Page 1

Leuze electronic

OUT

WARNPEPE

PE

GND

Vin

IN

GND

Vin

Leuze electronic Technical Data

Leuze electronic Mounting / Installation (all device variants)

Leuze electronic Mounting / Installation (all device variants)

Bus-Capable Optical Data Transmission

DDLS

Technical Description

200

PROFIBUS / RS 485

2 Technical Data

2.1 General technical data

Electrical data

Supply vo ltage Vin 18 … 30 V DC

Current consumption without optics

heating

Current co nsumption w. optics heati ng appr ox. 800 mA wit h 24 V DC ( no load at swi tching outpu t)

Optical data

Sensing distance 0.2 … 120 m (D DLS 200/120…)

Transmission diode infrared lig ht, wavelength 880 nm

Opening a ngle ± 0.5 ˚ to optical axis

Ambient light > 10000 Lux acc. to EN 60947-5-2 (2000)

Laser safety class 1 acc. to EN 60825-1 (2001)

Input/output

Input 0 … 2 V DC: transmitter/receiver deactivated

Output 0 … 2 V DC: normal operation

Operating and display elements

Membran e buttons change the operating mode

Individual LEDs indicate voltage supply, operating mode, data traffic

LED strip bar graph display of the re ceiving level

Mechanical data

Housing aluminium diecast; light inlet/ outlet, glass

Weight approx. 1200 g

Protection class IP 65 acc. to EN 60529

Environmental conditions

Operatin g temperature -5 ˚C … +50 ˚C without optics heating

Storage temperature -30˚C … +7 0˚C

Air humidity max. 90% rel. humidity, non-cond ensing

Vibrations acc. to EN 60068-2- 6

Noise acc. to EN 60068-2- 64

Shock acc. to EN 60068-2- 27 and EN 6006 8-2-29

EMC acc. to EN 61326 ( 1998) + A1 (1999 )

approx. 20 0 mA with 24 V DC (no load at switching output)

0.2 … 200 m (D DLS 200/200…)

18 … 30 V DC : transm itter/receiver a ctivated

Vin-2VDC: limited performance reserve

output cu rrent max. 10 0 mA, short -circuit proof,

protected against surge voltage, transients and overheating

-30 ˚C … +50 ˚C with optics heating (non-condensing)

3 Mounting / Installation (all device variants)

3.1 Mounting and alignment

An optica l data transm ission system, consisting of 2 DDLS 200 devi ces, involve s mounting eac h of

the devices on mutually opposing, plane-parallel, flat and usually vertical walls with unobstructed view

of the op posing DDLS 2 00.

Make certain that, at the minimum operating dis tance A

with one anot her within ± A

vices lie within the op ening angle. T his also applie s for rotary t ransmission.

Note

The opening an gle (angle of radia tion) of the optics is ± 0.5 ˚ to the optica l axis! The hori-

zontal and vertical adjustment angles of the fine alignment with the adjustment screws is ±

6 ˚ for each. The optical transmission path between the DDLS 200s should not be interrupted. If interruptions cannot be avoided, be sure to read the notice in chapter 5.4.

Therefor e, pay close attention when selecting a suitable mountin g location!

Attention!

When laying out a mobile arrangement for a DDLS 200, pay particular attention that the

alignmen t of the devices relative to one another remai ns unchanged ov er the transmi ssion

path.

The transmission can be interrupted by e.g. jolts, vibrations or inclination of the mobile device due to irregularities in the floor or path.

Ensure adequate track stability!

Mount each device with 4 screws

device (see chapter 3.2 " Dimensioned drawing").

DDLS 200/XXX.1-YY DDLS 200/XXX.2-YY

TNT 35/7-24V

Figure 3.1: Mounting the device s

Note

The fine alignment of the transmission system is performed during commissioning

(see chapter 5.3.2 "Fine adjustment"). The position of the optical axis of the DDLS 200 can

be found in chapter 3.2 .

• 0.01 to ensu re that the trans mission/rece ption beams of the tw o de-

min

∅ 5 mm using 4 of the 5 fasten ing holes in the mo unting plate of th e

( frequency f1 ) ( frequency f2 )

Optical axis

the optical axe s of the devices are alig ned

min

• 0.01)

min

Horizontal

and vertical

max. ± (A

A

min

TNT 35/7-24V

Rotary trans-

mission

3.3 Electrical connection

Attention!

