Page 1

S400

Safety switch

EN 2014/07 - 607920

We reserve the right to

make technical changes

SAFE IMPLEMENTATION AND OPERATION

Original operating instructions

Page 2

© 2014

Leuze electronic GmbH + Co. KG

In der Braike 1

D-73277 Owen / Germany

Phone: +49 7021 573-0

Fax: +49 7021 573-199

http://www.leuze.com

Leuze electronic S400 2

Page 3

1 About this document. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.1 Other applicable documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2 Used symbols and signal words . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.1 Approved purpose and foreseeable improper operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.1.1 Proper use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.1.2 Foreseeable misuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.2 Competent personnel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.3 Responsibility for safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.4 Disclaimer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3 Device description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.1 Device overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4 Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.1 Special functions and performance characteristics of the S420-OSx series . . . . . . . . . . . . . . . . . . 10

4.2 Display elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

5 Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

6 Mounting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

6.1 Mounting the safety hinge switch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

7 Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

7.1 Connecting the contact block. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

8 Starting up the device. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

9 Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

9.1 To be performed prior to the initial start-up by competent personnel . . . . . . . . . . . . . . . . . . . . . . . 25

9.2 To be performed periodically by competent personnel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

9.3 To be performed daily by the operating personnel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

10 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

11 Disposing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

12 Service and support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

13 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

13.1 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

14 Ordering information and accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

14.1 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

15 EC Declaration of Conformity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Leuze electronic S400 3

Page 4

1 About this document

1.1 Other applicable documents

The information on the S400, S410 and S420 safety hinge switches is divided into two documents. Docu-

ment “S400 Application information” contains only the most important safety notices.

For the safe implementation, testing and operation, download document “S400 Safe implementation

and operation” from http://www.leuze.com/s400/ or request it from service.protect@leuze.de or

tel. +49 8141 5350-111.

Table 1.1: Documents on the safety hinge switch

Purpose and target group Title Source

About this document

Detailed information for all users S400 Safe implementation and

Basic information for technicians

and operating company

1.2 Used symbols and signal words

Table 1.2: Warning symbols and signal words

Symbol for dangers

NOTICE Signal word for property damage

Indicates dangers that may result in property damage if the measures for danger

avoidance are not followed.

CAUTION Signal word for minor injury

Indicates dangers that may result in minor injury if the measures for danger avoidance are not followed.

WARNING Signal word for serious injury

Indicates dangers that may result in severe or fatal injury if the measures for danger

avoidance are not followed.

On the Internet, download from:

operation (this document)

S400 Application information Print document part no. 607240

http://www.leuze.com/s400/

included in the delivery contents of the product

DANGER Signal word for life-threatening danger

Indicates dangers that will result in severe or fatal injury if the measures for danger

avoidance are not followed.

Table 1.3: Other symbols

Symbol for tips

Text passages with this symbol provide you with further information.

xxx Placeholder in the product description for all variants

Leuze electronic S400 4

Symbols for action steps

Text passages with this symbol instruct you to perform actions.

Page 5

2 Safety

Before using the safety hinge switch, a risk assessment must be performed according to valid standards

(e.g. EN ISO 12100, EN ISO 13849-1). For mounting, operating and testing, document S400 Sicher imple-

mentieren und betreiben, application information as well as all applicable national and international stan-

dards, regulations, rules and directives must be observed. Observe and print out relevant and supplied

documents and distribute to the affected personnel.

The following standards apply for the risk assessment at the protective device prior to using the safety

hinge switch:

• EN ISO 12100, Safety of machinery, risk assessment

• EN ISO 13849-1, Safety-related parts of control systems

The realizable category of the integration in control circuits according to EN ISO 13849-1 is dependent on

the used contact block and wiring.

In particular, the following national and international legal regulations apply for the start-up, technical

inspections and work with safety hinge switch:

• Machinery directive 2006/42/EC

• Low voltage directive 2006/95/EC

• Use of work equipment directive 2009/104/EC

• Safety regulations

• Accident-prevention regulations and safety rules

• Industrial safety regulation and employment protection act

• Product Safety Act

Safety

For safety-related information you may also contact the local authorities (e.g., industrial inspec-

torate, employer's liability insurance association, labor inspectorate, occupational safety and

health authority).

2.1 Approved purpose and foreseeable improper operation

2.1.1 Proper use

• The safety hinge switch must only be used after it has been selected in accordance with the respectively applicable instructions and relevant standards, rules and regulations regarding labor protection

and safety at work, and after it has been installed on the machine, connected, commissioned, and

checked by a competent and authorized person.

• When selecting the safety hinge switch it must be ensured that its safety-related capability meets or

exceeds the required performance level PL

• It must be in perfect condition and inspected regularly.

• The safety hinge switch may be used in combination with a safety relay or a safety control.

WARNING

A running machine can cause severe injuries!

Make certain that, during all conversions, maintenance work and inspections, the system is securely

shut down and protected against being restarted.

ascertained in the risk assessment.

r

S400, S410 and S420 safety hinge switches must be connected in such a way that a dangerous state can

only be activated while the protective device is closed and so that the dangerous state stops upon opening

of the protective device. It must not be used if the point of operation can be accessed during the lag time

before the dangerous state has ended. If stepping behind the guard is possible, a start/restart interlock is

mandatory.

Connection conditions:

• the dangerous state can only be activated while the protective device is closed

• opening the protective device while the machine is running triggers a stop command and ends the

dangerous state

Leuze electronic S400 5

Page 6

Safety

Furthermore, the S400, S410 or S420 safety hinge switch must not be used under the following conditions:

• rapidly changing ambient temperature (leads to condensation)

• in the event of strong physical shocks

• when ice has formed

• in explosive or easily flammable atmospheres

• in the event of aggressive chemical influences

• the mounting locations are not sufficiently stable

• the safety of multiple persons is dependent on the function of this safety switch (e.g. nuclear power

plants, trains, aircraft, motor vehicles, incinerators, medical devices)

For machines with longer slowdowns, a safety locking device must be used.

Handling the safety hinge switch:

Observe the permissible environmental conditions for storage and operation (see chapter 13 „Technical

data“).

Immediately replace damaged safety hinge switch according to these instructions.

Use cable gland, insulation materials and connecting wires of the appropriate protection rating.

Protect the safety hinge switch from penetrating foreign bodies (e.g. shavings, sand and blasting agent).

