TP3 and GND,performingthe same check

as in the previous step.

If the TOF sensor is good, the voltage

changes from + 5 V dc to 0 V dc

alternately.

• If the voltages change correctly, replace the

TOF sensor arm.

• If the voltage changes incorrectly, replace

the logic board.

Diagnostic Information 2-22

4226-001

Intermittent Problem Service Check

FRU Action

1 Logic Board Reconnect all connectors to the logic

board.

Check the following:

• Power supply ground

• Machine frame ground

• Static eliminator brush ground

• Printer interfacecable ground

If the voltages are low, check all dc

voltages at the logic board.

If the voltages are not correct, replace the

power supply.

If the failure remains, replace the logic

board.

2 Power Supply

Printhead Cable

Logic Board

3 Thermal Control

Failure

2-23

Check the customer’s outlet voltage and

ensure that it is within tolerance.

Check the continuity of the power cord.

Check all dc output voltages at the

connector CN9 pins and ensure they are

within tolerance while printing.

Check the electric leakage of the ac

wiring.

If the problem remains, replace the power

supply, printhead cable and logic board.

Go to the “Print Wire Drive FailureService

Check” on page 2-36.

4226-001

Operator Panel Service Check

Note: When the display is blank with no indications, go to the

“Power Failure Service Check” on page 2-30.

FRU Action

1 Operator Panel

Assembly

2 Logic Board If the buttons do not function, replace the

If the error code 63B, or 631 is displayed,

replace the operator panel assembly.

If there are undefined or no characters

displayed (except missing or extra dots),

replace the operator panel assembly.

Perform the “Button Test” on page 2-7.If

the switches did not operate correctly,

replace the operator panel assembly.

Note: If the problem is not fixed after

replacing the operator panel assembly,

replace the logic board.

logic board. Go to the “Paper Feed

Service Check” on page 2-25.

If the printer displays “IBM 4226” during

POST, replace the logic board.

If the message is not correct, but the

display is blank and if the carrier moves

during POST, go to the “POST Failure

Service Check” on page 2-28.

If the carrier did not move during POST,

replace the operator panel assembly.

Diagnostic Information 2-24

4226-001

Paper Feed Service Check

Remove the paper jam if it exists, load paper and press Form Feed.

FRU Action

1 Logic Board

Forms Motor

Assembly

If the paper does not move, go to the

following step (2), “Feed Gears” on page

2-26.

If the paper moves slightly, remove all

paper from the printer. Perform “Sensor

Test 1” on page 2-7. Check that the jam

sensor status changes correctly by using

a piece of paper.

If the jam sensor status does not change,

measure the voltage between TP6 and

GND, while performing “SensorTest1”on

page 2-7. If the jam sensor is good, the

voltage changes from + 5 V dc to 0 V dc

alternately. If the voltage does not change,

replace the jam sensor assembly. If the

voltagedoes change correctly, replace the

logic board.

If the jam sensor status changes, check

that the TOF sensor status changes

correctly by using a piece of paper.

If the TOF sensor status does not change

correctly, measure the voltage between

TP3 and GND, while performing “Sensor

Test 1” on page 2-7. If the TOF sensor is

good, the voltage changes from + 5 V dc

to 0 V dc alternately. If the voltage

changes correctly,replacethe TOFsensor

assembly. If not, replace the logic board.

2-25

4226-001

FRU Action

2CamAssembly

Feed Gears

Tractor Pins

Tractor Pads

If the TOF sensor status changes

correctly, remove the paper jam, load

forms and POR. Press Form Feed and

carefully observe the feed motion.

• If the printer detects an error code 002, and

ifbothpressurerollersmovedupordown,

perform the print test for about ten pages.

• If the pressure rollers did not move, check

the connection between the upper and lower

pressure roller assemblies and cam. If both

linkages are good, replace the cam

assembly.

If a paper jam still occurs, remove the

paper jam, perform the print test again

and observe if the feed roller shafts rotate.

• If the shafts do not rotate, check the feed

gears (large feed gear, feed idler gear, feed

gear,idlergear) replacing the defectivegear.

• If the shafts do rotate, and if the paper

travels to or past the TOF sensor, verify that

the top edge of the paper is correct.

If so, turn power off, and turn the feedidler

gear clockwise by hand.

• If the paper did not move up smoothly,

remove the tractor drive idler gear and

manually turn the tractor shaft gear

clockwise.