Connection of the device and maintenance work while under voltage must only be carried

out by a q ualified electrician.

If faults cannot be corrected, the device should be removed from operation and protected

against p ossible use.

Before connecting the device, be sure that the supply voltage agrees with the value printed

on the na meplate.

The power supply unit used to power the DDLS 200 must have protected electrical separation by way of a safety transformer with double insulation according to EN 60742 (equivalent

IEC 60742).

Be sure that the earthing conductor is connected correctly. Error-free operation is guaranteed only when the device is properly earthed.

Described in this section is the electrical connection of the supply voltage, the input and the output.

These connections and their functions are identical for all device variants.

The connec tion of the respectiv e bus system is descri bed in the following chapters.

To establish the electrical connections, you must first remove the red housing top with the optics. To

this, loosen the three housing hex screws. The housing top is now only electrically connected to

do

the base by means of a connector. C arefully pull th e housing top straight for ward without s kewing.

Carefully pull off the

housing top

Loosen the 3

housing

screws

Figure 3 .3: Removing the housing top

TNT 35/7-24V

Leuze electronic Safety Notices

1 Safety Notices

1.1 Safety standards

The optical DDLS 200 data transmission system was developed, manufactured and tested in accordance with applicable safety standards. It c orresponds to the state of the ar t.

1.2 Intended use

The DDLS 2 00 optical data transmission sy stem has been de signed and dev eloped for the o ptical

transmission of data in the infrared range.

Attention!

The protec tion of personne l and the device cannot be guara nteed if the devi ce is operated

in a mann er not corres ponding to its intended us e.

Areas of app lication

The DDLS 200 is suit able for the following areas of application:

utomated hi gh-bay warehouses

•A

• Stationa ry data transmissio n between buildings

• Anywhere, where data transmission to and from s tationary or moving objects (vi sual contact) over

relatively long distances (up to 200 m) is required.

• Rotary transmission

1.3 Working safely

Attention Laser!

The DDLS 200 data transmission system is an infrared laser device of Laser Class 1 in accordance with EN 60825. Do not look directly at the laser beam at close range!

Laser Cla ss 1 permits the use of optical instru ments for the direct observation of the laser

beam. The laser beam outl et is located on the front side in t he upper third o f the optics window.

Observe t he legal and lo cal regulations applicable to the operati on of laser uni ts.

Attention!

Access an d changes to the devic e, except where expre ssly described in thi s operating manual, are not autho rised.

Leuze elec tronic Technical description DDL S 200 3

Technical Data Leuzeelectronic

2.2 Dimensioned drawing

Permissible cables:

M16 x 1.5:

round cabl e Ø 5 … 10 mm

Acontrol panel

B tr ansmission optics

Creception optics

D optical axis

Figure 2.1: Dimensioned drawing DDLS 200 for copper cable

Permissible cables:

TNT 35/7-24V

Figure 2.2: Dimensioned drawing DDLS 200 for fibre optic cable

M16 x 1.5:

round cabl e Ø 5 … 10 mm

M20 x 1.5:

round cabl e Ø 7 … 12 mm

Acontrol panel

B tr ansmission optics

Creception optics

D optical axis

Leuze electronic Technical description DDLS 200 5

Mounting / Installation (all device variants) Leuze electronic

3.2 Arrangement of adjacent transmission systems

To prevent mutual interference of adjacent transmission systems, the following measures should be

taken in add ition to exact alignme nt:

• With a freq uency-offset arrangement, the d istance between two parallel tra nsmission path s must

not be less than 300 mm (DDLS 200/120…) or 500 mm (DDLS 200/200…).

• With arrang ements usin g identical f requencies, th e distance bet ween two parallel transmis sion

paths mus t be at least 500 mm + tan (0.5˚) x sensing distance (DDLS 200/200…), or

300 mm + tan (0.5˚)xsensing distance (DDLS 200/120 …).

DDLS 200/XXX.1-YY DDLS 200/XXX.2-YY

( frequency f1 ) (frequency f2 )

Frequency-offset arrangement!