Cover before performing painting work.

Immediately clean any contamination from the safety hinge switch that impacts function according to

these instructions.

Do not open the cover on the rear side.

Make no structural changes to the safety hinge switch.

The safety hinge switch must be exchanged after a maximum of 20 years.

2.1.2 Foreseeable misuse

Any use other than that defined under the "approved purpose" or

hinge switch is considered improper use!

E.g. - using without non-detachably mounted actuator

• looping into the safety circuit parts that are not relevant to safety

• using the hinge switch as a limit stop

2.2 Competent personnel

Prerequisites for competent personnel:

• suitable technical training

• knows the rules and regulations for labor protection, safety at work and safety technology and can

assess the safety of the machine

• knows the instructions for the safety hinge switch and the machine and understands them

• was instructed by the responsible individuals on the mounting and operation of the machine and of

the safety hinge switch

2.3 Responsibility for safety

Manufacturer and operating company must ensure that the machine and implemented safety hinge switch

function properly and that all affected persons are adequately informed and trained.

The type and content of all imparted information must not lead to unsafe actions by users.

which goes beyond that use of the safety

Leuze electronic S400 6

Page 7

The manufacturer of the machine is responsible for:

• safe machine construction

• safe implementation of the safety hinge switch

• imparting all relevant information to the operating company

• adhering to all regulations and directives for the safe starting-up of the machine

The operating company is responsible for:

• instructing the operating personnel

• maintaining the safe operation of the machine

• adhering to all regulations and directives for labor protection and safety at work

• regular testing by competent personnel

2.4 Disclaimer

Leuze electronic GmbH + Co. KG is not liable in the following cases:

• Safety hinge switch is not used as intended

• Safety notices are not adhered to

• Testing is not performed by competent and authorized personnel

• Faulty mounting, connection, start-up

• Deficient execution of tests for proper protective function

• Reasonably foreseeable misuse is not taken into account (e.g. manipulation, reaching behind the

safety device)

• Technical data is not observed

Safety

Leuze electronic S400 7

Page 8

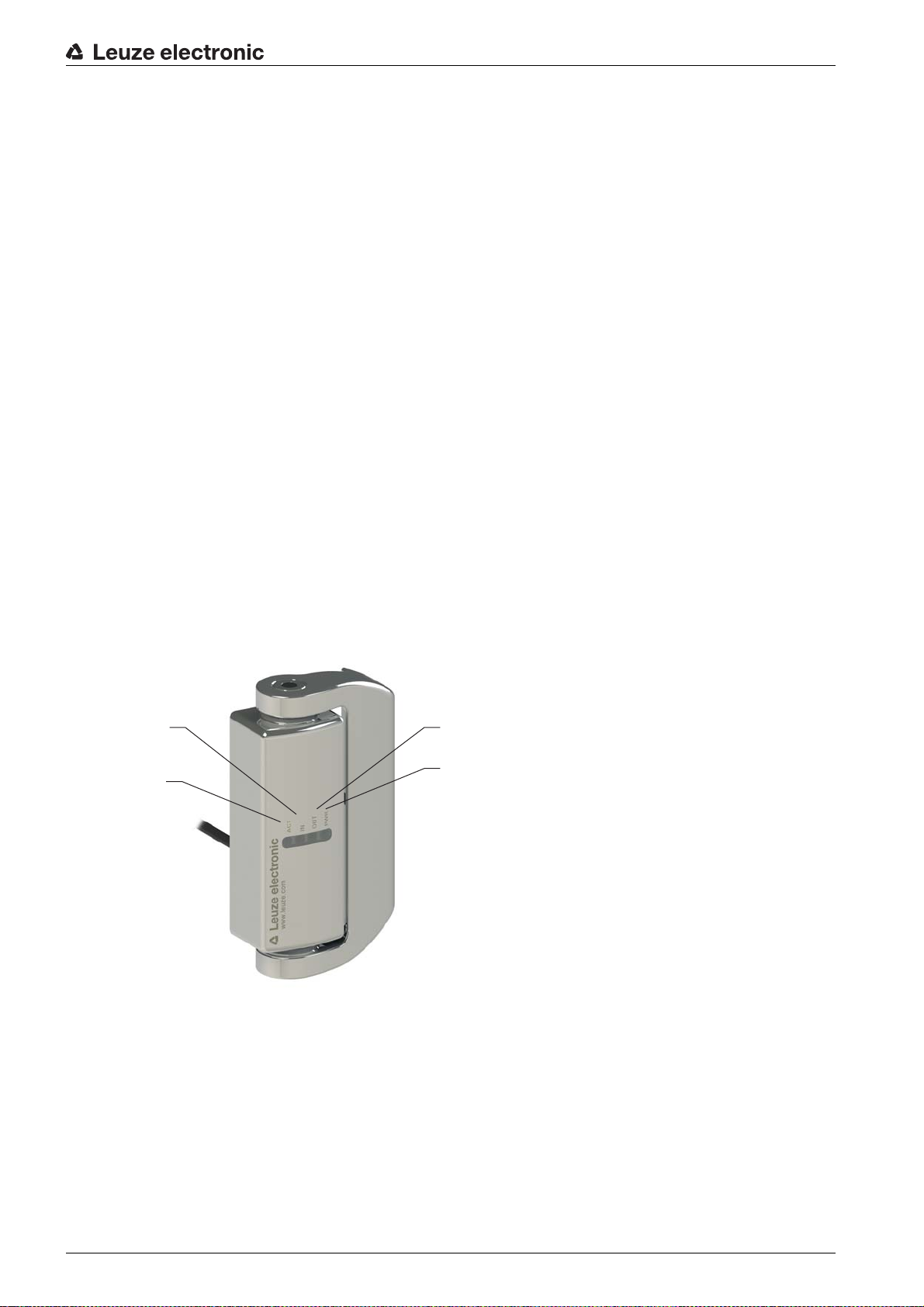

3 Device description

1

3

2

1

3.1 Device overview

The S400, S410 and S420 safety hinge switches are very compact and stable electro-mechanical

switching devices in a housing made of metal (stainless steel for the S420); the devices satisfy protection

rating IP 67 and IP 69K. The actuator is integrated into the housing. Depending on the version, electrical

connection is done either via a cable or a M12 plug with optional cable entry from above, below or on the

wall side (mounting side). This enables monitoring of all types of doors, hoods, flaps, etc. The opening

angle of the safety hinge switch is up to 180°. The switching angle is adjustable and can be adjusted

multiple times if necessary (e.g. misadjusted door).