• If the paper does not move up smoothly,

Check if the tractor pins and both tractor

pads are broken or loose and replace as

required.

If the paper does move up smoothly,

remove the feed idler gear while manually

turning the large gear counterclockwise by

hand.

• If the large gear does not turn smoothly,

check and replace the following parts as

required: (metal bushing, feed idler gear,

largegearrollershafts).

• If the large gear does turn smoothly,

continue.

Diagnostic Information 2-26

4226-001

FRU Action

3 Logic Board

If the paper does move smoothly, remove

connector CP2 and measure the

Forms Motor

Assembly

resistance of the following pins using the

lowest ohm range. The correct resistance

should be approximately 7 ohms.

CP2-1 & CP2-5

CP2-2 & CP2-5

CP2-3 & CP2-6

CP2-4 & CP2-6

• If all the above resistances are correct,

replace the logic board.

• If they are not correct, replace the forms

motor assembly.

4 Feed Gears Ensure that the feed gears engage

correctly.

• Turn the forms drive motor while observing

the gears.

• If the gears do not engage correctly,reinstall

the suspected gear.

• If the stopper lugs of the suspected gear are

loose, broken or worn, replace the defected

gear.

2-27

4226-001

POST Failure Service Check

FRU Action

1 Logic Board POR the printer.

If the alarm sounds during POST, and the

error code displayed is 005, by-pass the

cover open sensor CJ19 on the operator

panel board by using the jumper wire in

the parts packet.

• If the alarm still sounds, replace the logic

board. If the alarm still sounds, check the

following:

• Cover magnet of the access cover.

• Operator panel position.

• Connector terminal surface of the operator

panel cable.

• If the aboveitems are all correct, replace the

logic board. If not, repair or replace the

suspected item.

2 Operator Panel

Assembly

If the alarm does not sound and “IBM

4226” is not displayed, check if the power

indicator turns on. If it does, replace the

logic board. If it does not, go to the “Power

Failure Service Check” on page 2-30.

If the error code displayed is not 005 and

the display is blank, verify the check

indicator turns on.

• If it does, replace the operator panel

assembly.

• If it does not, replace the logic board.

Diagnostic Information 2-28

4226-001

FRU Action

3 Printer Interface

Cable

If the alarm does not sound and “IBM

4226” is displayed, check the following:

• Turn the power off.

• Remove the printer interface cable from the

printer.

• Turn the power on.

Observe the display and Check indicator

and if the failure re-occurs, replace the

logic board. If the failure does not reoccur,the problem may exist in the printer

interface cable or the host. Replace the

printer interface cable.

2-29

4226-001

Power Failure Service Check

FRU Action

1 Operator Panel If the operator panel or cable is damaged

or disconnected, the machine is

completely inoperable.

If the power LED is not on steady, check

the cable continuity and replace the cable

or the operator panel.

POR the printer. If the Power indicator

turns on, go to the “POST Failure Service

Check” on page 2-28.

2 Power Supply If the printer is completely inoperable,

disconnect the power supply cable from

the Logic Board. Measure the following

voltages.

CP 9-1 & CP 9-4 (+ 40 V dc)

CP 9-2 & CP 9-5 (+ 40 V dc)

CP 9-3 & CP 9-6 (+ 40 V dc)

CP 9-9 & CP 9-7 (+ 5 V dc)

CP 9-10 & CP 9-8 (+ 5 V dc)

If one or more of the voltages are not

present, replace the power supply.

3 Logic Board Measure the voltage between TP2

(printhead drive + 40 V dc) and GND on

the logic board.

If the voltage at TP2 is between +36 and

+42 V dc, measure the voltage between

TP1 (motor drive + 40 V dc) and GND on

the logic board.

If the voltage is between +36 and +42 V

dc, replace the logic board.

Diagnostic Information 2-30

4226-001

FRU Action

4 Printhead

Cables

Printhead

5 Forms Motor

Ribbon Motor

Cam Motor

Carrier Motor

If the voltage at TP1 is not between +36

and +42 V dc, disconnect the printhead

cables(CP4) from the logic board and turn

the printer on. If the Power LED lights,

there is a short in the printhead cables or

printhead.

Disconnect the forms motor, the ribbon

motor, the cam motor and the carrier

motor from the logic board. Turn the power

on. If the power problem remains, replace

the logic board.