( frequency f

2 ) (frequency f1 )

Min. 300 mm (DDLS 200/120…)

Min. 500 mm (DDLS 200/200…)

Identica l frequency arrangement

DDLS 200/XXX.1-YY DDLS 200/XXX.2-YY

Figure 3. 2: Arrangement of adjacent tra nsmission systems

1 ) (frequency f2 )

( frequency f

Min. tan (0.5 ˚) x sensing dis-

DDLS 200/XXX.1-YYDDLS 200/XXX.2-YY

Leuze electronic Technical description DDLS 200 7

Mounting / Installation (all device variants) Leuze electronic

The conn ection compartme nt in the housing b ase with the screwed cable gland s is now freely acce ssible.

PE

OUT

WARN

GND

Max. core

cross se ction:

2

1.5 mm

IN

Off

On

Figure 3.4: Positions of the general, non-bus-specific terminals and switches

Vin

IN

PEPEGND

Vin

S1

3.3.1 Supply voltage

Connect th e supply volta ge, including th e earth lead, to the spring termina ls labelled Vin, GND and

PE (see fi gure 3.4).

Note

The conne ction terminals V in, GND and PE are prov ided double to sim plify wiring through

the supply voltage to other devic es.

The earth lead can alternatively be connected at the screw terminal in the housing base

(max. co re cross se ction 2.5 mm

If you would like to wire through th e supply voltage, you s hould replace the filler plugs on the

right side of the housing base with an M16 x 1.5 scr ewed cable glan d and guide the co ntinuing supply voltage cable through this gland. The housing seal is, in this way, ensured (Protection Cl ass IP 65).

The hous ing top can be r emoved and replac ed while under voltage.

Ter min al Function

Vin Positive supply voltage

GND Negative s upply voltage 0VDC

PE Earth lead

OUT

WARN

IN Switching inpu t for transmitter/receiver

Switch Function

S1 On : the switching input is not analysed.

2

)

+18 … +30 V DC

Switching ou tput, activated if level

drops be low the warnin g level

cut-off:

0 … 2VDC: transmitter/receiver

switched off, no transmission

18 … 30 V DC: transmitter /receiver

active, normal function

transmitte r/receiver unit is al ways in

The

operation.

Off: the switchin g input is analysed.

nding on th e input voltage, no rmal

Depe

function or transmitter/receiver unit

switched o ff.

Leuze elec tronic Technical description DDL S 200 2

4 Technical description DDLS 200 Leuze electronic

6 Technical description DDLS 200 Leuze electronic

8 Technical description DDLS 200 Leuze electronic

Page 2

COM

COM

B'

OUT

WARNPEPE

GND

Vin

IN

GND

Vin

SHIELD AREA

BS

A400A

COM

COM

+'

Leuze electronic Mounting / Installation (all device variants)

Leuze electronic PROFIBUS / RS 485

Commissioning / Operation (all device models) Leuzeelectronic

Commissioning / Operation (all device models) Leuzeelectronic

3.3.2 Switching input

The DDLS 200 is equipped with a switching input IN, via which the transmitter/receiver unit can be

switched of f, i.e. no infrar ed light is tra nsmitted and at the bus termi nals the corresp onding bus bia s

level is present / the bus driver is high resistance.

Input voltage: 0 … 2 V DC: transmitter/rec eiver switched of f, no transmissi on

(relative to GND) 18 … 30 V DC: transmitter/receiver active, normal function

For easier operation, the switching input can be activated/deactivated via switch S1:

Position S1: On the switch ing input is no t analysed. Th e transmitter/ receiver

Off The switching input is analysed. Depending on the input volt-

Note!

When transmitter/receiver unit is switched off, the system behaves in the same way as in

the event of a light beam interruption (see chapter 5.4 "Operation").

The switching input can be used, for exampl e, during a corr idor change to co mpletely avoi d

interference effec ts from other sensors or the data transmission.

unit is always in operation (internal preselection of the switching input with Vin).

age, norm al function or tra nsmitter/receiver unit switched off.

3.3.3 Switching output

The DDLS 200 is equ ipped with a sw itching output OUT WARN which is activated i f the receiving le vel

in the recei ver drops.