Device description

1 Safety hinge switch

2 Cable entry or M12 plug

3 Opening for adjusting the switching angle

Figure 3.1: S400 safety hinge switch

Figure 3.2: S410 safety hinge switch

Leuze electronic S400 8

Page 9

Device description

Figure 3.3: S420 safety hinge switch

The S400 series has a total width of 49 mm.

The S410 series has a total width of 79 mm.

The S420 series has a total width of 76 mm.

The M4 models are equipped with slow action contacts (2NC/1NO).

The M1 models are equipped with snap-action contacts (2NC/1NO).

The 9 models are equipped with slow action contacts (2NC/2NO).

The OS models are equipped with two safety-related switching outputs (OSSDs), two inputs and a signal

output.

Leuze electronic S400 9

Page 10

4 Functions

2

1

3

4

S400, S410 and S420 safety hinge switches are used as a mechanical hinges and simultaneously for posi-

tion monitoring of turning, bearing-mounted guards. The integrated safety contacts are force-opened as

soon as the preset switching angle is reached. As a result, the machine can only be switched on if the

protective device is closed.

In all models, the switching angle can be reset multiple times (e.g. when the door is misaligned) via the

protected adjusting screw. The covered screw mounting has a strong manipulation-resistant effect.

The S420 series satisfies strict requirements, e.g. in the food, pharmaceutical and cosmetic industries,

thanks to the stainless steel housing in accordance with safety class IP 67 and IP 69K with mechanical

load values up to 2000 N.

For the S420 series, versions are contact-supported or available with electronic inputs and OSSDs.

4.1 Special functions and performance characteristics of the S420-OSx series

• 2 electronic inputs

• 2 safety-related switching outputs (OSSDs)

• 1 signal output of actuator status

• Series connection of up to 32 S420-OSx

• Safety category 4, PL e, SIL CL 3

• Diagnosis display (LEDs) of operating voltage, self test, actuator status, OSSD status and input status

Functions

4.2 Display elements

1LED ACT

2LED IN

3LED OUT

4LED PWR

Leuze electronic S400 10

Page 11

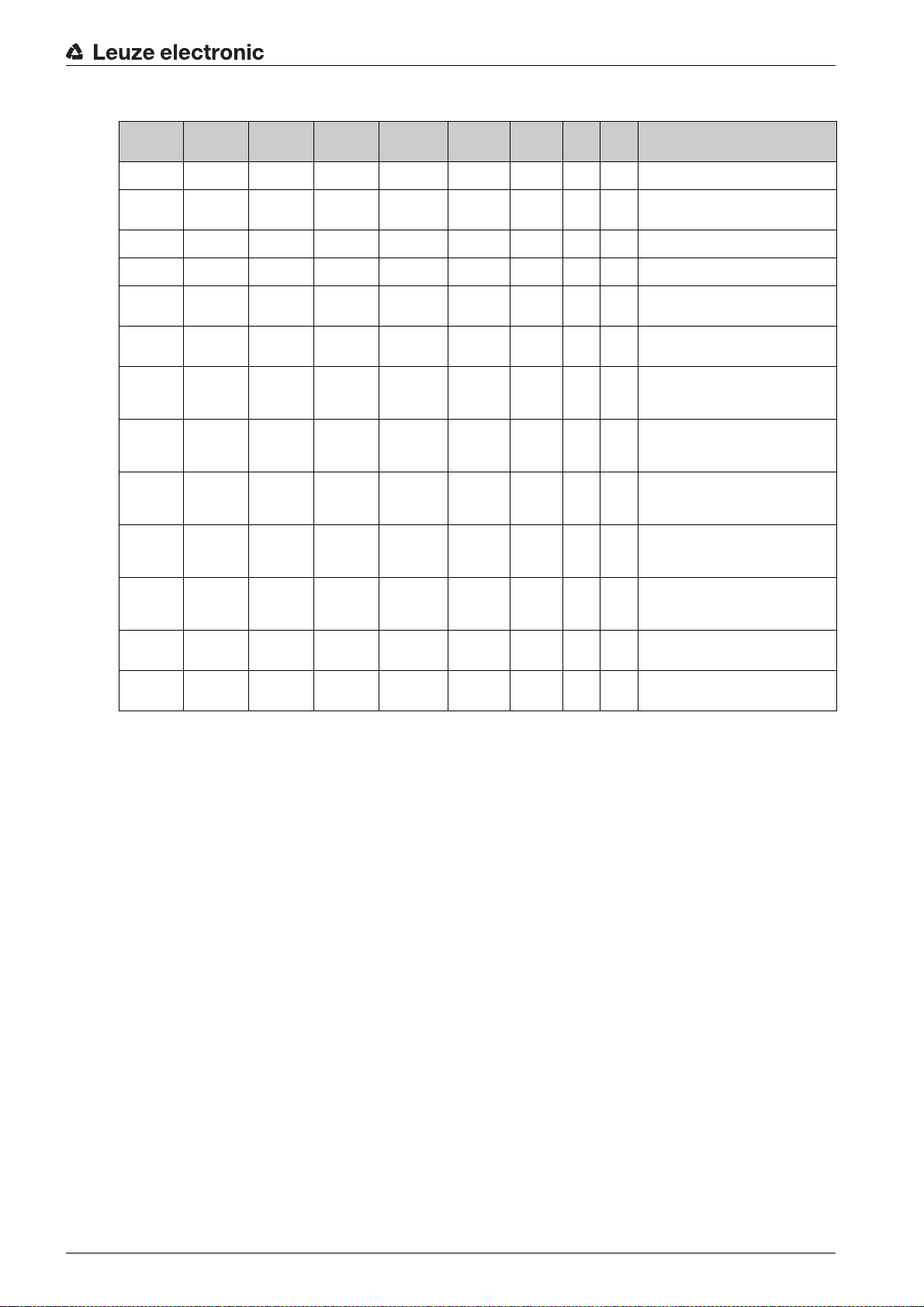

Table 4.1: Meaning of the LEDs

Functions

LED PWR LED OUT LED IN LED ACT S420-OSx

off off off off off no

orange off off off U

green green green green operation yes yes on on monitored operation

green off green off operation no yes off off input condition fulfilled

green off off green operation yes no off on actuator detected, input condition not

green off off off operation no no off off actuator not detected, input condition

green off flashing

green off flashing

green green green flashing

green off off flashing

orange/

green

orange/

green

green operation yes irregular off on check and deactivate both input signals

green operation no irregular off off check and deactivate both input signals

orange/

green

orange/

green

status

switched onb) b) off off internal test mode

B

operation on the limit yes on off check actuator/realign door

operation on the limit no off on check and deactivate both input sig-

Actuator

detected

a)