If the machine POSTs, one of the motors

is holding down the +40 V dc line.

Reconnect them one at a time, turning the

printer on between each connection.

Replace the part that causes the power

failure.

2-31

4226-001

Print Quality Service Check

This procedure should be used only when you have print quality

problems without any other visible machine problem. That is, the

machine runs, feeds the correct number of pages without an error

indication and stops normally.

The Symptom Description Table provides the details of the problem

with defect samples.

Print Test

Two types of print tests are provided for the verification of print

quality. One test prints the built-in character image, while the other

prints several specific test patterns. The following methods describe

the print quality checking procedures.

To run the Print Demo in the utility function:

1. Make sure the "Ready" indicator is on.

2. Press Start/Stop; the "Ready" indicator turns off.

3. Press Menu/Quit; then press Item − or Item ↓ to select "Print

Demo".

4. Press Start/Stop;thePrintDemowillstart.

5. Press hold Start/Stop to stop this test.

If you need correct print samples, s ee the IBM 4226 Printer User's

Reference.

To run the print test procedure:

1. POR the printer.

2. Press and hold Menu/Quit during POST until the message

"Sensor Test 1" is displayed.

3. Press Item − until "Print Test" is displayed.

4. Press Start/Stop to start printing. The message changes to

"Printing".

5. Press and hold Start/Stop to stop printing.

6. Turn the power off to exit this test mode.

If you need the correct print samples, see Chapter 3, Diagnostic Test

in the IBM 4226 printer Maintenance Information Manual.

Diagnostic Information 2-32

4226-001

Print Test Patterns

Test Patterns Function

Pattern 101

(Special Box Pattern)

Pattern 102

(Draft Font Pattern)

Pattern 103

(Print Wire Pattern)

Pattern 104

(Unidirectional Grid Pattern)

Pattern 105

(Bidirectional Grid Pattern)

Pattern 106

(Non-Volatile Memory

(NVM) Dump)

This test pattern is used to check

the TOF position, print registration,

print density,or to find dirty or void

spots.

This test pattern is used to verify

the style of the selected font and to

check the draft print quality.

this test pattern is used to check

the impression of each wire or to

find the missing dots.

This test pattern is used to check

the alignment of vertical and

horizontal line spacing in the

unidirectional printing mode.

This test pattern is used to check

the alignment of vertical and

horizontal line spacing in

bidirectional printing mode.

This pattern prints the contents of

the Non-Volatile Memory (NVM). it

consists of two parts, including 32

bytes of customer configuration

data, and 16 bytes of error logs

with 16 bytes of counters.

2-33

4226-001

Quick Check Table

Symptom Action

No Print

Light print

Light zone

Light spots

Scratches

Voids

Missing dots

Extra dots

Horizontal streaks

• Set the lever to position 1 and adjust the gap

between the printhead and platen.

• If the printhead cable is loose, folded or

broken, reconnect or replace it.

• If the printer interface mode mismatches the

physical connection, change the

configuration data or switch the I/F mode

selection switch on the rear of the logic

board.

• If the ribbon is worn, replace the ribbon

cartridge.

• Be sure the ribbon cartridge is installed

correctly.

• Check for loose ribbon motor and ribbon

drive mounting screws.

• Be sure the printhead to platen gap is

adjusted correctly.

Be sure the printhead cable connector is

seated properly to the printhead and the

and the logic board.

Be sure the printhead nose is clean.

Check the position of the forms thickness

lever and be sure it is set to “1”.

If the ribbon shield is dirty, replace the

ribbon cartridge.

Poor resolution

Blurred density

Uneven density

Fuzzy text

Smeared text

Be sure the printhead nose is clean.

If the ribbon shield is dirty, replace the

ribbon cartridge.

If the ribbon is worn, replace the ribbon

cartridge.

Be sure the printhead to platen gap is

equal at left and right ends. If adjusting the

gap does not fix the problem, replace the

carrier frame assembly.

Diagnostic Information 2-34

4226-001

Symptom Action

Incorrect registration

Incorrect margins

Distortion

Wavy text

Incorrect vertical

registration

Incorrect line spacing

If the carrier drive belt is worn, adjust or

replace it.

Be sure the carrier motor turns smoothly

and silently (no noise), while printing.

Clean and lubricate the carrier shaft.