Output voltage: 0 … 2 V DC: operating range

(relative to GND) Vin - 2 V DC: warning or shutoff range

The switching output is protected against: short-circuit, surge current, surge voltage, overheating

Note!

The DDLS 200 is still completely functional when th e level of the rece iving signal drops to

the warning signal level. No performance reserve remains.

and transi ents.

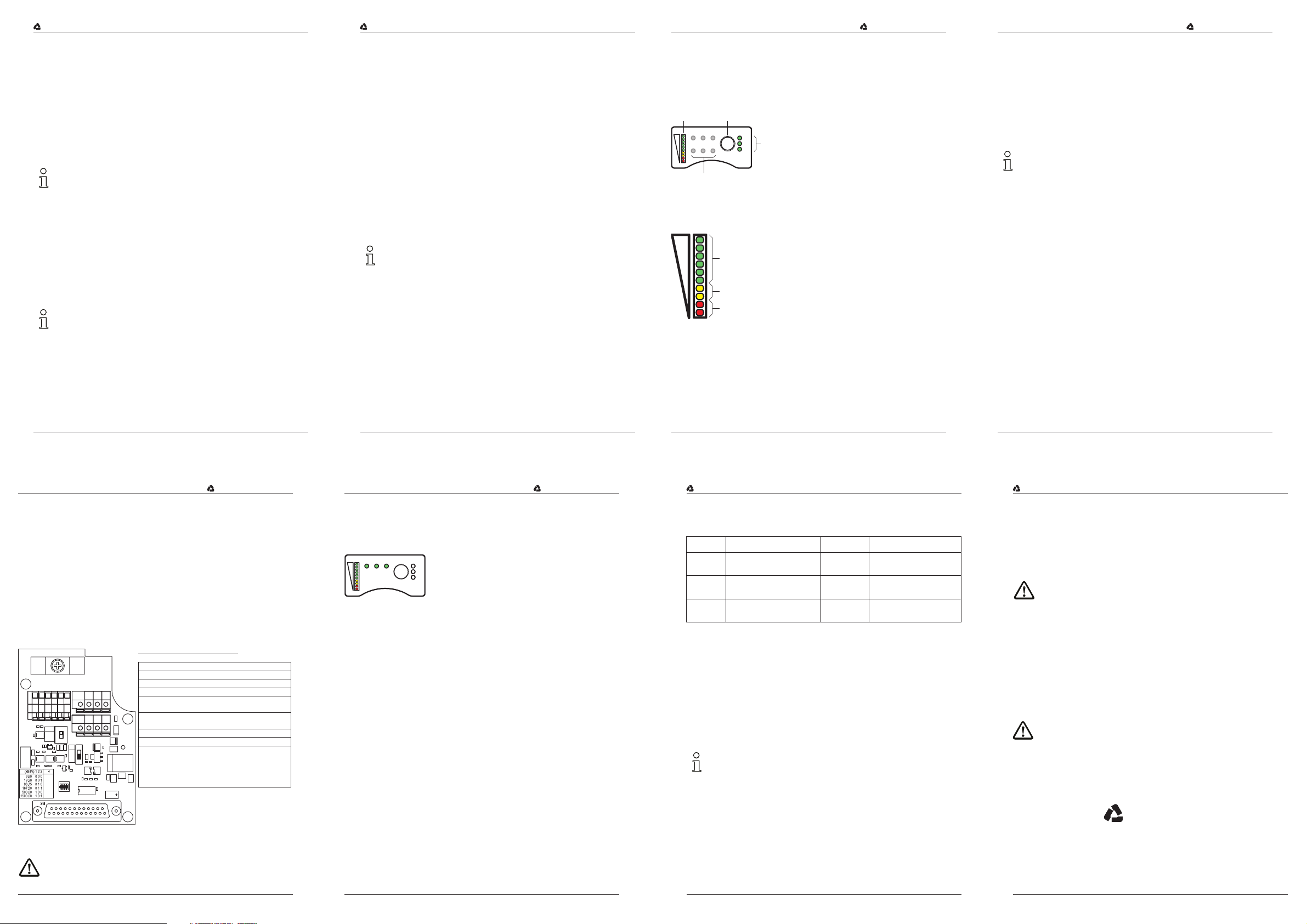

4.2 Device configuration PROFIBUS

Termination (bus connection, factory setting: 'Off' = no termination)

The PROFIBUS can be terminated via the switch S2 in the DDL S 200. If the term ination is active

(S2 = On), internal bus resistors are connected as per the PROFIBUS standard and the PROFIBUS

is not wired through at terminals A’ and B’.