OS1/

IN

b)

O3 Description

OS2

off off S420-OSx not switched on

fulfilled

not fulfilled

nals, test actuator/realign door

green off flashing

green red flash-

red off off off error (inter-

ing

orange/

green

off off error (out-

flashing

orange/

green

operation on the limit irregular off on check and deactivate both input sig-

put)

nal)

yes yes off off check for cross connection and short

b) b) off b) restart or exchange

nals, test actuator/realign door

circuit, restart

a) 2 input signals are present

b) irrelevant

Hinge switches of the S420 series with integrated OSSDs independently monitor the fulfillment of the input

condition and the redundancy of the actuator monitoring.

If one of the input signals is switched off, the S420-OSx switches both OSSDs off. Before activating the

OSSDs again, both input signals must be switched off and then reactivated.

In the event of very slow or minimal partial opening of the actuator, the S420-OSx switches both OSSDs

off. Before activating the OSSDs again, the actuator must be opened completely and then shut again.

In the event of fundamental errors (e.g. short circuit of the OSSDs) the diagnosis LEDs illuminate or blink

red. After trouble shooting and the following reset (switch-off of supply voltage), the S420-OSx switches

back to the normal operating mode.

Leuze electronic S400 11

Page 12

5 Applications

The safety hinge switch is suitable for e.g. the following protective devices:

• turning or swiveling moveable guards, flaps and hoods

• in environments with high dust concentration or high levels of particulate matter

• for stricter hygiene requirements (S420)

Applications

Leuze electronic S400 12

Page 13

6 Mounting

>180°

≤180°

1

2

3

3

2

WARNING

Severe accidents may result if the safety hinge switch is not mounted properly!

The protective function of the safety hinge switch is only ensured if correctly mounted and adjusted for

the respective, intended area of application.

Mounting may only be performed by competent personnel.

Observe standards, regulations and these instructions.

Protect the housing from materials penetrating the enclosure, consider environmental conditions (see

chapter 13 „Technical data“).

Use separate mechanical limit stop (see figure 6.1).

Set the switching angle so that the guard cannot be circumvented (e.g. by reaching around or walking

behind).

Test to ensure proper function.

6.1 Mounting the safety hinge switch

Prerequisites for mounting:

• M5 (M6 for S420) fastening screws of the correct length (see figure 6.1)

Mounting

1

2

5 / M 6

M

6+T

T

1 Frame (e.g. hollow chamber aluminum profile)

2 Safety hinge switch

Figure 6.1: Hinge mounts; length of the fastening screws = 6 + T mm

Wrong Correct

Figure 6.2: Mechanical limit stop (1) for the moving part of the protective device

Leuze electronic S400 13

1 Mechanical limit stop

2 Door

3Profile

Page 14

Figure 6.3: Maximum load of the S400 safety hinge switches

1000 N

max

1500 N

max

25 Nm

max

500 N

max

750 N

max

12 Nm

max

2000 N

max

2000 N

max

50 Nm

max

H/2H/2

H (100 min - 300 max)

F

max

D

300 max

F

max

(N)=25.000/D (mm)

max

Mounting

Figure 6.4: Maximum load of the S410 safety hinge switches

Figure 6.5: Maximum load of the S420 safety hinge switches

Select the mounting locations for safety hinge switches and additional hinges (if necessary) so that the

following conditions are satisfied:

• accessible to qualified personnel for testing and replacement

• form-fitting mounting is possible

Leuze electronic S400 14

Figure 6.6: Door with 1 safety hinge switch S400

F

Force exerted by door weight in N

max

D Distance from the center of gravity of the door to the hinge axis in mm

Page 15

F

H/8H/8 H/5H/1.81

H (300 min - 2500 MAX)

D

F

max

1000 max

F

max

(N)=250.000/D (mm)

max

H/2H/2

H (100 min - 300 max)

F

max

D

300 max

F

max

(N)=12.500/D (mm)

max

max

(N)=200.000/D (mm)

max

Mounting

D

H/1.66 H/5H/5

F

max

H (200 min - 1600 max)

800 max

F

Force exerted by door weight in N

max

D Distance from the center of gravity of the door to the hinge axis in mm

Figure 6.7: Door with 1 safety hinge switch S400 and 1 additional AC-H-S400 or AC-H-S400-S hinge

Leuze electronic S400 15

F

Force exerted by door weight in N

max

D Distance from the center of gravity of the door to the hinge axis in mm

Figure 6.8: Door with 1 safety hinge switch S400 and 2 additional AC-H-S400 or AC-H-S400-S hinges

F

Force exerted by door weight in N

max

D Distance from the center of gravity of the door to the hinge axis in mm

Figure 6.9: Door with 1 safety hinge switch S410

Page 16

F

F

max

(N)=100.000/D (mm)

max

H/1.66 H/5H/5

H (200 min - 1600 max)

D

F

max

800 max

F

max

(N)=200.000/D (mm)

max

H/8H/8 H/5H/1.81

H (300 min - 2500 MAX)

D

F

max

1000 max

H/2H/2

H (100 min - 500 max)

F

max

D

100 min - 500 max

A

Force exerted by door weight in N

max

D Distance from the center of gravity of the door to the hinge axis in mm

Figure 6.10: Door with 1 safety hinge switch S410 and 1 additional hinge AC-H-S410

Mounting

Leuze electronic S400 16

F

Force exerted by door weight in N

max

D Distance from the center of gravity of the door to the hinge axis in mm

Figure 6.11: Door with 1 safety hinge switch S410 and 2 additional hinges AC-H-S410

F

Force exerted by door weight in N

max

D Distance from the center of gravity of the door to the hinge axis in mm

Figure 6.12: Door with 1 safety hinge switch S420

Page 17

F

H/1.66 H/5H/5

H (200 min - 1600 max)

D

F

max

200 min - 1600 max

A

B

H/8H/8 H/5H/1.81

H (300 min - 2500 max)

D

F

max

200 min - 2000 max

A

B

B

Force exerted by door weight in N

max

D Distance from the center of gravity of the door to the hinge axis in mm

Figure 6.13: Door with 1 safety hinge switch S420 and 1 additional hinge AC-H-S420

Mounting

F

Force exerted by door weight in N

max

D Distance from the center of gravity of the door to the hinge axis in mm

Figure 6.14: Door with 1 safety hinge switch S420 and 2 additional hinges AC-H-S420

NOTICE

The safety hinge switch may be damaged if mounted improperly!