Check the tension pulley and bracket for

wear or looseness. Tighten the bracket

mounting screws or replace the tension

pulley assembly.

Adjust the character alignment. If you

cannot adjust it correctly, readjust the

carrier drive belt tension and perform the

“Character Alignment Adjustment” on

page 4-5 again.

Replace or lubricate the feed gears or

metal bushing.

Be sure the feed motor turns smoothly

and silently (no noise) while feeding

paper. Replace the forms motor assembly.

Replace or tighten any broken tractor

pads or pins.

2-35

Clean or replace the roller shafts.

4226-001

Print Wire Drive Failure Service Check

FRU Action

1 Printhead

Logic Board

Printhead Cable

If the problem appears as a missing or

extra dot, or no print wire, perform the

“Print Test” on page 2-32 to determine the

failing print wire(s).

If the same wires still fail, turn power off,

remove the connector CP-4 from the logic

board and check the cable continuity with

the coil resistance of the specified magnet

wire signal in “Resistance Table 1” on

page 2-37, using the lowest ohm range.

If the resistances are correct, the problem

may be the printhead or the logic board.

Replace the printhead and if the problem

remains, replace the old printhead and

replace the logic board.

Note: it is a good practice to inspect the

printhead nose carefully. If all wires are

not aligned to the head surface, the case

may break or strain print wires in the

printhead.

If resistances are not correct, remove

connector CP18 from the printhead.

Check the cable continuity of the specified

magnet wire signal and its common signal

in “Resistance Table 2” on page 2-37,

using the lowest ohm range. If the

continuity is good, replace the printhead

cable.If the continuity is not good, replace

the printhead.

Diagnostic Information 2-36

4226-001

Resistance Table 1

Pin Number Pin Description

CP4-1 & CP4-2 No. 1 Print Wire Magnet

CP4-20 & CP4-19 No. 2 Print Wire Magnet

P4-4 & CP4-3 No. 3 Print Wire Magnet

CP4-17 & CP4-18 No. 4 Print Wire Magnet

CP4-5 & CP4-6 No. 5 Print Wire Magnet

CP4-15 & CP4-16 No. 6 Print Wire Magnet

CP4-8 & CP4-7 No. 7 Print Wire Magnet

CP4-13 & CP4-14 No. 8 Print Wire Magnet

CP4-10 & CP4-11 No. 9 Print Wire Magnet

Resistance Table 2

Pin Number Pin Description

CP4-1 & CP18-1 No. 1 Print Wire Magnet

CP4-2 & CP18-2 No. 1 Print Wire Common

CP4-20 & CP18-20 No. 2 Print Wire Magnet

CP4-19 & CP18-19 No. 2 Print Wire Common

CP4-4 & CP18-4 No. 3 Print Wire Magnet

CP4-3 & CP18-3 No. 3 Print Wire Common

CP4-17 & CP18-17 No. 4 Print Wire Magnet

CP4-18 & CP18-18 No. 4 Print Wire Common

CP4-5 & CP18-5 No. 5 Print Wire Magnet

CP4-6 & CP18-6 No. 5 Print Wire Common

CP4-15 & CP18-15 No. 6 Print Wire Magnet

CP4-16 & CP18-16 No. 6 Print Wire Common

CP4-8 & CP18-8 No. 7 Print Wire Magnet

CP4-7 & CP18-7 No. 7 Print Wire Common

CP4-13 & CP18-13 No. 8 Print Wire Magnet

CP4-14 & CP18-14 No. 8 Print Wire Common

CP4-10 & CP18-10 No. 9 Print Wire Magnet

CP4-11 & CP18-11 No. 9 Print Wire Common

2-37

4226-001

Ribbon Drive Service Check

Note: Turn the power off, remove the ribbon cartridge and turn

power on.

FRU Action

1 Ribbon

Cartridge

If the ribbon drive shaft rotates during

POST, install the ribbon cartridge and

perform the “Print Test” on page 2-32.If

the feed knob rotates continuously while

printing, rotate the drive knob on the

ribbon cartridge manually.

If the ribbon does not feed smoothly,

replace the ribbon cartr idge.

If the ribbon feeds smoothly, check the

following items and adjust, clean or

replace defective parts as necessary:

• Dirt on the printhead nose.

• Printhead mounting position and loosened

screws.

• Incorrect gap between the printhead and

platen.

• Dirty or damaged ribbon shield.