Activate the terminatio n when the PRO FIBUS segmen t begins or en ds at the DDLS 200.

Setting the transmission rate (baud rate, fac tory setting: '000' = 9.6 kBit/s)

You must set the transmission rate of your PROFIBUS segment using the three DIP switches S3-1

through S3-3 . Possible transmissio n rates are:

• 9.6 kBit/s • 19.2 kBit/s

• 93.75 kBit/s • 18 7.5 kBit/s

• 500 kBit/s • 1500 kBit/s

Set the tr ansmission rat e in accordance w ith the table pri nted on the connec tion circuit board (see figure 4.1).

5 Commissioning / Operation (all device models)

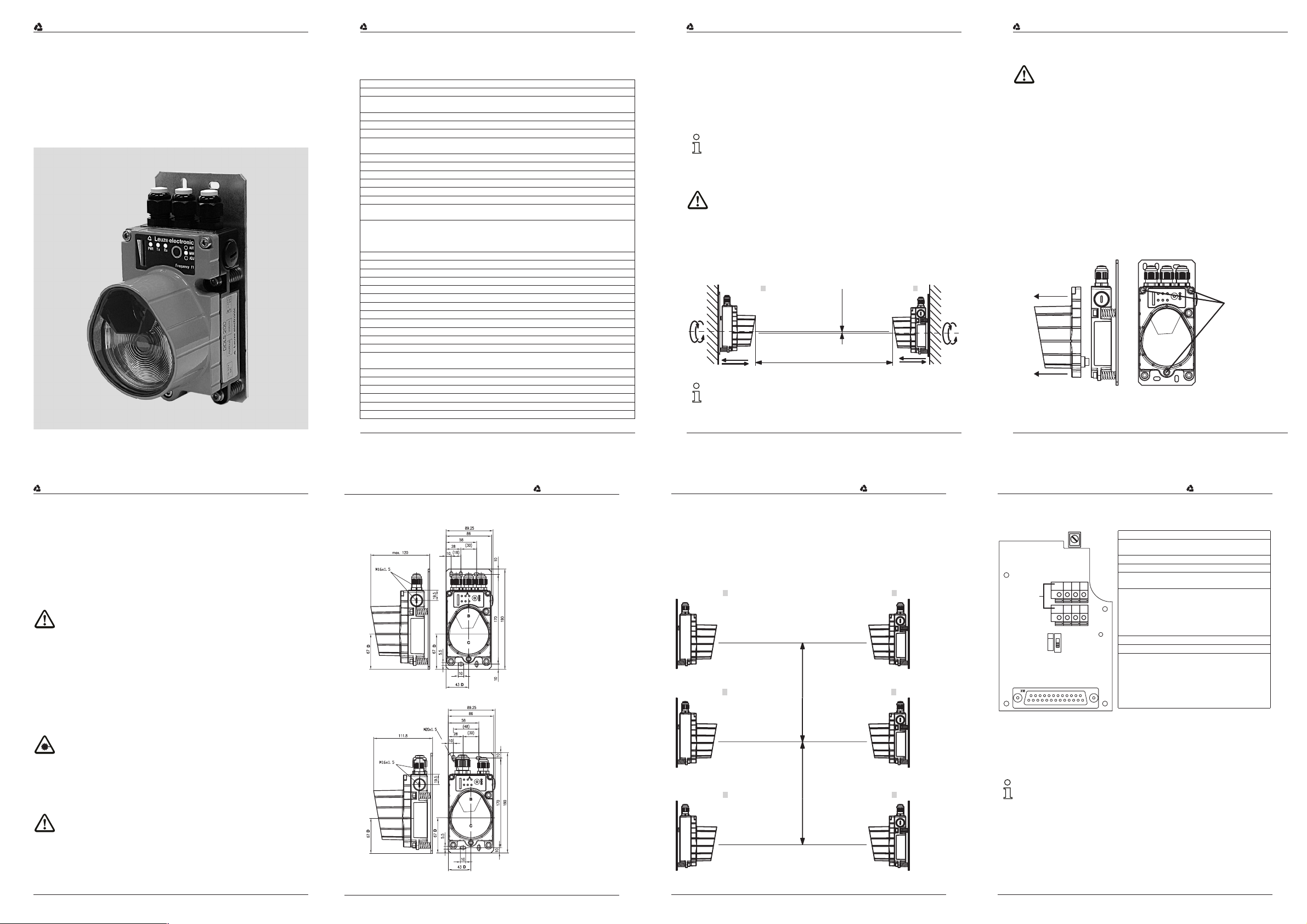

5.1 Indicator and operating elements

All DDLS 200 device models have the following indic ator and operating elements:

• Bar graph with 10 LEDs

• Operating mode LEDs AUT, MAN, ADJ

• Operating mode buttons

Bar graph Operating mode buttons

AUT

Operatin g mode LEDs

MAN

ADJ

LEDs dependent on device model

Figure 5. 1: Indicator and operating elements common to all DDLS 200 devic e models

If the PWR or UL LED f l ashes after s witching on, there are two poss ible causes: either a hardware

error ha s occurred or the transmitter/re ceiver unit has sw itched off via the sw itching input IN (chapter

3..3.2).

If the PWR or UL LED remains dark after switching on, there is either no voltage supply present (check

connections and voltage) or a hardware error has occurred.

5.3.2 Fine adjustment

If you have mounted and switched on the two DDLS 200s of a given optical transmission path and

they are both in the "Automatic" operating mode, you can perform the fine adjustment of the devices

relative to one another wit h the aid of the t hree alignment screws.

Note!

Note that with "alignment", the transmitter with the beam which is to be positioned as exactly

as possible on the opposing receiver is always meant.

At the max imum sensing di stance, the bar g raph does not s how end-scale de flection even

with optim al alignment!

Bar graph

Changeover PROFIBUS / RS 485 (factory setting: 'Off' = PROFIBUS)

The DDLS 200 has, as a s tandard function, a re peater function (s ignal processing) a nd is, with regard