Screws that are too long or too short as well as faulty bore holes may damage the hinge.

Measure the length of the mounting screws exactly (see figure 6.1).

The position of the mounting bore holes should be exactly parallel to the profile axis.

Use only additional hinges from the respective series.

Prepare the bore holes for the safety hinge switch at the indicated positions (M5 or M6) (see chapter 3

„Device description“).

If necessary, prepare bore holes for additional hinges at the indicated positions (M5 or M6) (see

chapter 3 „Device description“).

If necessary, put seal underneath.

The axes of all hinges must align.

Leuze electronic S400 17

Screw down safety hinge switch and additional hinges with 2–3 Nm (M5) or 10–12 Nm (M6).

Page 18

Mounting

Set the switching angle of the safety hinge switch with a Phillips or flat-headed screwdriver (adjustment

range: maximum 1 turn for S400 and S410, maximum 1.5 turns for S420).

Provide limit stop at maximum opening angle (180°).

Test whether the guard can be circumvented; if necessary, readjust the switching angle (acc. to

EN ISO 13857).

WARNING

Failure of the switching function in the event of moisture, dust and tampering!

Always plug the opening for adjusting the switching angle.

Plug the opening for adjusting the switching angle with the sealing plug (see figure 6.15).

Leuze electronic S400 18

Page 19

Figure 6.15: Sealing plug AC-SEPL-S4xx

The S420 series includes a cloth for cleaning after mounting.

Mounting

Leuze electronic S400 19

Page 20

7 Electrical connection

WARNING

Serious accidents may result if the electrical connection is faulty!

Electrical connection may only be performed by competent and authorized personnel.

7.1 Connecting the contact block

Prerequisites:

• temperature stability of the cable insulation material must be greater than the maximum temperature

of the housing (see chapter 13 „Technical data“)

• connection via protected wiring

• maximum current load is observed (see chapter 13 „Technical data“)

• Take electrostatic precautionary measures (ESD) before handling the S420-OSx.

• Only operate the safety-related chain with separate 24 V current supply (SELV).

3

Electrical connection

7

5

3

7

5

6

4

8

6

4

8

Figure 7.1: Contact block 2NC + 1NO (S400-M4xxx, S410-M4xxx with slow action contacts. S400-

M1xxx, S410-M1xxx with snap-action contact)

4

3

2

1

7

6

5

8

Figure 7.2: OSSD contact block versions (S420-OSx)

DANGER

Risk of death by electric shock!

Interrupt the voltage supply to the safety hinge switch.

Connect the contact block according to the application-specific circuit diagram.

Provide NC contacts ( ) for looping into the safety circuit.

If current limiting is not provided for safety-related contacts, upstream fuses must be present.

Avoid over-tightening, bending or stretching the cables.

Leuze electronic S400 20

Page 21

Electrical connection

BK

BKWH

RD

RDWH

BN

BU

GNYE

3

4

1

7

8

2

6

5

BK = black

WH = white

RD = red

BN = brown

BU = blue

GN = green

YE = yellow/green)

Figure 7.3: Assignments of connecting cables S400-M4CB2-B, S400-M4CB2-T, S400-M4-CB2PUR-W,

S410-M1CB2-B, S410-M1CB2-T and S410-M4-CB2PUR-W

3

4

5

6

7

8

1

1

7

6

2

5

3

4

8

Figure 7.4: Assignments of 8-pin M12 plugs S400-M4M12-B, S400-M4M12-T, S400-M4-CB02M12-W,

S400-M1-CB02M12-W, S410-M1M12-B, S410-M1M12-T and S410-M4-CB02M12-W

Figure 7.5: Pin assignment S420-9x, S420-OSx

Table 7.1: Pin assignment/core colors S420-9x

Pin Wire color Assignment

1black NC 1

2 black/white NC 1

3red NC 2

4 red/white NC 2

5brown NO 1

6blue NO 1

7violet NO 2

8 violet/white NO 2

Leuze electronic S400 21

Shield yellow/green FE - functional earth, shield

Page 22

Table 7.2: Pin assignment/core colors S420-OSx

S400-M4M12-B S400-M4M12-B

Var . B

Var . A

MSI-SR4B

0V

-K3

-A2-A1 -A3

-K4

-K4

-K3

0V

PE PE

0V

13 23 41A1 S22 S12 S31 S33 S34 S35

33

-K3

-K4

+24V

2 AOPD-

1 AOPD+

2 AOPD+

IV-0

RES-0

RES-I

543 6 7 8

543 6 7 8

A2 14 24 42

A1

A2

-K3

L- L-

34

*

A1

A2

-K4

*

1

2

1

2

L+ L+

+24V +24V

1

2

1

2

1

2

-S1

Pin Wire color Assignment

1brown A1

2red IS1

3blue A2

4 red/white OS1

5black O3

6violet IS2

7 black/white OS2

8 violet/white n.c.

Electrical connection

* Spark extinction circuit, suitable spark extinction provided

Figure 7.6: Connection example S400-M4M12-B

Leuze electronic S400 22

Page 23

Electrical connection

+24V

0V

+24V

+24V

T0

I1

PE

0V

0V

I0

0V

0V

A1

PE

+24V

T1

0V

A2

-H1

I2

I5

I4

I10I8

I11

I9

I3

I6

I7

M0T0

A1

A2

-K1

A1

A2

-K2

O1-

O0-

O3

O1

O0

O2

-A1

ESB200

2/1

1/2

1/1

2/2

S400-M4M12-B

543 6 7 8

-A3

MSI 100

S420-OSx

IS2IS1A1 A2

O3OS2OS1

S420-OSx

IS2IS1A1 A2

O3OS2OS1

S420-OSx

IS2IS1A1 A2

O3OS2OS1

T1

-H2

-H3

-H4

-A2

-A3

Figure 7.7: Connection example S420-OSx

Leuze electronic S400 23

Page 24

8 Starting up the device

WARNING

Improper commissioning may result in serious injury

Commissioning may only be performed by competent and authorized personnel

Prerequisites:

• Safety hinge switch is mounted, adjusted, plugged and connected according to these instructions

• operating personnel have been trained in the correct use

Test the function of the safety hinge switch (see chapter 9 „Testing“).