If all items are good, go to the “Print Wire

Drive Failure Service Check” on page

2-36.

Diagnostic Information 2-38

4226-001

FRU Action

2 Ribbon Drive

Double Gear

Planet Gear

Spring

Ribbon Drive

Assembly

3 Logic Board

Ribbon Drive

Motor Assembly

If the ribbon drive shaft does not rotate

during POST, turn the power off, remove

the ribbon drive assembly and turn power

on while observing the ribbon drive motor

shaft.

If the ribbon drive motor turns normally,

check the r ibbon planet gear spring for

damage.

If the spring is mounted incorrectly, install

or replace the planet gear spring.

If the gear is mounted correctly, check all

gears of the ribbon feed.

If the gears are not engaged correctly,

replace the ribbon drive double gear.

If the gears are engaged correctly, replace

the ribbon drive assembly.

If the ribbon drive motor does not turn

normally, turn the printer off, disconnect

the ribbon motor connector CP6 from the

logic board and measure the resistance of

the following pins:

2-39

CP6-1 & CP6-5

CP6-2 & CP6-5

CP6-3 & CP6-6

CP6-4 & CP6-6

The correct resistance of all

measurements is approximately 150 ohm.

If all the resistances are correct, replace

the logic board. If the resistances are not

correct, replace the ribbon drive motor

assembly.

4226-001

3. Diagnostic Aids

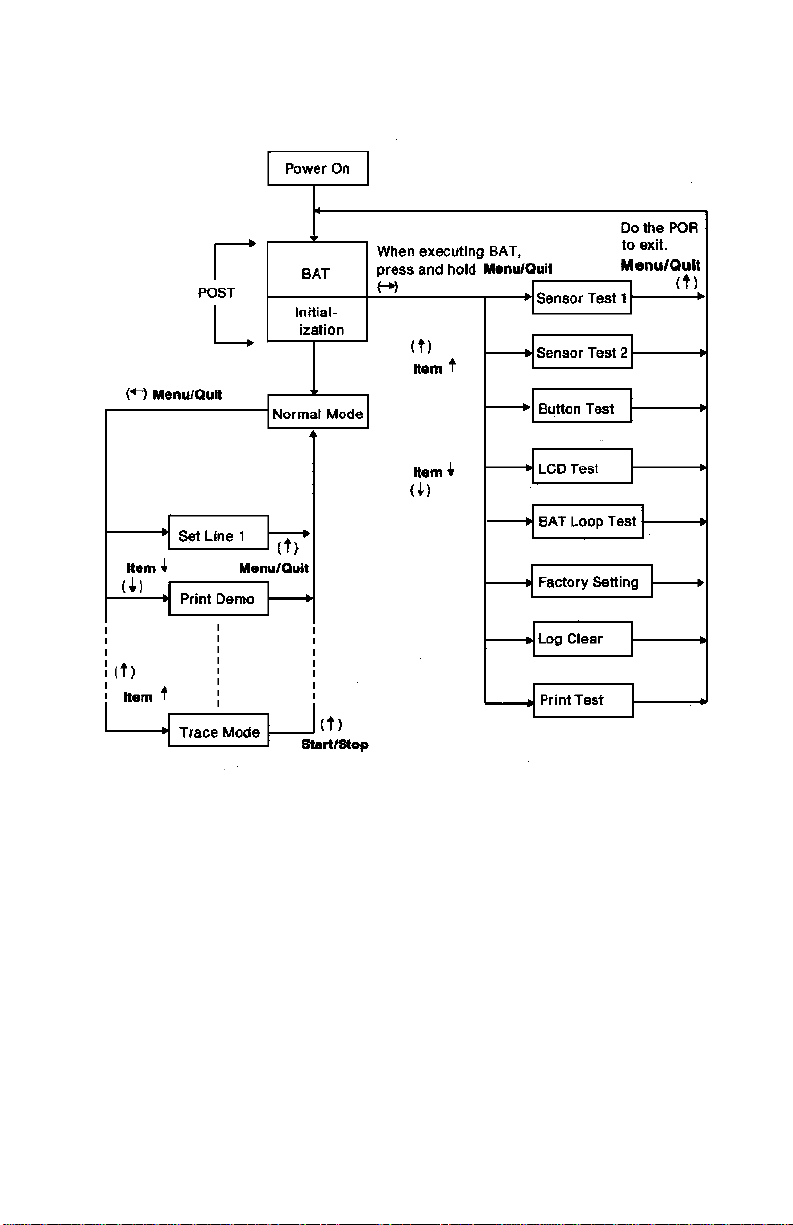

Offline Test (Resident Non-Automatic Tests)

Test Execution

Offline test aid in detecting intermittent problems or to observe the

NVM contents. To run the test, do the following:

• POR.