to the PROFIBUS, to be viewed as a repeater.

Note!

Please ob serve the guidel ines specified in EN 5017 0 (Vol. 2) regarding the u se of repeaters .

The delay time of a data transmission path is maximum 1.5 µs + 1 T

It is also possible to transmit other RS 485 protocols. For PROFIBUS applications, S3-4

should be set to 'Off' ('0'). DI P-switch S3-4 ca n be used to switch off the repeater fun ction

for non-PROFIBUS appl ications (S3- 4 = 'On'). In this case, no s ignal regene ration takes

TNT 35/7-24V

place; th e RS 485 proto col must, how ever, still p rovide certa in features

Please contact th e manufacturer if you would like to use the DDLS 200 for other protocols.

.

Bit

The bar graph displays the quality of the received signal (receiving level) at its own (operating modes

"Automatic" and "Manual") or opposing (operating mode "Adjust") DDLS 200 (figure 5 ..2).

Good receiving level, optical data transmission active, performance reserve, output OUT WARN not active

Operating range:

Warning range:

TNT 35/7-24V

Cut-off range:

(0 … 2VDC)

Receiving level in the warning range, continued error-free

data transmission, no performance reserve, output OUT

WARN active (Vin - 2 V DC), peripheral error message with

INTERBUS fibre optic cable model

Receiving level minimal, optical data transmission separated,

output OUT WARN active (Vin - 2 V DC)

Figure 5.2: Meaning of the bar graph for displaying the receiving level

Operating mo de LEDs

The three green LEDs AUT, MAN and ADJ indicate the current operating mode (see chapter 5.2 "Operating m odes") of the DDLS 200.

• AUT: operating mode "Automatic"

• MAN: operating mode "Manual"

• ADJ: operating mode "Adjust"

The DDLS 200 supports fast and easy fine adjustment. The optimisation of the alignment between

the two d evices of one t ransmission path can be perfor med by just one person. Use the following

descrip tive steps as a set of numb ered instructions:

1. Both device s are locate d close to one a nother (> 1 m). Ideally, the ba r graphs of both devices

display maximum end-scale deflection.