The safety hinge switch is then ready for use.

Starting up the device

Leuze electronic S400 24

Page 25

9 Testing

WARNING

Severe accidents may result if tests are not performed properly!

Tests may only be performed by competent and authorized personnel

S400, S410 and S420 safety hinge switches are maintenance-free.

For the testing intervals, observe nationally applicable regulations.

Document all tests in a comprehensible manner.

9.1 To be performed prior to the initial start-up by competent personnel

Check whether the safety hinge switch is operated according to its specified environmental conditions

(see chapter 13 „Technical data“).

Test to ensure proper mechanical and electrical function (see chapter 9.2 „To be performed periodically

by competent personnel“).

9.2 To be performed periodically by competent personnel

Mechanical function

Stop the dangerous state.

Check that the components are securely fastened.

Test the cable entry for leaks and check that the opening for setting the switching angle is plugged.

Check safety hinge switch and cable entry for damage, deposits, deformation and wear.

Open and close the protective device several times, testing the ease of movement while doing so.

Testing

Electrical function

WARNING

Severe accidents may result if tests are not performed properly!

Make certain that there are no persons in the danger zone.

Stop the dangerous state and open the protective device.

Make certain that the machine cannot be started while the protective door is open.

Close the protective door and start the machine.

Test several times whether the machine stops upon opening of the protective door.

Make certain that the guard cannot be circumvented and that the switching angle is set to a sufficiently

small value (EN ISO 13857).

Test whether the dangerous state ends before the point of operation can be reached (EN ISO 13855).

9.3 To be performed daily by the operating personnel

WARNING

Severe accidents may result if tests are not performed properly!

Make certain that there are no persons in the danger zone.

Stop the dangerous state and open the protective device.

Check the safety hinge switch and cable entry for damage or tampering.

Test the cable entry for leaks and check that the opening for setting the switching angle is plugged with

the original plug.

Make certain that the machine cannot be started while the protective device is open.

Close the protective device and start the machine.

Test whether the machine stops upon opening of the protective device.

Leuze electronic S400 25

Page 26

10 Cleaning

There must be no soiling (e.g moisture and dust), especially at the joints of the safety hinge switch and the

area near the sealing plug (switching angle adjustment).

Prerequisites for regular cleaning:

• machine is switched off

• voltage supply to the safety switch is interrupted

Clean the safety hinge switch (e.g. with a vacuum cleaner).

Cleaning

Leuze electronic S400 26

Page 27

11 Disposing

The nationally valid regulations for electro-mechanical components are to be observed when disposing.

Disposing

Leuze electronic S400 27

Page 28

12 Service and support

Telephone number for 24-hour standby service:

+49 (0) 7021 573-0

Service hotline:

+49 (0) 8141 5350-111

Monday to Thursday, 8.00 a.m. to 5.00 p.m. (UTC+1)

Friday, 8.00 a.m. to 4.00 p.m. (UTC +1)

E-mail:

service.protect@leuze.de

Return address for repairs:

Service Center

Leuze electronic GmbH + Co. KG

In der Braike 1

D-73277 Owen / Germany

Service and support

Leuze electronic S400 28

Page 29

13 Technical data

Table 13.1: General technical data

Switch type Interlock device without guard interlocking in accor-

SIL in accordance with IEC 61508:2010 SIL 3

SILCL in accordance with IEC/EN 62061:2005 SILCL 3

Technical data

dance with EN 1088

Performance Level (PL) in accordance with

PL e

EN ISO 13849-1:2008

Category in accordance with EN ISO 13849-

Cat. 4

1:2008

Internal actuator Safety switch in hinge, encapsulated

Max. load S400-xxx:

axial: 1500 N

radial: 1000 N

torsional: 25 Nm

S410-xxx:

axial: 750 N

radial: 500 N

torsional: 12 Nm

S420-xxx:

axial: 2000 N

radial: 2000 N

torsional: 50 Nm

Actuation speed min. 2°/s, max. 90°/s

Actuation angle max. 180°

Actuating path with forced separation min. +4° (from switching point)

min. +6° (from switching point), (S420-9xx)

Mechanical life time in accordance with EN/

6

10

switching cycles

IEC 60947-5-1

Actuation frequency according to EN/

IEC 60947-5-1

Service life (T

) in accordance with EN ISO

M

max. 720 per hour

max. 600 per hour(S420-xxx)

20 years

13849-1:2008

Number of cycles before dangerous failure (B10

)

d

5,000,000

according to EN 61810-2

Usage category according to EN/IEC 60947-5-1 AC 15 / DC 13: U

24 V, Ie 2 A

e

Dimensions (dimensional drawings) see chapter 3 „Device description“

Table 13.2: Safety

Protection class IP 67, IP 69K

Contact allocation 2NC + 1NO

2NC + 2NO (S420-9xx)

Contact material silver alloy, solid

Leuze electronic S400 29

Page 30

Switching principle S400-M4x: slow-action contact

S410-M4x: slow-action contact

S400-M1x: snap-action contact

S410-M1x: snap-action contact

S420-9x: slow-action contact

S420-OSx: PNP

Contact opening Force-fit

Rated insulation voltage 30 V AC, 36 V DC

Conventional thermal current max. 2 A

Short-circuit protection according to IEC 60269-1 2 A, 500 V, type gG

Table 13.3: Electrical characteristics S420-OSx

Technical data

Supply voltage U

B

24 V DC, -15 % … +10 %

Switchable load per OSSD, max. 6 W

Power consumption < 1 W

Rated impulse withstand voltage U

imp

1.5 kV

Overvoltage category III

Inputs IS1/IS2

Absorbed switching current per input 5 mA

Safe outputs OS1/OS2

Cutoff voltage U

e

24 V DC

Output type PNP

Switched current per OSSD, max. 0.25 A

Short-circuit indicator Yes

Overcurrent protected Yes

Switch-off test pulses < 300

s

Permissible capacitance between two outputs < 200 nF

Permissible capacitance between outputs and

< 200 nF

ground

Signal outputs O3

Output type PNP

Max. switched current 0.1 A

Short-circuit indicator No

Overcurrent protected Yes

Table 13.4: Housing

Housing material metal

stainless steel, AISI 316L (S420-xxx)