• Press and hold Menu/Quit during POST until the "Sensor Test

1" message is displayed.

• Press Item

or Item↑to select a test item.

↓

• Press Start/Stop to start selected test.

• Press Menu/Quit to stop all tests except BAT Loop and the

Button tests.

• Turn the power off to exit test mode.

The test menu includes a sensor test which displays the status of the

sensors in the following manner:

• Underline - sensor is inactive.

• Box pattern - sensor is active.

If the EOF switch is on, the printer is in the EOF state. If the TOF

sensor is on, the paper is under the TOF sensor.

Diagnostic Aids 3-1

4226-001

Sensor Test 1

Device Display Type On State

TOF Sensor TOF Photointerrupter Form in printer

EOF Switch EOF Micro-switch No paper on the

tractor

Jam Sensor JAM Photointerrupter Paper under the

sensor

GapLeverPosition

Sensor

GAP Photointerrupter The forms thickness

lever position is set

between 1 and 2.5

Note: The gap lever position is in the off state when the forms

thickness lever position is set between 3 and 6.

Sensor Test 2

Device Display Type On State

Cover Open

Sensor

Cam Sensor CAM Photointerrupter Shut off (cam is at

Head or Carrier

Motor Thermal

Sensor

Cover Hole device Cover open

home)

HEAT Posistor High temperature

Button Test

This test verifies the button operation on the operator panel. When

anybutton is pressed, the alarm sounds continuously until the button

is released. If two or more buttons are pressed simultaneously, the

alarm does not sound. To end the test, perform a POR.

LCD Test

This test verifies the LCD Ram Read/Write functions. All dots on the

LCD flash on and off at one-second intervals. If an error is detected,

Error Code 631 is displayed and the test stops.

3-2

4226-001

BATLoopTest

This test is helpful in determining intermittent problems. The test

repeats each test item of the BAT. To end the test, perform a POR.

Factory Setting

This test sets the printer to the factory settings.

To run this test:

• Press the Scroll

or Scroll ↓to select the setting.

↑

• Press Store

The following settings are selectable at shipment:

Setting U.S. Non-U.S.

Page length 11 inches 12 inches

Character set 1 2

Codepage 437 850

Download Codepage 437 850

Log Clear

This test clears the NVM log when Start/Stop is pressed.

Diagnostic Aids 3-3

4226-001

Print Test

This test detects print quality problems and stores the results in the

NVM dump area.

WARNING: Do not run this test for more than 10 pages or printhead

damage may occur.

Pattern 101

(Special Box Pattern) - Checks the print registration, print density or

dirty / voided spots.

Pattern 102

(Draft Font Pattern) - Verifies the draft font style and print quality.

Pattern 103

(Print Wire Pattern) - Checks the impression of each print wire.

Pattern 104

(Unidirectional Grid Pattern) - Checks alignment of vertical and

horizontal line spacing in unidirectional mode.

3-4

4226-001

Pattern 105

(Bidirectional Grid Pattern) - Checks alignment of vertical and

horizontal line spacing in bidirectional mode.

Pattern 106

(NVM Dump) - Prints the contents of NVM. This consists of two

parts (including 80 bytes of data), address X’00’ through X’2F’

(which is the configuration or the customer setup data), and address

X’50’ through X’6F’ data (which is the sequential error logs with

counter).

Diagnostic Aids 3-5

4226-001

Note: Error Log in the Pattern 106.

• Error codes are printed on the top line of the Error Log and their

corresponding counters are printed below. (An error code X’00’

indicates no errors are registered in the counter.)

• Each new error appears on the left-most position and the

previous error code shifts to the right, one position.

• If the new error code is the same as the previous error code, the

counter is increased by 1. The maximum count number for the

same error is 256 and the counter remains at this value (X’FF’).

No more than the 16 most recent error codes can be printed in

the error log area.