2. Switch both devices to "Manual" (MAN) by pressing t he button for a relativel y long time (> 2 s).

Data transmission remains active, only the internal cut-off threshold is changed to the warning

threshold (yellow LEDs).

3. While in the "Manual" operating mode, move until data transmission of the DDLS 200 is interrupted. The devices are not yet optimally aligned with one another.

4. Briefly pr ess the button to switch both devices to the " Adjust" operatin g mode (ADJ). Data

transmission remains interrupted.

5. The device s can now be in dividually alig ned. The result of the alignm ent can be read directly in

the bar grap h.

6. When both d evices are aligned, briefly pressin g the button on one of th e devices is enough to

switch both back to the "Manual" operating mode (MAN). Data transmission is again active; the

vehicle can continue its path. If data transmission is interrupted again, repeat steps 3 through 6.

7. If the data transmission and the alignment are OK through the end of the path of motion, switch

both devices back to the "Automatic" (AUT) operating mode by pressing the button for a rela-

ng time (> 2 s). The optical data tran sceiver is now r eady for operatio n.

tively lo

Operating mo de buttons

With the operating mode button, you c an switch betw een the three o perating mode s "Automatic ",

"Manual" and "Adjust" (see chapter 5.2 "Operating modes").

Leuze electronic Technical description DDLS 200 9

PROFIBUS / RS 485 Leuze electronic

4 PROFIBUS / RS 485

The PROFIBUS model of the DDLS 200 has the following features:

• Electrica lly isolated interface

• The DDLS does not occupy a PROFIBUS address

• Integrated repeater function ( signal processin g), can be switched off

• Protocol-in dependent data transmission, i.e. transmissi on of the FMS, DP, MP I,

FMS/DP mixed operation protocols

• Connectabl e bus termin ator (termi nation)

• 6 baud rates can be set

4.1 Electrical connection PROFIBUS

The elec trical connec tion to the PR OFIBUS is made at the terminals A, B, and COM. The terminals

A’, B’ and COM are provided for wiring throug h the bus.

PROFIBU S - terminals and switches

BS

SHIELD AREA

COM

– + –' +'

COM

A B A'A'B'

Figure 4. 1: Connection circuit board o f the PROFIB US model

OUT

COM

COM

WARN

GND

Vin

S2

Term.

Off

On

IN

PEPEGND

S1

IN

Off

On

On =

S3

RS 485

On01

Off

Off =

Profibus

Attention!

Please be sure to observe the installation requirements (bus cables, cable lengths, shielding, etc. ) defined in th e PROFIBUS s tandard EN 501 70 (Vol. 2).

Vin

Ter min al Function

A400A

A , – (N) PROFIBUS or (–) RS 485

B, + (P) PROFIBUS or (+) RS 485

COM Potential equalisatio n

A’, –’ (N) PROFIBUS or (–) RS 485 of the

B’, +’ (P) PROFIBUS or (+) RS 485 of the

Switch Function

S2 Termination On/O ff

S3-1 … S3-3 Setting the baud rate of the

S3

-4

wired-through bus

wired th rough bus

PROFIBUS segment

angeover PROF IBUS (Off) /

Ch

RS 485 (On)

Leuze electronic T echnical description DDLS 200 11

PROFIBUS / RS 485 Leuze electronic

4.3 LED Indicators PROFIBUS

In addition to the indicator and operating elements present in all device models (bar graph, buttons,

LEDs AUT, MAN, ADJ; see chapter 5.1 "Indicator and operating elements"), the PROFIBUS model

also has the following indicators:

LED PWR: green = operating indicator

PWR Tx Rx

AUT

MAN

ADJ

LED Tx: green = d ata are being transmitted to t he bus

LED Rx: green = d ata are being received by the bus

Figure 4. 2: Indicator/opera ting elements for the PROFIBUS model

green flashing= transmitter /receiver unit switched off

off = no operating voltage

green flashing= with baud rates set to very low values,

off = no data on the transmission lin e

green flashing= with baud rates set to very low values,

off = no data on the reception line

via switch ing input IN or hardware error

the LEDs Tx and Rx flicker. At very

high baud rat es (> 50 kBit/s), flashing

LEDs Tx and Rx indicate faulty bus

communic ation.

the LEDs Tx and Rx flicker. At very

high baud rat es (> 50 kBit/s), flashing

LEDs Tx and Rx indi

communic ation.

cate faulty bus

13 Technical description DDLS 200 Leuze electronic

Leuze electronic Commissioning / Operation (all device models)

5.2 Operating modes

The following table provides an overview of the DDLS 200 operating modes.