Surface roughness R

Leuze electronic S400 30

(S420) < 0,8 m

a

Page 31

Table 13.5: Connection

Number of cable entries 1

Connection type 2 m PVC cable:

S400-M4CB2-B

S400-M4CB2-T

S410-M1CB2-B

S410-M1CB2-T

S420-9CB2-LW

S420-OS-CB2-LW

2 m PUR cable:

S400-M4-CB2PUR-W

S410-M4-CB2PUR-W

M12 plug:

S400-M4M12-B

S400-M4M12-T

S410-M1M12-B

S410-M1M12-T

Technical data

0.2 m PVC cable with M12 plug:

S400-M4-CB02M12-W

S400-M1-CB02M12-W

S410-M4-CB02M12-W

S420-9-CB02M12-LW

S420-OS-CB02M12-LW

Conductor cross-section (stranded) S400-M4CB2-B: 7 x 0.5 mm

S400-M4CB2-T: 7 x 0.5 mm

S410-M1CB2-B: 7 x 0.5 mm

2

2

2

Cable routing side S400-xxx-B: floor-side with left installation

S410-xxx-B: floor-side with left installation

S400-xxx-T: from above with left installation

S410-xxx-T: from above with left installation

S400-xxx-W: wall side mounting

S410-xxx-W: wall side mounting

Table 13.6: Timing

Reaction time, input signal shutoff, typ. 7 ms

Reaction time, input signal shutoff, max. 12 ms

Reaction time, actuator switching point, typ. 7 ms

Reaction time, actuator switching point, max. 12 ms

Table 13.7: Environment

Temperature range, operation -25 … +80 °C

-25 … +70 °C (S420-OSx)

Dirt level, external,

3

according to EN/IEC 60947-1

Leuze electronic S400 31

Page 32

Technical data

27

71

17

M5

M5

30

100.6

81

7

49

12

22.5

22.5

27

71

17

M5

M5

30

100.6

81

7

49

12

17

M5

M5

71

27

30

81

M12x1

10.5100.6

12

7

49

22.5

13.1 Dimensions

30

17

M5

71

81

100.6

M5

10.5

M 12 x1

12

22.5

Figure 13.1: Dimensions of S400-M4CB2-B in mmFigure 13.2: Dimensions of S400-M4M12-B in mm

27

7

49

Figure 13.3: Dimensions of S400-M4CB2-T in

Figure 13.4: Dimensions of S400-M4M12-T in mm

mm

Leuze electronic S400 32

Page 33

100.6

27

71

17

M5

16.5

M

5

30

100.6

81

7

49

12

22.5

8.9

31.4

Ø12

17

71

50

M5

M5

30

81

100.6

14

79

12

22.5

21

6.5

17

71

50

M5

M5

30

81

100.6

M12 x 1

14

79

12

22.5

21

6.5

71

M5

M5

50

81

100.6

17

30

1421

12

22.5

6.5

79

71

M5

M 5

81

100.6

M

12 x 1

50

17

30

10.5

1421

12

22.5

6.5

79

31.4

81

22.5

Technical data

30

17

M5

M 5

71

16.5

27

12

Ø

8.9

12

7

49

Figure 13.5: Dimensions of S400-Mx-

CB02M12-W in mm

Figure 13.7: Dimensions of S410-M1CB2-B in

mm

Figure 13.6: Dimensions of S400-M4-CB2PUR-W in

mm

Figure 13.8: Dimensions of S410-M1M12-B in mm

Figure 13.9: Dimensions of S410-M1CB2-T

Leuze electronic S400 33

in mm

Figure 13.10:Dimensions of S410-M1M12-T in mm

Page 34

Figure 13.11:Dimensions of S410-M4-

17

71

50

M5

16.5

M5

30

81

100.6

14

79

12

22.5

21

6.5

Ø

12

8.9

15.5

31.5

76

14 22

6.5

6

Ø12

40

29 26.5 9

==

88

6

M6

M6

M6

21.5

99.4

50

126

15.5

31.5

76

14 22

6.5

6

Ø12

40

29 26.5 9

==

88

6

M6

M6

M 6

21.5

99.4

50

126

CB02M12-W and S410-M4CB2PUR-W in mm

Technical data

Figure 13.12:Dimensions of S420-9CB2-LW

and S420-OS-CB2-LW in mm

Figure 13.13:Dimensions of S420-9-CB02M12-LW

and S420-OS-CB02M12-LW in mm

Leuze electronic S400 34

Page 35

14 Ordering information and accessories

Table 14.1: S400, S410 and S420 safety hinge switches

Part no. Article Description

63000400 S400-M4CB2-B 2 m PVC cable, cable entry at bottom (with left installation)

63000401 S400-M4M12-B 8-pin M12 plug, cable entry at bottom (with left installation)

63000402 S400-M4CB2-T 2 m PVC cable, cable entry at top (with left installation)

63000403 S400-M4M12-T 8-pin M12 plug, cable entry at top (with left installation)

63000406 S400-M4-CB02M12-W 0.2 m PVC cable with 8-pin M12 plug, cable entry at wall side

63000407 S400-M1-CB02M12-W 0.2 m PVC cable with 8-pin M12 plug, cable entry at wall side

63000411 S400-M4-CB2PUR-W 2 m PUR cable, cable entry at wall side

63000404 S410-M1CB2-B 2 m PVC cable, cable entry at bottom (with left installation),

total width 79 mm

63000405 S410-M1M12-B 8-pin M12 plug, cable entry at bottom (with left installation),

total width 79 mm

Ordering information and accessories

63000408 S410-M1CB2-T 2 m PVC cable, cable entry at top (with left installation)

63000409 S410-M1M12-T 8-pin M12 plug, cable entry at top (with left installation)

63000410 S410-M4-CB02M12-W 0.2 m PVC cable with 8-pin M12 plug, cable entry at wall side

63000412 S410-M4-CB2PUR-W 2 m PUR cable, cable entry at wall side

63000420 S420-9CB2-LW Stainless steel, 2 m PVC cable, cable entry at wall side (with

63000421 S420-OS-CB2-LW Stainless steel, 2 safety-related switching outputs, 2 m PVC

63000422 S420-9-CB02M12-LW Stainless steel, 0.2 m PVC cable with 8-pin M12 plug, cable

63000423 S420-OS-CB02M12-LW Stainless steel, 2 safety-related switching outputs, 0.2 m PVC

14.1 Accessories

Table 14.2: Accessories for the safety hinge switches S400, S410 and S420

left installation), total width 76 mm

cable, cable entry at wall side (with left installation), total width

76 mm

entry at wall side (with left installation), total width 76 mm

cable with 8-pin M12 plug, cable entry at wall side (with left

installation), total width 76 mm

Article Part no. Description

AC-H-S400 63000770 Additional hinge for S400 safety hinge switch

AC-H-S400-S 63000775 Additional hinge, small for the S400 safety hinge switch

AC-MP3-S400 63000771 Mounting plate set, flat, long version, for S400 safety hinge