PrintTestSample

3-6

4226-001

Trace (Hexadecimal Print)

The hex trace mode can help the user test and troubleshoot

programs. You can use the hex trace procedure to get a

hexadecimal printout of the data stream sent to the printer. All data,

including control and character data, print in hexadecimal instead of

ASCII.

To activate trace print:

1. Press Menu/Quit. The "Set Line 1" message is displayed.

2. Press Item↑once.

3. The "Trace Mode" is shown on the operator panel.

4. Press Start/Stop to start the trace printing.

5. Press Start/Stop again to stop the trace printing.

6. When the trace printing ends, do a POR.

When printing with this function, print width is automatically defined

by setting default values in NVM. Printing format is as follows:

Narrow Width Pattern

Diagnostic Aids 3-7

4226-001

Wide Width Pattern

Hexadecimal Print Sample (Wide Width)

3-8

4226-001

4. Repair Information

This chapter contains adjustments and removal procedures. Before

analyzing or repairing the printer, you must by-pass the cover open

circuit using the jumper wire in the parts packet. When replacing

parts, be sure to use the appropriate diagnostic procedure and

adjustment.

Handling ESD-Sensitive Parts

Many electronic products use parts that are known to be sensitive to

electrostatic discharge (ESD). To prevent damage to ESD-sensitive

parts, follow the instructions below in addition to all the usual

precautions, such as turning off power before removing logic boards:

• Keep the ESD-sensitive part in its original shipping container

(a special “ESD bag”) until you are ready to install the part into

the machine.

• Make the least-possible movements with your body to prevent

an increase of static electricity from clothing fibers, carpets, and

furniture.

• Put the ESD wrist strap on your wrist. Connect the wrist band to

the system ground point. This discharges any static electricity in

your body to the machine.

• Hold the ESD-sensitive part by its edge connector shroud

(cover); do not touch its pins. If you are removing a plugable

module, use the correct tool.

• Do not place the ESD-sensitive part on the machine cover or on

a metal table; if you need to put down the ESD-sensitive part for

any reason, first put it into its special bag.

• Machine covers and metal tables are electrical grounds. They

increase the risk of damage because they make a discharge

path from your body through the ESD-sensitive part. (Large

metal objects can be discharge paths without being grounded.)

• Prevent ESD-sensitive parts from touching other personnel.

Install machine covers when not working on the machine, and

do not put unprotected ESD-sensitive parts on a table.

• Keep all ESD-sensitive parts in a grounded metal cabinet

(case).

• Low humidity increases static electricity during cold weather.

Repair Information 4-1

4226-001

Adjustments

CAUTION: Be sure to unplug the power cord whenever you are

working on the printer with any of the covers removed.

Note: Before returning the printer to the customer, reset all

customer setup values. Refer to the IBM 4226 Printer User’s

Reference for instructions.

Carrier Assembly Adjustment

Note: After power is turned off and the ribbon cassette is removed,

the moving load of the carrier assembly should be equal in all

positions when it is moved left ore right by hand. Whenever you

replace or adjust carrier related parts, perform the character

alignment adjustment, see “EOF Switch Adjustment” on page 4-6.

Symptoms Actions

Dry oil pad

The carrier drags when you move it

left and right by hand.

Broken bearings

When moving the carrier by hand,

it drags intermittently or makes

abnormal noise. To check for

broken bearings, remove the

carrier drive belt.

Broken ribbon drive assembly

When turning the ribbon feed knob

by hand, the ink ribbon

intermittently drags, sticks or does

not turn.

4-2

Remove the printhead and

lubricate the two oil pads with an

appropriate amount of IBM # 6 oil.

Replace the carrier motor if the

motor bearings are bad or replace

the tension pulley assembly if the

tension pulley bearing is bad.

Replace the ribbon cartridge. If the

problem still occurs, replace the

ribbon drive assembly.

4226-001

Symptoms Actions

Broken carrier shaft bushing or

support shaft bushing.

When moving the carrier by hand,

the carrier intermittently drags or

does not move.

Broken ribbon shield

When feeding the form in the

printer, the form feeding drags or

breaks at the ribbon shield.

REplace the carrier frame

assembly.

Replace the ribbon cartridge.

Carrier Belt Adjustment

Note: Whenever you replace or adjust carrier related parts, perform

the character alignment adjustment, see “EOF Switch Adjustment”

on page 4-6.

1. Remove the top cover.

2. Remove the front cover.

3. Move the carrier to the left end.