Operating

mode

Automatic,

AUT LED illu-

minates

Manual,

MAN LED

illuminate s

Adjust, ADJ

LED illum inates

Description

Normal operation Active Its own receiving level, display of

Adjustme nt operation,

cut-off threshold on higher level

Adjustme nt operation,

cut-off threshold on higher level

Changing the operating mode

AUT –> MAN Press the operating mode button for more than 2 seconds.

MAN –> ADJ Press the operating mode button on one of the two devices.

ADJ –> MAN Press the operating mode button on one of the two devices.

MAN –> AUT Press the operating mode button for more than 2 seconds.

Only the device on which the button was pressed switches to the "Manual" operating

mode (MAN LED illuminates).

Both devices switch to the "Adjust" operating mode (both ADJ LEDs illuminate) when

both were previously in the "Manual" operating mode.

Both devices switch to the "Manual" operating mode (both MAN LEDs illuminate) .

Only the dev ice on which the button was pressed swit ches to the "Autom atic" operating mode (AUT LED illuminates).

Note!

To switch to the "Adjust" (ADJ) operating mode, both devices belonging to a transmission

path must first be in the "Manual" (MA N) operating mode. It is not possible to switch directly

from the "Automatic" to the "Adjust" operating mode or vice versa.

5.3 Initial commissioning

5.3.1 Switch on device / function check

After ap plying the ope rating voltag e, the DDLS 200 first performs a self -test. If the self-test is successfully completed, the PWR or UL LED illuminates continuously and the DDLS 200 switches to the "Automatic" oper ating mode. If the connecti on to the opposing device e xists, data can be transmi tted

immediately.

Optical data

transmission

Active Its own receiving level, display of

Separated Receivi ng level of the opposing

Bar graph assignment

the alignment quality of the

opposing device

the alignment quality of the

opposing device

device, disp lay of the alignment

quality of own device

15 Tech nical descrip tion DDLS 200 Leuze e lectronic

Leuze electronic Commissioning / Operation (all device models)

5.4 Operation

In runnin g operation ("Au tomatic" opera ting mode) the D DLS operates ma intenance-free . Only the

glass optics need to be cl eaned occasional ly in the event of soi ling. This can be ch ecked by analysin g

the switching output OUT WARN (with the INTERBUS fib re optic cable model, a perip heral error m essage is also av ailable). If the ou tput is set, soilin g of the DDLS 200's glas s optics is often the cause

(see chapter 6. 1 "Cleaning"

).

It must stil l be ensured that t he light beam is n ot interrupted at a ny time.

Attention!

If, during operation of the DDLS 200, the light beam is interrupted or one of the two devices

is switched voltage free, the effect of the int erruption on the e ntire network is equivalent to

the interruption of a data line!

In the event of an interruption (light beam interruption or switched voltage-free), the

DDLS 200 swi tches off the network to a non-interac ting state. The system reac tions in the

event of an interruption are to be defined to gether with the supplier of the PL C.

6 Maintenance

6.1 Cleaning

The optic al window of th e DDLS 200 is to be cleaned month ly or as needed (w arning output) . To clean,

use a soft cloth and a cleaning agent (standard glass cleaner).

Attention!

Do not use solvents and cleaning agents containing acetone. Use of improper cleaning

agents can damage the optical window.

TNT 35/7-24V

Leuze electronic

Leuze Mayser electronic Ltd.

Tel. Int. + 44 (0) 1480/408500

Fax Int. + 44 (0) 1480/403808

E-mail: mail@leuzemayser.co.uk

http://www.leuzemayser.co.uk

TNT 35/7-24V

10 Technical description DDLS 200 Leuze electronic

12 Technical description DDLS 200 Leuze electronic

Leuze electronic Technical description DDLS 200 14

Leuze electronic T echnical description DDLS 200 16

Loading...

Loading...