switch

AC-MP1-S400 63000772 Mounting plate set, angled, long version, for S400 safety hinge

switch

AC-H-S410 63000773 Additional hinge for S410 safety hinge switch

Leuze electronic S400 35

Page 36

Ordering information and accessories

M5

M5

35

27

21

45

65

7

44.5

12

22.5

Article Part no. Description

AC-H-S420 63000778 Additional hinge for S420 safety hinge switch

AC-S-S420 63000779 Seal set between S420 safety hinge switch and mounting posi-

tion

AC-SEPL-S4xx 63000774 Safety plug for safety hinge switch S4xx

CB-M12-5000E-8GF 678060 PUR, 8-pin, 5 m, shielded, M12 coupling, straight, prefabri-

cated on one end

CB-M12-10000E-8GF 678061 PUR, 8-pin, 10 m, shielded, M12 coupling, straight, prefabri-

cated on one end

CB-M12-15000E-8GF 678062 PUR, 8-pin, 15 m, shielded, M12 coupling, straight, prefabri-

cated on one end

CB-M12-25000E-8GF 678063 PUR, 8-pin, 25 m, shielded, M12 coupling, straight, prefabri-

cated on one end

30

17

M5

71

81

100.6

M5

27

7

12

22.5

49

Figure 14.1: Dimensions of AC-H-S400 additional

hinge in mm

Figure 14.2: Dimensions of AC-H-S400-S additional

hinge in mm

Leuze electronic S400 36

Page 37

Ordering information and accessories

71

50

M5

M5

17

81

100,6

30

1421

12

22,5

79

6,5

Figure 14.3: Dimensions of AC-H-S410 additional

hinge in mm

126

31.5

99.4

15.5

29 26.5 9

M6

88

50

14 22

40

76

M 6

M6

6

==

6.5

Figure 14.4: Dimensions of AC-H-S420 additional

hinge in mm

Leuze electronic S400 37

Page 38

15 EC Declaration of Conformity

Leuze electronic GmbH + Co. KG

In der Braike 1

D-73277 Owen

Telefon +49 (0) 7021 573-0

Telefax +49 (0) 7021 573-199

www.leuze.com

Leuze electronic GmbH + Co. KG, Sitz Owen, Registergericht Stuttgart, HRA 230712

Persönlich haftende Gesellschafterin Leuze electronic Geschäftsführungs-GmbH,

Sitz Owen, Registergericht Stuttgart, HRB 230550

Geschäftsführer: Ulrich Balbach

USt.-IdNr. DE 145912521 │ Zollnummer 2554232

Es gelten ausschließlich unsere aktuellen Verkaufs- und Lieferbedingungen

Only our current Terms and Conditions of Sale and Delivery shall apply

Nr. 609340-2014/07

EG-KONFORMITÄTS-

ERKLÄRUNG

(ORIGINAL)

EC DECLARATION OF

CONFORMITY

(ORIGINAL)

DECLARATION CE DE

CONFORMITE

(ORIGINAL)

Der Hersteller The Manufacturer Le constructeur

Leuze electronic GmbH + Co. KG

In der Braike 1, PO Box 1111

73277 Owen, Germany

erklärt, dass die nachfolgend

aufgeführten Produkte den einschlägigen Anforderungen der

genannten EG-Richtlinien und

Normen entsprechen.

declares that the following listed

products full the relevant provisions of the mentioned EC Directives and standards.

déclare que les produits identiés

suivants sont conformes aux

directives CE et normes mentionnées.

Produktbeschreibung: Description of product: Description de produit:

Sicherheits-Schalter

S20, S200, S300, S400, S410, S420

Sicherheits-Zuhaltung

L10, L100, L200

NOT-HALT-Befehlsgerät

ERS200

Seriennummer siehe Typschild

Safety Switch

S20, S200, S300, S400, S410, S420

Safety Locking Device

L10, L100, L200

E-STOP command device

ERS200

Serial no. see name plates

Interrupteur de sécurité

S20, S200, S300, S400, S410, S420

Interverrouillage de sécurité

L10, L100, L200

Appareil de commande d'ARRÊT

D'URGENCE

ERS200

N° série voir plaques signalétiques

Angewandte EG-Richtlinie(n): Applied EC Di rective(s): Directive(s) CE appliquées:

2006/42/EG 2006/42/EC 2006/42/CE

2004/108/EG 2004/108/EC 2004/108/CE

2006/95/EG 2006/95/EC 2006/95/CE

Angewandte Normen: Applied standards: Normes appliquées:

EN/IEC 60947-5-1; EN ISO 13849-1; EN 1088

Benannte Stelle /

Baumusterprüfbescheinigung:

Notied Body /

Certicate of Type Examination:

Organisme notié /

Attestation d'examen CE de type:

IMQ S.p.A.

Istituto Italiano Del Marchio Di Qualitá

Via Quintiliano 43

I-20138 Milano

/

CAO2.03747(S20); CAO2.03748 (L100) );

CAO2.04212 (L200); CAO2.03749 (S200, S300);

CAO2.03756 (S400); CAO2.03749 (ERS200, L10-M);

CAO2.03750 (L10-P)

Bevollmächtigter für die Zusam-

menstellung der technischen

Unterlagen:

Authorized person to compile the

technical le:

Personne autorisée à constituer

le dossier technique:

André Thieme; Leuze electronic GmbH + Co. KG

Liebigstr. 4; 82256 Fuerstenfeldbruck; Germany

Owen, 02.07.2014

Datum / Date / Date

Ulrich Balbach, Geschäftsführer / Director / Directeur

EC Declaration of Conformity

Leuze electronic S400 38

Loading...

Loading...